Influence of granite stone powder on the basic properties and gas permeability characteristics of mechanism sand concrete

-

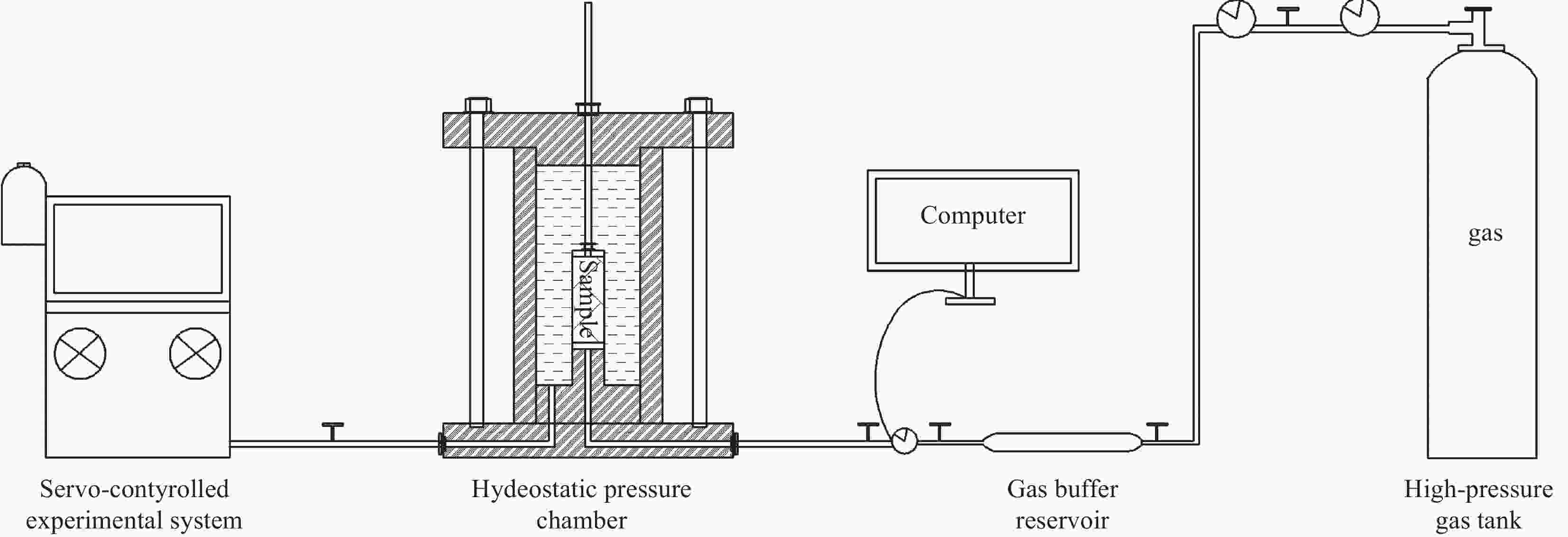

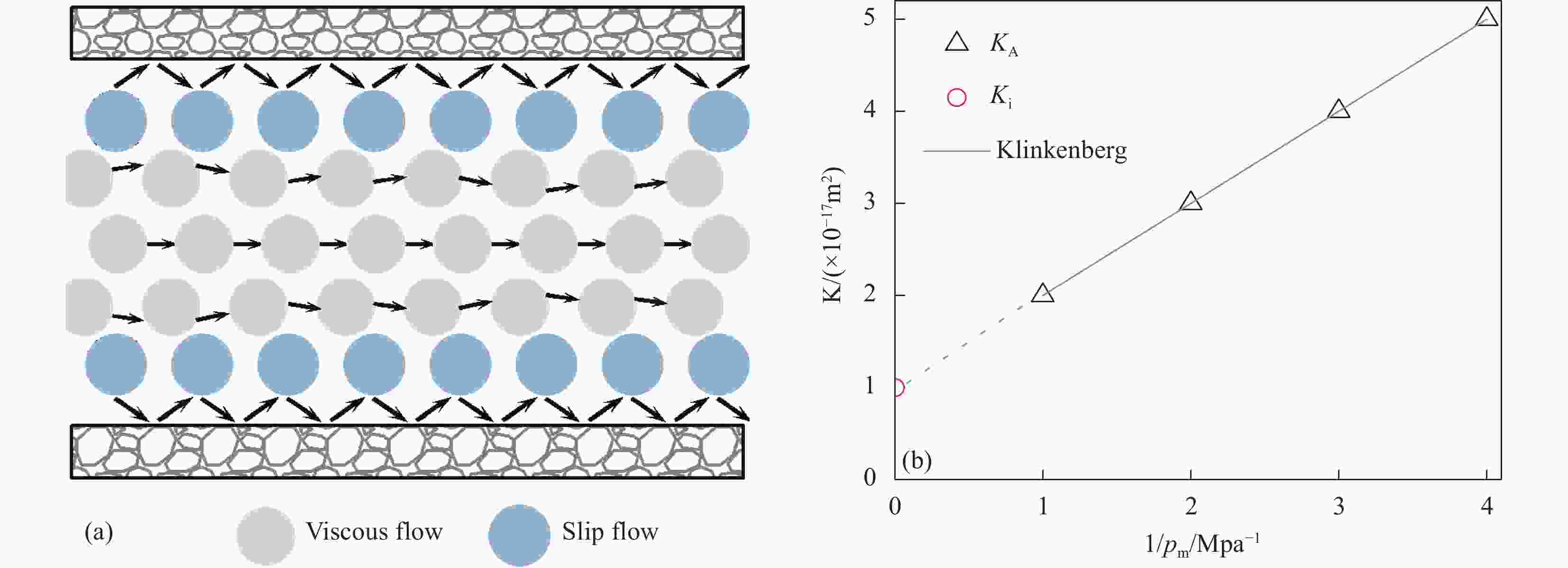

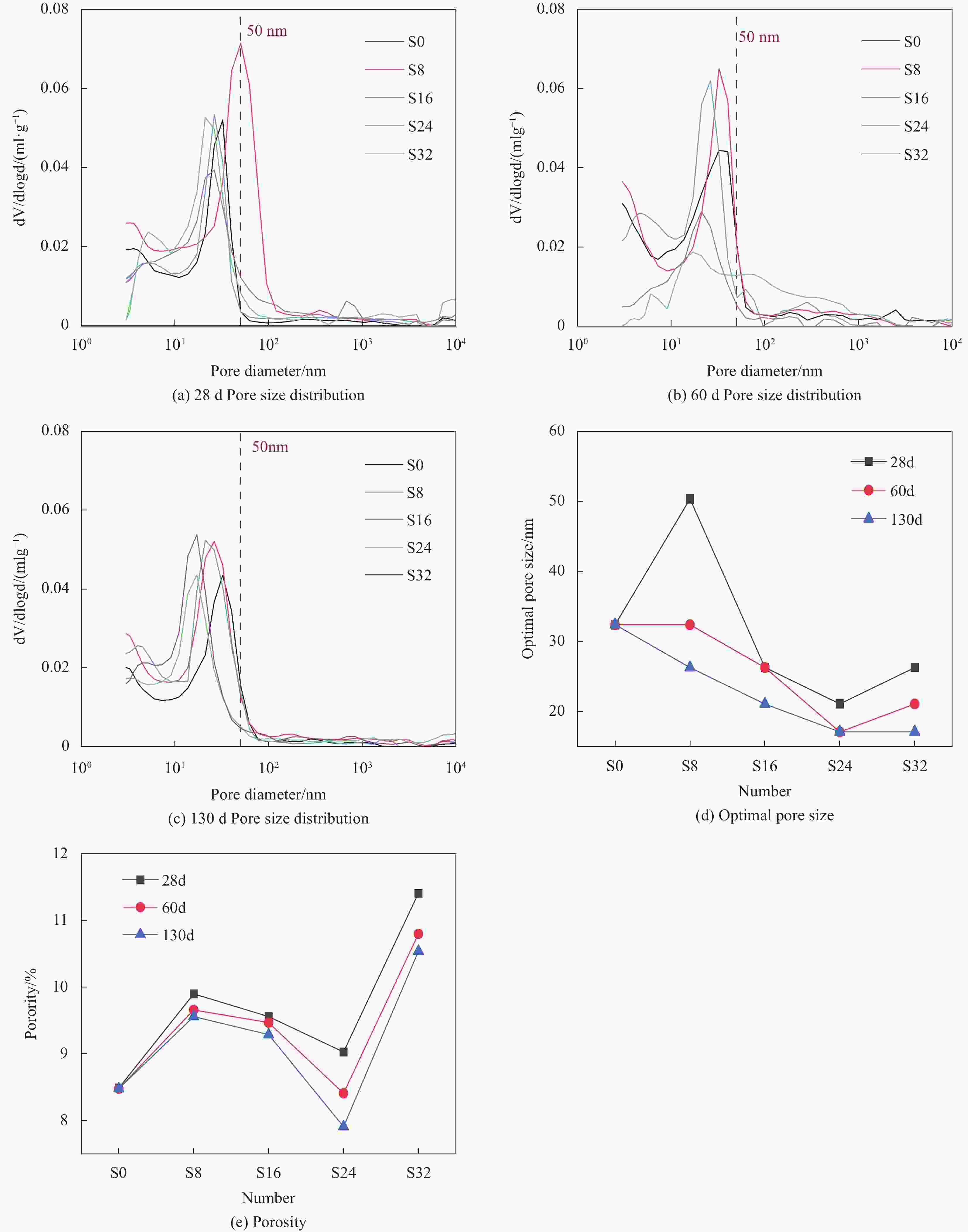

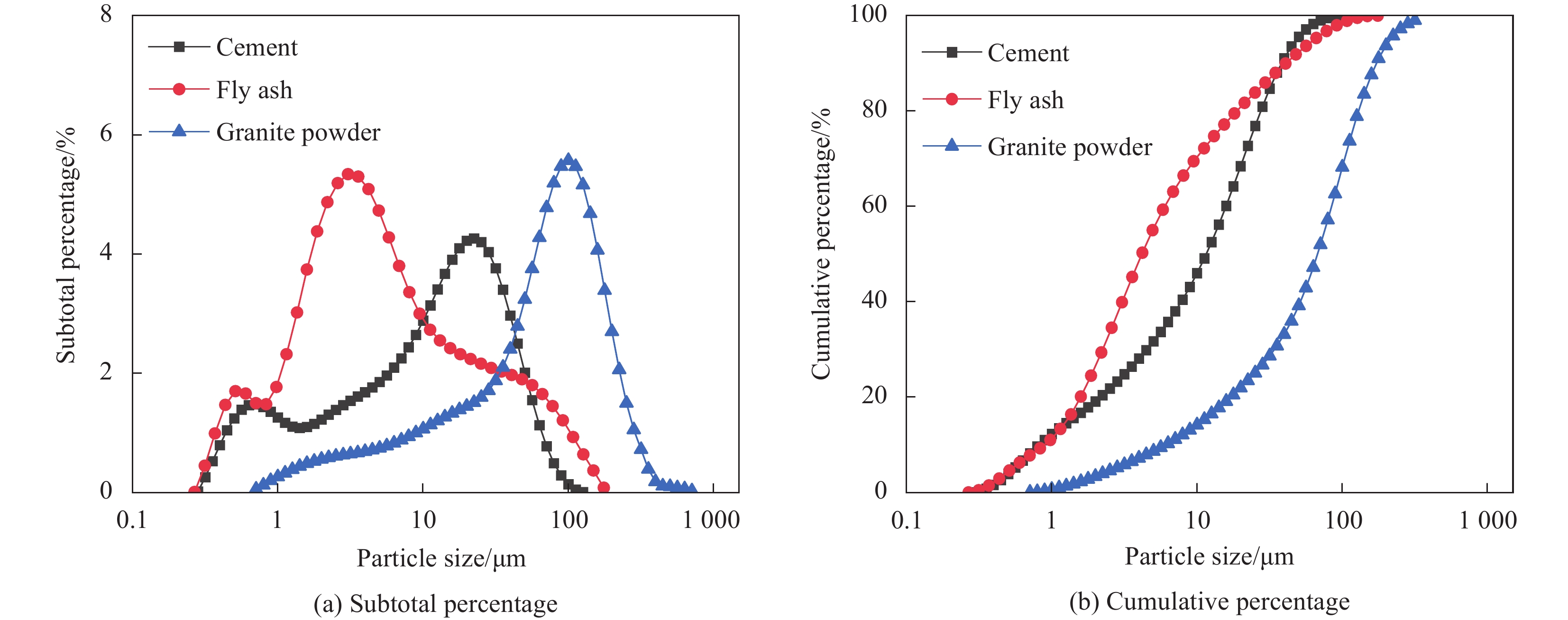

摘要: 采用花岗岩石粉等质量(0%~32%)替代部分水泥制备机制砂混凝土,应用等温量热、压汞、准稳态气体渗透等方法测试机制砂混凝土的水泥水化热、孔隙结构、力学强度及气体渗透性能,结合灰色关联分析建立不同龄期(28~130 d)石粉-机制砂混凝土气体渗透特性与孔隙特征之间关系。结果表明:机制砂混凝土中掺入适量石粉可减缓水化放热、改善孔隙结构、提高抗压强度及降低气体渗透系数;8%石粉掺量机制砂混凝土的抗压强度最高、气体渗透系数最低,其灰色关联分析表明有效孔隙率和小于100 nm孔隙对气体渗透性影响最显著。Abstract: Granite powder (0%-32%) was used to replace part of cement clinker to prepare machine-made sand concrete. The Isothermal Calorimetry, Mercury Intrusion Porosimetry as well as Gas Penetration testing-methods were employed to measure the hydration heat, pore structure, mechanical strength and gas permeability of the concrete. Combined with the gray-correlation analysis method, the relationship between gas permeability properties and pore-structure characteristics was established for concrete at various curing ages (28-130 d). The results show that appropriate granite powder added can slow down the hydration heat release rate, refine pore structure, increase compressive strength, and reduce gas permeability. The compressive strength value of the concrete with 8% granite powder is the highest while its gas permeability coefficient reaches the lowest. The gray-correlation analysis shows that the effective porosity and the pore with the size less than 100 nm play the most significant impact on gas permeability.

-

表 1 水泥、粉煤灰和石粉化学组成

Table 1. Chemical composition of cement, fly ash, and stone powder

Chemical components /% SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O Cement 26.15 7.87 3.81 53.85 2.01 3.88 0.63 1.00 Fly ash 52.63 29.47 5.42 4.79 1.52 0.86 1.73 1.70 Granite powder 16.18 5.40 2.44 48.19 25.51 0.21 0.51 0.68 表 2 机制砂混凝土配合比

Table 2. Machine-made sand concrete mix

Number Water-to-binder ratio Cementing material/(kg·m−3) Machine-made

sand/(kg·m−3)Coarse aggregate/

(kg·m−3)Water reducing

agent/%Cement Fly ash Granite powder S0 0.38 320 101 0 804 1066 1.00 S8 286 34 1.00 S16 253 67 1.00 S24 219 101 2.20 S32 185 135 2.80 表 3 水化特征点出现时间(h)

Table 3. Time of occurrence of hydration feature points (h)

Phase No. S0 S8 S16 S24 S32 Start of the acceleration period 2.33 2.65 3.02 2.9 2.63 Time of appearance of the first wave 11.86 12.09 12.18 11.91 15.27 Time of appearance of the second wave 16.41 16.03 16.08 16.03 15.8 表 4 S8气体渗透系数与孔结构数据

Table 4. S8 gas permeability coefficient and pore structure data

Time/d Gas permeability

coefficient /(×10−17m2)Poriness/% Specific surface

area /(m2·g−1)Effective

porosity/%Pore tortuosity Aperture size/(mL·g−1) Gel pore Small pore Macropore Air hole 28 0.48 9.90 13.44 4.42 4.94 0.20 0.39 0.03 0.01 60 0.39 9.66 14.11 2.98 6.78 0.23 0.28 0.03 0.02 130 0.18 9.56 12.94 2.45 7.69 0.20 0.27 0.02 0.05 表 5 S8气体渗透系数与孔结构灰色关联分析

Table 5. Gray relational analysis of gas permeability coefficient and pore structure

Number Poriness Specific surface area Effective porosity Pore tortuosity Aperture size Gel pore Small pore Macropore Air hole S8 +0.906 +0.896 +0.954 -0.813 +0.883 +0.943 +0.877 +0.698 -

[1] 于本田, 陈延飞, 王焕, 等. 大掺量高吸附性石粉高强机制砂混凝土收缩开裂抑制试验[J]. 复合材料学报, 2021, 38(08): 2737-2746. doi: 10.13801/j.cnki.fhclxb.20210430.001YU Bentian, CHEN Yanfei, WANG Huan, et al. Experiment on control measures of shrinkage and cracking of high strength manufactured sand concrete containing a large amount of high absorbency stone powder[J]. Acta Materiae Compositae Sinica, 2021, 38(08): 2737-2746(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210430.001 [2] 王将华, 薛翠真, 张宇, 等. 花岗岩石粉对砂浆干燥收缩性能的影响[J]. 材料导报, 2023, 37(22): 111-116.WANG Jianghua, XUE Cuizhen, ZHANG Yu, et al. Effect of granite powder on drying shrinkage[J]. Materials Reports, 2023, 37(22): 111-116(in Chinese). [3] 薛汇林, 陈明亮, 唐志波, 等. 机制砂中石粉对混凝土物理力学性能的宏细观影响机制[J]. 工程科学与技术, 2023, 55(06): 151-160.XUE Huilin, CHEN Mingliang, TANG Zhibo, et al. Macro-micro mechanisms for the effects of stone powder in manufactured sand on physical and mechanical properties of concrete[J]. Advanced Engineering Sciences, 2023, 55(06): 151-160(in Chinese). [4] 于本田, 刘通, 王焕, 等. 花岗斑岩石粉含量对混凝土性能及微观结构的影响[J]. 吉林大学学报(工学版), 2022, 52(05): 1052-1062. doi: 10.13229/j.cnki.jdxbgxb20200963YU Bentian, LIU Tong, WANG Huan, et al. Influence of granite porphyry stone powder content on properties and microstructure of concrete[J]. Journal of Jilin University(Engineering and Technolog), 2022, 52(05): 1052-1062(in Chinese). doi: 10.13229/j.cnki.jdxbgxb20200963 [5] ZHANG H, JI T, HE B, et al. Performance of ultra-high performance concrete (UHPC) with cement partially replaced by ground granite powder (GGP) under different curing conditions[J]. Construction and Building Materials, 2019, 213(JUL.20): 469-482. [6] 李林, 张学峰, 徐斌, 等. 花岗岩机制砂石粉含量对混凝土性能的影响[J]. 交通科技, 2021, (03): 128-132. doi: 10.3963/j.issn.1671-7570.2021.03.029LI Lin, ZHANG Xuefeng, XU Bin, et al. Influence of stone powder content in granite manufactured sand on performance of concrete[J]. Transportation Science and Technology, 2021, (03): 128-132(in Chinese). doi: 10.3963/j.issn.1671-7570.2021.03.029 [7] YING P , LIU F , REN S , et al. The Research on the effect of Granite Powder on Concrete Performance[C]//International Conference on Civil, Architectural and Hydraulic Engineering, 2012. [8] 石加顺. 非饱和水泥基材料气体渗透性研究 [D]. 南京: 东南大学, 2020.SHI Jiashun. Study on gas permeability of unsaturated cementitious materials [D]. Nanjing: Southeast University, 2020(in Chinese). [9] 王珩, 杨虎, 戈雪良, 等. 粉煤灰混凝土水渗透与空气渗透性能的相关性分析[J]. 新型建筑材料, 2017, 44(08): 105-110. doi: 10.3969/j.issn.1001-702X.2017.08.027WANG Heng, YANG Hu, GE Xueliang, et al. The correlation analysis between the water permeability and the air permeability of fly ash concrete[J]. New Building Materials, 2017, 44(08): 105-110(in Chinese). doi: 10.3969/j.issn.1001-702X.2017.08.027 [10] ALIGIZAKI K K. Pore structure of cement-based materials: testing, interpretation and requirements [M]. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements, 2006. [11] 罗明勇. 大掺量矿渣水泥基材料孔隙结构与透气性研究 [D]. 北京: 清华大学, 2013.LUO Mingyong. Pore structure characterization and gaspermeability of cement-based materials Containing High Volume of GGBS [D]. Beijing: Tsinghua University , 2013(in Chinese). [12] SALMAS C E, ANDROUTSOPOULOS G P. A Novel Pore Structure Tortuosity Concept Based on Nitrogen Sorption Hysteresis Data[J]. Industrial and Engineering Chemistry Research, 2011, 40(2): 721-730. [13] 中国人民共和国住房和城乡建设部, 国家市场监督管理总局. 混凝土物理力学性能实验方法标准: GB/T 50081-2019: [S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People's Republic of China, State Administration of Market Supervision and Administration. Standard for test methods of concrete physical and mechanical properties: GB/T 50081-2019: [S]. Beijing: Standards Press of China, 2019(in Chinese). [14] 王中平, 吴科如, 张青云, 等. 混凝土气体渗透系数测试方法的研究[J]. 建筑材料学报, 2001, 4(4): 317-321. doi: 10.3969/j.issn.1007-9629.2001.04.003WANG Zhongping, WU Keru, ZHANG Qingyun, et al. Study of test method for coefficient of gas permeability of concrete[J]. Journal of Building Materials, 2001, 4(4): 317-321(in Chinese). doi: 10.3969/j.issn.1007-9629.2001.04.003 [15] 石加顺, 钱如胜, 张云升, 等. 水泥基材料气体渗透性测试方法及与耐久性关系的研究进展[J]. 材料导报, 2021, 35(1): 10.SHI Jiashun, QIAN Rusheng, ZHANG Yunsheng, et al. Advances in gas permeability test methods and its relationships with durability for cementitious materials[J]. Materials Reports, 2021, 35(01): 1121-1130(in Chinese). [16] 钱如胜. 非饱和水泥基材料气体传输特性与机理研究 [D]. 南京: 东南大学, 2022.QIAN Rusheng. Investigations on gas transport characteristics and mechanism of unsaturated cementitious materials [D]. Nanjing: Southeast University, 2022(in Chinese). [17] ROY S, RAJU R, CHUANG H F, et al. Modeling gas flow through microchannels and nanopores[J]. Journal of applied physics, 2003, 93(8): 4870-4879. doi: 10.1063/1.1559936 [18] TANIKAWA W, SHIMAMOTO T. Comparison of Klinkenberg-corrected gas permeability and water permeability in sedimentary rocks[J]. International Journal of Rock Mechanics & Mining Sciences, 2009, 46(2): 229-238. [19] KLINKENBERG L J. The permeability of porous media to liquids and gases[J]. Drilling and production practice, 1941: 200-213. [20] QIAN R, SHI J, LI Y, et al. Investigation on parameters optimization for gas permeability testing of concrete: Inlet-gas pressure and confining pressure[J]. Construction and Building Materials, 2020, 250(1): 118901. [21] AZZEH M, NEAGU D C, COWLING P I. Fuzzy grey relational analysis for software effort estimation[J]. Empirical Software Engineering, 2010, 15(1): 60-90. doi: 10.1007/s10664-009-9113-0 [22] 周立霞, 王起才. 粉煤灰粒度分布及其活性的灰色关联分析[J]. 硅酸盐通报, 2011, 30(03): 656-661+666. doi: 10.16552/j.cnki.issn1001-1625.2011.03.013ZHOU Lixia, WANG Qicai. Grey incidence analysis between particle size distribution of fly ash and its activity[J]. Bulletin of The Chinese Ceramic Society, 2011, 30(03): 656-661+666(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2011.03.013 [23] 邓懋, 申波, 吴洪梅, 等. 石灰石粉含量和粒径对水泥水化热的影响[J]. 硅酸盐通报, 2023, 42(2): 420-428+438. doi: 10.16552/j.cnki.issn1001-1625.20221222.001DENG Mao, SHEN Bo, WU Hongmei, et al. Effects of limestone powder content and particle size on hydration heat of cement[J]. Bulletin of The Chinese Ceramic Society, 2023, 42(2): 420-428+438(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.20221222.001 [24] 王子明, 韦庆东, 郝利炜, 等. 相变物质对水泥水化放热和混凝土性能的影响[J]. 商品混凝土, 2007, (3): 3.WANG Ziming, WEI Qingdong, HAO Liwei, et al. Impact of phase change material on the exothermic hydration process of cement property of concrete[J]. Ready-Mixed Concrete, 2007, (3): 3(in Chinese). [25] ALIGIZAKI K. Detemination of Pore Structure Parameters in Hardened Cementitious Materials [D]. Staitekolich City: The Pennsylvania State University, 1995. [26] 郭育霞, 贡金鑫, 李晶. 石粉掺量对混凝土力学性能及耐久性的影响[J]. 建筑材料学报, 2009, 12(03): 266-271.GUO Yuxia, GONG Jinxin, LI Jing. Influence of mass fractions of limestone powder on mechanical property and durability of concrete[J]. Journal of Building Materials, 2009, 12(03): 266-271(in Chinese). [27] 陈尚伟, 徐立斌, 胡伟伟, 等. 泵送山砂混凝土配制技术研究[J]. 混凝土, 2012, (08): 107-109+114.CHEN Shangwei, XU Libin, HU Weiwei, et al. Study of the preparation of pump concrete with pit sand[J]. Concrete , 2012, (8): 107-109, 114(in Chinese). [28] TAHIR C, KNALED M. Effects of Crushed Stone Dust on Some Properties of Concrete[J]. Cement and Concrete Research, 1996, 26(7): 1121-1130. doi: 10.1016/0008-8846(96)00078-6 [29] 张季阳. 基于CT图像的石粉对机制砂混凝土力学性能的影响研究 [D]. 贵阳: 贵州大学, 2023.ZHANG Jiyang. Research on the influence of stone powder on the mechanical properties of mechanized sand concrete based on ct images [D]. Guiyang: Guizhou University , 2023(in Chinese). [30] 杨词范. 石粉掺量和细度对水工混凝土耐久性能影响试验研究[J]. 水利技术监督, 2022, 178(8): 36-39.YANG Cifan. Experimental study on the influence of stone powder content and fineness on the durability of hydraulic concrete[J]. Techenical Supervision in Water Resources, 2022, 178(8): 36-39(in Chinese). [31] 史才军, 王德辉, 贾煌飞, 等. 石灰石粉在水泥基材料中的作用及对其耐久性的影响[J]. 硅酸盐学报, 2017, 45(11): 1582-1593. doi: 10.14062/j.issn.0454-5648.2017.11.05SHI Caijun, WANG Dehui, JIA Huangfei, et al. Role of limestone powder and its effect on durability of cement-based materials[J]. Journal of the Chinese Ceramic Society, 2017, 45(11): 1582-1593(in Chinese). doi: 10.14062/j.issn.0454-5648.2017.11.05 [32] NATH P, SARKER P K. Effect of mixture proportions on the drying shrinkage and permeation properties of high strength concrete containing class F fly ash[J]. KSCE journal of civil engineering, 2013, 17(6): 1437-1445. doi: 10.1007/s12205-013-0487-6 [33] 章玉容, 方润华, 王建东, 等. 粉煤灰混凝土气体渗透与微观结构的时变相关性[J]. 浙江工业大学学报, 2021, 49(1): 72-75.ZHANG Yurong, FANG Runhua, WANG Jiandong, et al. Time-dependent correlation between gas permeability and microstructural parameters of fly ash concrete[J]. Journal of Zhejiang University of Technology, 2021, 49(1): 72-75(in Chinese). [34] 边帆. 潮差环境混凝土透气性与氯离子扩散性的试验研究 [D]. 杭州: 浙江工业大学, 2018.BIAN Fan. Research on gas permeability and chloride diffusivity of concrete under the tidal environment [D]. Hangzhou: Zhejiang University of Technology, China, 2018(in Chinese). [35] ZHANG J, BIAN F, ZHANG Y, et al. Effect of pore structures on gas permeability and chloride diffusivity of concrete[J]. Construction and Building Materials, 2018, 163(28): 402-413. [36] Yio M, Wong H S, Buenfeld N R. 3D pore structure and mass transport properties of blended cementitious materials[J]. Cement and Concrete Research, 2019, 117: 23-37. doi: 10.1016/j.cemconres.2018.12.007 [37] QIAN R, LIU C, LIU G, et al. Effects of various inlet-gas mediums on apparent permeability of concrete under steady-state flow: Comparison between carbon-dioxide and oxygen[J]. Cement and Concrete Composites, 2021, 119(7): 103995. [38] QIAN R, ZHANG Y, ZHANG Y, et al. Various gas transport properties in concrete considering transporting mechanisms and testing methods-A review[J]. Construction and Building Materials, 2023: 131636. -

下载:

下载: