Axial compressive property of 3 D braided-unidirectional hybrid tubes

-

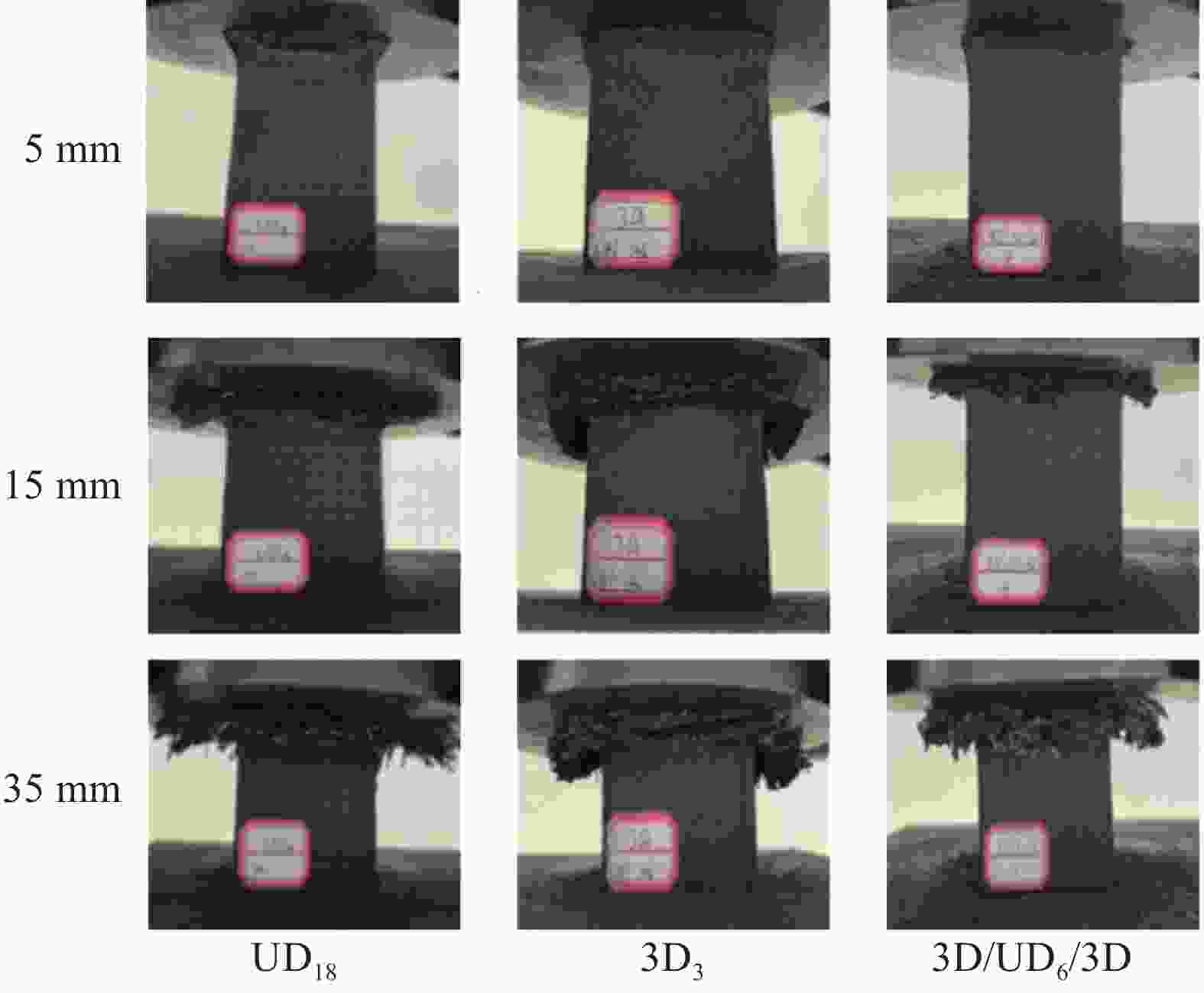

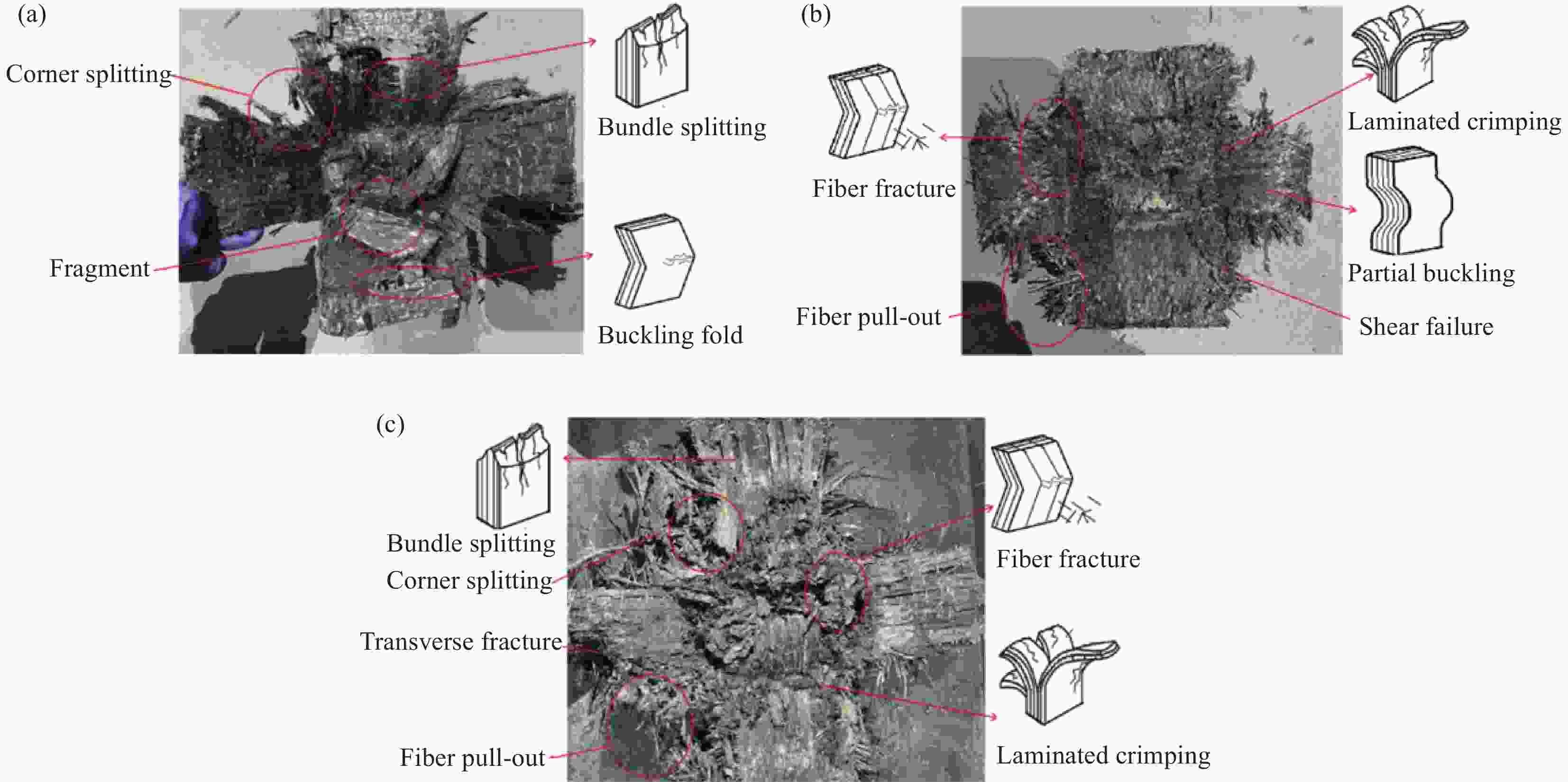

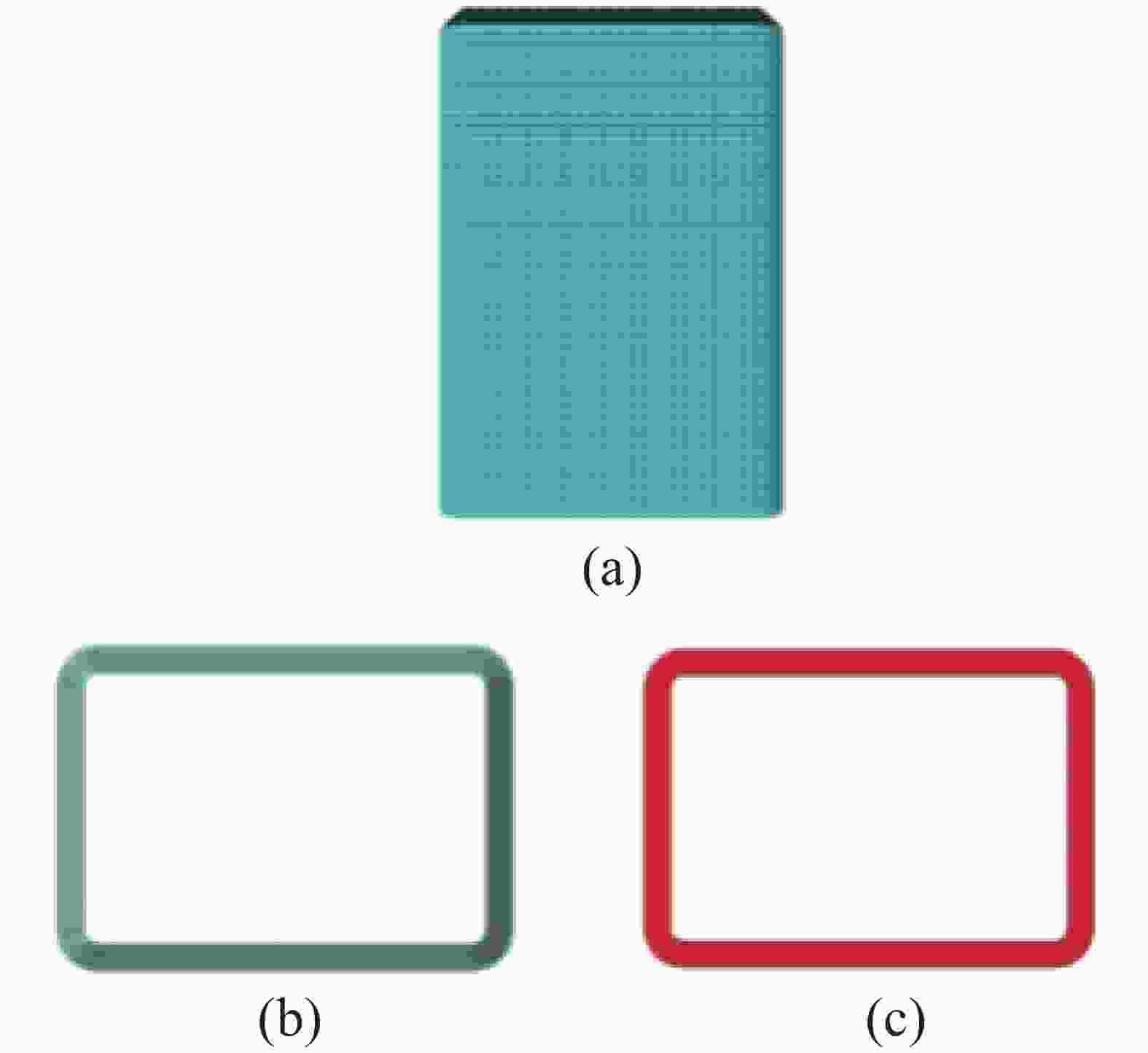

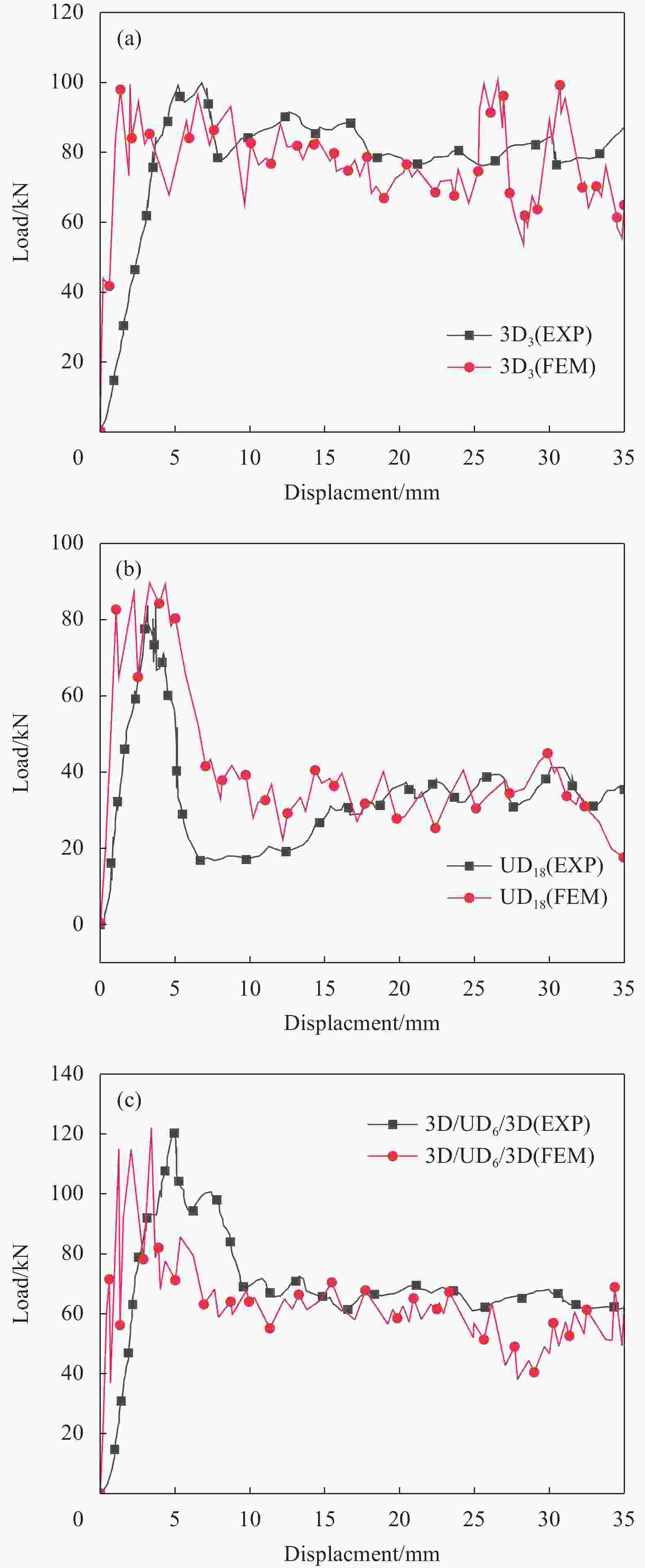

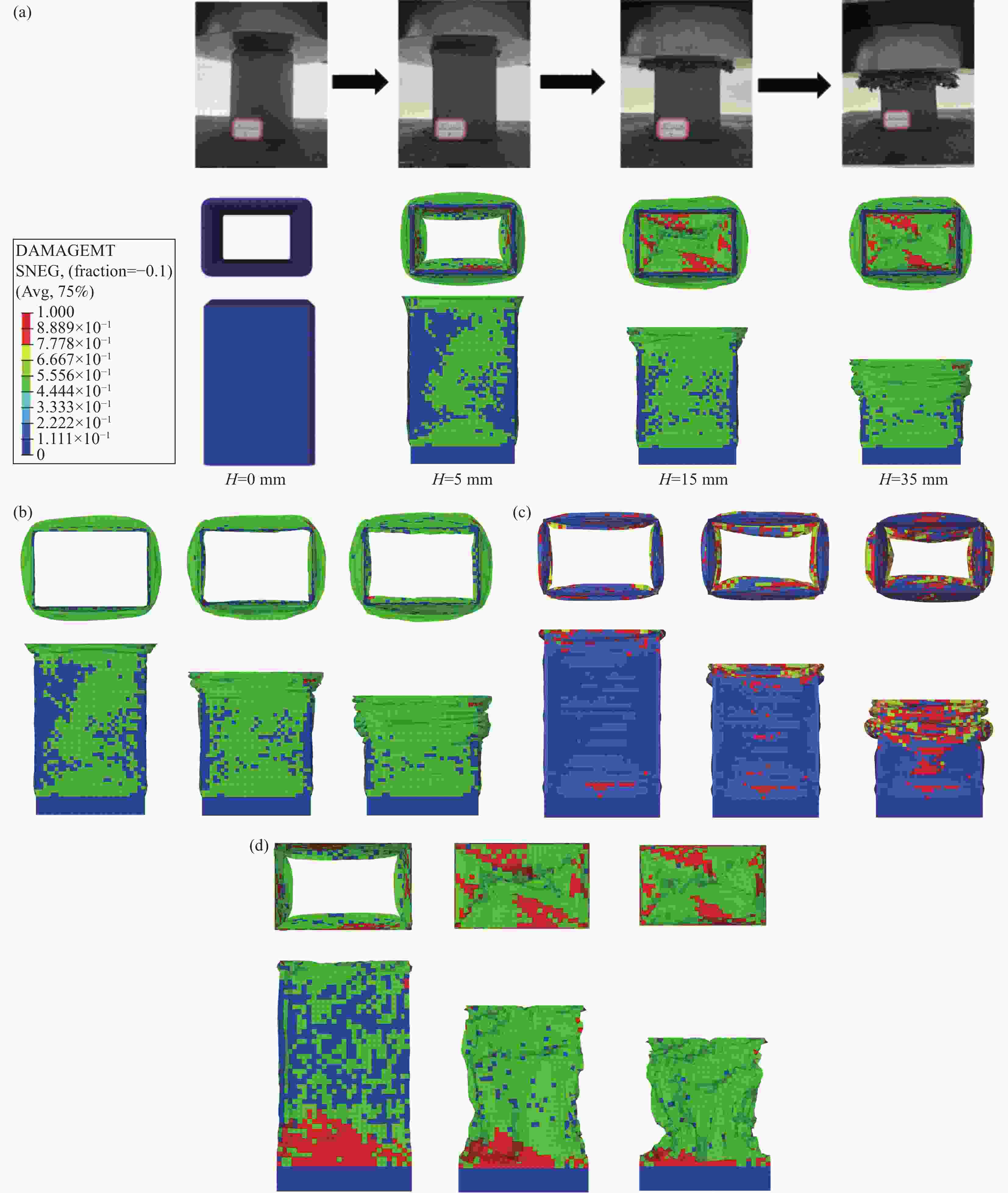

摘要: 采用准静态轴向压缩实验和有限元仿真相结合的方法,对三维编织(3 dimensional braided,3D)-单向铺层(unidirectional ply, UD)混合的碳纤维复合材料管的轴向压缩性能和破坏机制进行了研究。实验表明,3D-UD混合管具有更稳定的压缩吸能模式;相比UD管,混合管的峰值载荷、总吸能和比吸能分别提高了20.3%、109.2%和67.1%。进一步对3D-UD混合管的破坏过程进行了有限元仿真分析,仿真得到的载荷-位移曲线与实验结果吻合较好,验证了仿真模型的有效性。结合实验结果与混合管损伤变形的仿真分析,发现由于外层3D和内层3D对夹层UD的束缚和支撑作用抑制了UD管管壁因弯折过大而断裂,同时由于夹层UD管的稳定破坏吸能使得3D管未发生严重的编织层卷曲现象,因此3D-UD混合管可以有效抵抗管壁变形,提高轴向压缩下的稳定性和吸能性。Abstract: Using the method of combining quasi-static axial compression experiment with finite element simulation, the axial compression characteristics and failure mechanisms of 3D braided-unidirectional ply (3D-UD) hybrid tubes were investigated. Test results show that the peak load, total absorbed energy and specific energy absorption (SEA) of 3D-UD hybrid tube are increased by 20.3%, 109.2% and 67.1% respectively compared to the UD tube, and the compression energy absorption mode becomes more stable. In addition, the failure process of 3D-UD hybrid tubes was simulated by finite element method. The results show that load-displacement curves curve are in good accordance with experiment results so that the reliability of the simulation model is verified. Combined with the experimental results and the simulation analysis of the damage deformation of the mixed tube, it is found that the binding and supporting effects of the outer layer 3D and the inner layer 3D on the sandwich UD inhibit the breakage of the UD tube wall due to excessive bending. At the same time, the stability failure and energy absorption of the sandwich UD tube prevent the 3D tube from serious braided layer crimp. Therefore, the mixed tube can effectively resist the wall deformation and improve the stability and energy absorption under axial compression.

-

Key words:

- axial compression /

- finite element simulation /

- 3 D-UD /

- stability /

- energy absorption

-

表 1 试件的几何结构参数

Table 1. Geometric structure parameters of specimens

3 D/UDratio Layer Form Thickness/mm Trigger mode fiber volume fraction/% 1:0 3 [3 D/3 D/3 D] 4.0 45°bevel 53.4 2:1 8 [3 D-UD6-3 D] 4.0 45°bevel 54.2 0:1 18 [UD18] 4.0 45°bevel 55.7 表 2 复合材料管的径向压缩实验结果

Table 2. Axial compression test results of composite tubes

Specimen Pmax /kN ECF/% E/J SEA/(J·g−1) 3 D3 100.1 80.3 2807.0 56.5 UD18 82.9 45.3 1095.5 31.4 3 D-UD6-3 D 120.2 54.5 2292.5 52.5 表 3 T700 12 K/环氧树脂复合材料材料参数

Table 3. Material parameters of T700 12 K/epoxy resin composite material

Property Value Property Value Xt/Yt /MPa 1384/30 G12/ G13/G23/GPa 3.6 E1 t/E2 t /GPa 138/7 τ12 /MPa 67.4 υ12 0.317 τ13/τ23 /MPa 67.4 υ13/υ23 0.3 GⅠt/ GⅡ/(MN·m-1) 1/8 Xc/Yc /MPa 652/87.5 Gft/Gfc/Gs/(MN·m-1) 60/50/2 Notes:E1 t and E2 t are Young's modulus in X and Y directions, respectively;Xt is the tensile strength in the X direction;Yt is the tensile strength in the Y direction; Xc is the compression strength in the X direction;Yc is the compressive strength in the Y direction;G12, G13 and G23 are shear modulus in X, Y and Z directions, respectively;υ12, υ13 and υ23 are Poisson's ratios in X, Y and Z directions respectively;τ12 is the in-plane shear strength;τ13 and τ23 are the interlaminar shear strength in the direction of 13 and the shear strength in the direction of 23 respectively;GⅠt and GⅡ are Fracture energy release rate of type I and type II;Gft, Gfc and Gs are the release rates of fiber tens compression and shear failure energy, respectively. 表 4 各复合材料管实验/仿真性能参数误差对比

Table 4. Error comparison of experimental/simulation performance parameters for composite tubes

Specimen Pmax(EXP)/kN Pmax(FEM)/kN Error/% E(EXP)/J E(FEM) /J Error /% 3 D3 100.1 98.0 2.1 2807.0 2699.6 3.8 UD18 82.9 89.6 8.1 1095.5 1220.2 11.3 3 D-UD6-3 D 120.3 121.9 1.3 2292.5 2131.5 7.1 -

[1] 孙政, 付艳恕, 詹博文, 等. 复合材料吸能圆管轴向准静态压缩失效机制研究[J]. 塑料科技, 2017, 45(4): 36-40.Sun Zheng, Fu Yanshu, Zhan Bowen, et al. Study on Failure Mechanism of Axially Quasi-static Compression of Composite Energy-absorption Circular Tube[J]. Plastics Science and Technology, 2017, 45(4): 36-40. (In Chinese [2] 马其华, 查一斌, 周天俊. Al-CFRP复合管的径向压缩性能[J]. 工程塑料应用, 2019, 47(11): 99-104. doi: 10.3969/j.issn.1001-3539.2019.11.018Ma Qihua, Zha Yibin, Zhou Tianjun. Radial compressive properties of Al-CFRP composite tubes[J]. Engineering Plastics Application, 2019, 47(11): 99-104. (In Chinese doi: 10.3969/j.issn.1001-3539.2019.11.018 [3] Liu Q , Lin Y Z , Zone, Z J , et al. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle[J]. Composite Structures, 2013, 97: 231-238. [4] 乔阳阳, 白远利. 纤维增强复合材料断裂模型综述(英文)[J]. 汽车安全与节能学报, 2018, 9(1): 1-10. doi: 10.3969/j.issn.1674-8484.2018.01.001Qiao Yangyang, Bai Yuanli. A Review on Failure Modeling Methods of Fiber Reinforced Polymer Matrix Composites[J]. Journal of Automotive Safety and Energy, 2018, 9(1): 1-10. (In Chinese doi: 10.3969/j.issn.1674-8484.2018.01.001 [5] 查一斌, 马其华, 周天俊. 准静态径向压缩载荷下碳纤维缠绕薄壁铝管吸能特性分析[J]. 机械强度, 2020, 42(6): 1430-1437.Zha Yinin, Ma Qihua, Zhou Tianjun. Analysis of Energy Absorption Characteristics of Al-CFRP Hybrid Tubes under Qusic-static Radial Compression[J]. Journal of Mechanical Strength, 2020, 42(6): 1430-1437. (In Chinese [6] MOURITZ A P, BANNISTER M K, FALZON P J, et al. Review of applications for advanced three-dimensional fibre textile composites[J]. Composites Part A:Applied Science and Manufacturing, 1999, 30(12): 1445-1461. doi: 10.1016/S1359-835X(99)00034-2 [7] DRANSFIELD K, BAILLIE C, MAI Y-W. Improving the delamination resistance of CFRP by stitching-a review[J]. Composites Science and Technology, 1994, 50(3): 305-317. doi: 10.1016/0266-3538(94)90019-1 [8] LADANI R B, NGUYEN A T T, WANG C H, et al. Mode II interlaminar delamination resistance and healing performance of 3D composites with hybrid z-fibre reinforcement[J]. Composites Part A:Applied Science and Manufacturing, 2019, 120: 21-32. doi: 10.1016/j.compositesa.2019.02.010 [9] HOFFMANN J, SCHARR G. Mechanical properties of composite laminates reinforced with rectangular z-pins in monotonic and cyclic tension[J]. Composites Part A:Applied Science and Manufacturing, 2018, 109: 163-170. doi: 10.1016/j.compositesa.2018.03.004 [10] 李政宁, 陈革, KO Frank. 三维编织工艺及机械的研究现状与趋势[J]. 玻璃钢/复合材料, 2018, (5): 109-115.Li Zhengning, Chen Ge, Frank Ko. The Development and Tendency of 3D Braiding Technology and Machinegy[J]. Fiber Reinforced Plastics/ Composites, 2018, (5): 109-115. (In Chinese [11] 孙梦尧, 张典堂, 钱坤. 三维五向编织复合材料低速冲击损伤区域的量化表征[J]. 复合材料学报: 2023, 40(09): 5411-5422.Sun Mengyao, Zhang Diantang, Qian Kun. Quantitative characterization of low-velocity impact damage in three dimensional five- directional braided composites[J]. Acta Materiae Compositae Sinica: 2023, 40(09): 5411-5422. (In Chinese [12] 张超, 许希武, 许晓静 . 三维多向编织复合材料宏细观力学性能有限元分析研究进展[J]. 复合材料学报,2015 ,32 (5 ):1241 -1251 .Zhang Chao, Xu Xiwu, Xu Xiaojing . Research progress in finite element analysis on macro-meso mechanical properties of 3D multi-directional braided composites.[J]. Acta Materiae Compositae Sinica,2015 ,32 (5 ):1241 -1251 . (In Chinese)[13] 张徐梁, 阳玉球, 阎建华, 等. 碳纤维-玻璃纤维混杂增强环氧树脂三维编织复合材料薄壁圆管压溃吸能特性与损伤机制[J]. 复合材料学报, 2021, 38(9): 2814-2821.Zhang Xuliang, Yang Yuqiu, Yan Jianhua, et al. Crushing energy absorption characteristics and damage mechanism of carbon fiber-glass fiber hybrid reinforced epoxy 3D braided composite thin-walled circular tube[J]. Acta Materiae Compositae Sinica, 2021, 38(9): 2814-2821. (In Chinese [14] Kostar TD, Chou TW, Popper P. Characterization and comparative study of three-dimensional braided hybrid composites[J]. Journal of Materials Science, 2000, 35(9): 2175-2183. doi: 10.1023/A:1004710522640 [15] Wan YZ, Huang Y, He F, et al. Tribological properties of three-dimensional braided carbon/Kevlar/epoxy hybrid composites under dry and lubricated conditions[J]. Materials Science & Engineering A, 2007, 452-453: 202-209. [16] Swolfs Y, Mcmeeking RM, Rajan VP, et al. Global load-sharing model for unidirectional hybrid fibre-reinforced composites[J]. Journal of the Mechanics and Physics of Solids, 2015, 84: 380-94. doi: 10.1016/j.jmps.2015.08.009 [17] Nisini E, Santulli C, Liverani A. Mechanical and impact characterization of hybrid composite laminates with carbon, basalt and flax fibres[J]. Composites Part B:Engineering, 2017, 127: 92-9. doi: 10.1016/j.compositesb.2016.06.071 [18] Zfaa B, Mnma A. Investigation on energy absorption of natural and hybrid fiber under axial static crushing[J]. Composites Science and Technology, 2017, 151: 52-61. doi: 10.1016/j.compscitech.2017.07.028 [19] Swolfs Y, Gorbatikh L, Verpoest I. Fibre hybridisation in polymer composites: A review[J]. Composites Part A:Applied Science & Manufacturing, 2014, 67(67): 181-200. [20] 谷元慧, 刘晓东, 钱坤, 等. 三维编织复合材料圆管力学性能研究进展[J]. 化工新型材料, 2020, 48(2): 258-262.Gu Yuanhui, Liu Xiaodong, Qian Kun, et al. Research process on mechanical property of 3D braided composite circular tube[J]. New Chemical Materials, 2020, 48(2): 258-262. (In Chinese [21] 熊信发, 王校培, 王坤, 等. 三维编织复合材料圆管轴向压缩性能及破坏机理[J]. 南京航空航天大学学报, 2023, 55(4): 702-710.Xiong Xinfa, Wang Xiaopei, Wang kun, et al. Axial compression properties and failure mechanism of 3D braided composite tube[J]. Journal of Nanjing University of Aeronautics & Astromautics, 2023, 55(4): 702-710. (In Chinese -

点击查看大图

点击查看大图

计量

- 文章访问数: 66

- HTML全文浏览量: 34

- 被引次数: 0

下载:

下载: