Anionic polymerization reaction injection molding process of carbon fiber reinforced nylon 6 composite

-

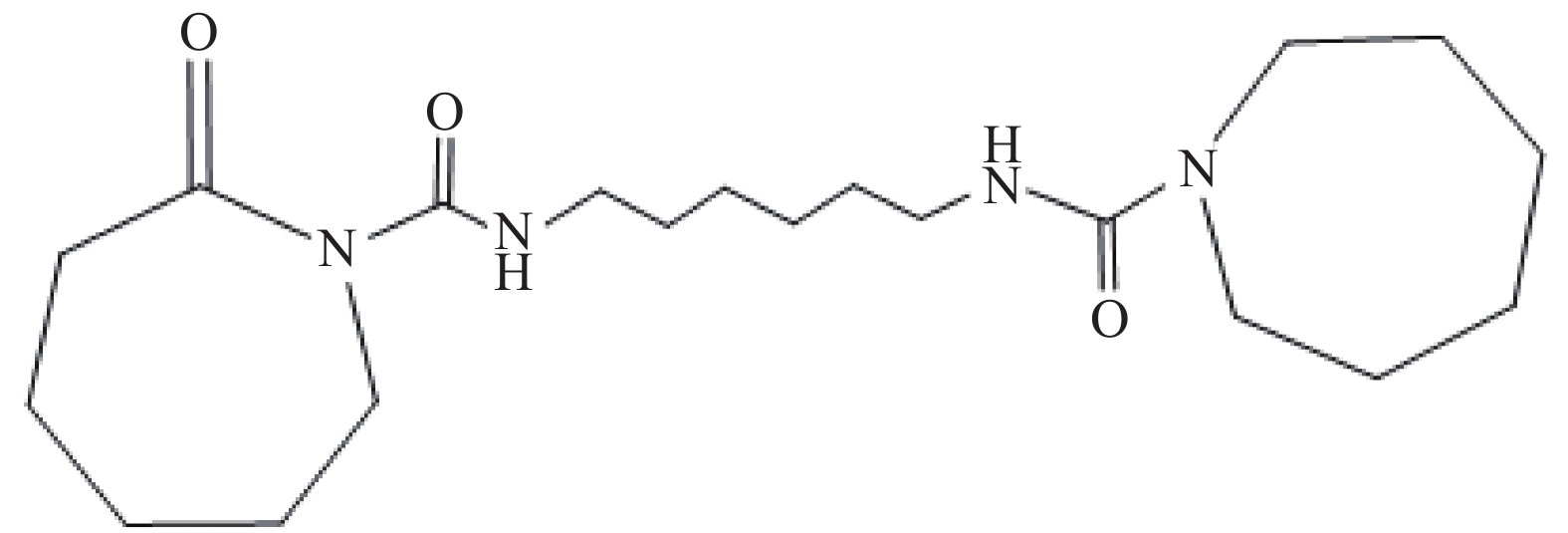

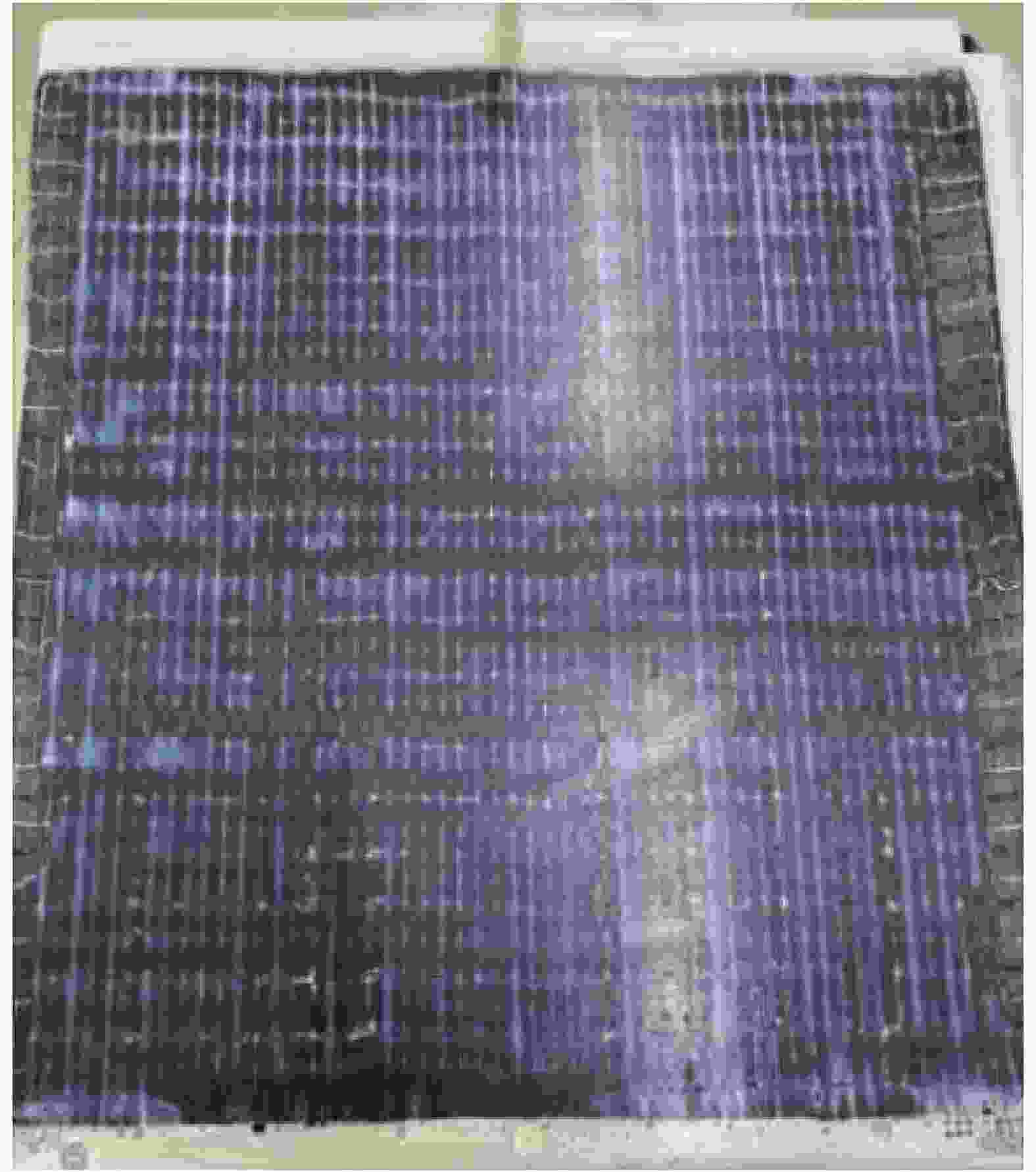

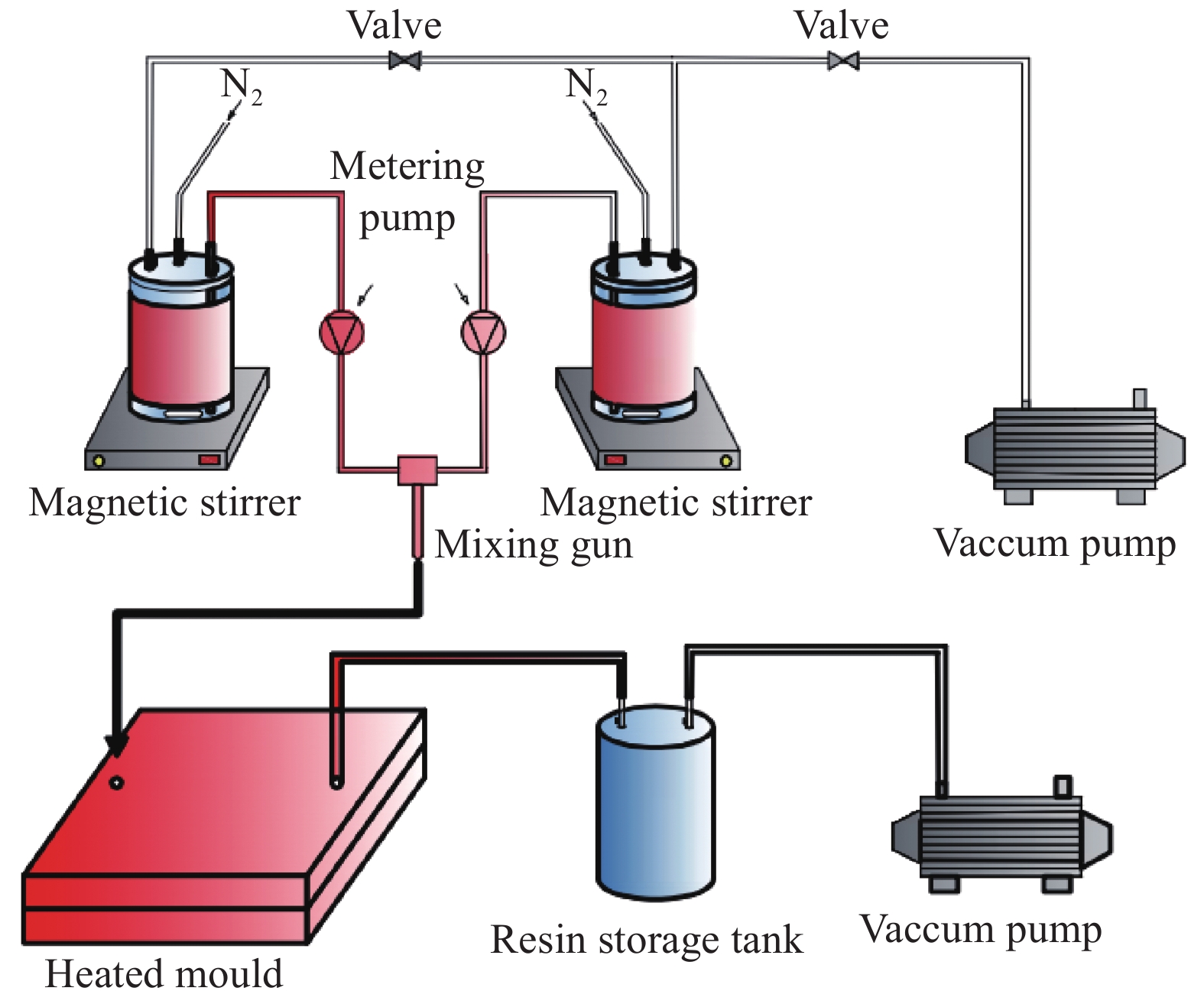

摘要: 以己内酰胺为原料,自制己内酰胺钠(C10)、双酰化内酰胺-1,6-己二胺(C20)分别为引发剂和活化剂,首先对适用于反应注射成型技术(RIM)的尼龙6(PA6)阴离子聚合工艺进行探究。实验结果表明,提高引发剂浓度可提升聚合反应速率,转化率受影响并不明显,但分子量有所降低;而提高活化剂浓度,会导致聚合反应不完全;随着聚合温度的升高,反应速率明显加快,同时分子量增大,结晶度呈下降趋势。最终选取1.5 mol%的C10、1 mol%的C20,浸胶温度100℃、聚合温度180℃的工艺参数,利用自行研制的反应注射设备成功制备了单向碳纤维增强尼龙6 (CF/PA6)复合材料单向板,其沿纤维方向的拉伸强度可达974.2 MPa,弯曲强度达786.9 MPa。Abstract: Caprolactam was used as raw material, sodium caprolactam (C10) and diacyllactam-1,6-hexanediamine (C20) as initiators and activators respectively. The anionic polymerization process of nylon 6 (PA6) suitable for reaction injection molding (RIM) technology was explored. The results show that polymerization rate can be improved by increasing the concentration of C10, but the limiting viscosity number is the opposite. However, increasing the concentration of C20 alone results in incomplete polymerization and low conversion. With the increase of polymerization temperature, the degree of polymerization can be increased. Finally, the unidirectional carbon fiber (CF)/PA6 composites with good properties were prepared by selecting the technological parameters of C10 1.5 mol%, C20 1 mol%, dipping temperature of 100℃ and polymerization temperature of 180℃. The tensile strength along the fiber direction can reach 974.2 MPa, and the bending strength can reach 786.9 MPa.

-

Key words:

- nylon 6 /

- anionic polymerization /

- polymerization process /

- reaction injection molding /

- composite

-

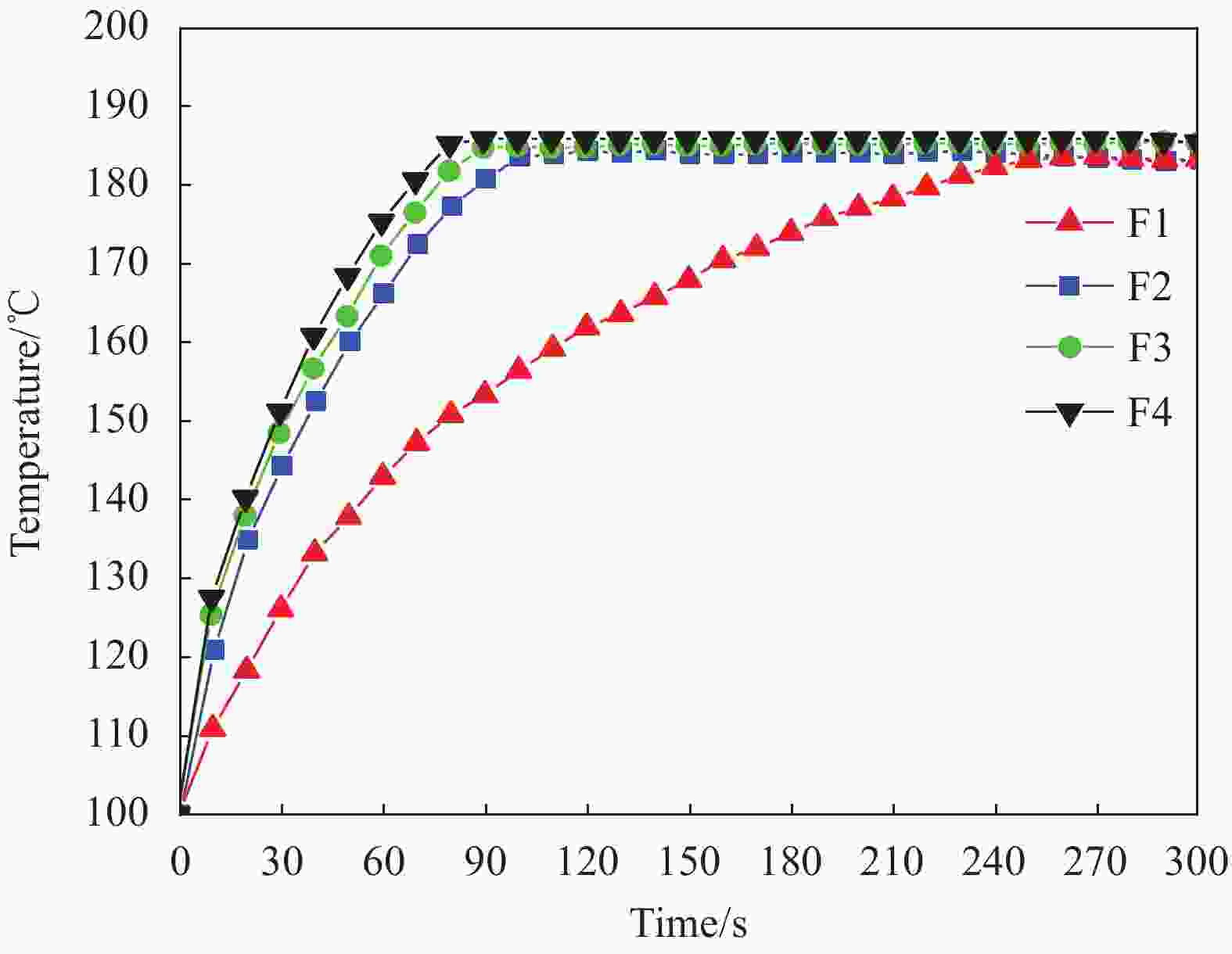

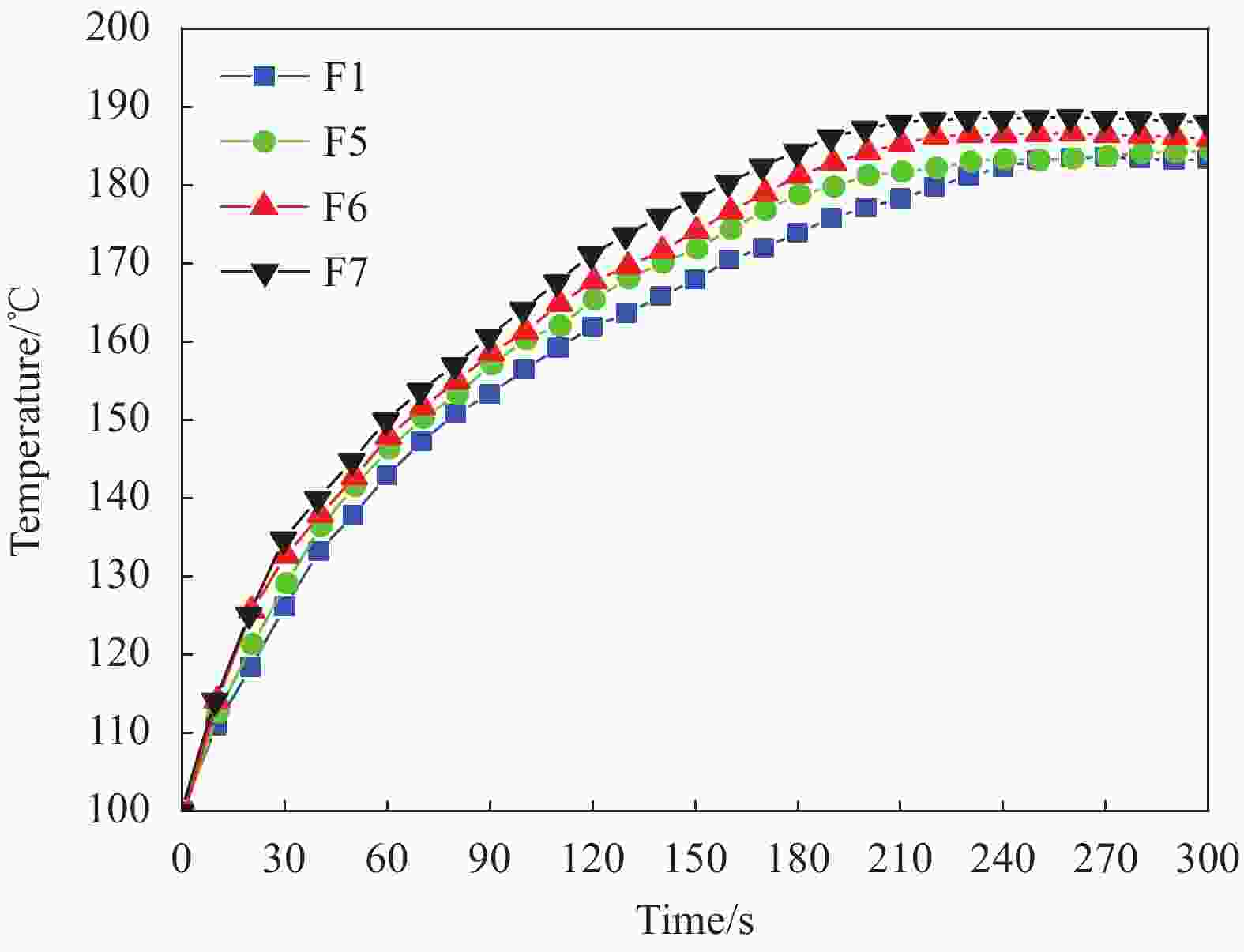

表 1 聚合实验配方

Table 1. Experimental formula of polymerization

Formulation C10/mol% C20/mol% F1 1 1 F2 1.5 1 F3 2 1 F4 2.5 1 F5 1 1.5 F6 1 2 F7 1 2.5 Notes: C10—Sodium caprolactam; C20—Diacyllactam-1, 6-hexamediamine. 表 2 不同聚合温度下聚合产物PA6结晶数据

Table 2. Crystallization data of polymerization products PA6 at different polymerization temperatures

Polymerization temperature/℃ Crystallization onset temperature/℃ Crystallization termination temperature/℃ Peak temperature/℃ Crystallization enthalpy/(J·g-1) Crystallinity/ % 160 179.4 164.7 171.6 61.69 26.82 170 173.6 160.2 167.9 45.59 19.82 180 180.9 165.2 172.8 48.92 21.27 190 180.9 163.8 172.5 48.69 21.17 表 3 CF/PA6复合材料物理性质与力学性能

Table 3. Physical properties and mechanical properties of CF/PA6 composites

Characterization of CF/PA6 Value Conversion rate/% 96.43 Liminting viscosity number/(mg·L-1) 83.24 Crystallinity/% 24.82 0° tensile strength/MPa 974.2 90° tensile strength/MPa 20.46 0° flexural strength/MPa 786.9 90° flexural strength/MPa 38.55 -

[1] 王玉洁, 黄明福, 陈晋南. 注射成型技术研究进展[J]. 广东化工, 2007, 34(2):31-33.WANG Yujie, HUANG Mingfu, CHEN Jinnan. Research progress of injection molding technology[J]. Guangdong Chemical Industry,2007,34(2):31-33(in Chinese). [2] 张玉龙. 高技术复合材料制备手册[M]. 北京: 国防工业出版社, 2003: 374-386.ZHANG Yulong. Handbook for the preparation of high-tech composites[M]. Beijing: National Defense Industry Press, 2003: 374-386(in Chinese). [3] 王有槐. 聚酰胺工程塑料的发展[J]. 工程塑料应用, 1993(2):52-56, 11.WANG Youhuai. Development of polyamide engineering plastics[J]. Application of Engineering Plastics,1993(2):52-56, 11(in Chinese). [4] 代芳, 吕召胜, 王金立, 等. 2015年我国热塑性工程塑料研究进展[J]. 工程塑料应用, 2016, 44(3):125-134.DAI Fang, LV Zhaosheng, WANG Jinli, et al. Research progress of thermoplastic engineering plastics in China in 2015[J]. Application of Engineering Plastics,2016,44(3):125-134(in Chinese). [5] RJJSWIJK K V, BERSEE H E N. Reactive processing of textile fiber-reinforced thermoplastic composites-An overview[J]. Composites Part A: Applied Science & Manufacturing,2007,38(3):666-681. [6] RIJSWIJK K V, BERSEE H E N, JAGER W F, et al. Optimisation of anionic polyamide-6 for vacuum infusion of thermoplastic composites: Influence of polymerisation temperature on matrix properties[J]. Polymer Testing,2006,37(6):949-956. [7] CHEN K, JIA M, HUA S, et al. Optimization of initiator and activator for reactive thermoplastic pultrusion[J]. Journal of Polymer Research,2019,26(2):40. [8] 阚泽, 刘正英, 张凯, 等. 真空导入成型阴离子聚合尼龙6聚合体系及性能[J]. 高等学校化学学报, 2012, 33(8):1866-1871.KAN Ze, LIU Zhengying, ZHANG Kai, et al. Polymerization system and properties of anionic polyamide 6 polymerized in vacuum[J]. Acta Chemistry Sinica,2012,33(8):1866-1871(in Chinese). [9] LEE J, LIM J W, KIM M. Effect of thermoplastic resin transfer molding process and flame surface treatment on mechanical properties of carbon fiber reinforced polyamide 6 composite[J]. Polymer Composites,2020,41:25445. [10] 杨凡, 高远博, FREDRICK N M, 等. 原位聚合制备碳纤维增强MC尼龙6复合材料及其性能表征[J]. 材料开发与应用, 2018, 33(5):90-95.YANG F, GAO Y B, FREDRICK N M, et al. Preparation and characterization of carbon fiber reinforced MC nylon 6 Composites by in situ polymerization[J]. Materials Development and Application,2018,33(5):90-95(in Chinese). [11] 孙华, 薛平, 陈轲, 等. RTM成型玻璃纤维增强阴离子聚合尼龙6复合材料及其性能研究[J]. 复合材料学报, 2021, 38(2):414-423.SUN Hua, XUE Ping, CHEN Ke, et al. Study on preparation and properties of glass fiber-reinforced anionic nylon 6 composites by RTM process[J]. Acta Materiae Compositae Sinica,2021,38(2):414-423(in Chinese). [12] ZALDUA, MAIZ, CALLE D L, et al. Nucleation and crystallization of PA6 composites prepared by T-RTM: Effects of carbon and glass fiber loading[J]. Polymers,2019,11(10):1680. doi: 10.3390/polym11101680 [13] CHEN K, JIA M Y, SUN H, et al. Thermoplastic reaction injection pultrusion for continuous glass fiber-reinforced polyamide-6 composites[J]. Materials,2019,12(3):463. doi: 10.3390/ma12030463 [14] 张嘉阳, 刘刚, 李龙, 等. 国产CCF300碳纤维单向织物液体成型工艺性及其复合材料力学性能[J]. 复合材料学报, 2016, 33(1):17-26.ZHANG Jiayang, LIU Gang, LI Long, et al. Liquid forming process and mechanical properties of domestic CCF300 carbon fiber unidirectional fabric[J]. Acta Composite Materials Sinica,2016,33(1):17-26(in Chinese). [15] 尹兆旭. 碳纤维单向布加固混凝土技术在旧桥改建中的应用[J]. 公路, 2001(12):45-47.YIN Zhaoxu. Application of CFRP unidirectional reinforcement concrete technology in old bridge reconstruction[J]. Highway,2001(12):45-47(in Chinese). [16] 蔡正杰. 超大风力发电叶片用碳纤维单向织物[P]. 中国, CN202786636 U, 2013-03-13.CAI Zhengjie. Unidirectional carbon fiber fabric for super large wind turbine blades[P]. China, CN202786636 U, 2013-03-13(in Chinese) [17] 中国国家标准化管理委员会. "塑料 聚酰胺 第1部分: 黏数测定." GB/T 12006.1—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. "Plastics polyamides Part 1: Determination of viscosity number." GB/T 12006.1—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [18] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M[S]. West Conshohocken: American Society for Testing and Materials International, 2013. [19] ASTM. Standard test method for flexural properties of polymer matrix composite materials: ASTM D7264/D7264M[S]. West Conshohocken: American Society for Testing and Materials International, 2015. [20] ZHILKOVA K, MATEVA R, KYULAVSKA M. Copolymers of ε-caprolactam and polypropylene oxide via anionic polymerization: Synthesis and properties[J]. Journal of Polymer Research,2017,24(10):162-172. doi: 10.1007/s10965-017-1324-2 [21] BOLGOV S A, BEGISHEV V P, MALKIN A Y, et al. Role of the functionality of activators during isothermal crystallization accompanying the activated anionic polymerization of ϵ-caprolactam[J]. Polymer Science U.s.s.r,1981,23(6):1485-1492. doi: 10.1016/0032-3950(81)90118-0 [22] 陈轲. 玻纤增强尼龙复合材料反应注射拉挤成型的研究[D]. 北京: 北京化工大学, 2019.CHEN Ke. Study on reaction injection pultrusion of glass fiber reinforced polyamide-6 composites[D]. Beijing: Beijing University of Chemical Technology, 2019(in Chinese). -

下载:

下载: