Green continuous preparation of silver-loaded helical alginate composite fibers based on microfluidic technology

-

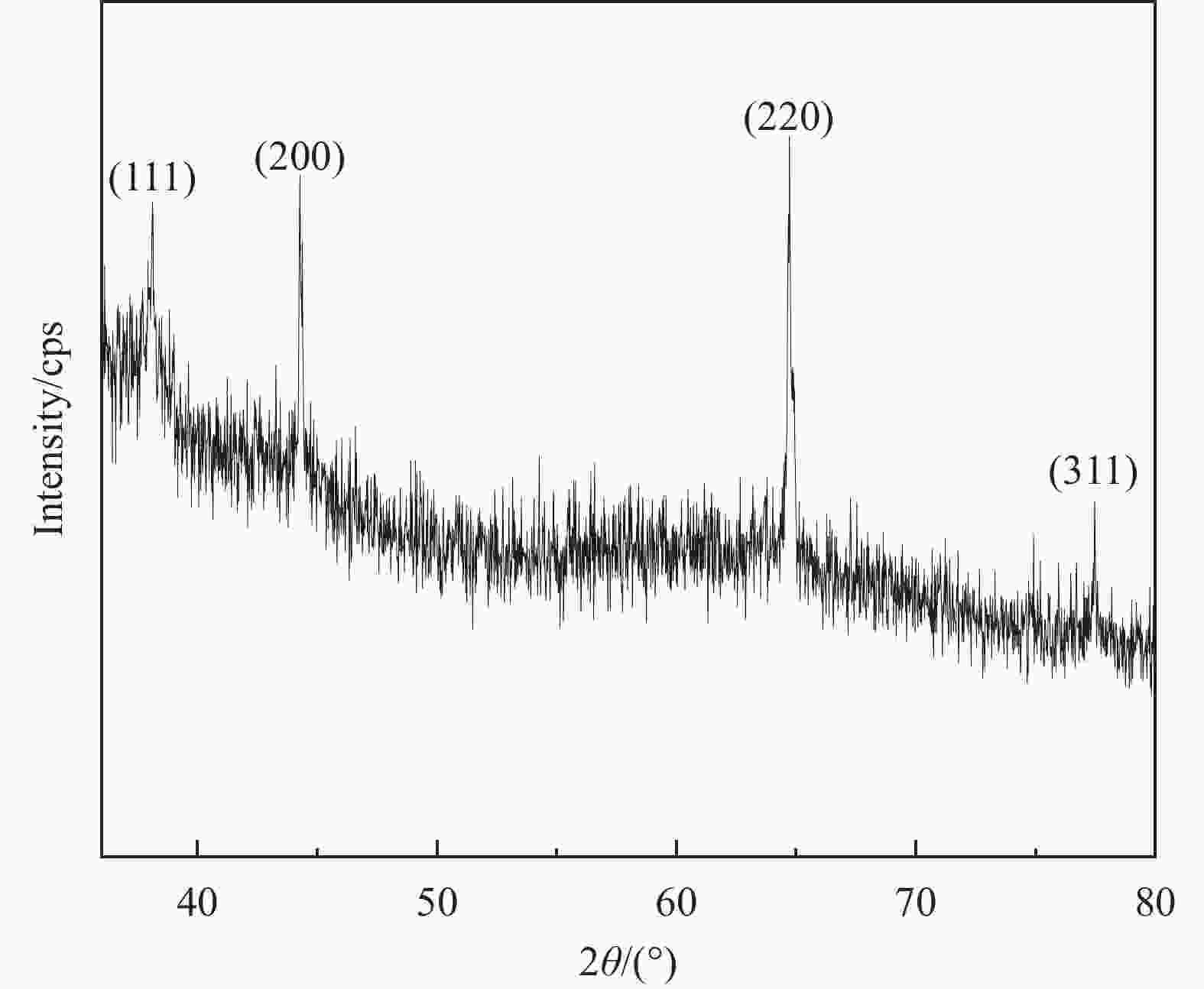

摘要: 提高螺旋海藻纤维抗菌性可保障纤维应用安全及稳定性,然而由于抗菌剂和海藻纤维制备过程中试剂间的相容性等问题难以克服,致使共混纺丝过程步骤繁琐,复合纤维的螺旋形貌和性能难以保证。鉴于此,本文以绿色柠檬酸钠 (TSC) 作为纳米银粒子 (AgNPs) 抗菌剂的还原稳定剂和海藻纤维螺旋形貌的成型促进剂,基于微流控技术构建了载银螺旋海藻复合纤维的连续纺丝系统,并对螺旋复合纤维的形貌、力学、热稳定、银元素释放和抑菌等性能进行了表征。结果表明,AgNPs呈球形,粒径较为均一,在4~12 nm之间。在抗菌剂‒纤维连续制备下,AgNPs能够均匀分布在纤维内部,且增大AgNPs负载量,不仅有利于增强纤维断裂强度和热稳定性,还促进了螺旋复合纤维形成,使断裂伸长率和弹性显著高于线形复合纤维。当AgNPs负载量大于200 mg/kg时,抗菌率可达99.9%以上,且具有长效、高效的抗菌潜力。本研究为抗菌螺旋海藻纤维性能调控提供了理论基础,为复合材料的连续化精准构筑提供了技术指导。Abstract: In order to enhance the antimicrobial properties of helical fiber and ensure its safety and stability in various applications, it is crucial to address the compatibility issues of preparation reagents between the antibacterial agent and alginate fiber. These compatibility issues often lead to complex blending and spinning processes, which pose challenges in achieving the desired helical morphology and performance of the composite fibers. To overcome these challenges, this study utilizes environmentally friendly sodium citrate (TSC) as the reducer and stabilizer for silver nanoparticles (AgNPs) antimicrobial agents and meanwhile a shaping promoter for the helical morphology of alginate fiber. A continuous spinning system for silver-loaded helical alginate composite fiber was established using microfluidic technology. The morphology, mechanical properties, thermal stability, release of silver, and antibacterial properties of the helical composite fibers were characterized. The results show that AgNPs have a spherical shape with a uniform particle size ranging from 4 to 12 nm, and can be evenly distributed inside the fiber during the continuous spinning. Additionally, increasing the loading amount of AgNPs not only can enhance the fracture strength and thermal stability, but also promote the formation of helical composite fibers, resulting in significantly higher elongation at break and elasticity compared to linear composite fibers. When the loading of AgNPs was greater than 200 mg/kg, the antibacterial rate of over 99.9%, andlong-lasting, efficient antimicrobial potential. This study provides a theoretical basis for the performance regulation of antimicrobial alginate fibers and technical guidance for the continuous and precise construction of composite materials.

-

Key words:

- microfluidic /

- sodium alginate /

- silver nanoparticles /

- sodium citrate /

- antibacterial activity

-

图 2 不同条件下AgNPs溶液的UV-vis谱图 (a,d,g)、DLS粒径图 (b,e,h) 和AgNPs溶液的直观图 (c,f,i)

(a~c:不同AgNO3浓度 (mmol/L);d~f:不同TSC浓度 (mmol/L);g~i:不同紫外照射时间 (min) )

Figure 2. UV–vis spectroscopy (a,d,g) , DLS particle size diagram (b,e,h) , and visual images of AgNPs solutions (c, f, i) under different conditions

(a~c: different AgNO3 concentrations (mmol/L) ; d~f: different TSC concentrations (mmol/L) ; g~I: different UV irradiation time (min) )

表 1 载银海藻复合纤维的拉伸力学性能

Table 1. Tensile mechanical properties of silver-loaded alginate composite fibers

Sample Linear

F-0Linear

F-100Linear

F-200Linear

F-400Helical

F-0Helical

F-100Helical

F-200Helical

F-400Fracture strength/

(cN·dtex-1)0.23 ± 0.10a 0.49 ± 0.23b 0.63 ± 0.11c 0.74 ± 0.11d 0.22 ± 0.01a 0.49 ± 0.07b 0.64 ± 0.09c 0.73 ± 0.09d Elongation/% 12.47 ± 3.27 12.79 ± 4.65 13.25 ± 2.14 12.56 ± 1.33 132.66 ± 4.70a 137.00 ± 7.29b 142.28 ± 5.93c 148.2 ± 4.56d Initial Modulus/

(cN·dtex-1)5.11 ± 2.51a 16.25 ± 4.21b 22.38 ± 4.23c 23.78 ± 3.40d 0.08 ± 0.04 0.10 ± 0.02 0.09 ± 0.02 0.10 ± 0.02 Notes: All data are expressed as a mean ± standard deviation. Data in a row labeled with the different symbols were significantly different from each other (P < 0.05) . 表 2 载银螺旋海藻复合纤维的抑菌圈直径

Table 2. Inhibition zone diameters of silver-loaded helical alginate composite fibers

Strain Average inhibition zone diameters (mm) Silver-loaded alginate composite fibers F-0 F-100 F-200 F-400 E. coli 0 1.5 1.95 2.4 S. aureus 0 1.43 3.15 4.8 -

[1] ZHANG C J, LIU Y, CUI L, et al. Bio-based calcium alginate nonwoven fabrics: flame retardant and thermal degradation properties[J]. Journal of Analytical and Applied Pyrolysis, 2016, 122: 13-23. doi: 10.1016/j.jaap.2016.10.030 [2] GAO C J, WANG X D, DU Q, et al. Generation of perfusable hollow calcium alginate microfibers with a double co-axial flow capillary microfluidic device[J]. Biomicrofluidics, 2019, 13(6): 064108. doi: 10.1063/1.5116225 [3] TANG M J, WANG W, LI Z L, et al. Controllable microfluidic fabrication of magnetic hybrid microswimmers with hollow helical structures[J]. Industrial & Engineering Chemistry Research, 2018, 57(29): 9430-9438. [4] XIN C, YANG L, LI J W, et al. Conical hollow microhelices with superior swimming capabilities for targeted cargo delivery[J]. Advanced Materials, 2019, 31(25): 1808226. doi: 10.1002/adma.201808226 [5] MHANNA R, QIU F, ZHANG L, et al. Artificial bacterial flagella for remote-controlled targeted single-cell drug delivery[J]. Small, 2014, 10(10): 1953-1957. doi: 10.1002/smll.201303538 [6] ZHAO Y, MIAO X, LIN J, et al. Coiled plant tendril bioinspired fabrication of helical porous microfibers for crude oil cleanup[J]. Glob Chall, 2017, 1(3): 1600021. doi: 10.1002/gch2.201600021 [7] RADETIĆ M. Functionalization of textile materials with silver nanoparticles[J]. Journal of Materials Science, 2012, 48(1): 95-107. doi: 10.1007/s11003-012-9477-y [8] DUMONT M, VILLET R, GUIRAND M, et al. Processing and antibacterial properties of chitosan-coated alginate fibers[J]. Carbohydrate Polymers, 2018, 190: 31-42. doi: 10.1016/j.carbpol.2017.11.088 [9] WEI S Y, TIAN F S, GE F, et al. Helical nanofibrils of block copolymer for high-performance ammonia sensors[J]. ACS Applied Materials & Interfaces, 2018, 10(26): 22504-22512. [10] QUAN K C, ZHANG Z X, REN Y J, et al. Homogeneous distribution of magnetic, antimicrobial-carrying nanoparticles through an infectious biofilm enhances biofilm-killing efficacy[J]. ACS Biomaterials Science & Engineering, 2019, 6(1): 205-212. [11] LU Z S, XIAO J, WANG Y, et al. In situ synthesis of silver nanoparticles uniformly distributed on polydopamine-coated silk fibers for antibacterial application[J]. Journal of Colloid and Interface Science, 2015, 452: 8-14. doi: 10.1016/j.jcis.2015.04.015 [12] VALENTI L E, GIACOMELLI C E. Stability of silver nanoparticles: agglomeration and oxidation in biological relevant conditions[J]. Journal of Nanoparticle Research, 2017, 19(5): 156-165. doi: 10.1007/s11051-017-3860-4 [13] ZHAO X H, LI Q, MA X M, et al. The preparation of alginate-AgNPs composite fiber with green approach and its antibacterial activity[J]. Journal of Industrial and Engineering Chemistry, 2015, 24: 188-195. doi: 10.1016/j.jiec.2014.09.028 [14] SUI J S, YAN J Y, LIU D, et al. Continuous synthesis of nanocrystals via flow chemistry technology[J]. Small, 2019, 16(15): 1902828. [15] SONG Y, YU X Q, CHEN S. Recent advances in microfluidic fiber-spinning chemistry[J]. Journal of Polymer Science, 2023: 1-16. [16] LI L L, LI X D, WANG H. Microfluidic synthesis of nanomaterials for biomedical applications[J]. Small Methods, 2017, 1(8): 1700140. doi: 10.1002/smtd.201700140 [17] YU Y R, FU F F, SHANG L R, et al. Bioinspired helical microfibers from microfluidics[J]. Advanced Materials, 2017, 29(18): 1605765. doi: 10.1002/adma.201605765 [18] BARNES G, WOODCOCK R. Liquid rope-coil effect[J]. American Journal of Physics, 1958, 26(4): 205-209. doi: 10.1119/1.1996110 [19] 谭昕玥, 巨晓洁, 谢锐, 等. 具有油相隔离层的微流控法可控制备中空微纤维[J]. 复合材料学报, 2022, 38(3): 1-9.TAN X Y, JV X J, XIE R , et al. Properties of high toughness polyimide resin by polymerization of monomers reactants method[J]. Acta Materiae Compositae Sinica, 2022, 38(3): 1-9(in Chinese). [20] MENG Z J, WANG W, XIE R, et al. Microfluidic generation of hollow Ca-alginate microfibers[J]. Lab on a Chip, 2016, 16(14): 2673-2681. doi: 10.1039/C6LC00640J [21] TOTTORI S, TAKEUCHI S. Formation of liquid rope coils in a coaxial microfluidic device[J]. RSC Advances, 2015, 5(42): 33691-33695. doi: 10.1039/C5RA01037C [22] 王之豪, 宋欣, 殷亚然, 等. 微流控纺丝中凝胶速率对螺旋纤维形貌的调控机制[J]. 化工学报, 2022, 73(11): 5158-5166.WANG Z H, SONG X, YIN Y R, et al. Regulation of gelation rate on the morphology of helical fibers during microfluidic spinning[J]. Journal of Chemical Industry and Engineering, 2022, 73(11): 5158-5166(in Chinese). [23] PASCU B, NEGREA A, CIOPEC M, et al. Silver nanoparticle synthesis via photochemical reduction with sodium citrate[J]. International Journal of Molecular Sciences, 2022, 24(1): 255-272. doi: 10.3390/ijms24010255 [24] ANARAKI N I, SADEGHPOUR A, IRANSHAHI K, et al. New approach for time-resolved and dynamic investigations on nanoparticles agglomeration[J]. Nano Research, 2020, 13(10): 2847-2856. doi: 10.1007/s12274-020-2940-4 [25] WAN X X, LI J , LI N, et al. Preparation of spherical ultrafine silver particles using y-type microjet reactor[J]. Materials, 2023, 16(6): 2217-2231. [26] SCHMIDT P P, PAGANO K, LENARDI C, et al. Photo-induced microfluidic production of ultrasmall glyco gold nanoparticles[J]. Angew Chem Int Ed Engl, 2023, 62(1): 202210140. doi: 10.1002/anie.202210140 [27] SILVESTRINI S, CAROFIGLIO T, MAGGINI M. Shape-selective growth of silver nanoparticles under continuous flow photochemical conditions[J]. Chemical Communications, 2013, 49(1): 84-86. doi: 10.1039/C2CC35652J [28] HAFERMANN L, KöHLER J M. Photochemical micro continuous-flow synthesis of noble metal nanoparticles of the platinum group[J]. Chemical Engineering & Technology, 2015, 38(7): 1138-1143. [29] 中国国家标准化管理委员会. 纺织品 抗菌性能的评价 第3部分: 振荡法: GB/T 20944.3-2008 [S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Textiles—evaluation for antibacterial activity part 3: shake flask method: GB/T 20944.3-2008 [S]. Beijing: Standards Press of China, 2008(in Chinese). [30] AMENDOLA V, MENEGHETTI M. Size evaluation of gold nanoparticles by UV-vis spectroscopy[J]. Journal of Physical Chemistry C, 2009, 113: 4277-4285. doi: 10.1021/jp8082425 [31] LI H S, XIA H B, WANG D Y, et al. Simple synthesis of monodisperse, quasi-spherical, citrate-stabilized silver nanocrystals in water[J]. Langmuir, 2013, 29(16): 5074-5079. doi: 10.1021/la400214x [32] JIANG X C, CHEN C Y, CHEN W M, et al. Role of citric acid in the formation of silver nanoplates through a synergistic reduction approach[J]. Langmuir, 2009, 26(6): 4400-4408. [33] GENTRY S T, KENDRA S F, BEZPALKO M W. Ostwald ripening in metallic nanoparticles: stochastic kinetics[J]. The Journal of Physical Chemistry C, 2011, 115(26): 12736-12741. doi: 10.1021/jp2009786 [34] LIU Y L, LI Y, SI Y F, et al. Synthesis of nanosilver particles mediated by microbial surfactants and its enhancement of crude oil recovery[J]. Energy, 2023, 272: 127123. doi: 10.1016/j.energy.2023.127123 [35] ZENG A Q, YANG R J, TONG Y J, et al. Functional bacterial cellulose nanofibrils with silver nanoparticles and its antibacterial application[J]. International Journal of Biological Macromolecules, 2023, 235: 123739. doi: 10.1016/j.ijbiomac.2023.123739 [36] HOFFMAN R M, BESTE L F. Some relations of fiber properties to fabric hand[J]. Textile Research Journal, 1951, 21: 66. doi: 10.1177/004051755102100202 [37] SUN L N, ZHU R S, HU H M, et al. Preparation and characterization of poly(ethylene terephthalate-co-aliphatic amide) copolymer fibers with excellent hygroscopicity and softness[J]. Polymers for Advanced Technologies, 2022, 33(12): 4233-4249. doi: 10.1002/pat.5855 [38] LIU Y, J S WANG, ZHU P, et al. Thermal degradation properties of biobased iron alginate film[J]. Journal of Analytical and Applied Pyrolysis, 2016, 119: 87-96. doi: 10.1016/j.jaap.2016.03.014 [39] WANG Q Q, ZHANG L, LIU Y Y, et al. Characterization and functional assessment of alginate fibers prepared by metal-calcium ion complex coagulation bath[J]. Carbohydrate Polymers, 2020, 232: 115693. doi: 10.1016/j.carbpol.2019.115693 [40] SHARMA V K, YNGARD R A, LIN Y. Silver nanoparticles: Green synthesis and their antimicrobial activities[J]. Advances in Colloid and Interface Science, 2009, 145: 83-96. doi: 10.1016/j.cis.2008.09.002 [41] KORKMAZ N, CEYLAN Y, TASLIMI P, et al. Biogenic nano silver: synthesis, characterization, antibacterial, antibiofilms, and enzymatic activity[J]. Advanced Powder Technology, 2020, 31(7): 2942-2950. doi: 10.1016/j.apt.2020.05.020 [42] KAVIYA S, SANTHANALAKSHMI J, VISWANATHAN B, et al. Biosynthesis of silver nanoparticles using citrus sinensis peel extract and its antibacterial activity[J]. Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy, 2011, 79(3): 594-598. doi: 10.1016/j.saa.2011.03.040 [43] KHONA M, BHEKISISA C. D, SORAYA P. M. Hyperbranched polymer nanofibrous membrane grafted with silver nanoparticles for dual antifouling and antibacterial properties against Escherichia coli, Staphylococcus aureus and Pseudomonas aeruginosa[J]. Reactive and Functional Polymers, 2020, 148: 104494. doi: 10.1016/j.reactfunctpolym.2020.104494 [44] AUGUSTINE R, KALARIKKAL N, THOMAS S. Electrospun PCL membranes incorporated with biosynthesized silver nanoparticles as antibacterial wound dressings[J]. Applied Nanoscience, 2015, 6(3): 337-344. -

点击查看大图

点击查看大图

计量

- 文章访问数: 33

- HTML全文浏览量: 35

- 被引次数: 0

下载:

下载: