Ultra-wide range composite flexible pressure sensor based on air layer structure and carbon nanotube modified dielectric layer

-

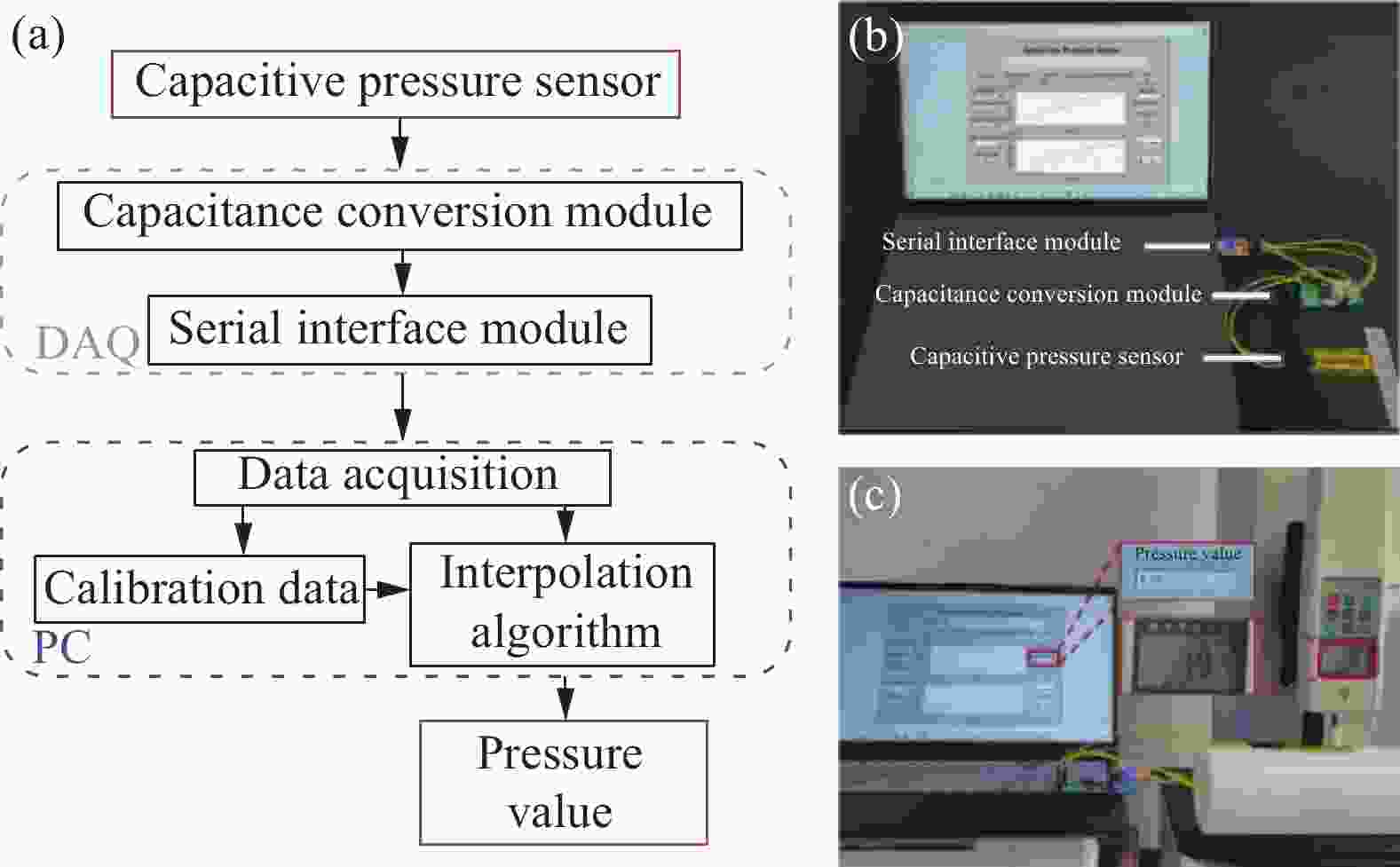

摘要: 宽检测范围和高灵敏度是保证柔性压力传感器在多种应用场景内保持高分辨率和高精度的关键参数。虽然目前已探索了多种微结构和复合材料介质层以提高传感器的灵敏度,但检测范围普遍较窄,并且宽检测范围和高灵敏度二者相互制约的问题始终无法解决。为此,设计了一种由空气层和多壁碳纳米管(MWCNTs)修饰的聚(偏二氟乙烯-三氟乙烯)P(VDF-TrFE)复合膜共同作为介质层的电容式柔性压力传感器。压力载荷下,空气层和复合介质层协同作用,使传感器检测范围从0.1~3.6 MPa扩宽至0.1~10 MPa,是目前已报道柔性压力传感器的最宽检测范围。同时,传感器在0.1~0.5 MPa和0.5~10 MPa范围内均展现出1.673 MPa−1和0.302 MPa−1的较高灵敏度以及优异的线性度。此外,考虑到实际应用,还开发了一套电容式压力传感器应力在线监测系统,准确性也达到了95.0 % 以上。基于传感器及其检测系统的开发与设计,成功展示了传感器在柔性电子器件领域和微小压力监测领域的潜在应用。

-

关键词:

- 柔性压力传感器 /

- 聚(偏二氟乙烯-三氟乙烯) /

- 多壁碳纳米管 /

- 超宽检测范围 /

- 高灵敏度

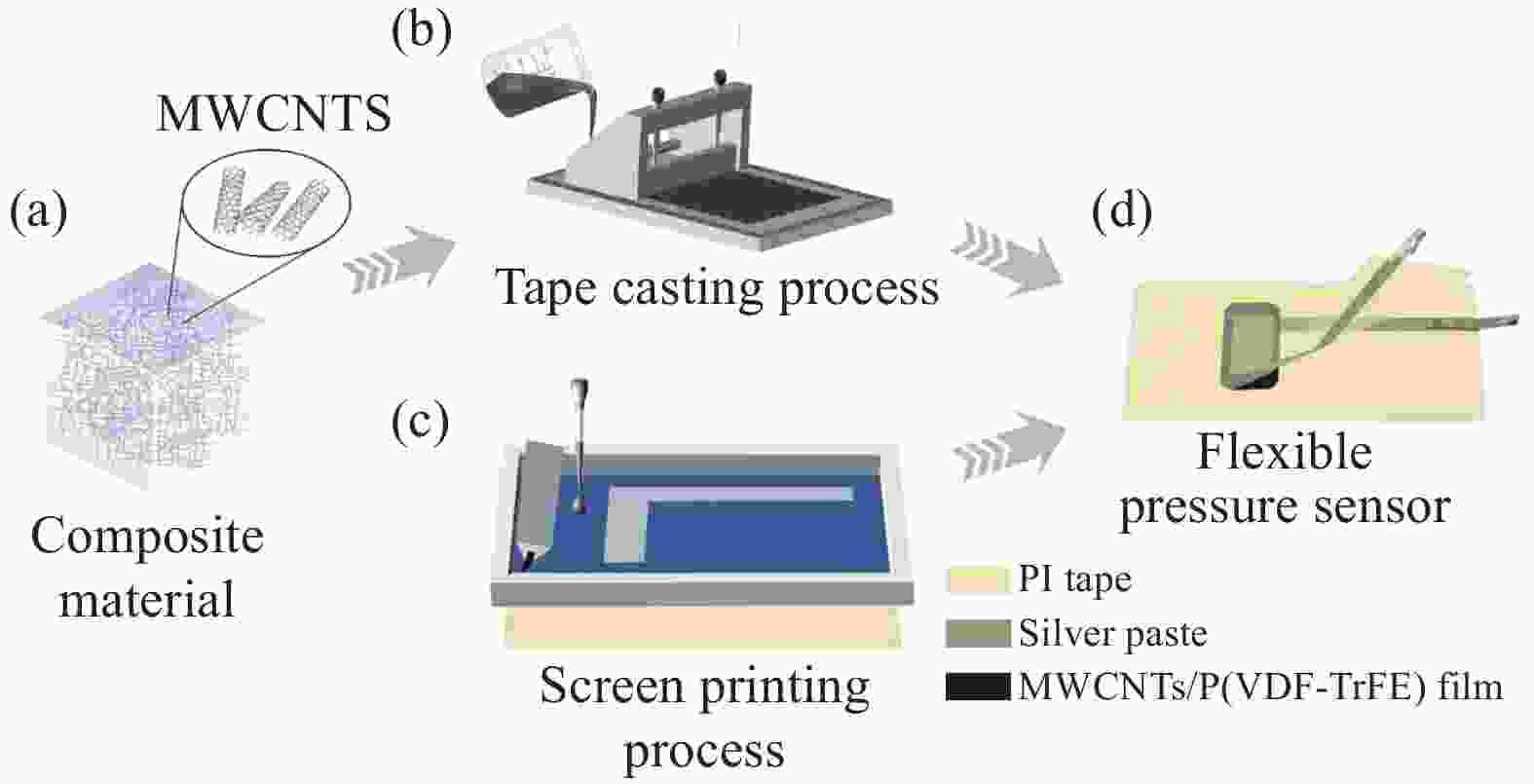

Abstract: A wide detecting range and high sensitivity are crucial factors to fabricate the flexible pressure sensors with high resolution and precision across various application scenarios. Despite the exploration of numerous microstructures and composite material mediums to enhance the sensitivity of pressure sensors, the detection range has remained narrow, because of the constraint between wide detection range and high sensitivity. In this study, a capacitive flexible pressure sensor with ultra-wide detecting range have been developed, where a multi-walled carbon nanotubes (MWCNTs) reinforced poly(vinylidene fluoride-co-trifluoroethylene) P(VDF-TrFE) composite was used as the dielectric layer. At same time, to enhance the sensitivity, an air layer was introduced between dielectric layer and packager layers. Consequently, the detected range as-fabricated sensor could reach to 0.1 – 10 MPa, which was wider than those of the reported flexible sensors. Additionally, it exhibits a high sensitivity (1.673 MPa−1 and 0.302 MPa−1) and excellent linearity in the ranges of 0.1 - 0.5 MPa and 0.5 - 10 MPa, respectively. Furthermore, an online monitoring system for capacitive pressure sensor stress was designed, of which the accuracy reached up to 95.0 %. Based on these results, the designed sensor and detecting system exhibited the potential applications flexible electronic devices and miniature pressure monitoring devices.-

Key words:

- Flexible pressure sensor /

- P(VDF-TrFE) /

- MWCNTs /

- Ultra-wide detecting range /

- High sensitivity

-

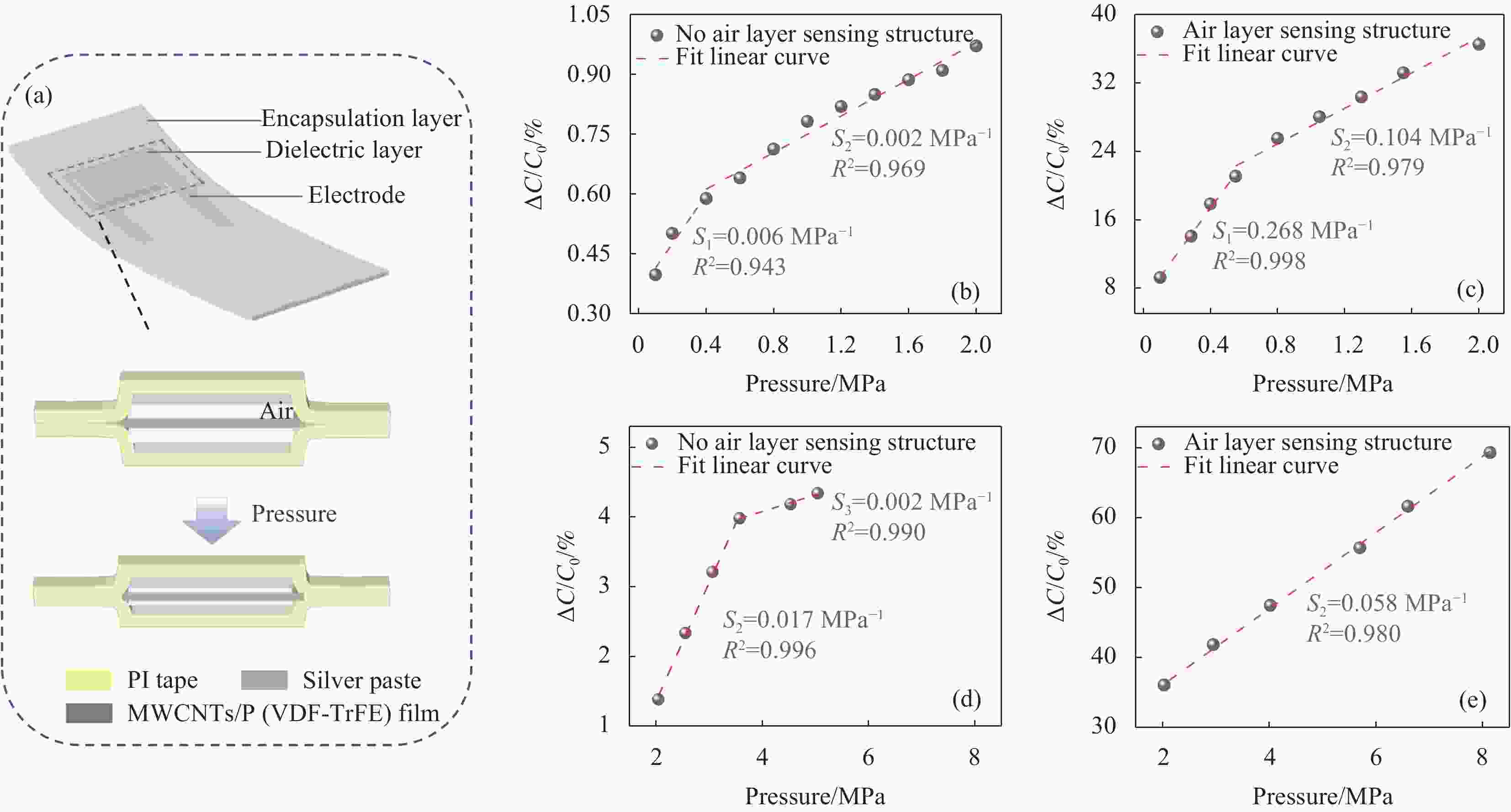

图 2 (a)柔性压力传感器结构示意图;(b,c)低应力范围(0.1-2 MPa)内不同制备工艺对传感灵敏度的影响;(d,e)高应力范围(2-8 MPa)内不同制备工艺对传感灵敏度的影响

Figure 2. (a) Structure of flexible pressure sensor; (b,c) The influence of different preparation processes on the sensitivity of the sensor in the low stress range (0.1-2 MPa); (d,e) The influence of different preparation processes on the sensitivity of the sensor in the high stress range (2-8 MPa).

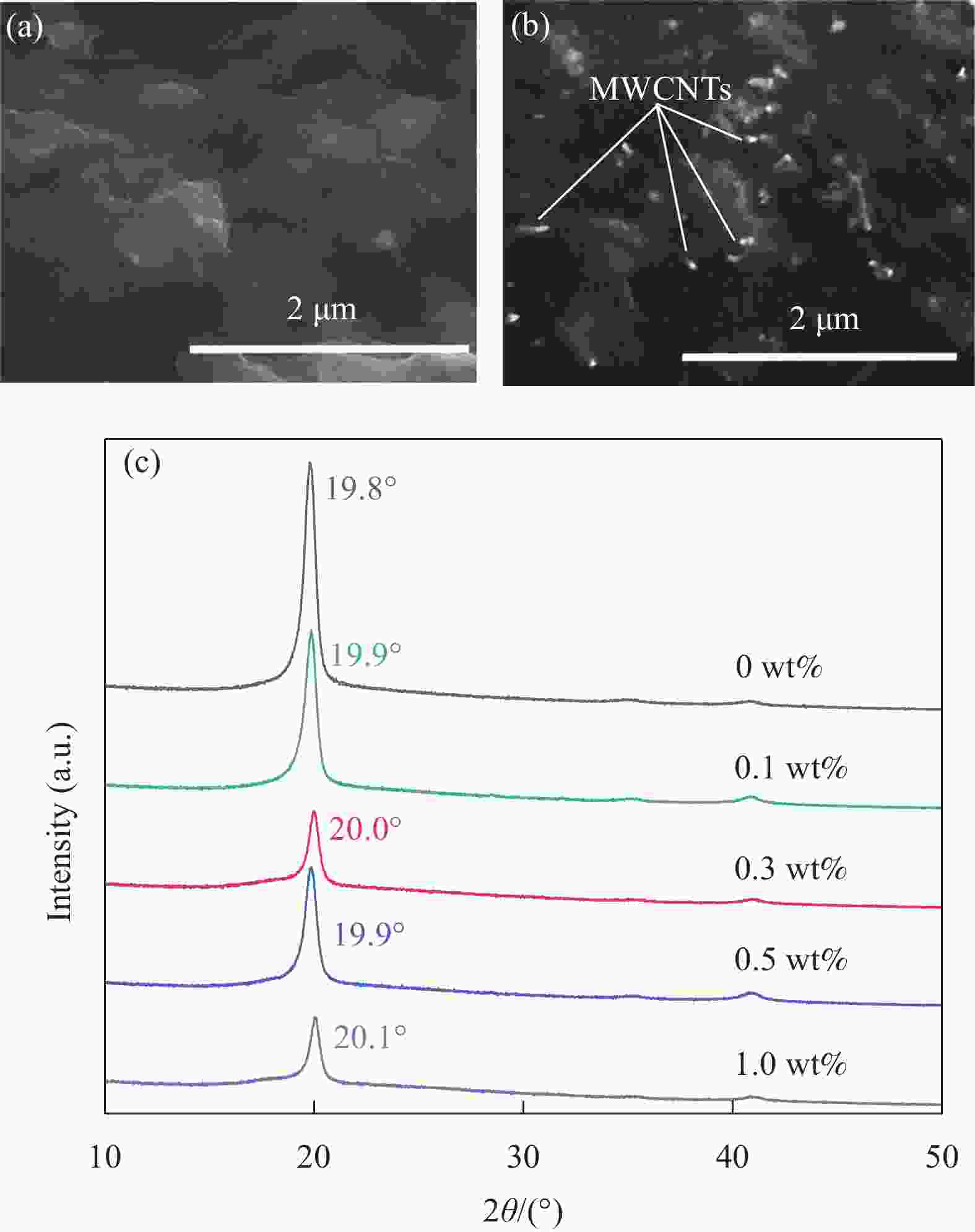

图 3 介质层膜SEM电镜结果:(a)纯聚合物; (b)复合膜; (c)不同质量比多壁碳纳米管(MWCNTs)/聚(偏二氟乙烯-三氟乙烯)P(VDF-TrFE)复合膜的X射线衍射测试结果

Figure 3. SEM results of dielectric layer: (a) pure polymer; (b) composite membranes; (c) X-ray diffraction test results of multi-walled carbon nanotubes (MWCNTs)/ poly(vinylidene fluoride-co-trifluoroethylene) P(VDF-TrFE) composite films with different mass ratios.

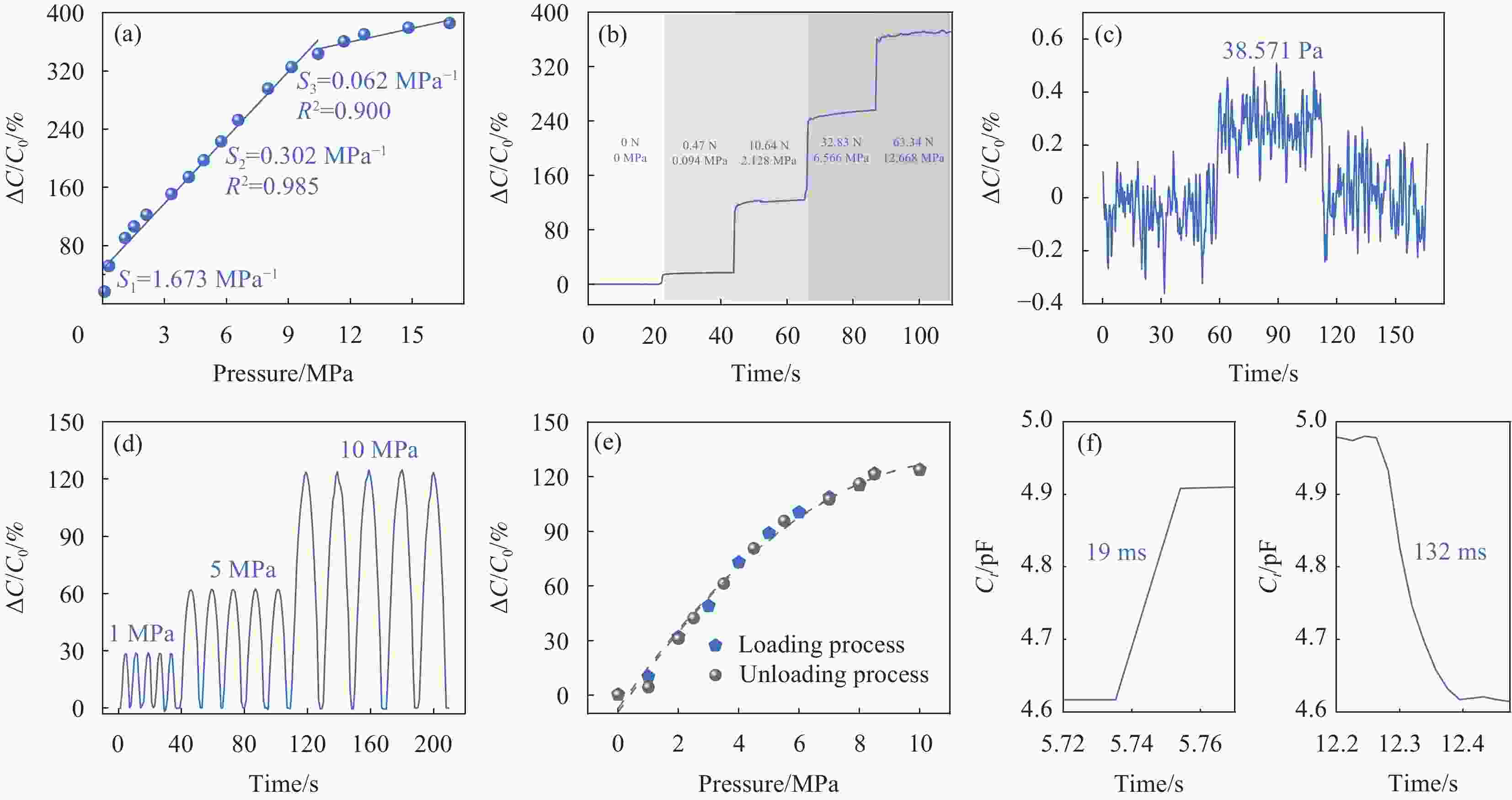

图 5 柔性压力传感器传感性能测试结果:(a)压力与相对电容变化率;(b)压力传感器在不同压力下的响应;(c) 38.571 Pa压力下传感器的响应-恢复曲线;(d)不同载荷下传感器多次重复测试的电容变化;(e)10 MPa载荷下传感器加载卸载电容变化曲线;(f) 68 kPa压力下传感器的响应时间和恢复时间

Figure 5. Sensing performance test results of the flexible pressure sensor: (a) pressure and relative capacitance change rate diagram; (b) The response of the pressure sensor under different pressures; (c) Sensor response-recovery curve at 38.571 Pa pressure; (d) Changes in the capacitance of the sensor under multiple repeated tests under different loads; (e) Change curve of sensor loading and unloading capacitance under 10 MPa load; (f) Response time and recovery time of the sensor at 68 kPa pressure

表 1 不同质量比MWCNTs/P(VDF-TrFE)复合膜性能对比

Table 1. Comparison of properties of MWCNTs/P (VDF-TrFE) composite films with different mass ratios

Concentration/wt% $ {{\varepsilon }}_{\rm{r}} $(F=50 kHz) E/GPa $ \dfrac{{{\varepsilon }}_{\rm{r}}}{\mathit{E}} $ 0 11.625 1.404 \ 0.1 11.957 1.588 7.530 0.3 12.531 1.645 7.618 0.5 12.599 1.748 7.208 1.0 13.138 1.773 7.410 Notes:εr-Dielectric constant of composite film; E-Young's modulus of composite film 表 2 电容式柔性压力传感器性能对比

Table 2. Performance comparison of capacitive flexible pressure sensors

Materials Thickness Pressure Range Response Time References CNS/GNP/TPU 0.8 mm 1.2 MPa - [32] TPM/PDMS 350 μm 1 MPa - [33] P(VDF-HFP)-based ion gel 250 μm 1.7 MPa 6 ms(5 kPa) [34] CB/CNTs/PDMS 2.2 mm 1.3 MPa 150 ms(5 kPa) [3] CNTs/PDMS - 2.55 MPa 60 ms(82.5 kPa) [35] MWCNTs/P(VDF-TrFE) 140 μm 10 MPa 19 ms(68 kPa) This work Notes: CNS-carbon nanostructures; GNP-graphene nanoplatelets; TPU-thermoplastic polyurethane; TPM-thermoplastic micro spheres; PDMS-polydimethylsiloxane; P(VDF-HFP)-poly(vinylidenefluofide-co-hexafluoropropylene); CB-carbon black; CNTs-carbon nanotubes; MWCNTs-multi-walled carbon nanotubes; P(VDF-TrFE)-poly(vinylidene fluoride-co-trifluoroethylene) 表 3 压力机与传感器系统测试结果对比

Table 3. Comparison of test results between forcemeter and sensor system

Forcemeter Results /N System Results/N Absolute Error/N 1.93 2.09 0.16 5.16 5.66 0.50 10.47 10.76 0.29 29.57 30.08 0.51 35.15 35.10 0.05 44.07 43.40 0.67 52.22 51.02 1.20 57.86 56.41 1.45 -

[1] PIERRE CLAVER U, Zhao G. Recent Progress in Flexible Pressure Sensors Based Electronic Skin[J]. Advanced Engineering Materials, 2021, 23(5): 1-17. [2] ZHONG M, ZHANG L, LIU X, et al. Wide linear range and highly sensitive flexible pressure sensor based on multistage sensing process for health monitoring and human-machine interfaces[J]. Chemical Engineering Journal, 2021, 412(January): 128649. [3] SHI Y, LU X, ZHAO J, et al. Flexible Capacitive Pressure Sensor Based on Microstructured Composite Dielectric Layer for Broad Linear Range Pressure Sensing Applications[J]. Micromachines, 2022, 13(2). [4] CHENG T, YANG X L, YANG S, et al. Flexible Transparent Bifunctional Capacitive Sensors with Superior Areal Capacitance and Sensing Capability based on PEDOT: PSS/MXene/Ag Grid Hybrid Electrodes[J]. Advanced Functional Materials, 2023, 33(5): 1-10. [5] GONG Y, ZHANG Y Z, FANG S, et al. Wireless Human-Machine Interface Based on Artificial Bionic Skin with Damage Reconfiguration and Multisensing Capabilities[J]. ACS Applied Materials and Interfaces, 2022, 14(41): 47300-47309. doi: 10.1021/acsami.2c14907 [6] YANG S, DING K, WANG W, et al. Electrospun fiber-based high-performance flexible multi-level micro-structured pressure sensor: Design, development and modelling[J]. Chemical Engineering Journal, 2022, 431(P4): 133700. [7] SU M, LI P, LIU X, et al. Textile-Based Flexible Capacitive Pressure Sensors: A Review[J]. Nanomaterials, 2022, 12(9): 1-24. [8] LEE H J, CHUN K Y, OH J H, et al. Wearable Triboelectric Strain-Insensitive Pressure Sensors Based on Hierarchical Superposition Patterns[J]. ACS Sensors, 2021, 6(6): 2411-2418. doi: 10.1021/acssensors.1c00640 [9] ZHANG J W, ZHANG Y, LI Y Y, et al. Textile-Based Flexible Pressure Sensors: A Review[J]. Polymer Reviews, 2022, 62(1): 65-94. doi: 10.1080/15583724.2021.1901737 [10] WANG J, SUZUKI R, SHAO M, et al. Capacitive Pressure Sensor with Wide-Range, Bendable, and High Sensitivity Based on the Bionic Komochi Konbu Structure and Cu/Ni Nanofiber Network[J]. ACS Applied Materials and Interfaces, 2019, 11(12): 11928-11935. doi: 10.1021/acsami.9b00941 [11] HE Z, CHEN W, LIANG B, et al. Capacitive Pressure Sensor with High Sensitivity and Fast Response to Dynamic Interaction Based on Graphene and Porous Nylon Networks[J]. ACS Applied Materials and Interfaces, 2018, 10(15): 12816-12823. doi: 10.1021/acsami.8b01050 [12] MISHRA R B, ELATAB N, HUSSAIN A M, et al. Recent Progress on Flexible Capacitive Pressure Sensors: From Design and Materials to Applications[J]. Advanced Materials Technologies, 2021, 6(4): 1-34. [13] YANG J C, MUN J, KWON S Y, et al. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics[J]. Advanced Materials, 2019, 31(48): 1-50. [14] LUO Y, ABIDIAN M R, AHN J H, et al. Technology Roadmap for Flexible Sensors[J]. ACS Nano, 2023, 17(6): 5211-5295. doi: 10.1021/acsnano.2c12606 [15] ZHANG J, YAO H, MO J, et al. Finger-inspired rigid-soft hybrid tactile sensor with superior sensitivity at high frequency[J]. Nature Communications, 2022, 13(1): 1-9. doi: 10.1038/s41467-021-27699-2 [16] WU Q, QIAO Y, GUO R, et al. Triode-Mimicking Graphene Pressure Sensor with Positive Resistance Variation for Physiology and Motion Monitoring[J]. ACS Nano, 2020, 14(8): 10104-10114. doi: 10.1021/acsnano.0c03294 [17] PYO S, CHOI J, KIM J. Flexible, Transparent, Sensitive, and Crosstalk-Free Capacitive Tactile Sensor Array Based on Graphene Electrodes and Air Dielectric[J]. Advanced Electronic Materials, 2018, 4(1): 1-8. [18] SHUAI X, ZHU P, ZENG W, et al. Highly Sensitive Flexible Pressure Sensor Based on Silver Nanowires-Embedded Polydimethylsiloxane Electrode with Microarray Structure[J]. ACS Applied Materials and Interfaces, 2017, 9(31): 26314-26324. doi: 10.1021/acsami.7b05753 [19] ZHOU Q, JI B, WEI Y, et al. A bio-inspired cilia array as the dielectric layer for flexible capacitive pressure sensors with high sensitivity and a broad detection range[J]. Journal of Materials Chemistry A, 2019, 7(48): 27334-27346. doi: 10.1039/C9TA10489E [20] HWANG J, KIM Y, YANG H, et al. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor[J]. Composites Part B: Engineering, 2021, 211(October 2020): 108607. [21] SHI L, LI Z, CHEN M, et al. Quantum effect-based flexible and transparent pressure sensors with ultrahigh sensitivity and sensing density[J]. Nature Communications, 2020, 11(1): 1-9. doi: 10.1038/s41467-019-13993-7 [22] KIM Y R, KIM M P, PARK J, et al. Binary Spiky/Spherical Nanoparticle Films with Hierarchical Micro/Nanostructures for High-Performance Flexible Pressure Sensors[J]. ACS Applied Materials and Interfaces, 2020, 12(52): 58403-58411. doi: 10.1021/acsami.0c18543 [23] JIN X, XU Z, WANG B, et al. A highly sensitive and wide-range pressure sensor based on orientated and strengthened TPU nanofiber membranes fabricated by a conjugated electrospinning technology[J]. Chemical Engineering Journal Advances, 2023, 14(April): 100491. [24] FAN Y, LIAO C, LEI X, et al. Piezo-capacitive behavior of a magnetically structured particle-based conductive polymer with high sensitivity and a wide working range[J]. Journal of Materials Chemistry C, 2018, 6(20): 5401-5411. doi: 10.1039/C8TC00302E [25] SUN Q J, Zhao X H, Zhou Y, et al. Fingertip-skin-inspired highly sensitive and multifunctional sensor with hierarchically structured conductive graphite/polydimethylsiloxane foams[J]. Advanced Functional Materials, 2019, 29(18): 1808829. doi: 10.1002/adfm.201808829 [26] YANG X, WANG Y, QING X. A flexible capacitive sensor based on the electrospun PVDF nanofiber membrane with carbon nanotubes[J]. Sensors and Actuators, A: Physical, 2019, 299: 111579. [27] CHHRTRY A, SHARMA S, YOON H, et al. Enhanced Sensitivity of Capacitive Pressure and Strain Sensor Based on CaCu3Ti4O12 Wrapped Hybrid Sponge for Wearable Applications[J]. Advanced Functional Materials, 2020, 30(31): 1-13. [28] SUNDARAM S, KELLNHOFER P, LI Y, et al. Learning the signatures of the human grasp using a scalable tactile glove[J]. Nature, 2019, 569(7758): 698-702. doi: 10.1038/s41586-019-1234-z [29] KIM U, JUNG D, JEONG H, et al. Integrated linkage-driven dexterous anthropomorphic robotic hand[J]. Nature Communications, 2021, 12(1): 1-13. doi: 10.1038/s41467-020-20314-w [30] WU Y, ZHAO X, LI F, et al. Evaluation of mixing rules for dielectric constants of composite dielectrics by MC-FEM calculation on 3D cubic lattice[J]. Journal of Electroceramics, 2003, 11: 227-239. doi: 10.1023/B:JECR.0000026377.48598.4d [31] BHAVANASI V, KUMAR V, PARIDA K, et al. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide[J]. ACS applied materials & interfaces, 2016, 8(1): 521-529. [32] KE K, MCMASTER M, CHRISYOPHERSON W, et al. Highly sensitive capacitive pressure sensors based on elastomer composites with carbon filler hybrids[J]. Composites Part A:Applied Science and Manufacturing, 2019, 126(August): 105614. [33] TAGAWA Y, LEE S, SOMEYA T, et al. A Capacitive Pressure Sensor with Linearity and High Sensitivity over a Wide Pressure Range using Thermoplastic Microspheres[J]. Advanced Electronic Materials, 2023, 9(9). [34] YANG R, DUTTA A, LO B, et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids[J]. Nature Communications, 2023, 14(1). [35] FU X, ZHANG J, XIAO J, et al. A high-resolution, ultrabroad-range and sensitive capacitive tactile sensor based on a CNT/PDMS composite for robotic hands[J]. Nanoscale, 2021, 13(44): 18780-18788. doi: 10.1039/D1NR03265H [36] CHEN S, LI M, HUANG Y, et al. Matrix-Addressed Flexible Capacitive Pressure Sensor with Suppressed Crosstalk for Artificial Electronic Skin[J]. IEEE Transactions on Electron Devices, 2020, 67(7): 2940-2944. doi: 10.1109/TED.2020.2991684 -

点击查看大图

点击查看大图

计量

- 文章访问数: 62

- HTML全文浏览量: 34

- 被引次数: 0

下载:

下载: