Research Progress of Nano-enhanced Microcapsule Composite Phase Change Materials

-

摘要: 相变材料(PCM)可以弥合热能供需在时间和空间上的差距,被广泛应用于热能存储和热管理系统中。然而,单一的PCM具有易泄漏、体积变化、相分离和腐蚀等缺陷,因此,通过微胶囊技术将PCM封装制备微胶囊复合相变材料(MEPCM),并通过不同纳米填料增强其性能,既可以有效克服以上缺陷,又能提高其热性能和运行稳定性。本文首先介绍了MEPCM的芯材和壳体的选择原则、MEPCM的组成及制备策略,着重阐述了不同维度纳米填料对MEPCM热性能的影响,总结了MEPCM在建筑、纺织品及热管理等领域中的应用,最后,展望了纳米填料在合理设计和构建高性能MEPCM方面的未来研究方向和挑战。Abstract: Phase change materials (PCM) can bridge the gap between heat supply and demand in time and space, and are widely used in heat storage and thermal management systems. However, a single PCM has defects such as easy leakage, volume change, phase separation and corrosion. Therefore, microencapsulated PCM to prepare microencapsulated composite phase change materials (MEPCM) by microencapsulated technology and enhanced by different nano-fillers can not only effectively overcome the above defects, but also improve its thermal performance and operational stability. This paper first introduces the selection principle of the core material and shell of MEPCM, the composition and preparation strategy of MEPCM, focuses on the influence of nano-fillers of different dimensions on the thermal properties of MEPCM, and summarizes the application of MEPCM in the fields of construction, textiles and thermal management. The future research directions and challenges of nano-fillers in rational design and construction of high-performance MEPCM are also discussed.

-

Key words:

- Phase change materials /

- Microcapsules /

- Thermal energy storage /

- Nano-filler /

- Thermal properties

-

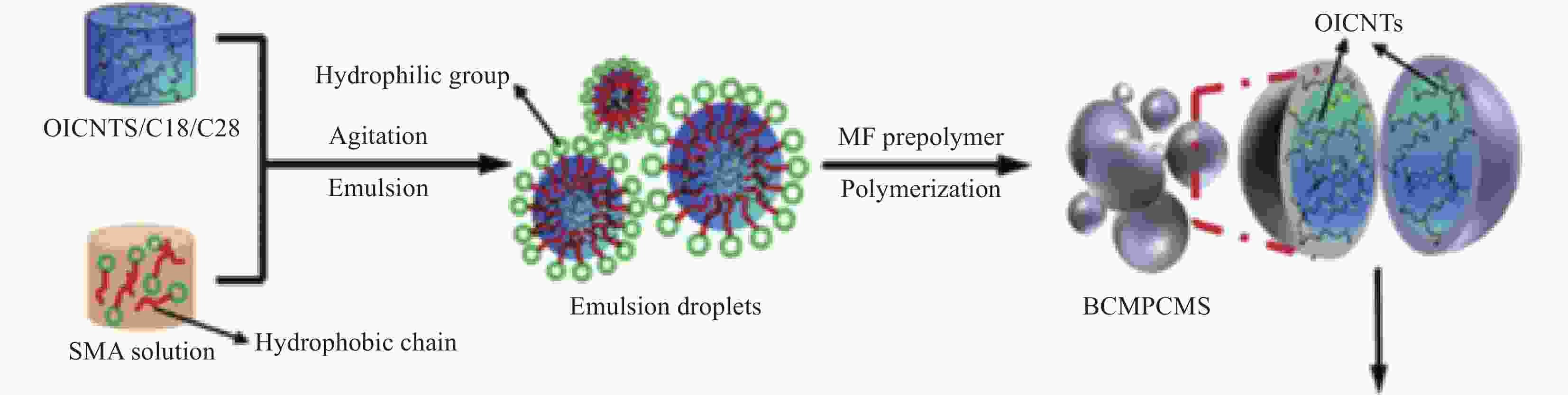

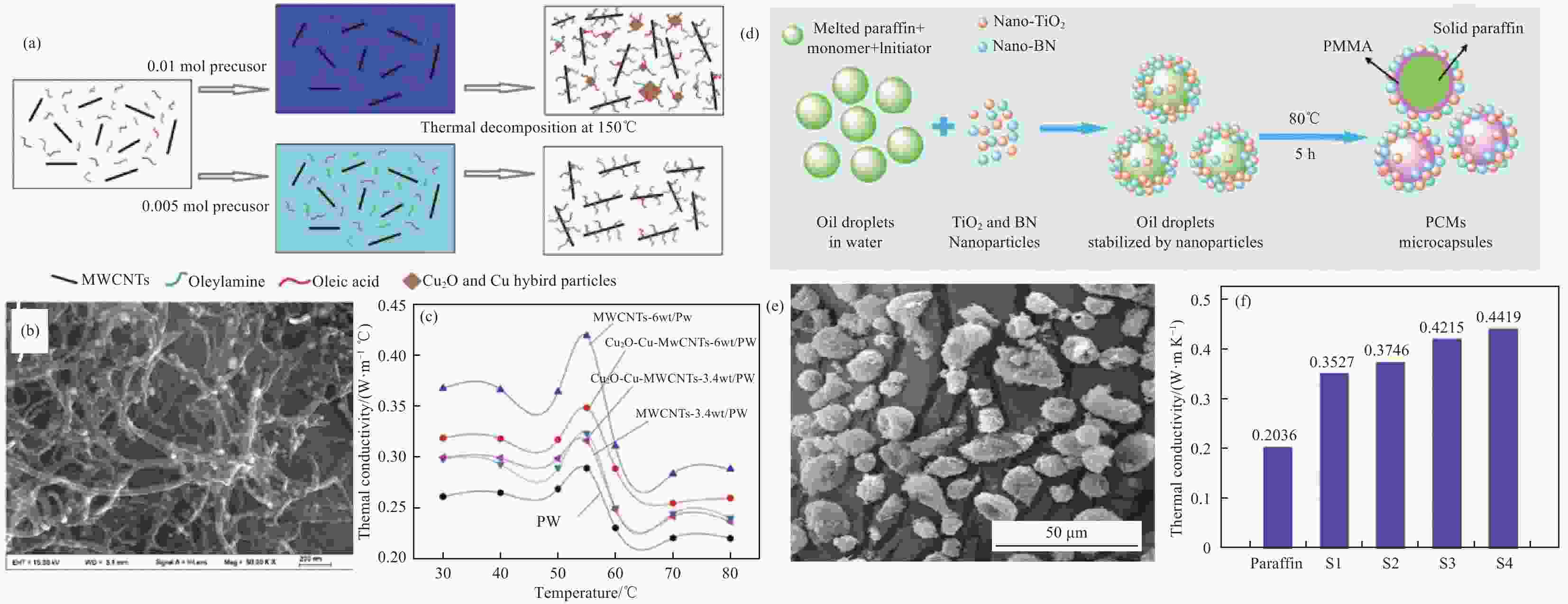

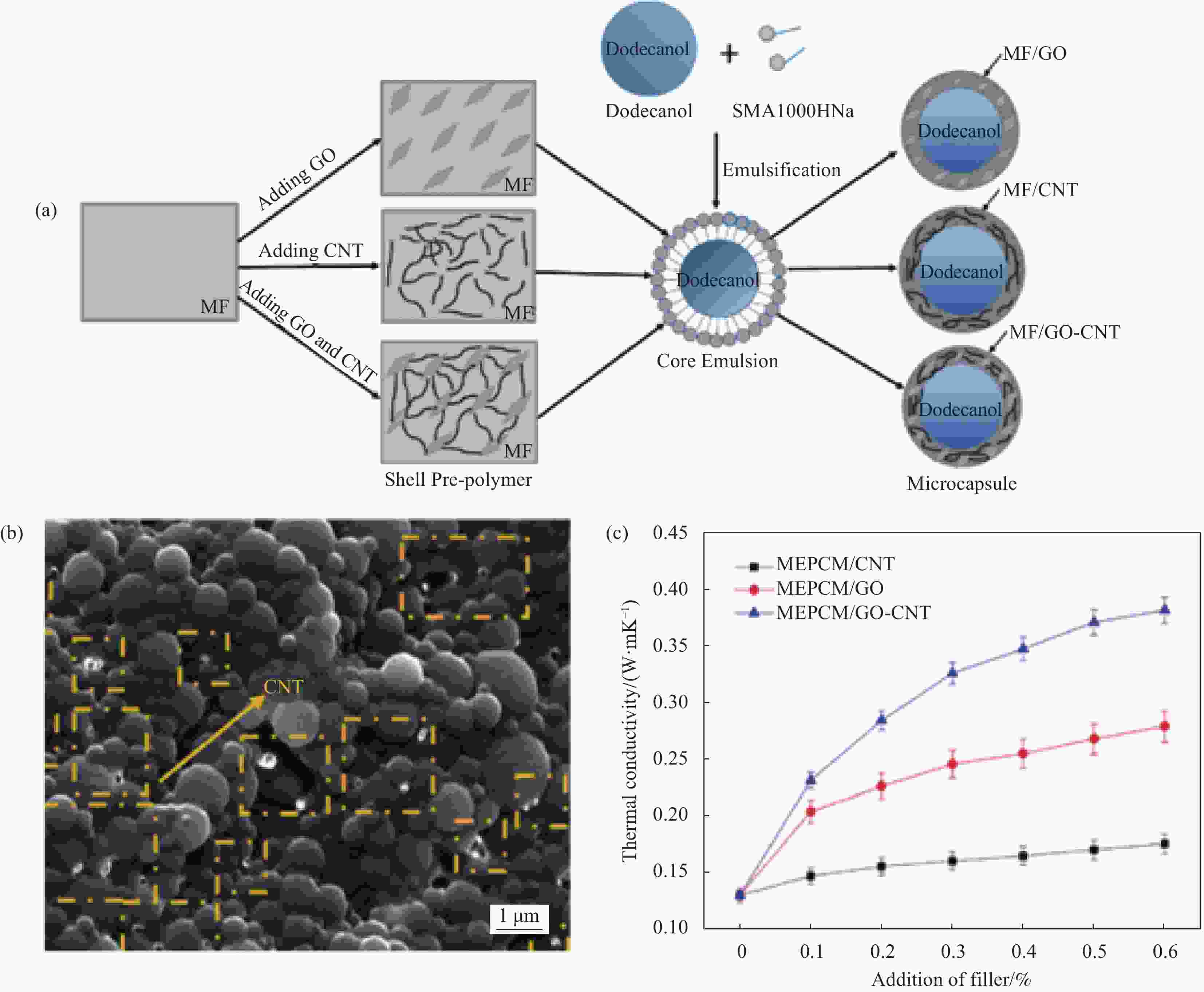

图 11 (a) Cu2O-Cu-MWCNTs/石蜡复合材料的合成, (b) Cu2O-Cu-MWCNTs 复合材料的 SEM 图,(c) 纯石蜡、MWCNT/石蜡和 Cu2O-Cu-MWCNT/石蜡复合材料的热导率和温度的关系图;(d) 石蜡和PMMA/BN/TiO2 混合壳的MEPCM的制备示意图,(e) PMMA/BN/TiO2 壳制备的MEPCM的SEM图,(f)纯石蜡和不同BN用量的MEPCM的热导率/TiO2 杂化纳米颗粒[96-97]。

Figure 11. (a) Synthesis of Cu2O-Cu-MWCNTs/paraffin composites, (b) SEM photographs of Cu2O- Cu-MWCNTs composite, (c) Dependence of the thermal conductivity of pure paraffin, MWC- NTs/paraffin and Cu2O-Cu-MWCNTs/paraffin composites on the temperature, (d) Schematic fabrication of MEPCMs with paraffin core and PMMA/BN/TiO2 hybrid shell, (e) SEM images of MEPCMs prepared with PMMA/BN/TiO2 shell, (f) Thermal conductivity of pure paraffin and MEPCMs with different dosages of BN/TiO2 hybrid nanoparticles [96-97].

表 1 不同类型壳体材料的优缺点[15]

Table 1. Advantages and disadvantages of different types of shell materials[15]

Common shell materials Advantages Disadvantages Organic shell

Melamine-formaldehyde (MF) resin

Urea-formaldehyde (UF) resin

Poly(urea-urethane) (PUU)

Polyurea (PU)

Acrylic resins

Inorganic shell

Silica(SiO2)

Titania(TiO2)

Calcium carbonate(CaCO3)

Zinc oxide (ZnO)

Alumina(Al2O3)

Organic and inorganic hybrid shell

Silver nanoparticles in organic shell

Iron nanoparticles in organic shell

Silicon nitride in organic shell

Good structure stability

Superb durability after many thermal cycles

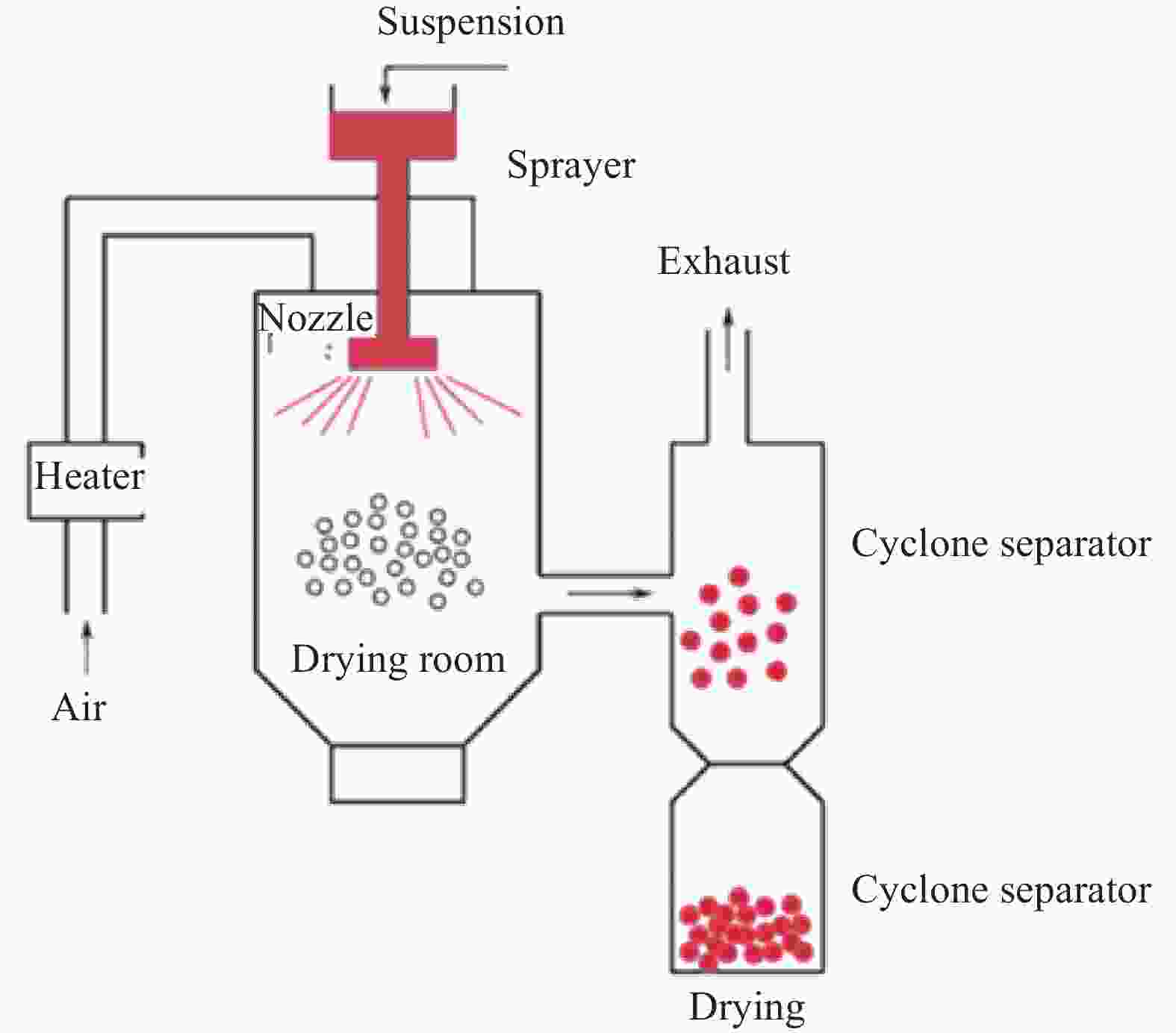

Excellent UV stability,

non-toxicity, easily handle,

exceptional mechanical strength

Better utilization than organic shell

Exceptional thermal stability

High thermal conductivity

high corrosion resistance, multifunctionality

good thermal conductivity, low cost

Outstanding thermal conductivity

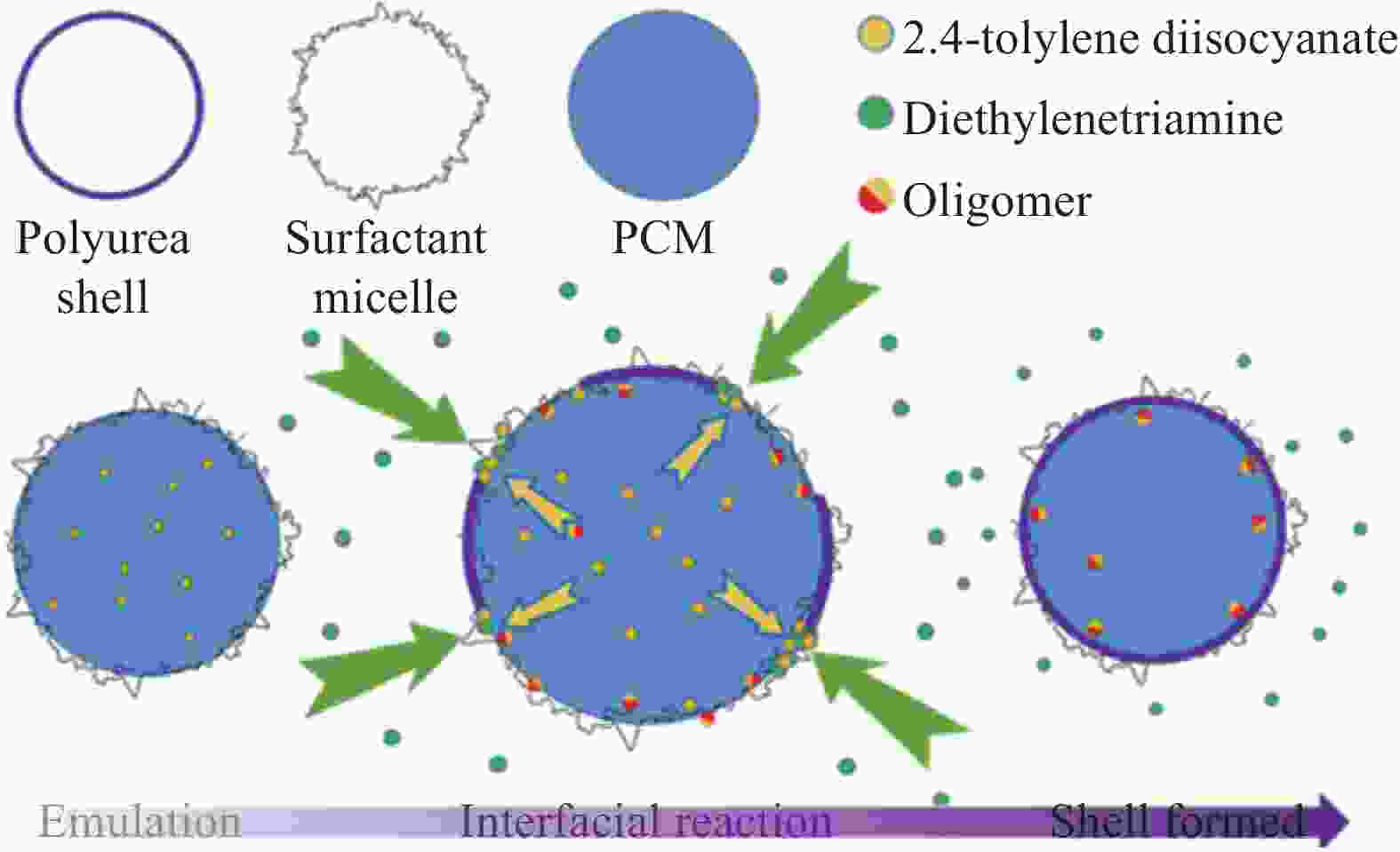

Mechanical strength

Chemical stability

Poor chemical and thermal stabilities

Low thermal conductivity

Toxicity

Flammability

Poor thermal stability

Low long-term stability

Brittle

Easy to fracture leading to the leakage

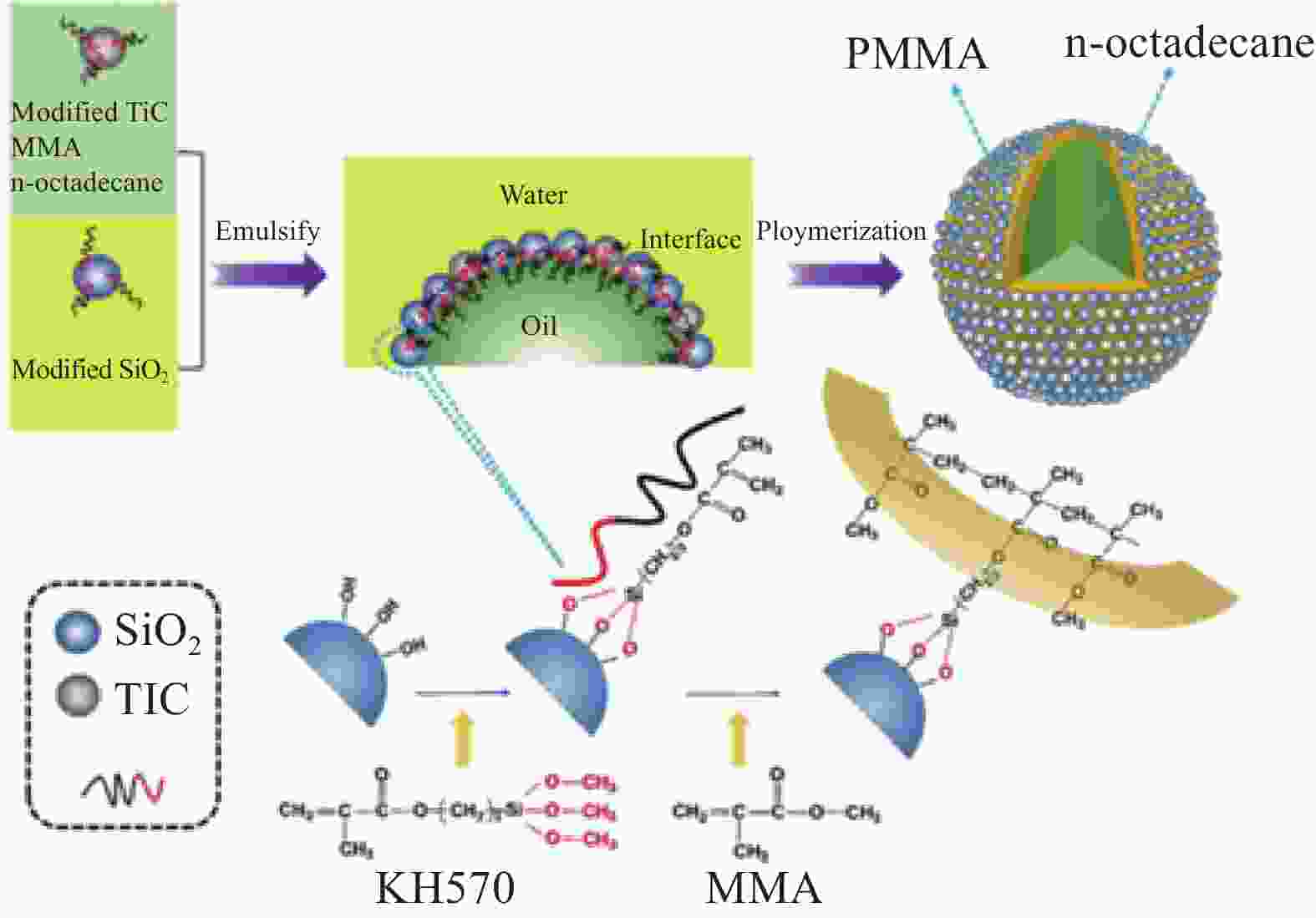

High cost

Easy to fracture leading to the leakage

Inorganic additives are easy to detach

from the surface表 2 典型壳体材料封装PCM芯材制备的MEPCM性能对比

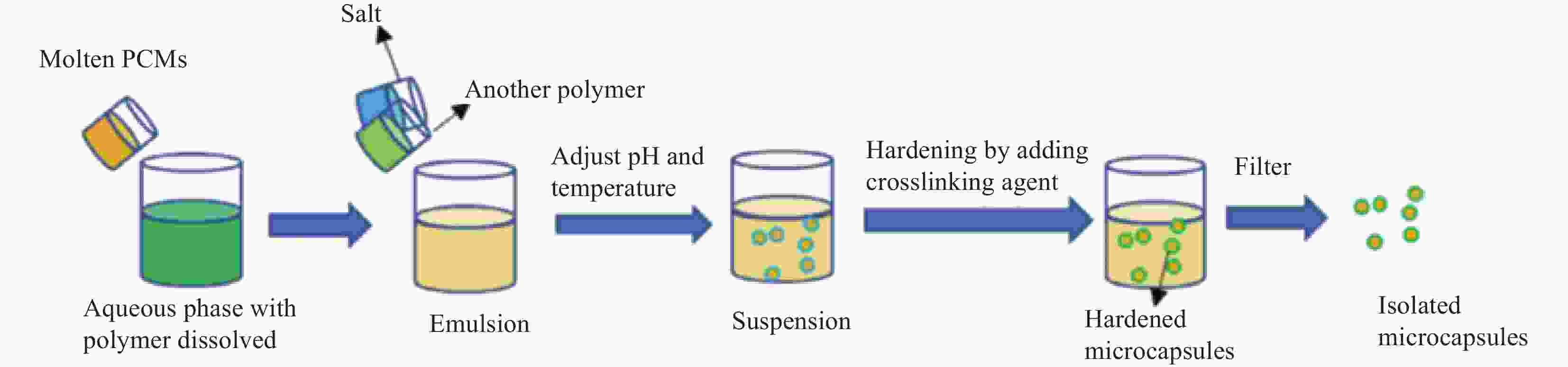

Table 2. Typical shell materials in the preparation of MEPCM

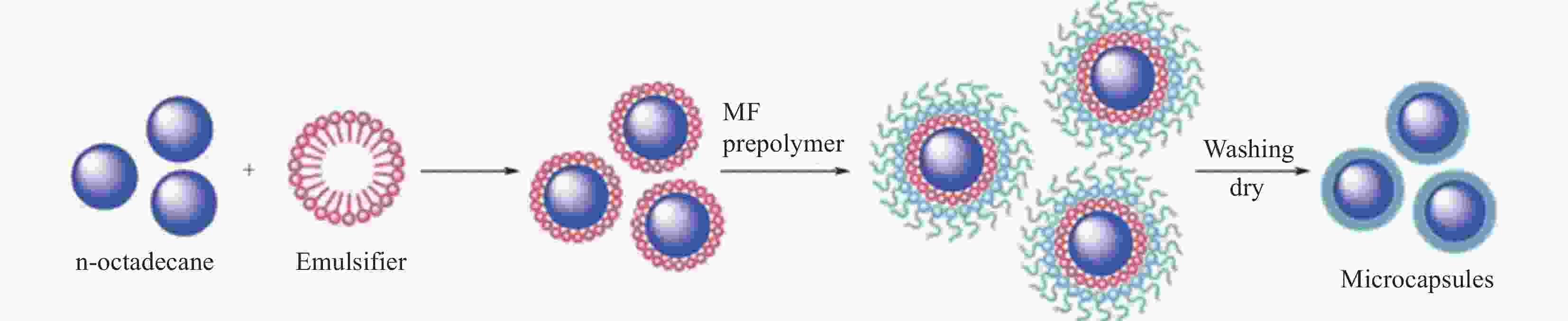

Shell Type Shell Materials Core Materials Encapsulation Methods Enthalpy (J/g) Encapsulation

Rate (%)Refs. Organic shells MF Lauryl alcohol In-situ polymerization 79.5 91.2 [16] MUF Paraffins In-situ polymerization 134.3 77.1 [17] PU Methyl laurate Interfacial polymerization 136.2 - [18] PMMA stearic acid Emulsion polymerization 102 52.2 [19] Inorganic shells SiO2 polyethylene glycol In-situ polymerization 130 80 [20] TiO2 N-Eicosane Interfacial polymerization 188.27 [21] CaCO3 Paraffins Emulsion polymerization 171.9 56.6 [22] ZnO/SiO2 N-Docosane Interfacial polymerization 139 [23] Organic-Inorganic hybrid MF-SiO2 N-Octadecane Emulsion polymerization 167.1 - [24] PMMA-BN/TiO2 Paraffins Emulsion polymerization 124.4 72.1 [25] PUA-TiO2 N-Octadecane Interfacial polymerization 181.1 77.3 [26] Notes:MUF is the Melamine urea formaldehyde, PMMA is the Polymethylmethacrylate, PUA is the Polyurethane acrylate, BN is the Boron nitride. 表 3 四种化学法的优点和缺点

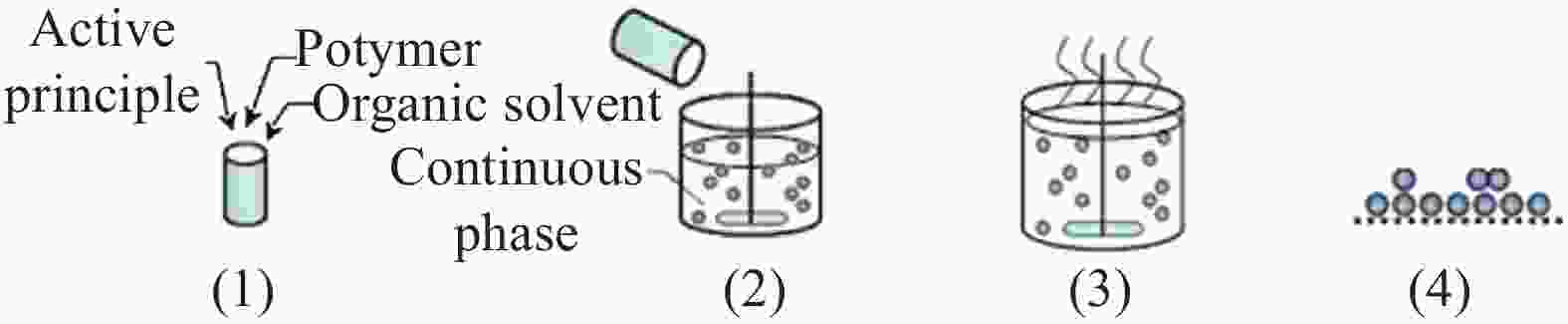

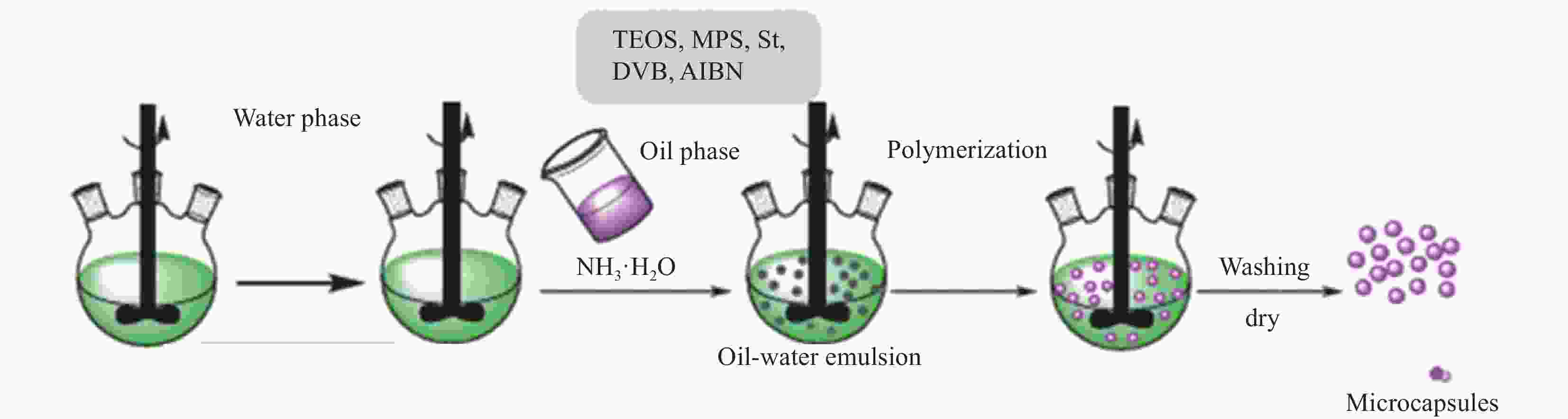

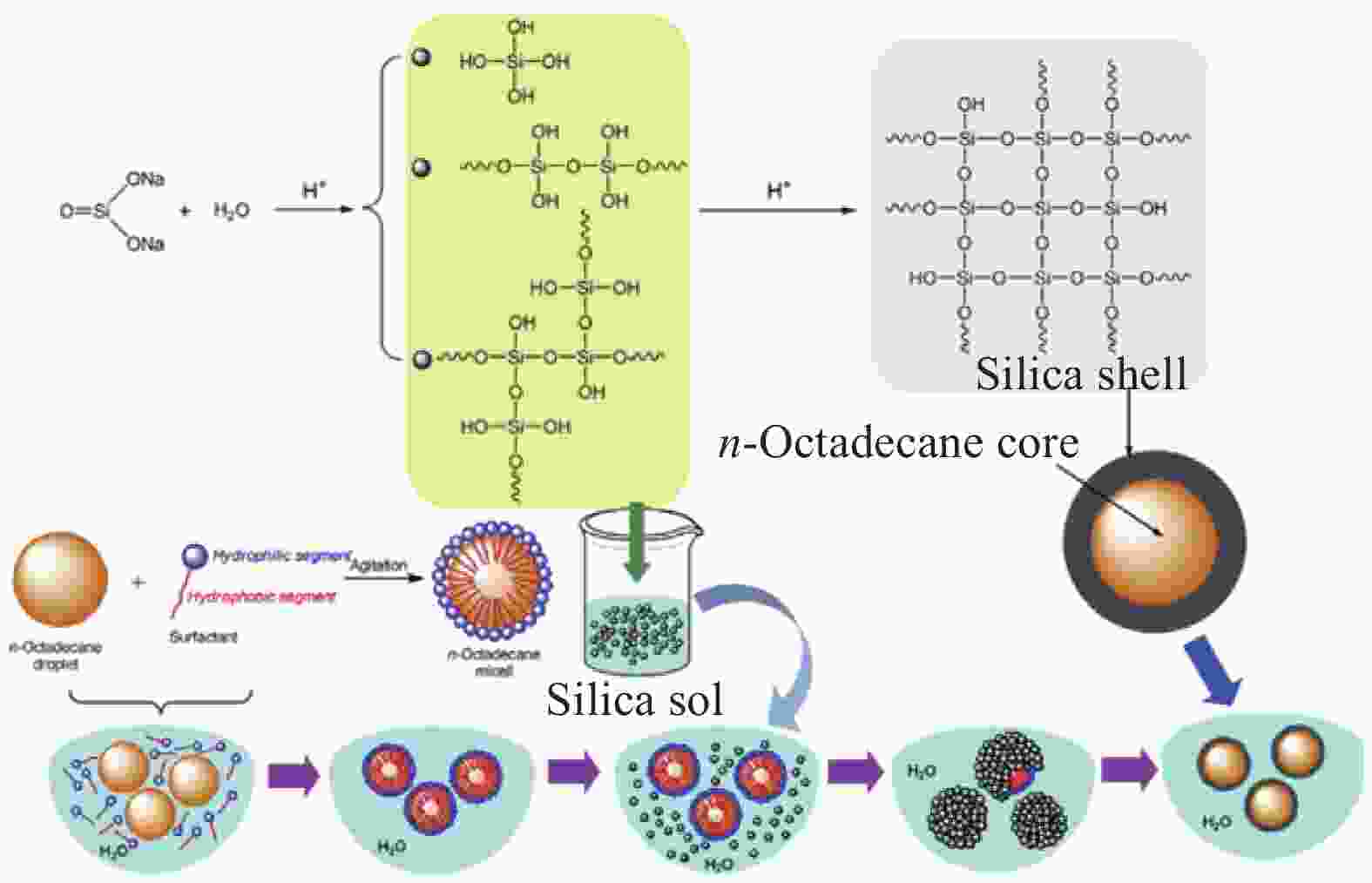

Table 3. Advantages and disadvantages of the four chemical methods

Technique Advantages Disadvantages In-situ polymerization High encapsulation efficiency; Stable shape; Uniform coating Complex operation; Harmful for the environment Interfacial polymerization High reaction speed; Simple operation; Low permeability The monomer is required to have a high reactivity; Harmful for the environment Suspension polymerization Environmentally; friendly; Facile reaction; condition High packaging rate High energy; consumption; Expensive; Not used for inorganic PCMs Emulsion polymerization Stable; High packaging rate; High preparation efficiency; Environmentally

friendlyComplicated; Expensive 表 4 物理法、化学法及物理-化学法的优点和缺点

Table 4. Advantages and disadvantages of physical method, chemical method and physical-chemical method

Technique Advantages Disadvantages

Physical method

Chemical method

Physical-chemical methodThe preparation process is simple, easy to operate, and the cost is low; no chemical reagents are needed, and it is environmentally friendly.

The size, shape and wall material of microcapsules can be precisely controlled to improve the stability and performance of the material; the functional modification of the microcapsule wall can be achieved through chemical reactions, expanding the application fields of the material.

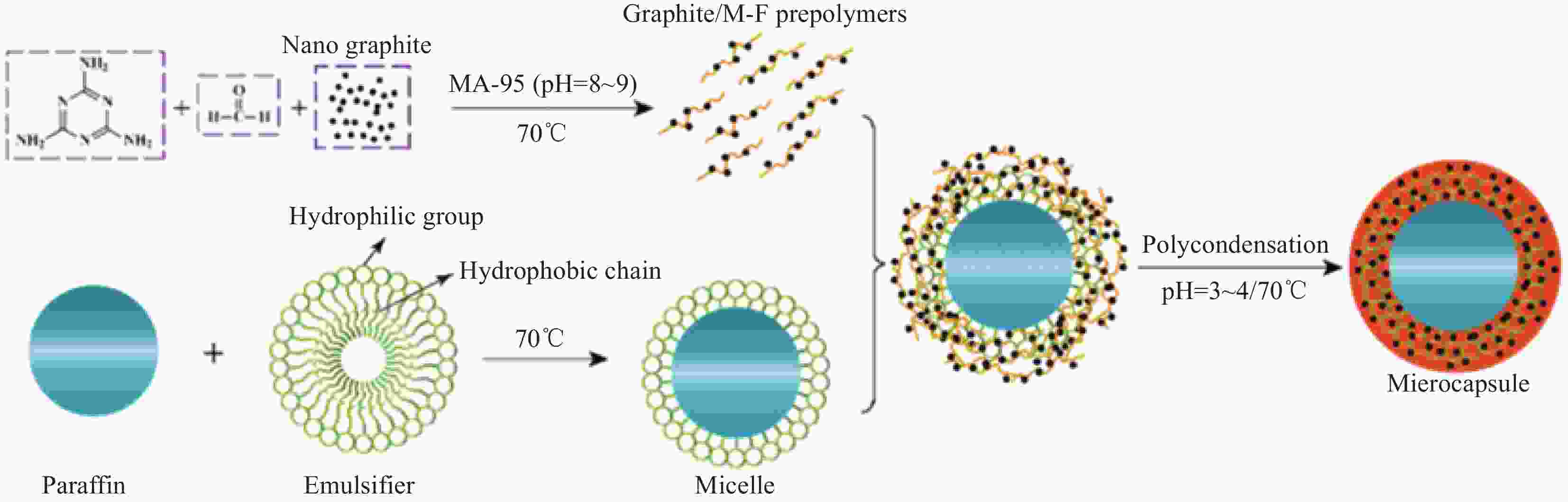

Combining the advantages of physical methods and chemical methods, the shortcomings of each can be overcome to a certain extent; the size control of microcapsules and the functional modification of wall materials can be taken into account during the preparation process.The size and shape of microcapsules are difficult to control, which affects the performance stability of the material; it is difficult to achieve functional modification of the microcapsule wall, which limits the application scope of the material.

The preparation process is complex, requires the use of chemical reagents, and requires high operating techniques; some chemical reagents may cause pollution to the environment and need to be handled with caution.

The preparation process is relatively complex, requiring comprehensive consideration of physical and chemical factors, and high operational technical requirements; appropriate process conditions need to be carefully selected to ensure the performance stability of microcapsule composite phase change materials. -

[1] TAHIRI F E, CHIKH K, KHAFALLAH M. Optimal management energy system and control strategies for isolated hybrid solar-wind-battery-diesel power system[J]. Emerging Science Journal, 2021, 5(2): 111-124. doi: 10.28991/esj-2021-01262 [2] QERIMI D, DIMITRIESKA C, VASILEVSKA S, et al. Modeling of the solar thermal energy use in urban areas[J]. Civil Engineering Journal, 2020, 6(7): 1349-1367. doi: 10.28991/cej-2020-03091553 [3] PASARKAR N P, YADAV M, MAHANWAR P A. A review on the micro-encapsulation of phase change materials: classification, study of synthesis technique and their applications[J]. Journal of Polymer Research, 2023, 30(1): 13. doi: 10.1007/s10965-022-03380-0 [4] 王成君, 段志英, 王爱军, 等. 基于共晶系相变材料的研究进展[J]. 材料导报, 2021, 35(13): 13058-13066. doi: 10.11896/cldb.20040110WANG C J, DUAN Z Y, WANG A J et al. Research progress based on eutectic phase change materials[J]. Materials Reports, 2021, 35(13): 13058-13066(in Chinese). doi: 10.11896/cldb.20040110 [5] ZHANG H, XU C, FANG G. Encapsulation of inorganic phase change thermal storage materials and its effect on thermophysical properties: A review[J]. Solar Energy Materials and Solar Cells, 2022, 241: 111747 doi: 10.1016/j.solmat.2022.111747 [6] ZHANG N, YUAN Y, CAO X, et al. Latent heat thermal energy storage systems with solid–liquid phase change materials: a review[J]. Advanced Engineering Materials, 2018, 20(6): 1700753. doi: 10.1002/adem.201700753 [7] GAO H, WANG J, CHEN X, et al. Nanoconfinement effects on thermal properties of nanoporous shape-stabilized composite PCMs: A review[J]. Nano Energy, 2018, 53: 769-797. doi: 10.1016/j.nanoen.2018.09.007 [8] KANG L, REN L, NIU H, et al. Paraffin@ SiO2 microcapsules-based phase change composites with enhanced thermal conductivity for passive battery cooling[J]. Composites Science and Technology, 2022, 230: 109756. doi: 10.1016/j.compscitech.2022.109756 [9] XIA Y, CUI W, JI R, et al. Design and synthesis of novel microencapsulated phase change materials with enhancement of thermal conductivity and thermal stability: Self-assembled boron nitride into shell materials[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 586: 124225. doi: 10.1016/j.colsurfa.2019.124225 [10] HUANG H, SHI T, HE R, et al. Phase-Changing Microcapsules Incorporated with Black Phosphorus for Efficient Solar Energy Storage[J]. Advanced Science, 2020, 7(23): 2000602. doi: 10.1002/advs.202000602 [11] NIU S, CHENG J, ZHAO Y, et al. Preparation and characterization of multifunctional phase change material microcapsules with modified carbon nanotubes for improving the thermal comfort level of buildings[J]. Construction and Building Materials, 2022, 347: 128628. doi: 10.1016/j.conbuildmat.2022.128628 [12] CHINNASAMY V, HEO J, JUNG S, et al. Shape stabilized phase change materials based on different support structures for thermal energy storage applications-A review[J]. Energy, 2022: 125463. [13] 公雪, 王程遥, 朱群志. 微胶囊相变材料制备与应用研究进展[J]. 化工进展, 2021, 40(10): 5554-5576.GONG Xue, WANG Chengyao, ZHU Qunzhi. Research progress on preparation and application of microcapsule phase change materials[J]. Chemical Industry and Engineering Progress, 2021, 40(10): 5554-5576(in Chinese). [14] HUANG J, WANG T, ZHU P, et al. Preparation, characterization, and thermal properties of the microencapsulation of a hydrated salt as phase change energy storage materials[J]. Thermochimica Acta, 2013, 557: 1-6. doi: 10.1016/j.tca.2013.01.019 [15] LI Z, ZHOU M, WU F, et al. Direct compaction properties of Zingiberis Rhizoma extracted powders coated with various shell materials: Improvements and mechanism analysis[J]. International Journal of Pharmaceutics, 2019, 564: 10-21. doi: 10.1016/j.ijpharm.2019.04.021 [16] KUMAR G N, Al-Aifan B, PARAMESHWARAN R, et al. Facile synthesis of microencapsulated 1-dodecanol/melamine-formaldehyde phase change material using in-situ polymerization for thermal energy storage[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2021, 610: 125698. doi: 10.1016/j.colsurfa.2020.125698 [17] HAN S, CHEN Y, LYU S, et al. Effects of processing conditions on the properties of paraffin/melamine-urea-formaldehyde microcapsules prepared by in situ polymerization[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 585: 124046. doi: 10.1016/j.colsurfa.2019.124046 [18] HU D, WANG Z, MA W. Fabrication and characterization of a novel polyurethane microencapsulated phase change material for thermal energy storage[J]. Progress in Organic Coatings, 2021, 151: 106006. doi: 10.1016/j.porgcoat.2020.106006 [19] ZHANG T, CHEN M, ZHANG Y, et al. Microencapsulation of stearic acid with polymethylmethacrylate using iron (III) chloride as photo-initiator for thermal energy storage[J]. Chinese Journal of Chemical Engineering, 2017, 25(10): 1524-1532. doi: 10.1016/j.cjche.2017.04.013 [20] SUN Z, SUN K, ZHANG H, et al. Development of poly (ethylene glycol)/silica phase-change microcapsules with well-defined core-shell structure for reliable and durable heat energy storage[J]. Solar Energy Materials and Solar Cells, 2021, 225: 111069. doi: 10.1016/j.solmat.2021.111069 [21] PEYHURAJAN V, SIVAN S, KONATTA J, et al. Facile approach to improve solar thermal energy storage efficiency using encapsulated sugar alcohol based phase change material[J]. Solar Energy Materials and Solar Cells, 2018, 185: 524-535. doi: 10.1016/j.solmat.2018.06.007 [22] JIANG Z, YANG W, HE F, et al. Microencapsulated paraffin phase-change material with calcium carbonate shell for thermal energy storage and solar-thermal conversion[J]. Langmuir, 2018, 34(47): 14254-14264. doi: 10.1021/acs.langmuir.8b03084 [23] SUN K, LIU H, WANG X, et al. Innovative design of superhydrophobic thermal energy-storage materials by microencapsulation of n-docosane with nanostructured ZnO/SiO2 shell[J]. Applied Energy, 2019, 237: 549-565. doi: 10.1016/j.apenergy.2019.01.043 [24] ZHAI D, HE Y, ZHANG X, et al. Preparation, Morphology, and thermal performance of microencapsulated phase change materials with a MF/SiO2 composite shell[J]. Energy & Fuels, 2020, 34(12): 16819-16830. [25] SUN N, XIAO Z. Synthesis and performances of phase change materials microcapsules with a polymer/BN/TiO2 hybrid shell for thermal energy storage[J]. Energy & Fuels, 2017, 31(9): 10186-10195. [26] QIU X Z, TAO Y, Xu X Q, et al. Synthesis and characterization of paraffin/TiO2-P (MMA-co-BA) phase change material microcapsules for thermal energy storage[J]. Journal of Applied Polymer Science, 2018, 135(27): 46447. doi: 10.1002/app.46447 [27] SHCHUKINA E M, GRAHAM M, ZHENG Z, et al. Nanoencapsulation of phase change materials for advanced thermal energy storage systems[J]. Chemical Society Reviews, 2018, 47(11): 4156-4175. doi: 10.1039/C8CS00099A [28] GHOSH D, GHOSE J, DATTA P, et al. Strategies for phase change material application in latent heat thermal energy storage enhancement: Status and prospect[J]. Journal of Energy Storage, 2022, 53: 105179. doi: 10.1016/j.est.2022.105179 [29] ZHAO Y, ZHANG X, HUA W. Review of preparation technologies of organic composite phase change materials in energy storage[J]. Journal of Molecular Liquids, 2021, 336: 115923. doi: 10.1016/j.molliq.2021.115923 [30] HOSSAIN M S, PANDEY A K, SELVARAJ J, et al. Two side serpentine flow based photovoltaic-thermal-phase change materials (PVT-PCM) system: Energy, exergy and economic analysis[J]. Renewable Energy, 2019, 136: 1320-1336. doi: 10.1016/j.renene.2018.10.097 [31] JAVADI F S, METSELAAR H S C, Ganesan P. Performance improvement of solar thermal systems integrated with phase change materials (PCM), a review[J]. Solar Energy, 2020, 206: 330-352. doi: 10.1016/j.solener.2020.05.106 [32] LI W, HUANG R, ZONG J, et al. Microencapsulation and Morphological Characterization of Renewable Microencapsulated Phase-Change Materials with Cellulose Diacetate Shell[J]. ChemistrySelect, 2017, 2(21): 5917-5923. doi: 10.1002/slct.201701078 [33] METHAAPANON R, KORNBONGKOTMAS S, ATABOONWONGSE C, et al. Microencapsulation of n-octadecane and methyl palmitate phase change materials in silica by spray drying process[J]. Powder Technology, 2020, 361: 910-916. doi: 10.1016/j.powtec.2019.10.114 [34] LEE H, DESHMUKH P R, Kim J H, et al. Spray drying formation of metal oxide (TiO2 or SnO2) nanoparticle coated boron particles in the form of microspheres and their physicochemical properties[J]. Journal of Alloys and Compounds, 2019, 810: 151923. doi: 10.1016/j.jallcom.2019.151923 [35] WANG X, YIN H, CHEN Z, et al. Epoxy resin/ethyl cellulose microcapsules prepared by solvent evaporation for repairing microcracks: Particle properties and slow-release performance[J]. Materials Today Communications, 2020, 22: 100854. doi: 10.1016/j.mtcomm.2019.100854 [36] EKANEM E E, ZHANG Z, VLADISAVLJEVIC G T. Facile microfluidic production of composite polymer core-shell microcapsules and crescent-shaped microparticles[J]. Journal of colloid and interface science, 2017, 498: 387-394. doi: 10.1016/j.jcis.2017.03.067 [37] XING J, ZHOU Y, YANG K, et al. Microencapsulation of fatty acid eutectic with polyvinyl chloride shell used for thermal energy storage[J]. Journal of Energy Storage, 2021, 34: 101998. doi: 10.1016/j.est.2020.101998 [38] SU W, DARKWA J, KOKOGIANNAKIS G. Review of solid-liquid phase change materials and their encapsulation technologies[J]. Renewable and Sustainable Energy Reviews, 2015, 48: 373-391. doi: 10.1016/j.rser.2015.04.044 [39] CHO J S, KWON A, CHO C G. Microencapsulation of octadecane as a phase-change material by interfacial polymerization in an emulsion system[J]. Colloid and polymer science, 2002, 280(3): 260-266. doi: 10.1007/s00396-001-0603-x [40] LEE J, PARK S J, PARK C S, et al. Effect of a surfactant in microcapsule synthesis on self-healing behavior of capsule embedded polymeric films[J]. Polymers, 2018, 10(6): 675. doi: 10.3390/polym10060675 [41] XU B, WEI Z, HONG X, et al. Preparation and characterization of novel microencapsulated phase change materials with SiO2/FeOOH as the shell for heat energy storage and photocatalysis[J]. Journal of Energy Storage, 2021, 43: 103251. doi: 10.1016/j.est.2021.103251 [42] CAI C, OUYANG X, ZHOU L, et al. Co-solvent free interfacial polycondensation and properties of polyurea PCM microcapsules with dodecanol dodecanoate as core material[J]. Solar Energy, 2020, 199: 721-730. doi: 10.1016/j.solener.2020.02.071 [43] TRIVEDI G V N, PARAMESHWARAN R. Microencapsulated phase change material suspensions for cool thermal energy storage[J]. Materials Chemistry and Physics, 2020, 242: 122519. doi: 10.1016/j.matchemphys.2019.122519 [44] WANG X, ZHANG C, WANG K, et al. Highly efficient photothermal conversion capric acid phase change microcapsule: Silicon carbide modified melamine urea formaldehyde[J]. Journal of Colloid and Interface Science, 2021, 582: 30-40. doi: 10.1016/j.jcis.2020.08.014 [45] WANG K, YAN T, MENG L, et al. A Review on Microencapsulated Phase-Change Materials: Preparation, Photothermal Conversion Performance, Energy Storage, and Application[J]. Solar RRL, 2023: 2300447. [46] ARSHADY R. Suspension, emulsion, and dispersion polymerization: A methodological survey[J]. Colloid and polymer science, 1992, 270: 717-732. doi: 10.1007/BF00776142 [47] TANWAR S, KAUR R. Development and investigation of microencapsulated caprylic acid-based phase change materials for thermal energy storage applications[J]. International Journal of Energy Research, 2021. [48] OKTAY B, BASTURK E, KAHRAMAN M V, et al. Designing Coconut Oil Encapsulated Poly (stearyl methacrylate-co-hydroxylethyl metacrylate) Based Microcapsule for Phase Change Materials[J]. ChemistrySelect, 2019, 4(17): 5110-5115. doi: 10.1002/slct.201900340 [49] ŞAHAN N, PAKSOY H. Designing behenic acid microcapsules as novel phase change material for thermal energy storage applications at medium temperature[J]. International Journal of Energy Research, 2020, 44(5): 3922-3933. doi: 10.1002/er.5193 [50] PUUPPONEN S, SEPPALA A, VARTIAO, et al. Preparation of paraffin and fatty acid phase changing nanoemulsions for heat transfer[J]. Thermochimica acta, 2015, 601: 33-38. doi: 10.1016/j.tca.2014.12.020 [51] BAKESHLOU Z, NIKFARJAM N. Thermoregulating papers containing fabricated microencapsulated phase change materials through Pickering emulsion templating[J]. Industrial & Engineering Chemistry Research, 2020, 59(46): 20253-20268. [52] WANG H, ZHAO L, SONG G, et al. Organic-inorganic hybrid shell microencapsulated phase change materials prepared from SiO2/TiC-stabilized pickering emulsion polymerization[J]. Solar Energy Materials and Solar Cells, 2018, 175: 102-110. doi: 10.1016/j.solmat.2017.09.015 [53] WANG Z, MA W, HU D, et al. Synthesis and characterization of microencapsulated methyl laurate with polyurethane shell materials via interfacial polymerization in Pickering emulsions[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 600: 124958. doi: 10.1016/j.colsurfa.2020.124958 [54] ARSHAD A, JABBAL M, YAN Y, et al. The micro-/nano-PCMs for thermal energy storage systems: a state of art review[J]. International Journal of Energy Research, 2019, 43(11): 5572-5620. doi: 10.1002/er.4550 [55] HUANG Y, STONEHOUSE A, ABEYKOON C. Encapsulation methods for phase change materials-A critical review[J]. International Journal of Heat and Mass Transfer, 2023, 200: 123458. doi: 10.1016/j.ijheatmasstransfer.2022.123458 [56] HAWLADER M N A, UDDIN M S, KHIN M M. Microencapsulated PCM thermal-energy storage system[J]. Applied energy, 2003, 74(1-2): 195-202. doi: 10.1016/S0306-2619(02)00146-0 [57] SANTOS M G, BOZZA F T, THOMAZINIM, et al. Microencapsulation of xylitol by double emulsion followed by complex coacervation[J]. Food Chemistry, 2015, 171: 32-39. doi: 10.1016/j.foodchem.2014.08.093 [58] LI M, MU B, ALTABEY W A. A review study on preparation and application of microencapsulated phase change materials[J]. International Journal of Sustainable Materials and Structural Systems, 2018, 3(2): 151-170. doi: 10.1504/IJSMSS.2018.097835 [59] HE F, WANG X, WU D. New approach for sol-gel synthesis of microencapsulated n-octadecane phase change material with silica wall using sodium silicate precursor[J]. Energy, 2014, 67: 223-233. doi: 10.1016/j.energy.2013.11.088 [60] LUAN J, LIU Y, TAO J, et al. Influence of acid and alkali reaction system on the morphology and thermal properties of paraffin@ SiO2 phase change microcapsules for heat storage[J]. Journal of Renewable and Sustainable Energy, 2022, 14(4): 044102. doi: 10.1063/5.0098752 [61] ZHANG Y, TAO W, WANG K, et al. Analysis of thermal properties of gypsum materials incorporated with microencapsulated phase change materials based on silica[J]. Renewable Energy, 2020, 149: 400-408. doi: 10.1016/j.renene.2019.12.051 [62] FARID M M, KHUDHAIR A M, RAZACK S A K, et al. A review on phase change energy storage: materials and applications[J]. Energy conversion and management, 2004, 45(9-10): 1597-1615. doi: 10.1016/j.enconman.2003.09.015 [63] YAN J, HU D, WANG Z, et al. Construction strategies and thermal energy storage applications of shape-stabilized phase change materials[J]. Journal of Applied Polymer Science, 2022, 139(4): 51550. doi: 10.1002/app.51550 [64] OYA T, NOMURA T, TSUBOTA M, et al. Thermal conductivity enhancement of erythritol as PCM by using graphite and nickel particles[J]. Applied Thermal Engineering, 2013, 61(2): 825-828. doi: 10.1016/j.applthermaleng.2012.05.033 [65] KHODADADI J M, HOSSEINIZADEH S F. Nanoparticle-enhanced phase change materials (NEPCM) with great potential for improved thermal energy storage[J]. International communications in heat and mass transfer, 2007, 34(5): 534-543. doi: 10.1016/j.icheatmasstransfer.2007.02.005 [66] Al-SHANNAQ R, KURDI J, Al-MUHTASEB S, et al. Innovative method of metal coating of microcapsules containing phase change materials[J]. Solar Energy, 2016, 129: 54-64. doi: 10.1016/j.solener.2016.01.043 [67] ZHU Y, CHI Y, LIANG S, et al. Novel metal coated nanoencapsulated phase change materials with high thermal conductivity for thermal energy storage[J]. Solar energy materials and solar cells, 2018, 176: 212-221. doi: 10.1016/j.solmat.2017.12.006 [68] LIU J, CHEN L, FANG X, et al. Preparation of graphite nanoparticles-modified phase change microcapsules and their dispersed slurry for direct absorption solar collectors[J]. Solar energy materials and solar cells, 2017, 159: 159-166. doi: 10.1016/j.solmat.2016.09.020 [69] KE W D, WU X W, ZHANG J L. In situ polymerization of organic and inorganic phase change microcapsule and enhancement of infrared stealth via nano iron[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2021, 627: 127124. doi: 10.1016/j.colsurfa.2021.127124 [70] PARVATE S, SINGH J, VENNAPUSA J R, et al. Copper nanoparticles interlocked phase-change microcapsules for thermal buffering in packaging application[J]. Journal of Industrial and Engineering Chemistry, 2021, 102: 69-85. doi: 10.1016/j.jiec.2021.06.029 [71] SUN Y, WANG R, LIU X, et al. Improvements in the thermal conductivity and mechanical properties of phase-change microcapsules with oxygen-plasma-modified multiwalled carbon nanotubes[J]. Journal of Applied Polymer Science, 2017, 134(44): 45269. doi: 10.1002/app.45269 [72] ARSHAD A, JABBAL M, YAN Y. Preparation and characteristics evaluation of mono and hybrid nano-enhanced phase change materials (NePCMs) for thermal management of microelectronics[J]. Energy conversion and management, 2020, 205: 112444. doi: 10.1016/j.enconman.2019.112444 [73] SUN Z, ZHAO L, WAN H, et al. Construction of polyaniline/carbon nanotubes-functionalized phase-change microcapsules for thermal management application of supercapacitors[J]. Chemical Engineering Journal, 2020, 396: 125317. doi: 10.1016/j.cej.2020.125317 [74] MENG X, QIN S, FAN H, et al. Long alkyl chain-grafted carbon nanotube-decorated binary-core phase-change microcapsules for heat energy storage: Synthesis and thermal properties[J]. Solar Energy Materials and Solar Cells, 2020, 212: 110589. doi: 10.1016/j.solmat.2020.110589 [75] ZENG J, CAO Z, YANG D, et al. Thermal conductivity enhancement of Ag nanowires on an organic phase change material[J]. Journal of thermal analysis and calorimetry, 2010, 101(1): 385-389. doi: 10.1007/s10973-009-0472-y [76] KANG M, LIU Y, LIN W, et al. The thermal behavior and flame retardant performance of phase change material microcapsules with halloysite nanotube[J]. Journal of Energy Storage, 2023, 60: 106632. doi: 10.1016/j.est.2023.106632 [77] WANG X, LI Y, DAS P, et al. Layer-by-layer stacked amorphous V2O5/Graphene 2D heterostructures with strong-coupling effect for high-capacity aqueous zinc-ion batteries with ultra-long cycle life[J]. Energy Storage Materials, 2020, 31: 156-163. doi: 10.1016/j.ensm.2020.06.010 [78] GUO Y, WANG T, YANG Q, et al. Highly efficient electrochemical reduction of nitrogen to ammonia on surface termination modified Ti3C2Tx MXene nanosheets[J]. ACS nano, 2020, 14(7): 9089-9097. doi: 10.1021/acsnano.0c04284 [79] XU M, LIANG T, SHI M, et al. Graphene-like two-dimensional materials[J]. Chemical reviews, 2013, 113(5): 3766-3798. doi: 10.1021/cr300263a [80] WONG T L, VALLES C, NASSER A, et al. Effects of boron-nitride-based nanomaterials on the thermal properties of composite organic phase change materials: A state-of-the-art review[J]. Renewable and Sustainable Energy Reviews, 2023, 187: 113730. doi: 10.1016/j.rser.2023.113730 [81] RAMANATHAN T, ABDALA A A, STANKOVICH S, et al. Functionalized graphene sheets for polymer nanocomposites[J]. Nature nanotechnology, 2008, 3(6): 327-331. doi: 10.1038/nnano.2008.96 [82] ZHANG Z, LIU Y, LIANG Z, et al. High thermal storage ability and photothermal conversion capacity phase change capsule with graphene oxide covalently grafted silica shell[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2023, 657: 130594. doi: 10.1016/j.colsurfa.2022.130594 [83] AISWARYA V, DAS S. Magnetized graphene oxide–Modified microencapsulated phase change material for enhanced heat transfer performance with reduced leakage[J]. Thermal Science and Engineering Progress, 2023, 41: 101807. doi: 10.1016/j.tsep.2023.101807 [84] LIU Z, CHEN Z, YU F. Microencapsulated phase change material modified by graphene oxide with different degrees of oxidation for solar energy storage[J]. Solar Energy Materials and Solar Cells, 2018, 174: 453-459. doi: 10.1016/j.solmat.2017.09.034 [85] CHEN D Z, QIN S Y, TSUI G C P, et al. Fabrication, morphology and thermal properties of octadecylamine-grafted graphene oxide-modified phase-change microcapsules for thermal energy storage[J]. Composites Part B:Engineering, 2019, 157: 239-247. doi: 10.1016/j.compositesb.2018.08.066 [86] LAN W, SHANG B, WU R, et al. Thermally-enhanced nanoencapsulated phase change materials for latent functionally thermal fluid[J]. International Journal of Thermal Sciences, 2021, 159: 106619. doi: 10.1016/j.ijthermalsci.2020.106619 [87] XIA Y, CUI W, JI R, et al. Design and synthesis of novel microencapsulated phase change materials with enhancement of thermal conductivity and thermal stability: Self-assembled boron nitride into shell materials[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2020, 586: 124225. doi: 10.1016/j.colsurfa.2019.124225 [88] WANG X, CHENG Q, WU M, et al. Thermal properties optimization of lauric acid as phase change material with modified boron nitride nanosheets-sodium sulfate for thermal energy storage[J]. Journal of Energy Storage, 2023, 61: 106781. doi: 10.1016/j.est.2023.106781 [89] HUANG H, SHI T, HE R, et al. Phase-Changing Microcapsules Incorporated with Black Phosphorus for Efficient Solar Energy Storage[J]. Advanced Science, 2020, 7(23): 2000602. doi: 10.1002/advs.202000602 [90] JIN W, HUANG Q, HUANG H, et al. The preparation of a suspension of microencapsulated phase change material (MPCM) and thermal conductivity enhanced by MXene for thermal energy storage[J]. Journal of Energy Storage, 2023, 73: 108868. doi: 10.1016/j.est.2023.108868 [91] ZHAO K, GUO Z, WANG J, et al. Enhancing solar photothermal conversion and energy storage with titanium carbide (Ti3C2) MXene nanosheets in phase-change microcapsules[J]. Journal of Colloid and Interface Science, 2023, 650: 1591-1604. doi: 10.1016/j.jcis.2023.07.114 [92] QIU X, LU L, WANG J, et al. Fabrication, thermal properties and thermal stabilities of microencapsulated n-alkane with poly (lauryl methacrylate) as shell[J]. Thermochimica Acta, 2015, 620: 10-17. doi: 10.1016/j.tca.2015.10.001 [93] RODRIGUEZ-UBINAS E, RUIZ-VALERO L, VEGA S, et al. Applications of phase change material in highly energy-efficient houses[J]. Energy and Buildings, 2012, 50: 49-62. doi: 10.1016/j.enbuild.2012.03.018 [94] HU D, LIU H, MA W. Rational design of nanohybrids for highly thermally conductive polymer composites[J]. Composites Communications, 2020, 21: 100427. doi: 10.1016/j.coco.2020.100427 [95] RABADY R I, DUAA S M. Thermal conductivity enhancement of sodium thiosulfate pentahydrate by adding carbon nano-tubes/graphite nano-particles[J]. Journal of Energy Storage, 2020, 27: 101166. doi: 10.1016/j.est.2019.101166 [96] XU B, WANG B, ZHANG C, et al. Synthesis and light-heat conversion performance of hybrid particles decorated MWCNTs/paraffin phase change materials[J]. Thermochimica Acta, 2017, 652: 77-84. doi: 10.1016/j.tca.2017.03.003 [97] SUN N, XIAO Z. Synthesis and performances of phase change materials microcapsules with a polymer/BN/TiO2 hybrid shell for thermal energy storage[J]. Energy & Fuels, 2017, 31(9): 10186-10195. [98] HU D, LIU H, YANG M, et al. Construction of boron nitride nanosheets-based nanohybrids by electrostatic self-assembly for highly thermally conductive composites[J]. Advanced Composites and Hybrid Materials, 2022, 5(4): 3201-3211. doi: 10.1007/s42114-022-00463-w [99] LIU Z, CHEN Z, YU F. Enhanced thermal conductivity of microencapsulated phase change materials based on graphene oxide and carbon nanotube hybrid filler[J]. Solar Energy Materials and Solar Cells, 2019, 192: 72-80. doi: 10.1016/j.solmat.2018.12.014 [100] GAO G, ZHANG T, JIAO S, et al. Preparation of reduced graphene oxide modified magnetic phase change microcapsules and their application in direct absorption solar collector[J]. Solar Energy Materials and Solar Cells, 2020, 216: 110695. doi: 10.1016/j.solmat.2020.110695 [101] JOHN G, KONIG-HAAGEN A, KING’ONDU C K, et al. Galactitol as phase change material for latent heat storage of solar cookers: Investigating thermal behavior in bulk cycling[J]. Solar Energy, 2015, 119: 415-421. doi: 10.1016/j.solener.2015.07.003 [102] KONUKLU Y, OSTRY M, PAKSOY H O, et al. Review on using microencapsulated phase change materials (PCM) in building applications[J]. Energy and Buildings, 2015, 106: 134-155. doi: 10.1016/j.enbuild.2015.07.019 [103] KAZANCI B, CELLAT K, PAKSOY H. Preparation, characterization, and thermal properties of novel fire-resistant microencapsulated phase change materials based on paraffin and a polystyrene shell[J]. RSC advances, 2020, 10(40): 24134-24144. doi: 10.1039/D0RA04093B [104] CAO V D, PILEHVAR S, SALAS-BRINGAS C, et al. Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications[J]. Solar Energy, 2019, 178: 295-307. doi: 10.1016/j.solener.2018.12.039 [105] CHENG J, ZHOU Y, MA D, et al. Preparation and characterization of carbon nanotube microcapsule phase change materials for improving thermal comfort level of buildings[J]. Construction and Building Materials, 2020, 244: 118388. doi: 10.1016/j.conbuildmat.2020.118388 [106] JEONG S G, CHANG S J, WI S, et al. Development and performance evaluation of heat storage paint with MPCM for applying roof materials as basic research[J]. Energy and Buildings, 2016, 112: 62-68. doi: 10.1016/j.enbuild.2015.12.001 [107] SUN W, WANG X, ZHANG X, et al. Design and synthesis of microencapsulated phase-change materials with a poly (divinylbenzene)/dioxide titanium hybrid shell for energy storage and formaldehyde photodegradation[J]. The Journal of Physical Chemistry C, 2020, 124(38): 20806-20815. doi: 10.1021/acs.jpcc.0c06656 [108] ALVA G, LIN Y, LIU L, et al. Synthesis, characterization and applications of microencapsulated phase change materials in thermal energy storage: A review[J]. Energy and Buildings, 2017, 144: 276-294. doi: 10.1016/j.enbuild.2017.03.063 [109] ZHANG G, CAI C, WANG Y, et al. Preparation and evaluation of thermo-regulating bamboo fabric treated by microencapsulated phase change materials[J]. Textile Research Journal, 2019, 89(16): 3387-3393. doi: 10.1177/0040517518813681 [110] NEJMAN A, CIESLAK M. The impact of the heating/cooling rate on the thermoregulating properties of textile materials modified with PCM microcapsules[J]. Applied Thermal Engineering, 2017, 127: 212-223. doi: 10.1016/j.applthermaleng.2017.08.037 [111] ALAKY AKSOY S, ALKANl C, TOZUM M S, et al. Preparation and textile application of poly (methyl methacrylate-co-methacrylic acid)/n-octadecane and n-eicosane microcapsules[J]. The Journal of the Textile Institute, 2017, 108(1): 30-41. doi: 10.1080/00405000.2015.1133128 [112] GAO Y, GENG X, WANG X, et al. Synthesis and characterization of microencapsulated phase change materials with chitosan-based polyurethane shell[J]. Carbohydrate Polymers, 2021, 273: 118629. doi: 10.1016/j.carbpol.2021.118629 [113] SUN Z, ZHAO L, WAN H, et al. Construction of polyaniline/carbon nanotubes-functionalized phase-change microcapsules for thermal management application of supercapacitors[J]. Chemical Engineering Journal, 2020, 396: 125317. doi: 10.1016/j.cej.2020.125317 [114] ZHANG Y, LIU H, NIU J, et al. Development of reversible and durable thermochromic phase-change microcapsules for real-time indication of thermal energy storage and management[J]. Applied Energy, 2020, 264: 114729. doi: 10.1016/j.apenergy.2020.114729 [115] GAO J, WU K, XIE Z, et al. Constructing inter-facial barrier from tribo-positive shell microcapsules to suppress space charge in thermochromic phase change composites for smart electronics[J]. Compo-sites Science and Technology, 2023, 244: 110291. doi: 10.1016/j.compscitech.2023.110291 [116] CHEN R, GE X, LI X, et al. Facile preparation method of phase change microcapsule with organic-inorganic silicone shell for battery thermal management[J]. Composites Science and Technology, 2022, 228: 109662. doi: 10.1016/j.compscitech.2022.109662 [117] ROBERTS N S, Al-SHANNAQ R, KURDI J, et al. Efficacy of using slurry of metal-coated microencapsulated PCM for cooling in a micro-channel heat exchanger[J]. Applied Thermal Engineering, 2017, 122: 11-18. doi: 10.1016/j.applthermaleng.2017.05.001 [118] Zhang S, Niu J. Two performance indices of TES apparatus: Comparison of MPCM slurry vs. stratified water storage tank[J]. Energy and Buildings, 2016, 127: 512-520. doi: 10.1016/j.enbuild.2016.05.085 [119] LI W, WAN H, LOU H, et al. Enhanced thermal management with microencapsulated phase change material particles infiltrated in cellular metal foam[J]. Energy, 2017, 127: 671-679. doi: 10.1016/j.energy.2017.03.145 [120] ZHANG Y, LI X, LI J, et al. Solar-driven phase change microencapsulation with efficient Ti4O7 nanoconverter for latent heat storage[J]. Nano Energy, 2018, 53: 579-586. doi: 10.1016/j.nanoen.2018.09.018 [121] ZHENG Z, JIN J, XU G K, et al. Highly stable and conductive microcapsules for enhancement of joule heating performance[J]. ACS nano, 2016, 10(4): 4695-4703. doi: 10.1021/acsnano.6b01104 [122] ARSHAD A, JABBAL M, YAN Y, et al. The micro-/nano-PCMs for thermal energy storage systems: a state of art review[J]. International Journal of Energy Research, 2019, 43(11): 5572-5620. doi: 10.1002/er.4550 [123] XIAO D, LIANG W, XIE Z, et al. A temperature-responsive release cellulose-based microcapsule loaded with chlorpyrifos for sustainable pest control[J]. Journal of Hazardous Materials, 2021, 403: 123654. doi: 10.1016/j.jhazmat.2020.123654 [124] ZHANG X, WANG X, WU D. Design and synthesis of multifunctional microencapsulated phase change materials with silver/silica double-layered shell for thermal energy storage, electrical conduction and antimicrobial effectiveness[J]. Energy, 2016, 111: 498-512. doi: 10.1016/j.energy.2016.06.017 -

点击查看大图

点击查看大图

计量

- 文章访问数: 69

- HTML全文浏览量: 45

- 被引次数: 0

下载:

下载: