Preparation and properties of lignocellulose network ionic thermoelectric gels

-

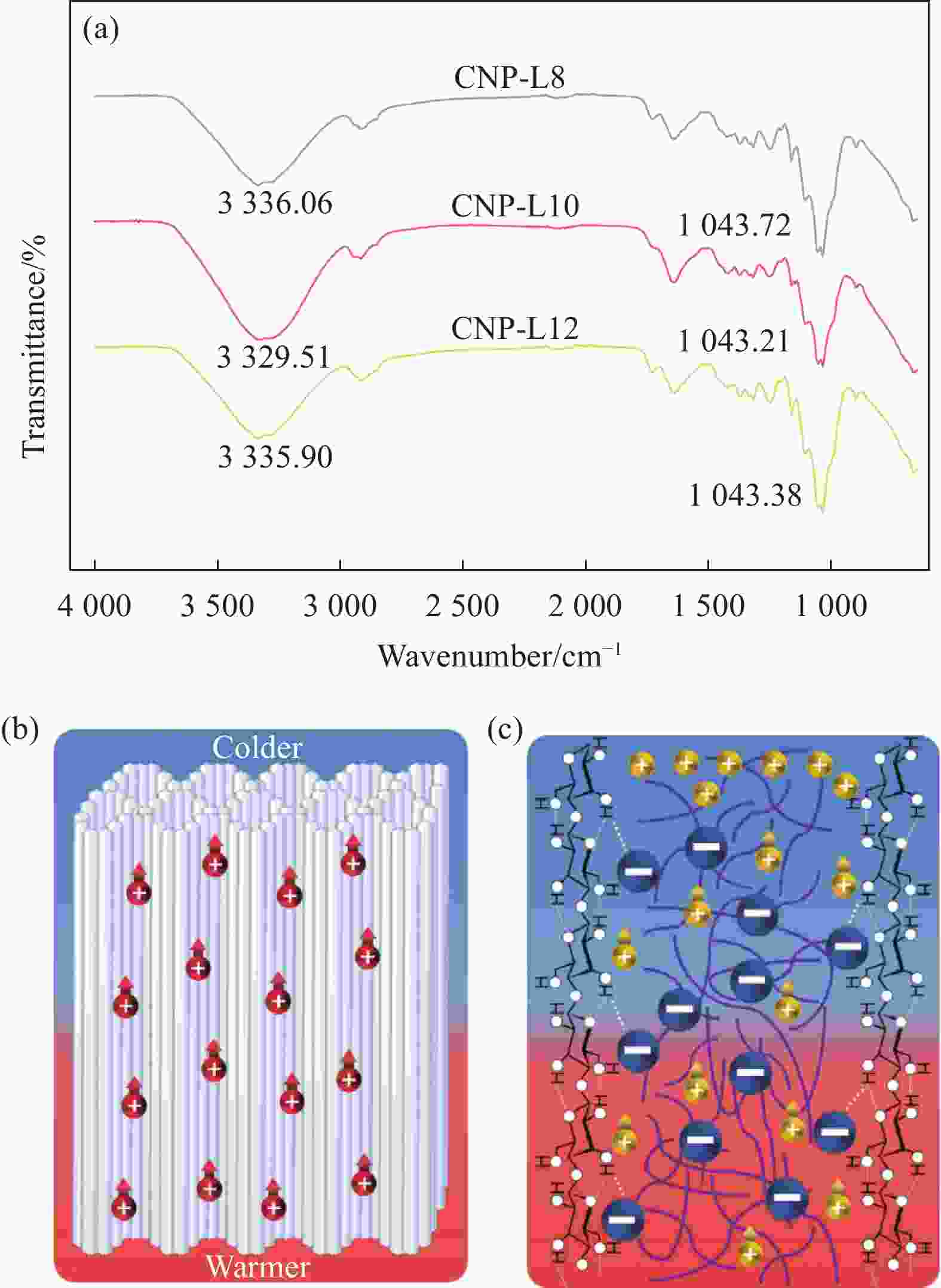

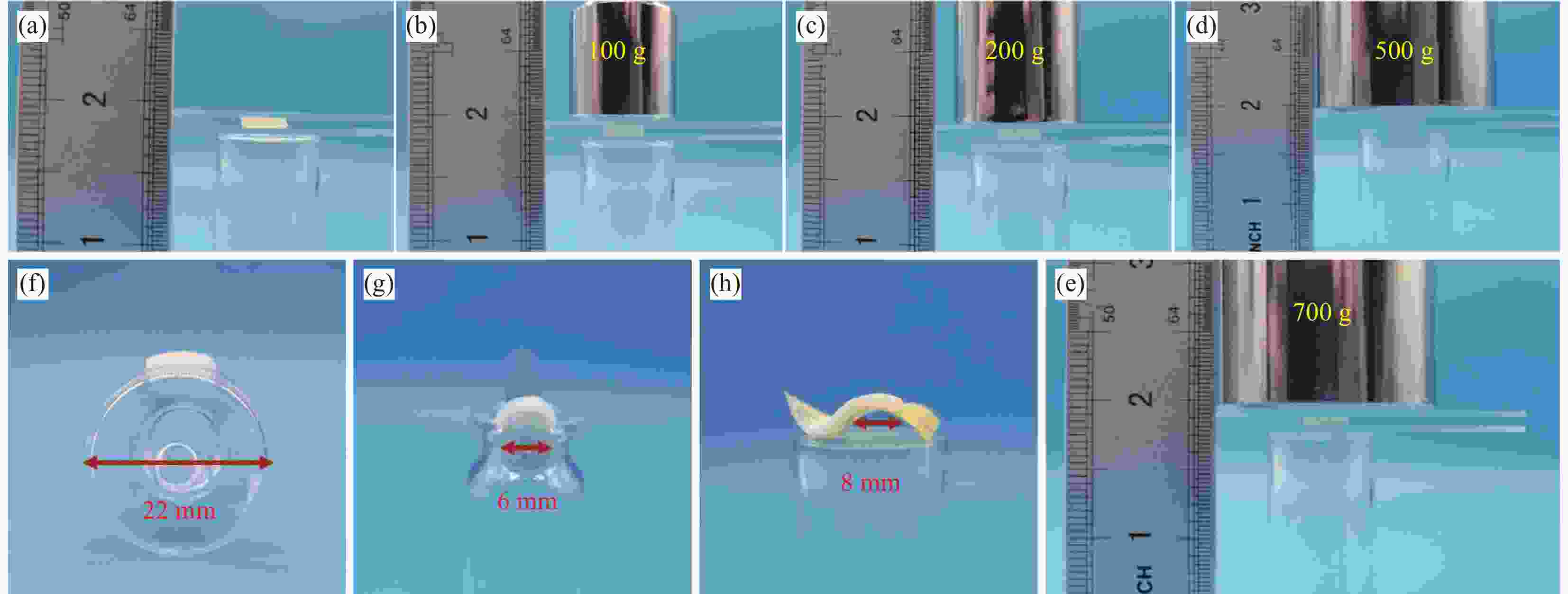

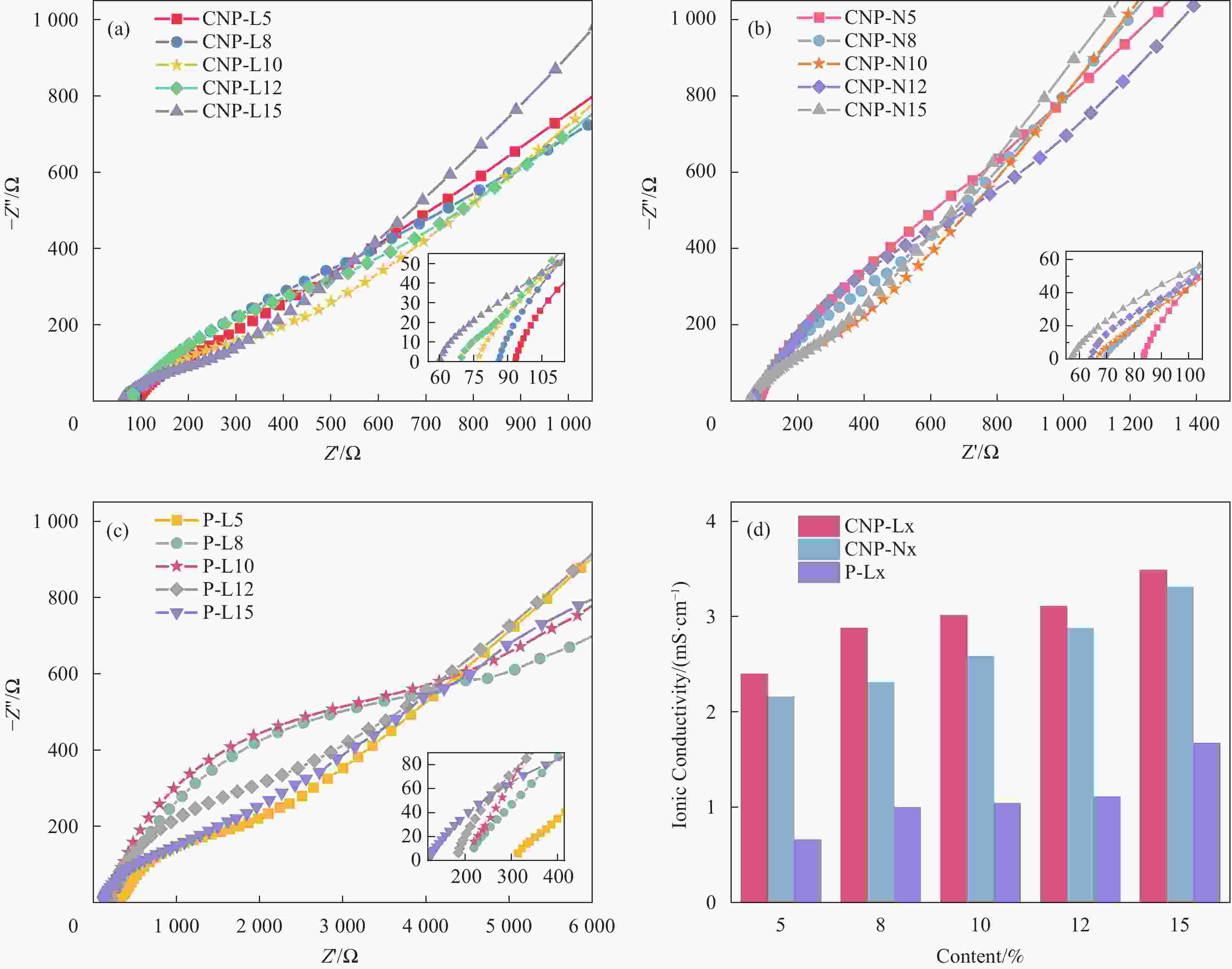

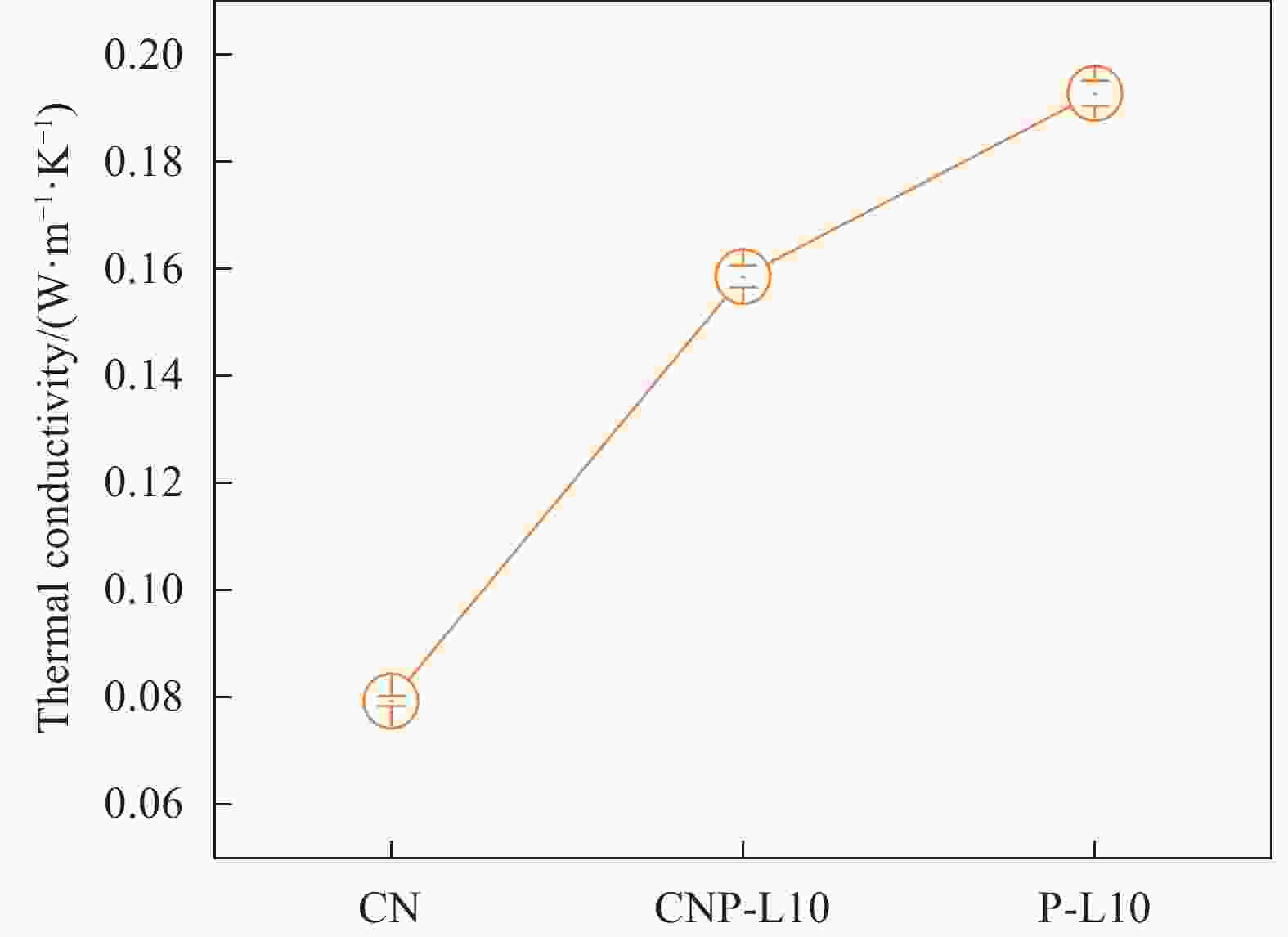

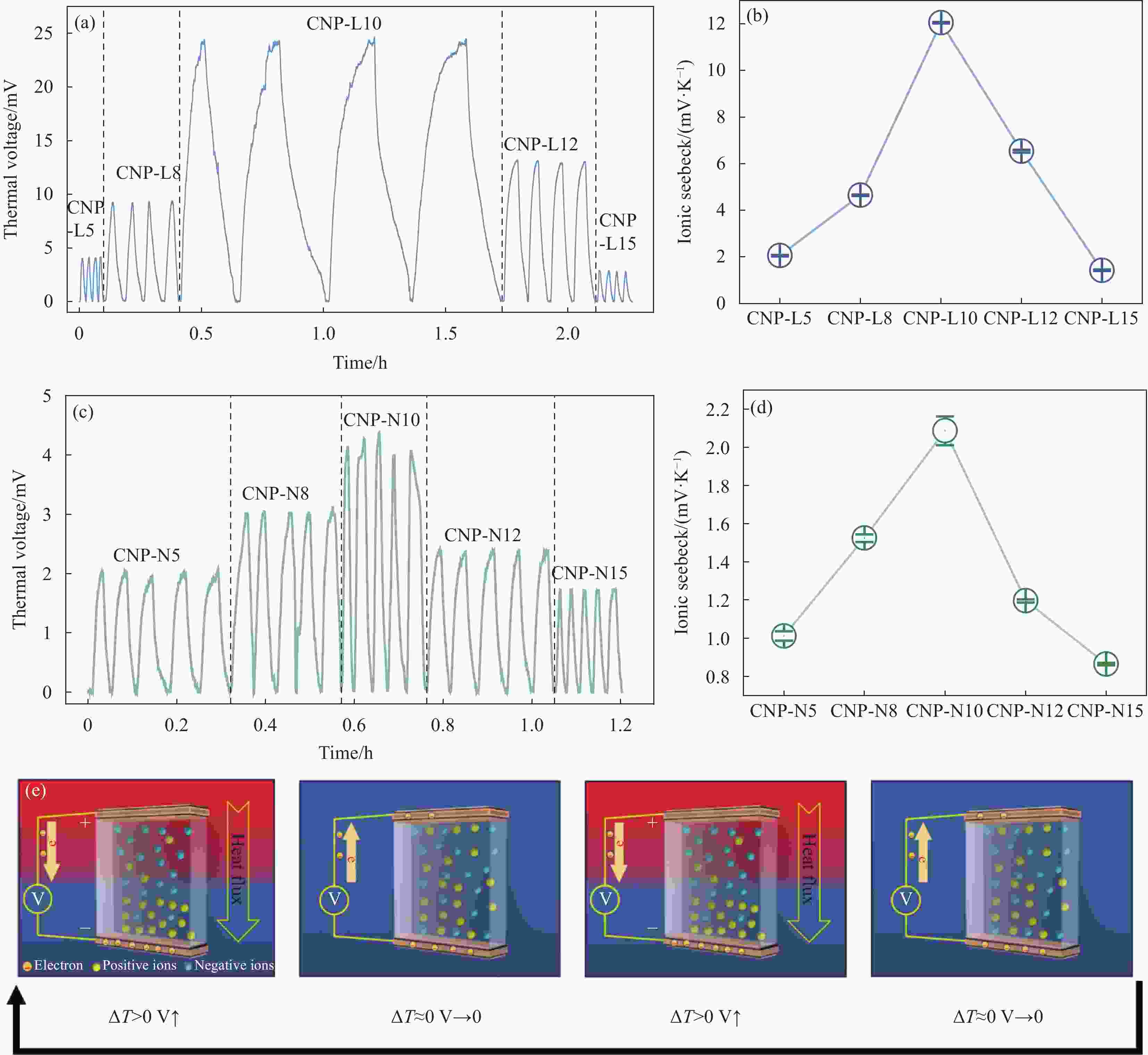

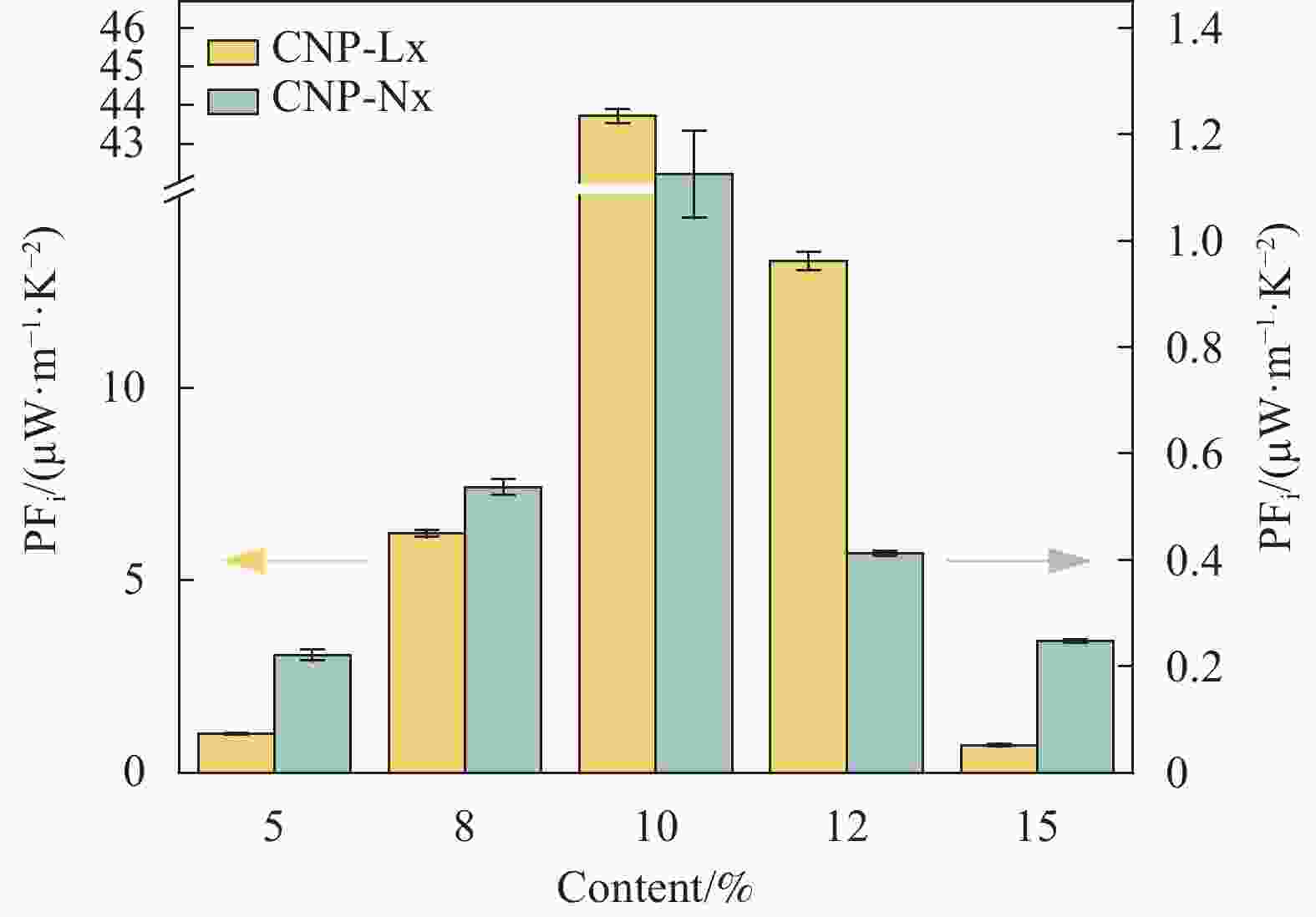

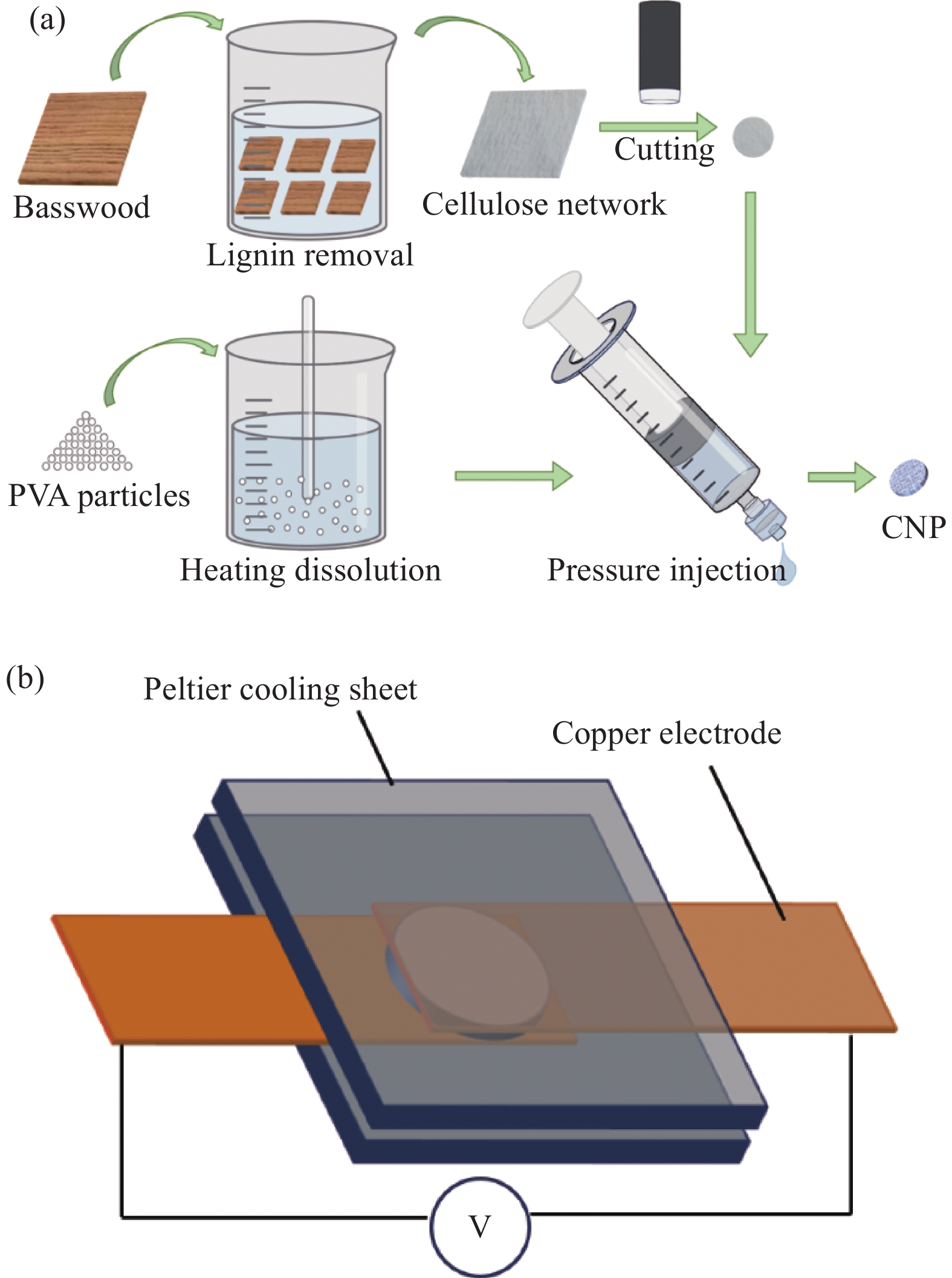

摘要: 热电材料可实现热能直接转换为电能,在生活和工业废热再利用方面得到越来越多的应用。然而,传统的无机热电材料存在热功率(或塞贝克系数)低和导热率高的问题,在低品位废热(<130 ℃)收集方面不具备优势。利用离子热扩散效应(Soret效应),以纤维素作为网络、聚乙烯醇(PVA)为电解质基质,用简单的注射器注射法制备了纤维素网络离子热电凝胶,并研究了不同含量的NaOH、LiOH作为离子供体的热电性能差异。采用FTIR对材料内部基团进行表征,同时自制的热电测试装置证明了其较高的热功率。研究结果表明木质纤维素网络的加入使离子电导率达到3.31 mS·cm−1,相比纯PVA离子凝胶提升了98.2%。同时,纤维素的加入降低了热导率,使其在人体体温和26 ℃室温的温差中保持上下面温差恒定较长时间。在2 ℃温差下离子塞贝克系数达到+12 mV·k−1。该研究提出了一种具有成本效益且环保的低品位废热再利用方案,对人类社会的可持续发展具有较大意义。Abstract: Thermoelectric materials enable the direct conversion of thermal energy into electrical energy and are increasingly used in domestic and industrial waste heat reuse. However, traditional inorganic thermoelectric materials suffer from low thermal power (or Seebeck coefficient) and high thermal conductivity, and do not offer advantages in low-grade waste heat (<130℃) collection. Using the ionic thermal diffusion effect (Soret effect), cellulose network ionic thermoelectric gels were prepared by a simple syringe injection method using cellulose as the network and poly(vinyl alcohol) (PVA) as the electrolyte matrix, and the differences in the thermoelectric properties of different contents of NaOH and LiOH as the ion donor were investigated. FTIR was used to characterize the internal groups of the material, while a homemade thermoelectric test setup proved its higher thermopower. The results showed that the incorporation of cellulose resulted in an ionic conductivity of 3.31 mS·cm−1, which was enhanced by 98.2% compared to the pure PVA ionogel. At the same time, the addition of cellulose reduced the thermal conductivity to keep the upper and lower temperature difference constant for a longer period of time under the temperature difference between human body temperature and 26℃ room temperature. The ionic Seebeck coefficient reaches +12 mV·k−1 at 2℃ temperature difference. This research proposes a cost-effective and environmentally friendly solution for the reuse of low-grade waste heat, which is of greater significance for the sustainable development of human society.

-

图 3 纤维素网络(CN)与纤维素网络离子凝胶(CNP)的微观形貌SEM图像。(a) CN的轴向表面图像; (b) CNP的径向表面图像; (c) CN的轴向局部图像; (d) CNP的轴向局部图像

Figure 3. SEM images of the micromorphology of Cellulose network (CN) and Cellulose Network ion Gel (CNP). (a) Axial surface image of CN;(b) Radial surface image of CNP; (c) Axial localized image of CN; (d) Axial localized image of CNP

图 6 不同离子在不同含量时的CNP和不同LiOH含量的PVA凝胶的奈奎斯曲线和离子电导率。(a) 不同含量LiOH 的CNP的奈奎斯曲线; (b) 不同含量NaOH 的CNP的奈奎斯曲线; (c) 不同含量LiOH 的PVA凝胶的奈奎斯曲线; (d) 不同含量LiOH、NaOH 的CNP和不同含量LiOH 的PVA凝胶的离子电导率

Figure 6. Nyquist curves and ionic conductivity of CNP with different ions at different contents and PVA gels with different LiOH contents. (a) Nyquist curves of CNP at different contents of LiOH; (b) Nyquist curves of CNP at different contents of NaOH; (c) Nyquist curves of PVA gel at different contents of LiOH; (d) ionic conductivity of CNP at different contents of LiOH, NaOH and PVA gel at different contents of LiOH

图 9 不同离子在不同含量时的热电压和离子塞贝克系数曲线。(a) 不同含量LiOH 的CNP的热电压曲线; (b) 不同含量LiOH 的CNP的离子塞贝克系数; (c) 不同含量NaOH 的CNP的热电压曲线; (d) 不同含量NaOH 的CNP的离子塞贝克系数; (e) 热电压测试原理示意图

Figure 9. Thermal voltage and ionic Seebeck coefficient curves for different ions at different contents. (a) Thermal voltage profiles of CNP with different contents of LiOH; (b) Ionic Seebeck coefficients of CNP with different contents of LiOH; (c) Thermal voltage profiles of CNP with different contents of NaOH; (d) Ionic Seebeck coefficients of CNP with different contents of NaOH; (e) Thermal voltage test principle schematic

表 1 不同碱添加量的样品名称

Table 1. Sample names with different alkali additions

Material combinations

NameContents of LiOH or NaOH solutions/% 5 8 10 12 15 CNP + LiOH (CNP-Lx) CNP-L5 CNP-L8 CNP-L10 CNP-L12 CNP-L15 CNP + NaOH (CNP-Nx) CNP-N5 CNP-N8 CNP-N10 CNP-N12 CNP-N15 PVA + LiOH (P-Lx) P-L5 P-L8 P-L10 P-L12 P-L15 -

[1] GUAN X, OUYANG J Y. Enhancement of the Seebeck Coefficient of Organic Thermoelectric Materials via Energy Filtering of Charge Carriers[J]. Ccs Chemistry, 2021, 3(10): 2415-2427. doi: 10.31635/ccschem.021.202101069 [2] YU B, DUAN J, CONG H, et al. Thermosensitive crystallization–boosted liquid thermocells for low-grade heat harvesting[J]. Science, 2020, 370: 342-346. doi: 10.1126/science.abd6749 [3] 何雅玲. 热储能技术在能源革命中的重要作用[J]. 科技导报, 2022, 40(04): 1-2.HE Yaling. The important role of thermal energy storage technology in the energy revolution[J]. Science & Technology Review, 2022, 40(04): 1-2(in Chinese). [4] ZHU T, XU Z, HE J, et al. Hot deformation induced bulk nanostructuring of unidirectionally grown p-type (Bi, Sb)2Te3 thermoelectric materials[J]. Journal of Materials Chemistry A, 2013, 1(38): 11589-11594. doi: 10.1039/c3ta12764h [5] PEREZ-TABORDA J A, CABALLERO-CALERO O, VERA-LONDONO L, et al. High Thermoelectric zT in n-Type Silver Selenide films at Room Temperature[J]. Advanced Energy Materials, 2018, 8(8): 1702024. doi: 10.1002/aenm.201702024 [6] PARK T, PARK C, KIM B, et al. Flexible PEDOT electrodes with large thermoelectric power factors to generate electricity by the touch of fingertips[J]. Energy & Environmental Science, 2013, 6(3): 788-792. [7] KIM G H, SHAO L, ZHANG K, et al. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency[J]. Nature Materials, 2013, 12(8): 719-723. doi: 10.1038/nmat3635 [8] DUAN J, FENG G, YU B, et al. Aqueous thermogalvanic cells with a high Seebeck coefficient for low-grade heat harvest[J]. Nature Communications, 2018, 9(1): 5146. doi: 10.1038/s41467-018-07625-9 [9] 肖颖, 梁耕源, 雷博文, 等. 用于能量收集的离子热电材料研究进展[J]. 材料导报, 2023, 37(4): 1-9.XIAO Ying, LIANG Gengyuan, LEI Bowen, et al. Research Progress of Ionic Thermoelectric Materials for Energy Harvesting[J]. Science & Technology Review, 2023, 37(4): 1-9(in Chinese). [10] WU X, GAO N, JIA H, et al. Thermoelectric Converters Based on Ionic Conductors[J]. Chemistry–An Asian Journal, 2021, 16(2): 129-141. doi: 10.1002/asia.202001331 [11] PAI Y-H, TANG J, ZHAO Y, et al. Ionic Organic Thermoelectrics with Impressively High Thermopower for Sensitive Heat Harvesting Scenarios[J]. Advanced Energy Materials, 2023, 13(1): 2202507. doi: 10.1002/aenm.202202507 [12] BAHK J-H, FANG H, YAZAWA K, et al. Flexible thermoelectric materials and device optimization for wearable energy harvesting[J]. Journal of Materials Chemistry C, 2015, 3(40): 10362-10374. doi: 10.1039/C5TC01644D [13] GUAN X, CHENG H, OUYANG J. Significant enhancement in the Seebeck coefficient and power factor of thermoelectric polymers by the Soret effect of polyelectrolytes[J]. Journal of Materials Chemistry A, 2018, 6(40): 19347-19352. doi: 10.1039/C8TA08387H [14] ZHAO D, SULTANA A, EDBERG J, et al. The role of absorbed water in ionic liquid cellulosic electrolytes for ionic thermoelectrics[J]. Journal of Materials Chemistry C, 2022, 10(7): 2732-2741. doi: 10.1039/D1TC04466D [15] CHEN B, CHEN Q, XIAO S, et al. Giant negative thermopower of ionic hydrogel by synergistic coordination and hydration interactions[J]. Science Advances, 2021, 7(48): eabi7233. doi: 10.1126/sciadv.abi7233 [16] CHEN Q, CHEN B, XIAO S, et al. Giant Thermopower of Hydrogen Ion Enhanced by a Strong Hydrogen Bond System[J]. ACS Applied Materials & Interfaces, 2022, 14(17): 19304-19314. [17] CHI C, LIU G, AN M, et al. Reversible bipolar thermopower of ionic thermoelectric polymer composite for cyclic energy generation[J]. Nature Communications, 2023, 14(1): 306. doi: 10.1038/s41467-023-36018-w [18] LI T, ZHANG X, LACEY S D, et al. Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting[J]. Nature Materials, 2019, 18(6): 608-613. doi: 10.1038/s41563-019-0315-6 [19] JIN L, GREENE G W, MACFARLANE D R, et al. Redox-Active Quasi-Solid-State Electrolytes for Thermal Energy Harvesting[J]. ACS Energy Letters, 2016, 1(4): 654-658. doi: 10.1021/acsenergylett.6b00305 [20] ZHAO D, WANG H, KHAN Z U, et al. Ionic thermoelectric supercapacitors[J]. Energy & Environmental Science, 2016, 9(4): 1450-1457. [21] KIM B, HWANG J U, KIM E. Chloride transport in conductive polymer films for an n-type thermoelectric platform[J]. Energy & Environmental Science, 2020, 13(3): 859-867. [22] QIN B, WANG D, LIU X, et al. Power generation and thermoelectric cooling enabled by momentum and energy multiband alignments[J]. Science, 2021, 373(6554): 556-561. doi: 10.1126/science.abi8668 [23] JIANG B, YU Y, CUI J, et al. High-entropy-stabilized chalcogenides with high thermoelectric performance[J]. Science, 2021, 371(6531): 830-834. doi: 10.1126/science.abe1292 [24] LI H, ERBAŞ A, ZWANIKKEN J, et al. Ionic Conductivity in Polyelectrolyte Hydrogels[J]. Macromolecules, 2016, 49(23): 9239-9246. doi: 10.1021/acs.macromol.6b01276 [25] WANG H, ZHAO D, KHAN Z U, et al. Ionic Thermoelectric Figure of Merit for Charging of Supercapacitors[J]. Advanced Electronic Materials, 2017, 3(4): 1700013. doi: 10.1002/aelm.201700013 [26] CHEN Z, HU Y, SHI G, et al. Advanced Flexible Materials from Nanocellulose[J]. Advanced Functional Materials, 2023, 33(18): 2214245. doi: 10.1002/adfm.202214245 [27] SHU Y, ODUNMBAKU G O, HE Y, et al. Cation effect of inorganic salts on ionic Seebeck coefficient[J]. Applied Physics Letters, 2021, 118(10): 103902. doi: 10.1063/5.0043498 [28] AKBAR Z A, JEON J-W, JANG S-Y. Intrinsically self-healable, stretchable thermoelectric materials with a large ionic Seebeck effect[J]. Energy & Environmental Science, 2020, 13(9): 2915-2923. [29] YANG X, TIAN Y, WU B, et al. High-Performance Ionic Thermoelectric Supercapacitor for Integrated Energy Conversion-Storage[J]. Energy & Environmental Materials, 2022, 5(3): 954-961. -

下载:

下载: