Threshold properties of high modulus carbon fiber reinforced plastic composite with picosecond laser processing

-

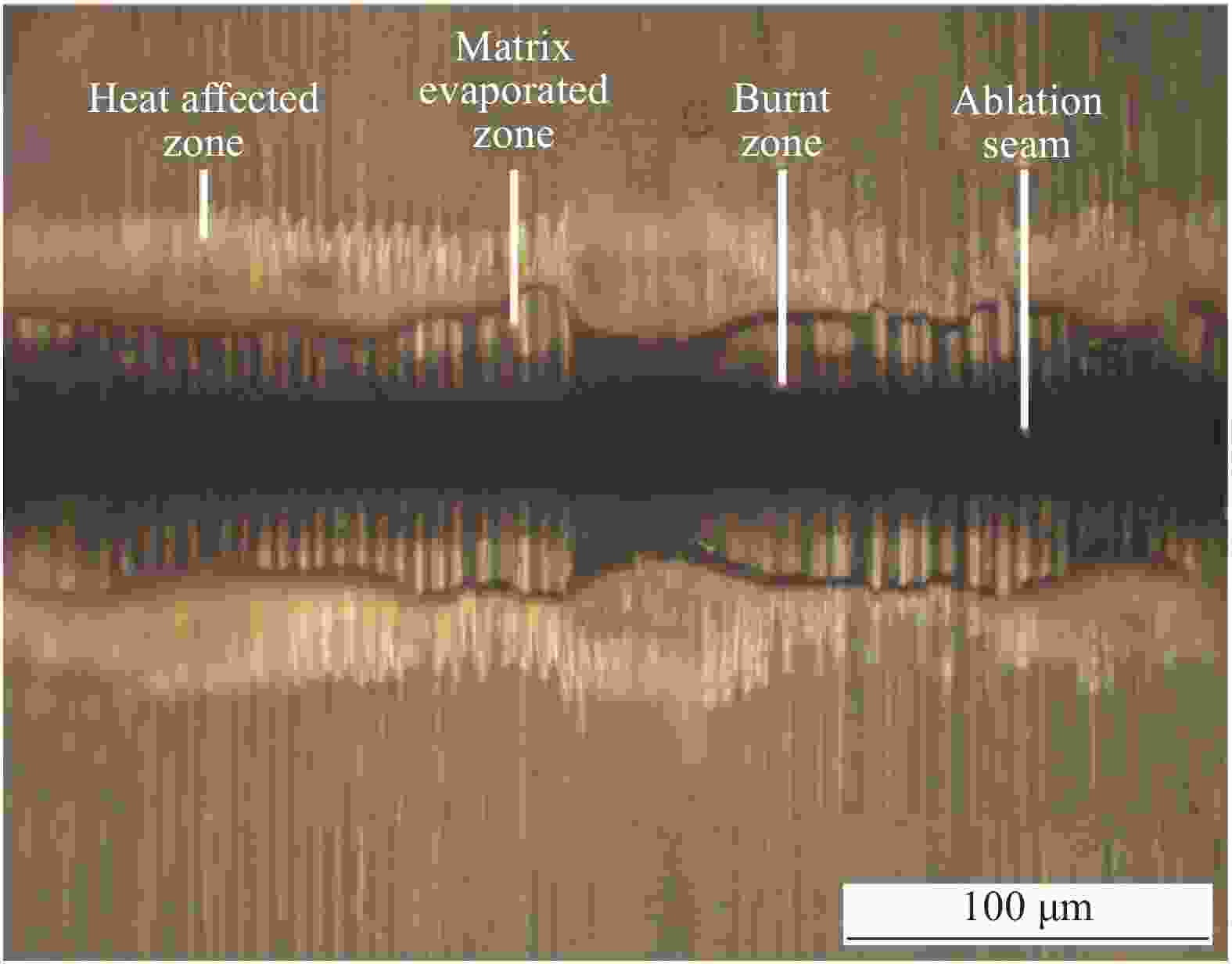

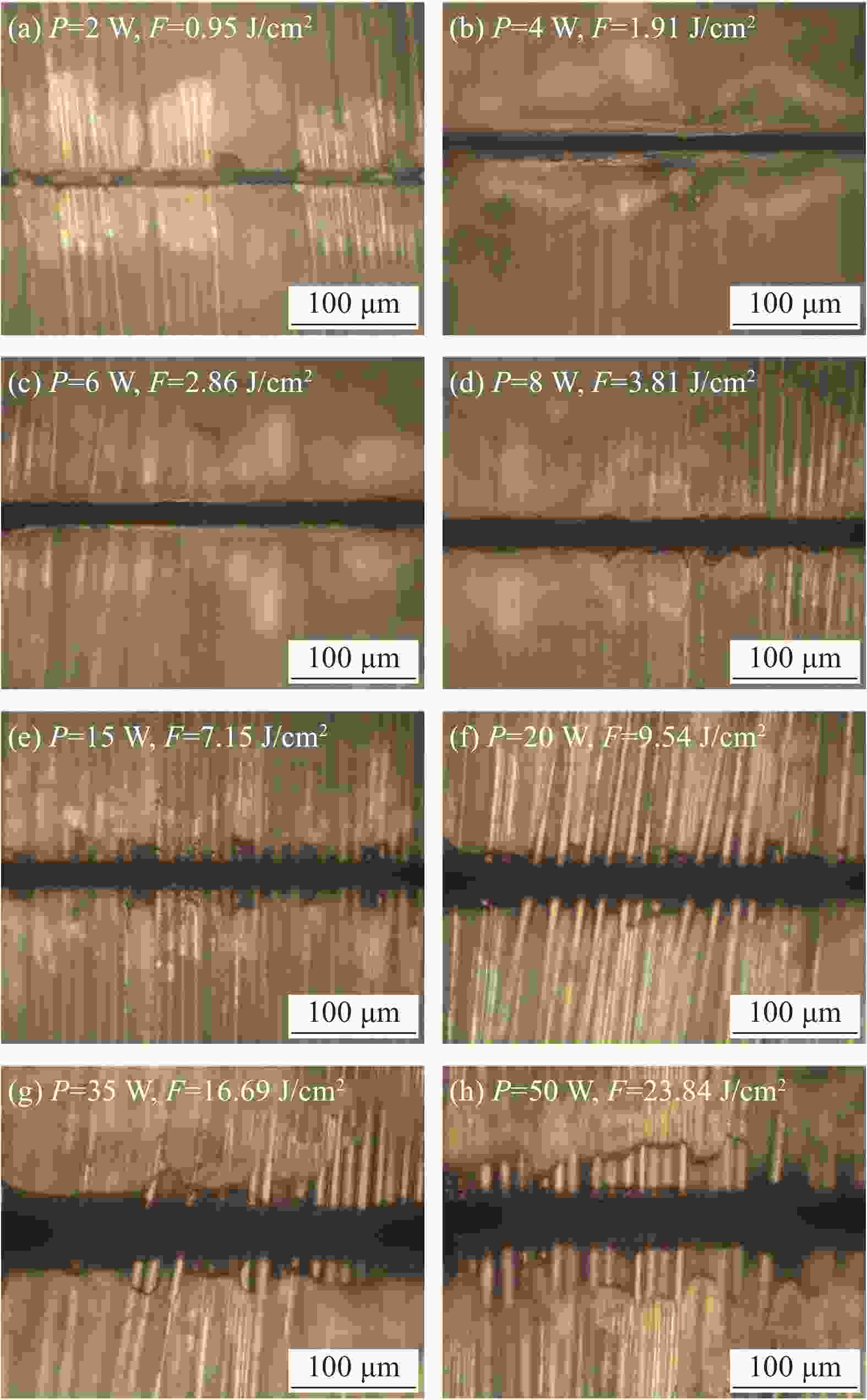

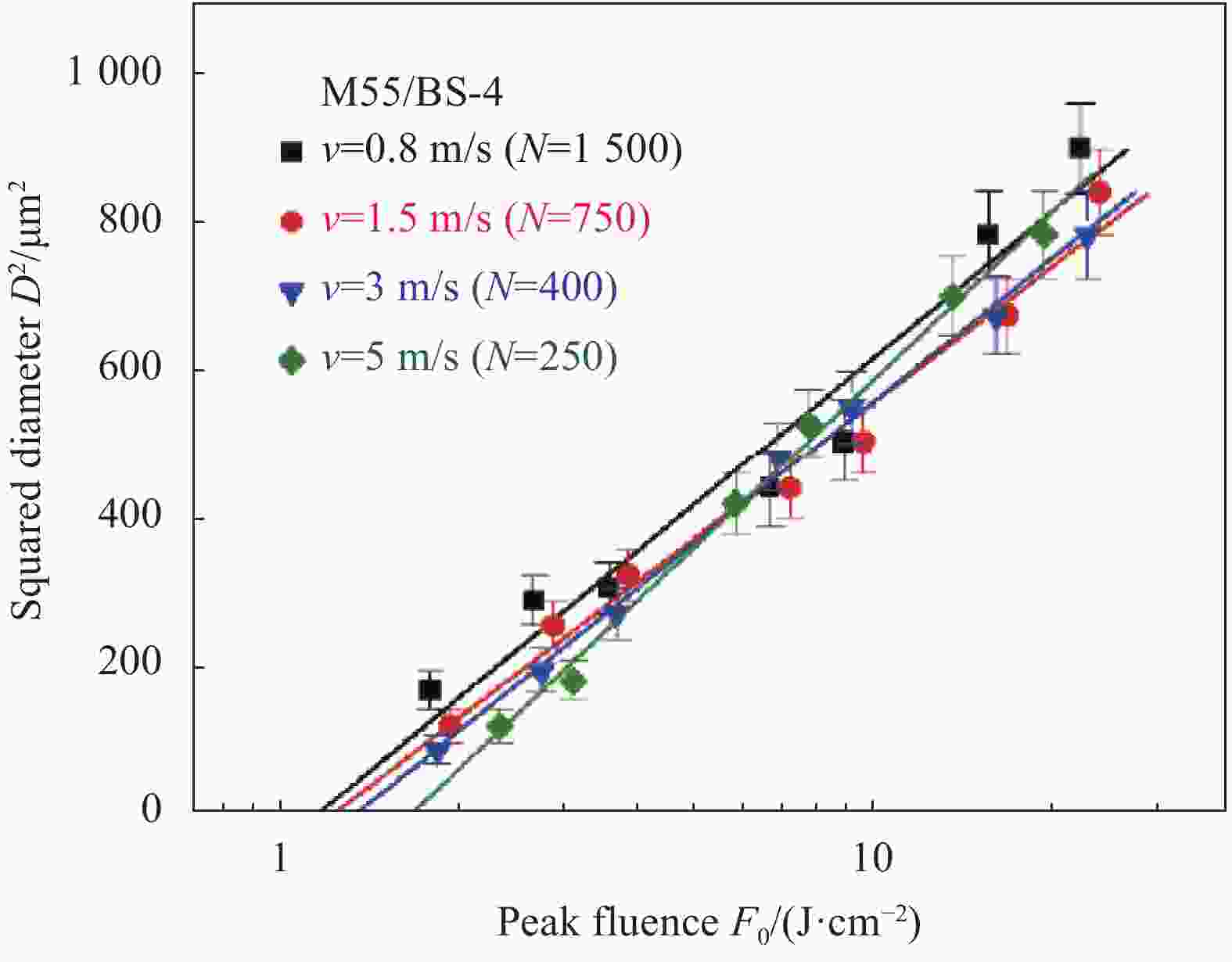

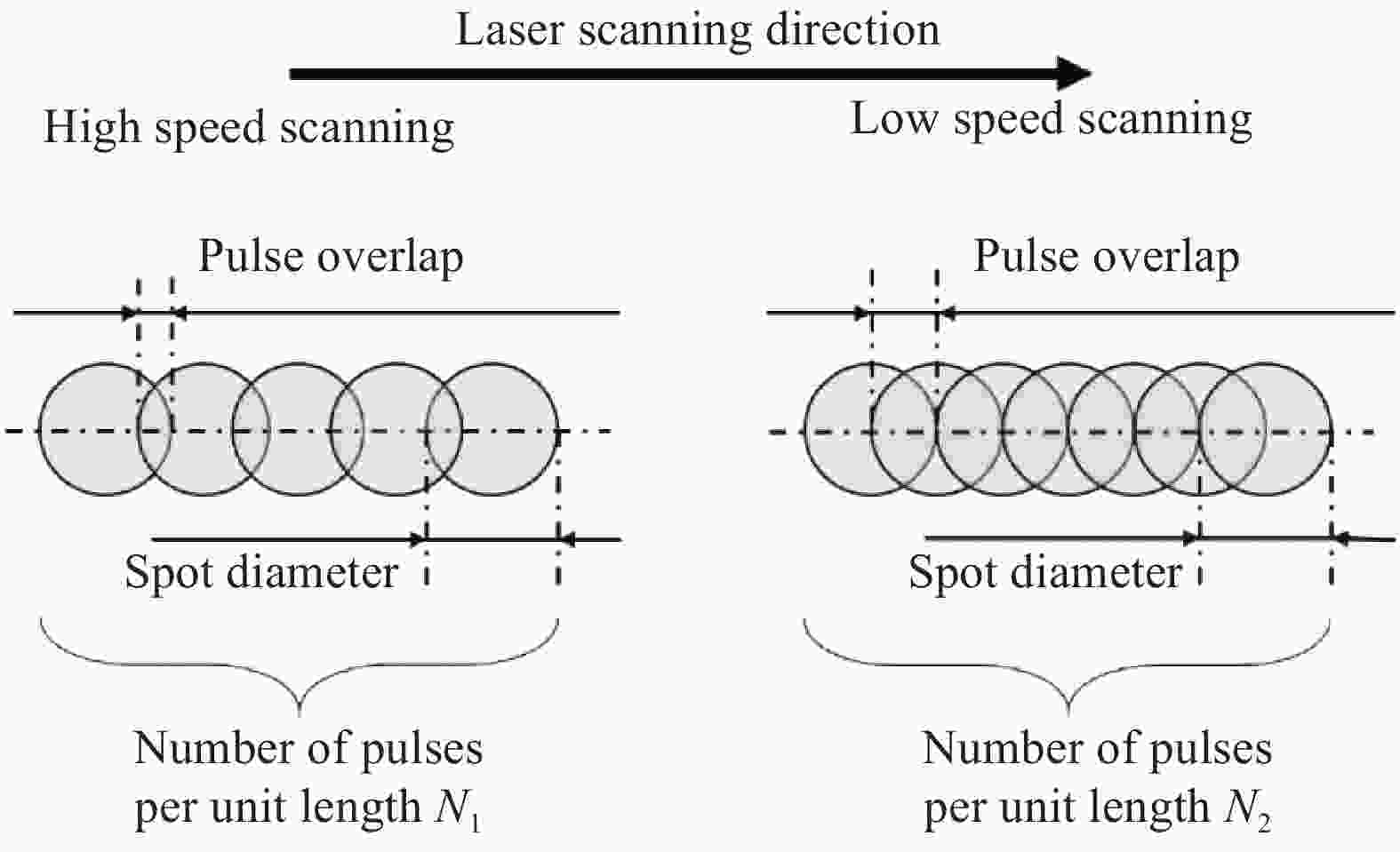

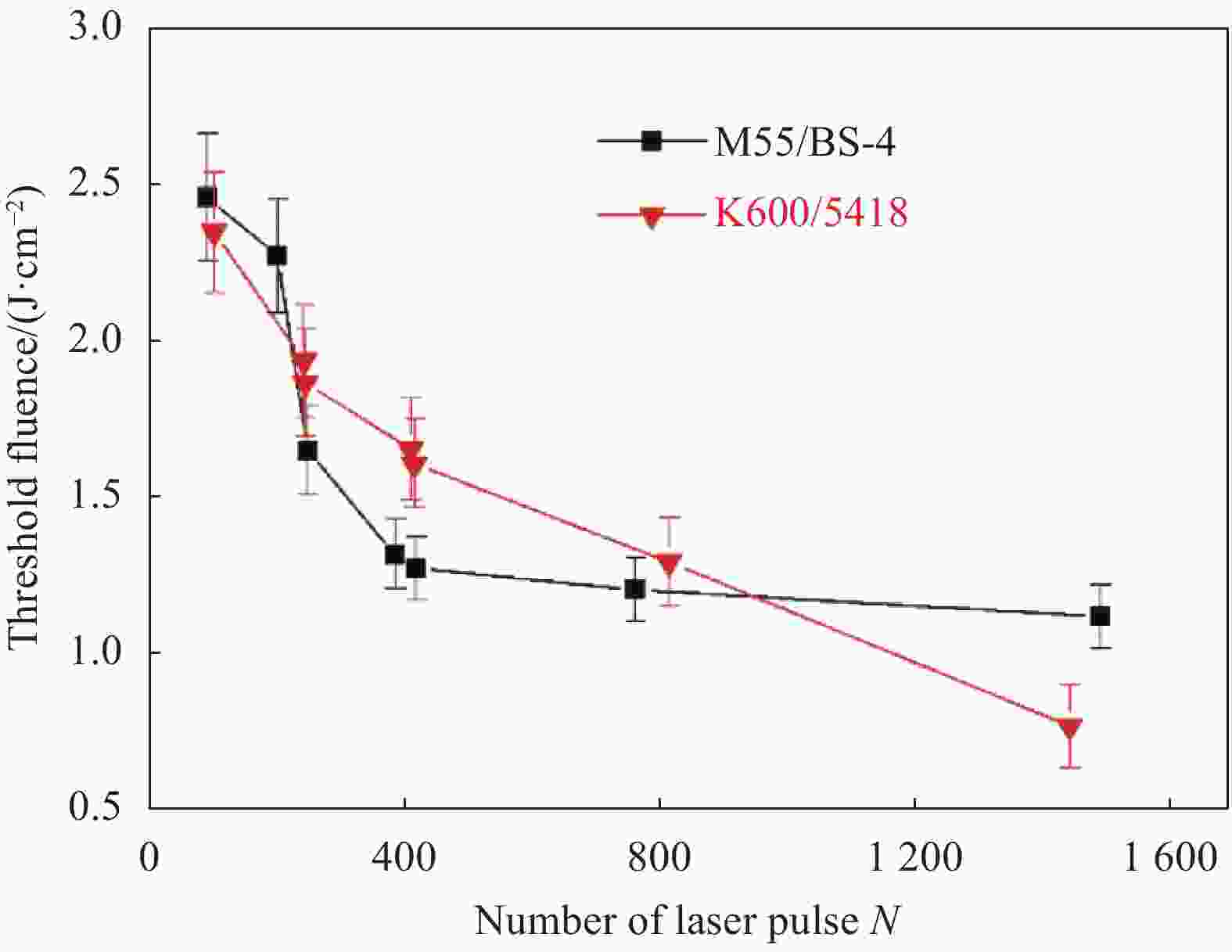

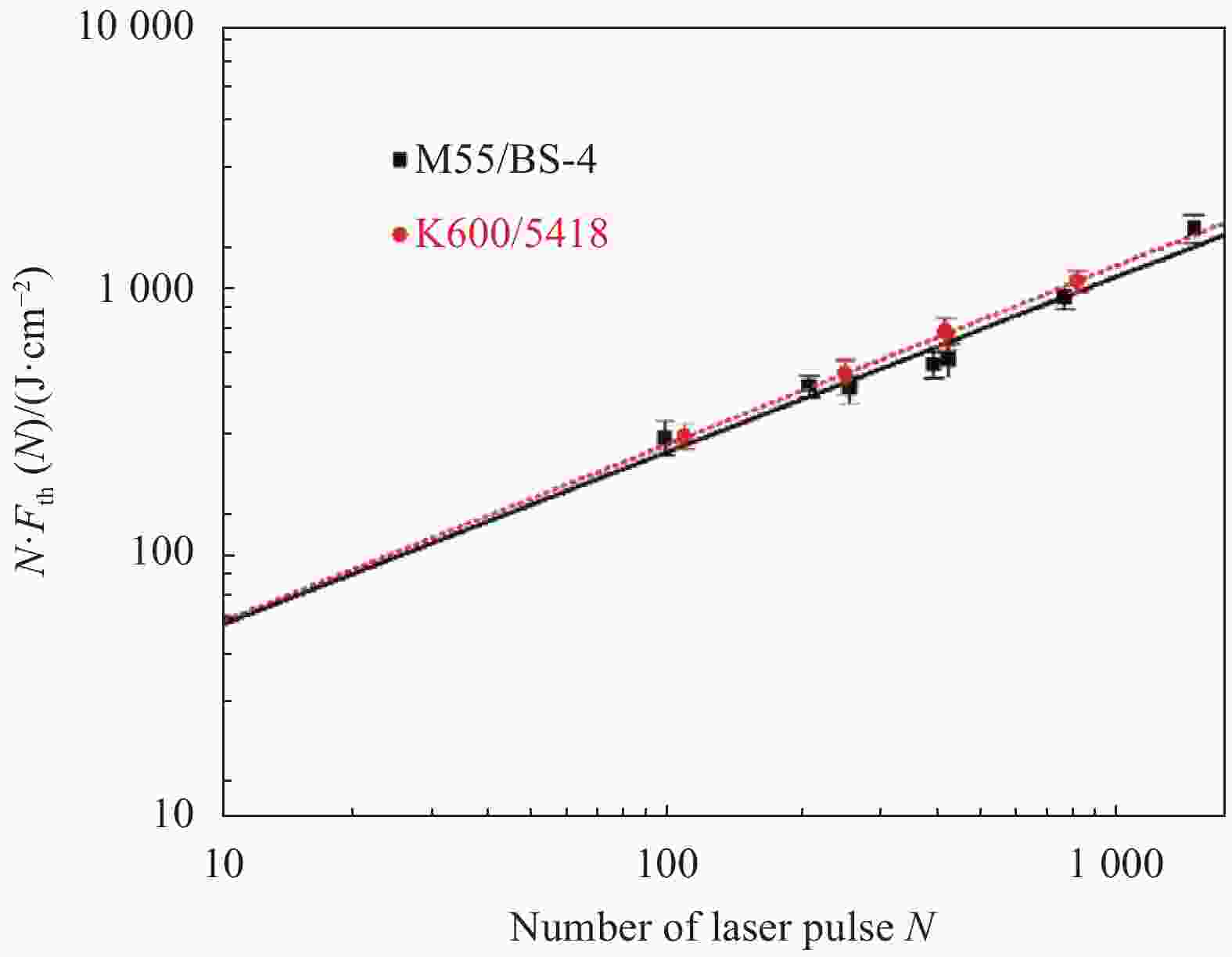

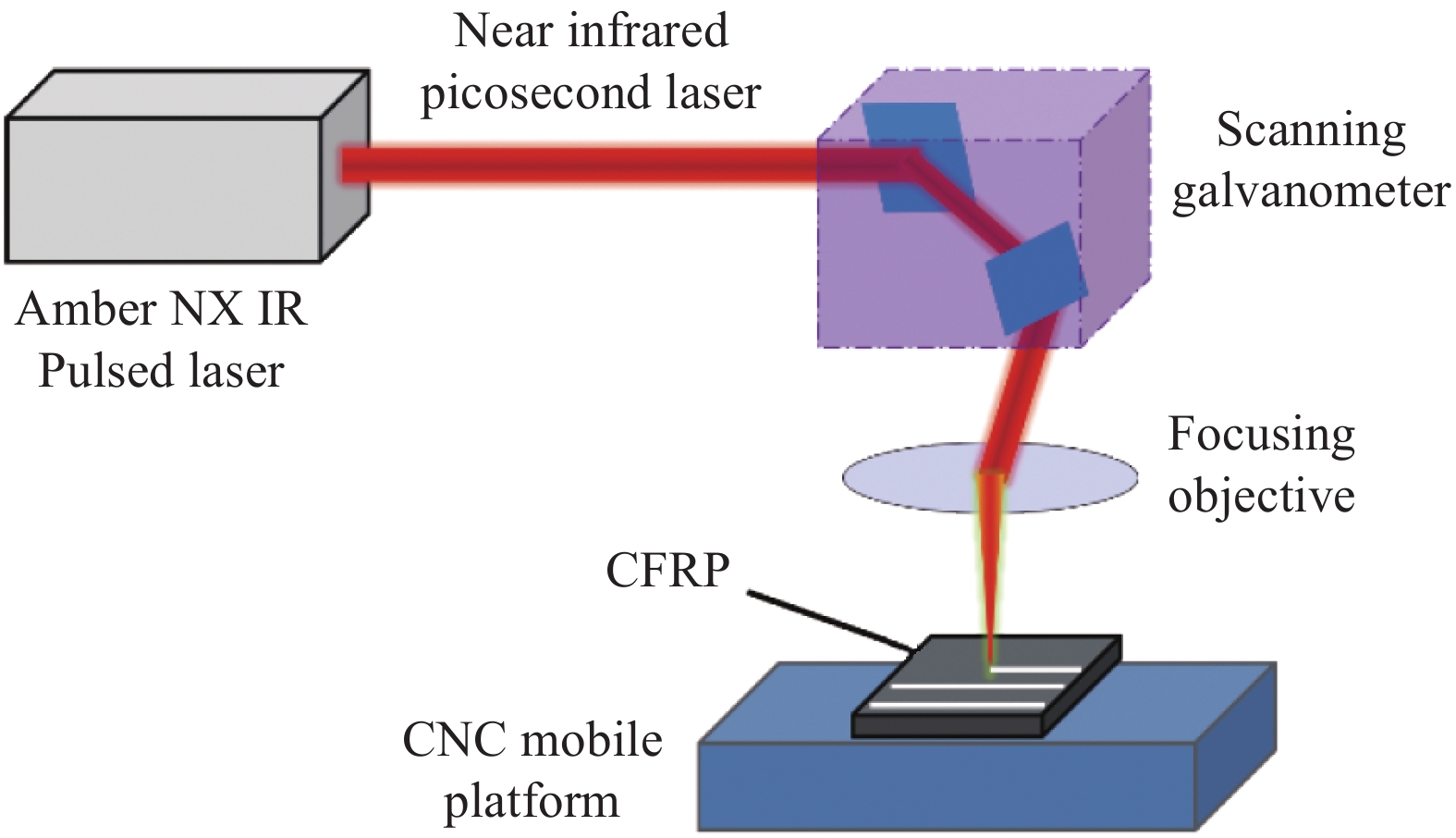

摘要: 对聚丙烯腈基高模量碳纤维/改性氰酸酯树脂复合材料(M55/BS-4)和一种沥青基高导热碳纤维/树脂基复合材料(K600/5418)的皮秒激光加工阈值和形貌特性进行了研究。通过面积外延法测定并比较了这两种碳纤维复合材料的近红外皮秒激光加工阈值及其阈值孵化效应,并预测了两种复合材料的单脉冲阈值;分析了入射能量通量(0.7~25 J/cm2)及光束扫描速度(0.2~5 m/s)对切口质量的影响规律。结果表明,碳纤维热导率的巨大差异导致不同碳纤维复合材料的加工阈值及形貌存在明显定量差距。使用可获得的最高扫描速度(5 m/s)和3.2倍(~8 J/cm2)单脉冲阈值的加工参数,可使材料的碳纤维和树脂几乎协同去除,加工形貌上表现为切缝入口宽度均匀、切割边缘整齐。使用更高扫描速度并配以合适的加工能量有望进一步提高加工质量。Abstract: The picosecond laser processing thresholds and morphology characteristics of polyacrylonitrile-based high modulus carbon fiber reinforced cyanate ester composite (M55/BS-4) and an asphalt-based high thermal conductivity carbon fiber reinforced plastic (K600/5418) were studied. Diameter-regression method was used to test and compare the ablation threshold, threshold incubation effect, and single-pulse thresholds for each composite were predicted. The influence of incident energy fluence (0.7-25 J/cm2) and beam scanning velocity (0.2-5 m/s) on the incision quality was analyzed. The results show that the great difference in the fiber thermal conductivity leads to significant quantitative difference in processing threshold and morphology. Using the highest scanning speed (5 m/s) available and fluence equivalent to 3.2 times the single-pulse threshold (i.e., about 8 J/cm2), carbon fiber and resin can be almost synergically removed, characterized by uniform slit inlet widths and neat cutting edge. The use of higher scanning speeds coupled with appropriate processing energy is expected to further improve the quality of processing.

-

Key words:

- high modulus /

- carbon fiber /

- plasticsmatrix /

- picosecond laser /

- ablation threshold /

- incubation effect

-

表 1 高模量碳纤维增强树脂基(CFRP)复合材料参数

Table 1. Parameters of high-modulus carbon fiberreinforced plastic composite (CFRP) composites

M55/BS-4 K600/5418 Layer way Single direction Single direction Layer direction [0]10 [0]10 Thickness/mm 1 1 Mass percent of fiber 66% 68% Density/(kg·m−3) 1.7 1.8 Thermal conductivity /(W·m−1·K−1) 131.2 377.3 表 2 激光器与共性加工参数

Table 2. Laser and processing parameters

Parameter Value Average power P/W 1 -50 Repetition frequency f / kHz 1 -1 000 Scanning speed vs / (m·s−1) 0.02-5 Scanning pass n 50 Pulse duration $ \tau $(1/2 light intensity)/ps 10 Wavelength $ \lambda $/nm 1064 表 3 M55/BS-4在不同激光扫描速度下的实际光斑直径与烧蚀阈值通量

Table 3. Actual spot diameters and ablative threshold fluence of M55/BS-4 at different laser scanning speeds

Speed/(m·s−1) Spot diameter d/μm Threshold fluence/(J·cm−2) 0.8 23.86±0.56 1.13±0.29 1.5 23.01±0.35 1.21±0.22 3.0 23.51±0.16 1.32±0.11 5.0 25.55±0.23 1.65±0.21 表 4 K600/5418在不同激光扫描速度下的实际光斑直径与烧蚀阈值通量

Table 4. Actual spot diameters and ablative threshold fluence of K600/5418 at different laser scanning speeds

Speed/(m·s−1) Spot diameter d/μm Threshold fluence/(J·cm−2) 0.8 23.11±0.48 0.78±0.19 1.5 24.56±0.27 1.30±0.16 3.0 25.27±0.20 1.61±0.16 5.0 25.14±0.20 1.87±0.21 表 5 M55/BS-4与K600/5418的孵化系数S与单脉冲阈值通量Fth(1)

Table 5. Incubation coefficient S and single-pulse threshold fluence Fth(1) of M55/BS-4 and K600/5418

M55/BS-4 K600/5418 S 0.65±0.06 0.87±0.07 Fth(1) /(J·cm−2) 2.44±0.88 2.68±0.67 -

[1] LIU H L, TANG Y, LU L S, et al. Investigation on fiber laser cutting of polyacrylonitrile-based carbon fiber tow[J]. Journal of Materials Processing Technology,2019,263:151-163. doi: 10.1016/j.jmatprotec.2018.08.015 [2] TAKAHASHI K, TSUKAMOTO M, MASUNO S, et al. Heat conduction analysis of laser CFRP processing with IR and UV laser light[J]. Composites Part A: Applied Science and Manufacturing,2016,84:114-122. doi: 10.1016/j.compositesa.2015.12.009 [3] HEIDERSCHEIT T, SHEN N, WANG Q, et al. Keyhole cutting of carbon fiber reinforced polymer using a long-duration nanosecond pulse laser[J]. Optics and Lasers in Engineering,2019,120:101-109. doi: 10.1016/j.optlaseng.2019.03.009 [4] OLIVEIRA V, SHARMA S P, DE MOURA M , et al. Surface treatment of CFRP composites using femtosecond laser radiation[J]. Optics and Lasers in Engineering,2017,94:37-43. doi: 10.1016/j.optlaseng.2017.02.011 [5] OLIVEIRA V, MOREIRA R D F, DE MOURA M, et al. Surface patterning of CFRP composites using femtosecond laser interferometry[J]. Applied Physics A,2018,124(3):231. doi: 10.1007/s00339-018-1662-x [6] STOCK J, ZAEH M F, CONRAD M. Remote laser cutting of CFRP: improvements in the cut surface[J]. Physics Procedia,2012,39:161-170. doi: 10.1016/j.phpro.2012.10.026 [7] GOEKE A, EMMEHNARM C. Influence of Laser Cutting Parameters on CFRP Part Quality[J]. Physics Procedia,2010,5:253-258. [8] SALAMA A, LI L, MATIVENGA P, et al. High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites[J]. Applied Physics A,2016,122:73-84. [9] SALAMA A, YAN Y Z, LI L, et al. Understanding the self-limiting effect in picosecond laser single and multiple parallel pass drilling/machining of CFRP composite and mild steel[J]. Materials and Design,2016,107:461-469. doi: 10.1016/j.matdes.2016.06.048 [10] FREITAG C, WIEDENMANN M, NEGEL J P, et al. High-quality processing of CFRP with a 1.1-kW picosecond laser[J]. Applied Physics A,2015,119(4):1237-1243. doi: 10.1007/s00339-015-9159-3 [11] FREITAG C, KONONENKO T V, WEBER R, et al. Influence of pulse repetition rate and pulse energy on the heat accumulation between subsequent laser pulses during laser processing of CFRP with ps pulses[J]. Applied Physics A,2018,124(7):479. doi: 10.1007/s00339-018-1891-z [12] WEBER R, FREITAG C, KONONENKO T V, et al. Short-pulse Laser Processing of CFRP[J]. Physics Procedia,2012,39(9):137-146. [13] KONONENKO T V, FREITAG C, KOMLENOK M S, et al. Oxygen-assisted multipass cutting of carbon fiber reinforced plastics with ultra-short laser pulses[J]. Journal of Applied Physics,2014,115(10):96-244. [14] KONONENKO T V, FREITAG C, KOMLENOK M S, et al. Heat accumulation effects in short-pulse multi-pass cutting of carbon fiber reinforced plastics[J]. Journal of Applied Physics,2015,118:103105. doi: 10.1063/1.4930059 [15] 蒋翼, 陈根余, 周聪, 等. 碳纤维复合材料皮秒激光切割工艺研究[J]. 激光技术, 2017, 41(06):821-825.JIANG Yi, CHEN Genyu, ZHOU Cong, et al. Research on picosecond laser cutting technology of carbon fiber composite material[J]. Laser Technology,2017,41(06):821-825(in Chinese). [16] HU J, ZHU D. Experimental study on the picosecond pulsed laser cutting of carbon fiber-reinforced plastics[J]. Journal of Reinforced Plastics & Composites,2018,37(15):993-1003. [17] 朱德志, 胡俊. 皮秒激光加工碳纤维复合材料工艺试验[J]. 航空制造技术, 2017, 60(20):54-59.ZHU Dezhi, HU Jun. Process test of carbon fiber composite material processed by picosecond laser[J]. Aeronautical Manufacturing Technology,2017,60(20):54-59(in Chinese). [18] 贺龙宇. 基于飞秒激光的CFRP制孔质量研究[D]. 天津: 天津工业大学, 2019.HE Longyu. Research on the mass of CFRP hole making based on femtosecond laser[D]. Tianjin: Tiangong University, 2019. [19] 赵煦. 基于短脉冲激光的碳纤维材料加工研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.ZHAO Xu. Research on carbon fiber processing based on short Pulse laser[D]. Harbin: Harbin Institute of Technology, 2014. [20] ZHANG Kaihu, ZHANG Xiaohui, JIANG Guigang, et al. Laser cutting of fiber-reinforced plastic laminate and its honeycomb sandwich structure[C]//AOPC 2020: Advanced Laser Technology and Application. Society of Photo-Optical Instrumentation Engineers (SPIE) Conference Series. San Francisco, 2020: 1156211. [21] 张开虎, 于洋, 张夏明, 等. 纤维增强树脂基复合材料激光切割热影响探析[J]. 导航与控制, 2019, 18(5):60-66.ZHANG Kaihu, YU Yang, ZHANG Xiaming, et al. Laser cutting induced heat affected zone in fiber reinforced polymer: A Comparative Analysis[J]. Navigation and Control,2019,18(5):60-66(in Chinese). [22] 张家雷, 王伟平, 刘仓理. 激光辐照下二维编织碳纤维/环氧树脂复合材料的烧蚀特征[J]. 复合材料学报, 2017, 34(3):494-500.ZHANG Jialei, WANG Weiping, LIU Cangli. Ablation characteristics of 2D braided carbon fiber/epoxy composites under laser irradiation[J]. Acta Materiae Compositae Sinica,2017,34(3):494-500(in Chinese). [23] LIU J M. Simple technique for measurements of pulsed Gaussian-beam spot sizes[J]. Optics Letters,1982,7(5):196-198. doi: 10.1364/OL.7.000196 [24] ROSENFELD M LORENZ, R. STOIAN, et al. Ultrashort-laser-pulse damage threshold of transparent materials and the role of incubation[J]. Applied Physics A,1999,69:373-376. doi: 10.1007/s003400050822 [25] MANNION P T, MAGEE J, COYNE E, et al. The effect of damage accumulation behavior on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air[J]. Applied Surface Science,2004,233:275-287. doi: 10.1016/j.apsusc.2004.03.229 -

下载:

下载: