Effects of high temperature heat treatment on the micro structure and mechanical performance of C/C-SiC composite materials

-

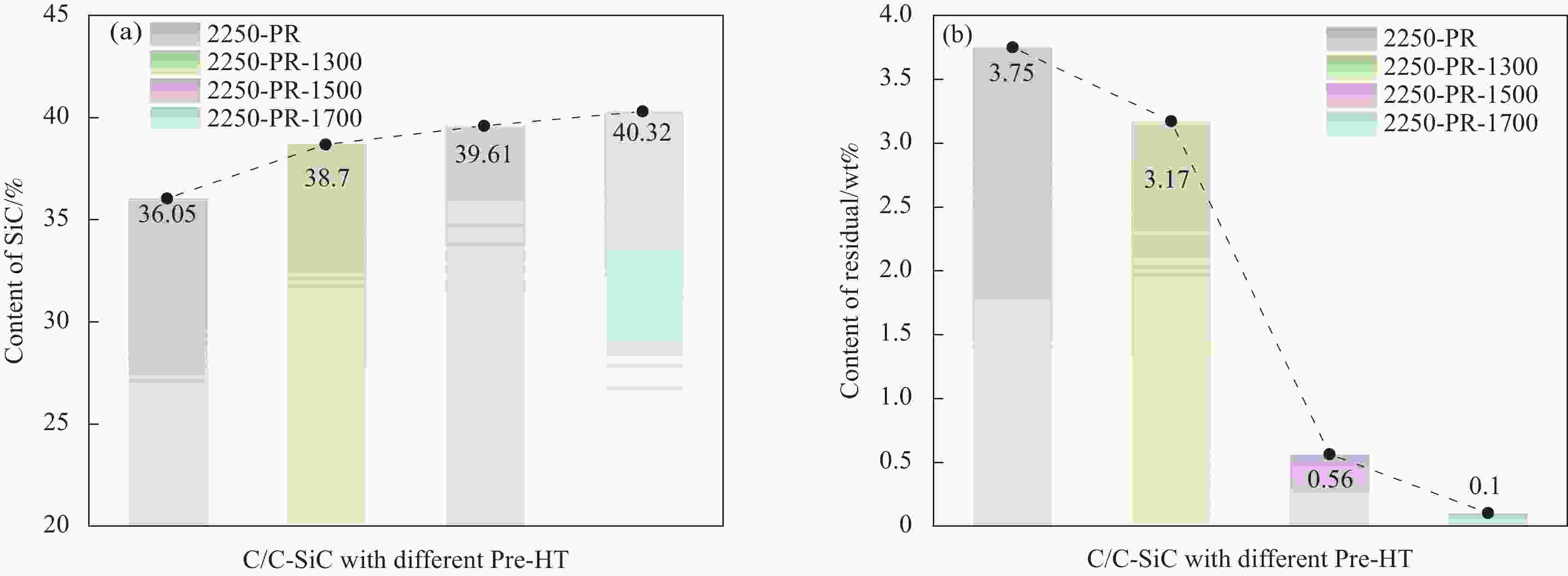

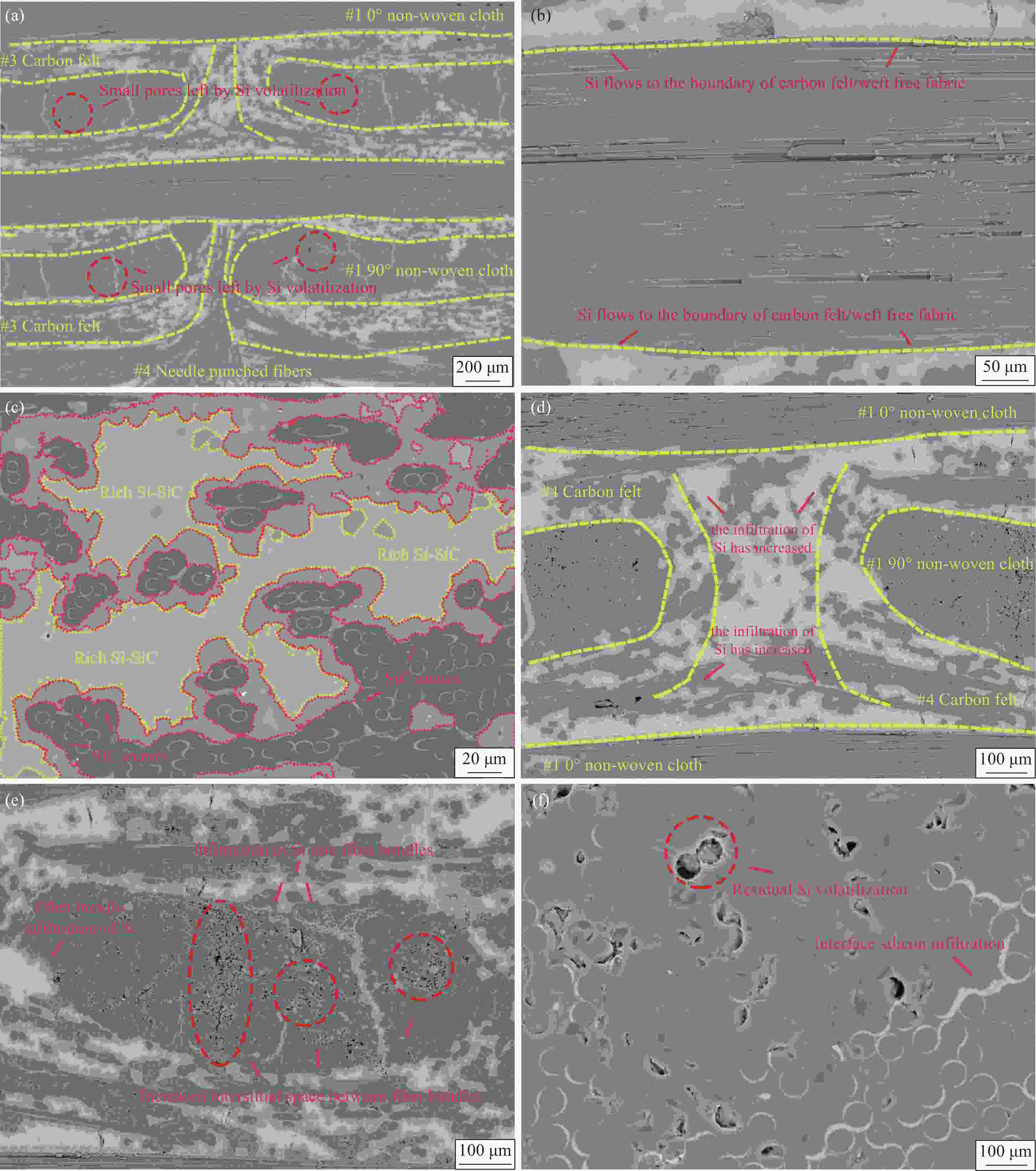

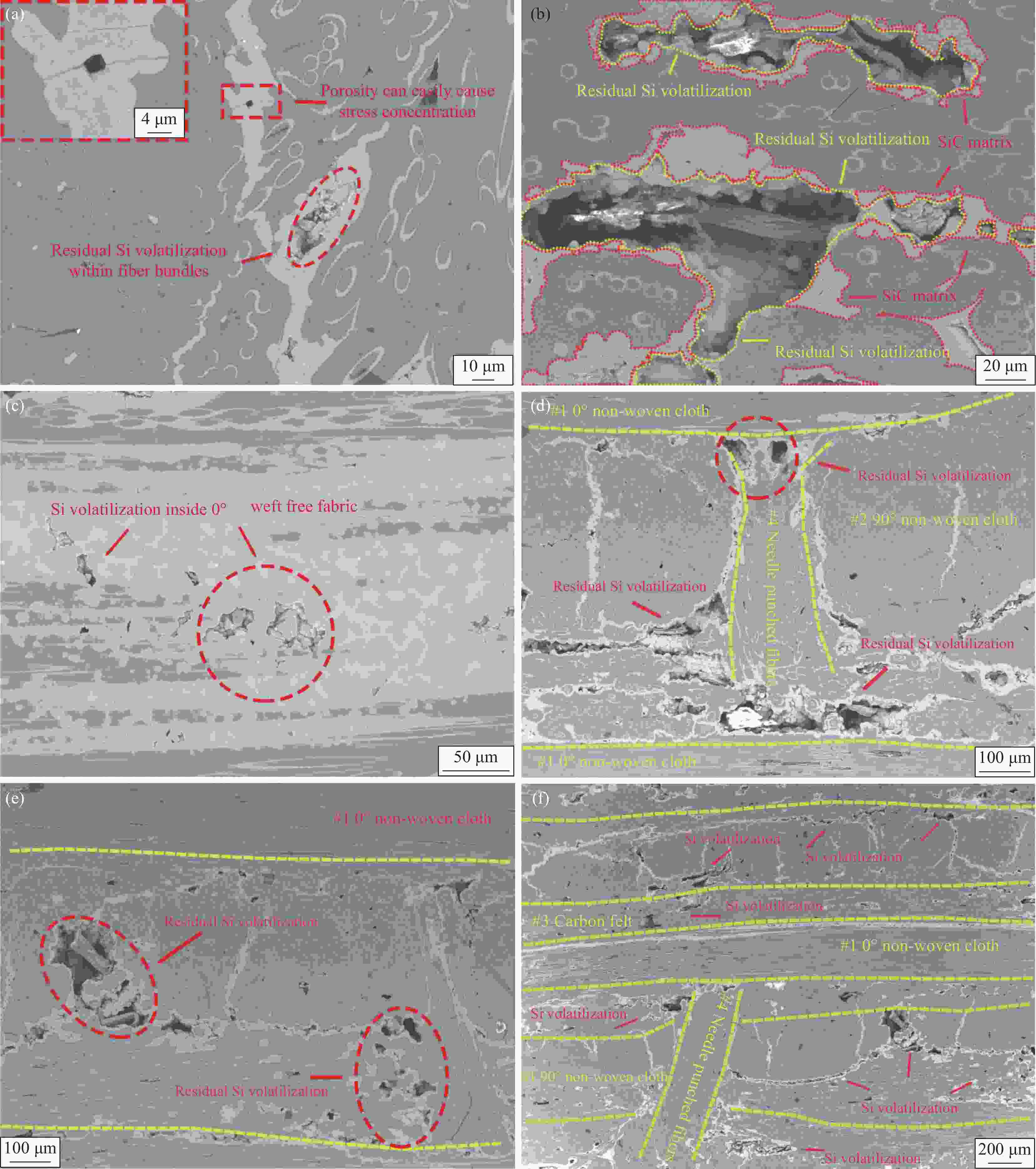

摘要: 后高温热处理对反应熔融浸渗法(RMI)制备C/C-SiC复合材料的微观结构与性能有着至关重要的影响。为研究后高温热处理对RMI制备C/C-SiC复合材料微观结构和力学性能影响及机制,本研究通过等温化学气相渗透法(CVI)工艺,以天然气为碳源气体,氮气为载气和稀释气体,在碳纤维预制体内部沉积热解碳基体,制得密度为1.2 g/cm3的C/C多孔体,然后通过反应熔融浸渗法制备出C/C-SiC复合材料,研究了不同后高温热处理温度对C/C-SiC复合材料相组成、内应力及力学性能的影响。将制备得到的C/C-SiC复合材料分别在1300℃、1500℃和1700℃下进行后高温热处理,研究了后高温热处理对C/C-SiC复合材料密度、孔隙率、基体成分、内应力以及对弯曲性能的影响。结果表明:经1300℃、1500℃及1700℃后热处理后,C/C-SiC复合材料的密度降低,开孔率增加,SiC基体含量上升,SiC基体的分布更为广泛,同时还伴随有残余Si挥发产生的大孔,残余Si含量显著降低。在1300℃、1500℃和1700℃的后热处理导致弯曲强度先增加后减小,1500℃后处理时弯曲强度最大为296.52 MPa,随着后处理温度提高,弯曲模量降低,1700℃后热处理下降程度最大。Abstract: The microstructure and properties of C/C-SiC composites prepared by reactive melt infiltration (RMI) are significantly affected by post-heat treatment. In order to study the effect and mechanism of post-heat treatment on the microstructure and mechanical properties of C/C-SiC composites prepared by RMI, the isothermal chemical vapor infiltration (CVI) process was used to deposit pyrolytic carbon matrix in the carbon fiber preform, and C/C porous bodies with a density of 1.2 g/cm3 were prepared by using natural gas as carbon source gas and nitrogen as carrier gas and dilution gas. Then C/C-SiC composites were prepared by reactive melt infiltration method. The effects of different post-heat treatment temperatures on the phase composition, internal stress and mechanical properties of C/C-SiC composites were studied. The prepared C/C-SiC composites were treated at 1300℃, 1500℃ and 1700℃ respectively. The effects of post-high temperature heat treatment on the density, porosity, matrix composition, internal stress and bending properties of the C/C-SiC composites were investigated. The results show that after heat treatment at 1300℃, 1500℃ and 1700℃, the density of C/C-SiC composites decreases, the porosity increases, the content of SiC matrix increases, the distribution of SiC matrix becomes more extensive, and the residual Si content decreases significantly with large pores caused by residual Si volatilization. At 1300℃, 1500℃ and 1700℃, the bending strength increases first and then decreases. At 1500℃, the bending strength reaches a maximum of 296.52 MPa. With the increase of the post-treatment temperature, the bending modulus decreases, and at 1700℃, the bending strength decreases the most.

-

Key words:

- C/C-SiC /

- RMI /

- High-temperature thermal treatment /

- Flexural properties /

- microscopic structure

-

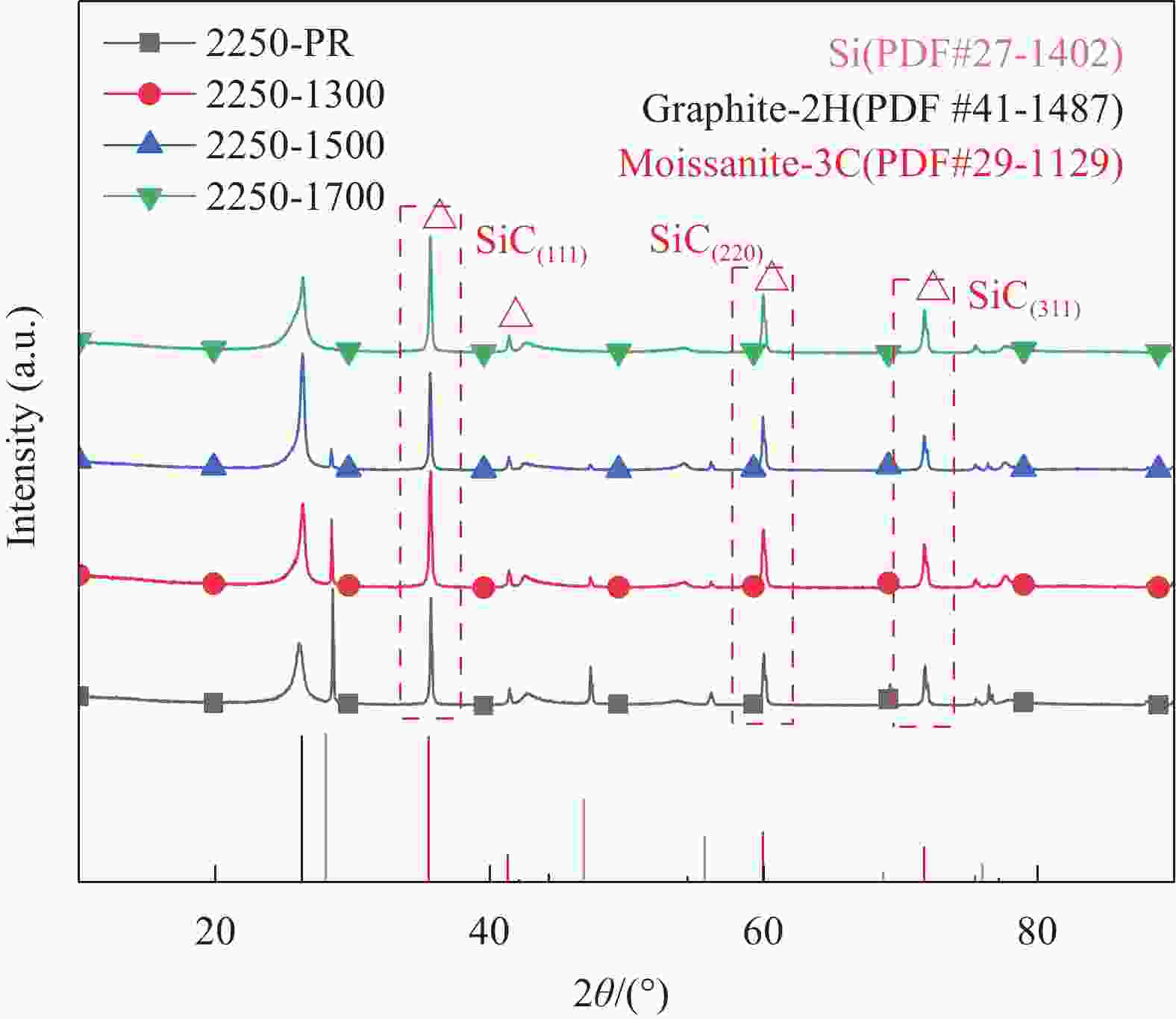

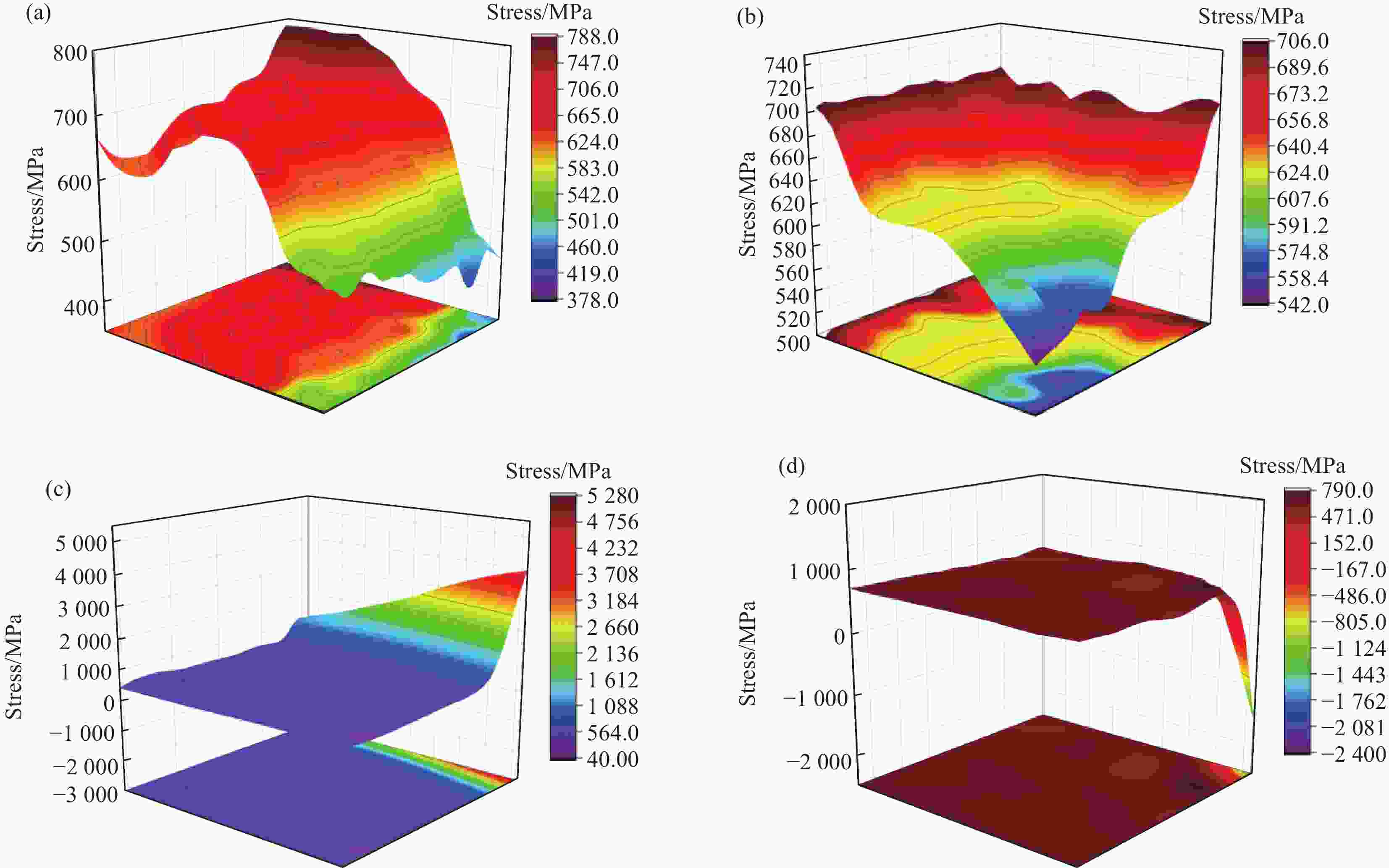

图 7 经不同温度后热处理后C/C-SiC复合材料XRD图谱的谱峰偏移:(a) SiC (111)晶面的谱峰偏移;(b) SiC (220) 晶面的谱峰偏移; (c) SiC (311) 晶面的谱峰偏移; (d) 石墨炭(002)晶面的谱峰偏移

Figure 7. The peak shift of the XRD spectrum of C/C-SiC composite material after heat treatment at different temperatures: (a) Spectral peak shift of SiC (111) crystal plane; (b) Spectral peak shift of SiC (220) crystal plane; (c) Spectral peak shift of SiC (311) crystal plane;(d) Spectral peak shift of graphite (002) crystal surface

图 8 不同后热处理温度处理后C/C-SiC复合材料的拉曼Mapping图:(a) 2250-PR mapping图; (b) 2250-PR-1300 mapping图;(c) 2250-PR-1500 mapping图; (d) 2250-PR-1700 mapping图

Figure 8. Raman Mapping of C/C-SiC composite materials treated at different post heat treatment temperatures: (a) 2250-PR mapping diagram; (b) 2250-PR-1300 mapping diagram; (c) 2250-PR-1500 mapping diagram; (d) 2250-PR-1700 mapping diagram.

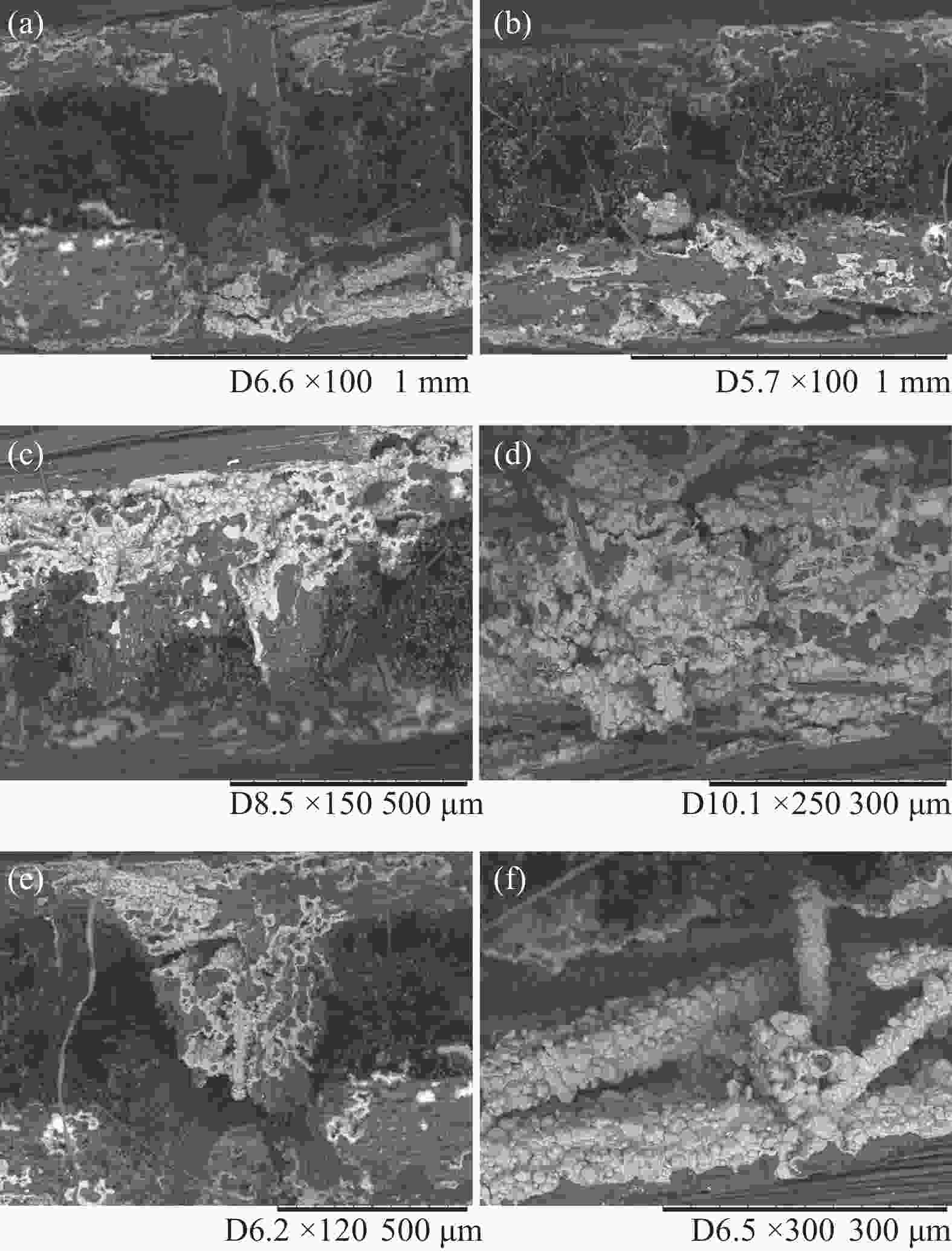

图 9 2250-PR-1300、2250-PR-1500及2250-PR-1700弯曲试样断口的SEM图。(a) 和(b) 1300℃后热处理; (c) 和(d)1500℃后热处理; (e) 和(f)1700℃后热处理

Figure 9. SEM images of the fracture surface of 2250-PR-1300、2250-PR-1500 and 2250-PR-1700 bending specimens. (a) and (b) Heat treatment after 1300℃; (c) and (d) Heat treatment after 1500℃; (e) and (f) Heat treatment after 1700℃

-

[1] DUAN J, ZHANG M, CHEN P, et al. Tribological behavior and applications of carbon fiber reinforced ceramic composites as high-performance frictional materials[J]. Ceramics International, 2021, 47(14): 19271. doi: 10.1016/j.ceramint.2021.02.187 [2] 虎琳, 肖志超, 张永辉. C/C-SiC炭陶复合材料的制备及应用进展[J]. 炭素, 2017, (2): 43-47.HU Lin, XIAO Zhichao, ZHANG Yonghui. Progress in Preparation and Application of C/C-SiC Carbon Ceramic Composite Materials[J]. Carbon, 2017, (2): 43-47(in Chinese). [3] NASLAIN R. SiC-matrix composites: nonbrittle ceramics for thermo-structural application[J]. International Journal of Applied Ceramic Technology, 2005, 2(2): 75-84. doi: 10.1111/j.1744-7402.2005.02009.x [4] 张波, 李瑞珍, 解惠贞. 熔融渗硅法制备C/C-SiC复合材料工艺参数研究[J]. 材料导报, 2015, (S1): 389-392+396.ZHANG Bo, LI Ruizhen, XIE Huizhen. Research of the parameter of liquid silicon in filtration process for C/C-SiCcomposites[J]. Materials Review, 2015, (S1): 389-392+396(in Chinese). [5] 徐永东, 张立同, 成来飞, 等. 碳/碳化硅摩阻复合材料的研究进展[J]. 硅酸盐学报, 2006, 34(8): 992-999.XU Y D, ZHANG L T, CHENG L F, et al. Research progress on carbon/silicon carbide friction composite[J]. Journal of the Chinese Ceramic Society, 2006, 34(8): 992-999(in Chinese). [6] JAYASEELAN D D, DE Sá R G, BROWN P, et al. Reactive infiltration processing (RIP) of ultra high temperature ceramics (UHTC) into porous C/C composite tubes[J]. Journal of the European Ceramic Society, 2011, 31(3): 361-368. doi: 10.1016/j.jeurceramsoc.2010.10.013 [7] GUO W, XIAO H, YASUDA E, et al. Oxidation kinetics and mechanisms of a 2D-C/C composite[J]. Carbon, 2006, 44(15): 3269-3276. doi: 10.1016/j.carbon.2006.06.027 [8] XU J, YANG T, YANG Y, et al. Ultra-high temperature oxidation behavior of micro-laminated ZrC/MoSi2 coating on C/C composite[J]. Corrosion Science, 2018, 132. [9] PATEL M, SAURABH K, PRASAD V V B, et al. High temperature C/C-SiC composite by liquid silicon infiltration: a literature review[J]. Bulletin of Materials Science, 2012, 35(1): 63-73. doi: 10.1007/s12034-011-0247-5 [10] FLAUDER S, LANGHOF N, KRENKEL W. Tailored macro-pores during the formation of C/C-SiC via liquid phase pyrolysis[J]. Journal of the European Ceramic Society, 2020. [11] KUMAR S, RANJAN A, MANOCHA L M, et al. SiC-Based Composites Through Liquid Infiltration Routes [M]//MAHAJAN Y R, JOHNSON R. Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications. Cham; Springer International Publishing. 2020: 831-875. [12] 姜娟, 李开元, 范尚武, 等. C/C多孔体的高温热处理对C/SiC复合材料结构及力学性能的影响[J]. 材料导报, 2013, 27(2): 86-88.JIANG Juan, LI Kaiyuan, FAN Shangwu, et al. The Effect of High Temperature Heat Treatment of C/C Porous Body on the Structure and Mechanical Properties of C/SiC Composite Materials[J]. Materials Reports, 2013, 27(2): 86-88(in Chinese). [13] LIU S H, ZHANG L T, YIN X W, et al. Microstructure and mechanical properties of SiC and carbon hybrid fiber reinforced SiC matrix composite[J]. International Journal of Applied Ceramic Technology, 2011, 8(2): 308-316. doi: 10.1111/j.1744-7402.2010.02588.x [14] 周新贵. PIP工艺制备陶瓷基复合材料的研究现状[J]. 航空制造技术, 2014, (6): 30-34.ZHOU X G. Research status of ceramic matrix composites via PIP process[J]. Aeronautical Manufacturing Technology, 2014, (6): 30-34(in Chinese). [15] GUO W, YE Y, BAI S, et al. Preparation and formation mechanism of C/C–SiC composites using polymer-Si slurry reactive melt infiltration[J]. Ceramics International, 2020, 46(5): 5586-5593. doi: 10.1016/j.ceramint.2019.11.002 [16] SI Z J, XIANG X, ZHAO K C, et al. Influence factors of C/C–SiC dual matrix composites prepared by reactive melt infiltration[J]. Materials & Design, 2009, 30(9): 3738-3742. [17] JIN X, FAN X, LU C, et al. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites[J]. Journal of the European Ceramic Society, 2018, 38(1): 1-28. doi: 10.1016/j.jeurceramsoc.2017.08.013 [18] TONG Y, BAI S, LIANG X, et al. Reactive melt infiltration fabrication of C/C-SiC composite: Wetting and infiltration[J]. Ceramics International, 2016, 42(15): 17174-17178. doi: 10.1016/j.ceramint.2016.08.007 [19] 王林山, 熊翔, 肖鹏, 等. 高温热处理对C/C-SiC复合材料制备与力学性能的影响[J]. 新型炭材料, 2005, 20(3): 245-248.WANG Lin-shan, XIONG Xiang, XIAO Peng, et al. Effect of high temperature treatment on the fabrication and mechanical properties of C/C-SiC composites[J]. New Carbon Materials, 2005, 20(3): 245-248(in Chinese). [20] LI S, CHEN X, CHEN Z. The effect of high temperature heat-treatment on the strength of C/C to C/C-SiC joints[J]. Carbon, 2010, 48(11): 3042-3049. doi: 10.1016/j.carbon.2010.04.030 [21] 王静. 近零膨胀C/C-SiC复合材料的反应烧结法制备及性能研究[D]. 长沙: 国防科学技术大学, 2013.WANG Jing. Preparation and Properties of Near-Zero Expansion C/C-SiC Composites by Reaction Bonding Technique[D]. Changsha : National University of Defense Technology, 2013(in Chinese). [22] 王秋野, 韩琳, 赵浛宇. C/SiC复合材料制备技术及应用现状[J]. 纤维复合材料, 2023, 40(1): 115-119.WANG Qiuye, HAN Lin, ZHAO Hanyu. Preparation Technology and Application Status of C/SiC Composite Materials[J]. Fiber composite materials, 2023, 40(1): 115-119 (in Chinese). [23] ZHANG L, REN C, JI C, et al. Effect of fiber orientations on surface grinding process of unidirectional C/SiC composites[J]. Applied Surface Science, 2016, 366: 424-431. doi: 10.1016/j.apsusc.2016.01.142 [24] 邱宇, 雷振坤, 亢一澜, 等. 微拉曼光谱技术及其在微结构残余应力检测中的应用[J]. 机械强度, 2004, (4): 389-392 doi: 10.3321/j.issn:1001-9669.2004.04.008QIU Yu, LEI Zhenkun, KANG Yilan, et al. Microraman spectroscopy and its Application in Residual Stress Detection of Microstructure[J]. Journal of Mechanical Strength, 2004, (4): 389-392(in Chinese). doi: 10.3321/j.issn:1001-9669.2004.04.008 -

点击查看大图

点击查看大图

计量

- 文章访问数: 107

- HTML全文浏览量: 50

- 被引次数: 0

下载:

下载: