Axial compressive performance and design model of fiber wound GFRP tube confined concrete

-

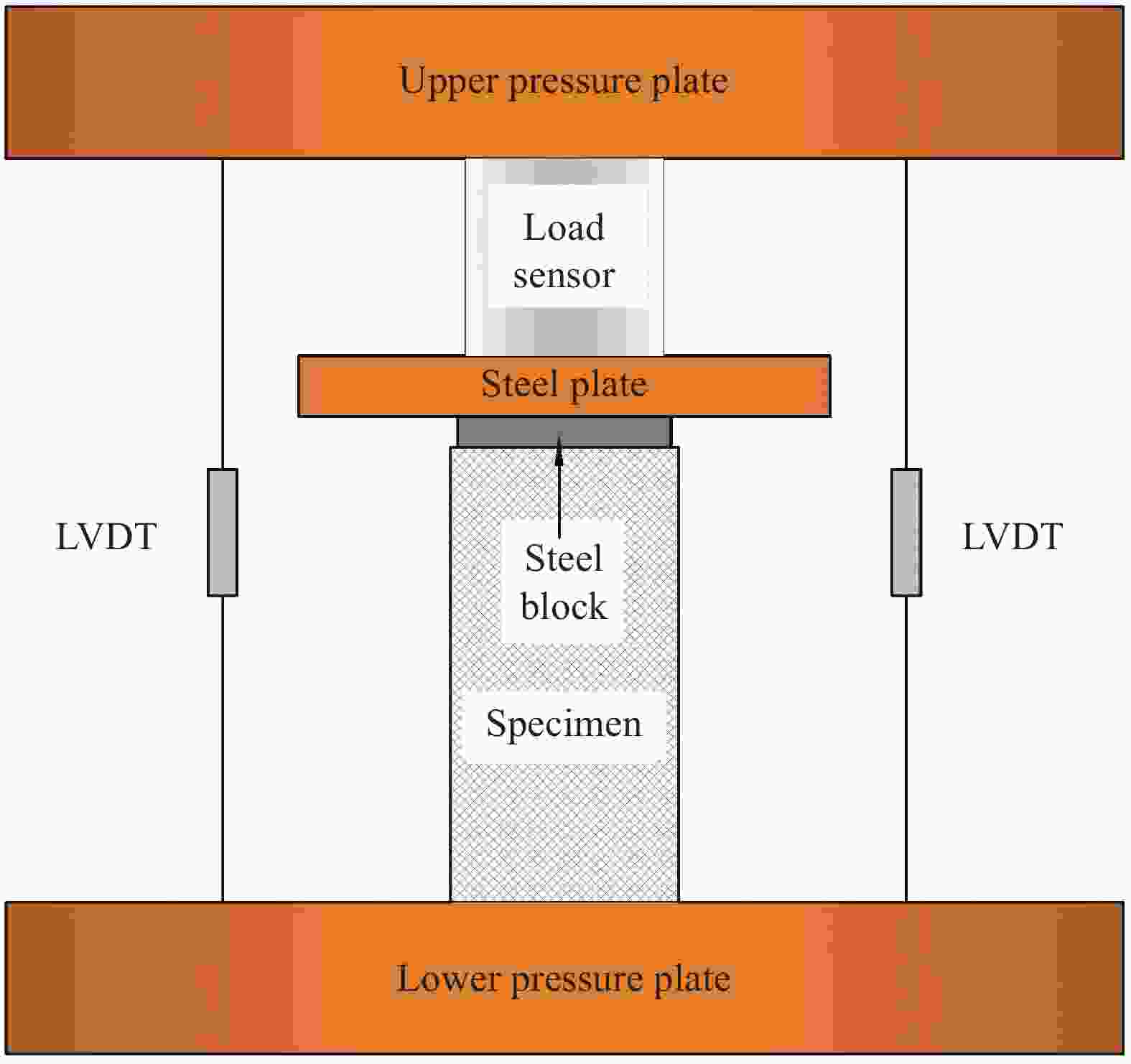

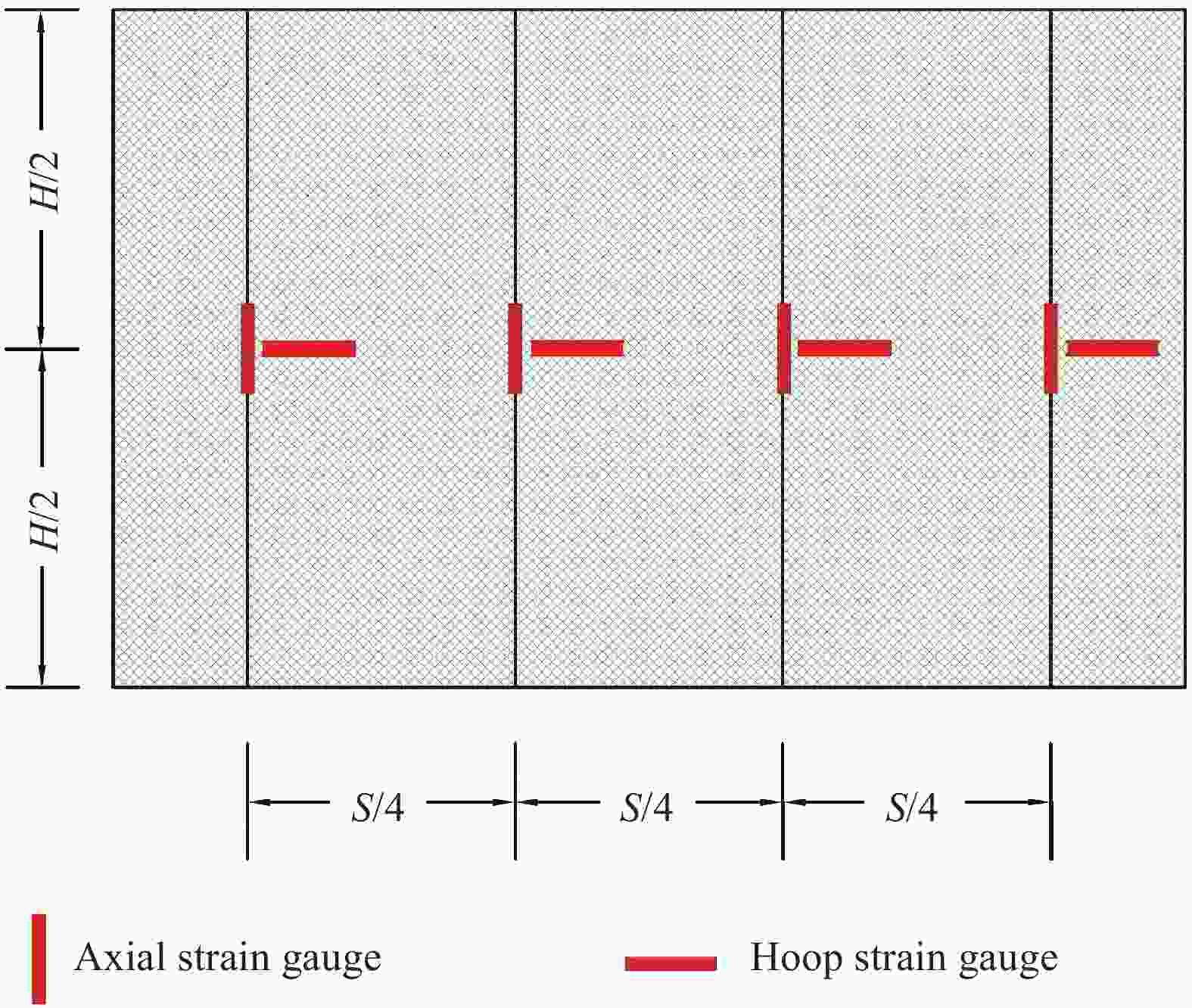

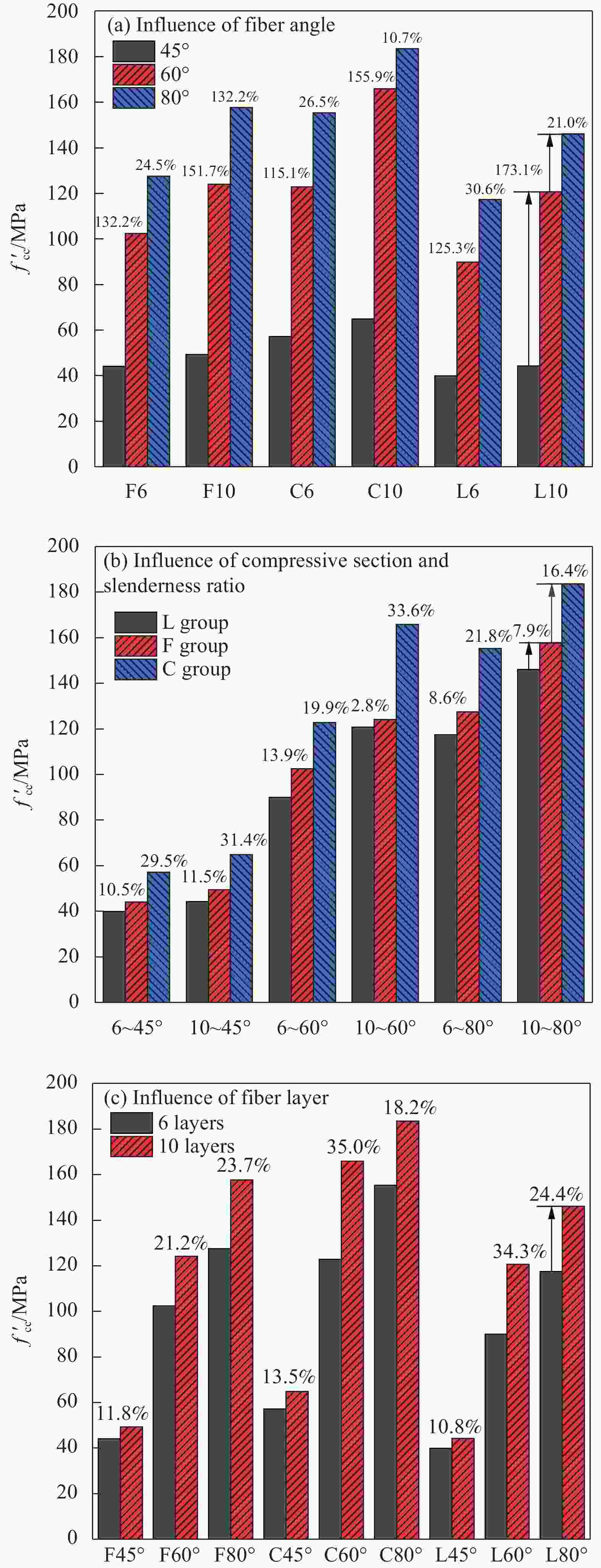

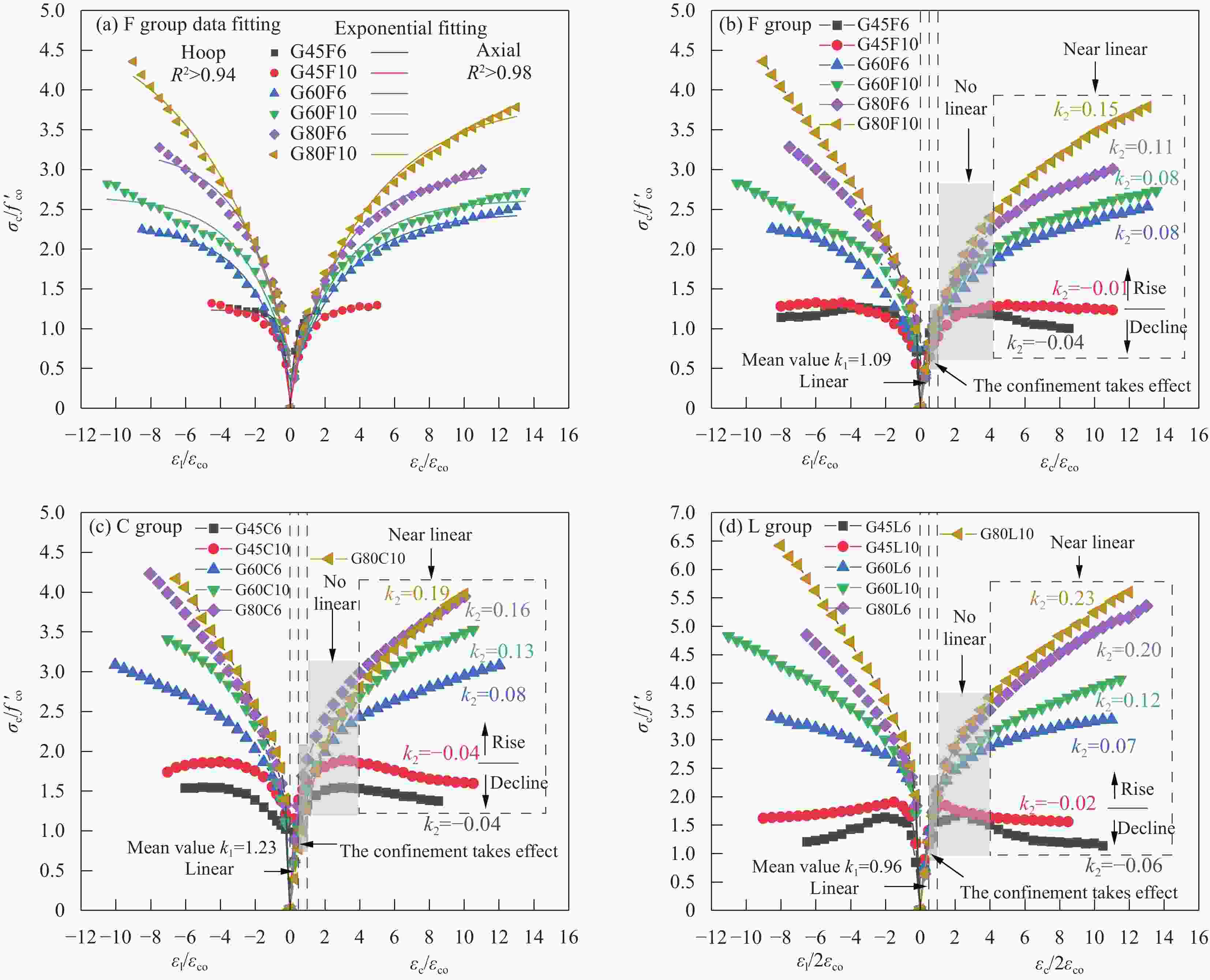

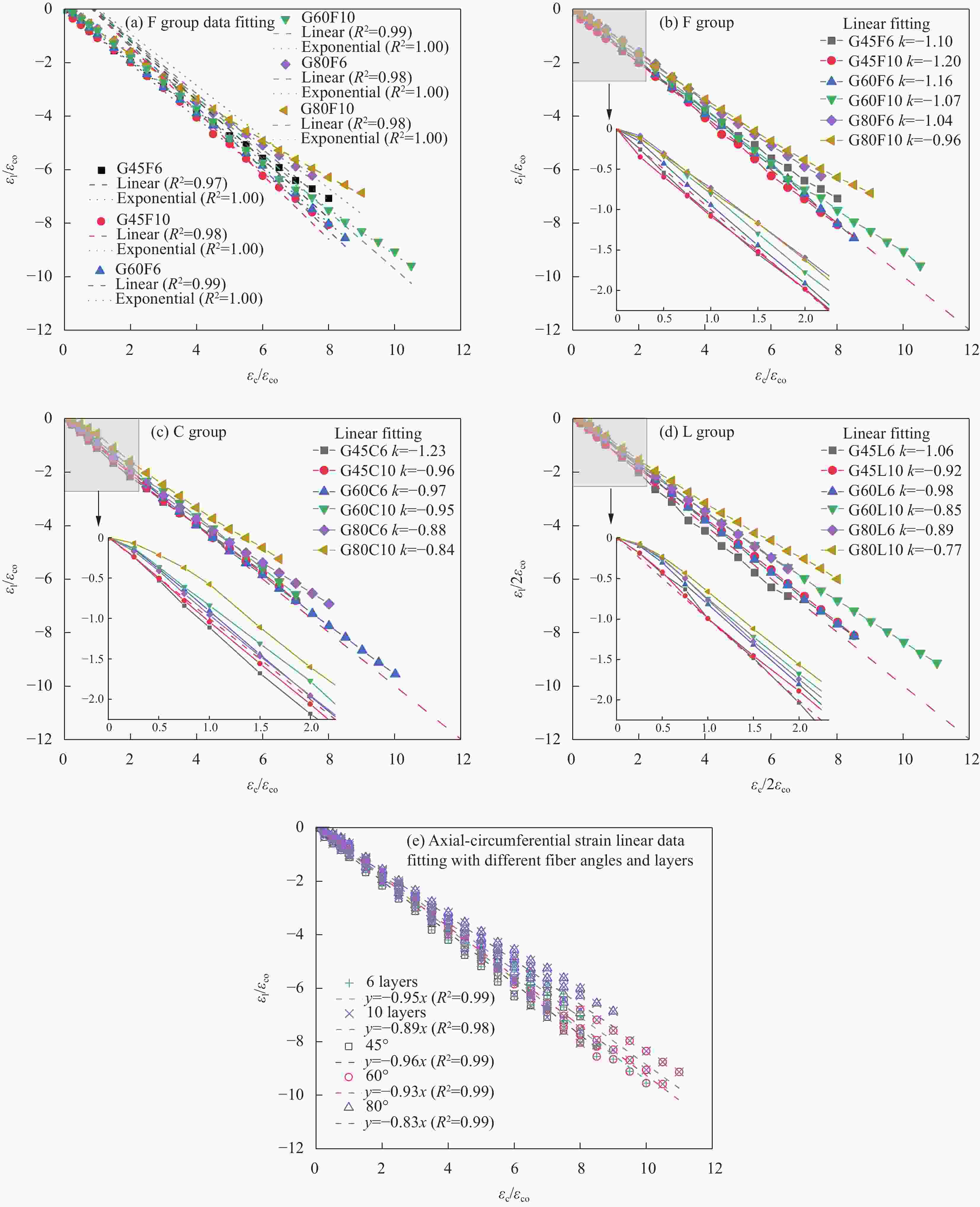

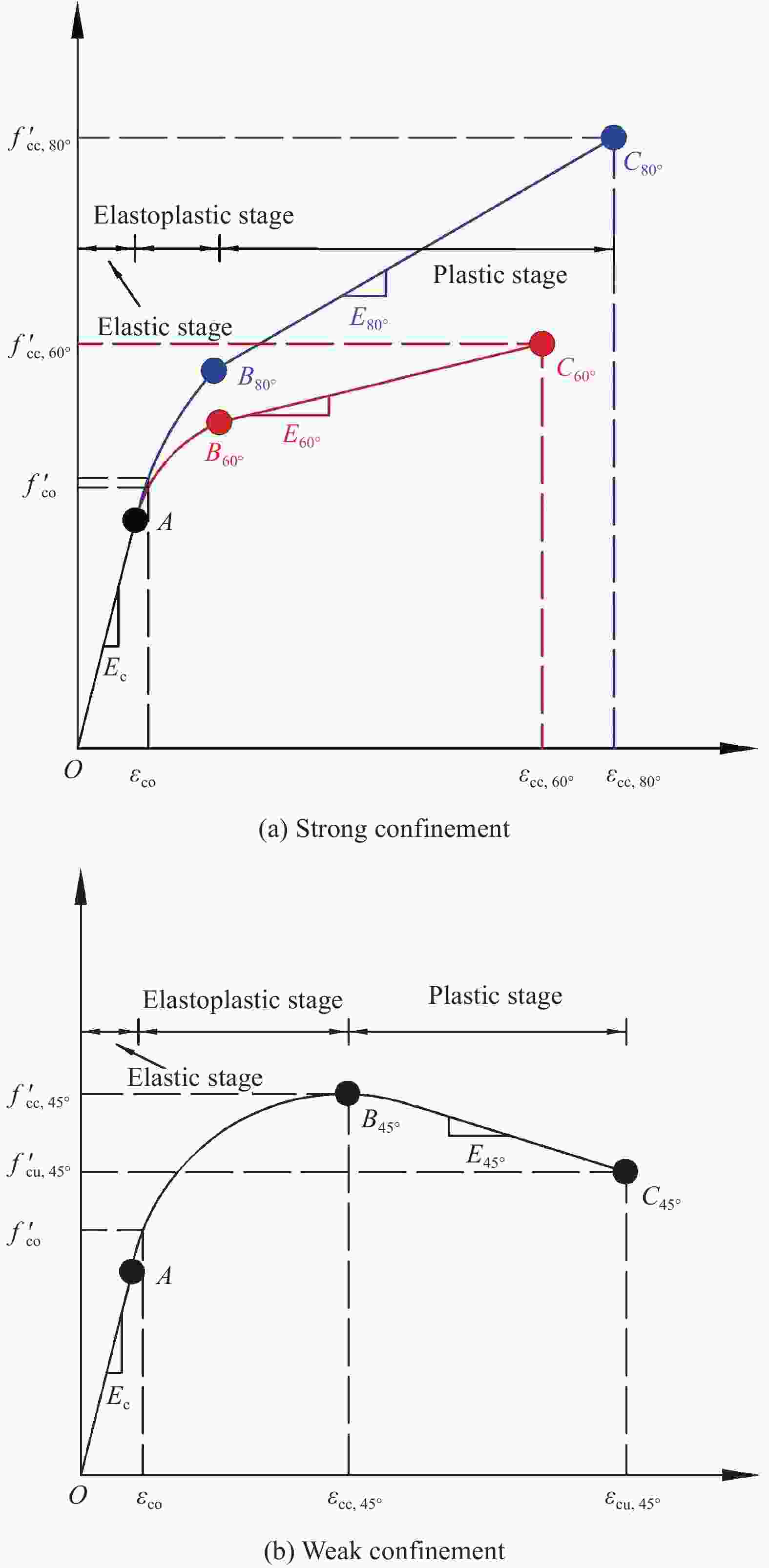

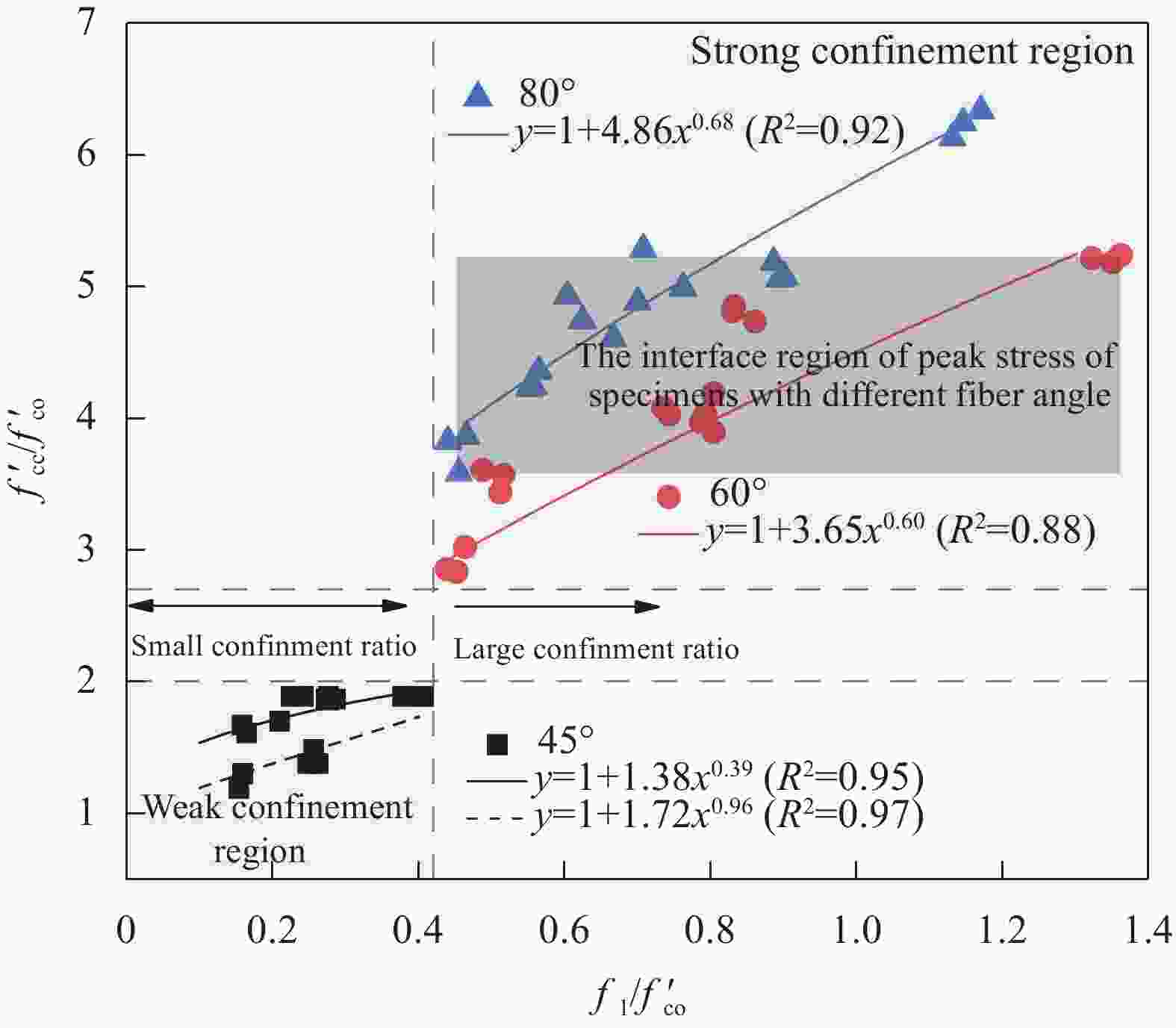

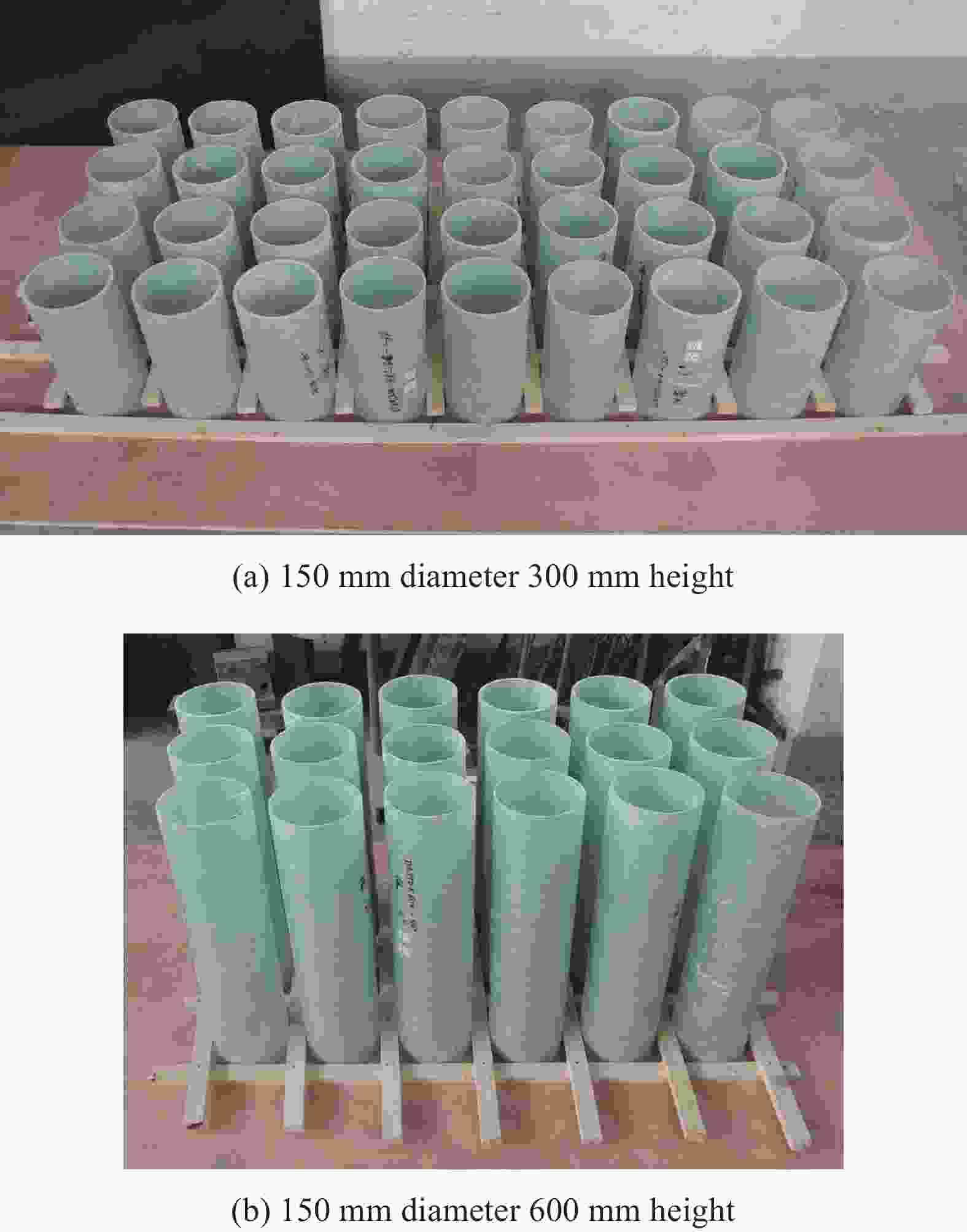

摘要: 设计制作了18组54个纤维缠绕GFRP管约束混凝土圆柱试件,参数包括纤维层数(6、10)、纤维角度($ \pm 45^\circ $、$ \pm 60^\circ $、$ \pm 80^\circ $)、长细比(2、4)和受压截面(全截面、核心混凝土),基于轴心受压试验结果,提出了依据纤维角度的面向设计的峰值应力预测模型。研究结果表明:GFRP管可有效提高约束试件的强度和延性。试件的峰值强度随着纤维角度和层数的增大而增大,长细比大的试件峰值强度的提升幅度更大,全截面受压会对约束试件的环向性能造成不利的影响。约束模式主要由纤维角度决定,其中$ \pm 60^\circ $和$ \pm 80^\circ $角度的试件为强约束,呈脆性破坏,$ \pm 45^\circ $角度的试件为弱约束,呈延性破坏。通过研究峰值强度与有效约束强度之间的数学关系,所得到的面向设计的简化模型,对于求解不同纤维角度试件的峰值强度具有足够的精度,可为相关的工程实际应用提供参考。Abstract: 54 fiber-wound GFRP tube confined concrete cylindrical specimens classified in eighteen groups were designed and manufactured, and the parameters included the number of fiber layers (6, 10), fiber angle ($ \pm 45^\circ $, $ \pm 60^\circ $, $ \pm 80^\circ $), slenderness ratio (2, 4) and compression section (full section, core concrete). Based on the axial compression test results, a design-oriented peak stress prediction model in terms of fiber angle was proposed. The results show that GFRP tube can effectively improve the strength and ductility of confined specimens. The peak strength of the specimen increases with the increase of fiber angle and layer number, and the increase of the peak strength of the specimen with large slenderness ratio is larger. The full section compression will adversely affect the circumferential properties of the confined specimen. The confined pattern is mainly determined by the fiber angle. The specimens with ±60° and ±80° angles are strong confinement, and reveal brittle failure mode. The specimens with ±45° angle are weak confinement, and reveal ductile failure mode. By studying the mathematical relationship between the peak strength and the effective confinement strength, the simplified design-oriented model was derived, which has sufficient precision for solving the peak strength of specimens with different fiber angles, and can provide reference for relevant engineering applications.

-

Key words:

- GFRP tube /

- confined concrete /

- fiber angle /

- axial compressive performance /

- confine pattern /

- design model

-

表 1 纤维缠绕GFRP管约束混凝土试件参数

Table 1. Specimen parameters of fiber wound GFRP tube confined concrete

GroupDiameter×

High/mmCompr-ession

sectionSpecimen number θ/(°) n F 150$ \times $300 Full section G45 F6-1,2,3 $ \pm 45 $ 6 G45 F10-1,2,3 10 G60 F6-1,2,3 $ \pm 60 $ 6 G60 F10-1,2,3 10 G80 F6-1,2,3 $ \pm 80 $ 6 G80 F10-1,2,3 10 L 150$ \times $600 Full section G45 L6-1,2,3 $ \pm 45 $ 6 G45 L10-1,2,3 10 G60 L6-1,2,3 $ \pm 60 $ 6 G60 L10-1,2,3 10 G80 L6-1,2,3 $ \pm 80 $ 6 G80 L10-1,2,3 10 C 150$ \times $300

Core concreteG45 C6-1,2,3 $ \pm 45 $ 6 G45 C10-1,2,3 10 G60 C6-1,2,3 $ \pm 60 $ 6 G60 C10-1,2,3 10 G80 C6-1,2,3 $ \pm 80 $ 6 G80 C10-1,2,3 10 Notes:In the specimen number, G represents GFRP specimen; 45, 60 and 80 represent fiber wound angle $ \theta $; F, L and C represent the corresponding specimen size and compression section; 6 and 10 represent the number of fiber wound layers $ n $; −1,2,3 represents the three identical specimens. 表 2 纤维缠绕GFRP管性能参数

Table 2. Performance parameters of fiber wound GFRP tube

$ \pm 45^\circ $ $ \pm 60^\circ $ $ \pm 80^\circ $ $ {E}_{\mathrm{i}\mathrm{a}} $/GPa 29.0 18.0 16.5 $ {E}_{\mathrm{p}\mathrm{a}} $/GPa 29.0 12.4 9.7 $ {f}_{\mathrm{c}\mathrm{t}}^{\prime} $/MPa 112.3 102.6 94.4 $ {\varepsilon }_{\mathrm{c}\mathrm{t}} $/% 0.39 0.83 0.97 $ {E}_{\mathrm{i}\mathrm{h}} $/GPa 18.0 29.4 35.1 $ {E}_{\mathrm{p}\mathrm{h}} $/GPa 3.7 23.4 35.1 $ {f}_{\mathrm{l}\mathrm{t}} $/MPa 111.8 410.2 578.6 $ {\varepsilon }_{\mathrm{l}\mathrm{t}} $/% 3.01 1.75 1.65 Notes:$ {E}_{\mathrm{i}\mathrm{a}} $ is the initial axial stiffnes; $ {E}_{\mathrm{p}\mathrm{a}} $ is the secant stiffness at peak axial stress;$ {f}_{\mathrm{c}\mathrm{t}}^{\prime} $ is the peak axial stress; $ {\varepsilon }_{\mathrm{c}\mathrm{t}} $ is the peak axial strain; $ {E}_{\mathrm{i}\mathrm{h}} $ is the initial hoop stiffnes; $ {E}_{\mathrm{p}\mathrm{h}} $ is the secant stiffness at peak hoop stress; $ {f}_{\mathrm{l}\mathrm{t}} $ is the peak hoop stress; $ {\varepsilon }_{\mathrm{l}\mathrm{t}} $ is the peak hoop strain. 表 3 纤维缠绕GFRP管约束混凝土轴压试验结果

Table 3. Axial compression test results of fiber wound GFRP tube confined concrete

Specimen number $ {f}_{\mathrm{c}\mathrm{c}}^{\prime} $/MPa $ {f}_{\mathrm{c}\mathrm{c}}^{\prime}/{f}_{\mathrm{c}\mathrm{o}}^{\prime} $ $ {f}_{\mathrm{l}} $/MPa $ {f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime} $ $ {\varepsilon }_{\mathrm{c}\mathrm{c}} $/% $ {\varepsilon }_{\mathrm{f}\mathrm{e}} $/% G45 F6-1,2,3 44.1 1.27 5.5 0.16 0.4 / G45 F10-1,2,3 49.3 1.42 8.9 0.26 0.9 / G60 F6-1,2,3 102.4 2.94 15.5 0.44 2.6 1.4 G60 F10-1,2,3 124.1 3.57 27.9 0.80 2.7 1.5 G80 F6-1,2,3 127.5 3.66 16.4 0.47 2.2 1.2 G80 F10-1,2,3 157.7 4.53 21.6 0.62 2.5 1.2 G45 L6-1,2,3 39.9 1.72 5.4 0.23 0.5 / G45 L10-1,2,3 44.2 1.91 9.2 0.40 0.4 / G60 L6-1,2,3 89.9 3.88 18.5 0.80 1.9 1.7 G60 L10-1,2,3 120.7 5.20 31.4 1.35 2.3 1.7 G80 L6-1,2,3 117.4 5.06 21.6 0.93 2.2 1.5 G80 L10-1,2,3 146.1 6.30 26.7 1.15 2.2 1.5 G45 C6-1,2,3 57.1 1.64 5.6 0.16 0.5 / G45 C10-1,2,3 64.8 1.86 9.7 0.28 0.5 / G60 C6-1,2,3 122.8 3.53 17.6 0.50 2.3 1.6 G60 C10-1,2,3 165.8 4.76 29.3 0.84 2.6 1.6 G80 C6-1,2,3 155.3 4.46 19.4 0.56 2.2 1.4 G80 C10-1,2,3 183.5 5.27 25.2 0.72 2.6 1.4 Notes:$ {f}_{\mathrm{c}\mathrm{o}}^{\prime}$ is the compressive strength of unconfined concrete; $ {f}_{\mathrm{c}\mathrm{c}}^{\prime} $ is the peak compressive strength of confined concrete; $ {f}_{\mathrm{l}} $ is the effective restraint strength; $ {\varepsilon }_{\mathrm{c}\mathrm{c}} $ is the peak axial strain; $ {\varepsilon }_{\mathrm{f}\mathrm{e}} $ is the hoop effective confinement strain. 表 4 纤维缠绕GFRP管约束混凝土峰值强度预测公式及指标评价

Table 4. Prediction formula and index evaluation of peak strength of fiber wound GFRP tube confined concrete

Prediction formula $ {f}_{\mathrm{c}\mathrm{c}}^{\prime}/{f}_{\mathrm{c}\mathrm{o}}^{\prime} $ $ \mathrm{I}\mathrm{A}\mathrm{E}/\mathrm{\%} $ $ \mathrm{M}\mathrm{A}\mathrm{P}\mathrm{E}/\mathrm{\%} $ Lam[8] $ 1+3.3\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right) $ 24.0 18.7 Saafi[9] $ 1+2.2{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.84} $ 49.1 28.1 Karbhari[10] $ 1+2.1{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.87} $ 53.4 29.4 Wu[11] $ 1+2.23{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.96} $ 50.8 28.4 Matthys[12] $ 1+2.3{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.85} $ 46.0 27.0 Youssef[13] $ 1+2.25{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{1.25} $ 57.1 31.4 Formula 5 $ 1+1.38{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.39} $ 7.9 8.5 Formula 6 $ 1+1.72{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.96} $ 9.0 9.1 Formula 7 $ 1+3.65{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.60} $ 7.2 7.7 Formula 8 $ 1+4.86{\left({f}_{\mathrm{l}}/{f}_{\mathrm{c}\mathrm{o}}^{\prime}\right)}^{0.68} $ 4.9 5.1 Notes: $ {f}_{\mathrm{c}\mathrm{c}}^{\prime}/{f}_{\mathrm{c}\mathrm{o}}^{\prime} $ is normalized peak strength; IAE is integral absolute error; MAPE is mean absolute percentage error. -

[1] HARRIES K A, KHAREL G. Experimental investigation of the behavior of variably confined concrete[J]. Cement and Concrete Research, 2003, 33(6): 873-880. doi: 10.1016/S0008-8846(02)01086-4 [2] LAM L, TENG J G. Ultimate condition of fiber reinforced polymer-confined concrete[J]. Journal of Composites for Construction, 2004, 8(6): 539-548. doi: 10.1061/(ASCE)1090-0268(2004)8:6(539) [3] AU C, BUYUKOZTURK O. Effect of fiber orientation and ply mix on fiber reinforced polymer-confined concrete[J]. Journal of Composites for Construction, 2005, 9(5): 397-407. doi: 10.1061/(ASCE)1090-0268(2005)9:5(397) [4] CHAALLAL O, HASSAN M, LEBLANC M. Circular columns confined with FRP: experimental versus predictions of models and guidelines[J]. Journal of Composites for Construction, 2006, 10(1): 4-12. doi: 10.1061/(ASCE)1090-0268(2006)10:1(4) [5] LI G Q, MARICHERLA D, SINGH K, et al. Effect of fiber orientation on the structural behavior of FRP wrapped concrete cylinders[J]. Composite Structures, 2006, 74(4): 475-483. doi: 10.1016/j.compstruct.2005.05.001 [6] EID R, ROY N, PAULTRE P. Normal- and high-strength concrete circular elements wrapped with FRP composites[J]. Journal of Composites for Construction, 2009, 13(2): 113-124. doi: 10.1061/(ASCE)1090-0268(2009)13:2(113) [7] ISSA C A, CHAMI P, SAAD G. Compressive strength of concrete cylinders with variable widths CFRP wraps: Experimental study and numerical modeling[J]. Construction and Building Materials, 2009, 23(6): 2306-2318. doi: 10.1016/j.conbuildmat.2008.11.009 [8] LAM L, TENG J G. Design-oriented stress–strain model for FRP-confined concrete[J]. Construction and Building Materials, 2003, 17(6-7): 471-489. doi: 10.1016/S0950-0618(03)00045-X [9] SAAFI M, TOUTANJI H A, LI Z J. Behavior of concrete columns confined with fiber reinforced polymer tubes[J]. ACI Materials Journal, 1999, 96(4): 500-509. [10] KARBHARI V M, GAO Y Q. Composite jacketed concrete under uniaxial compression-Verification of simple design equations[J]. Journal of Materials in Civil Engineering, 1997, 9(4): 185-193. doi: 10.1061/(ASCE)0899-1561(1997)9:4(185) [11] WU Y F, WANG L M. Unified strength model for square and circular concrete columns confined by external jacket[J]. Journal of Structural Engineering, 2009, 135(3): 253-261. doi: 10.1061/(ASCE)0733-9445(2009)135:3(253) [12] MATTHYS S, TOUTANJI H, TAERWE L. Stress-strain behavior of large-scale circular columns confined with FRP composites[J]. Journal of Structural Engineering, 2006, 132(1): 123-133. doi: 10.1061/(ASCE)0733-9445(2006)132:1(123) [13] YOUSSEF M N, FENG M Q, MOSALLAM A S. Stress-strain model for concrete confined by FRP composites[J]. Composites Part B:Engineering, 2007, 38(5-6): 614-628. doi: 10.1016/j.compositesb.2006.07.020 [14] 秦国鹏, 王连广, 周乐. GFRP管混凝土组合柱轴压性能研究[J]. 工业建筑, 2009, 39(10): 72-75.QIN Guopeng, WANG Lianguang, ZHOU Le. Study on bearing capacity of axially-loaded GFRP tube composite columns filled with concrete[J]. Industrial Construction, 2009, 39(10): 72-75(in Chinese). [15] 杨俊杰, 周涛, 章雪峰. FRP管实心混凝土柱承载力的轴压试验研究[J]. 建筑结构, 2014, 44(22): 72-75+89.YANG Junjie, ZHOU Tao, ZHANG Xuefeng. Experimental research on bearing capacity of FRP tube solid concrete column under axial loading[J]. Building Structure, 2014, 44(22): 72-75+89(in Chinese). [16] 张冰, 魏威, 冯贵森, 等. 纤维角度对GFRP约束混凝土短柱轴压性能的影响[J]. 建筑结构学报, 2019, 40(S1): 192-199.ZHANG Bing, WEI Wei, FENG Guisen, et al. Influences of fiber angles on axial compressive behavior of GFRP-confined concrete stub column[J]. Journal of Building Structures, 2019, 40(S1): 192-199(in Chinese). [17] BETTS D, SADEGHIAN P, FAM A. Investigation of the stress-strain constitutive behavior of ±55° filament wound GFRP pipes in compression and tension[J]. Composites Part B:Engineering, 2019, 172: 243-252. doi: 10.1016/j.compositesb.2019.05.077 [18] SILVA M A, RODRIGUES C C. Size and relative stiffness effects on compressive failure of concrete columns wrapped with glass FRP[J]. Journal of Materials in Civil Engineering, 2006, 18(3): 334-342. doi: 10.1061/(ASCE)0899-1561(2006)18:3(334) [19] 龙跃凌, 蔡兆琼, 黄启山, 等. GFRP管约束混凝土短柱轴压性能和尺寸效应研究[J]. 混凝土, 2015, (09): 47-49. [19] 杨俊杰, 杨城. GFRP管混凝土长柱轴压极限承载力研究[J]. 浙江工业大学学报, 2015, 43(06): 685-689+698. doi: 10.3969/j.issn.1002-3550.2015.09.013LONG Yueling, CAI Zhaoqiong, HUANG Qishan, et al. Research on axial load behavior and size efects of GFRP confined concrete stub columns[J]. Concrete, 2015, (09): 47-49(in Chinese). doi: 10.3969/j.issn.1002-3550.2015.09.013 [20] MIRMIRAN A, SHAHAWY M, BEITLEMAN T. Slenderness limit for hybrid FRP-concrete columns[J]. Journal of Composites for Construction, 2001, 5: 26-34. doi: 10.1061/(ASCE)1090-0268(2001)5:1(26) [21] 章雪峰, 单鲁阳, 杨城, 等. GFRP管混凝土组合长柱的轴心受压特性研究[J]. 建筑结构, 2018, 48(09): 72-77.ZHANG Xuefeng, SHAN Luyang, YANG Cheng, et al. Study on axial compressive capacity characteristics of long concrete-filled GFRP tube composite columns[J]. Building Structure, 2018, 48(09): 72-77(in Chinese). [22] 杨俊杰, 杨城. GFRP管混凝土长柱轴压极限承载力研究[J]. 浙江工业大学学报, 2015, 43(06): 685-689+698. doi: 10.3969/j.issn.1006-4303.2015.06.018YANG Junjie, YANG Cheng. Research on the bearing capacity of long GFRP-reinforced concrete composite columns subjected to axial compression[J]. Journal of Zhejiang University of Technology, 2015, 43(06): 685-689+698(in Chinese). doi: 10.3969/j.issn.1006-4303.2015.06.018 [23] 周乐, 王连广, 门兆红. GFRP管高强混凝土组合柱轴心受压试验研究[J]. 公路交通科技(应用技术版), 2009, 5(04): 82-84.ZHOU Le, WANG Lianguang, MEN Zhaohong. Experimental study on axial compression of GFRP tube high-strength concrete composite column[J]. Journal of Highway and Transportation Research and Development, 2009, 5(04): 82-84(in Chinese). [24] 王玉清, 徐静, 张鑫鑫, 等. GFRP管混凝土短柱轴压力学性能的试验研究[J]. 内蒙古工业大学学报(自然科学版), 2012, 31(02): 64-69.WANG Yuqing, XU Jing, ZHANG Xinxin, et al. Experimental resarch on behavior of axially loaded concrete columns confined with GFRP Pipes[J]. Journal of Inner Mongolia University of Technology, 2012, 31(02): 64-69(in Chinese). [25] JIN L, LI X R, FAN L L, et al. Size effect on compressive strength of GFRP-confined concrete columns: numerical simulation[J]. Journal of Composites for Construction, 2020, 24(5): 04020038. doi: 10.1061/(ASCE)CC.1943-5614.0001041 [26] 金浏, 李秀荣, 杜修力, 等. GFRP增强混凝土圆柱轴压强度尺寸效应: 细观分析[J]. 水利学报, 2019, 50(04): 409-419.JIN Liu, LI Xiurong, DU Xiuli, et al. Size effect of axial compressive strength of circular concrete columns strengthened by GFRP: A meso-scale analysis[J]. Journal of Hydraulic Engineering, 2019, 50(04): 409-419(in Chinese). [27] 张玉强, 武梦洋, 郭启琛, 等. 椭圆形GFRP管混凝土短柱轴压力学性能试验研究[J]. 混凝土, 2020, (08): 7-9+14. doi: 10.3969/j.issn.1002-3550.2020.08.002ZHANG Yuqiang, WU Mengyang, GUO Qichen, et al. Experimental research on axial compressive behavior of elliptical concrete-filled GFRP tubular stub columns[J]. Concrete, 2020, (08): 7-9+14(in Chinese). doi: 10.3969/j.issn.1002-3550.2020.08.002 [28] JUNG W Y, KWON M H, JU B S. Evaluation of compressive strength of concrete members laterally confined by various FRP composites and exposed to high temperatures[J]. Ksce Journal of Civil Engineering, 2015, 20(6): 2410-2419. [29] 张云峰, 程凡荣, 李文锦, 等. 冻融循环作用后GFRP管混凝土轴压短柱力学性能[J]. 混凝土, 2022, (06): 13-19. doi: 10.3969/j.issn.1002-3550.2022.06.003ZHANG Yunfeng, CHENG Fanrong, LI Wenjin, et al. Mechanical properties of short axially compressed columns of GFRP pipe concrete after freeze-thaw cycles[J]. Concrete, 2022, (06): 13-19(in Chinese). doi: 10.3969/j.issn.1002-3550.2022.06.003 [30] 梁旭宇, 池寅, 曾彦钦, 等. GFRP管约束超高性能混凝土单轴受压应力-应变关系试验研究[J]. 武汉大学学报(工学版), 2020, 53(06): 498-506.LIANG Xuyu, CHI Yin, ZENG Yanqin, et al. Experimental studies on stress-strain relationship of ultra-high performance concrete confined by GFRP tube under uniaxial compression[J]. Engineering Journal of Wuhan University, 2020, 53(06): 498-506(in Chinese). [31] HUANG D M, LIU Z Z, MA W T, et al. Steel fiber-reinforced recycled aggregate concrete-filled GFRP tube columns: axial compression performance[J]. Construction and Building Materials, 2023, 403: 133143. doi: 10.1016/j.conbuildmat.2023.133143 [32] CAO Q, LI H, LIN Z B. Study on the active confinement of GFRP-confined expansive concrete under axial compression[J]. Construction and Building Materials, 2019, 227: 116683. doi: 10.1016/j.conbuildmat.2019.116683 [33] XIE P, LAM L, JIANG T. Compressive behavior of GFRP tubes filled with self-compacting concrete[J]. Journal of Composites for Construction, 2023, 27(1): 04022103. doi: 10.1061/JCCOF2.CCENG-3937 [34] DABBAGH H, DELSHAD M, AMOOREZAEI K. Design-oriented stress-strain model for FRP-confined lightweight aggregate concrete[J]. Ksce Journal of Civil Engineering, 2020, 25(1): 219-234. [35] 杨霞, 杨文伟, 李顺涛. 采用CFRP增强的GFRP管混凝土短柱轴压性能试验研究[J]. 土木与环境工程学报(中英文), 2022, 44(04): 124-132.YANG Xia, YANG Wenwei, LI Shuntao. Experimental study on axial compression behavior of concrete-filled GFRP tube short columns strengthened with CFRP[J]. Journal of Civil and Environmental Engineering, 2022, 44(04): 124-132(in Chinese). [36] HE K, CHEN Y. Experimental evaluation of built-in channel steel concrete-filled GFRP tubular stub columns under axial compression[J]. Composite Structures, 2019, 219: 51-68. doi: 10.1016/j.compstruct.2019.03.057 [37] XUE B, GONG J. Study on steel reinforced concrete-filled GFRP tubular column under compression[J]. Thin-Walled Structures, 2016, 106: 1-8. doi: 10.1016/j.tws.2016.04.023 [38] YAHIAOUI D, SAADI M, BOUZID T. Compressive behavior of concrete containing glass fibers and confined with glass FRP composites[J]. International Journal of Concrete Structures and Materials, 2022, 16(37): 1-19. -

点击查看大图

点击查看大图

计量

- 文章访问数: 75

- HTML全文浏览量: 55

- 被引次数: 0

下载:

下载: