Constitutive model of recycled brick aggregate geopolymer concrete under compression before and after elevated temperature

-

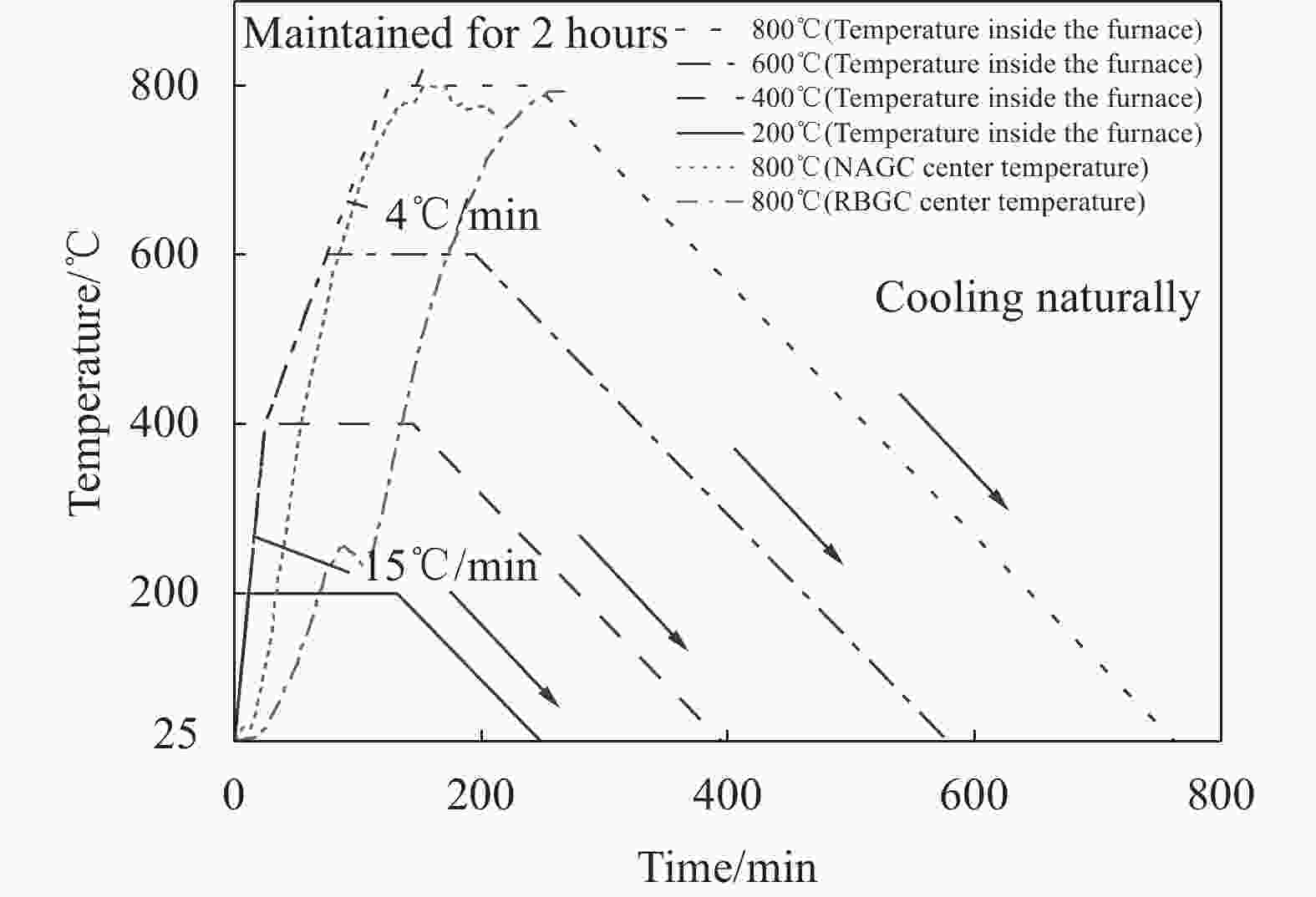

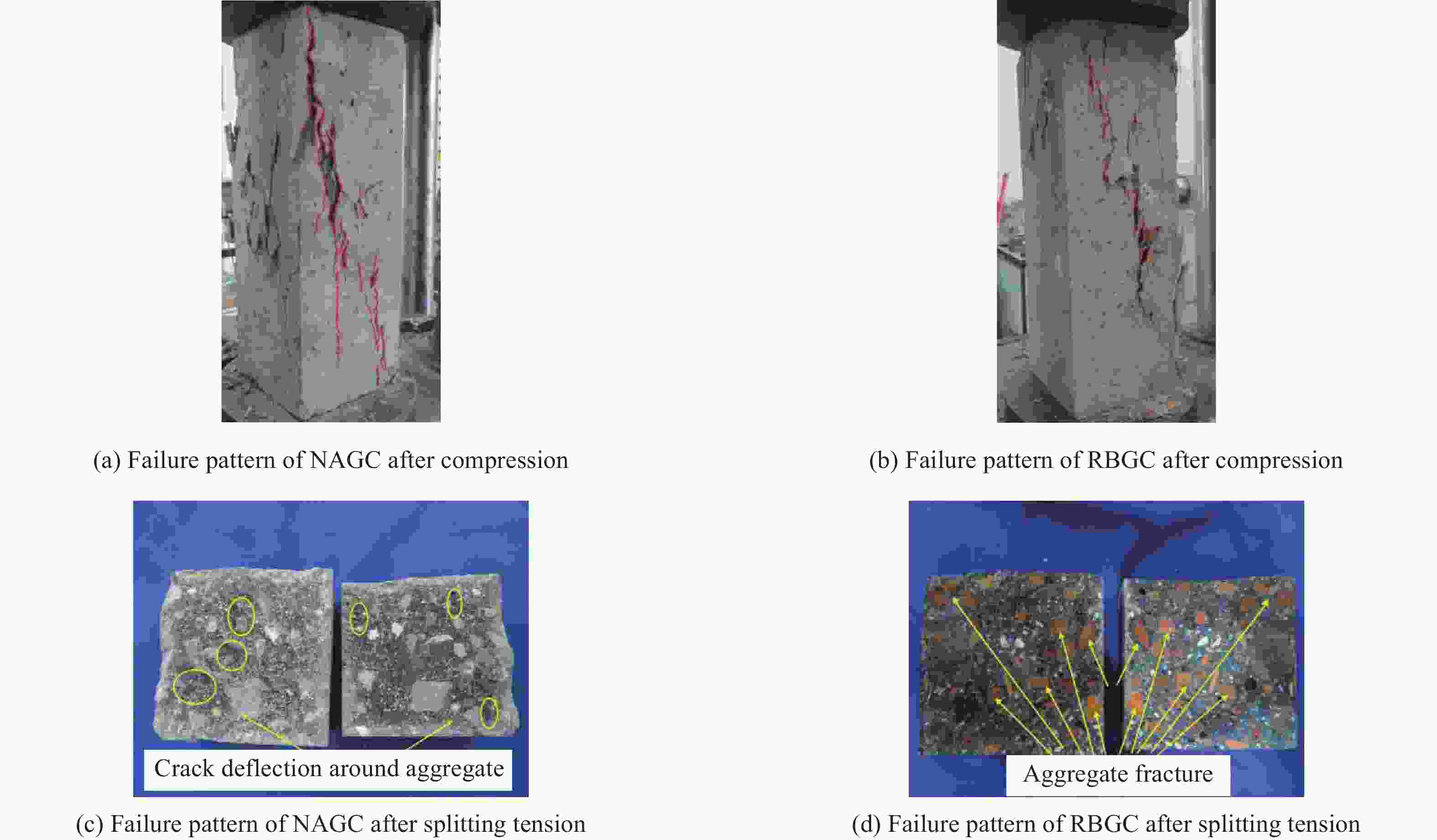

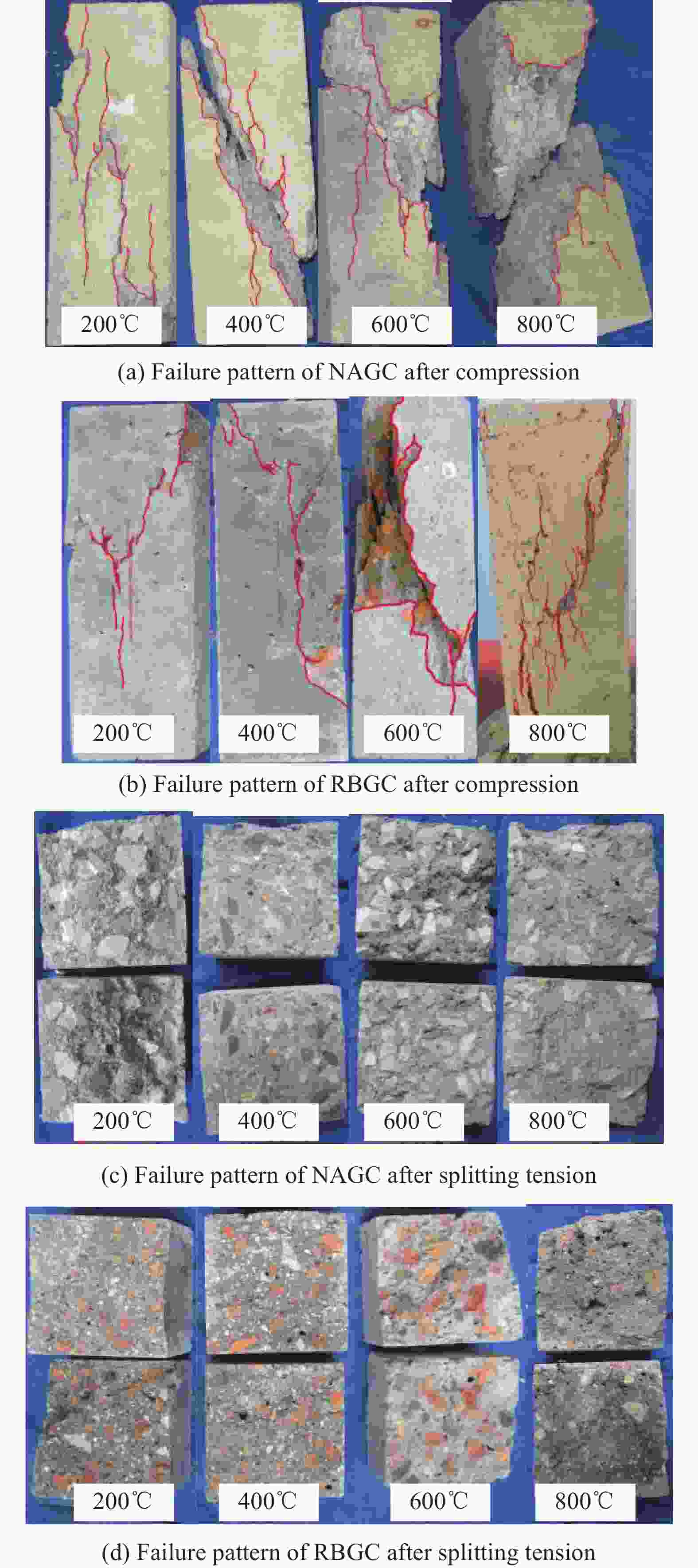

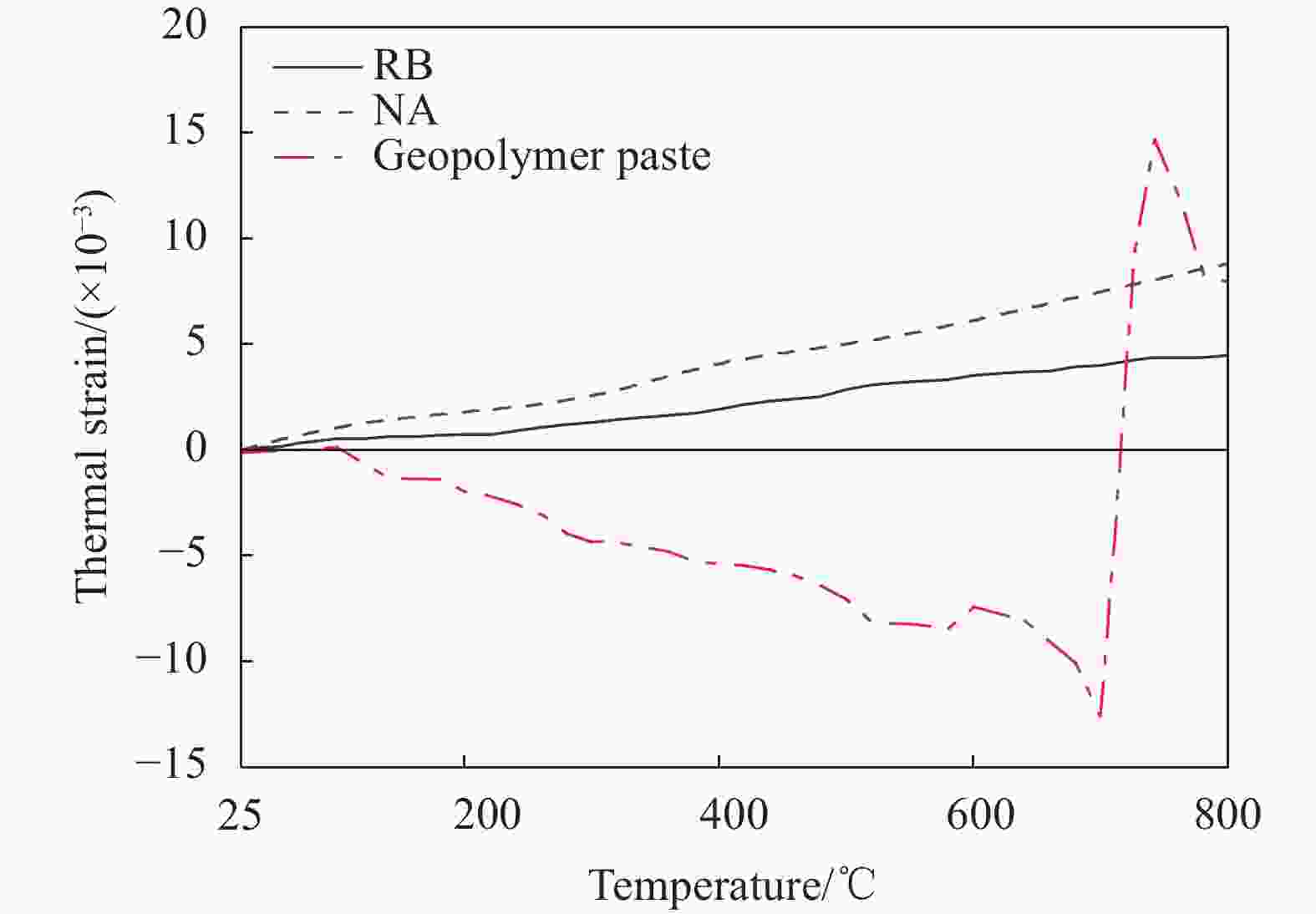

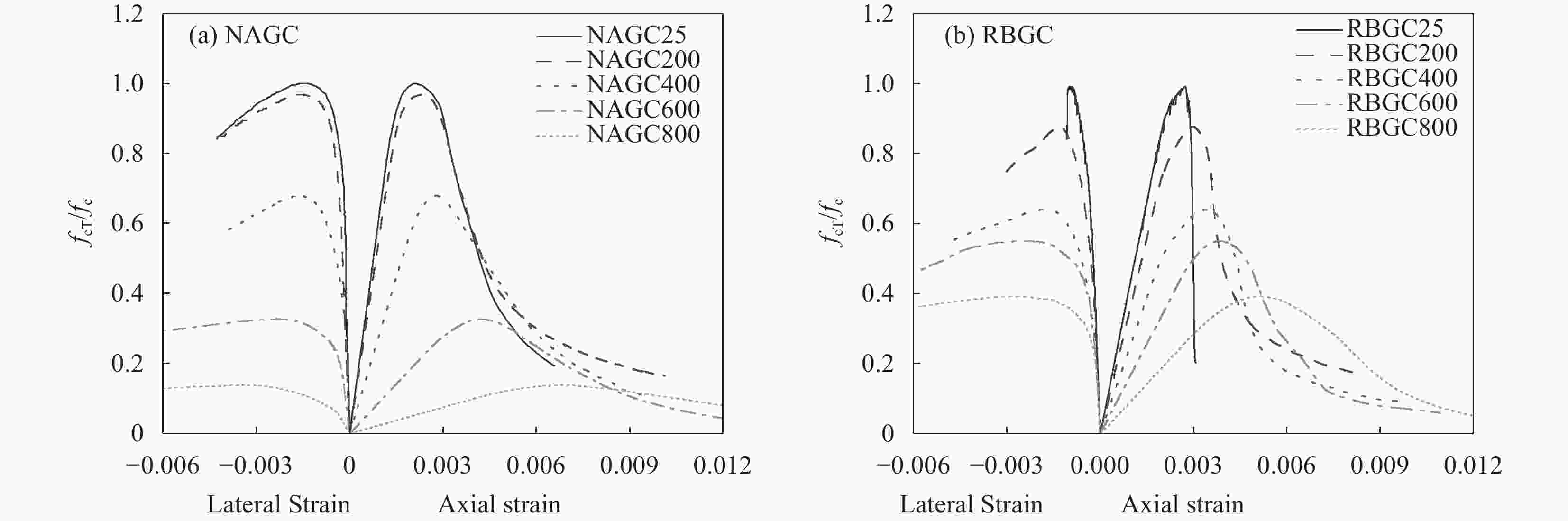

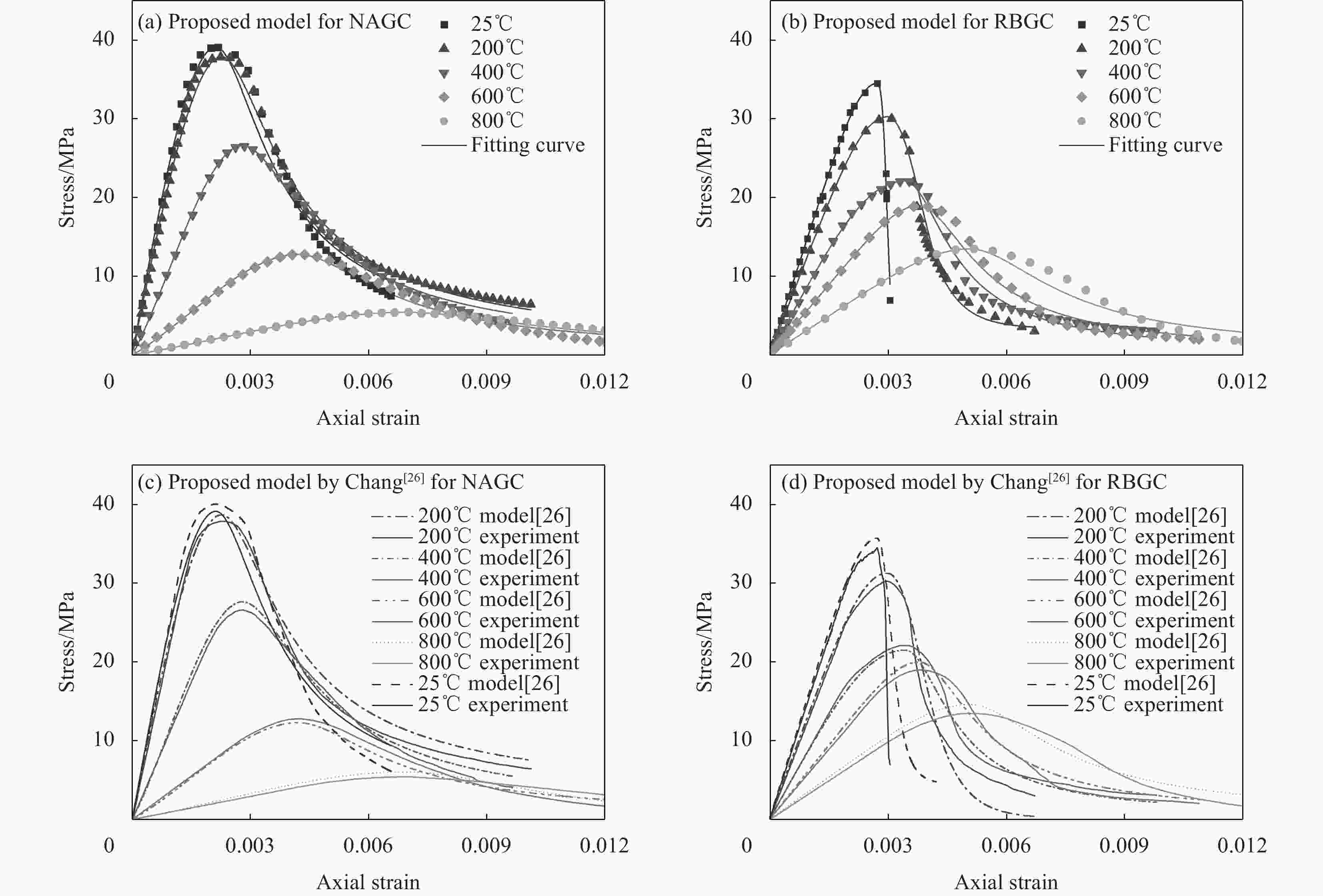

摘要: 再生砖骨料地聚物混凝土(RBGC)是一种极具潜力的可持续建筑材料,但高温前后RBGC性能的相关研究较少。本文首先探究了胶凝材料用量和粗骨料类型对地聚物混凝土轴压本构模型的影响,发现随着胶凝材料的增加,RBGC抗压强度、劈拉强度、弹性模量和峰值压应变的变化幅度均小于普通骨料地聚物混凝土(NAGC),RBGC的应力-应变曲线上升段线性段更长,下降段应力下降速度更快。其次研究了高温后RBGC和NAGC的力学性能,800℃时,RBGC强度和刚度损失分别比NAGC小22.1%和18.3%,发现RBGC表现出更好的耐高温性能,两种混凝土力学性能指标的计算应采用不同的模型。这是由于砖骨料温度膨胀系数接近地聚物砂浆,且高温下RBGC内部温度梯度小。最后,通过修正下降段形状参数,确定了高温前后RBGC和NAGC的应力-应变关系模型,模型与试验结果吻合较好。Abstract: Recycled brick aggregate geopolymer concrete (RBGC) is a sustainable building material with great potential, but there are few studies on the performance of RBGC before and after high temperatures. Firstly, the influence of the amount of cementitious material and the type of coarse aggregate on the axial compression constitutive model of geopolymer concrete was explored. It is found that with the increase of cementitious material, the compressive strength, split tensile strength, elastic modulus and peak compressive strength of RBGC decrease. The change amplitude of strain is smaller than that of ordinary aggregate geopolymer concrete (NAGC). The linear section of the rising section of the stress-strain curve of RBGC is longer, and the stress decreases faster in the falling section. Secondly, the mechanical properties of RBGC and NAGC after high temperature were studied. At 800°C, the strength and stiffness loss of RBGC are 22.1% and 18.3% smaller than that of NAGC respectively. And it is found that RBGC shows better high temperature resistance, and different models should be used to calculate the mechanical performance indicators of the two concretes. This is because the temperature expansion coefficient of brick aggregate is close to that of geopolymer mortar, and the internal temperature gradient of RBGC is small at high temperatures. Finally, by correcting the shape parameters of the descending section, the stress-strain relationship model of RBGC and NAGC before and after high temperature is determined, and the model is in good agreement with the test results.

-

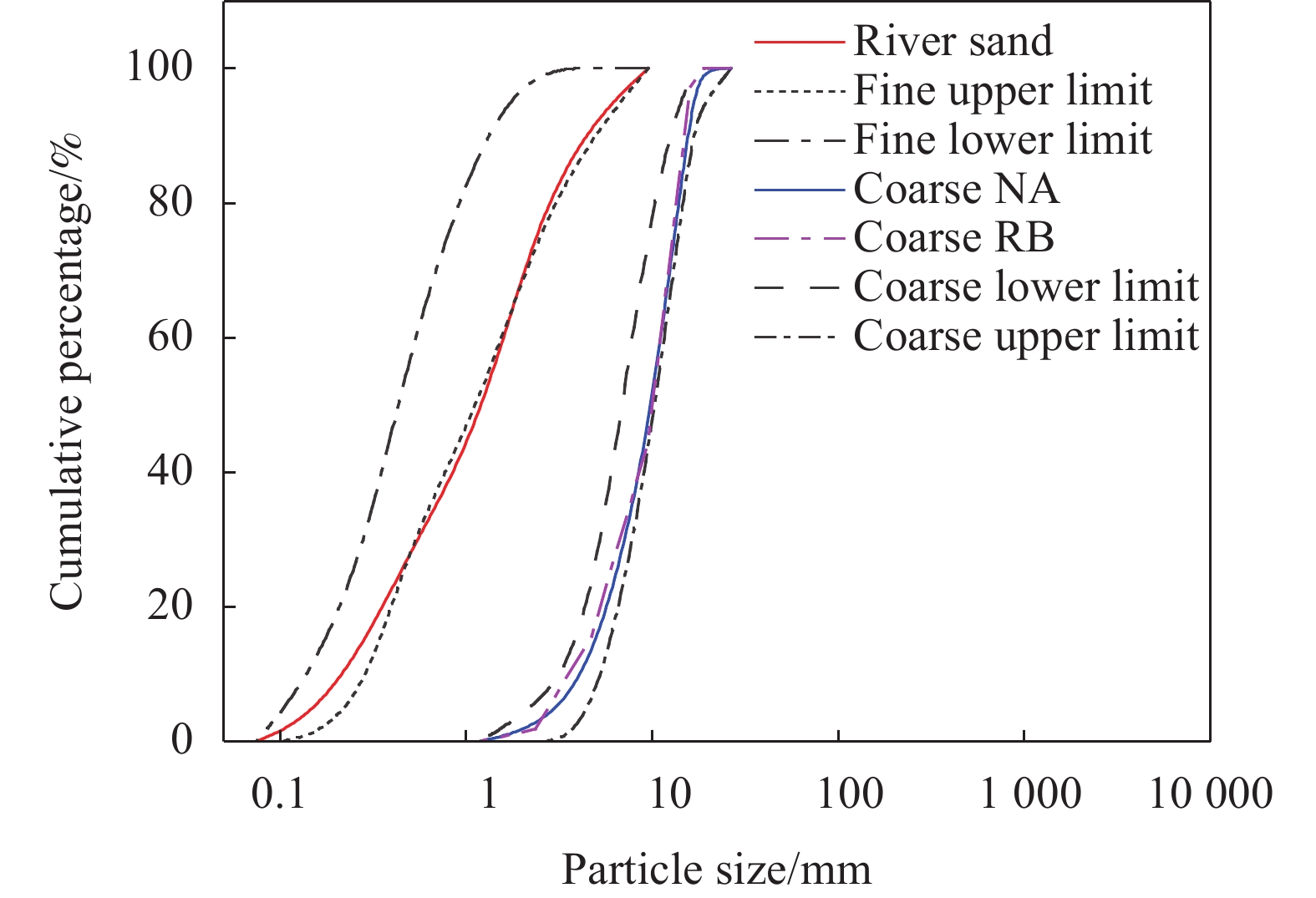

表 1 粗骨料和细骨料的物理性能

Table 1. Physical properties of coarse and fine aggregates

Type Particle

size/mmSpecific

gravity24 h water

absorption/%Fineness

modulusCrush

index/%Cylinder compressive

strength/MPaNatural river sand ≤5 2.67 1.2 2.6 — — Limestone 5~20 2.64 0.83 — 7.9 — Recycled brick aggregate 5~20 1.74 10.92 — 21.3 4.7 表 2 配合比设计和力学性能

Table 2. Mix proportion design and mechanical properties

No. Mix proportion/(kg·m−3) Dry density/

(kg·m−3)Elastic

modulus/GPafc

/MPaBinder SS SH Sand Coarse

aggregateAdded

waterSP NAGC-1 300 188 75 568 1224 35.5 2.5 2231 21.58 26.10 NAGC-2 400 188 75 504 1224 35.5 4.5 2244 25.17 39.13 NAGC-3 500 188 75 450 1224 35.5 5.5 2287 27.60 50.29 RBGC-1 300 188 75 568 1105 73.5 3.5 1893 11.03 21.23 RBGC-2 400 188 75 504 1105 73.5 4.5 1915 13.38 29.97 RBGC-3 500 188 75 450 1105 73.5 5.5 1931 15.39 34.50 Notes:GC stands for geopolymer concrete, RB and NA stand for limestone crushed stone and recycled brick aggregate; the numbers 1 to 3 represent the target strength from lowest to highest; fc is the compressive strength of NAGC and RBGC. 表 3 NAGC和RBGC抗压强度、弹性模量、峰值应变和劈拉强度拟合公式

Table 3. Fitting formulas of compressive strength, elastic modulus, peak strain and splitting tensile strength of NAGC and RBGC

Properties NAGC RBGC Compressive strength $ \dfrac{{{f_{{\text{cT}}}}}}{{{f_{\text{c}}}}} = \dfrac{1}{{1 + 13.75{{(T/1000)}^{3.70}}}} $ $ \dfrac{{{f_{{\text{cT}}}}}}{{{f_{\text{c}}}}} = - 0.84(T/1000) + 1.02 $ Elastic modulus $ \dfrac{{{E_{{\text{cT}}}}}}{{{E_{\text{c}}}}} = \dfrac{1}{{1 + 50.40{{(T/1000)}^{4.03}}}} $ $ \dfrac{{{E_{{\text{cT}}}}}}{{{E_{\text{c}}}}} = - 1.03(T/1000) + 1.02 $ Peak strains $ \dfrac{{{\varepsilon _{{\text{PT}}}}}}{{{\varepsilon _{\text{P}}}}} = 1 + 4.20{(T/1000)^{2.78}} $ $ \dfrac{{{\varepsilon _{{\text{PT}}}}}}{{{\varepsilon _{\text{P}}}}} = 1 + 1.16{(T/1000)^{1.76}} $ Splitting tensile strength $ \dfrac{{{f_{{\text{stT}}}}}}{{{f_{{\text{st}}}}}} = - 1.13(T/1000) + 1.00 $ $ \dfrac{{{f_{{\text{stT}}}}}}{{{f_{{\text{st}}}}}} = \left\{ \begin{gathered} - 0.69(T/1000) + 1.02{\text{,25}}^\circ C \leqslant {\text{T}} \leqslant 400^\circ C \\ - 1.52(T/1000) + 1.36{\text{,400}}^\circ C < {\text{T}} \leqslant 800^\circ C \\ \end{gathered} \right. $ Notes:fc , Ec , εp and fst are compressive strength, elastic modulus, peak strain and splitting tensile strength of the concrete at room temperature respectively; fcT , EcT , εpT and fstT are compressive strength, Elastic modulus, peak strain and splitting tensile strength of the concrete after high temperature respectively. 表 4 NAGC和RBGC回归参数α,β和n

Table 4. Regression parameters α,β and n of NAGC and RBGC

Type Parameter Temperature(℃) 25 200 400 600 800 NAGC n 1.50 1.48 0.99 0.95 1.06 α 2.24 2.09 2.33 3.24 2.94 RBGC n 5.47 4.47 3.33 6.39 5.14 β 44.09 9.27 - - - α - - 7.54 5.73 4.62 -

[1] 孙杰, 陈国珍, 吕康琪等. 橡胶地聚物混凝土力学性能及阻尼特性试验研究[J]. 复合材料学报, 2022, 39(11): 5321-5332. doi: 10.13801/j.cnki.fhclxb.20211201.002SUN Jie, CHEN Guozhen, LYU Kangqi, et al. Experimental study on mechanical properties and damping characteristics of rubber geopolymer concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5321-5332(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211201.002 [2] 丁兆洋, 苏群, 李明泽, 等. 水玻璃模数对地聚物再生混凝土力学性能的影响[J]. 建筑材料学报, 2023, 26(1): 61-70. doi: 10.3969/j.issn.1007-9629.2023.01.009DING Zhaoyang, SU Qun, LI Mingze, et al. Effect of modulus of water glass on mechanical properties of geopolymer recycled aggregate concrete[J]. Journal of Building Materials, 2023, 26(1): 61-70(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.01.009 [3] 万聪聪, 姜天华. 高性能地聚物混凝土早期收缩特性[J]. 复合材料学报, 2024, 41(2): 952-964.WAN Congcong, JIANG Tianhua. Early shrinkage characteristics of high performance geopolymer concrete[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 952-964(in Chinese). [4] MAHMOOD A H, FOSTER S J, CASTEL A. Effects of mixing duration on engineering properties of geopolymer concrete[J]. Construction and Building Materials, 2021, 303: 124449. [5] YANG Y M, FANG S, FENG W H, et al. Flexural and compressive performance of BFRP-reinforced geopolymer sea-sand concrete beams and columns: Experimental and analytical investigation[J]. Composite Structures, 2023, 318: 117089. doi: 10.1016/j.compstruct.2023.117089 [6] CHEN Z, YU J M, NONG Y M, et al. Beyond time: Enhancing corrosion resistance of geopolymer concrete and BFRP bars in seawater[J]. Composite Structures, 2023, 322: 117439. doi: 10.1016/j.compstruct.2023.117439 [7] 高丹盈, 景嘉骅, 周潇. 混杂纤维增强再生砖骨料混凝土增强机制与抗压性能计算方法[J]. 复合材料学报, 2018, 35(12): 3441-3449. doi: 10.13801/j.cnki.fhclxb.20180516.003GAO Danying, JING Jiahua, ZHOU Xiao. Reinforcing mechanism and calculation method of compressive behavior of hybrid fiber reinforced recycled brick aggregates concrete[J]. Acta Materiae Compositae Sinica, 2018, 35(12): 3441-3449(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180516.003 [8] 朱超, 赵文韬, 余伟航, 等. 再生砖混骨料混凝土基本力学性能与本构模型[J]. 复合材料学报, 2024, 41(2): 898-910.ZHU Chao, ZHAO Wentao, YU Weihang, et al. Basic mechanical properties and constitutive model of recycled brick-concrete aggregate[J]. Acta Materiae Compositae Sinica, 2024, 41(2): 898-910(in Chinese). [9] ZHENG Y Q, DU J T, ZHENG L Y, et al. Compressive behavior of geopolymer recycled brick aggregate concrete confined by steel tubes[J]. Journal of Building Engineering, 2023, 70: 106350. doi: 10.1016/j.jobe.2023.106350 [10] 李升涛, 陈徐东, 张伟, 等. 基于长江下游超细疏浚砂的碱激发矿渣混凝土力学性能[J]. 复合材料学报, 2022, 39(1): 335-343. doi: 10.13801/j.cnki.fhclxb.20210419.003LI Shengtao, CHEN Xudong, ZHANG Wei, et al. Mechanical properties of alkali activated slag concrete with ultra fine dredged sand from Yangtze River[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 335-343(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210419.003 [11] REN W B, XU J Y, BAI E L. Strength and ultrasonic characteristics of alkali-activated fly ash-slag geopolymer concrete after exposure to elevated temperatures[J]. Journal of Materials in Civil Engineering, 2016, 28(2): 4015124. doi: 10.1061/(ASCE)MT.1943-5533.0001406 [12] KHATTAB M, HACHEMI S, AL AJLOUNI M F. Evaluating the physical and mechanical properties of concrete prepared with recycled refractory brick aggregates after elevated temperatures’ exposure[J]. Construction and Building Materials, 2021, 311: 125351. doi: 10.1016/j.conbuildmat.2021.125351 [13] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republia of China. Standard for test methods of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [14] Comite Euro-Inernational Du Beton. CEB-FIP model code 1990: CEB-FIP MC90[S]. Lausanne: Concrete Structures, 2014. [15] DABBAGHI F, DEHESTANI M, YOUSEFPOUR H, et al. Residual compressive stress-strain relationship of lightweight aggregate concrete after exposure to elevated temperatures[J]. Construction and Building Materials, 2021, 298: 123890. [16] SOFI M, VAN DEVENTER J S J, MENDIS P A, et al. Engineering properties of inorganic polymer concretes (IPCs)[J]. Cement and Concrete Research, 2007, 37(2): 251-257. doi: 10.1016/j.cemconres.2006.10.008 [17] LEE N K, LEE H K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature[J]. Construction and Building Materials, 2013, 47: 1201-1209. doi: 10.1016/j.conbuildmat.2013.05.107 [18] UDDIN M T, MAHMOOD A H, KAMAL M R I, et al. Effects of maximum size of brick aggregate on properties of concrete[J]. Construction and Building Materials, 2017, 134: 713-726. doi: 10.1016/j.conbuildmat.2016.12.164 [19] ISLAM A, ALENGARAM U J, JUMAAT M Z, et al. Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete[J]. Construction and Building Materials, 2015, 101: 503-521. doi: 10.1016/j.conbuildmat.2015.10.026 [20] American Concrete Institute Committee. Building code requirements for structural concrete and commentary: ACI 318[S]. Michigan: American Concrete Institute, 2014. [21] KONG D L Y, SANJAYAN J G. Effect of elevated temperatures on geopolymer paste, mortar and concrete[J]. Cement and Concrete Research, 2010, 40(2): 334-339. doi: 10.1016/j.cemconres.2009.10.017 [22] ANDIÇ-ÇAKıR Ö, HıZAL S. Influence of elevated temperatures on the mechanical properties and microstructure of self consolidating lightweight aggregate concrete[J]. Construction and Building Materials, 2012, 34: 575-583. doi: 10.1016/j.conbuildmat.2012.02.088 [23] ABDULKAREEM O A, BAKRI A M A, KAMARUDIN H, et al. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete[J]. Construction and Building Materials, 2014, 50: 377-387. doi: 10.1016/j.conbuildmat.2013.09.047 [24] European Committee for Standardization. Eurocode 4: Design of composite steel and concrete structures, part 1-2: Genal rules-structural fire design: EN 1994-1-2[S]. London: Thomas Telford Ltd, 2005. [25] American Concrete Institute Committee. Code requirements for determining fire resistance of concrete and masonry construction assemblies: ACI/TMS 216.1M-14[S]. Michigan: American Concrete Institute, 2014. [26] CHANG Y F, CHEN Y H, SHEU M S, et al. Residual stress–strain relationship for concrete after exposure to high temperatures[J]. Cement and Concrete Research, 2006, 36(10): 1999-2005. doi: 10.1016/j.cemconres.2006.05.029 [27] LIU H B, LI Q Y, WANG P H. Assessment of the engineering properties and economic advantage of recycled aggregate concrete developed from waste clay bricks and coconut shells[J]. Journal of Building Engineering, 2023, 68: 106071. doi: 10.1016/j.jobe.2023.106071 [28] SHAIKH F U A, HOSAN A. Mechanical properties of steel fibre reinforced geopolymer concretes at elevated temperatures[J]. Construction and Building Materials, 2016, 114: 15-28. doi: 10.1016/j.conbuildmat.2016.03.158 [29] ALBIDAH A, ALQARNI A S, ABBAS H, et al. Behavior of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures[J]. Construction and Building Materials, 2022, 317: 125910. doi: 10.1016/j.conbuildmat.2021.125910 [30] JUNAID M T, KHENNANE A, KAYALI O. Stress-strain behaviour of alkali activated fly ash concrete at elevated temperatures[C]// 2nd International Conference on Advances in Cement and Concrete Technology in Africa. Tanzania: BAM Federal Institute for Materials Research, 2016. [31] ZHANG H Y, KODUR V, WU B, et al. Effect of temperature on bond characteristics of geopolymer concrete[J]. Construction and Building Materials, 2018, 163: 277-285. doi: 10.1016/j.conbuildmat.2017.12.043 [32] TURKEY F A, BEDDU S B, AHMED A N, et al. Effect of high temperatures on the properties of lightweight geopolymer concrete based fly ash and glass powder mixtures[J]. Case Studies in Construction Materials, 2022, 17: e01489. -

下载:

下载: