Field tests and load-displacement models of GFRP bars and steel bars for anti-floating anchors

-

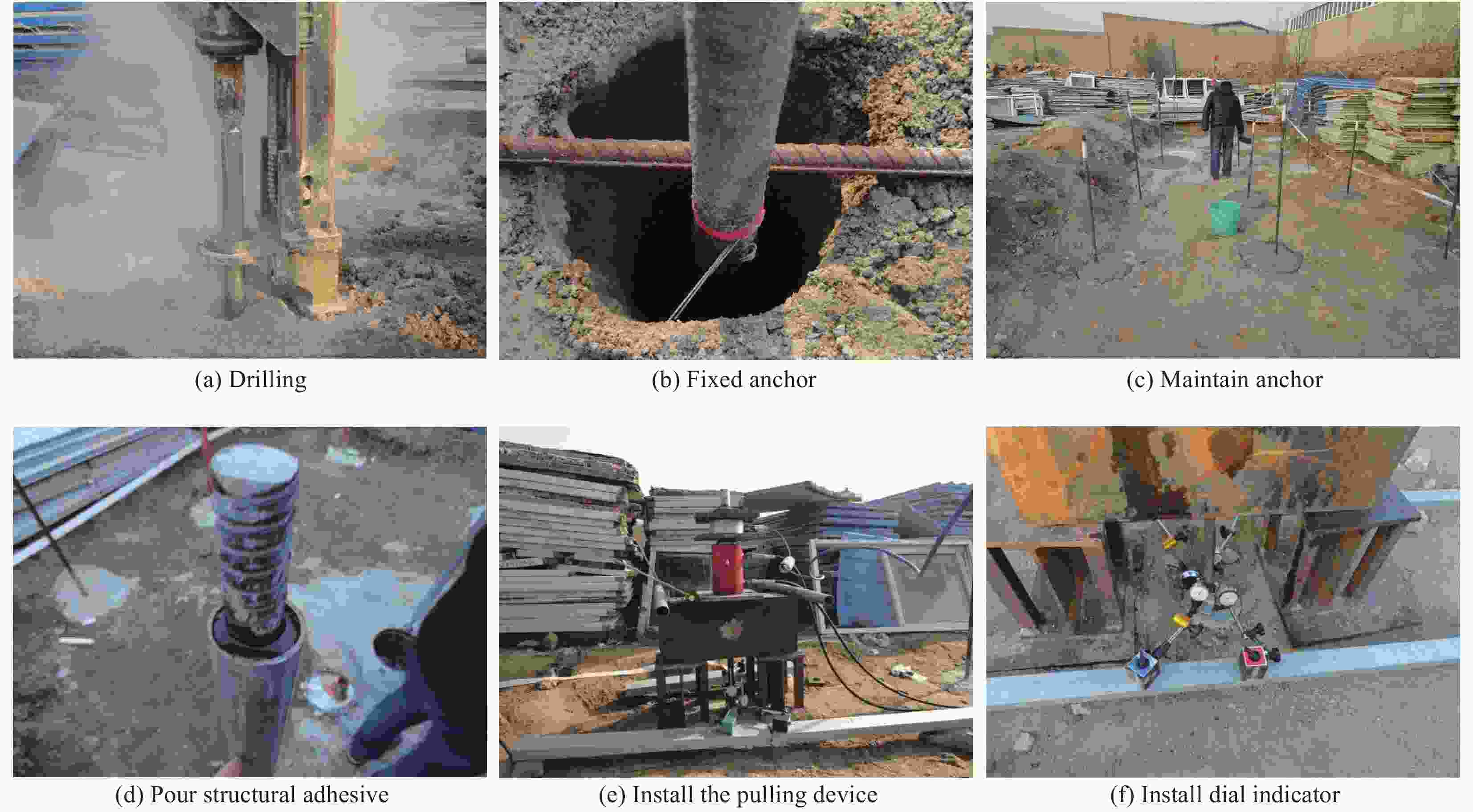

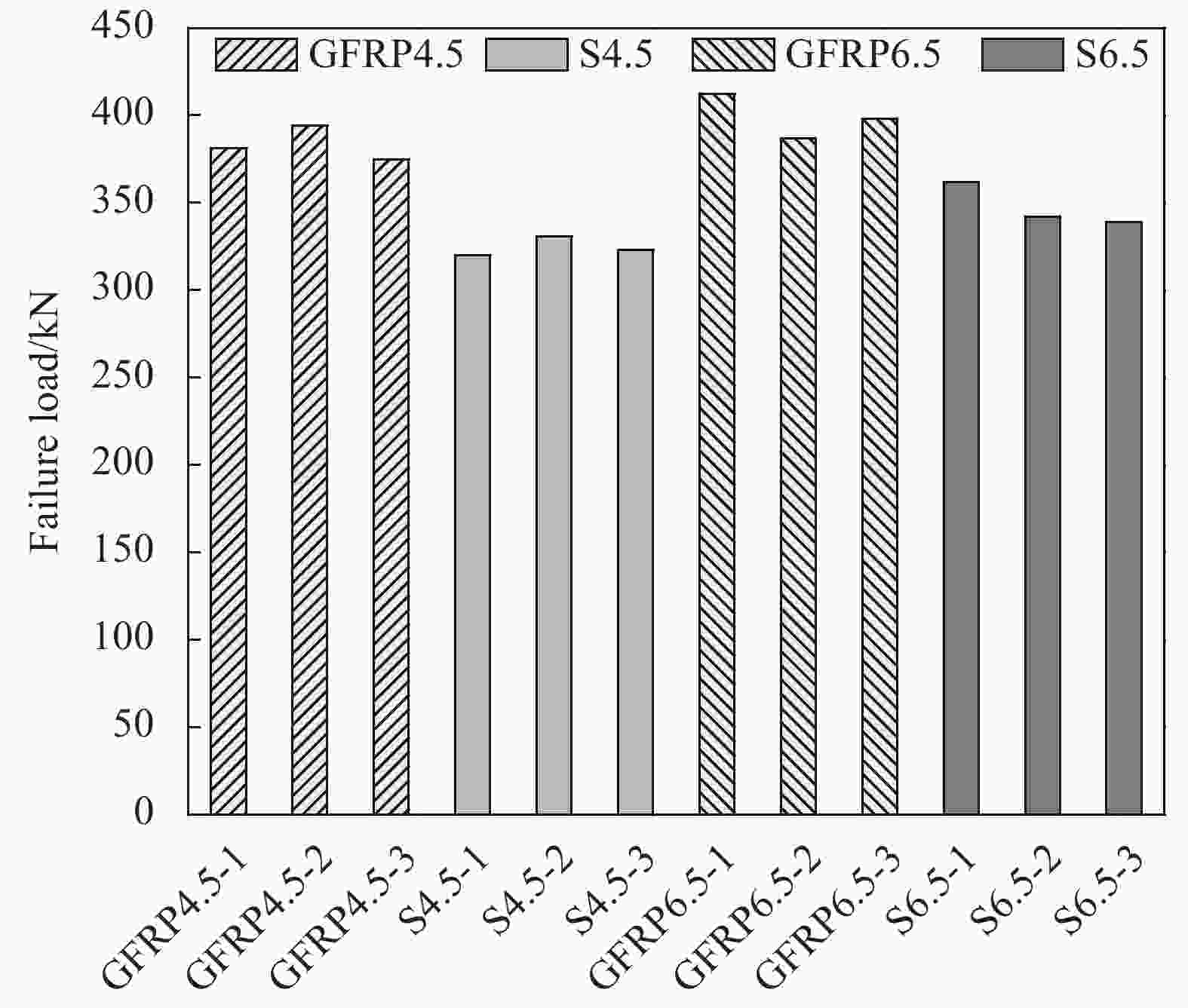

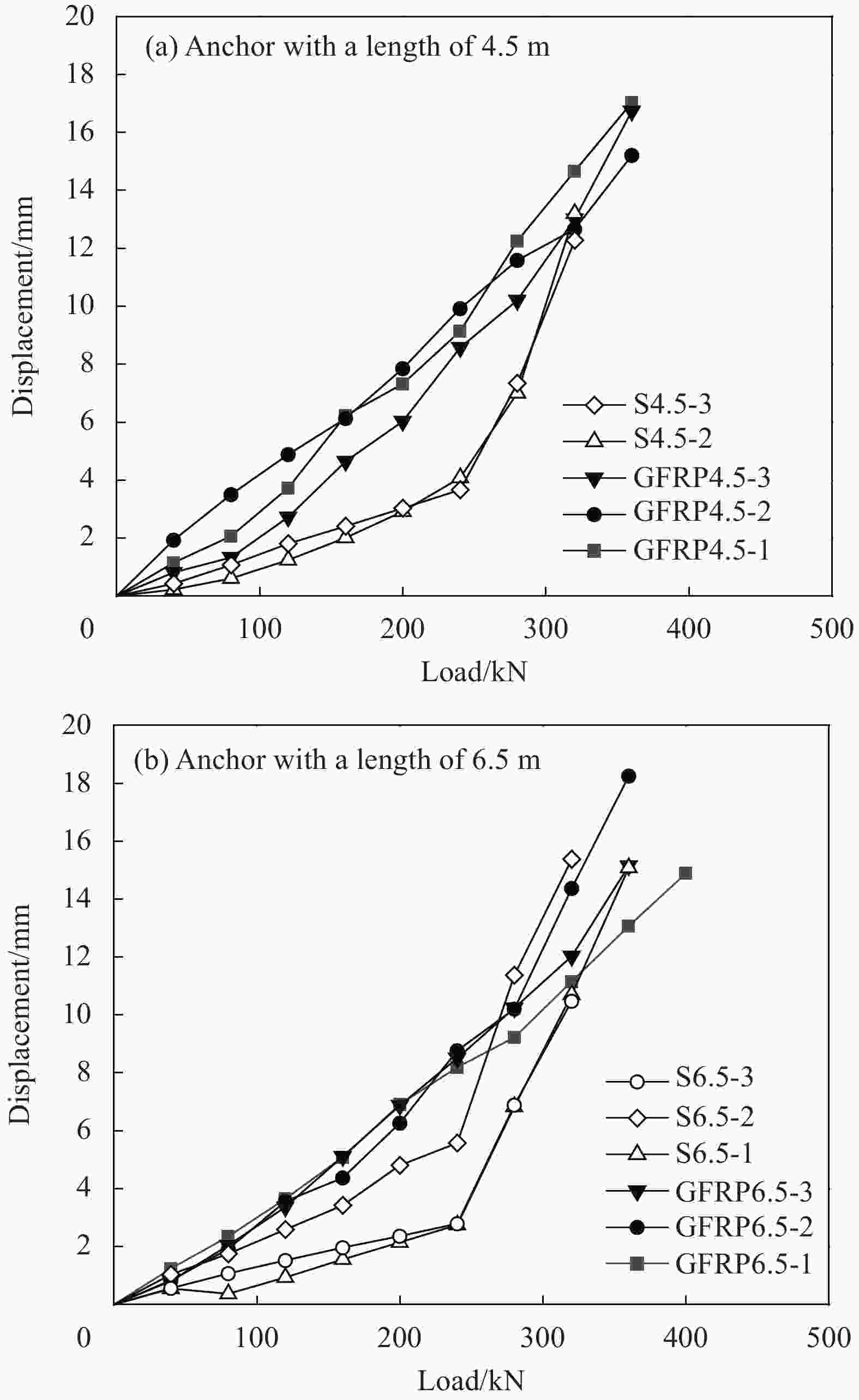

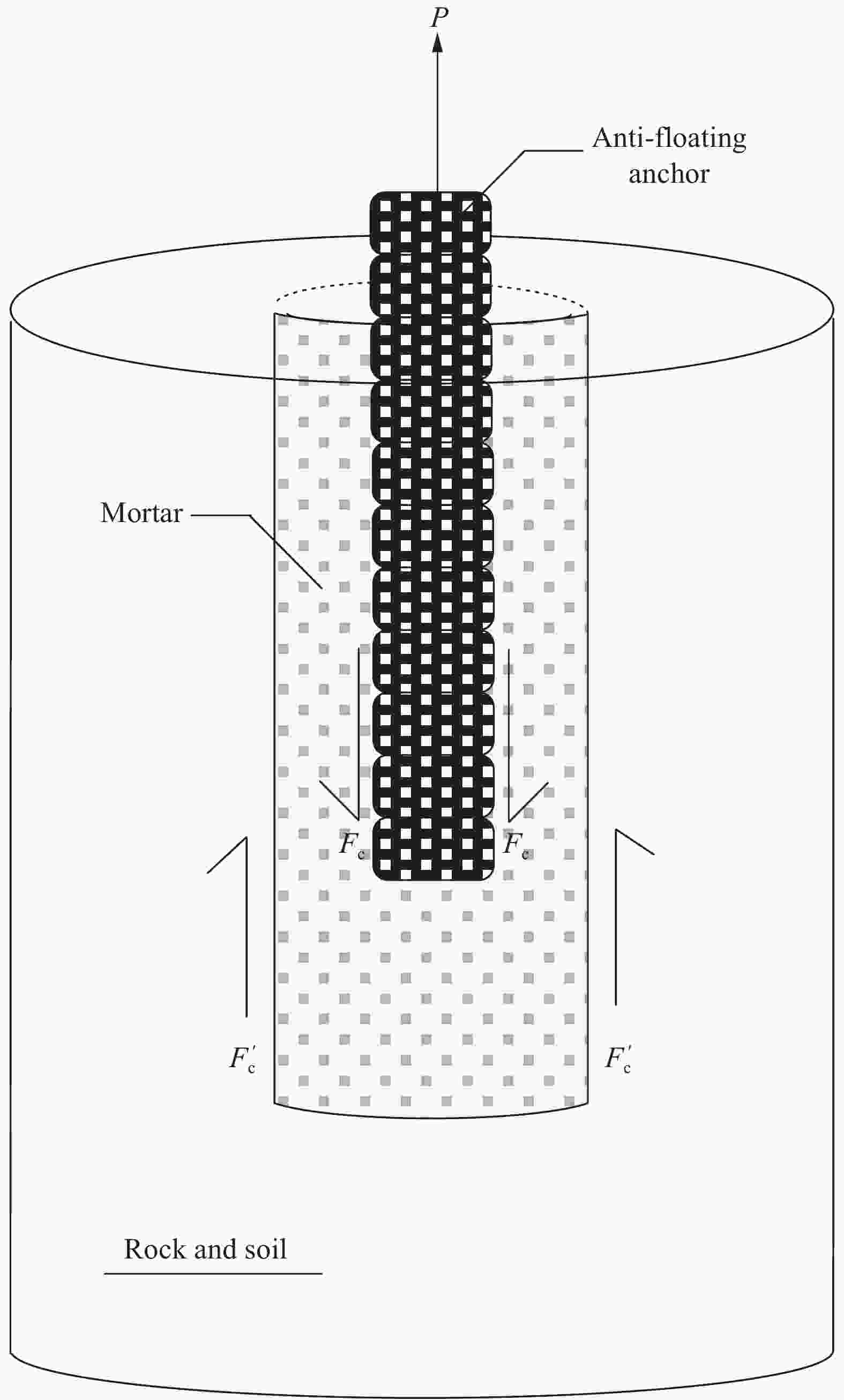

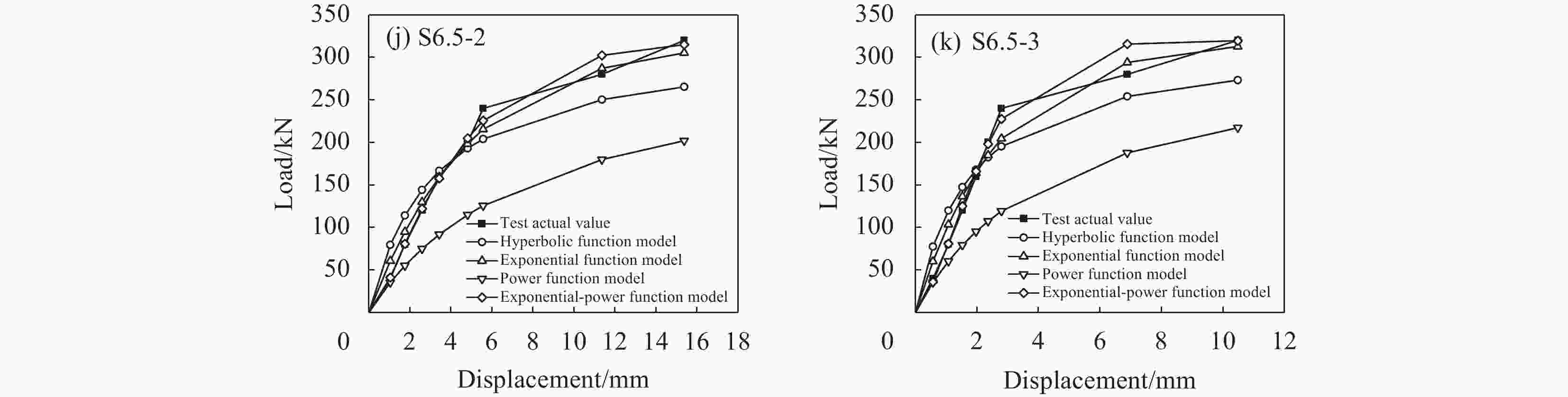

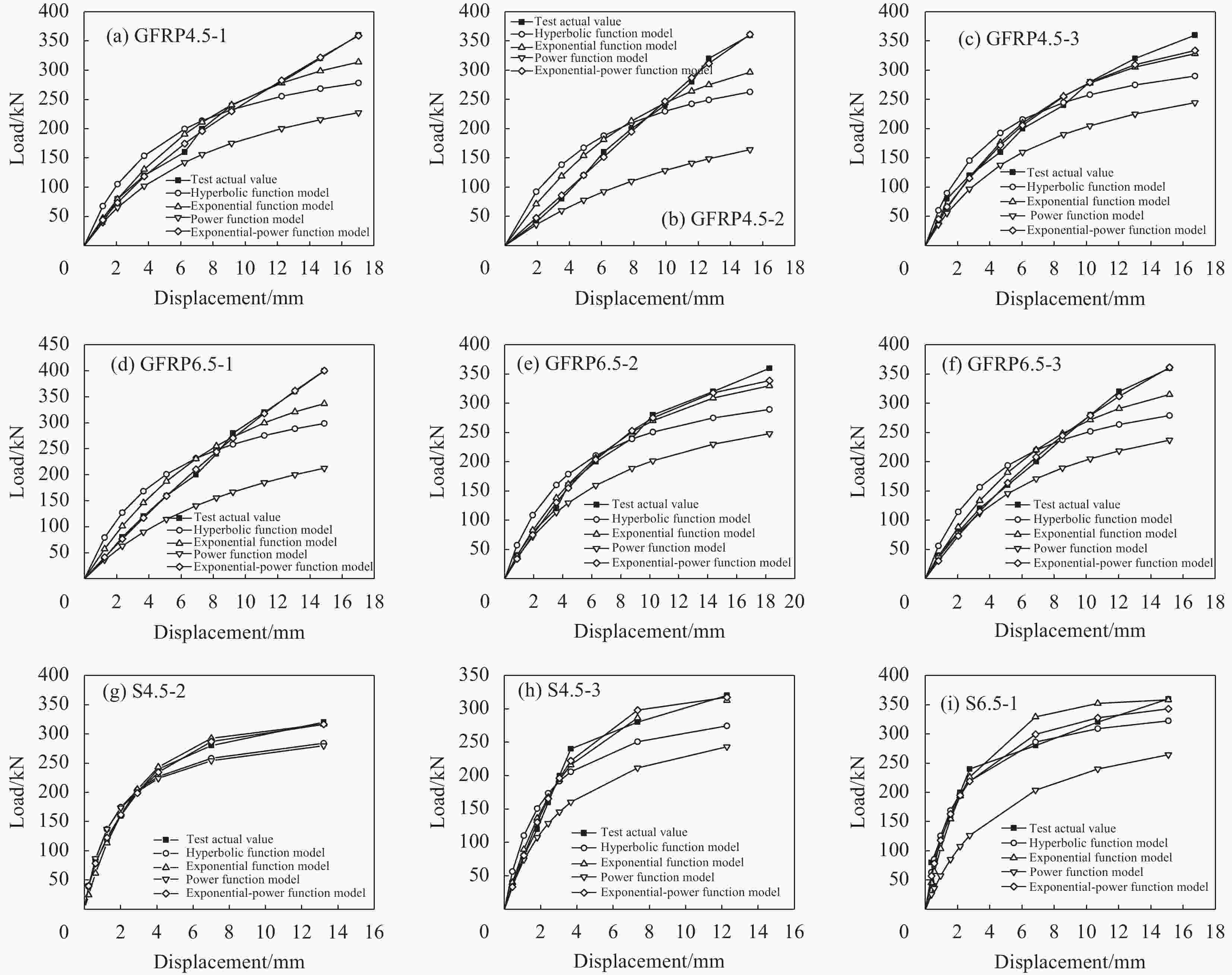

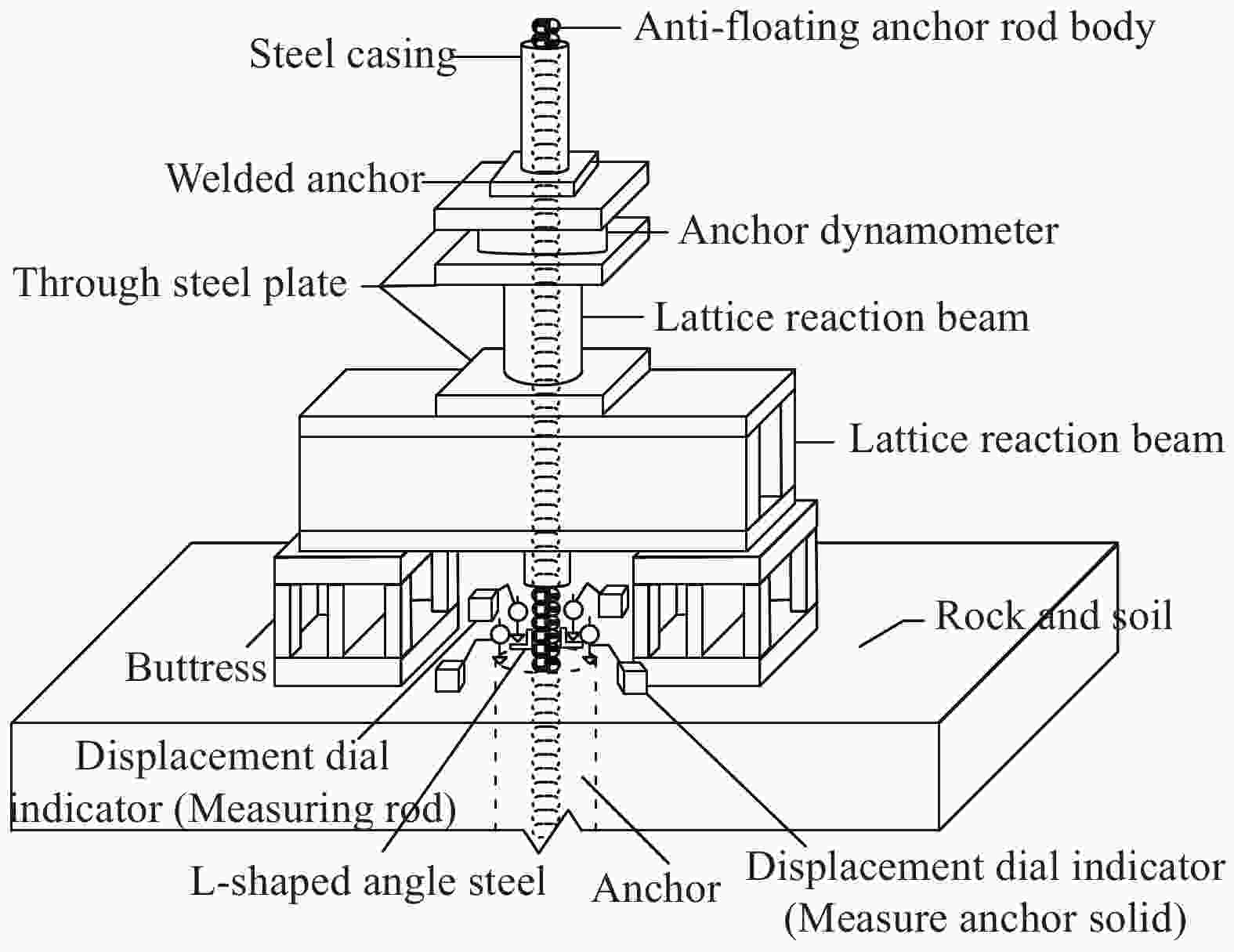

摘要: 玻璃纤维增强聚合物(Glass fiber reinforced polymer,GFRP)锚杆是从非金属锚杆中发展出的新型复合材料锚杆,具有自重轻、抗拉强度高、造价低、抗腐蚀性能好、抗电磁干扰能力强等优点。基于某中风化花岗岩场地的GFRP筋及钢筋抗浮锚杆的破坏性拉拔试验,对抗浮锚杆在拉拔过程中锚杆杆体及锚固体的位移进行测量,分析了不同材质、不同锚固长度的抗浮锚杆的承载性能及杆体、锚固体相对滑移量的差异,对比不同荷载-位移模型并获得了最适宜岩石抗浮锚杆的荷载-位移模型。试验结果表明:在中风化花岗岩中,相同锚固长度下的GFRP抗浮锚杆比钢筋抗浮锚杆的破坏荷载增加13%~14%,GFRP抗浮锚杆更易发生杆体拔出破坏,锚固系统仍有残余承载力未发挥,使用GFRP锚杆代替钢筋锚杆具有可行性;与锚固长度为4.5 m的GFRP抗浮锚杆相比,锚固长度为6.5 m的锚杆杆体相对于锚固体的滑移量更大,增大GFRP抗浮锚杆的锚固长度可有效增加其相对滑移量,但提升钢筋抗浮锚杆的锚固长度对其破坏形态无明显影响;双曲线函数及幂函数荷载-位移曲线模型与实测值吻合度较差,指-幂函数曲线模型对本次试验锚杆的破坏荷载预测精度最高,曲线整体走势较一致。Abstract: Glass fiber reinforced polymer (GFRP) anchor is a new type of composite anchor developed from non-metallic anchors. It has the advantages of light weight, high tensile strength, low cost, good corrosion resistance and strong electromagnetic interference resistance. Based on the destructive pull test of GFRP anchors and reinforced anti-floating anchor conducted on a medium-weathered granite site, the displacement of the anchor body and anchor solid during the drawing process of the anti-floating anchor was measured. The bearing capacity of anti-floating anchors with different materials and different anchoring lengths and the relative slip between anchor body and anchor were analyzed. The different load-displacement models were compared and the most suitable load-displacement model for rock anti-floating anchors was sought. The test results show that: In medium-weathered granite, the GFRP anti-floating anchors at the same anchoring length increase the failure load by 13% to 14% compared with the reinforced anti-floating anchors. GFRP anti-floating anchors are more prone to pull-out and failure of the anchor body, and the residual bearing capacity of the anchoring system is still not exerted. It is feasible to use GFRP anchors instead of steel anchors. Compared with the GFRP anti-floating anchor with an anchoring length of 4.5 m, the anchor body with an anchoring length of 6.5 m has a greater slippage relative to the anchor solid. Increasing the anchoring length of the GFRP anti-floating anchor can effectively increase its relative slip, and increasing the anchoring length has no obvious effect on the failure mode of the reinforced anti-floating anchor. The hyperbolic function and power function load-displacement curve models are in poor agreement with the measured values, while the finger-power function curve model has the highest accuracy in predicting the failure load of the anchors in this test, and the overall trend of the curve is more consistent.

-

Key words:

- GFRP anti-floating anchor /

- field pull-out test /

- bearing behavior /

- Q-s curve /

- load-displacement model

-

表 1 试验锚杆主要力学参数

Table 1. Main mechanical parameters of test bolt

Anchor material Tensile capacity/kN Tensile strength/MPa Shear strength/MPa Elastic modulus/GPa GFRP 416 675 150 41 Rebar 351 570 277 210 Note: GFRP—Glass fiber reinforced ploymer. 表 2 抗浮锚杆试验参数

Table 2. Anti-floating anchor test parameters

Anchor number Anchor rod diameter/mm Total length of anchor rod/mm Length of anchoring section/mm GFRP6.5-1 28 8000 6500 GFRP6.5-2 28 8000 6500 GFRP6.5-3 28 8000 6500 GFRP4.5-1 28 6000 4500 GFRP4.5-2 28 6000 4500 GFRP4.5-3 28 6000 4500 S6.5-1 28 8000 6500 S6.5-2 28 8000 6500 S6.5-3 28 8000 6500 S4.5-1 28 6000 4500 S4.5-2 28 6000 4500 S4.5-3 28 6000 4500 Notes: GFRP6.5—GFRP anti-floating anchors with an anchorage length of 6.5 m; GFRP4.5—GFRP anti-floating anchors with an anchorage length of 4.5 m; S—Steel bar. 表 3 试验结果统计

Table 3. Test results statistics

Anchor number Anchor length/m Failure load/kN Maximum rod lift/mm Anchor solid limit lift/mm Destruction form GFRP4.5-1 4.5 381 17.03 12.67 Shear slip failure GFRP4.5-2 4.5 394 15.21 11.47 Disconnect failure GFRP4.5-3 4.5 375 16.74 11.35 Shear slip failure GFRP6.5-1 6.5 412 14.89 12.25 Disconnect failure GFRP6.5-2 6.5 387 18.26 13.27 Shear slip failure GFRP6.5-3 6.5 398 15.16 12.45 Disconnect failure S4.5-1 4.5 320 58.05 15.89 Shear slip failure S4.5-2 4.5 331 13.21 8.47 Disconnect failure S4.5-3 4.5 323 12.28 8.13 Disconnect failure S6.5-1 6.5 362 15.09 11.67 Disconnect failure S6.5-2 6.5 342 15.39 12.16 Disconnect failure S6.5-3 6.5 339 10.49 7.58 Disconnect failure 表 4 抗浮锚杆各Q-s模型极限承载力计算精度

Table 4. Calculation accuracy of ultimate bearing capacity of each Q-s models of anti-floating anchors

Anchor

numberMeasured

ultimate

bearing

capacity/kNHyperbolic function

modelExponential function

modelPower function

modelExponential-power

function modelPredictive

value/kNRelative

error/%Predictive

value/kNRelative

error/%Predictive

value/kNRelative

error/%Predictive

value/kNRelative

error/%GFRP4.5-1 360 278.23 −22.71 313.99 −12.78 227.57 −36.79 359.07 −0.26 GFRP4.5-2 360 262.85 −26.99 296.55 −17.63 164.16 −54.40 361.07 0.30 GFRP4.5-3 360 290.05 −19.43 328.15 −8.85 244.42 −32.11 333.78 −7.28 GFRP6.5-1 400 298.83 −25.29 337.03 −15.74 212.65 −46.84 400.46 0.11 GFRP6.5-2 360 289.59 −19.56 329.96 −8.34 248.10 −31.08 338.92 −5.86 GFRP6.5-3 360 279.14 −22.46 315.20 −12.44 236.94 −34.18 361.56 0.43 S4.5-2 320 284.07 −11.23 316.87 −0.98 279.69 −12.60 316.57 −1.07 S4.5-3 320 274.58 −14.19 312.61 −2.31 243.22 −23.99 317.41 −0.81 S6.5-1 320 322.31 0.72 358.41 12.00 264.35 −17.39 343.00 7.19 S6.5-2 360 265.38 −26.28 305.39 −15.17 202.11 −43.86 315.21 −12.44 S6.5-3 320 273.44 −14.55 313.01 −2.18 217.35 −32.08 319.78 −0.07 表 5 抗浮锚杆各Q-s模型计算参数

Table 5. Calculation parameters of each Q-s models of anti-floating anchors

Anchor

numberHyperbolic function

model αExponential function

model β/mm−1Power function

model Ki/(kN·mm−1)Exponential-power function model a b k GFRP4.5-1 4.0254 −0.1454 34.4828 0.0023 −0.0729 −0.9053 GFRP4.5-2 5.6219 −0.1141 20.6718 0.2949 −0.0660 186.4119 GFRP4.5-3 4.0374 −0.1449 49.3827 0.2360 3.8378 −0.9430 GFRP6.5-1 5.0408 −0.1242 32.1285 −0.0224 −0.0673 0.3136 GFRP6.5-2 4.4397 −0.1360 47.6191 0.2325 1.0623 −0.8018 GFRP6.5-3 4.3914 −0.1374 49.3827 0.0031 −0.0664 −0.9239 S4.5-2 1.6707 −0.3502 173.9130 0.4572 1.8488 −0.8234 S4.5-3 2.0314 −0.3069 91.9540 0.4843 0.0940 0.4394 S6.5-1 1.7642 −0.3595 72.7273 0.1578 0.0407 −0.7045 S6.5-2 3.1663 −0.2006 38.2775 0.3956 110.2263 −0.9961 S6.5-3 1.7852 −0.3648 70.1754 0.8980 0.2717 1.2221 Note: a, b, k—Parameters to be fitted. -

[1] KUANG Z, ZHANG M Y, BAI X Y. Load-bearing characteristics of fibreglass uplift anchors in weathered rock[J]. Proceedings of the Institution of Civil Engineers-Geotechnical Engineering,2020,173(1):49-57. doi: 10.1680/jgeen.18.00195 [2] LI F, ZHAO Q L, CHEN H S, et al. Interface shear stress analysis of bond FRP tendon anchorage under different boundary conditions[J]. Composite Interfaces,2011,18(2):91-106. doi: 10.1163/092764411X571427 [3] 白晓宇, 张明义, 匡政, 等. 全长黏结GFRP抗浮锚杆荷载分布函数模型研究[J]. 中南大学学报(自然科学版), 2020, 51(7):1977-1988. doi: 10.11817/j.issn.1672-7207.2020.07.023BAI Xiaoyu, ZHANG Mingyi, KUANG Zheng, et al. Load distribution function model of full-length bond GFRP anti-floating anchor[J]. Journal of Central South University (Science and Technology),2020,51(7):1977-1988(in Chinese). doi: 10.11817/j.issn.1672-7207.2020.07.023 [4] ALVES J, EL-RAGABY A, EL-SALAKAWY E. Durability of GFRP bars’ bond to concrete under different loading and environmental conditions[J]. Journal of Composites for Construction,2010,15(3):249-262. [5] 贾金青, 宋二祥. 滨海大型地下工程抗浮锚杆的设计与试验研究[J]. 岩土工程学报, 2002, 24(6):769-771. doi: 10.3321/j.issn:1000-4548.2002.06.021JIA Jinqing, SONG Erxiang. Design and Experimental study of anti-floating anchor rods for large-scale underground engineering in binhai[J]. Chinese Journal of Geotechnical Engineering,2002,24(6):769-771(in Chinese). doi: 10.3321/j.issn:1000-4548.2002.06.021 [6] 张乐文, 汪稔. 岩土锚固理论研究之现状[J]. 岩土力学, 2002, 23(5):627-631. doi: 10.3969/j.issn.1000-7598.2002.05.022ZHANG Lewen, WANG Ren. Current status of research on rock-soil anchoring theory[J]. Rock and Soil Mechanics,2002,23(5):627-631(in Chinese). doi: 10.3969/j.issn.1000-7598.2002.05.022 [7] 白晓宇, 郑晨, 张明义, 等. 大直径GFRP抗浮锚杆蠕变试验及蠕变模型[J]. 岩土工程学报, 2020, 42(7):1304-1311.BAI Xiaoyu, ZHENG Chen, ZHANG Mingyi, et al. Creep tests and standard linear solid model for large-diameter glass fiber-reinforced polymer anti-floating anchors[J]. Chinese Journal of Geotechnical Engineering,2020,42(7):1304-1311(in Chinese). [8] TASTANI S P, PANTAZOPOU S J. Bond of GFRP bars in concrete: Experimental study and analytical interpretation[J]. Journal of Composites for Construction,2006,10(5):381-391. doi: 10.1061/(ASCE)1090-0268(2006)10:5(381) [9] 黄生文, 邱贤辉, 罗文兴. GFRP锚杆锚固特性研究[J]. 长沙理工大学学报(自然科学版), 2009, 6(3):33-39.HUANG Shengwen, QIU Xianhui, LUO Wenxing. Research on anchoring characteristics of GFRP anchor rod[J]. Journal of Changsha University of Science and Technology (Natural Science Edition),2009,6(3):33-39(in Chinese). [10] 张明义, 寇海磊, 白晓宇, 等. 玻璃纤维增强聚合物抗浮锚杆抗拔性能试验研究与机制分析[J]. 岩土力学, 2014, 35(4):1069-1076.ZHANG Mingyi, KOU Hailei, BAI Xiaoyu, et al. Experimental research and mechanism analysis of the anti-floating anchor rod pull-out performance of glass fiber reinforced polymer[J]. Rock and Soil Mechanics,2014,35(4):1069-1076(in Chinese). [11] KOU H L, GUO W, ZHANG M Y. Pullout performance of GFRP anti-floating anchor in weathered soil[J]. Tunnelling and Underground Space Technology, 2015, 49: 408-416. [12] 尤志嘉, 付厚利, 尤春安, 等. 土层锚固体应力传递机制[J]. 岩土力学, 2018, 39(1):85-92.YOU Zhijia, FU Houli, YOU Chun’an, et al. Stress transfer mechanism of soil anchorage[J]. Rock and Soil Mechanics,2018,39(1):85-92(in Chinese). [13] GOORANORIMI O, SUARIS W, NANNI A. A model for the bond-slip of a GFRP bar in concrete[J]. Engineering Structures,2017,146:34-42. doi: 10.1016/j.engstruct.2017.05.034 [14] 中国建筑科学研究院. 建筑基坑支护技术规程: JGJ120—2012[S]. 北京: 中国建筑工业出版社, 2012.China Academy of Building Research. Technical specification for foundation pit support: JGJ120—2012[S]. Beijing: China Building Industry Press, 2012(in Chinese). [15] 中国建筑科学研究院. 建筑地基基础设计规范: GB50007—2011[S]. 北京: 中国建筑工业出版社, 2011.China Academy of Building Research. Code for design of building foundation: GB50007—2011[S]. Beijing: China Building Industry Press, 2011(in Chinese). [16] HYETT A J, BAWDEN W F, MACSPORRAN G R, et al. A constitutive law for bond failure of fully-grouted cable bolts using a modified Hoek cell[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1995,32(1):11-36. [17] 付文光, 柳建国, 杨志银. 抗浮锚杆及锚杆抗浮体系稳定性验算公式研究[J]. 岩土工程学报, 2014, 36(11):1971-1982. doi: 10.11779/CJGE201411002FU Wenguang, LIU Jianguo, YANG Zhiyin. Study on the formula for checking the stability of anti-floating anchor rod and anti-floating system of anchor rod[J]. Chinese Journal of Geotechnical Engineering,2014,36(11):1971-1982(in Chinese). doi: 10.11779/CJGE201411002 [18] 王贤能, 曾卫东, 徐金台. 岩石抗浮锚杆的应用及分析[C]//中国岩石力学与工程学会第七次学术大会论文集. 西安, 2002: 831−835.WANG Xianneng, ZENG Weidong, XU Jintai. Application and analysis of rock anti-floating anchor[C]// Proceedings of the Seventh Academic Conference of Chinese Society of Rock Mechanics and Engineering. Xi’an, 2002: 831−835. [19] 贾金青, 宋二祥. 滨海大型地下工程抗浮锚杆的设计与试验研究[J]. 岩土工程学报, 2002, 24(6):669-771.JIA Jinqing, SONG Erxiang. Design and experimental study of anti-floating anchor in Binhai large underground project[J]. Journal of Geotechnical Engineering,2002,24(6):669-771(in Chinese). [20] 陈根全. 锚杆桩的抗拔试验[J]. 工程勘察, 1997, 25(2):15-16.CHEN Genquan. Uplift test of anchor pile[J]. Engineering Survey,1997,25(2):15-16(in Chinese). [21] 赵卫平, 朱彬荣. 高温后HSC粘结滑移基础参数测量与3D有限元数值模拟[J]. 工程力学, 2017, 34(4):177-186.ZHAO Weiping, ZHU Binrong. Measurement of HSC bond slip foundation parameters and 3D finite element numerical Simulation after high temperature[J]. Engineering Mechanics,2017,34(4):177-186(in Chinese). [22] 刘凌锋. FRP管与混凝土的粘结性能试验研究[D]. 南京: 东南大学, 2016.LIU Lingfeng. Experimental Study on bond performance of FRP pipe and concrete[D]. Nanjing: Southeast University, 2016(in Chinese). [23] 张季如, 唐保付. 锚杆荷载传递机理分析的双曲函数模型[J]. 岩土工程学报, 2002, 24(2):188-192. doi: 10.3321/j.issn:1000-4548.2002.02.013ZHANG Jiru, TANG Baofu. Hyperbolic function model to analyze load transfer mechanism on bolts[J]. Chinese Journal of Geotechnical Engineering,2002,24(2):188-192(in Chinese). doi: 10.3321/j.issn:1000-4548.2002.02.013 [24] 应志民, 张洁, 尚岳全. 锚杆荷载-位移曲线的指数函数模型研究[J]. 岩土力学, 2005, 26(8):1331-1334. doi: 10.3969/j.issn.1000-7598.2005.08.028YING Zhimin, ZHANG Jie, SHANG Yuequan. Exponential model for simulating load-displacement curve of anchor rod[J]. Rock and Soil Mechanics,2005,26(8):1331-1334(in Chinese). doi: 10.3969/j.issn.1000-7598.2005.08.028 [25] 许宏发, 钱七虎, 金丰年. 描述抗拔桩荷载-位移曲线的幂函数模型[J]. 岩土工程学报, 2000, 22(5):622-624. doi: 10.3321/j.issn:1000-4548.2000.05.026XU Hongfa, QIAN Qihu, JIN Fengnian. Power function model to describe load-displacement curve of tension pile[J]. Chinese Journal of Geotechnical Engineering,2000,22(5):622-624(in Chinese). doi: 10.3321/j.issn:1000-4548.2000.05.026 [26] 孙晓云, 张涛, 王明明, 等. 基于改进指-幂混合函数模型的锚杆承载力预测方法研究[J]. 岩石力学与工程学报, 2015, 34(8):1641-1649.SUN Xiaoyun, ZHANG Tao, WANG Mingming, et al. A revised model for predicting the bearing capacity of rock bolts based on mixed exponential and power unction[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(8):1641-1649(in Chinese). -

下载:

下载: