Flexible capacitive pressure sensor with a wide detection range based on porous carbon nanotube、carboxyl iron powder/silicone composite

-

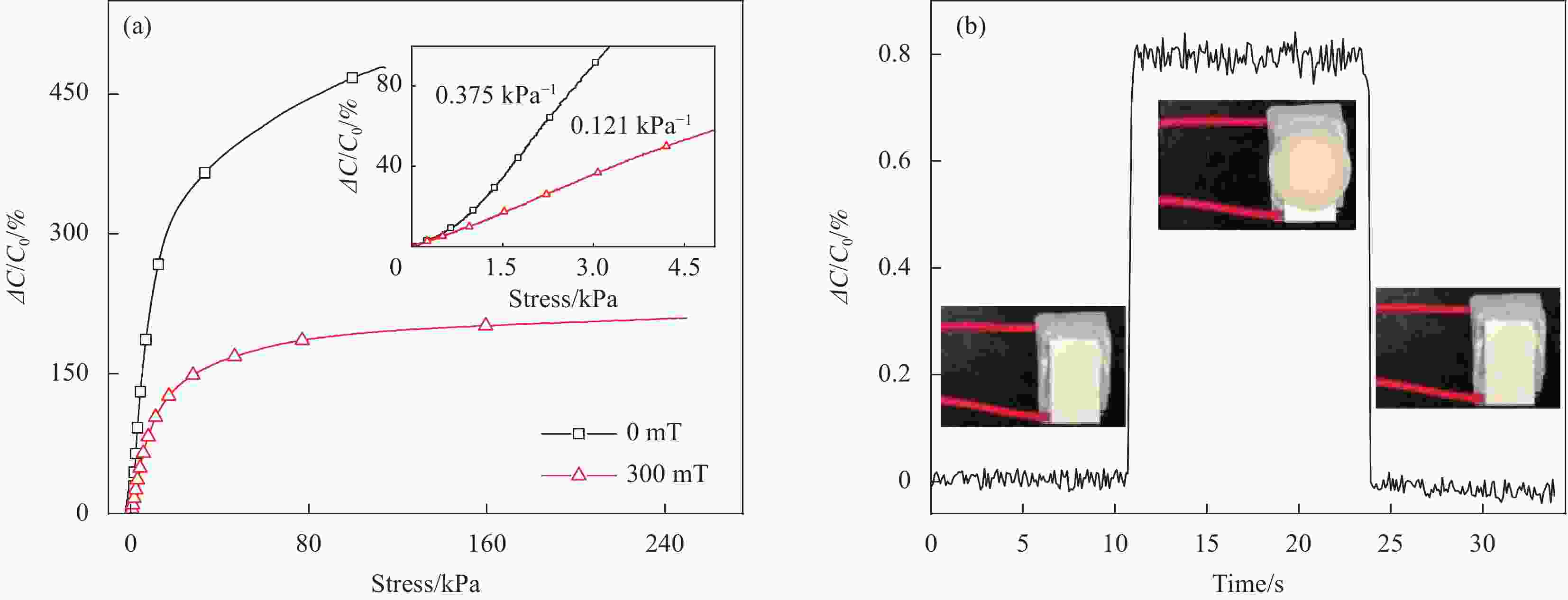

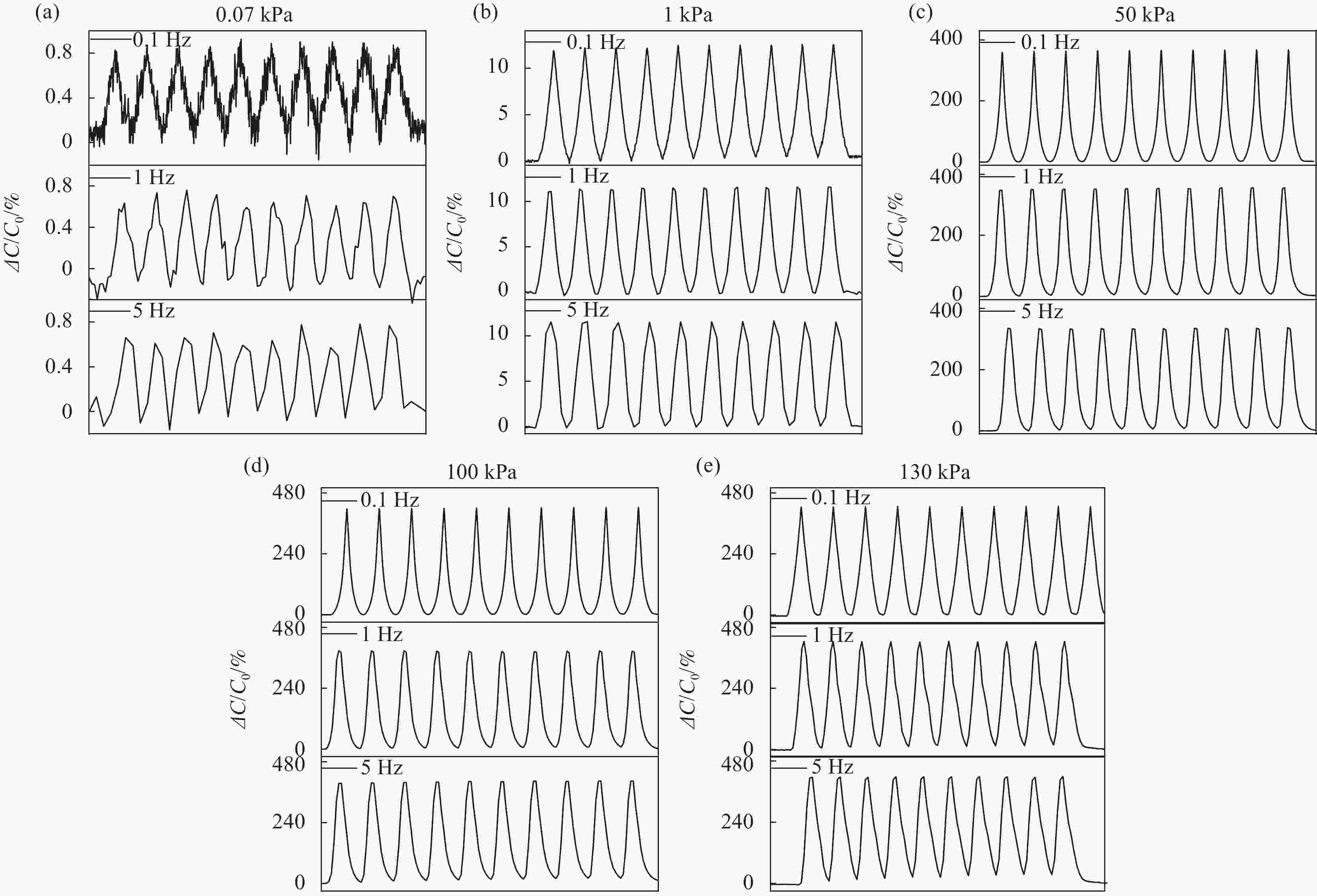

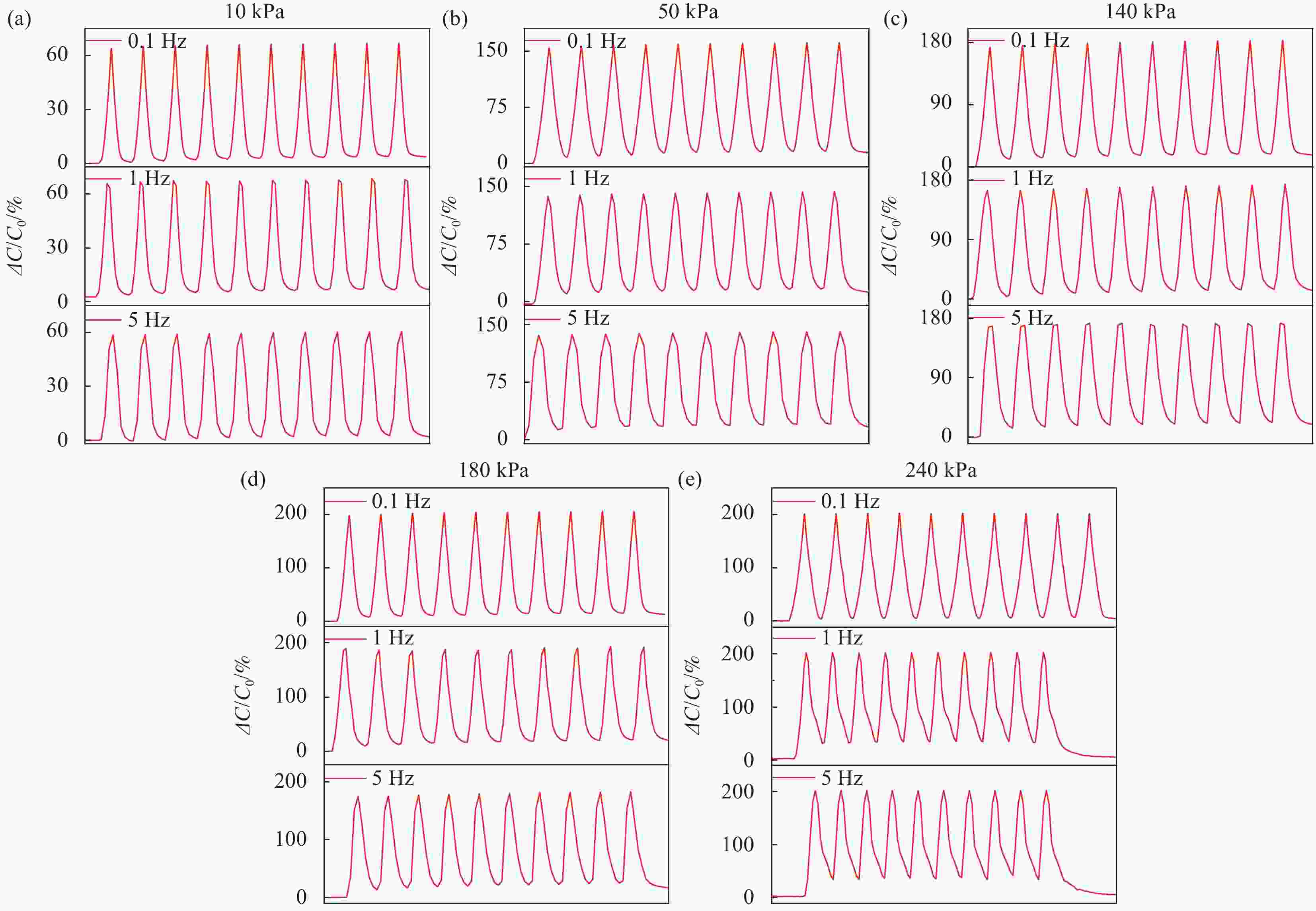

摘要: 柔性压容传感器由于其结构简单、响应速度快、灵敏度高、成本低等优点,在健康监测、机器人、可穿戴设备等领域有非常广泛的应用需求。然而,传统的柔性压容传感器难以兼顾有效应力检测下限和有效应力检测上限,这限制其在更宽领域范围的应用。本文以糖颗粒(SPs)为造孔剂,羰基铁粉(CIPs)为磁响应填料,碳纳米管(CNTs)为导电填料,通过与硅橡胶复合制得柔性多孔CNT、CIP/硅橡胶复合材料,并以此为介电层材料制备得到柔性压容传感器,其在0-5 Hz频率范围内的有效应力检测范围为0.07-180 kPa,优于大部分文献报道的柔性压容传感器。由于具有宽的有效应力测试范围,长周期服役稳定性和快速响应,该传感器可用于监测人体呼吸、手臂运动、机械臂运动和语音识别等方面,在健康监测、可穿戴电子设备以及智能机器人等领域具有很好的应用前景。Abstract: Featured by simple structure, fast response, high sensitivity, and low cost, etc., flexible capacitive pressure sensor has been widely used in the fields of health care, robotics, wearable devices and so on. However, the trade-off between the effective upper and lower detection limits greatly restricts the applications of the flexible capacitive pressure sensor. In this work, a flexible and porous carbon nanotube (CNT)/carbonyl iron particle (CIP)/silicone composite was produced by using sugar particles (SPs) as the as pore-forming agents, CIPs as the magneto-responsive fillers, CNTs as the conductive fillers and silicone rubber as the flexible matrix. After serving as the dielectric layer, the porous CNT、CIP/silicone composite endows the capacitive pressure sensor produced a wide effective detection range of 0.07-180 kPa (at the frequency range of 0-5 Hz), much wider than most capacitive pressure sensors reported. In virtue of the wide detection range, long-term stability and fast response, the sensor produced is capable of monitoring human breath, arm movement, talking, and robotic movement, thus showing great promise in health monitoring, wearable electronic devices, and intelligent robotics, etc.

-

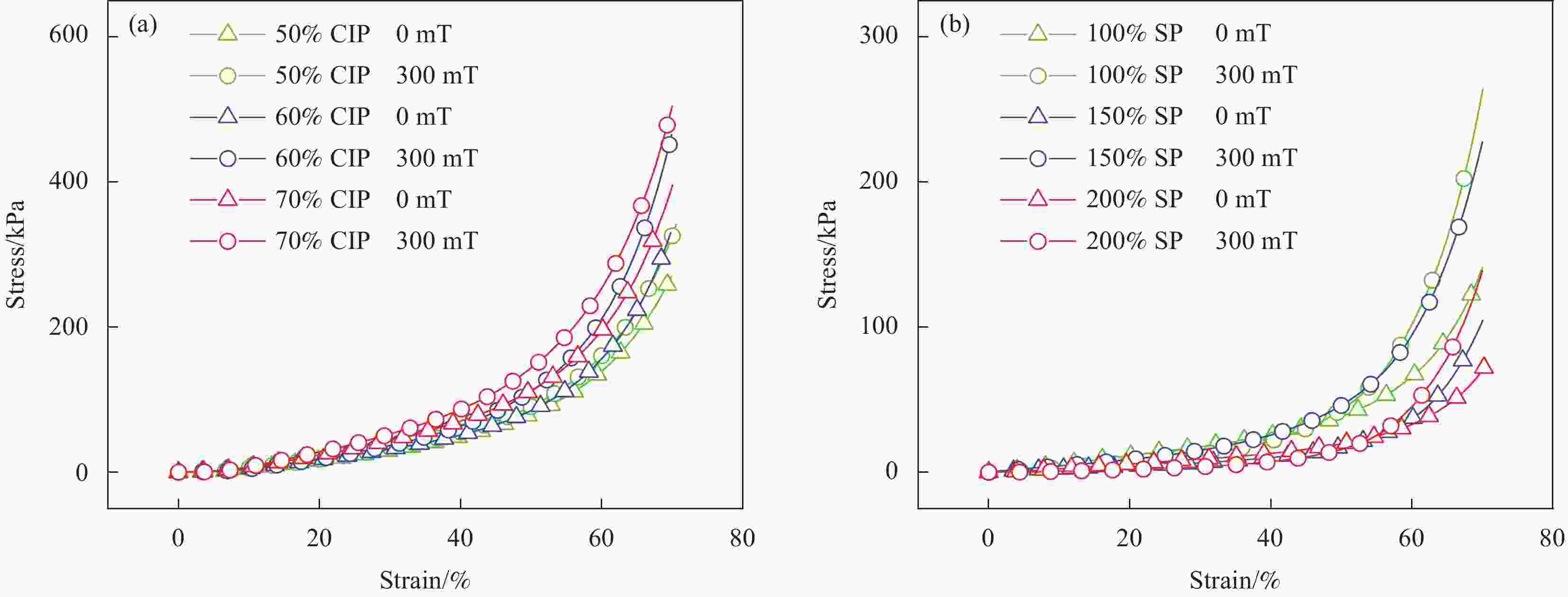

图 4 (a) 不同CNTs含量的多孔CNT、CIP/硅橡胶复合材料的电导率;(b) 不同CNTs含量的多孔CNT、CIP/硅橡胶复合材料的相对介电常数-压缩应变曲线。

Figure 4. (a) Electrical conductivity of the porous CNT、CIP/silicone composites with various CIP content; (b) dielectric constant - compressive strain curves of the porous CNT、CIP/silicone composites with various CIP content.

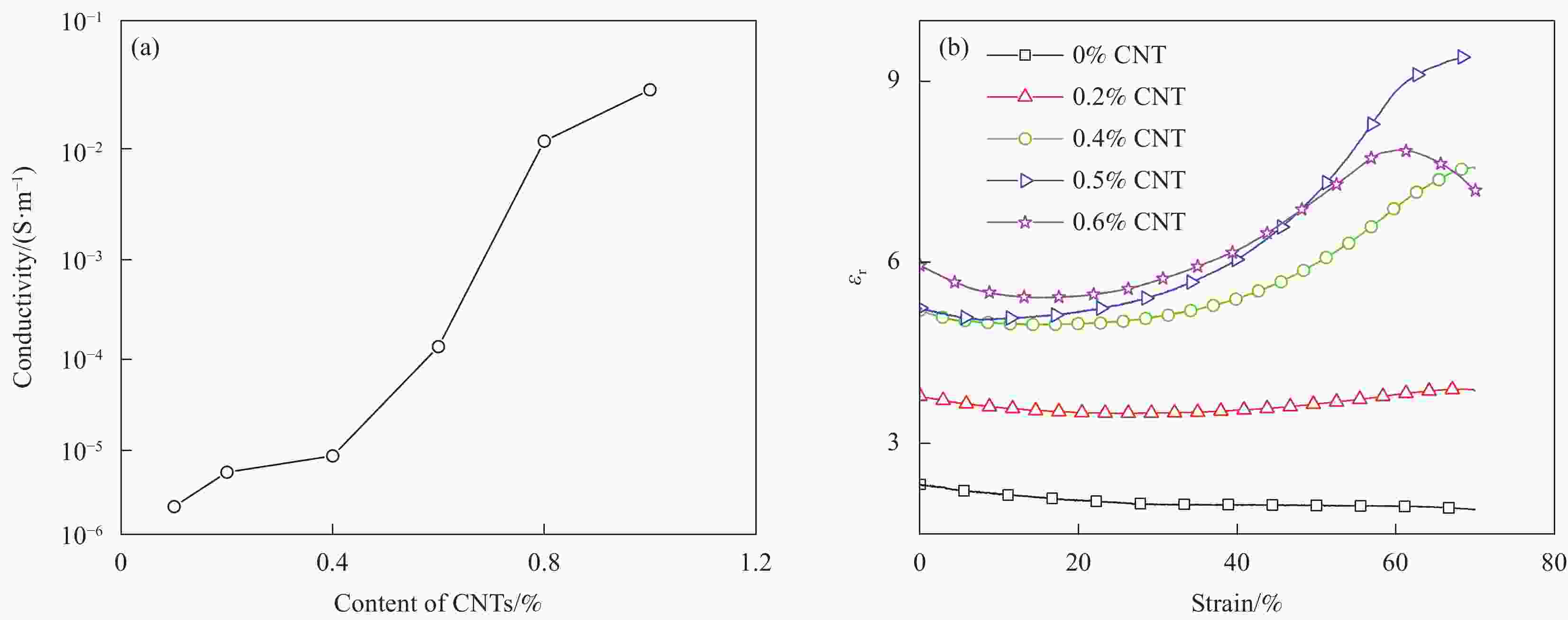

图 5 (a) 多孔CNT、CIP/硅橡胶压容传感器在0 mT和300 mT下的电容响应-压缩应力曲线;(b) 0.7 g的塑料块放在传感器表面时的电容响应。

Figure 5. (a) Capacitance response-compressive stress curves of the porous CNT、CIP/silicone capacitive pressure sensor at 0 and 300 mT; (b) capacitance response of the sensor when placing a 0.7 g plastic block on its top surface.

ΔC/C0—Relative change rate of the capacitance of the sensor compared to the initial capacitance during the compression process.

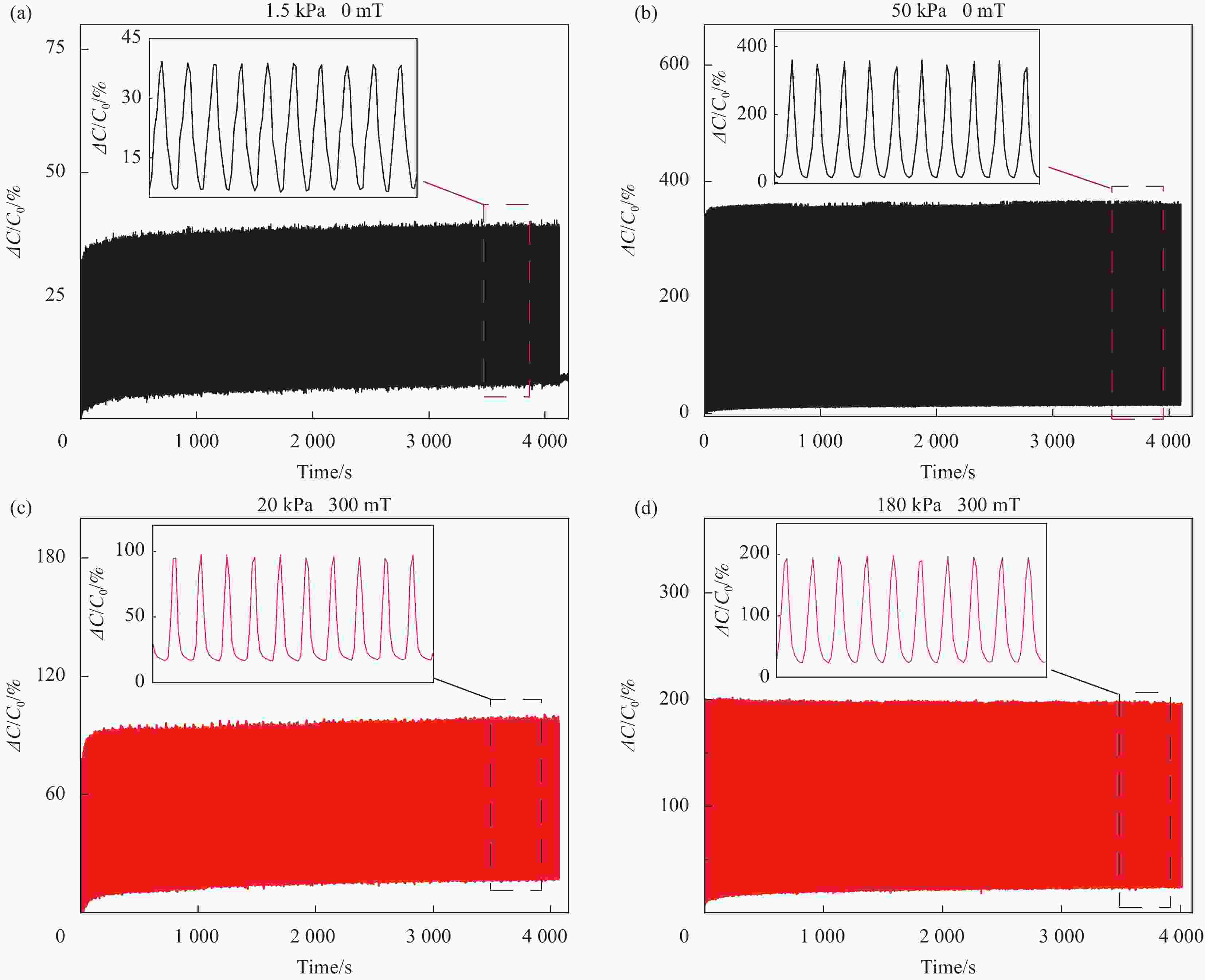

图 8 柔性多孔CNT、CIP/硅橡胶压容传感器的长周期服役稳定性测试。(a-b) 0 mT时,传感器对4000次循环载荷:1.5 kPa (a) 和50 kPa (b)的电容响应。(c-d) 300 mT时,传感器对4000次循环载荷:20 kPa (c) 和180 kPa (d) 的电容响应。

Figure 8. Long-term stability of the flexible porous CNT、CIP/silicone capacitive pressure sensor. (a-b) Capacitive response of the sensor to 4000 cycles of compressive stresses of 1.5 (a) and 50 kPa (b) under 0 mT. (c-d) Capacitive response of the sensor to 4000 cycles of compressive stresses of 20 (c) and 180 kPa (d) under 300 mT.

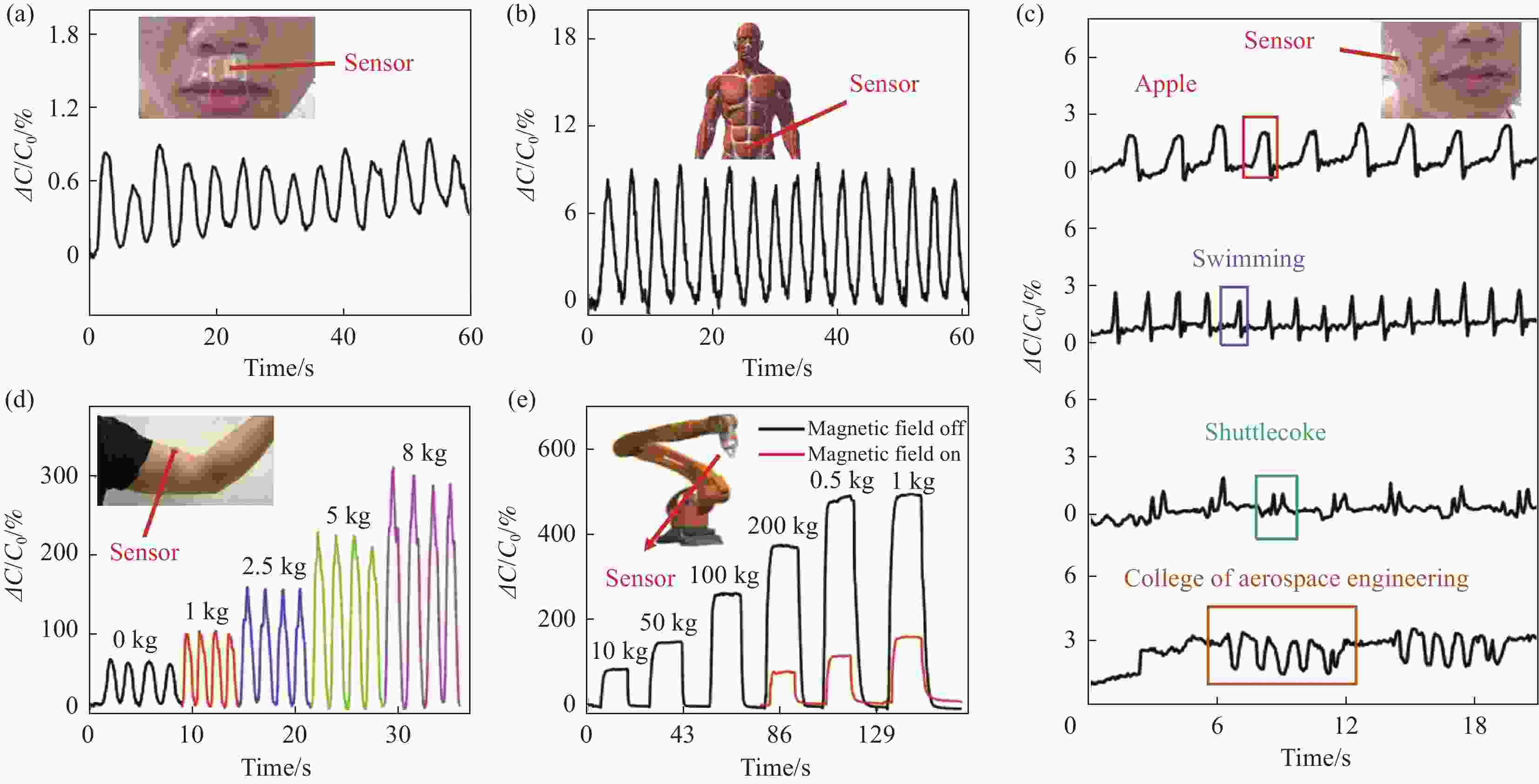

图 11 柔性多孔CNT、CIP/硅橡胶压容传感器的应用展示。(a) 实时监测鼻息;(b) 实时监测腹部呼吸;(c) 实时监测人说话时的面部肌肉运动;(d) 实时监测手臂抓取哑铃;(e) 在有无磁场下实时检测机械手臂夹持不同质量的重物

Figure 11. Applications of the flexible porous CNT、CIP/silicone capacitive pressure sensor. (a) Real-time monitoring of the nasal breathing; (b) real-time monitoring of the abdominal respiration; (c) real-time monitoring of the facial muscle movements when a testee speaking; (d) monitoring of the arm movement; (e) monitoring of a robotic arm holding objects of various weights before and after applying a magnetic field

表 1 含有0.5% CNTs,60% CIPs和150% SPs的CNT、CIP、SP/硅橡胶复合材料在超声波洗涤前后的质量变化

Table 1. Mass changes of the CNT、CIP、SP/silicone composite with 0.5% CNTs,60% CIPs and 150% SPs before and after ultrasonic washing

Sample Initial mass/g Remaining mass/g Percentage of mass remaining 1 5.9669 3.0848 51.70% 2 5.9715 3.0742 51.48% 3 6.0228 3.1354 52.06% 4 6.0303 3.1216 51.77% Notes: The theoretical residual mass fraction of CNT, CIP, SP/silicone rubber composite after completely removing SPs is 51.7%, and the contents of CNTs, CIPs and SPs in this paper are relative values, relative to the relative mass ratio of the base silicone rubber. For example, CNT, CIP, SP/silicone rubber composite containing 0.5% CNTs, 60% CIPs and 150% SPs refers to the composite prepared by mixing 0.5% CNTs, 60% CIPs and 150% SPs with silicone rubber as 100% according to the mass ratio. 表 2 不同CIPs含量的CIP/硅橡胶复合材料在压缩应变为70%时的压缩模量

Table 2. Compressive modulus of the bulk CIP/silicone composites with various CIP content at the strain of 70%

Magnetic field 50% CIP 60% CIP 70% CIP 0 mT 386 kPa 471 kPa 566 kPa 300 mT 487 kPa 664 kPa 720 kPa 表 3 不同SPs添加量的多孔CIP/硅橡胶复合材料在压缩应变为70%时的压缩模量

Table 3. Compressive modulus of the porous CIP/silicone composites with various SP content at the strain of 70%

Magnetic field 100%r SP 150% SP 200% SP 0 mT 201 kPa 150 kPa 103 kPa 300 mT 377 kPa 326 kPa 199 kPa 表 4 不同柔性传感器的有效应力检测范围

Table 4. Pressure detection ranges of the flexible pressure sensors reported.

Sensor Production Method Detection Range/kPa Refs. Bi2Te3 and Sb2Te3 film sensor Deposition, sputtering, and laser ablation 0.2-1.5 [25] Graphene/polyurethane foam sensor Freeze-drying, dip-coating, and chemical reduction 30-500 [26] Graphene/polydimethylsiloxane sensor Templating and spray-coating 0.2-25 [27] Graphene paper sensor Templating, dip-coating and thermal reduction 0.3-25 [28] Binary spiky/spherical nanoparticle film sensor Spray-coating and polymerization 0.05-120 [29] Polyaniline foam sensor Electro-deposition, chemical etching and pre-cracking 0.004-5 [30] Porous CNT、CIP/silicone composite sensor Mixing, curing and washing 0.07-180 This work -

[1] MORAN A, LEANNE C, ANDREW J, et al. Flexible pressure sensors for objective assessment of motor disorders[J]. Advanced Functional Materials, 2020, 30(20): 1905241. doi: 10.1002/adfm.201905241 [2] LUO Y, ABIDIAN M R, AHN J H, et al. Technology roadmap for flexible sensors[J]. ACS Nano, 2023, 17(6): 5211-5295. doi: 10.1021/acsnano.2c12606 [3] LIU H, WANG L, LIN G, et al. Recent progress in the fabrication of flexible materials for wearable sensors[J]. Biomaterials Science, 2022, 10(3): 614-632. doi: 10.1039/D1BM01136G [4] MENG K, XIAO X, WEI W, et al. Wearable pressure sensors for pulse wave monitoring[J]. Advanced Materials, 2022, 34(21): 2109357. doi: 10.1002/adma.202109357 [5] WANG X, YUJ, CUI Y, et al. Research progress of flexible wearable pressure sensors[J]. Sensors and Actuators A:Physical, 2021, 330: 112838. doi: 10.1016/j.sna.2021.112838 [6] DEMIDENKO N A, KUKSIN A V, MOLODYKH V V, et al. Flexible strain-sensitive silicone-CNT sensor for human motion detection[J]. Bioengineering, 2022, 9(1): 36. doi: 10.3390/bioengineering9010036 [7] HE J, SHI F, PANG Y, et al. Wearable superhydrophobic PPy/MXene pressure sensor based on cotton fabric with superior sensitivity for human detection and information transmission[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 128676. [8] KIM Y B, KIM U, SEOK D Y, et al. A novel capacitive type torque sensor for robotic applications [C]//2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM). IEEE, 2016: 993-998. [9] ZHU G J, REN P G, WANG J, et al. A highly sensitive and broad-range pressure sensor based on polyurethane mesodome arrays embedded with silver nanowires[J]. ACS Applied Materials & Interfaces, 2020, 12(17): 19988-19999. [10] HUANG C Y, YANG G, HUANG P, et al. Flexible pressure sensor with an excellent linear response in a broad detection range for human motion monitoring[J]. ACS Applied Materials & Interfaces, 2023, 15(2): 3476-3485. [11] MISHRA R B, EL-ATAB N, HUSSAIN A M, et al. Recent progress on flexible capacitive pressure sensors: from design and materials to applications[J]. Advanced Materials Technologies, 2021, 6(4): 2001023. doi: 10.1002/admt.202001023 [12] LI R, ZHOU Q, BI Y, et al. Research progress of flexible capacitive pressure sensor for sensitivity enhancement approaches[J]. Sensors and Actuators A:Physical, 2021, 321: 112425. doi: 10.1016/j.sna.2020.112425 [13] LIU S Y, LU J G. Influence of permittivity on the sensitivity of porous elastomer-based capacitive pressure sensors[J]. IEEE Sensors Journal, 2018, 18(5): 1870-1876. doi: 10.1109/JSEN.2017.2789242 [14] KE K, MCMASTER M, CHRISTOPHERSON W, et al. Highly sensitive capacitive pressure sensors based on elastomer composites with carbon filler hybrids[J]. Composites Part A:Applied Science and Manufacturing, 2019, 126: 105614. doi: 10.1016/j.compositesa.2019.105614 [15] ZHONG Y, GU F, WU L, et al. Porous conductive electrode for highly sensitive flexible capacitive pressure sensor over a wide range[J]. Journal of Alloys and Compounds, 2023, 934: 167919. doi: 10.1016/j.jallcom.2022.167919 [16] YANG L, LIU X, XIAO Y, et al. 3D printing of carbon nanotube (CNT)/thermoplastic polyurethane (TPU) functional composites and preparation of highly sensitive, wide-range detectable, and flexible capacitive sensor dielectric layers via fused deposition modeling (FDM)[J]. Advanced Materials Technologies, 2023, 8(7): 2201638. doi: 10.1002/admt.202201638 [17] BASTOLA A K, PAUDEL M, LI L, et al. Recent progress of magnetorheological elastomers: a review[J]. Smart Materials and Structures, 2020, 29(12): 123002. doi: 10.1088/1361-665X/abbc77 [18] YANG G, TIAN M Z, HUANG P, et al. Flexible pressure sensor with a tunable pressure-detecting range for various human motions[J]. Carbon, 2021, 173: 736-743. doi: 10.1016/j.carbon.2020.11.066 [19] MAIOLINO P, GALANTINI F, MASTROGIOVANNI F, et al. Soft dielectrics for capacitive sensing in robot skins: performance of different elastomer types[J]. Sensors and Actuators A:Physical, 2015, 226: 37-47. doi: 10.1016/j.sna.2015.02.010 [20] ZHU J, JI X, YIN M, et al. Poly(vinylidene fluoride) based percolative dielectrics with tunable coating of polydopamine on carbon nanotubes: toward high permittivity and low dielectric loss[J]. Composites Science and Technology, 2017, 144: 79-88. doi: 10.1016/j.compscitech.2017.03.017 [21] LI R, ZHOU Q, BI Y, et al. Research progress of flexible capacitive pressure sensor for sensitivity enhancement approaches[J]. Sensors and Actuators A:Physical, 2021, 321: 112425. doi: 10.1016/j.sna.2020.112425 [22] GUO Z, MO L, DING Y, et al. Printed and flexible capacitive pressure sensor with carbon nanotubes based composite dielectric layer[J]. Micromachines, 2019, 10(11): 715. doi: 10.3390/mi10110715 [23] WANG L. Variations in the capacitance and dielectric constant of multi-wall carbon nanotube filled silicone rubber composite during compressive creep[J]. Composites Science and Technology, 2016, 130: 1-8. doi: 10.1016/j.compscitech.2016.04.025 [24] MAO Y, ZHU Y, ZHAO T, et al. A portable and flexible self-powered multifunctional sensor for real-time monitoring in swimming[J]. Biosensors, 2021, 11(5): 147. doi: 10.3390/bios11050147 [25] TANG Z, JIA S, ZHOU C, et al. 3D printing of highly sensitive and large-measurement-range flexible pressure sensors with a positive piezoresistive effect[J]. ACS Applied Materials & Interfaces, 2020, 12: 28669-28680. [26] LIU L, ZHANG X, XIANG D, et al. Highly stretchable, sensitive and wide linear responsive fabric-based strain sensors with a self-segregated carbon nanotube (CNT)/polydimethylsiloxane (PDMS) coating[J]. Progress in Natural Science:Materials International, 2022, 32: 34-42. doi: 10.1016/j.pnsc.2021.10.012 [27] NAG A, MUKHOPADHYAY S C. Fabrication and implementation of carbon nanotubes for piezoresistive-sensing applications: a review[J]. Journal of Science:Advanced Materials and Devices, 2022, 7: 100416. doi: 10.1016/j.jsamd.2021.100416 [28] WU S, PENG S, YU Y, et al. Strategies for designing stretchable strain sensors and conductors[J]. Advanced Materials Technologies, 2020, 5: 1900908. doi: 10.1002/admt.201900908 [29] CAO M, SU J, FAN S, et al. Wearable piezoresistive pressure sensors based on 3D graphene[J]. Chemical Engineering Journal, 2021, 406: 126777. doi: 10.1016/j.cej.2020.126777 [30] WANG Y, ZHU W, DENG Y, et al. High-sensitivity self-powered temperature/pressure sensor based on flexible Bi-Te thermoelectric film and porous microconed elastomer[J]. Journal of Materials Science & Technology, 2022, 103: 1-7. [31] 王菲菲, 彭海益, 姚晓刚. 基于多向冷冻法制备的高灵敏度柔性电容式压力传感器[J]. 复合材料学报, 2023, 40(5): 2680-2687.WANG Feifei, PENG Haiyi, YAO Xiaogang. High-sensitive flexible capacitive pressure sensor based on multi-directional freezing method[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2680-2687 (in Chinese) [32] ZHAO S, RAN W, WANG D, et al. 3D dielectric layer enabled highly sensitive capacitive pressure sensors for wearable electronics[J]. ACS Applied Materials & Interfaces, 2020, 12(28): 32023-32030. [33] MAHATA C, ALGADI H, Lee J, et al. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications[J]. Measurement, 2020, 151: 107095. doi: 10.1016/j.measurement.2019.107095 [34] XIONG Y, SHEN Y, TIAN L, et al. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring[J]. Nano Energy, 2020, 70: 104436. doi: 10.1016/j.nanoen.2019.104436 [35] MA L, SHUAI X, HU Y, et al. A highly sensitive and flexible capacitive pressure sensor based on a micro-arrayed polydimethylsiloxane dielectric layer[J]. Journal of Materials Chemistry C, 2018, 6(48): 13232-13240. doi: 10.1039/C8TC04297G -

点击查看大图

点击查看大图

计量

- 文章访问数: 86

- HTML全文浏览量: 55

- 被引次数: 0

下载:

下载: