Prediction of in-plane mechanical properties of auxetic honeycombs based onmachine learning

-

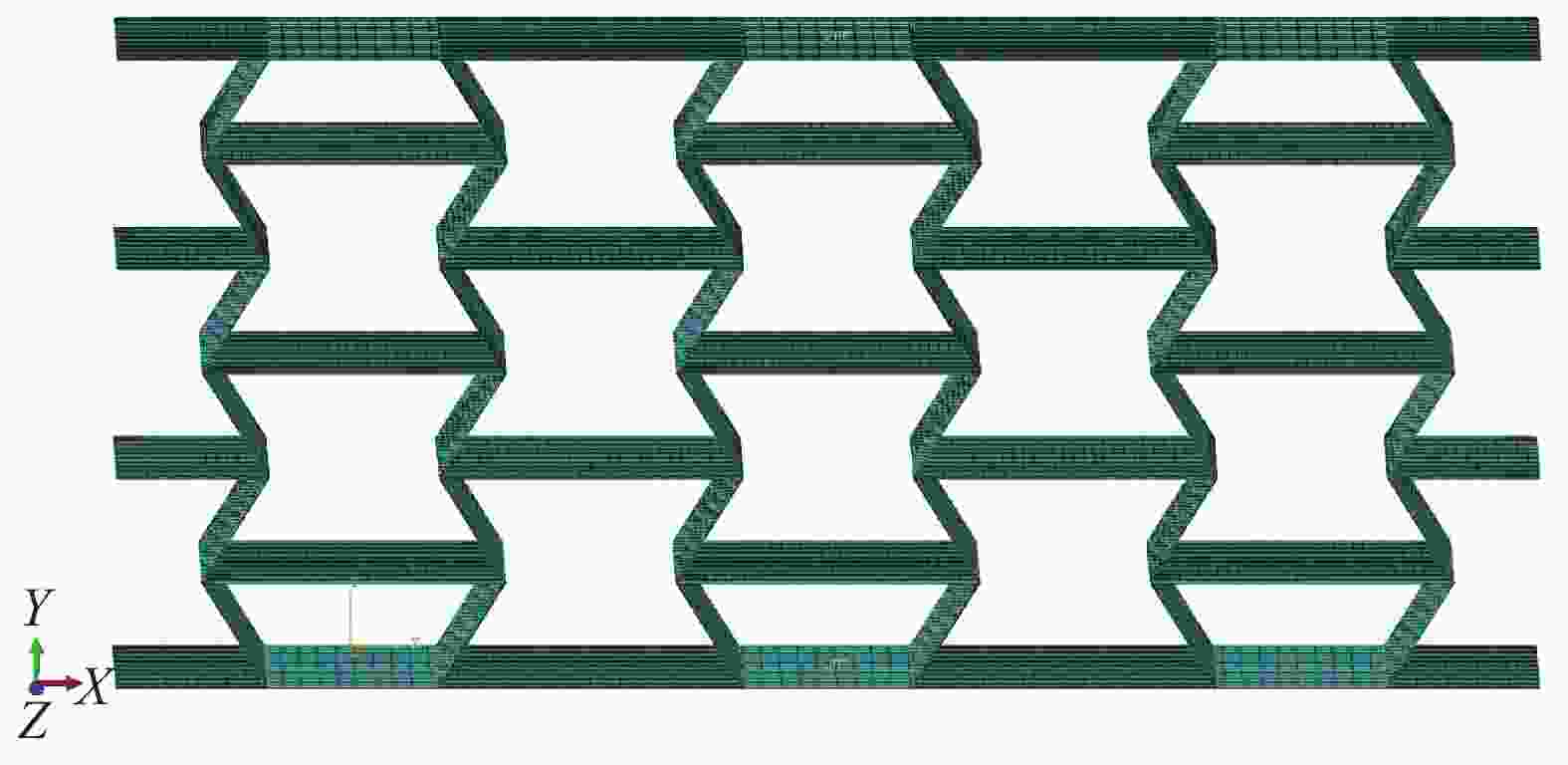

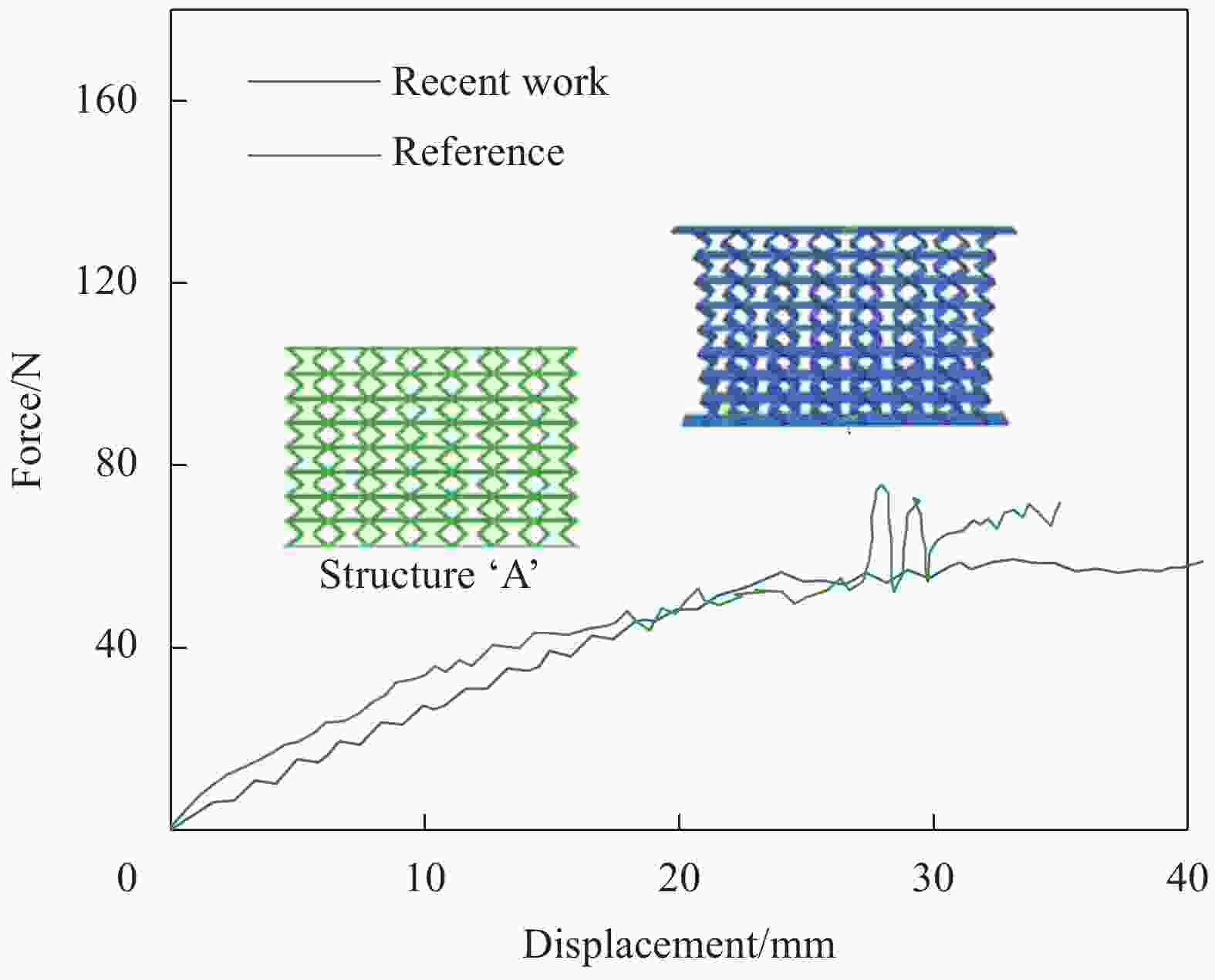

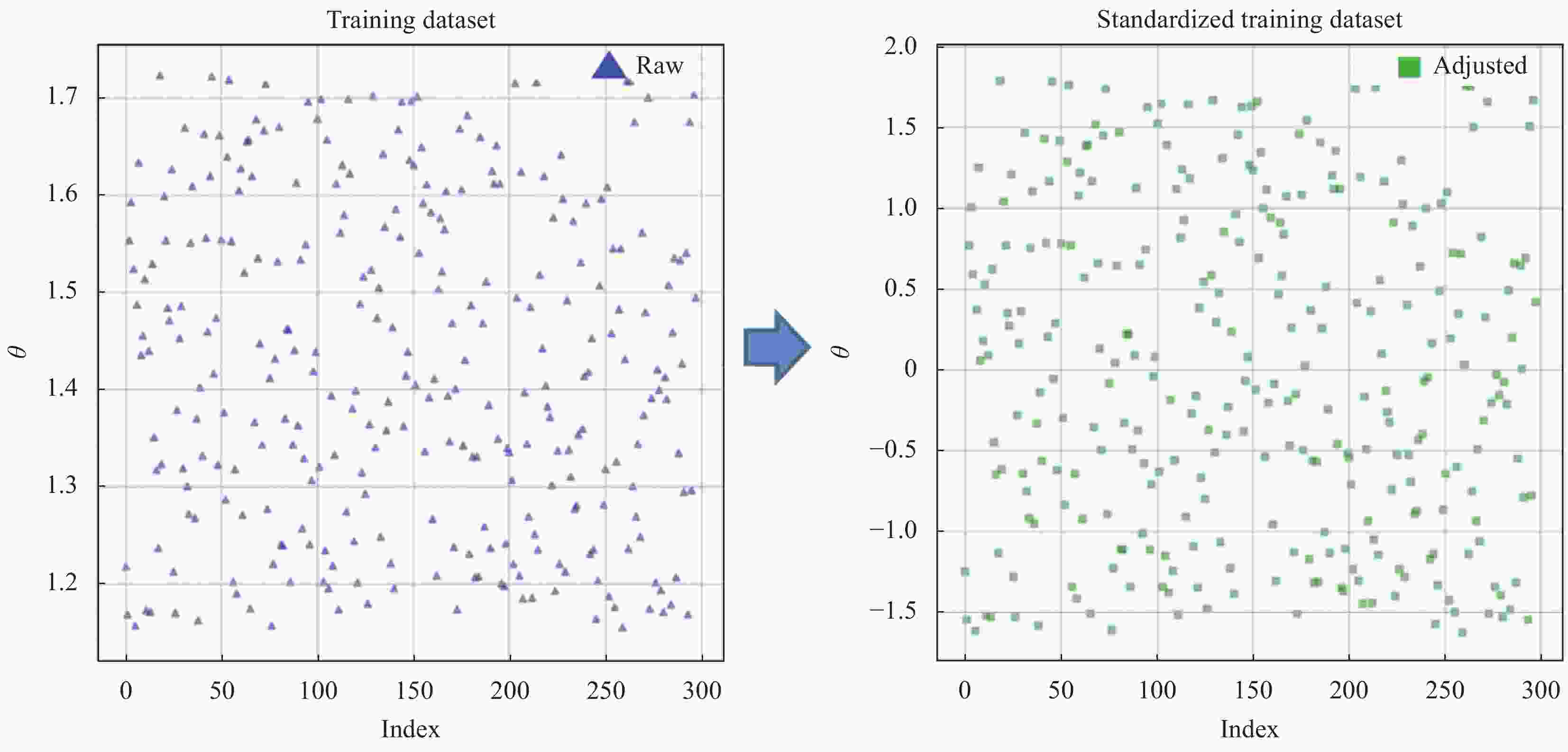

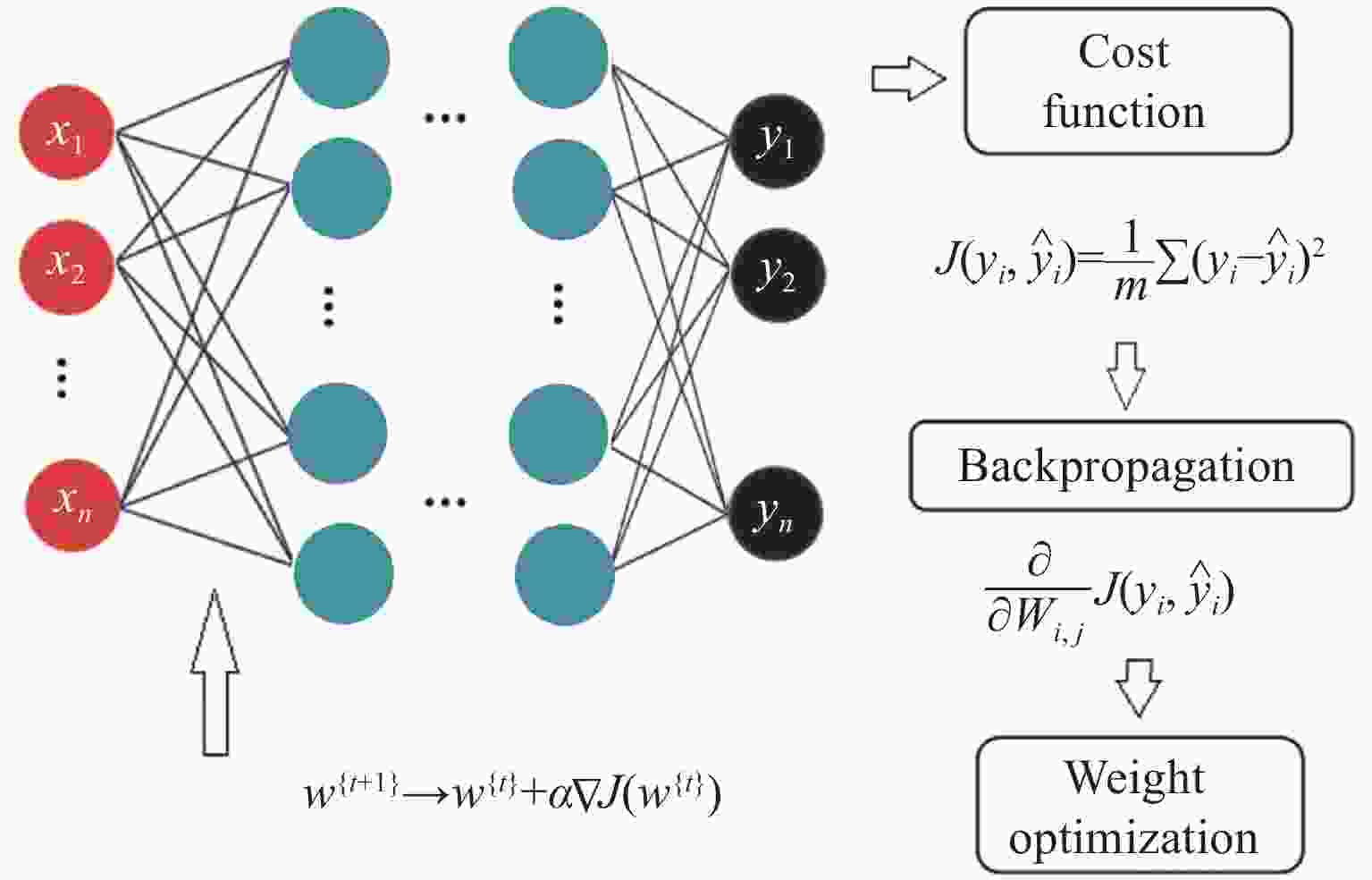

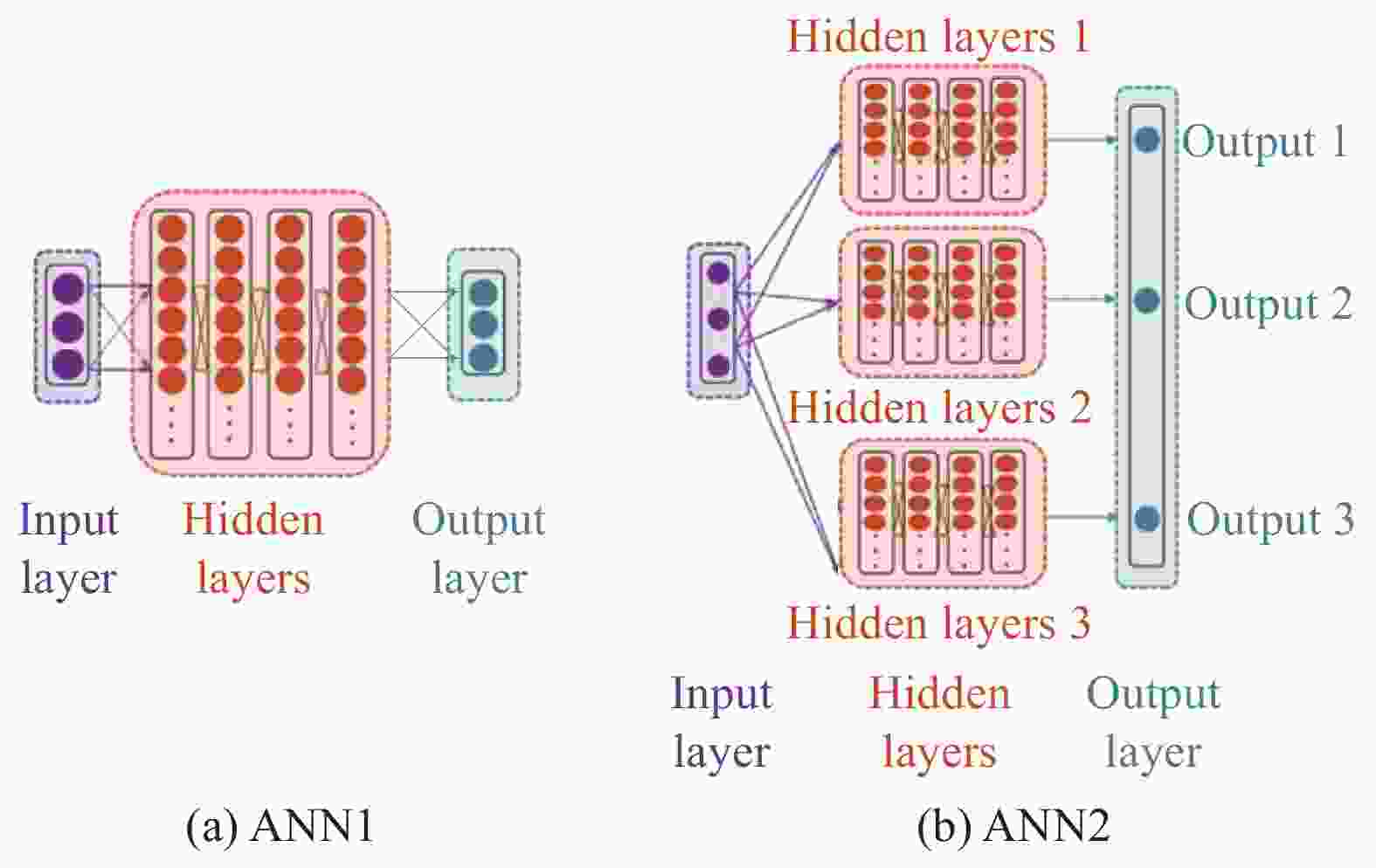

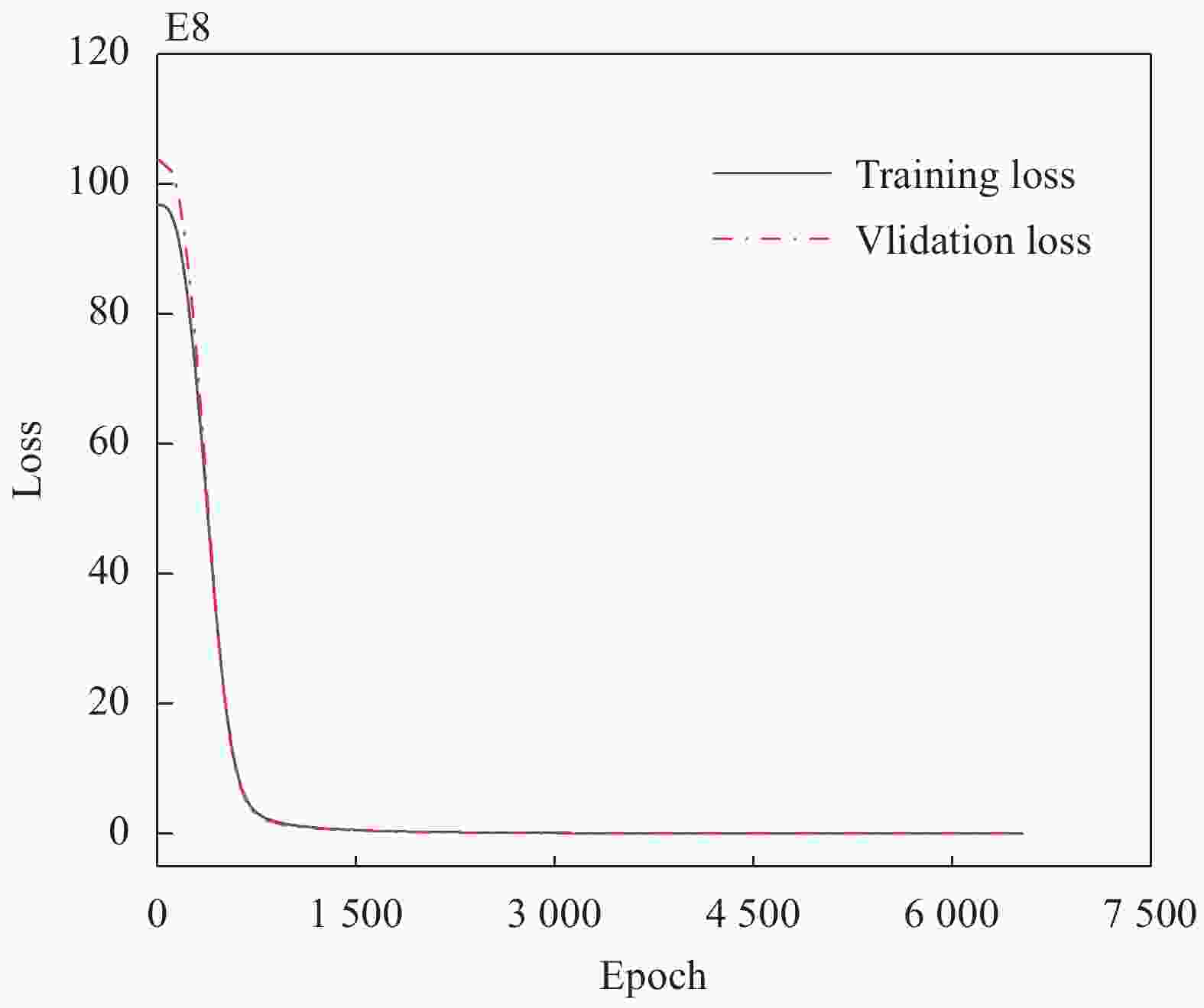

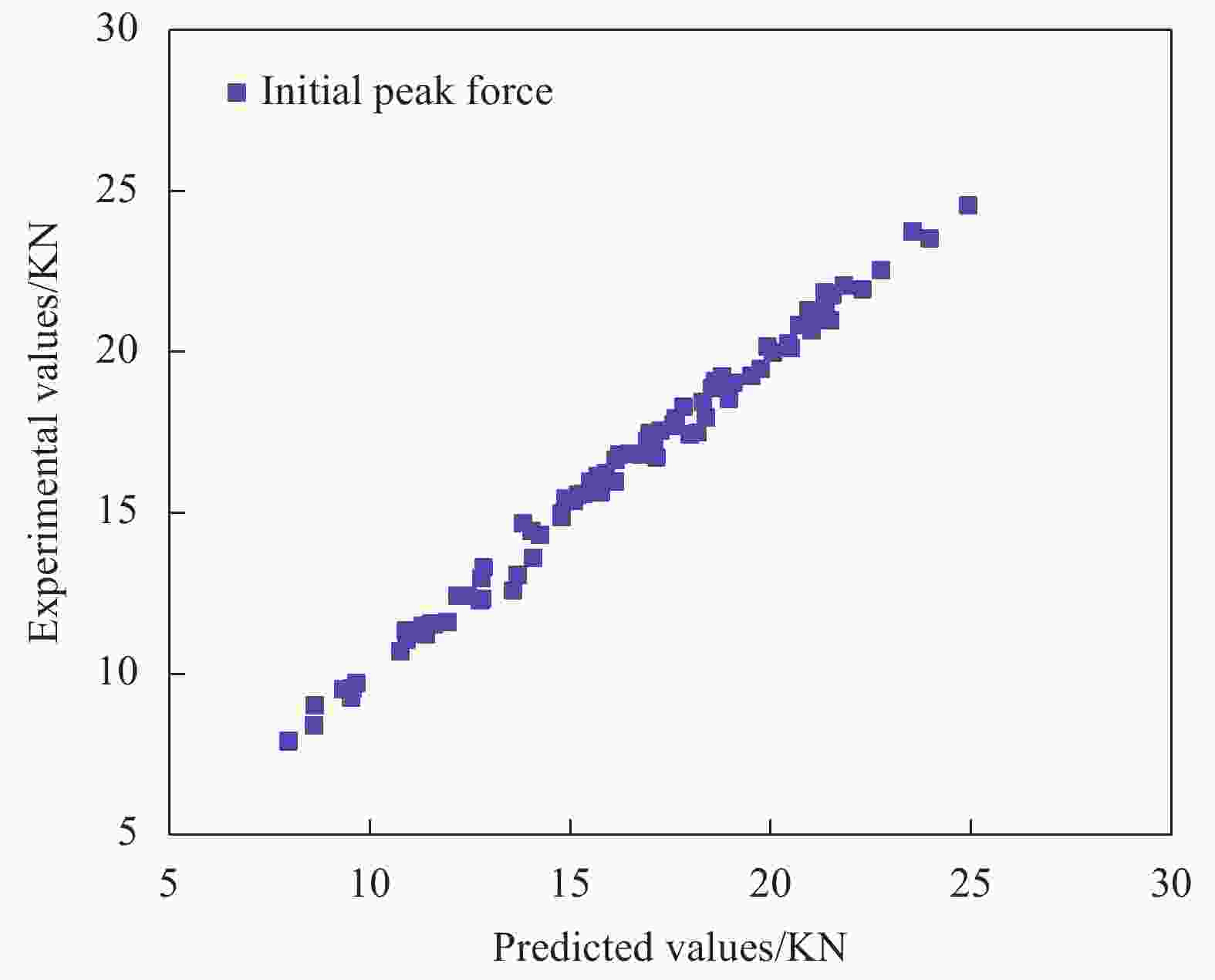

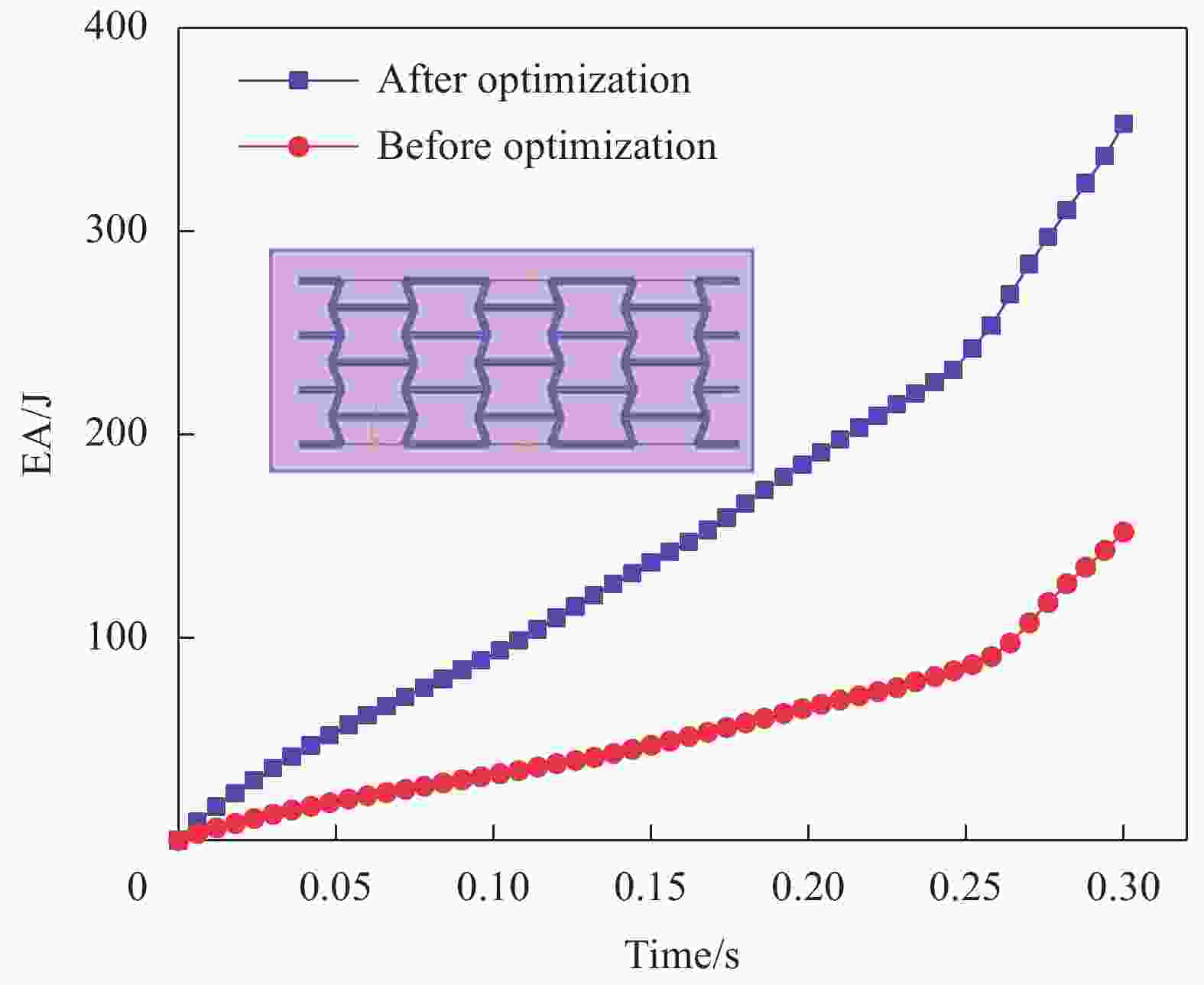

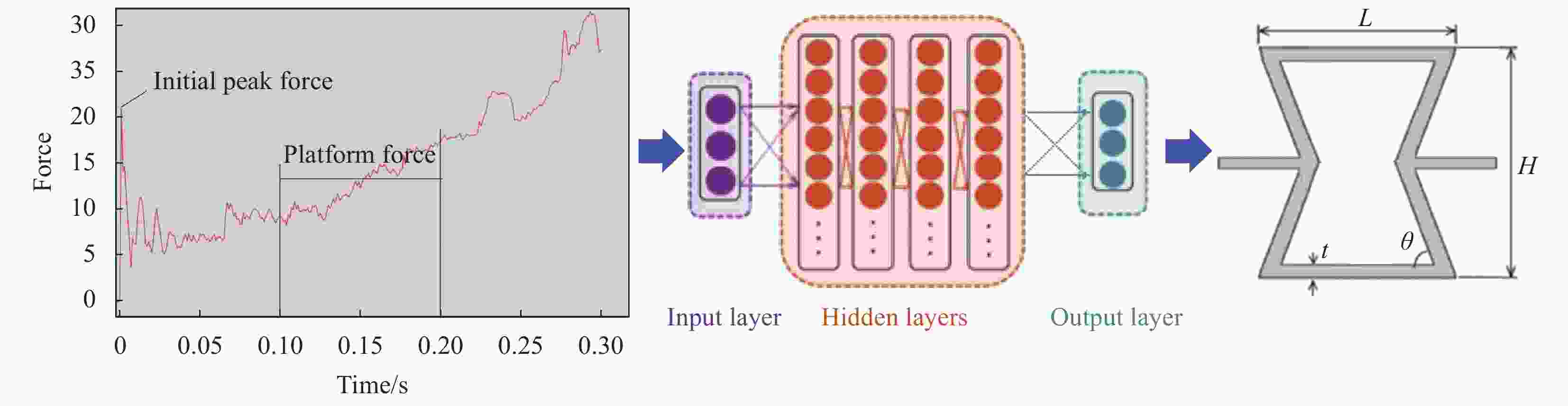

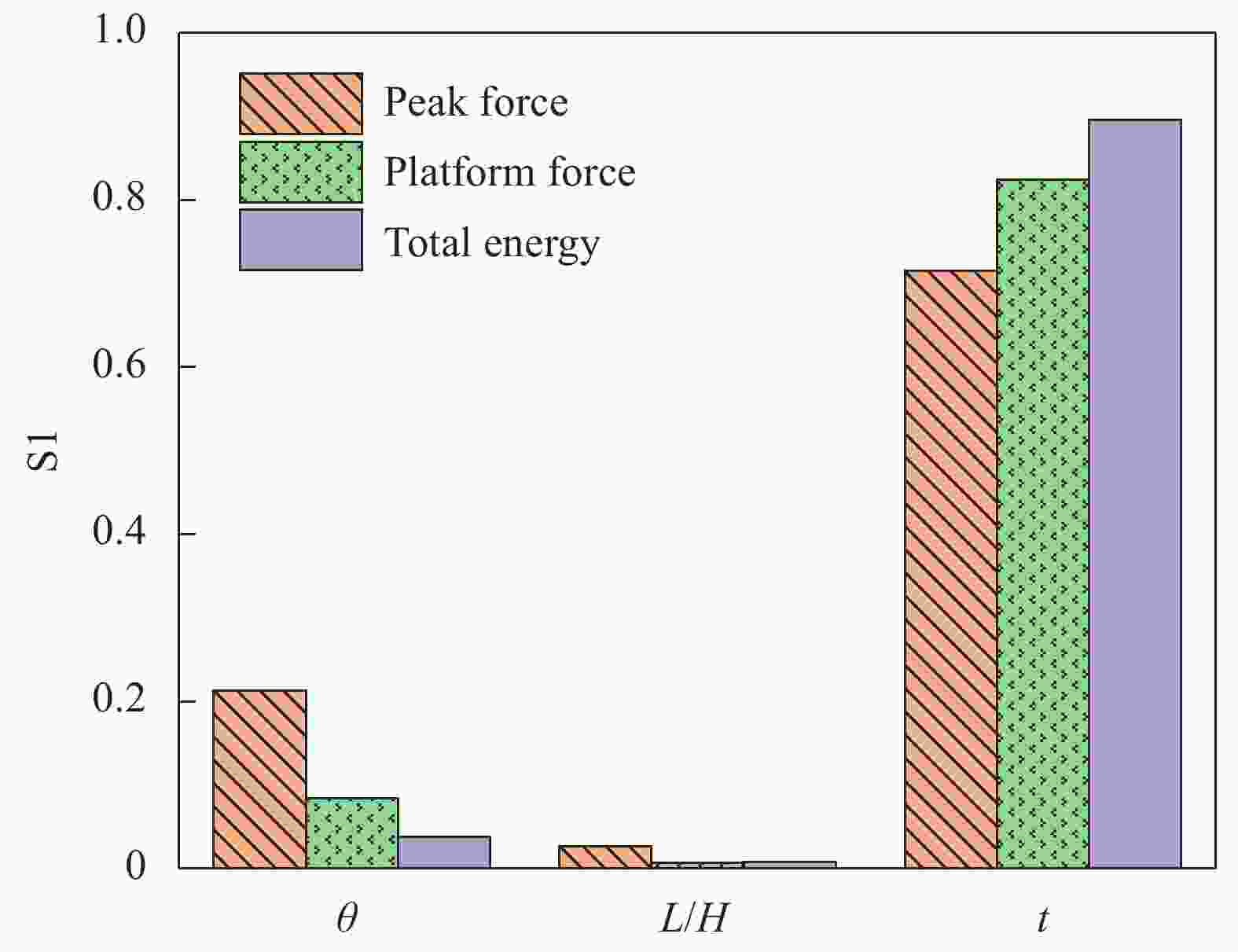

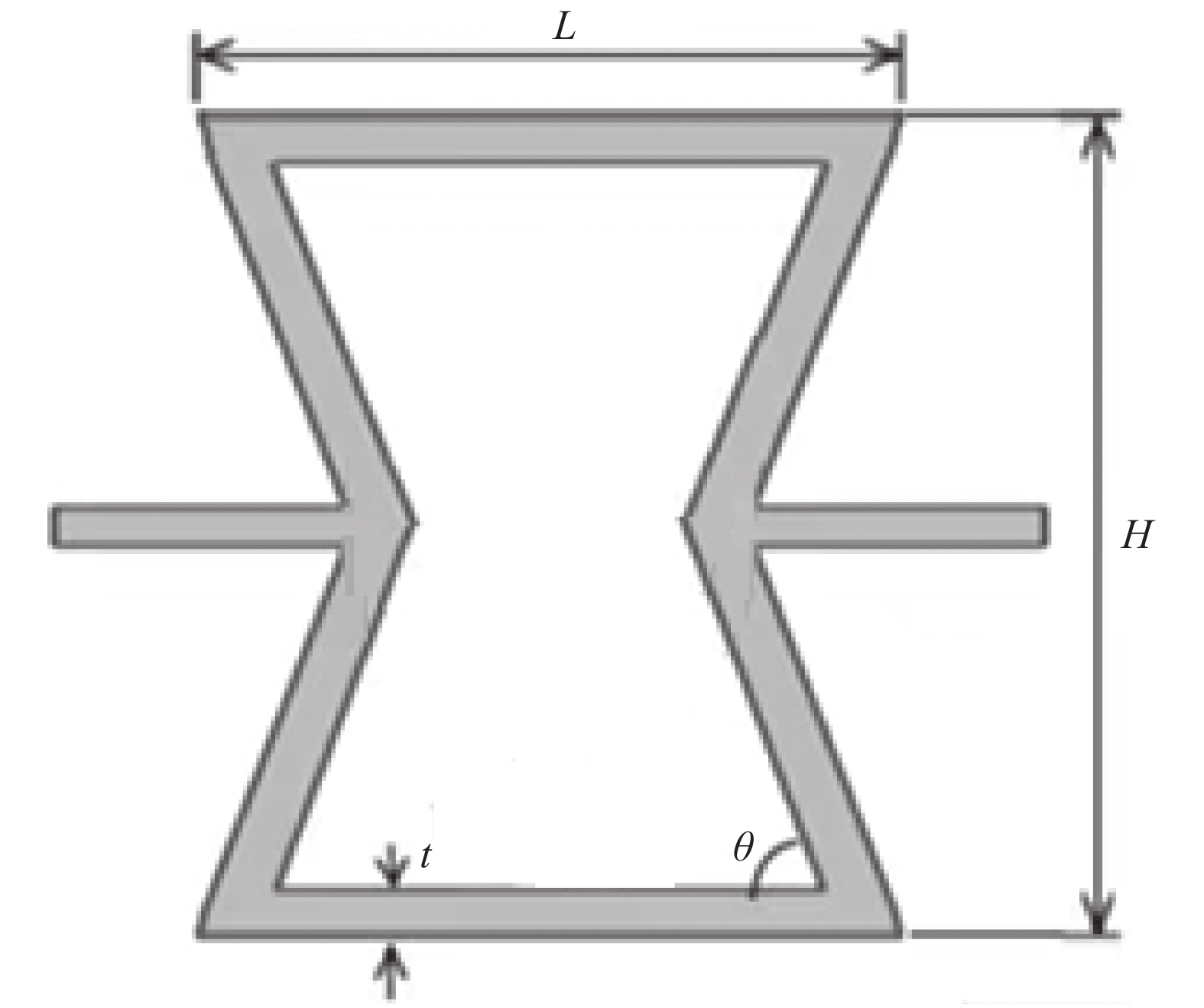

摘要: 负泊松比蜂窝结构具有优良的力学性能,本文开发并对比了两种多输入多输出的人工神经网络模型(ANN),用于预测不同几何参数下负泊松比蜂窝结构的能量吸收特性。采用蜂窝胞元的胞角$\theta $、直壁长度与胞元高度之比$ L/H $和厚度$ t $作为ANN的输入,输出是蜂窝结构的初始峰值力、平台力和蜂窝结构的总能量吸收。验证集的误差全部在8%内,且验证集和测试集的平均相关系数R2都大于98.2%,说明神经网络可以获得良好的预测效果,这表明ANN有能力学习和捕捉将蜂窝的拓扑结构及其力学性能联系起来的潜在物理机制。开发的两种神经网络中,与ANN1相比,ANN2的网络参数更多,网络结构更复杂,有更好的预测精度和训练速度。通过对给定几何参数的蜂窝结构的力学性能进行快速预测得到了吸能高的蜂窝结构。建立了反向设计网络对蜂窝结构进行反向设计,发现网络对蜂窝结构的胞角$\theta $和壁厚$t$预测效果良好,对$ L/H $的预测效果相对较差,因为$ L/H $对初始峰值力、平台力和总能量吸收影响很小。此外进行了蜂窝几何参数的敏感度分析,结果表明蜂窝结构的几何参数对初始峰值力、平台力和总能量吸收的敏感度趋势一致,蜂窝胞元厚度$t$的敏感度最高,$ L/H $对能量的敏感度最低。对于敏感度高的参数反向设计网络预测效果好,反之敏感度低的参数预测效果相对较差。总之,ANN为蜂窝结构吸能性能的研究提供了一种快速准确的方法,有望加快蜂窝结构的优化和设计进程。Abstract: It is well known that honeycombs with negative Poisson’s ratio have excellent mechanical properties. In this paper, two kinds of multi-input and multi-output artificial neural network models (ANN) were developed and compared to predict the energy absorption characteristics of honeycombs with negative Poisson's ratio under different geometric parameters. The cell angle θ, the ratio of straight wall length to cell height L/H and the thickness t of honeycomb cells are used as the inputs of ANN, and the outputs are the initial peak force, platform force and total energy absorption of honeycombs. The error in the verification set is all within 8%, and the average correlation coefficient R2 of the verification set and the test set is greater than 98.2%, which shows that the neural network can obtain good prediction effect and it has the ability to learn and capture the potential physical mechanism that relates the topology structure and mechanical properties of the honeycombs. Compared with ANN1, ANN2 has more network parameters, more complex network structure and better prediction accuracy and training speed. By quickly predicting the mechanical properties of the honeycomb with given geometric parameters, an optimized honeycomb was obtained. A reversed design network was established to reverse design the honeycomb, and it is found that the network has a good prediction effect on the cell angle θ and wall thickness t of the honeycomb, but the prediction effect of L/H is relatively weak, because the parameter L/H has little effect on the initial peak force, platform force and total energy absorption. In addition, the sensitivity analysis of input parameters was carried out. The results show that the sensitivity trend of geometric parameters of the honeycombs to initial peak force, platform force and total energy absorption is the same, the sensitivity of honeycomb cell thickness t is the highest, and the ratio of straight wall length to cell height L/H is the lowest. The reverse design network has good prediction performance for parameters with high sensitivity, while the prediction performance for parameters with low sensitivity is relatively poor. In a word, ANN provides a fast and accurate method for the study of energy absorption performance of honeycombs, which is expected to accelerate the optimization and design process of honeycomb structures.

-

表 1 蜂窝结构参数及其取值范围

Table 1. Structural parameters and their value ranges for the data set

Structural parameters Value range $\theta $/(°) 50-72 $ L/H $ $ 2\sqrt 3 /3 - \sqrt 3 $ $t$/mm 1-2 表 2 两种网络的预测效果对比

Table 2. Comparison of the prediction effects of the two networks

R2(ANN1) R2(ANN2) Initial peak force 0.99266 0.99278 Platform force 0.98225 0.99882 Total energy 0.99840 0.99854 表 3 反向设计网络的验证

Table 3. Verification of the reverse designed network

1 Initial peak force Platform force Total energy Design parameters Target value 24000 7000 350000 $\theta $ 1.20

Finite element value 24831 7278 365974

$L/H$ 1.25 Error 3.46% 3.97% 4.56% $t$ 2.05 2 Initial peak force Platform force Total energy Design parameters Target value 19000 4000 220000 $\theta $ 1.05

Finite element value 18959 3966 216625

$L/H$ 1.54 Error 0.216% 0.85 % 1.53% $t$ 1.76 3 Initial peak force Platform force Total energy Design parameters Target value 15000 2600 150000 $\theta $ 1.02

Finite element value 14415 2585 151943

$L/H$ 1.42 Error 3.9% 0.58% 1.3% $t$ 1.48 -

[1] 于靖军, 谢岩, 裴旭. 负泊松比超材料研究进展[J]. 机械工程学报, 2018, 54(13): 1-14. doi: 10.3901/JME.2018.13.001YU Jingjun, XIE Yan, PEI Xu. State-of-art metamaterials with negative Poisson’s ratio[J]. Journal of Mechanical Engineering, 2018, 54(13): 1-14(in Chinese). doi: 10.3901/JME.2018.13.001 [2] JIANG Y l, SHI K, ZHOU L N, et al. 3D-printed auxetic-structured intervertebral disc implant for potential treatment of lumbar herniated disc[J]. Bioactive Materials, 2022: 528-538. [3] ZHONG R, REN X, ZHANG X Y, et al. Mechanical properties of concrete composites with auxetic single and layered honeycomb structures[J]. Construction & Building Materials, 2022: 126453. [4] KRISHNAN B R, BISWAS A N, KUMAR K. V. A, et al. Auxetic structure metamaterial for crash safety of sports helmet[J]. Materials Today:Proceedings, 2022, 56: 1043-1049. doi: 10.1016/j.matpr.2021.09.110 [5] BOHARA R P, LINFORTH S, NGUYEN T, et al. Dual-mechanism auxetic-core protective sandwich structure under blast loading[J]. Composite Structures, 2022, 299: 116088. doi: 10.1016/j.compstruct.2022.116088 [6] 尤泽华, 肖俊华. 弧边内凹蜂窝负泊松比结构的面内冲击动力学数值研究[J]. 工程力学, 2022, 39(12): 248-256. doi: 10.6052/j.issn.1000-4750.2021.07.0572YOU Zehua, XIAO Junhua. Numerical study on in-plane impact dynamics of concave honeycomb structure with negative Poisson’s ratio[J]. Engineering Mechanics, 2022, 39(12): 248-256(in Chinese). doi: 10.6052/j.issn.1000-4750.2021.07.0572 [7] 尤泽华, 肖俊华, 王美芬. 弧边内凹蜂窝负泊松比结构的力学性能[J]. 复合材料学报, 2022, 39(7): 3570-3580.YOU Zehua, XIAO Junhua, WANG Meifen. Mechanical properties of arc concave honeycomb structure with negative Poisson’s ratio[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3570-3580(in Chinese). [8] 刘旭畅, 李爽, 杨金水. 一种新型手性负泊松比结构的减振性能[J]. 复合材料学报, 2024, 41(1): 493-500.LIU Xuchang, LI Shuang, YANG Jinshui. Damping performance of a new chiral negative Poisson's ratio structure[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 493-500(in Chinese). [9] 韩广, 郄彦辉, 班宝旺. 新型斜十字负泊松比结构弹性力学性能研究[J]. 机械强度, 2023, 45(1): 183-189. doi: 10.16579/j.issn.1001.9669.2023.01.023HAN Guang, QIE Yanhui, BAN Baowang. Study on elastic and mechanical properties of new oblique cross negative Poisson's ratio structure[J]. Journal of Mechanical Strength, 2023, 45(1): 183-189(in Chinese). doi: 10.16579/j.issn.1001.9669.2023.01.023 [10] 金泽华, 刘清洋, 马文朝, 等. 新型星形负泊松比抗冲击结构设计与入水冲击[J]. 兵工学报, 2022, 44: 1-18.JIN Zehua, LIU Qingyang, MA Wenchao, et al. Design of anti-impact structure with novel star-shaped negative poisson's ratio and research on water impact[J]. Journal of Ordnance Industry, 2022, 44: 1-18(in Chinese). [11] JIANG F, YANG S, ZHANG Y, et al. Fabrication and crushing response of graded re-entrant circular auxetic honeycomb[J]. International Journal of Mechanical Sciences, 2023, 242: 107999. doi: 10.1016/j.ijmecsci.2022.107999 [12] ZHU Y L, LUO Y, GAO D F, et al. In-plane elastic properties of a novel re-entrant auxetic honeycomb with zigzag inclined ligaments[J]. Engineering Structures, 2022: 114788. [13] LI X, LIU Z L, CUI S Q, et al. Predicting the effective mechanical property of heterogeneous materials by image based modeling and deep learning[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 347: 735-753. doi: 10.1016/j.cma.2019.01.005 [14] YU Y, HUR T, JUNG J, et al. Deep learning for determining a near-optimal topological design without any iteration[J]. Structural and Multidisciplinary Optimization, 2019, 59(3): 787-799. doi: 10.1007/s00158-018-2101-5 [15] GUO K, YANG Z, YU C H, et al. Artificial intelligence and machine learning in design of mechanical materials[J]. Materials Horizons, 2021, 8(4): 1153-1172. doi: 10.1039/D0MH01451F [16] 李想, 严子铭, 柳占立, 等. 基于仿真和数据驱动的先进结构材料设计[J]. 力学进展, 2021, 51(1): 82-105.LI Xiang, YAN Ziming, LIU Zhanli, et al. Advanced structural material design based on simulation and data-driven method[J]. Progress in Mechanics, 2021, 51(1): 82-105(in Chinese). [17] ZHU L, ZHANG C, GUO J, et al. Deep learning for electromagnetically induced transparency (EIT) metasurface optimization design[J]. Journal of Physics D:Applied Physics, 2022, 55(31): 315001. doi: 10.1088/1361-6463/ac670f [18] 钱淼, 周骥, 向忠, 等. 基于深度学习的多孔材料渗透率预测研究进展[J]. 计算机集成制造系统, 2023, https://kns.cnki.net/kcms2/detail/11.5946.TP.20230712.1005.010.html.QIAN Miao, ZHOU Ji, XIANG Zhong, et al. Research progress of porous material permeability prediction based on deep learning[J]. Computer Integrated Manufacturing Systems, 2023, https://kns.cnki.net/kcms2/detail/11.5946.TP.20230712.1005.010.html. (in Chinese). [19] GU G X, CHEN C T, Buehler M J. De novo composite design based on machine learning algorithm[J]. Extreme Mechanics Letters, 2018, 18: 19-28. doi: 10.1016/j.eml.2017.10.001 [20] WANG Y Z, ZENG Q L, WANG J Z, et al. Inverse design of shell-based mechanical metamaterial with customized loading curves based on machine learning and genetic algorithm[J]. Computer Methods in Applied Mechanics and Engineering, 2022, 401: 115571. doi: 10.1016/j.cma.2022.115571 [21] FONTES A, SHADMEHRI F. Data-driven failure prediction of fiber-reinforced polymer composite materials[J]. Engineering Applications of Artificial Intelligence, 2023, 120: 105834. doi: 10.1016/j.engappai.2023.105834 [22] ZHANG H J, WANG Y, LU K Y, et al. SAP-Net: Deep learning to predict sound absorption performance of metaporous materials[J]. Materials & Design, 2021, 212: 110156. [23] TIAN J, TANG K K, CHEN X Y, et al. Machine learning-based prediction and inverse design of 2D metamaterial structures with tunable deformation-dependent Poisson's ratio[J]. Nanoscale, 2022, 14(35): 12677-12691. doi: 10.1039/D2NR02509D [24] GAO Y, CHEN X J, WEI Y J, Graded honeycombs with high impact resistance through machine learning-based optimization[J], Thin-Walled Structures, 2023, 188: 110794. [25] WANG H, XIAO S H, ZHANG C. Novel planar auxetic metamaterial perforated with orthogonally aligned oval-shaped holes and machine learning solutions[J]. Advanced Engineering Materials, 2021, 23(7): 2100102. doi: 10.1002/adem.202100102 [26] ZHANG H J, WANG Y, ZHAO H G, et al. Accelerated topological design of metaporous materials of broadband sound absorption performance by generative adversarial networks[J]. Materials & Design, 2021, 207: 109855. [27] VYAVAHARE S V, TERAIYA S, KUMAR S. FDM manufactured auxetic structures: An investigation of mechanical properties using machine learning techniques[J]. International Journal of Solids and Structures, 2023: 112126. [28] LIAO Z Y, WANG Y J, Gao L, et al. Deep-learning-based isogeometric inverse design for tetra-chiral auxetics[J]. Composite Structures, 2022, 280: 114808. doi: 10.1016/j.compstruct.2021.114808 [29] LIU J Y, LIU H T, Energy absorption characteristics and stability of novel bionic negative Poisson’s ratio honeycomb under oblique compression[J]. Engineering Structures, 2022, 267: 114682. [30] ZHANG X, ZHANG H, WEN Z Z. Experimental and numerical studies on the crush resistance of aluminum honeycombs with various cell configurations[J]. International Journal of Impact Engineering, 2014, 66: 48-59. doi: 10.1016/j.ijimpeng.2013.12.009 [31] HAMZEHEI R, ZOLFAGHARIAN A, DARIUSHI S, et al. 3D-printed bio-inspired zero Poisson’s ratio graded metamaterials with high energy absorption performance[J]. Smart Materials and Structures, 2022, 31(3): 035001. doi: 10.1088/1361-665X/ac47d6 [32] 张晓楠, 晏石林, 欧元勋, 等. 负泊松比内凹蜂窝结构梯度设计与动态冲击响应[J]. 振动与冲击, 2023, 42(3): 193-198. doi: 10.13465/j.cnki.jvs.2023.03.023ZHANG Xiaonan, YAN Shilin, OU Yuanxun, et al. Gradient design and dynamic impact response of concave honeycomb structures with negative Poisson’s ratio[J]. Journal of Vibration and Shock, 2023, 42(3): 193-198(in Chinese). doi: 10.13465/j.cnki.jvs.2023.03.023 [33] HAGHIGHAT E, JUANES R. SciANN: A Keras/TensorFlow wrapper for scientific computations and physics-informed deep learning using artificial neural networks[J]. Computer Methods in Applied Mechanics and Engineering, 2020, 373: 113552. [34] TAN H L, HE Z C, Li E, et al. Crashworthiness design and multi-objective optimization of a novel auxetic hierarchical honeycomb crash box[J]. Structural and Multidisciplinary Optimization, 2021, 64: 2009-24. doi: 10.1007/s00158-021-02961-9 -

下载:

下载: