Optimization of the high-temperature strong plasticity of the new precipitation-enhanced nickel-iron-based superalloy GH4650T

-

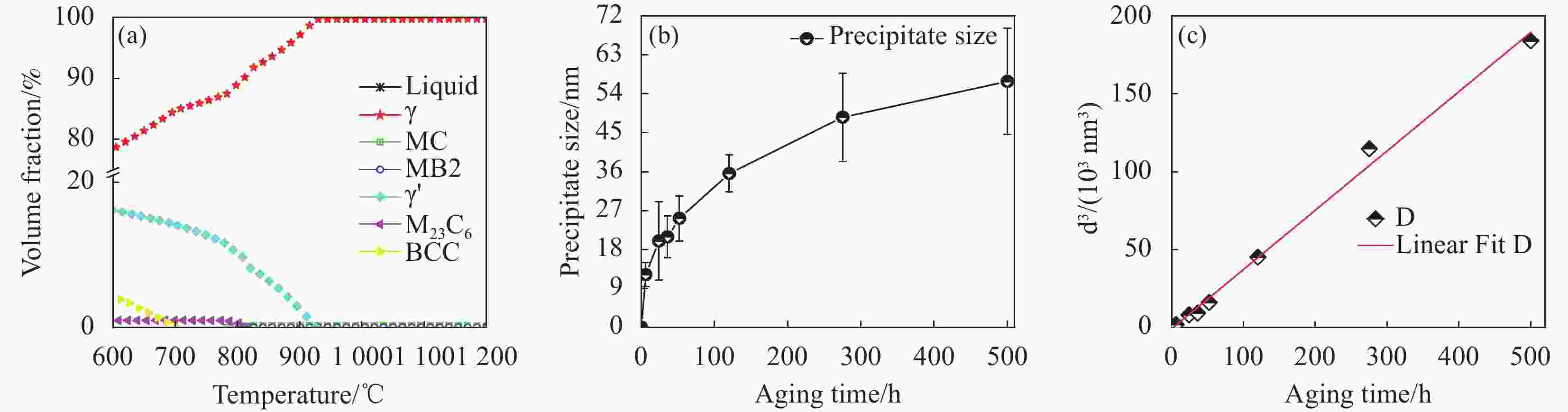

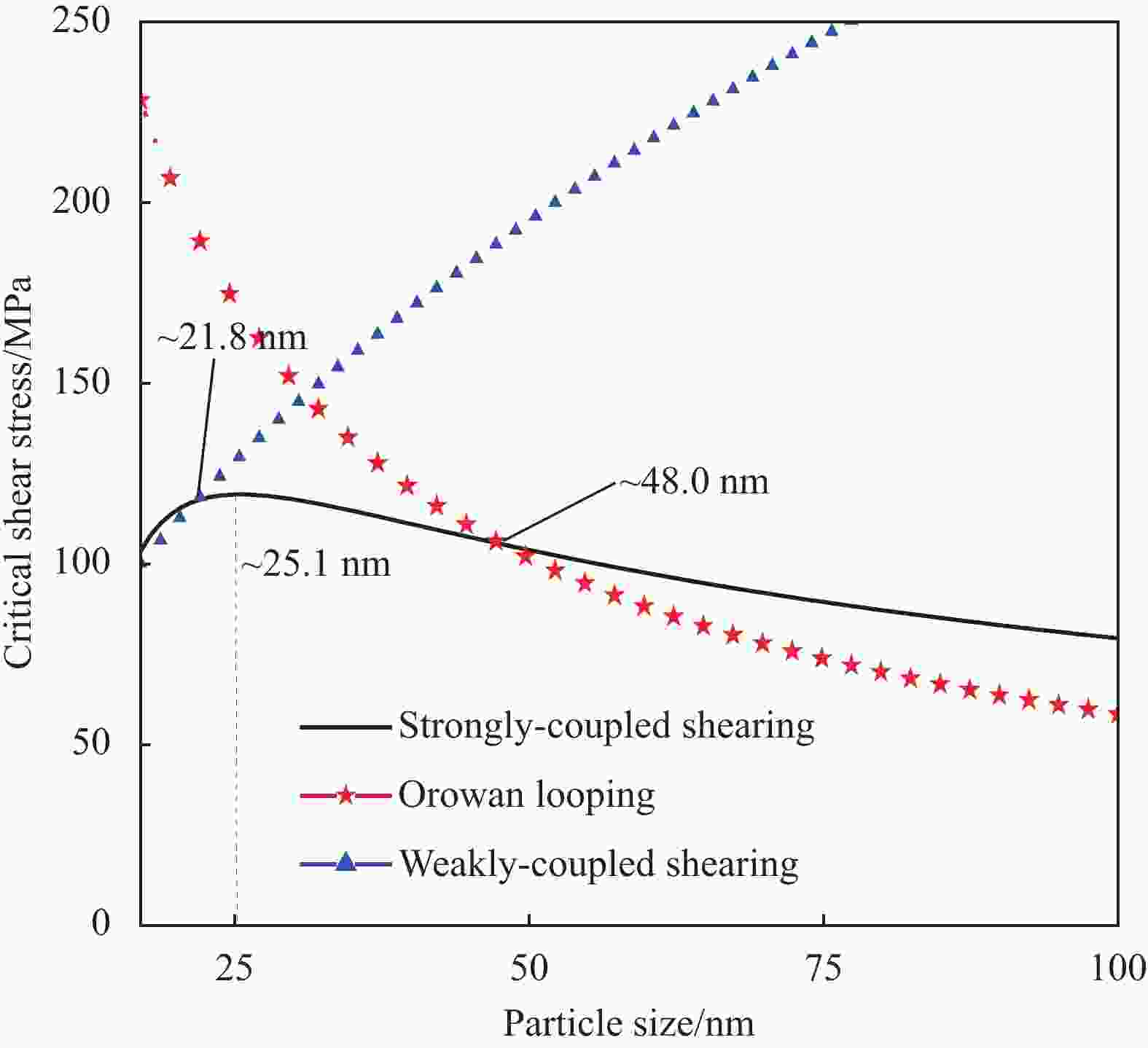

摘要: 研究了750 ℃等温时效热处理对固溶态GH4650T在700℃拉伸性能及变形断裂机制的影响。实验发现,随着时效时间的延长,合金拉伸强度先升高后降低,而拉伸塑性表现出相反的变化趋势;时效48 h后,合金具有最佳的拉伸强度,而时效5 h后,合金拉伸伸长率最小。微观组织结构分析表明,时效过程中,γ′相粗化长大动力学遵循Lifshitz-Slyozov-Wagner熟化规律;等温时效过程中,随着γ′相颗粒尺寸的增加,合金主要变形机制由弱耦合位错对切割颗粒转变为强耦合位错对切割颗粒然后转变为Orowan绕过颗粒,而合金断裂的方式由塑性穿晶断裂转变为沿晶断裂然后转变为沿晶加穿晶混合型断裂,并且随着γ′相颗粒尺寸的增加,塑性穿晶断裂的方式越加明显。基于这些实验结果,讨论了合金拉伸性能与变形断裂机制之间的关系。Abstract: The tensile properties and deformation mechanisms of a new precipitate-hardened Ni-Fe-base superalloy GH4650T are investigated after solutionizing and thermal aging at 750℃ for different hours. It is found that the strength increases firstly and decreases with time, whereas the tensile plasticity shows the opposite changing trend. After thermal aging for 48 h, the tensile strength is the best, whereas the elongation to fracture is the minimum at 5 h. Microstructural observations reveal that the grow kinetics of γ′ precipitates in the experimental alloy meet the Lifshitz-Slyozov-Wagner law, and the dominant deformation mechanism changes from particle shearing by weekly-coupled dislocations to by strongly-coupled dislocations and then to Orowan looping with increasing the γ′ precipitate size. Meanwhile, it is also found the fracture mechanism changes from transcrystalline fracture to intercrystalline fracture and then to ductile and brittle mixed fracture and the feature of ductile fractures becomes more and more obvious with precipitate size. Give these observations, the relationship between the tensile properties and the operative deformation and fracture mechanisms is discussed.

-

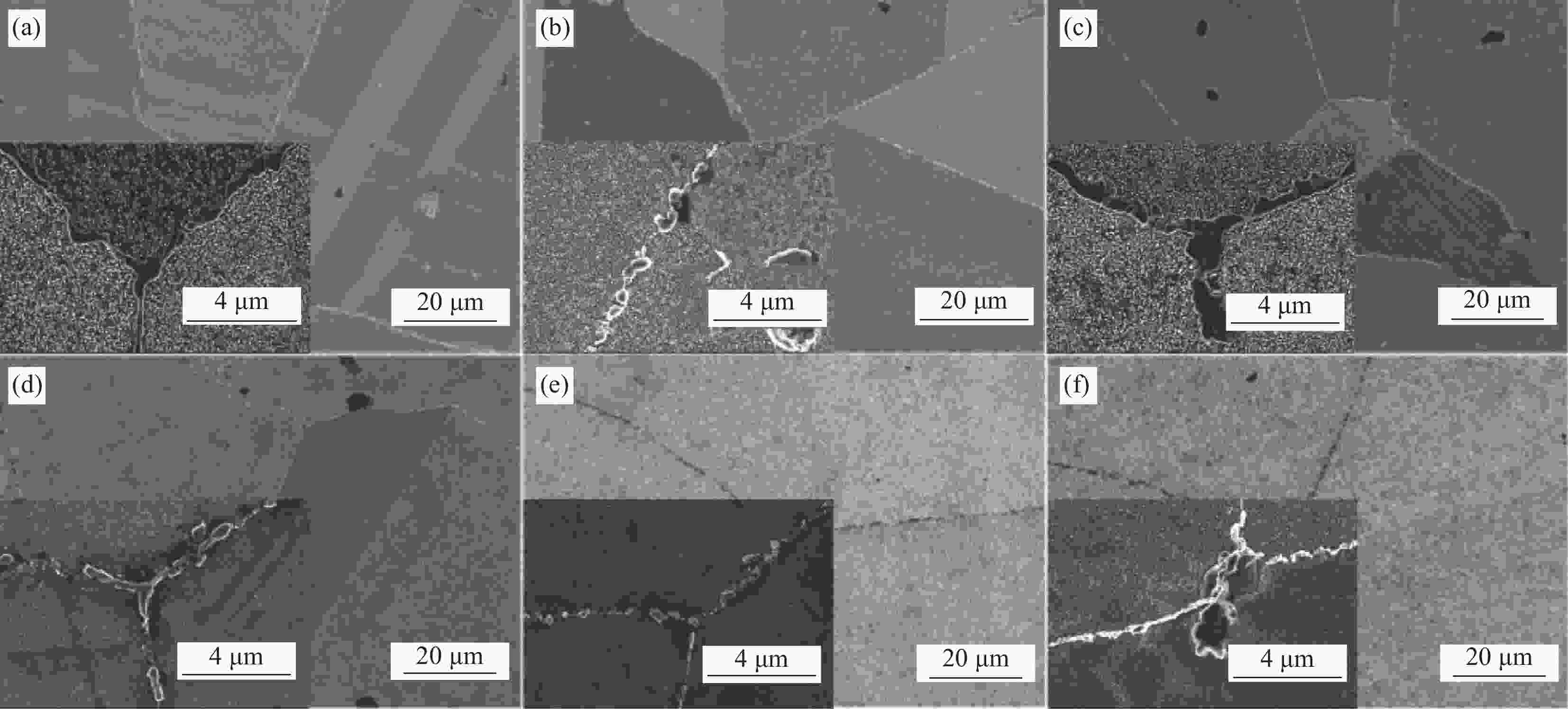

图 2 在750℃经过不同时间热处理后固溶态GH4650T合金晶界结构的SEM图片: (a) 750℃/5 h;(b) 750℃/36 h;(c) 750℃/48 h;(d) 750℃/120 h;(e) 750℃/275 h;(f) 750℃/500 h

Figure 2. SEM images showing the microstructures in the experimental alloy GH4650T after solutionizing and aging for different durations at 750℃: (a) 750℃/5 h; (b) 750℃/36 h; (c) 750℃/48 h; (d) 750℃/120 h; (e) 750℃/275 h; (f) 750℃/500 h.

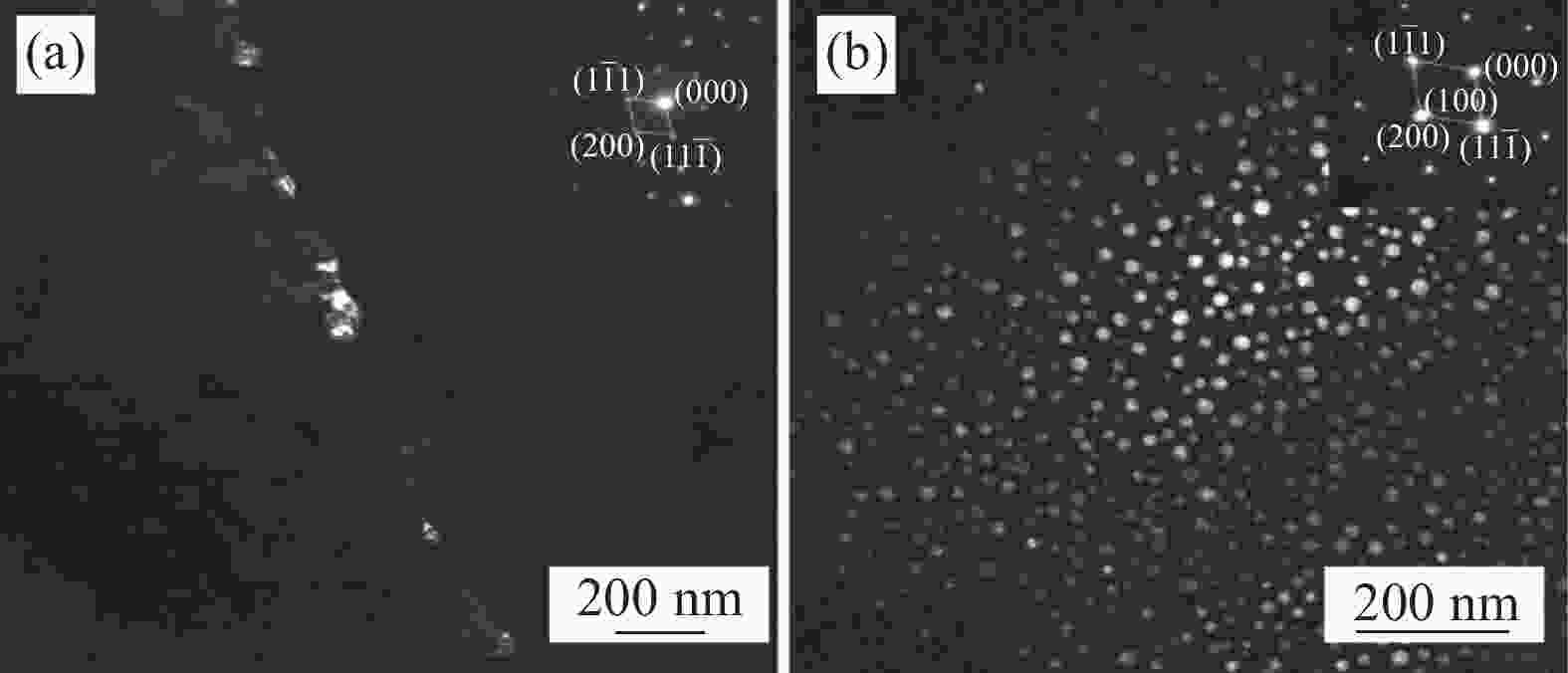

图 3 (a)经过固溶和750℃/275 h时效处理的GH4650T合金晶界M23 C6碳化物的TEM暗场像;(b)经过固溶和750℃/24 h时效处理的后GH4650T合金晶粒内部的γ′相颗粒的TEM暗场像

Figure 3. (a) TEM dark-field image showing the M23C6 carbides at grain boundary in GH4650T after solutionizing and aging for 275 h at 750℃;(b) TEM dark-field image showing the γ′ precipitates within grain interior in GH4650T after solutionizing and aging for 24 h at 750℃.

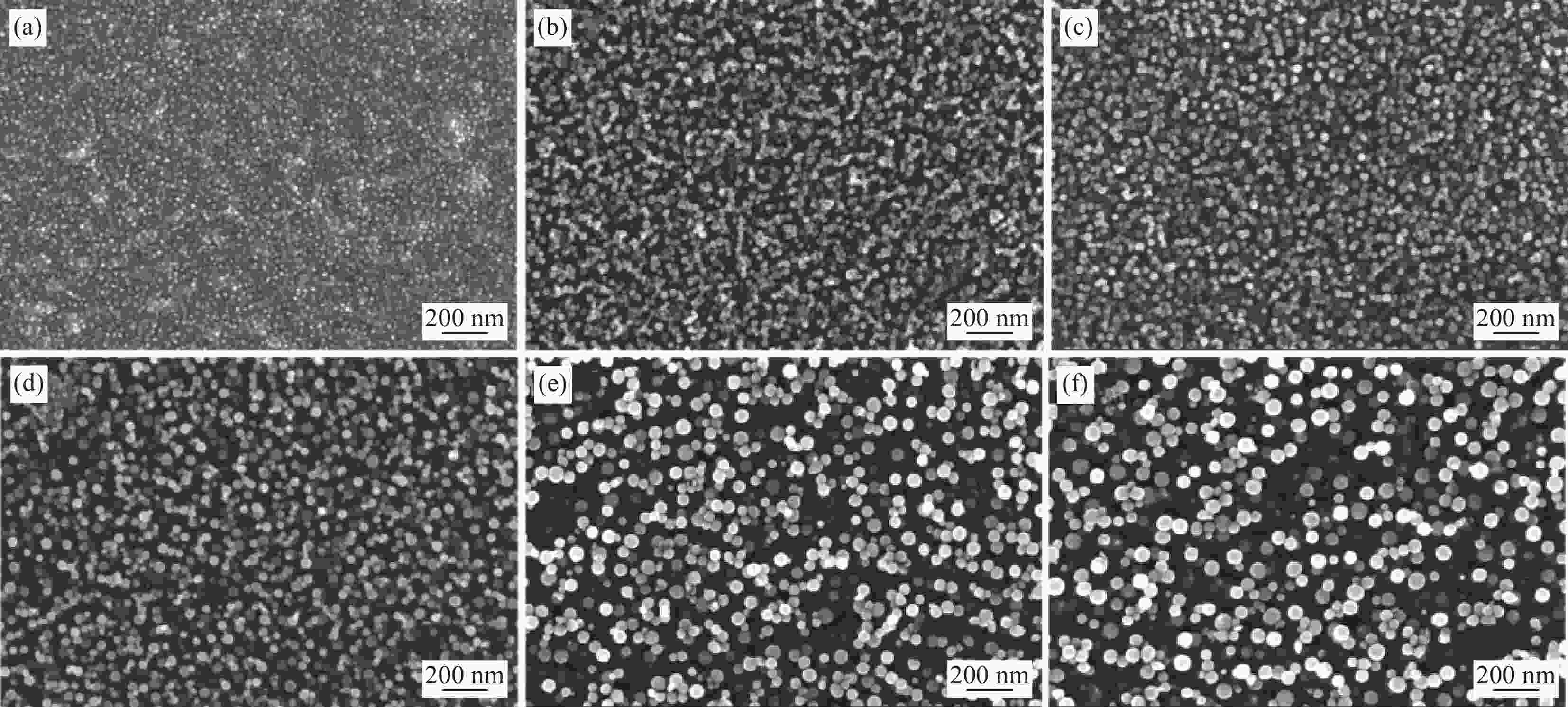

图 4 在750℃经过不同时间热处后固溶态GH4650T合金晶内的γ′相颗粒的SEM图片: (a) 750℃/5 h;(b) 750℃/36 h;(c) 750℃/48 h;(d) 750℃/120 h;(e) 750℃/275 h;(f) 750℃/500 h

Figure 4. SEM images showing the γ′ precipitates in the experimental alloy GH4650T after solutionizing and aging for different durations at 750℃: (a) 750℃/5 h;(b) 750℃/36 h;(c) 750℃/48 h;(d) 750℃/120 h; (e) 750℃/275 h;(f) 750℃/500 h

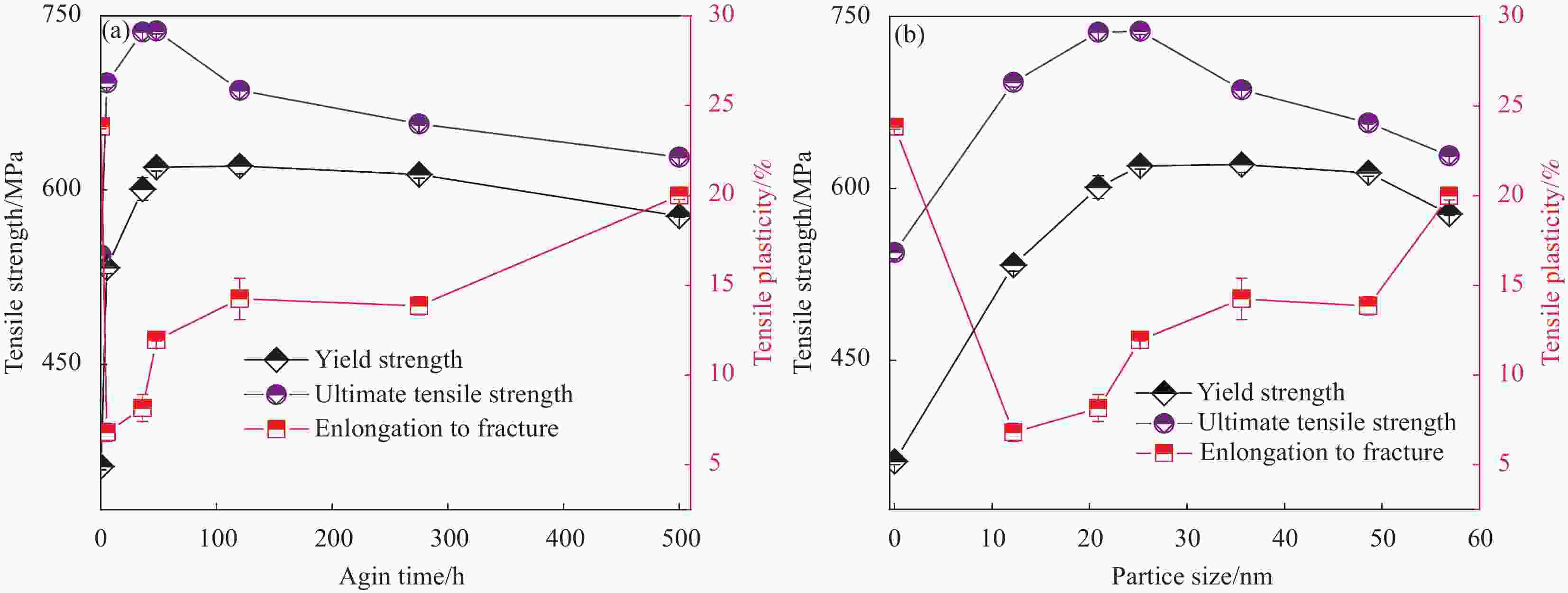

图 6 (a)GH4650T合金700℃时拉伸性能与750℃时效处理时间变化关系;(b) 700℃时GH4650T合金拉伸性能在750℃等温时效过程中随γ′相颗粒平均直径d的变化关系

Figure 6. (a) variations in the tensile properties of the experimental alloy GH4650T at 700℃ with the aging time during thermal aging at 750℃; (b) variations in the tensile properties of the experimental alloy GH4650T at 700℃ with the γ′ particle size during thermal aging at 750℃.

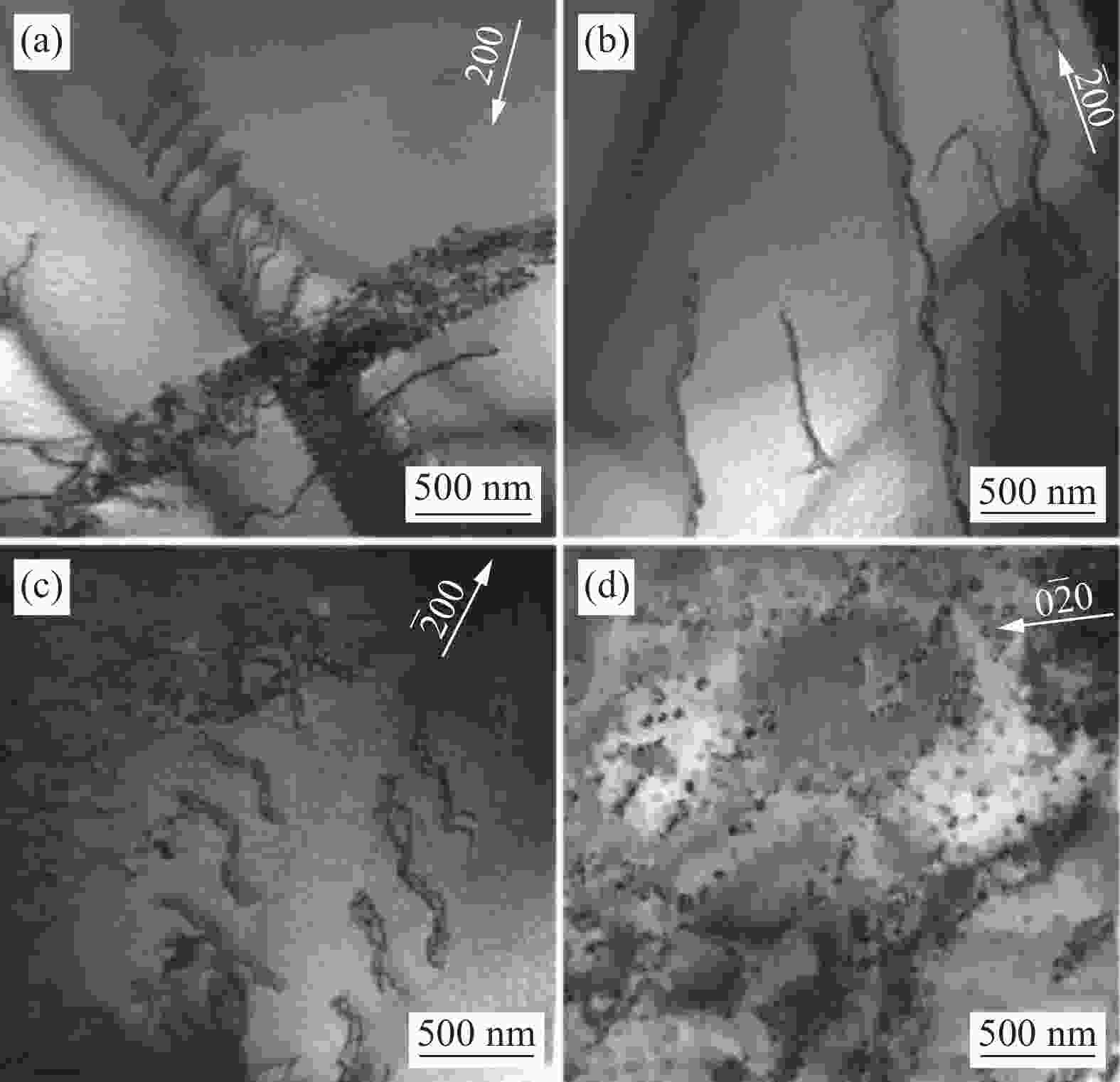

图 7 TEM图像显示不同热处理态合金在700℃经过大约1.0%塑性应变之后合金内的位错组态:(a)750℃ /5 h;(b)750℃ /36 h;(c) 750℃ /48 h;(d) 750℃ /275 h

Figure 7. TEM images illustrating the typical microstructures in the experimental alloy after various heat treatments and around 1.0% plastic strain at 700℃: (a) 750℃/5 h; (b)750℃/36 h; (c) 750℃/48 h; (d) 750℃/275 h.

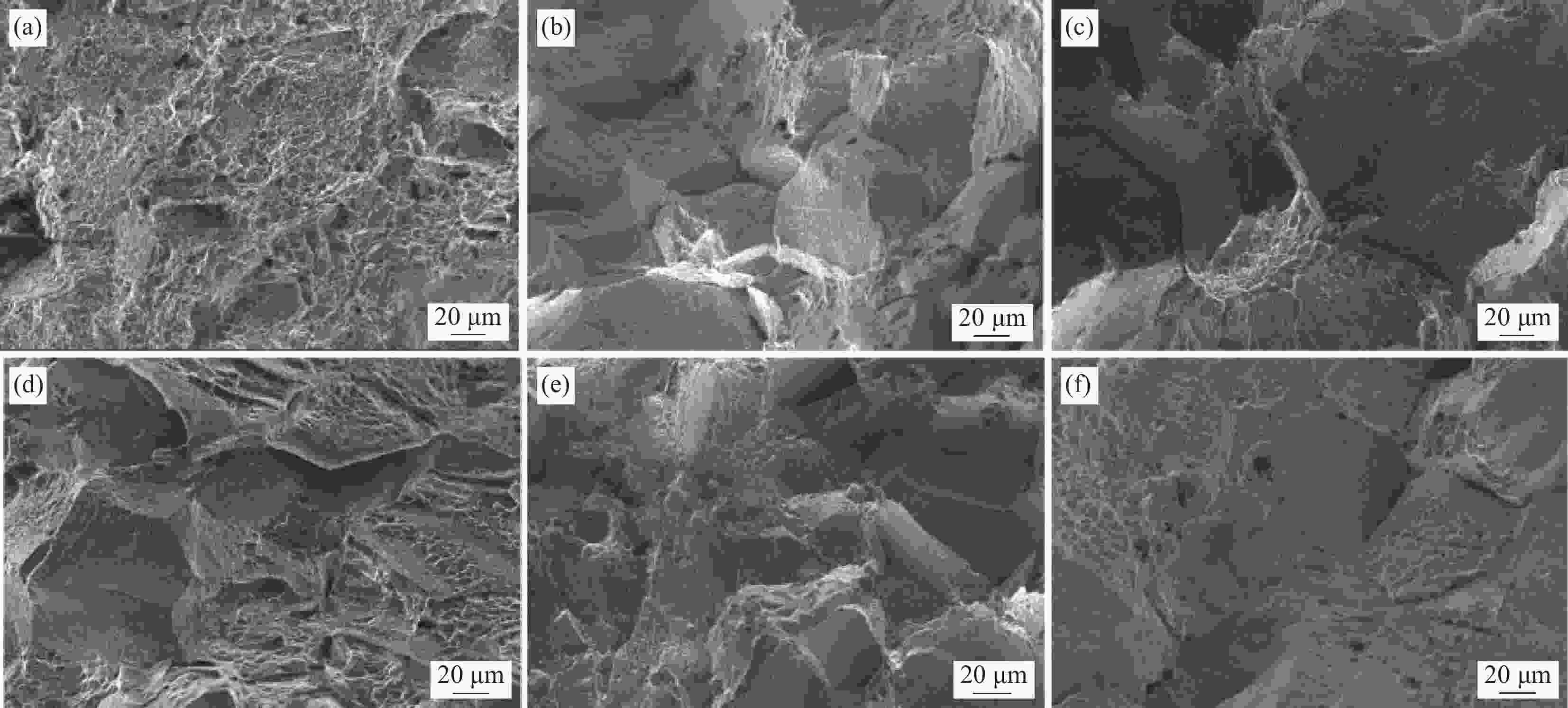

图 8 不同热处理态合金在700℃的拉伸断口形貌 SEM的图像:(a)固溶处理;(b)固溶处理+750℃/5 h;(c)固溶处理+750℃/36 h;(d) 750℃/48 h;(e) 750℃/275 h;(f) 750℃/500 h

Figure 8. SEM images showing the fracture morphologies of the experimental alloy after various heat treatments at 700℃: (a) solutionizing; (b) solutionizing+750℃/5 h; (c) solutionizing+750℃/36 h; (d) solutionizing+750℃/48 h; (e) solutionizing+750℃/275 h;(f) solutionizing+750℃/500 h.

-

[1] 刘正东, 陈正宗, 何西扣, 等. 630~700℃超超临界燃煤电站耐热管及其制造技术进展[J]. 金属学报, 2020, 56(4): 539-548. doi: 10.11900/0412.1961.2019.00419LIU Zhengdong, CHEN Zhengzong, HE Xikou, et al. Systematical Innovation of Heat Resistant Materials Used for 630~700 ℃ Advanced Ultra-Supercritical (A-USC)Fossil Fired Boilers[J]. Acta metallica, 2020, 56(4): 539-548(in Chinese). doi: 10.11900/0412.1961.2019.00419 [2] GIANFRANCESCO A D. Materials for Ultra-Supercritical and Advanced Ultra- Supercritical Power Plants[M]. woodhead Publishing, 2016. [3] ZHANG Z, ZHOU R, GE X, et al. Perspectives for 700°C ultra-supercritical power generation: Thermal safety of high- temperature heating surfaces[J]. Energy, 2020, 190: 116411. doi: 10.1016/j.energy.2019.116411 [4] 袁勇, 党莹樱, 杨珍, 等. 700℃先进超超临界机组末级过热器用新型镍铁基高温合金的组织与性能[J]. 机械工程材料, 2020, 44(1): 44-50. doi: 10.11973/jxgccl202001008YUAN Yong, DANG Yingying, YANG Zhen, et al. Microstructure and Properties of Ni-Fe-base Superalloy for 700℃ Advanced Ultra Supercritical Unit Final Superheater[J]. Mechanical engineering material, 2020, 44(1): 44-50. doi: 10.11973/jxgccl202001008 [5] ZHONG Z H, GU Y F, YUAN Y, et al. A new wrought Ni–Fe-base superalloy for advanced ultra-supercritical power plant applications beyond 700°C[J]. Materials Letters, 2013, 109: 38-41. doi: 10.1016/j.matlet.2013.07.060 [6] ZHANG P, YUAN Y, ZHONG L, et al. Microstructural stability and tensile properties of a new γ′-hardened Ni-Fe-base superalloy[J]. Materialia, 2013, 109: 38-41. [7] CHENG S, WANG J, WU Y, et al. Microstructure, thermal stability and tensile properties of a Ni–Fe–Cr based superalloy with different Fe contents[J]. Intermetallics, 2023, 153: 107785. doi: 10.1016/j.intermet.2022.107785 [8] SUN F, GU Y F, YAN J B, et al. Phenomenological and microstructural analysis of intermediate temperatures creep in a Ni–Fe-based alloy for advanced ultra-supercritical fossil power plants[J]. Acta Materialia, 2016, 102: 70-78. doi: 10.1016/j.actamat.2015.09.006 [9] WANG C S, GUO Y A, GUO J T, et al. Gamma prime stability and its influence on tensile behavior of a wrought superalloy with different Fe contents[J]. Journal of Materials Research, 2016, 31(9): 1361-1371. doi: 10.1557/jmr.2016.139 [10] WU Y, QIN X, WANG C, et al. Influence of phosphorus on hot deformation micro-structure of a Ni-Fe-Cr based alloy[J]. Materials Science and Engineering:A, 2019, 768: 138454. doi: 10.1016/j.msea.2019.138454 [11] HUANG Y, ZHANG R, ZHOU Z, et al. Effect of long-term aging on microstructural stability and tensile deformation of a Fe–Ni-based superalloy[J]. Materials Science and Engineering: A, 2022, 847: 143298. doi: 10.1016/j.msea.2022.143298 [12] ZHOU Z Q, ZHANG P, YAN J B, et al. Microstructural evolution of a new Ni-Fe-based superalloy deformed by creep[J]. Materials Chara-cterization, 2023, 201: 112917. doi: 10.1016/j.matchar.2023.112917 [13] HUANG Y, ZHANG R, ZHOU Z, et al. Microstructure optimization for higher strength of a new Fe–Ni-based superalloy[J]. Materials Science and Engineering:A, 2023, 865: 144632. doi: 10.1016/j.msea.2023.144632 [14] DU B, YANG J, CUI C, et al. Effects of grain refinement on the microstructure and tensile behavior of K417G superalloy[J]. Materials Science and Engineering:A, 2015, 623: 59-67. doi: 10.1016/j.msea.2014.11.041 [15] ZHANG P, YUAN Y, LI B, et al. Tensile deformation behavior of a new Ni-base superalloy at room temperature[J]. Materials Science and Engineering:A, 2016, 655: 152-159. doi: 10.1016/j.msea.2015.12.089 [16] GAO Z, ZHANG P, LI J, et al. Tunning the tensile deformation behavior and mechanism of nickel-based superalloy CM247LC by adjusting ageing treatment[J]. Materials Research Letters, 2023, 11(12): 1013-1021. doi: 10.1080/21663831.2023.2276340 [17] LIFSHITZ I M, SLYOZOV V V. The kinetics of precipitation from supersaturated solid solutions[J]. Journal of Physics and Chemistry of Solids, 1961, 19(1-2): 35-50. doi: 10.1016/0022-3697(61)90054-3 [18] WAGNER C L. Theorie der Alterung von Niederschlägen durch Umlöse[J]. (Ostwald-Reifung), Z. Metallkd, 1961, 65(7-8): 581-591. [19] NEMBACH E, NEITE G. Precipitation hardening of superalloys by ordered γ′-particles[J]. Progress in Materials Science, 1985, 29(3): 177-319. doi: 10.1016/0079-6425(85)90001-5 [20] GUO C H, ZHANG P, ZHOU Y L, et al. Micro-structural evolution and yield strength of a novel precipitate-strengthened Fe-based superalloy during thermal aging at 700℃[J]. Intermetallics, 2023, 163: 108077. doi: 10.1016/j.intermet.2023.108077 [21] REPPICH B, SCHEPP P, WEHNER G. Some new aspects concerning particle hardening mechanisms in γ' precipitating nickel-base alloys—II. Experiments[J]. Acta Metall -urgica, 1982, 30(1): 95-104. doi: 10.1016/0001-6160(82)90049-9 [22] ZHANG P, MA L, YANG G, et al. Extraordinary plastic behaviour of the γ′ precipitate in a directionally solidified nickel-based superalloy[J]. Philosophical Magazine Letters, 2016, 96(1): 19-26. doi: 10.1080/09500839.2015.1134832 [23] ARDELL A J. Intermetallics as Precipitates and Dispersoids in High-Strength Alloys[M]. 1994, 2: 257-286. [24] RAYNOR D, SILCOCK JM. Strengthening Mechanisms in γ′ Precipitating Alloys[J]. Metal Science Journal, 1970, 4(1): 121-130. doi: 10.1179/msc.1970.4.1.121 [25] GALINDO-NAVA E I, CONNOR L D, RAE C M F. On the prediction of the yield stress of unimodal and multimodal γ′ Nickel-base superalloys[J]. Acta Materialia, 2015, 98: -

点击查看大图

点击查看大图

计量

- 文章访问数: 74

- HTML全文浏览量: 49

- 被引次数: 0

下载:

下载: