| [1] |

杜善义, 方岱宁, 孟松鹤, 等. “近空间飞行器的关键基础科学问题”重大研究计划结题综述[J]. 中国科学基金, 2017, 31(2): 109-114. doi: 10.16262/j.cnki.1000-8217.2017.02.002DU S Y, FANG D N, MENG S H, et al. "Key basic scientific issues of near-space vehicles" major research project summary[J]. Chinese Science Foundation, 2017, 31(2): 109-114 (in Chinese). doi: 10.16262/j.cnki.1000-8217.2017.02.002

|

| [2] |

Das T K, Ghosh P, Das N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review[J]. Advanced Composites and Hybrid Materials, 2019, 2(2): 214-233. doi: 10.1007/s42114-018-0072-z

|

| [3] |

Uyanna O, Najafi H. Thermal protection systems for space vehicles: A review on technology development, current challenges and future prospects[J]. Acta Astronautica, 2020, 176: 341-356. doi: 10.1016/j.actaastro.2020.06.047

|

| [4] |

Parveez B, Kittur M, Badruddin I A, et al. Scientific Advancements in Composite Materials for Aircraft Applications: A Review[J]. Polymers, 2022, 14(22): 5007. doi: 10.3390/polym14225007

|

| [5] |

Allison J, Backman D, Christodoulou L. Integrated computational materials engineering: A new paradigm for the global materials profession[J]. JOM, 2006, 58(11): 25-27. doi: 10.1007/s11837-006-0223-5

|

| [6] |

Llorca J, González C, Molina-Aldareguía J M, et al. Multiscale Modeling of Composite Materials: a Roadmap Towards Virtual Testing[J]. Advanced Materials, 2011, 23(44): 5130-5147. doi: 10.1002/adma.201101683

|

| [7] |

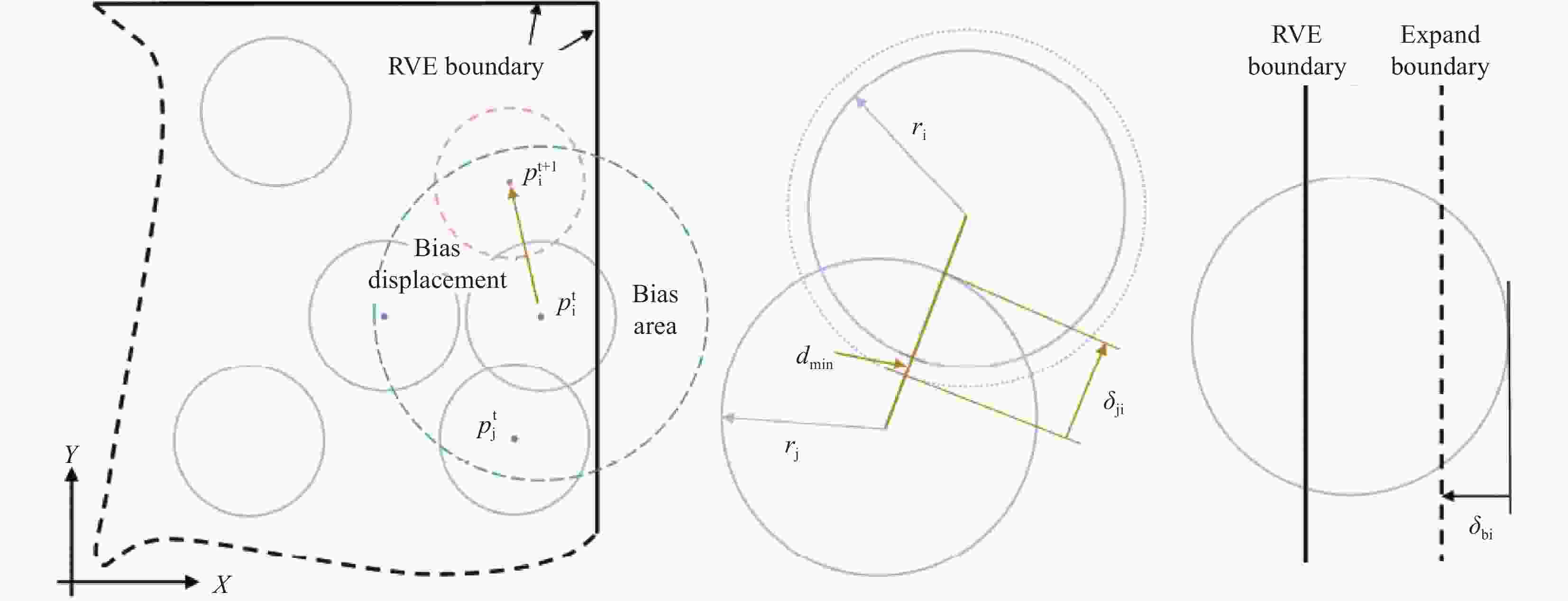

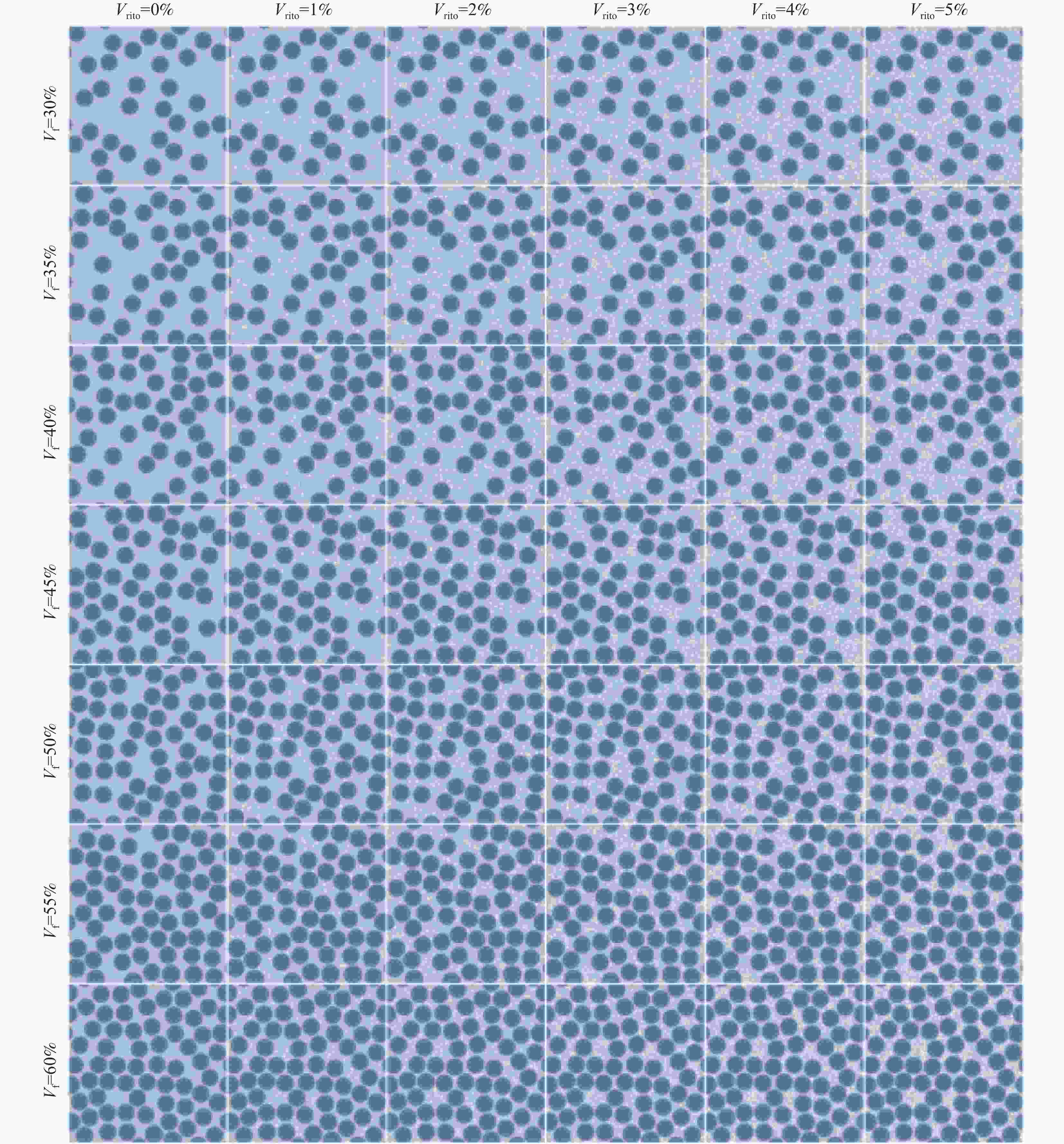

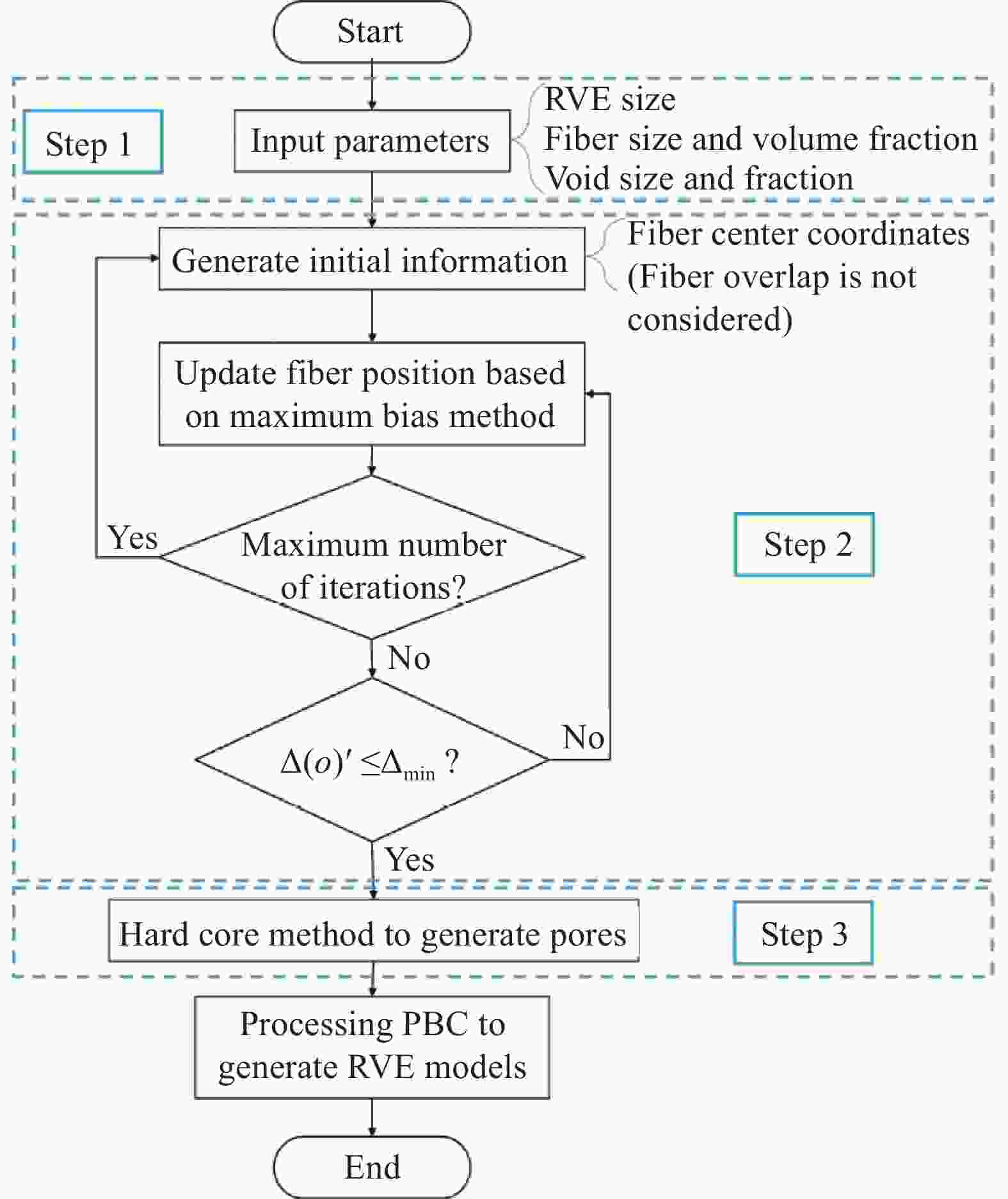

Tian W, Chao X, Fu M W, et al. An algorithm for generation of RVEs of composites with high particle volume fractions[J]. Composites Science and Technology, 2021, 207: 108714. doi: 10.1016/j.compscitech.2021.108714

|

| [8] |

田文龙, 齐乐华, 晁许江. 基于有限元压缩方法的复合材料RVE创建[J]. 力学学报, 2023, 55 (7): 1537.TIAN W L, QI L H, ZHAO X J. An efficient FE compression method for generating the RVEs of composites[J]. Chinese Journal of Theoretical and Applied Mechanics, 2023, 55(7): 1537-1547 (in Chinese).

|

| [9] |

Rintoul M D, Torquato S. Reconstruction of the Structure of Dispersions[J]. Journal of Colloid and Interface Science, 1997, 186(2): 467-476. doi: 10.1006/jcis.1996.4675

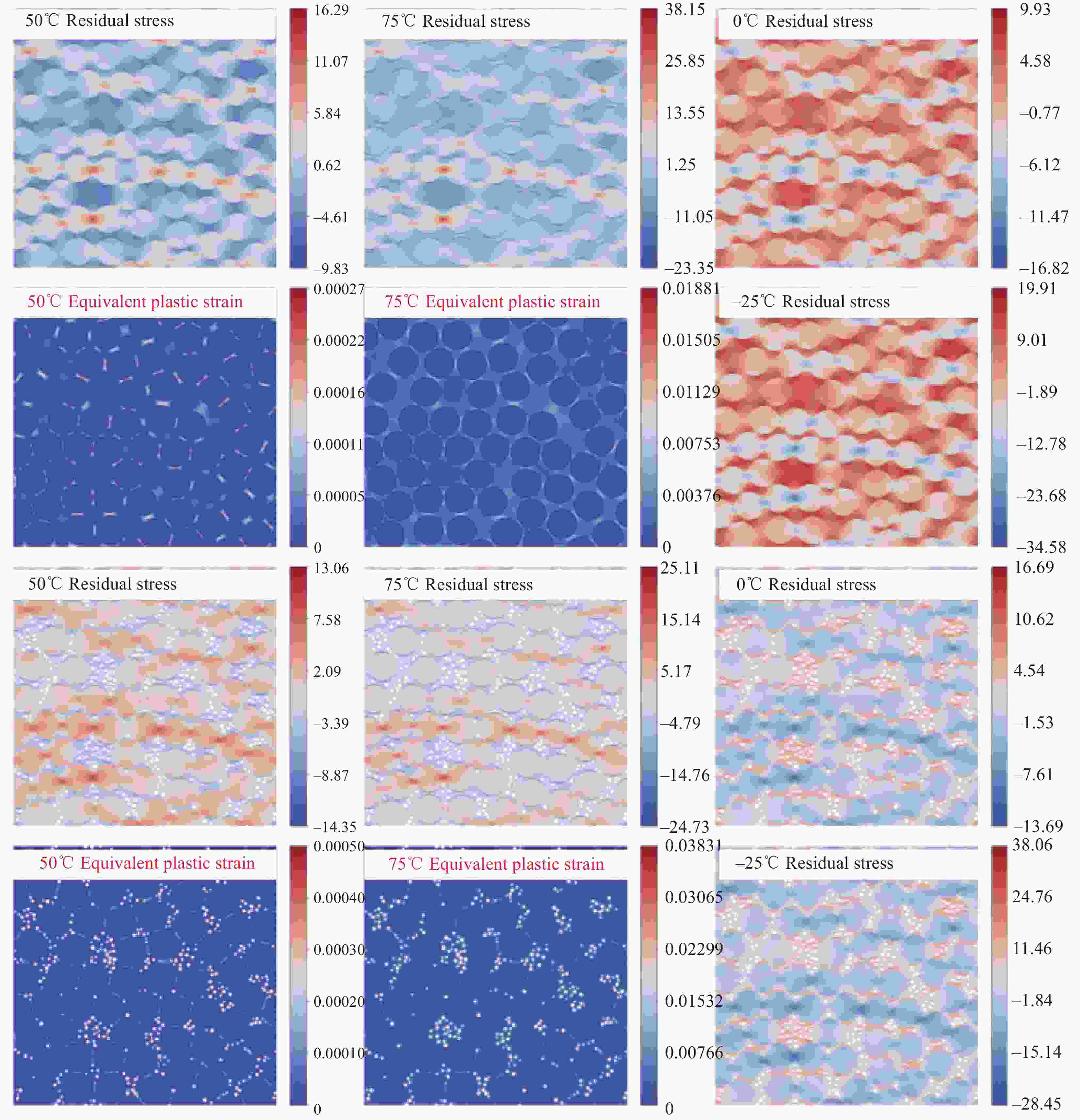

|

| [10] |

Melro A R, Camanho P P, Pinho S T. Generation of random distribution of fibres in long-fibre reinforced composites[J]. Composites Science and Technology, 2008, 68(9): 2092-2102. doi: 10.1016/j.compscitech.2008.03.013

|

| [11] |

Bisram M, Ahmed J, Hood A, et al. A novel method for creation of complex microstructure cells through artificial molecular dynamics simulations[J]. Composites Science and Technology, 2023, 232: 109849. doi: 10.1016/j.compscitech.2022.109849

|

| [12] |

Nakka R, Phanendra Kumar A, Harursampath D, et al. Influence of fibre cross-section profile on the multi-physical properties of uni-directional composites[J]. Composite Structures, 2023, 321: 117321. doi: 10.1016/j.compstruct.2023.117321

|

| [13] |

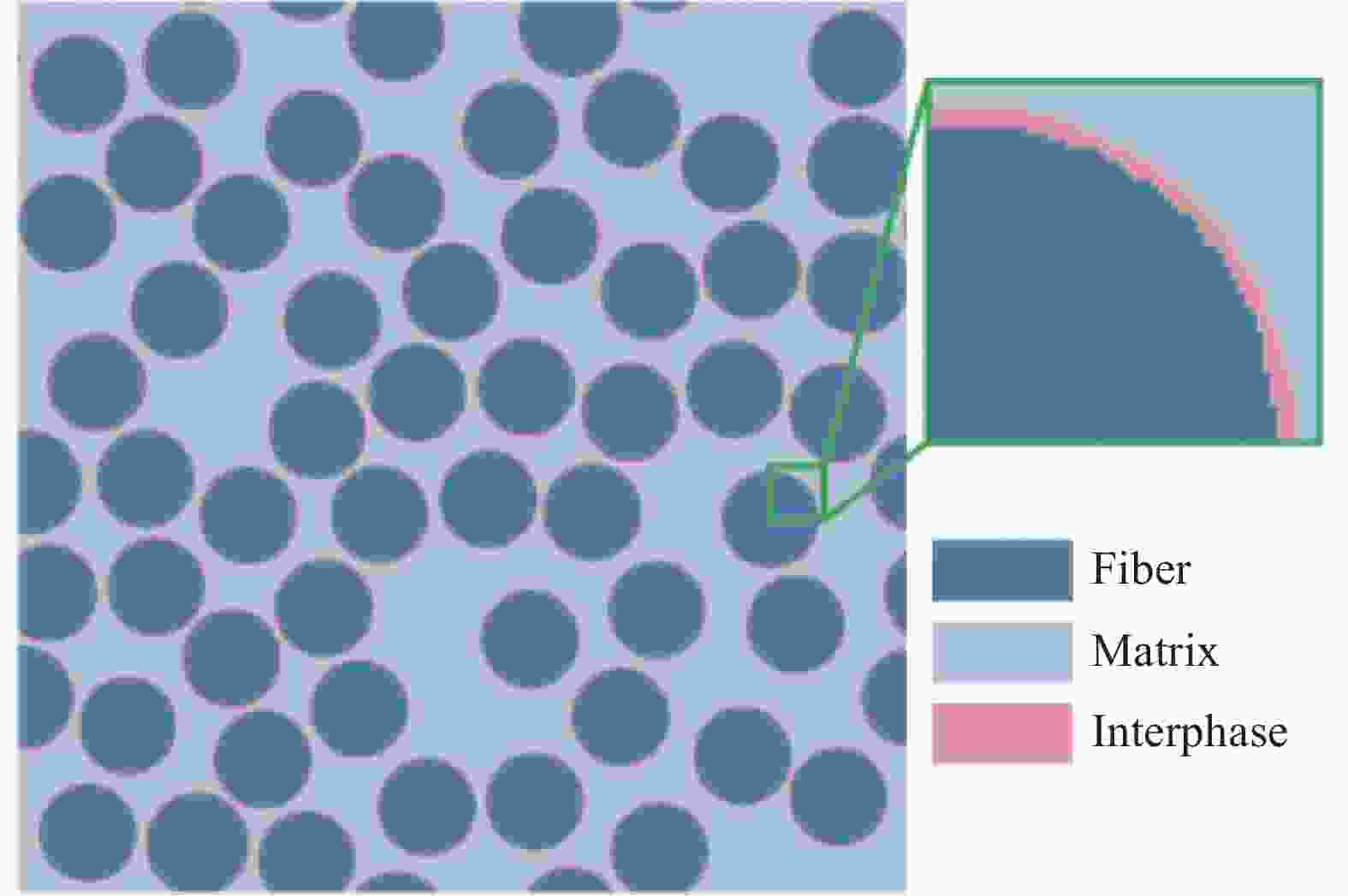

Cai C, Zhang T, Wang X, et al. A versatile and highly efficient algorithm to generate representative microstructures for heterogeneous materials[J]. Composites Science and Technology, 2023, 241: 110138. doi: 10.1016/j.compscitech.2023.110138

|

| [14] |

David Müzel S, Bonhin E P, Guimarães N M, et al. Application of the Finite Element Method in the Analysis of Composite Materials: A Review[J]. Polymers, 2020, 12(4): E818. doi: 10.3390/polym12040818

|

| [15] |

Panwar V, Gupta P, Bagha A K, et al. A Review on studies of Finite Element Model Updating and Updating of Composite Materials[J]. Materials Today: Proceedings, 2018, 5 (14, Part 2): 27912-27918.

|

| [16] |

Jagadeesh G V, Gangi Setti S. A review on micromechanical methods for evaluation of mechanical behavior of particulate reinforced metal matrix composites[J]. Journal of Materials Science, 2020, 55(23): 9848-9882. doi: 10.1007/s10853-020-04715-2

|

| [17] |

Naili C, Doghri I, Kanit T, et al. Short fiber reinforced composites: Unbiased full-field evaluation of various homogenization methods in elasticity[J]. Composites Science and Technology, 2020, 187: 107942. doi: 10.1016/j.compscitech.2019.107942

|

| [18] |

刘宝瑞, 方国东, 梁军. 基于 Voxel 有限元网格对球形夹杂复合材料的应力分析[J]. 复合材料学报, 2015, 32(6): 1769-1776.LIU B R, FANG G D, LIANG J. Stress analysis of spherical inclusion composites using Voxel finite element mesh[J]. Acta Materiae Compositae Sinica, 2015, 32(6): 1769-1776 (in Chinese).

|

| [19] |

Moulinec H, Suquet P. A numerical method for computing the overall response of nonlinear composites with complex microstructure[J]. Computer Methods in Applied Mechanics and Engineering, 1998, 157(1): 69-94.

|

| [20] |

Lucarini S, Upadhyay M, Segurado J. FFT based approaches in micromechanics: fundamentals, methods and applications[J]. Modelling and Simulation in Materials Science and Engineering, 2021, 30(2): 023002.

|

| [21] |

Schneider M. A review of nonlinear FFT-based computational homogenization methods[J]. Acta Mechanica, 2021, 232(6): 2051-2100. doi: 10.1007/s00707-021-02962-1

|

| [22] |

Lee M J. Comparison of Thermoelastic Micromechanical Response of Polycrystalline Microstructures using Finite Element Method and Fast Fourier Transform-based Method[D]. Ulsan National Institute of Science and Technology, 2019.

|

| [23] |

Magri M, Lucarini S, Lemoine G, et al. An FFT framework for simulating non-local ductile failure in heterogeneous materials[J]. Computer Methods in Applied Mechanics and Engineering, 2021, 380: 113759. doi: 10.1016/j.cma.2021.113759

|

| [24] |

Li J, Meng S, Tian X, et al. A non-local fracture model for composite laminates and numerical simulations by using the FFT method[J]. Composites Part B:Engineering, 2012, 43(3): 961-971. doi: 10.1016/j.compositesb.2011.08.055

|

| [25] |

Mehdikhani M, Gorbatikh L, Verpoest I, et al. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance[J]. Journal of Composite Materials, 2018, 53(12): 1579-1669.

|

| [26] |

Wang M, Zhang P, Fei Q, et al. Computational evaluation of the effects of void on the transverse tensile strengths of unidirectional composites considering thermal residual stress[J]. Composite Structures, 2019, 227: 111287. doi: 10.1016/j.compstruct.2019.111287

|

| [27] |

王猛, 郭飞, 于静巍, 等. 热残余应力对考虑微观孔隙碳纤维增强环氧树脂复合材料横向拉伸性能的影响[J]. WANG M, GUO F, YU J W, et al. Effects of thermal residual stress on transverse tensile strength of unidirectional carbon fiber reinforced epoxy composites considering void[J]. Acta Materiae Compositae Sinica, 2019, 36(5): 1101-1113复合材料学报, 2019, 36 (05): 1101-1113 (in Chinese).

|

| [28] |

Wang M. Computational evaluation of the effect of defects on the tensile properties of 2D woven composite considering thermal residual stress[J]. Composite Structures, 2022, 299: 116042. doi: 10.1016/j.compstruct.2022.116042

|

| [29] |

He C, Ge J, Cao X, et al. The effects of fiber radius and fiber shape deviations and of matrix void content on the strengths and failure mechanisms of UD composites by computational micromechanics[J]. Composites Science and Technology, 2022, 218: 109139. doi: 10.1016/j.compscitech.2021.109139

|

| [30] |

李波, 赵美英, 万小朋. 孔隙微观特征对碳纤维/环氧树脂复合材料横向拉伸强度的影响[J]. 复合材料学报, 2018, 35(7): 1864-1868. doi: 10.13801/j.cnki.fhclxb.20170825.001LI B, ZHAO M Y, WAN X P. Influence of void micro-characteristics on transverse tensile strength of unidirectional carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2018, 35(7): 1864-1868 (in Chinese). doi: 10.13801/j.cnki.fhclxb.20170825.001

|

| [31] |

Ashouri Vajari D, González C, Llorca J, et al. A numerical study of the influence of microvoids in the transverse mechanical response of unidirectional composites[J]. Composites Science and Technology, 2014, 97: 46-54. doi: 10.1016/j.compscitech.2014.04.004

|

| [32] |

Michel J C, Moulinec H, Suquet P. A computational scheme for linear and non-linear composites with arbitrary phase contrast[J]. International Journal for Numerical Methods in Engineering, 2001, 52(1-2): 139-160. doi: 10.1002/nme.275

|

| [33] |

Li J, Tian X-X, Abdelmoula R. A damage model for crack prediction in brittle and quasi-brittle materials solved by the FFT method[J]. International Journal of Fracture, 2012, 173(2): 135-146. doi: 10.1007/s10704-011-9671-1

|

| [34] |

Yang S, Tewari A, Gokhale A M. Modeling of non-uniform spatial arrangement of fibers in a ceramic matrix composite[J]. Acta Materialia, 1997, 45(7): 3059-3069. doi: 10.1016/S1359-6454(96)00394-1

|

| [35] |

Sun Q, Zhou G, Meng Z, et al. Failure criteria of unidirectional carbon fiber reinforced polymer composites informed by a computational micromechanics model[J]. Composites Science and Technology, 2019, 172: 81-95. doi: 10.1016/j.compscitech.2019.01.012

|

| [36] |

Foreman J P, Porter D, Behzadi S, et al. Predicting the thermomechanical properties of an epoxy resin blend as a function of temperature and strain rate[J]. Composites Part A:Applied Science and Manufacturing, 2010, 41(9): 1072-1076. doi: 10.1016/j.compositesa.2009.10.015

|

| [37] |

Wang B, Fang G, Liu S, et al. Effect of heterogeneous interphase on the mechanical properties of unidirectional fiber composites studied by FFT-based method[J]. Composite Structures, 2019, 220: 642-651. doi: 10.1016/j.compstruct.2019.04.049

|

| [38] |

Sun Q, Meng Z, Zhou G, et al. Multi-scale computational analysis of unidirectional carbon fiber reinforced polymer composites under various loading conditions[J]. Composite Structures, 2018, 196: 30-43. doi: 10.1016/j.compstruct.2018.05.025

|

| [39] |

Dong C. Development of a Model for Predicting the Transverse Coefficients of Thermal Expansion of Unidirectional Carbon Fibre Reinforced Composites[J]. Applied Composite Materials, 2008, 15(3): 171-182. doi: 10.1007/s10443-008-9065-3

|

| [40] |

Zhang F, Ye Y, Li M, et al. Computational modeling of micro curing residual stress evolution and out-of-plane tensile damage behavior in fiber-reinforced composites[J]. Composite Structures, 2023, 322: 117370. doi: 10.1016/j.compstruct.2023.117370

|

| [41] |

Wang B, Wang Z, Fang G, et al. Inverse determine the interfacial strength and surface geometry effects concerning carbon fiber reinforced epoxy composites by experiment aided FFT-based spectral analysis[J]. Polymer Composites, 2022, 43(12): 9205-9217. doi: 10.1002/pc.27098

|

点击查看大图

点击查看大图

下载:

下载: