Synergistic flame retardant effect of lignin containing silicon-nitrogen with ammonium polyphosphate on polylactic acid

-

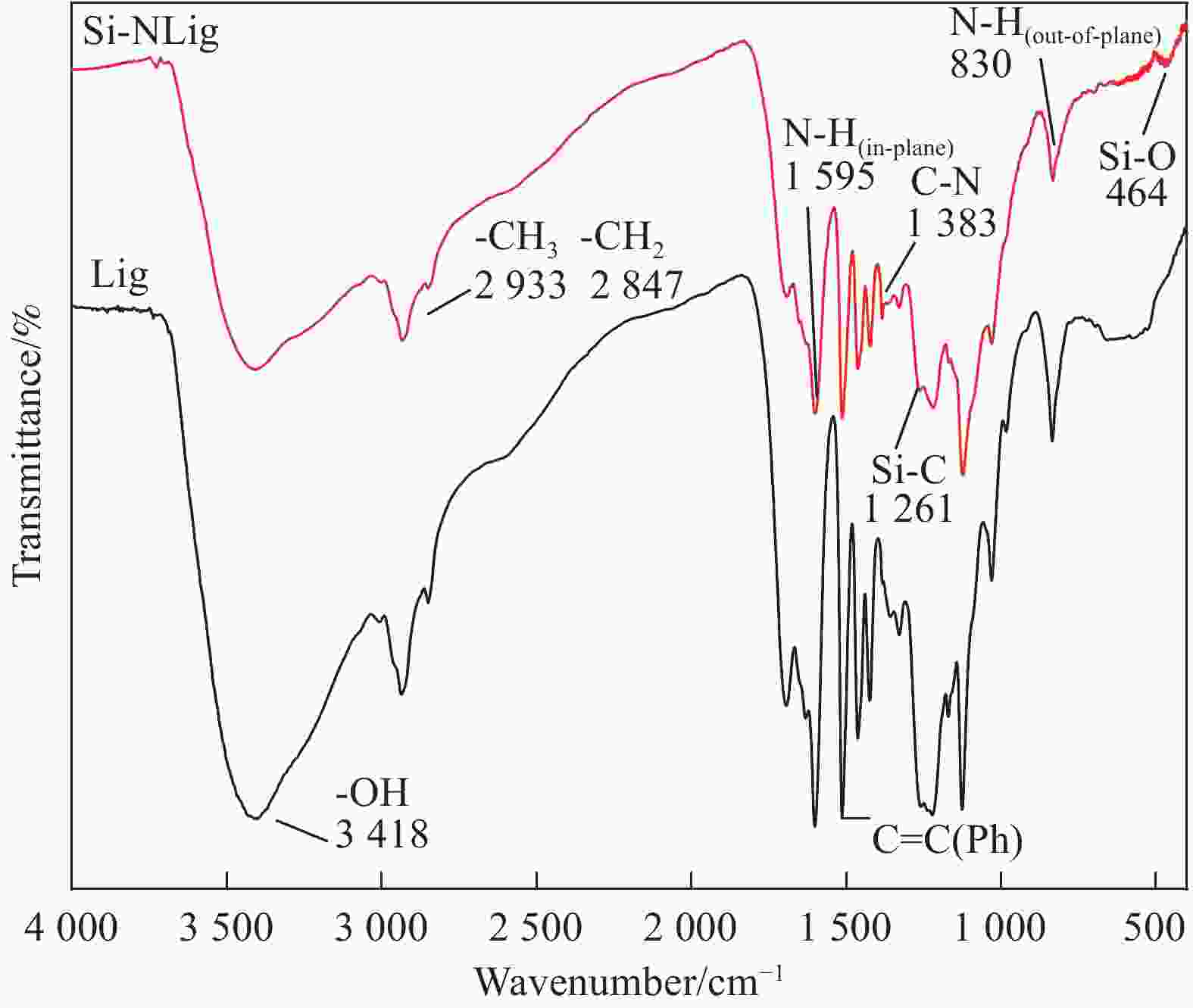

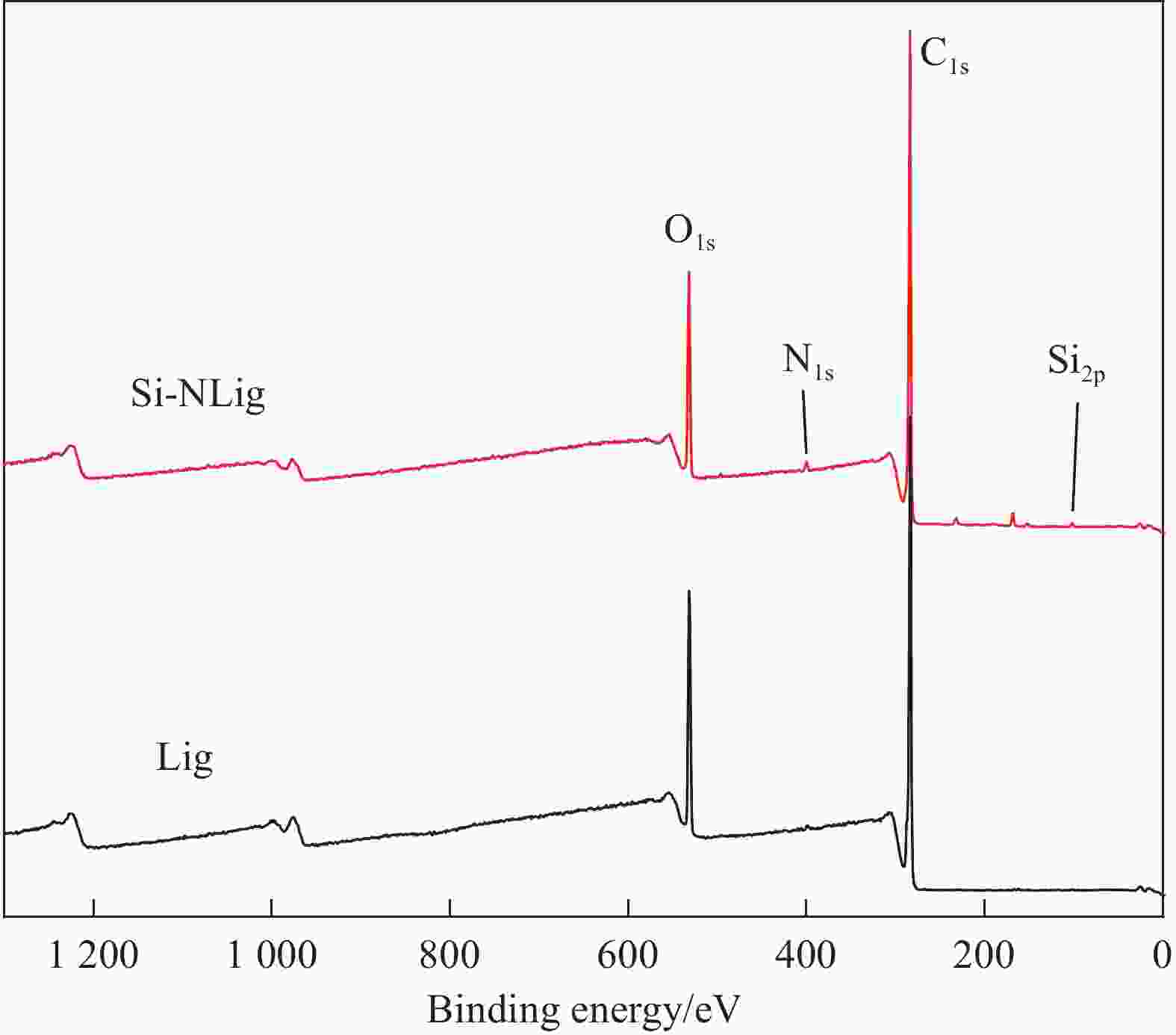

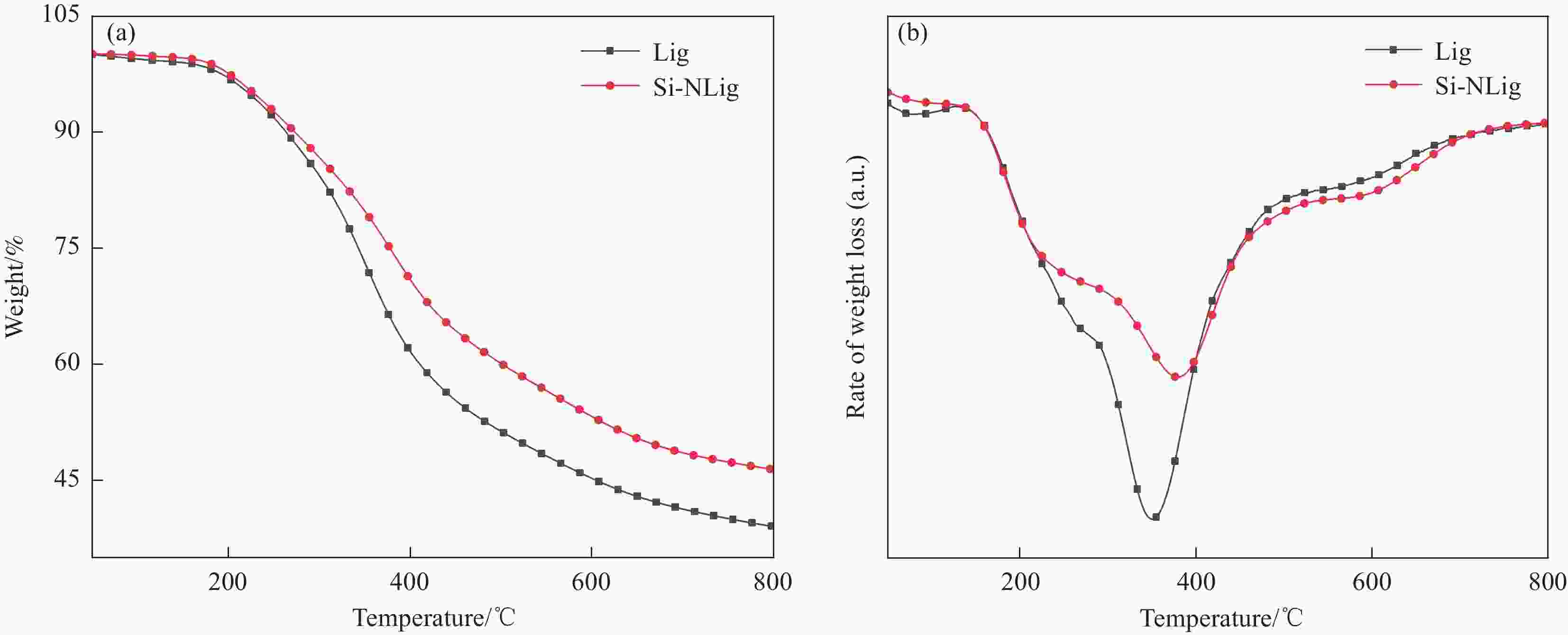

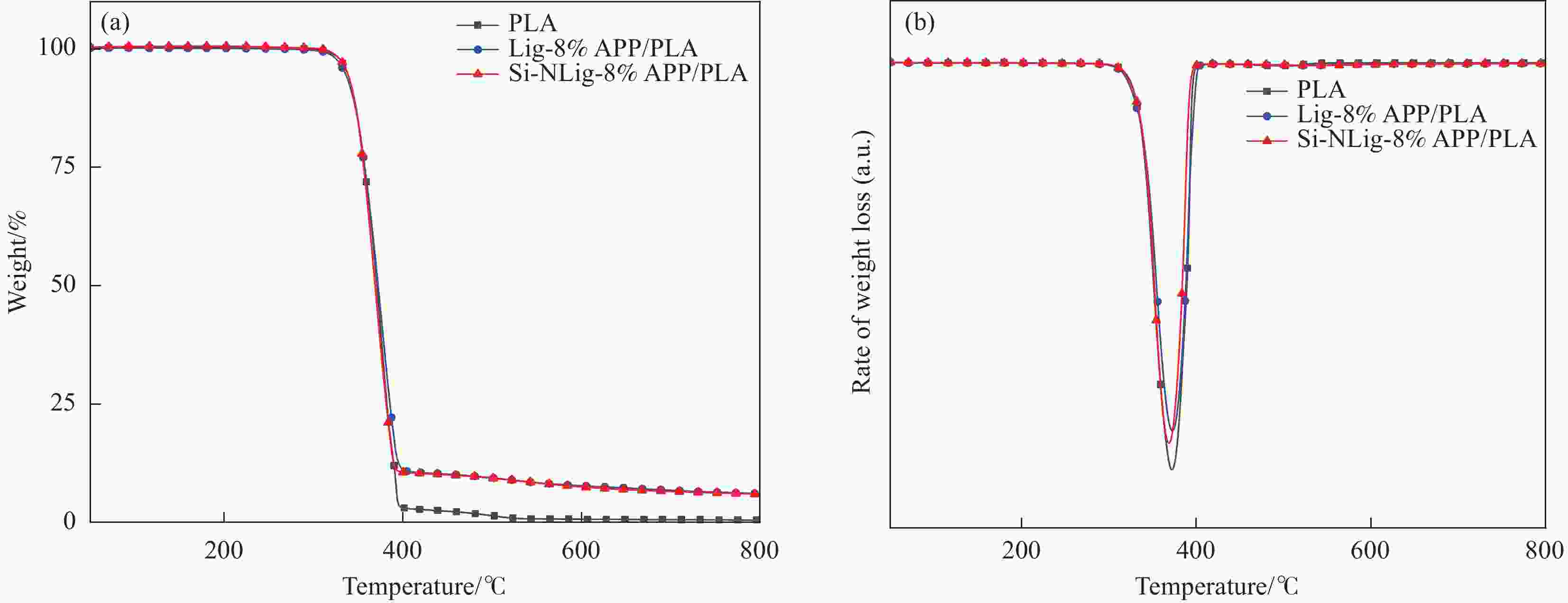

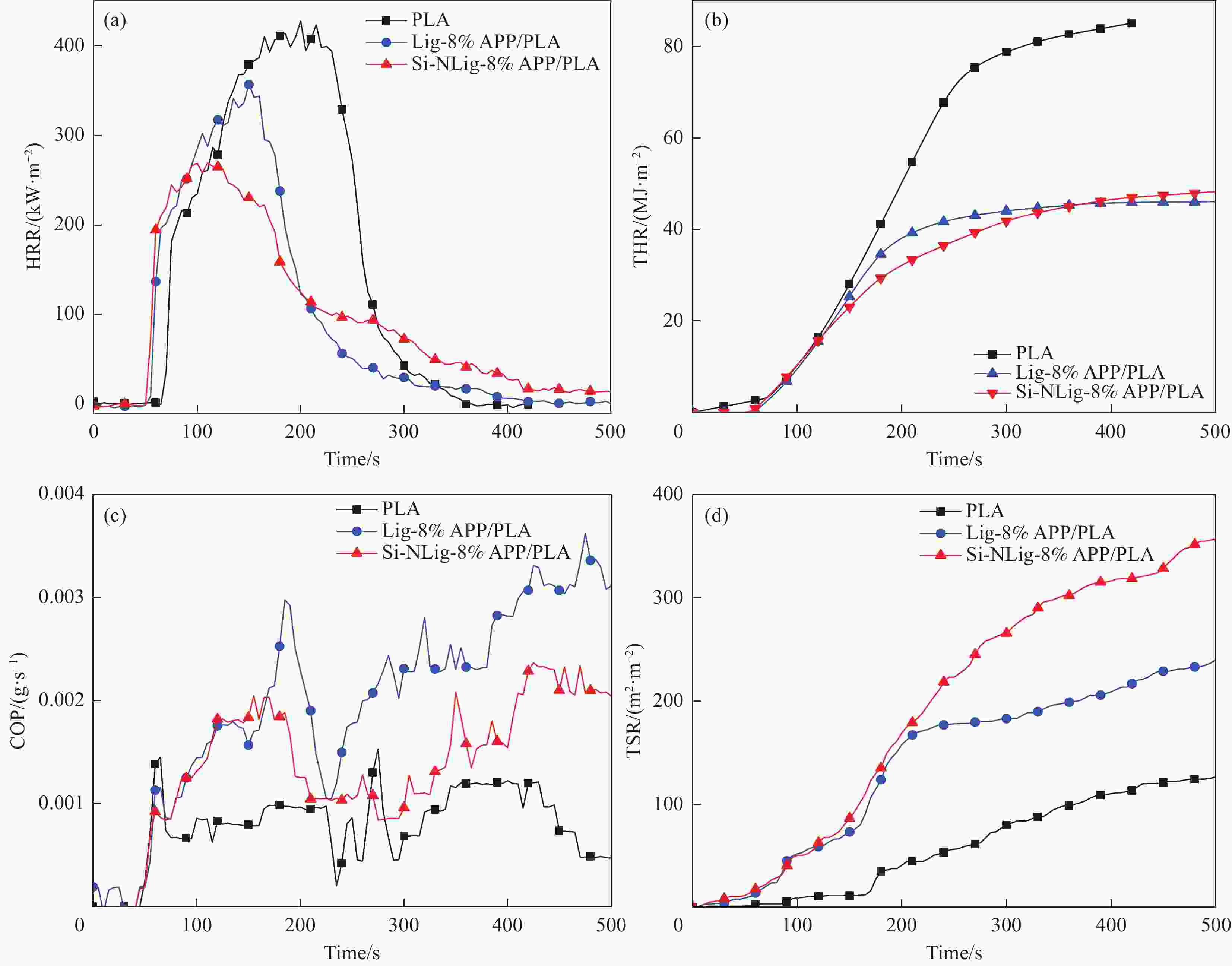

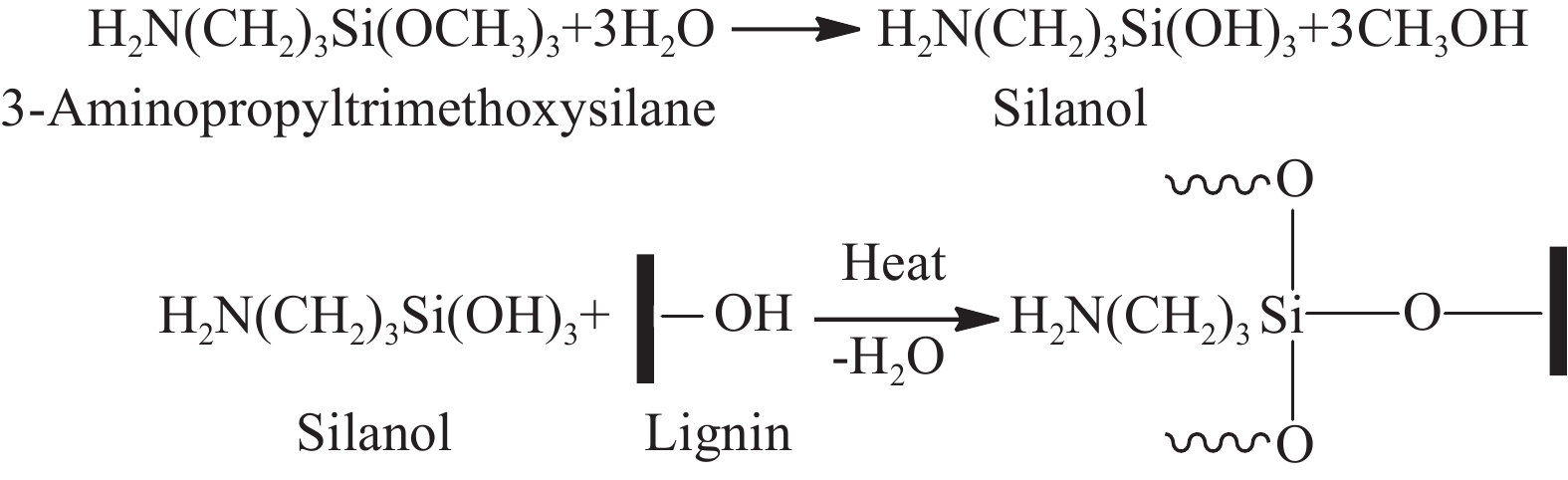

摘要: 聚乳酸(PLA)作为生物基可降解塑料逐渐成为研究热点,但由于其极易燃烧,在包装、电器等领域的应用受到限制,为了解决此类问题,对碱木质素(Lig)改性合成了含硅-氮元素的木质素(Si-NLig),通过热失重分析(TGA)发现,Si-NLig在空气中的T5%提高了20 ℃,且高温残留量由2.3%提高至25.5%。将 Si-NLig作为成炭剂,与聚磷酸铵(APP)复配,通过熔融共混法制成阻燃聚乳酸材料(Si-NLig-APP/PLA),对其阻燃性能、力学性能、燃烧行为等进行了研究。研究表明,Si-NLig与APP质量比为1∶4,10wt%的添加量可使Si-NLig-8%APP/PLA的极限氧指数(LOI)值达到27%,UL-94垂直燃烧达到V-0级别,而同等条件下Lig-8%APP/PLA的LOI值为26%,UL-94仅为V-2级别。同时,与Lig-8%APP/PLA相比,Si-NLig-8%APP/PLA的热释放速率峰值(PHRR)降低了27%;残炭的拉曼光谱分析发现Si-NLig-8%APP/PLA的石墨化程度比Lig-8%APP/PLA提高了36.7%,为其良好的阻燃性能提供了理论依据。Si-NLig的引入使得阻燃PLA力学性能得到了改善,拉伸强度提升了21%。可见Si-NLig在无卤阻燃PLA领域中具有潜在的应用前景。Abstract: Polylactic acid (PLA) as a biobased degradable plastic has increasingly become a research hotspot. However, PLA’s application in packaging and electrical appliances is limited due to its high combustibility. In order to solve the above problem, lignin containing silicon-nitrogen synergistic(Si-NLig) was synthesized by modification of alkali lignin (Lig), and its thermogravimetric analysis (TGA) results showed that the T5% increased by 20℃ and the high temperature residue increased from 2.3% to 25.5% in air. And Si-NLig was used as a charring agent, and compounded with ammonium polyphosphate (APP) to prepared flame retardant polylactic acid (Si-NLig-APP/PLA) by melt blending and hot-press molding, and the PLAs’ flame retardant properties, mechanical properties, and combustion behavior, were investigated. The results showed that addition of 10wt% Si-NLig-APP with the mass ratio 1∶4 made Si-NLig-8%APP/PLA reach the limiting oxygen index (LOI) value of 27% and the vertical burning UL-94 V-0 level, while the LOI value of Lig-8%APP/PLA with Lig as charring agent at the same condition was 26% and the vertical burning UL-94 only passed V-2 rating. Meanwhile, the peak heat release rate (PHRR) reduced by 27% compared to Lig-8%APP/PLA. Raman spectroscopy was used to characterize the structure of the residual char after cone calorimeter testing, it was found that the degree of graphitization of Si-NLig-8%APP/PLA increased by 36.7% compared to that of Lig-8%APP/PLA, which provides a theoretical basis for its good flame retardancy. Introduction of Si-NLig led to the enhancement of mechanical properties of the flame retardant PLA with tensile strength increasing by 21%. It can be seen that Si-NLig has potential application prospect in the field of halogen-free flame retardant PLA.

-

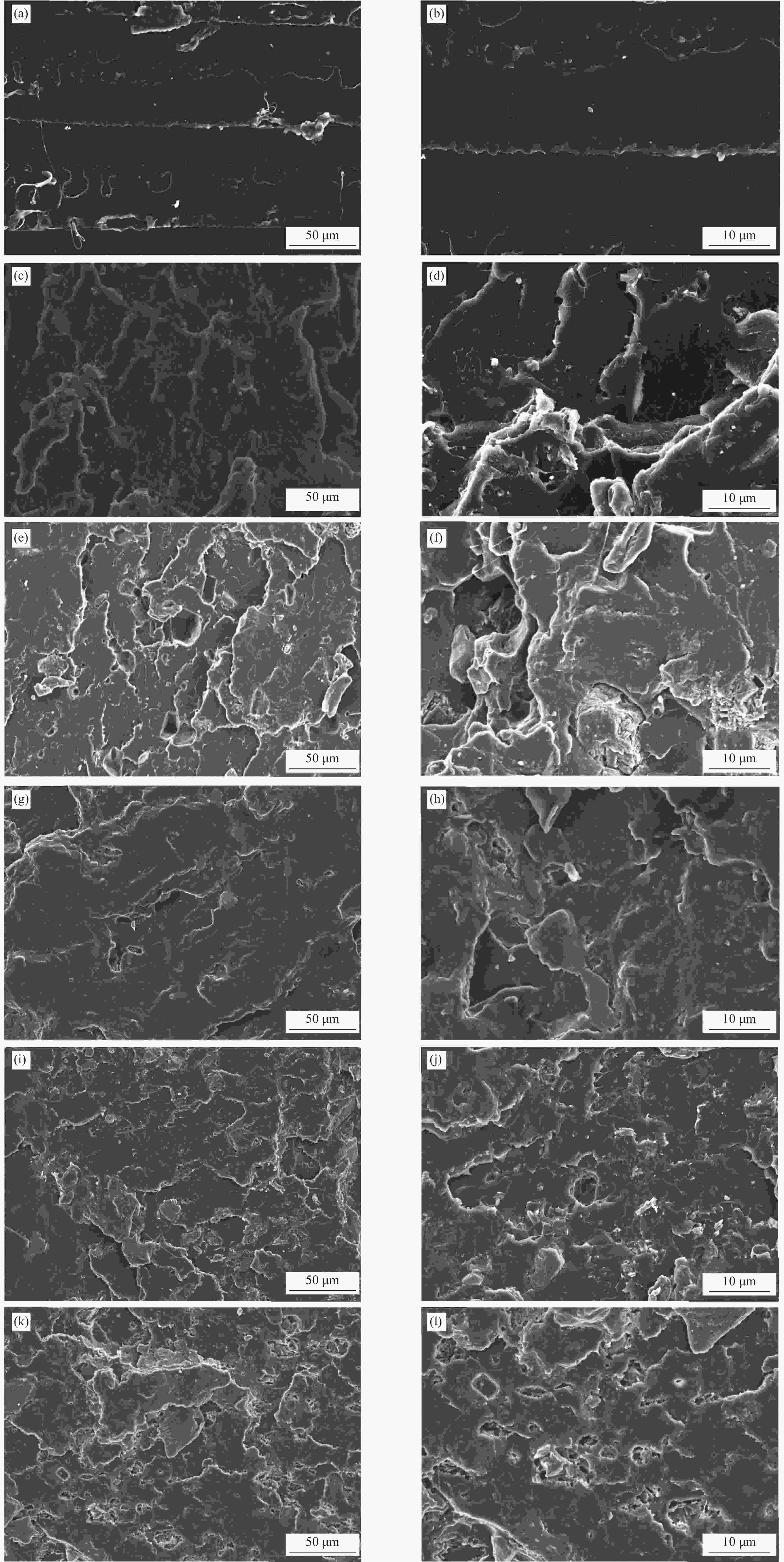

图 6 PLA(a, b)、Lig-8%APP/PLA(c, d)、10%APP/PLA(e, f)、Si-NLig-8%APP/PLA(g, h)、 Si-NLig-12%APP/PLA(i, j)和Si-NLig-16%APP/PLA(k, l)的冲击横截面SEM

Figure 6. SEM of fracture surface of PLA(a, b), Lig-8%APP/PLA(c, d), 10%APP/PLA(e, f), Si-NLig-8%APP/PLA(g, h), Si-NLig-12%APP/PLA (i, j) and Si-NLig-16%APP/PLA (k, l)

表 1 PLA和阻燃PLA配方

Table 1. Formulations of PLA and flame retardant PLA

Sample PLA /

wt%APP /

wt%Lig /

wt%Si-NLig /

wt%PLA 100 0 0 0 10%APP/PLA 90 10 0 0 Lig-8%APP/PLA 90 8 2 0 Si-NLig-6.4%APP/PLA 92 6.40 0 1.60 Si-NLig-3.33%APP/PLA 90 3.33 0 6.67 Si-NLig-6%APP/PLA 90 6 0 4 Si-NLig-6.67%APP/PLA 90 6.67 0 3.33 Si-NLig-8%APP/PLA 90 8 0 2 Si-NLig-12%APP/PLA 85 12 0 3 Si-NLig-16%APP/PLA 80 16 0 4 Notes: PLA- Polylactic acid; APP - Ammonium polyphosphate. 表 2 Lig和Si-NLig的元素组成

Table 2. Element contents of Lig and Si-NLig obtained by XPS

Sample C / (At.%) O / (At.%) N / (At.%) Si / (At.%) Lig 81.16 18.41 0.43 -- Si-NLig 80.16 15.81 1.28 1.45 表 3 Lig和Si-NLig空气氛围下的热降解参数

Table 3. Thermal degradation parameters of Lig and Si-NLig in air

Sample T5% / ℃ Tmax / ℃ Vmax / (%·min−1) Residue at 550℃/ % Tmax1 Tmax2 Tmax3 Vmax1 Vmax2 Vmax3 Lig 212 270 371 500 2.8 4.0 15.9 2.3 Si-NLig 232 317 474 556 7.5 5.4 5.3 25.5 Notes: T5% - Temperature corresponding to mass loss 5% of material; Tmax - Temperature corresponding to the maximum thermal degradation rate; Vmax - Degradation rate at the maximum degradation temperature. 表 4 Lig和Si-NLig氮气氛围下的热失重参数

Table 4. Thermal degradation parameters of Lig and Si-NLig in N2

Sample T5% / ℃ Tmax / ℃ Vmax / (%·min−1) Residue at 700℃ / % Lig 222 350 5.5 41.3 Si-NLig 228 377 3.7 48.6 Notes: T5% - Temperature corresponding to mass loss 5% of material; Tmax - Temperature corresponding to the maximum thermal degradation rate; Vmax - Degradation rate at the maximum degradation temperature. 表 5 PLA和阻燃PLA阻燃性能测试结果

Table 5. Results of flame retardant performances for PLA and flame retardant PLA

Sample LOI / % UL-94 vertical burning t1 / s t2 / s Rating Dripping Ignition cotton PLA 19.5 >60 -- NR YES YES 10%APP/PLA 28 2 1 V-0 YES NO Lig-8%APP/PLA 26 5 2 V-2 YES YES Si-NLig-6.4%APP/PLA 27 3 1 V-2 YES YES Si-NLig-3.33%APP/PLA 25 6 1 V-2 YES YES Si-NLig-6%APP/PLA 27 9 7 V-2 YES YES Si-NLig-6.67%APP/PLA 27 4 0 V-2 YES YES Si-NLig-8%APP/PLA 27 2 0 V-0 YES NO Si-NLig-12%APP/PLA 28 1 0 V-0 YES NO Si-NLig-16%APP/PLA 30 0 0 V-0 YES NO Notes: t1/ t2 - Duration of sample burning; LOI - Limiting oxygen index. 表 6 PLA和阻燃PLA力学性能测试结果

Table 6. Test results of mechanical properties of PLA and flame retardant PLA

Sample Tensile strength

/ MPaElongation at break

/ %Impact strength

/ (kJ·m-2)PLA 70.0±4.6 14.2±0.9 5.6±0.3 10%APP/PLA 39.8±1.1 10.7±1.4 4.5±0.1 Lig-8%APP/PLA 51.9±2.9 9.9±0.7 4.7±0.4 Si-NLig-8%APP/PLA 62.8±3.1 8.3±1.1 5.5±0.4 Si-NLig-12%APP/PLA 65.8±4.3 8.1±0.6 4.5±0.1 Si-NLig-16%APP/PLA 49.1±3.9 8.0±0.6 3.8±0.5 表 7 PLA和阻燃PLA空气氛围下的热降解参数

Table 7. Thermal degradation parameters of PLA and flame retardant PLA in air

Sample T5% / ℃ Tmax / ℃ Vmax / (%·min−1) Residue at 800℃ / % PLA 337 371 65.7 0 Lig-8%APP/PLA 335 372 59.4 8.4 Si-NLig-8%APP/PLA 337 368 61.3 8.4 Notes: T5% - Temperature corresponding to mass loss 5% of material; Tmax - Temperature corresponding to the maximum thermal degradation rate; Vmax - Degradation rate at the maximum degradation temperature. 表 8 PLA和阻燃PLA的锥形量热仪测试分析结果

Table 8. Cone calorimeter testing analysis results of PLA and flame retardant PLA

Sample TTI / s TPHRR / s PHRR /

(kW·m−2)MHRR /

(kW·m−2)THR /

(MJ·m−2)FPI /

(m2s·kW−1)Mean COY /

(kg·kg−1)Mean CO2Y /

(kg·kg−1)PLA 74 200 411 137.4 79.9 0.158 0.024 4.803 Lig-8%APP/PLA 61 150 356 97.6 45.7 0.171 0.080 4.162 Si-NLig-8%APP/PLA 58 110 269 99.7 48.5 0.216 0.054 4.231 Notes: TTI - Time to ignition; PHRR - Peak heat release rate; THR - Total heat release; TSR - Total smoke release; MHRR - Mean heat release rate. 表 9 Lig-8%APP/PLA和Si-NLig-8%APP/PLA炭层的拉曼光谱分析结果

Table 9. Raman spectroscopic analysis results of residual carbon in Lig-8%APP/PLA and Si-NLig-8%APP/PLA

Sample AD AG AD/AG Lig-8%APP/PLA 1024 327 3.13 Si-NLig-8%APP/PLA 1290 651 1.98 -

[1] DENG S, BAI H Z, LIU Z W, et al. Toward supertough and heat-resistant stereocomplex-type Polylactide/elastomer blends with impressive melt stability via in situ formation of graft copolymer during one-pot reactive melt blending[J]. Macromolecules, 2019, 52(4): 1718-1730. doi: 10.1021/acs.macromol.8b02626 [2] SHI W Y, CHEN Z Z. Mechanical, rheological, and crystallinity properties of polylactic acid/polyethylene glycol-polydimethylsiloxane copolymer blends by melt blending[J]. Journal of Applied Polymer Science, 2022, 140(4): 1-11. [3] Makovicka L O , Katarina K , Hua S L , et al. Ignition and burning of selected tree species from tropical and northern temperate zones[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6 (2): 195-202. [4] 于文灏. 聚乳酸/含磷阻燃剂共混物的制备及性能研究 [D]. 江南大学, 2022.YU Wenhao. Preparation and properties of polylactic acid/phosphorus containing flame retardant blends [D]. Jiangnan University, 2022(in Chinese). [5] YANG W J, ZHOU Q K, PAN W H, et al. Synthesis of vanillin-based porphyrin for remarkably enhancing the toughness, UV-resistance and self-extinguishing properties of polylactic acid[J]. Chemical Engineering Journal, 2023, 469: 143935. doi: 10.1016/j.cej.2023.143935 [6] 王自博, 吕锦翔, 肖丹. 基于生物材料阻燃PLA研究进展[J]. 塑料科技, 2022, 50(07): 96-100. doi: 10.15925/j.cnki.issn1005-3360.2022.07.020WANG Zibo, LU Jinxiang, XIAO Dan. Research progress in flame retardant PLA based on biomaterials[J]. Plastics Science and Technology, 2022, 50(07): 96-100(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2022.07.020 [7] ZHANG D H, PEI M, WEI K, et al. Flame retardant properties and mechanism of polylactic acid-conjugated flame retardant composites[J]. Frontiers in Chemistry, 2022, 10: 894112. doi: 10.3389/fchem.2022.894112 [8] WANG C, WU Y C, LI Y C, et al. Flame-retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant[J]. Polymers for Advanced Technologies, 2018, 29(1): 668-676. doi: 10.1002/pat.4105 [9] ORTA O R, WESSEELINK A K, BETHEA T N, et al. Brominated flame retardants and organochlorine pesticides and incidence of uterine leiomyomata: A prospective ultrasound study[J]. Environmental Epidemiology, 2021, 5(1): e127. doi: 10.1097/EE9.0000000000000127 [10] 贝钰, 翁述贤, 贾普友, 等. 木质素基阻燃剂的研究进展[J]. 生物质化学工程, 2023, 57 (02): 71-78.BEI Jue, WENG Shuxian, JIA Puyou, etc. Research progress of lignin based flame retardants[J]. Biomass Chemical Engineering, 2023, 57 (02): 96-100 (in Chinese). [11] ZHAN Y Y, WU X J, WANG S S, et al. Synthesis of a bio-based flame retardant via a facile strategy and its synergistic effect with ammonium polyphosphate on the flame retardancy of polylactic acid[J]. Polymer Degradation and Stability, 2021, 191: 109684. doi: 10.1016/j.polymdegradstab.2021.109684 [12] 靳昕怡, 窦娟, 魏丽菲, 等. 无卤阻燃剂在聚合物阻燃中的应用研究进展[J]. 高科技纤维与应用, 2022, 47(6): 67-73. doi: 10.3969/j.issn.1007-9815.2022.06.011JIN Xinyi, DOU Juan, WEI Lifei, et al. Research on the application of halogen-free flame retardant in polymer flame retardants[J]. Hi-Tech Fiber and Application, 2022, 47(6): 67-73(in Chinese). doi: 10.3969/j.issn.1007-9815.2022.06.011 [13] 王菁, 陈蕾, 李圣军, 等. 添加型阻燃剂的研究进展与发展趋势[J]. 合成纤维工业, 2022, 45(5): 69-74. doi: 10.3969/j.issn.1001-0041.2022.05.013WANG Jing, CHEN Lei, LI Shengjun, et al. Research progress and development trend of additive flame retardants[J]. China Synthetic Fiber Indutry, 2022, 45(5): 69-74(in Chinese). doi: 10.3969/j.issn.1001-0041.2022.05.013 [14] Federico U , Carlo B , Martina R , et al. Synthesis of sustainable flame retarded polypropylene by using waste material[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6 (2): 165-171. [15] 王丽琼, 李立影, 梁洁, 等. 三嗪和磷腈阻燃剂作碳源阻燃聚乳酸复合材料的性能研究[J]. 安全与环境学报, 2021, 21(03): 1040-1047. doi: 10.13637/j.issn.1009-6094.2019.1640WANG Liqiong, LI Liying, LIANG Jie, et al. Effect to be gained by using the triazine and phosphazene flame retardants as carbon sources on the properties of polylactic acid[J]. Journal of Safety and Environment, 2021, 21(03): 1040-1047(in Chinese). doi: 10.13637/j.issn.1009-6094.2019.1640 [16] YAO Z Y, QIAN L J, QIU Y, et al. Flame retardant and toughening behaviors of bio-based DOPO-containing curing agent in epoxy thermoset[J]. Polymers for Advanced Technologies, 2020, 31(3): 461-471. doi: 10.1002/pat.4782 [17] MA D, LI J. Synthesis of a bio-based triazine derivative and its effects on flame retardancy of polypropylene composites[J]. Journal of Applied Polymer Science, 2020, 137(1): 245-253. [18] 白毓黎, 白富栋, 张通等. 木质素基阻燃剂制备的研究进展[J]. 当代化工, 2020, 49(10): 2314-2317. doi: 10.3969/j.issn.1671-0460.2020.10.049BAI Yuli, BAI Fudong, ZHANG Tong, etc. Research progress of lignin-based flame retardant[J]. Contemporary Chemical Industry, 2020, 49(10): 2314-2317(in Chinese). doi: 10.3969/j.issn.1671-0460.2020.10.049 [19] XIA Y R, CAI W H , LIU Y H, et al. Facile fabrication of starch-based, synergistic intumescent and halogen-free flame retardant strategy with expandable graphite in enhancing the fire safety of polypropylene[J]. Industrial Crops & Products, 2022, 184: 115002. [20] ZHANG L Y, XUE W, GU L M. Study on properties and application of pyrophosphate flame retardant microcapsules prepared from hemicellulose maleate[J]. Cellulose, 2020, 27(7): 3931-3946. doi: 10.1007/s10570-020-03045-5 [21] WANG M T, YIN G Z, YANG Y, et al. Bio-based flame retardants to polymers: A review[J]. Advanced Industrial and Engineering Polymer Research, 2023, 6(2): 132-155. doi: 10.1016/j.aiepr.2022.07.003 [22] CARVALHO R M, SILVA D P S R, VEIGA S R N, et al. The influence of montmorillonite on the flame-retarding properties of intumescent bio-based PLA composites[J]. Journal of Applied Polymer Science, 2022, 139(22): 52243. doi: 10.1002/app.52243 [23] YANG H T, YU B, XU X D, et al. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials[J]. Green Chemistry, 2020, 22: 2129-2161. doi: 10.1039/D0GC00449A [24] ZHANG R, XIAO X F, TAI Q L. Modification of lignin and its application as char agent in intumescent flame-retardant poly(lactic acid)[J]. Polymer engineering and science, 2012, 52(12): 2620-2626. doi: 10.1002/pen.23214 [25] 中国国家标准化管理委员会. 塑料 用氧指数法测定燃烧行为, GB/T2406-2008[S]. 北京, 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Plastics determination of combustion behavior using the oxygen index method, GB/T2406-2008 [S]. beijing, China Standards Press, 2008(in Chines). [26] 中国国家标准化管理委员会. 塑料 燃烧性能的测定 水平法和垂直法, GB/T 2408-2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People's Republic of China. Determination of burning properties of plastics-horizontal and vertical methods, GB/T 2408-2021 [S]. Beijing: China Standards Press, 2021(in Chinese). [27] ISO. Reaction-to-fire tests-Heat release, smoke production and mass loss rate−part 1: heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement): ISO 5660-1: 2015 [S]. Geneva: ISO, 2015. [28] 中国国家标准化管理委员会. 塑料拉伸性能的测定第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2−2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People's Republic of China. Plastics-determination of tensile properties-part 2: test conditions for moulding and extrusion plastics: GB/T 1040.2−2006 [S]. Beijing: China Standards Press, 2006(in Chinese). [29] 中国国家标准化管理委员会. 塑料悬臂梁冲击强度的测定: GB/T 1843−2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Plastics−determination of izod impact strength: GB/T 1843−2008 [S]. Beijing: China Standards Press, 2008(in Chinese). [30] 杨晓涵, 宋艳, 林肯等. 木质素基成炭剂的制备及在膨胀阻燃聚丙烯的应用[J]. 高分子材料科学与工程, 2022, 38(12): 39-46. doi: 10.16865/j.cnki.1000-7555.2022.0270YANG Xiaohan, SONG Yan, LIN Ken, etc. Preparation of lignin-based char-forming agent and its application in intumescent flame retardant polypropylene[J]. Polymer Materials Science and Engineering, 2022, 38(12): 39-46(in Chinese). doi: 10.16865/j.cnki.1000-7555.2022.0270 [31] OTT M W, DIETZ C, TROSIEN S, et al. Co-curing of epoxy resins with aminated lignins: insights into the role of lignin homo crosslinking during lignin amination on the elastic properties[J]. Holzforschung, 2021, 75(4): 390-398. doi: 10.1515/hf-2020-0060 [32] YANG H C, PU H T, GONG F H. Preparation of poly (methyl methacrylate)-grafted attapulgite by surface-Initiated radical polymerization[J]. Journal of Applied Polymer Science, 2014, 131(22): 1725-1730. [33] SONG Y, LI J C, YAN N, et al. Preparation of γ-divinyl-3-aminopropyltriethoxysilane modified lignin and its application in flame retardant poly(lactic acid)[J]. Materials, 2018, 11(9): 1505. doi: 10.3390/ma11091505 [34] 吴迪超, 陈超, 侯兴隆等. 热解温度对纤维素和木质素成炭结构的影响[J]. 生物质化学工程, 2021, 55(03): 1-9. doi: 10.3969/j.issn.1673-5854.2021.03.001WU Dichao, CHEN Chao, HOU Xinglong, etc. Effect of pyrolysis temperature on structures of chars forming from cellulose and lignin[J]. Biomass Chemical Engineering, 2021, 55(03): 1-9(in Chinese). doi: 10.3969/j.issn.1673-5854.2021.03.001 [35] HU X, SUN J H, LI X, et al. Effect of phosphorus-nitrogen compound on flame retardancy and mechanical properties of polylactic acid[J]. Journal of Applied Polymer Science, 2021, 138(7): 49829. doi: 10.1002/app.49829 [36] 王楠, 宋艳, 李锦春等. 含磷木质素基成炭剂的合成及在阻燃聚丙烯中的应用[J]. 高分子材料科学与工程, 2018, 34(04): 7-13.WANG Nan, SONG Yan, LI Jinchun, etc. Synthesis of lignin-based charring agent containing phosphorus and its application in flame retardant polypropylene[J]. Polymer Materials Science and Engineering, 2018, 34(04): 7-13(in Chinese) [37] JIA L J, HUANG W Z, ZHAO Y J, et al. Ultra-light polylactic acid/combination composite foam: a fully biodegradable flame retardant material[J]. International journal of biological macromolecules, 2022, 220: 754-765. doi: 10.1016/j.ijbiomac.2022.08.093 -

下载:

下载: