Effects of resin coating and seawater immersion on mechanical performance of basalt textile reinforced seawater sea sand concrete

-

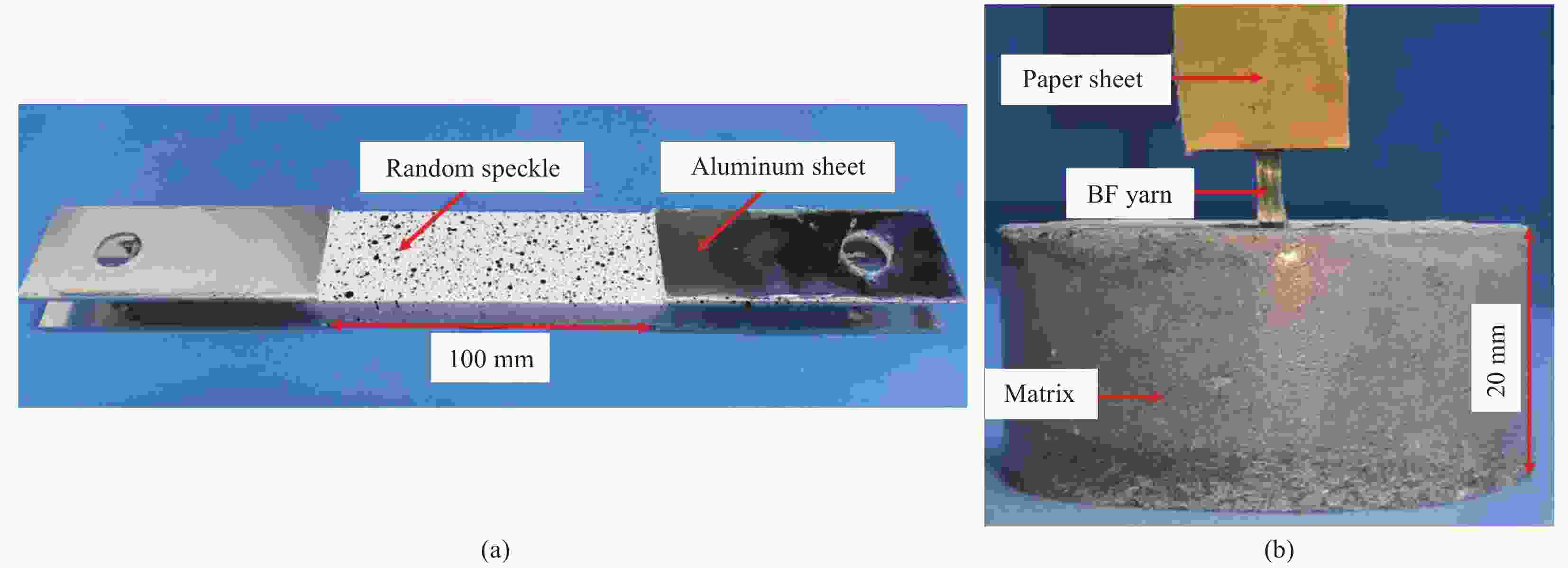

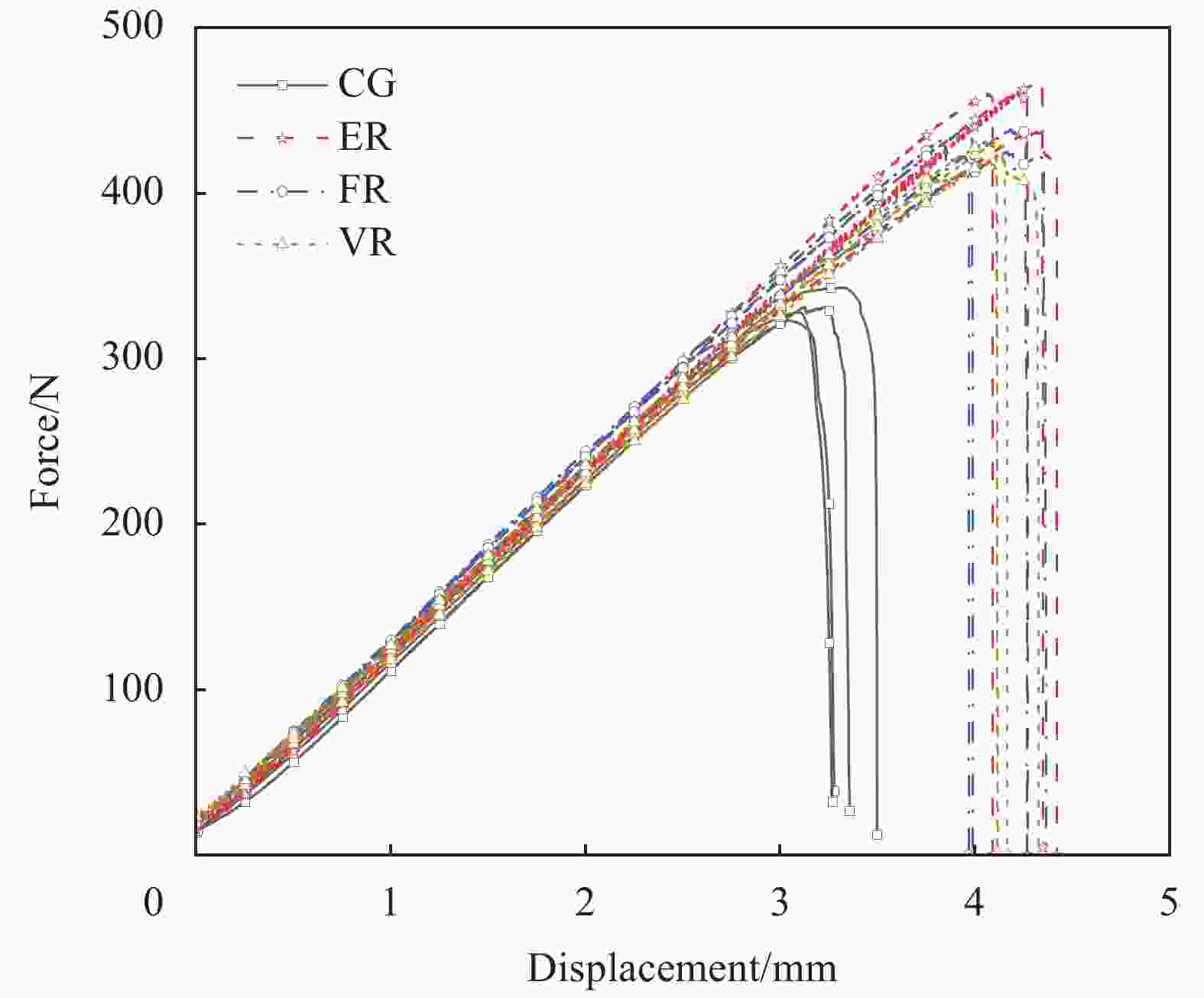

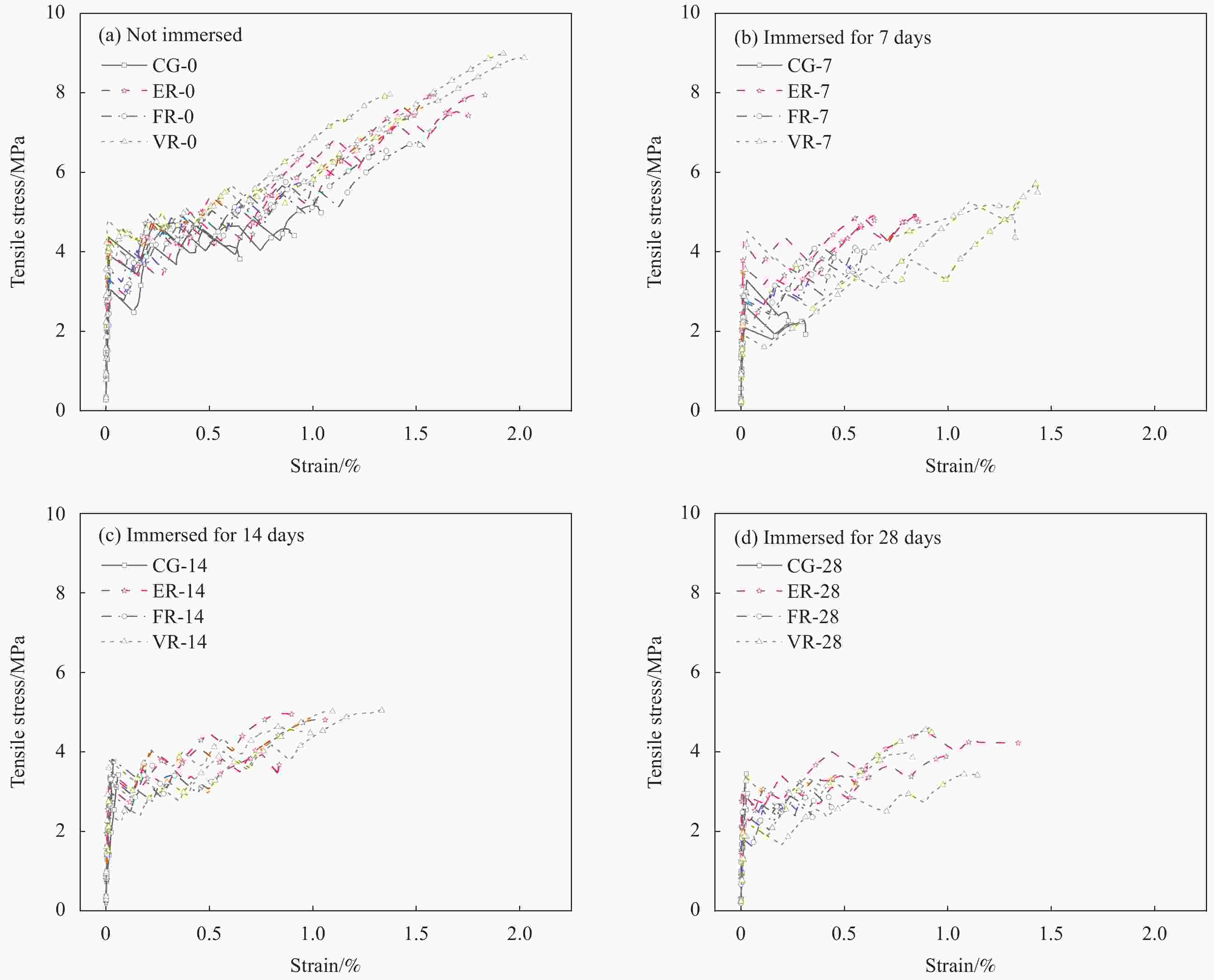

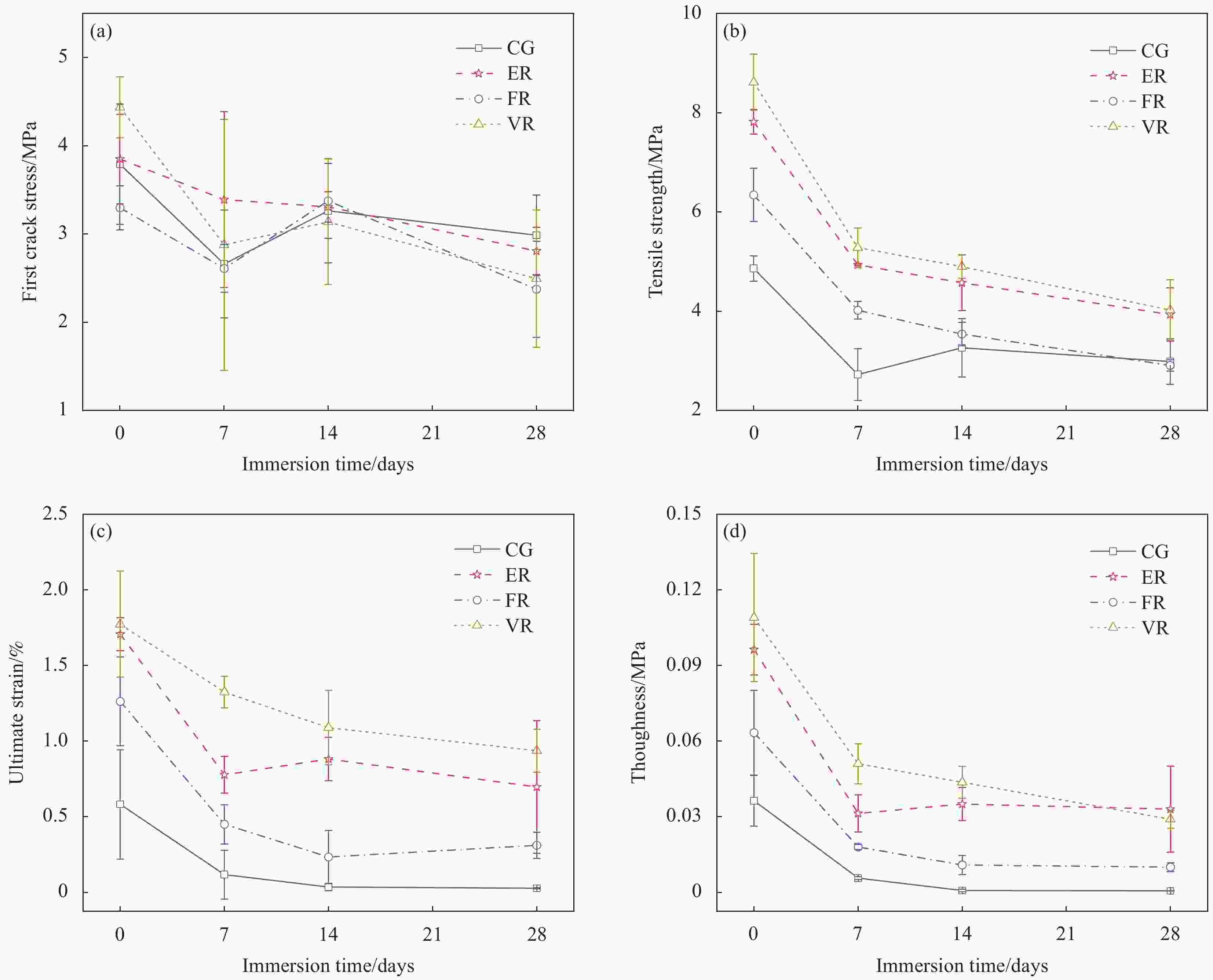

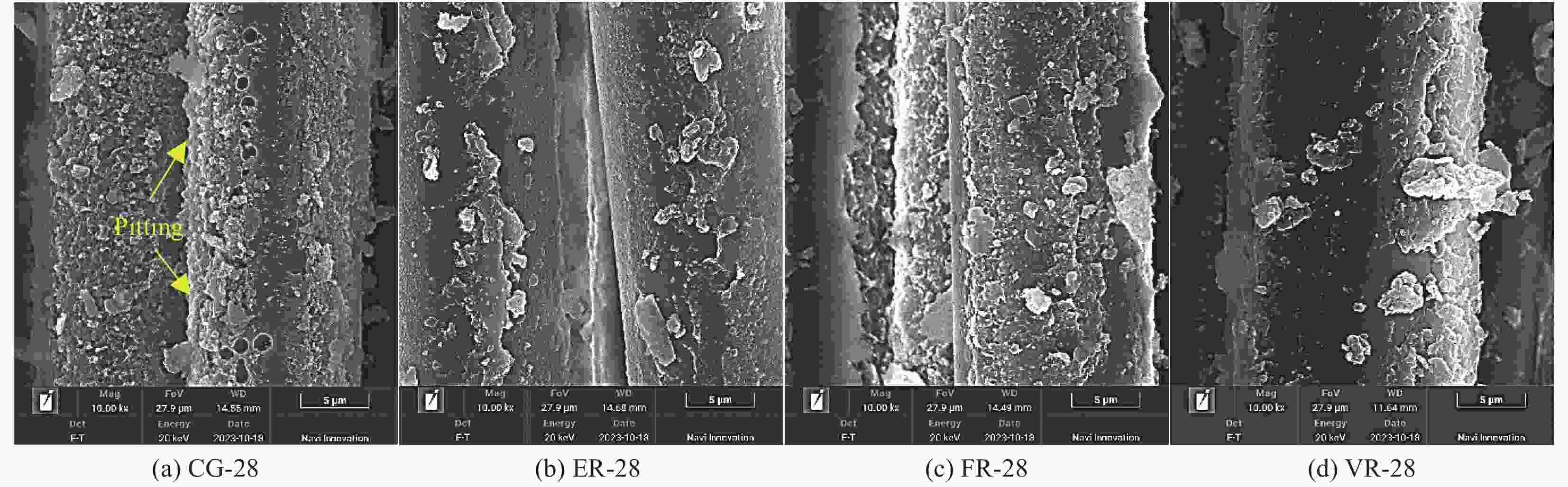

摘要: 为了研究不同树脂(环氧树脂、呋喃树脂、乙烯基树脂)涂层及海水浸泡对玄武岩纤维织物增强海水海砂混凝土(BTR-SSC)力学性能的影响,采用万能试验机对各树脂涂层纤维束和海水浸泡不同时间下BTR-SSC试件进行静态拉伸试验,并通过拔出试验评估纤维-基体界面黏结性能。结合数字图像相关分析得到裂纹与应变分布,并采用扫描电镜分析损伤机理。通过界面黏结强度计算公式实现以裂纹分布和基体强度评估界面长期性能。结果表明:三种树脂对纤维束的增强效果显著且相近(32%左右),均可显著提升BTR-SSC力学性能,乙烯基树脂涂层表现最佳,抗拉性能和界面黏结性能分别提升77%和180%。海水浸泡下BTR-SSC试件力学性能明显劣化,未处理试件仅高温浸泡14 d后便脆断,环氧树脂、呋喃树脂和乙烯基树脂涂层试件浸泡7 d时相对未处理试件抗拉强度分别提升81%、48%和94%,浸泡28 d时仍呈多裂缝开展,界面黏结性能分别损失64%、57%和55%。该成果将有助于提升BTR-SSC在海洋环境中长期性能并促进其在海工结构中的应用。Abstract: In order to study the effects of different resin (epoxy resin, furan resin, vinyl resin) coatings and seawater immersion on the mechanical properties of basalt textile reinforced seawater sea sand concrete (BTR-SSC), a universal testing machine was used to perform static tensile tests on the fiber yarns of each resin coating and the BTR-SSC specimens immersed in seawater for different time, and the fiber-matrix interface bonding performance was evaluated by pull-out test. The crack and strain distribution were obtained by digital image correlation analysis, and the damage mechanism was analyzed by scanning electron microscopy. The long-term performance of the interface was evaluated by crack distribution and matrix strength through the calculation formula of interface bond strength. The results show that the reinforcing effects of the three resins on the fiber yarns are significant and similar (around 32%), which could significantly improve the mechanical properties of BTR-SSC. The vinyl resin coating had the best performance, and the tensile properties and interfacial bonding properties are increased by 77% and 180%, respectively. The mechanical properties of BTR-SSC specimens are significantly degraded under seawater immersion. The untreated specimens are brittle after 14 days of high temperature immersion. The tensile strength of epoxy resin, furan resin and vinyl resin coated specimens increase by 81%, 48% and 94% respectively after 7 days of immersion compared with untreated specimens. After 28 days of immersion, there are still multiple cracks developed, and the interfacial bonding properties are lost by 64%, 57% and 55%, respectively. The results will help to improve the long-term performance of BTR-SSC in the marine environment and promote its application in marine structures.

-

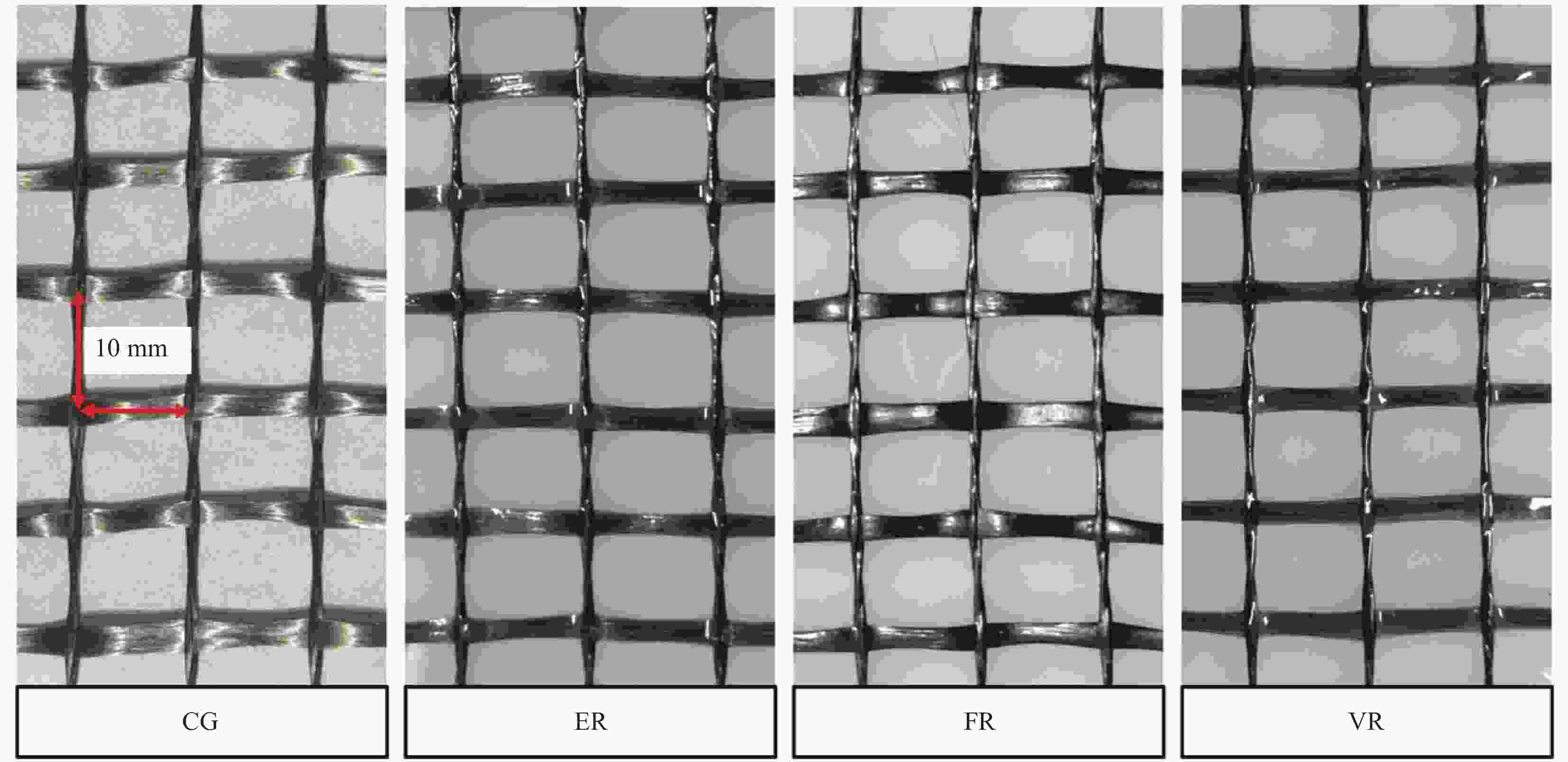

图 1 不同树脂涂层玄武岩纤维织物外观图

Figure 1. Surface morphology of basalt textile coated with different resins

'CG' represents the untreated specimen, namely the control group, 'ER' represents the specimen coated with epoxy resin, 'FR' represents the specimen coated with furan resin, and 'VR 'represents the specimen coated with vinyl resin

表 1 玄武岩纤维丝的物理及力学性能参数

Table 1. Physical and mechanical parameters of basalt fiber filaments

Type Specification Tensile

strength/

MPaElastic

modulus/

GPaElongation /% Diameter /μm Basalt fiber 3 K 1650 85 3 12 表 2 树脂的物理及力学性能参数

Table 2. Physical and mechanical parameters of resins

Type Model Initial viscosity after mixing/(mPa·s) Tensile strength/

MPaBreaking

Elongation/%Mass ratio Resin∶Curing agent∶

AcceleratorEpoxy resin JN-LS 70 46 8 100∶40 Vinyl resin CHEMPULSE 901 350±100 76-90 5-6 100∶1.2∶0.2 Furan resin GM-2 200±100 5-15 3-4 100∶2 表 3 海水海砂混凝土配合比(kg/m3)

Table 3. Mix proportion of the seawater sea sand concrete(kg/m3)

Water-binder ratio Cement Fly ash Seawater Sea sand(0-1.2 mm) Defoamer Superplasticizer Suspension stabilizer 0-0.6 mm 0.6-1.2 mm 0.37 643 161 299 364 728 1.6 1.45 0.4 表 4 人工海水的化学组成

Table 4. Chemical composition of artificial seawater

Solvent NaCl MgCl2 Na2SO4 CaCl2 KCl NaHCO3 Concentration

/(g·L−1)24.53 5.2 4.09 1.16 0.695 0.201 表 5 不同树脂涂层玄武岩纤维束抗拉力学性能参数

Table 5. Tensile mechanical performance parameters of basalt fiber yarns with different resin coatings

Specimen ID Ultimate load/N Tensile strength /MPa Ultimate strain /% CG 331.4(8.4) 1077(27) 3.17(0.12) ER 456.5(13.3) 1484(43) 4.23(0.12) FR 434.1(6.6) 1411(22) 4.04(0.17) VR 426.3(6.5) 1385(21) 4.09(0.03) Note: The values in the parentheses are standard deviations. 表 6 不同海水浸泡时间下不同树脂涂层BTR-SSC抗拉力学性能参数

Table 6. Tensile mechanical performance parameters of BTR-SSC with different resin coatings immersed in seawater for different time

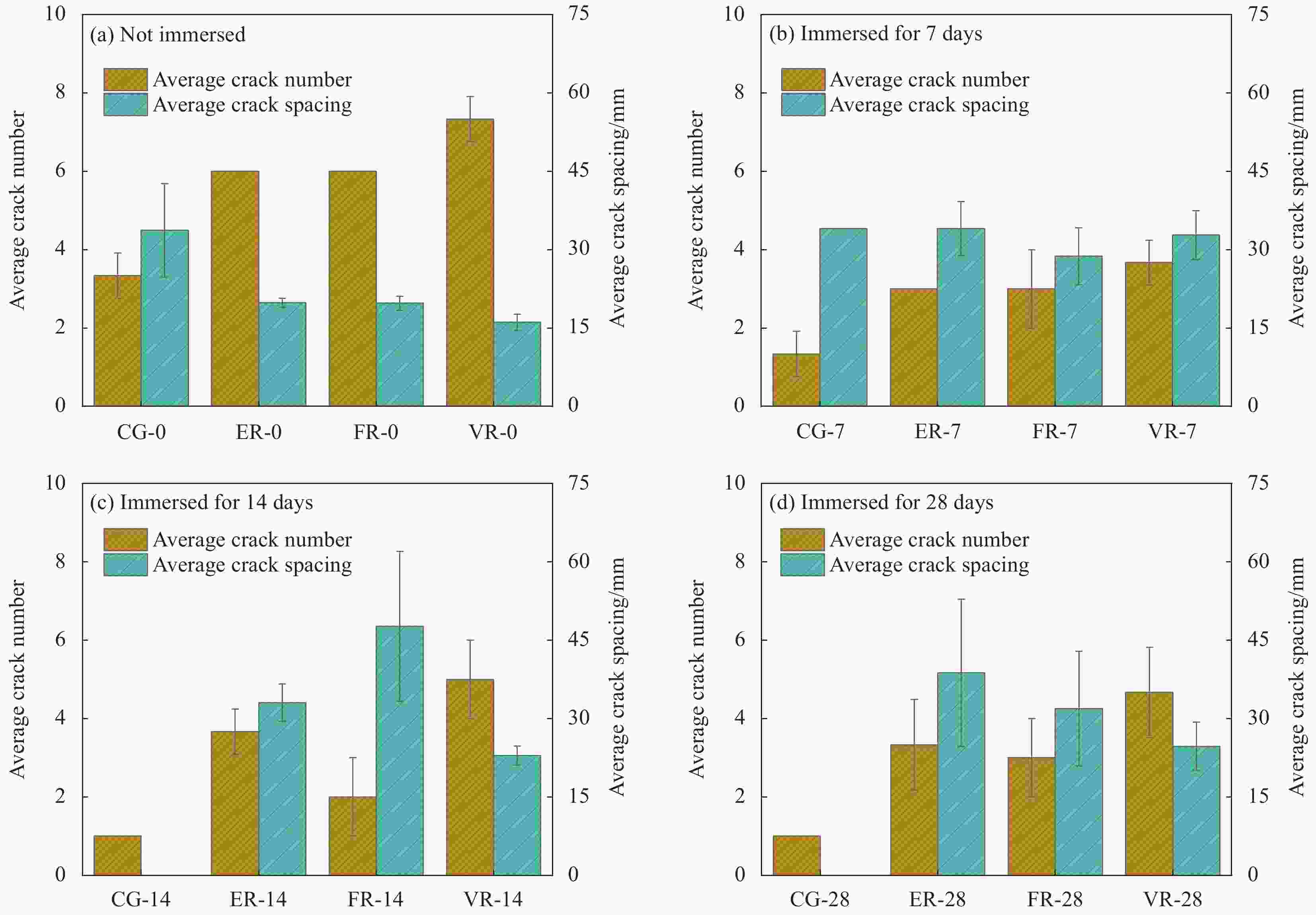

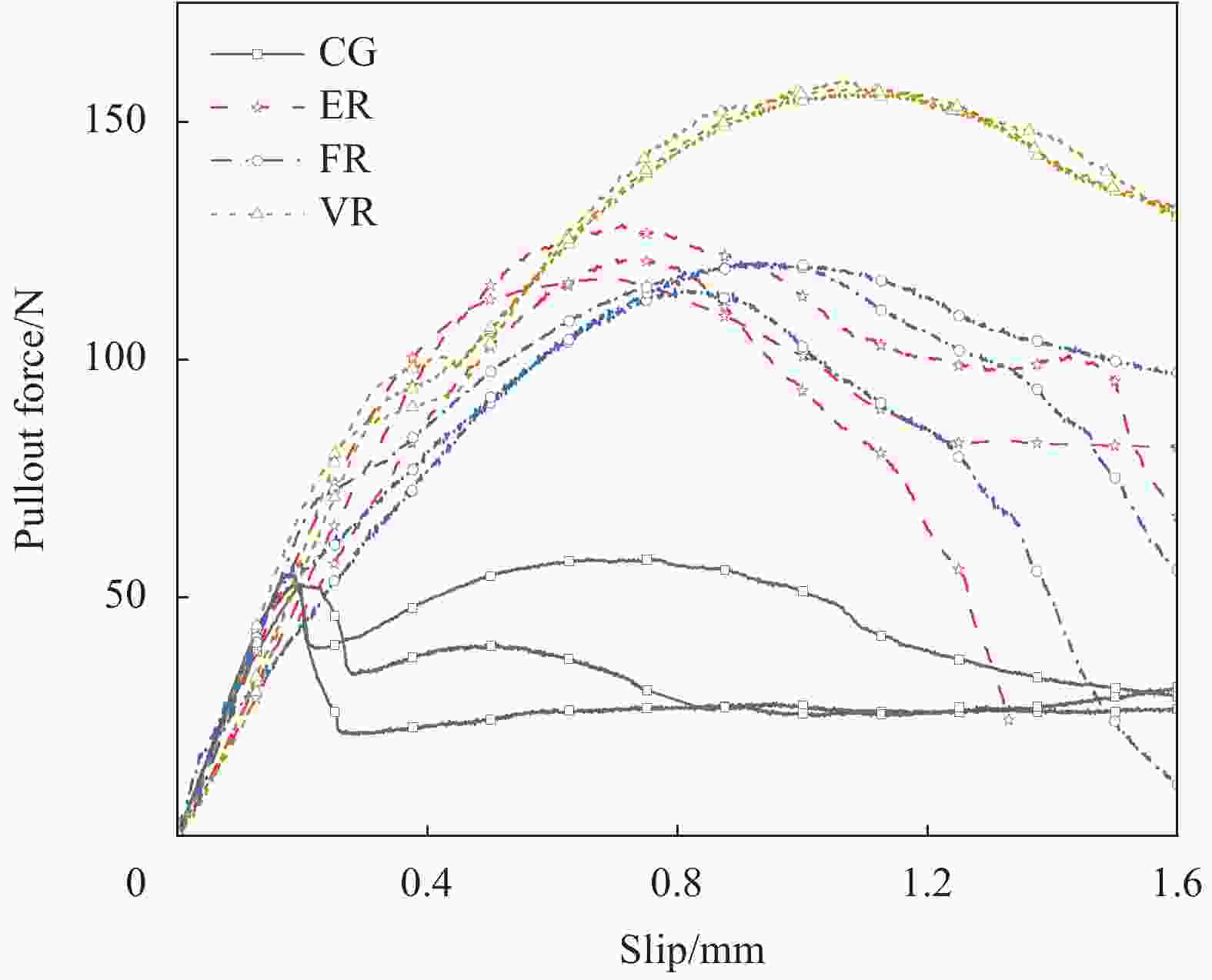

Specimen ID Immersion time/days First crack stress/MPa Tensile strength /MPa Strength retention rate /% Peak strain /% Toughness /MPa Crack number Crack spacing /mm CG-0 0 3.79(0.68) 4.86(0.26) - 0.58(0.36) 0.036(0.010) 3.3(0.5) 34(9) ER-0 3.85(0.51) 7.82(0.25) - 1.71(0.11) 0.096(0.010) 6(0) 20(1) FR-0 3.30(0.25) 6.35(0.54) - 1.26(0.29) 0.063(0.017) 6(0) 20(1) VR-0 4.44(0.34) 8.61(0.56) - 1.77(0.35) 0.109(0.025) 7.3(0.6) 16(2) CG-7 7 2.66(0.61) 2.72(0.52) 56 0.12(0.16) 0.006(0.001) 1.3(0.6) 34(0) ER-7 3.39(1.00) 4.93(0.02) 63 0.78(0.12) 0.031(0.007) 3(0) 34(5) FR-7 2.61(0.27) 4.02(0.18) 63 0.45(0.13) 0.018(0.001) 3(1) 29(5) VR-7 2.88(1.42) 5.28(0.40) 61 1.32(0.10) 0.051(0.008) 3.7(0.6) 33(5) CG-14 14 3.26(0.59) 3.26(0.59) brittle failure 0.04(0.02) 0.001(0.001) 1(0) - ER-14 3.31(0.17) 4.57(0.56) 58 0.88(0.14) 0.035(0.007) 3.7(0.6) 33(4) FR-14 3.38(0.43) 3.54(0.23) 56 0.23(0.18) 0.011(0.004) 2(1) 48(14) VR-14 3.14(0.71) 4.90(0.23) 57 1.09(0.25) 0.044(0.006) 5(1) 23(2) CG-28 28 2.99(0.46) 2.99(0.46) brittle failure 0.03(0.00) 0.001(0.000) 1(0) - ER-28 2.81(0.27) 3.93(0.54) 50 0.70(0.44) 0.033(0.017) 3.3(1.2) 39(14) FR-28 2.37(0.55) 2.91(0.12) 46 0.31(0.09) 0.010(0.002) 3(1) 32(11) VR-28 2.49(0.78) 4.02(0.61) 47 0.94(0.14) 0.029(0.004) 4.7(1.2) 25(5) Note: The values in the parentheses are standard deviations. 表 7 不同树脂涂层玄武岩纤维束拔出力学性能

Table 7. Pull-out mechanical performance of basalt fiber yarns with different resin coatings

Specimen ID Pull-out stiffness /(N·mm−1) Ultimate pull-

out force /Nτm /MPa Pull-out work /10−3 J CG 304(16) 56(3) 1.41 13.3(13.3) ER 253(40) 122(6) 2.23 55.6(2.9) FR 337(30) 119(3) 2.05 71.7(10.8) VR 369(50) 157(1) 2.76 113.1(1.5) Note: The values in the parentheses are standard deviations. 表 8 不同海水浸泡时间下不同树脂涂层BTR-SSC界面黏结性能计算参数

Table 8. Parameters required for the calculation of interfacial bonding performance of BTR-SSC with different resin coatings immersed in seawater for different time

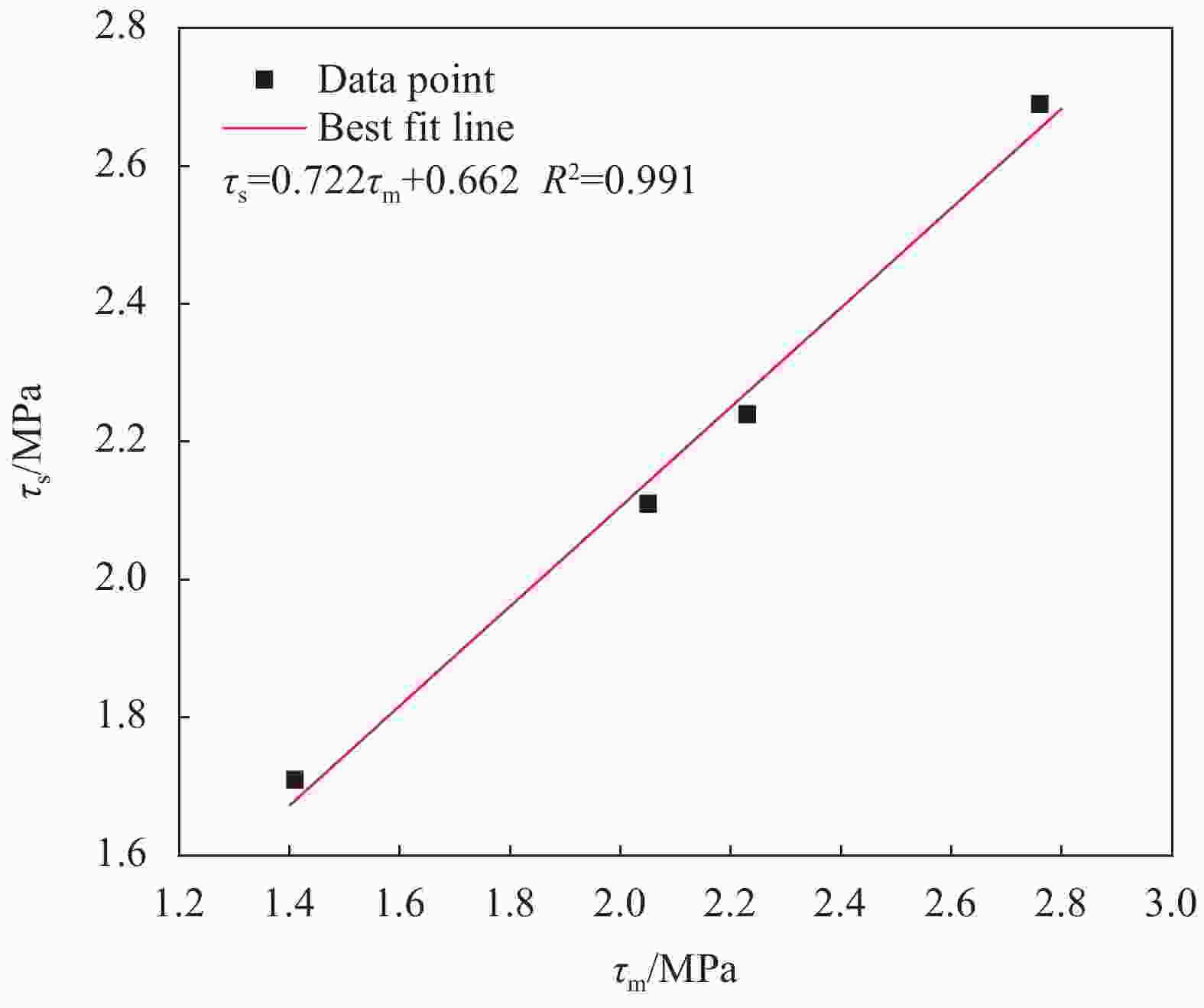

Specimen ID σmu/MPa x/mm r/mm Vf/% K1 τs/MPa CG-0 3.8 34 0.313 1.03 1.31 1.71 ER-0 20 0.436 1.84 0.99 2.24 FR-0 20 0.461 2.06 1.05 2.11 VR-0 16 0.453 1.98 0.82 2.69 CG-7 2.9 34 0.313 1.03 1.31 1.28 ER-7 34 0.436 1.84 1.68 0.99 FR-7 29 0.461 2.06 1.52 1.09 VR-7 33 0.453 1.98 1.70 0.98 CG-14 3.3 - 0.313 1.03 - - ER-14 33 0.436 1.84 1.63 1.16 FR-14 48 0.461 2.06 2.52 0.75 VR-14 23 0.453 1.98 1.18 1.60 CG-28 2.7 - 0.313 1.03 - - ER-28 39 0.436 1.84 1.93 0.80 FR-28 32 0.461 2.06 1.68 0.91 VR-28 25 0.453 1.98 1.29 1.20 Notes: σmu is the tensile strength of the matrix, x is the average crack spacing, r is the equivalent radius of fiber yarn, Vf is the fiber volume fraction, K1 is the bond strength factor, τs is the shear bonding strength. -

[1] FENG G, ZHU D, GUO S, et al. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions[J]. Cement and Concrete Composites, 2022, 134: 104758. doi: 10.1016/j.cemconcomp.2022.104758 [2] YI Y, ZHU D, RAHMAN M Z, et al. Tensile properties deterioration of BFRP bars in simulated pore solution and real seawater sea sand concrete environment with varying alkalinities[J]. Composites Part B:Engineering, 2022, 243: 110115. doi: 10.1016/j.compositesb.2022.110115 [3] 朱德举, 李高升. 短切纤维及预应力对玄武岩织物增强水泥基复合材料拉伸力学性能的影响[J]. 复合材料学报, 2017, 34(11): 2631-2641. doi: 10.13801/j.cnki.fhclxb.20170301.003ZHU Deju, LI Gaosheng. Effect of short fibers and prestressing on the tensile mechanical properties of basalt textile reinforced cementitious matrix composite[J]. Acta Materiae Compositae Sinica, 2017, 34(11): 2631-2641(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170301.003 [4] DONNINI J, CORINALDESI V, NANNI A. Mechanical properties of FRCM using carbon fabrics with different coating treatments[J]. Composites Part B:Engineering, 2016, 88: 220-228. doi: 10.1016/j.compositesb.2015.11.012 [5] WILLIAMS PORTAL N, FLANSBJER M, JOHANNESSON P, et al. Tensile behaviour of textile reinforcement under accelerated ageing conditions[J]. Journal of Building Engineering, 2016, 5: 57-66. doi: 10.1016/j.jobe.2015.11.006 [6] MICELLI F, AIELLO M A. Residual tensile strength of dry and impregnated reinforcement fibres after exposure to alkaline environments[J]. Composites Part B:Engineering, 2019, 159: 490-501. doi: 10.1016/j.compositesb.2017.03.005 [7] HRISTOZOV D, WROBLEWSKI L, SADEGHIAN P. Long-term tensile properties of natural fibre-reinforced polymer composites: Comparison of flax and glass fibres[J]. Composites Part B:Engineering, 2016, 95: 82-95. doi: 10.1016/j.compositesb.2016.03.079 [8] ÖZKAN Ş, DEMIR F. The hybrid effects of PVA fiber and basalt fiber on mechanical performance of cost effective hybrid cementitious composites[J]. Construction and Building Materials, 2020, 263: 120564. doi: 10.1016/j.conbuildmat.2020.120564 [9] LI Y, ZHANG J, HE Y, et al. A review on durability of basalt fiber reinforced concrete[J]. Composites Science and Technology, 2022, 225: 109519. doi: 10.1016/j.compscitech.2022.109519 [10] SILVA F d A, BUTLER M, HEMPEL S, et al. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete[J]. Cement and Concrete Composites, 2014, 48: 26-34. doi: 10.1016/j.cemconcomp.2014.01.007 [11] MESSORI M, NOBILI A, SIGNORINI C, et al. Mechanical performance of epoxy coated AR-glass fabric Textile Reinforced Mortar: Influence of coating thickness and formulation[J]. Composites Part B:Engineering, 2018, 149: 135-143. doi: 10.1016/j.compositesb.2018.05.023 [12] ZAMIR M, SRIPADA R, PELED A. Hybrid fillers in carbon-fabric-reinforced cement-based composites[J]. Cement and Concrete Composites, 2019, 98: 113-124. doi: 10.1016/j.cemconcomp.2019.02.005 [13] GUO S, REN J, YANG T, et al. Influences of surface treatment on the mechanical performances of carbon and basalt textiles-reinforced concretes under harsh environments[J]. Composites Part B:Engineering, 2022, 246: 110195. doi: 10.1016/j.compositesb.2022.110195 [14] ZHU D, BAI X, YAO Q, et al. Effects of volume fraction and surface coating of textile yarns on the tensile performance of AR-glass textile reinforced concrete[J]. Journal of Building Engineering, 2023, 71: 106420. doi: 10.1016/j.jobe.2023.106420 [15] BENMOKRANE B, ELGABBAS F, AHMED E A, et al. Characterization and Comparative Durability Study of Glass/Vinylester, Basalt/Vinylester, and Basalt/Epoxy FRP Bars[J]. Journal of Composites for Construction, 2015, 19(6): 04015008. doi: 10.1061/(ASCE)CC.1943-5614.0000564 [16] IPAKCHI H, SHEGEFT A, REZADOUST A M, et al. Bio-resourced furan resin as a sustainable alternative to petroleum-based phenolic resin for making GFR polymer composites[J]. Iranian Polymer Journal, 2020, 29(4): 287-299. doi: 10.1007/s13726-020-00793-w [17] ELDRIDGE A, FAM A. Environmental Aging Effect on Tensile Properties of GFRP Made of Furfuryl Alcohol Bioresin Compared to Epoxy[J]. Journal of Composites for Construction, 2014, 18(5): 04014010. doi: 10.1061/(ASCE)CC.1943-5614.0000467 [18] FILIPPOU C A, CHRYSOSTOMOU C Z. Analytical model for textile reinforced mortar under monotonic loading[J]. Construction and Building Materials, 2020, 258: 120178. doi: 10.1016/j.conbuildmat.2020.120178 [19] AVESTON J, KELLY A. Theory of multiple fracture of fibrous composites[J]. Journal of Materials Science, 1973, 8(3): 352-362. doi: 10.1007/BF00550155 [20] ACI 549.4 R-13 Guide to Design and Construction of Externally Bonded FabricReinforced Cementitious Matrix (FRCM) Systems for repair and strengthening concrete and masonry structures: [S]. American: American Concrete Institute, 2013. [21] 徐虹, 张可, 卢岩, 等. 玄武岩纤维-碳纤维混杂平纹织物增强环氧树脂基复合材料的制备与力学性能[J]. 复合材料学报, 2018, 35(04): 767-773. doi: 10.13801/j.cnki.fhclxb.20170704.001XU Hong, ZHANG Ke, LU Yan, WANG Xianghui, LIU Shuan, DOU Yanli. Preparation and mechanical properties of carbon-basalt hybrid fiber plain fabric reinforced epoxy resin matrix composites[J]. Acta Materiae Compositae Sinica, 2018, 35(04): 767-773(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170704.001 [22] ASTM D1141-1998(2008) Standard Practice for the Preparation of Substitute Ocean Water: [S]. American: American Society for Testing and Materials, 1998. [23] 朱德举, 李新亮, 李安令. 经纬向纤维体积分数对耐碱玻璃纤维织物增强混凝土拉伸力学性能的影响[J]. 复合材料学报, 2022, 39(01): 322-334. doi: 10.13801/j.cnki.fhclxb.20210306.002ZHU Deju, LI Xinliang, LI Anling. Influence of warp and weft fiber volume fractions on tensile mechanical properties of alkali-resistant glass textile reinforced concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(01): 322-334(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210306.002 [24] 中国国家标准化管理委员会. 碳纤维复丝拉伸性能试验方法: GB/T 3362-2017: [S]. 北京: 中国标准出版社, 2017.Standardization Administration of the People’s Republic of China. Test methods for tensile properties of carbon fiber multifilament: GB/T 3362—2017[S]. Beijing: China Standards Press, 2017(in Chinese). [25] YI Y, ZHU D, GUO S, et al. A review on the deterioration and approaches to enhance the durability of concrete in the marine environment[J]. Cement and Concrete Composites, 2020, 113: 103695. doi: 10.1016/j.cemconcomp.2020.103695 [26] DONG Z, WU G, ZHAO X-L, et al. Durability test on the flexural performance of seawater sea-sand concrete beams completely reinforced with FRP bars[J]. Construction and Building Materials, 2018, 192: 671-682. doi: 10.1016/j.conbuildmat.2018.10.166 [27] DU Y, ZHANG M, ZHOU F, et al. Experimental study on basalt textile reinforced concrete under uniaxial tensile loading[J]. Construction and Building Materials, 2017, 138: 88-100. doi: 10.1016/j.conbuildmat.2017.01.083 [28] WEI B, CAO H, SONG S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater[J]. Corrosion Science, 2011, 53(1): 426-431. doi: 10.1016/j.corsci.2010.09.053 [29] LOPEZ DE VERGARA U, SARRIONANDIA M, GONDRA K, et al. Polymerization and curing kinetics of furan resins under conventional and microwave heating[J]. Thermochimica Acta, 2014, 581: 92-99. doi: 10.1016/j.tca.2014.02.017 [30] GUO X, XIONG C, JIN Z, et al. A review on mechanical properties of FRP bars subjected to seawater sea sand concrete environmental effects[J]. Journal of Building Engineering, 2022, 58: 105038. doi: 10.1016/j.jobe.2022.105038 -

点击查看大图

点击查看大图

计量

- 文章访问数: 126

- HTML全文浏览量: 80

- 被引次数: 0

下载:

下载: