Temperature field in the central area of CFRP induction heating coil

-

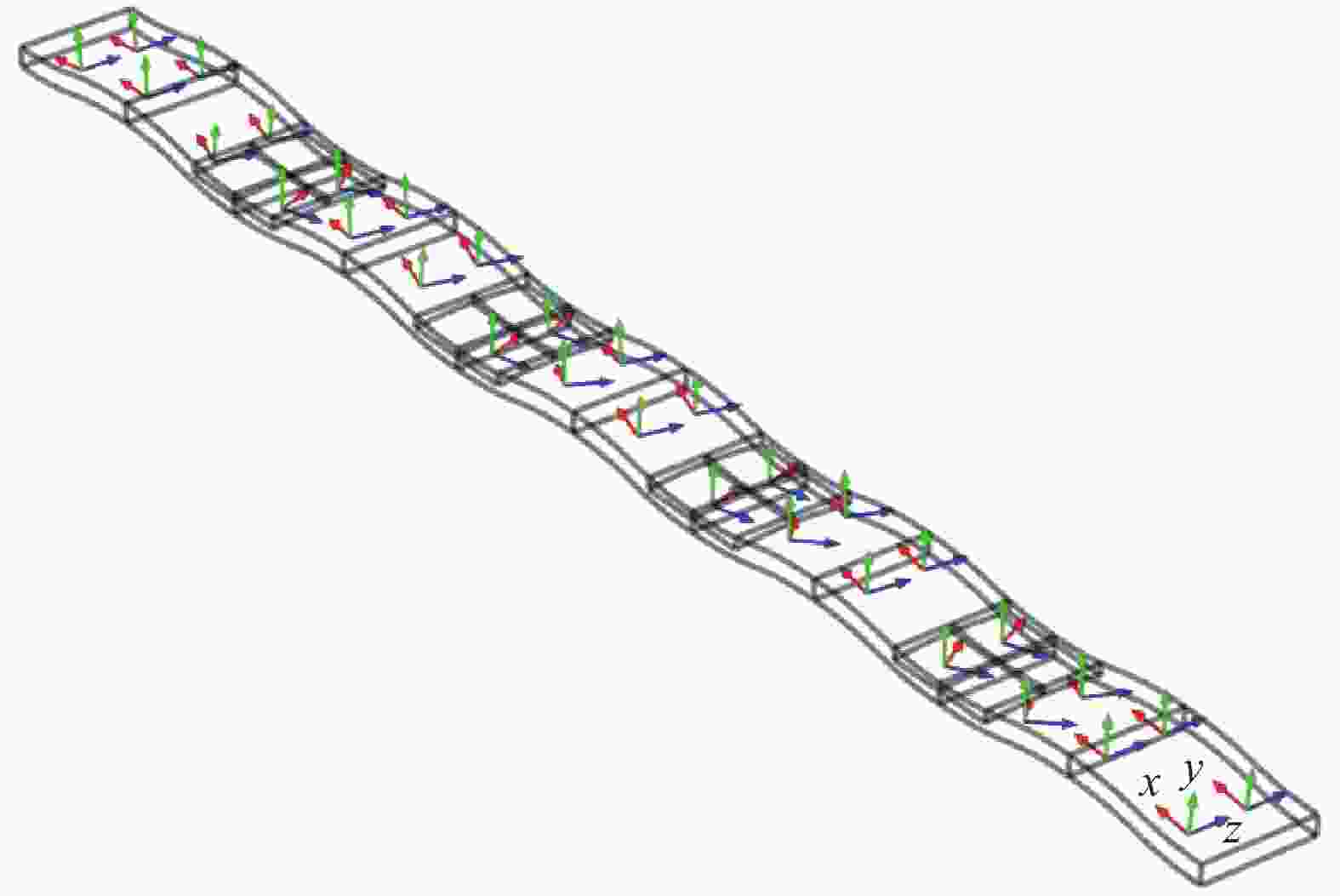

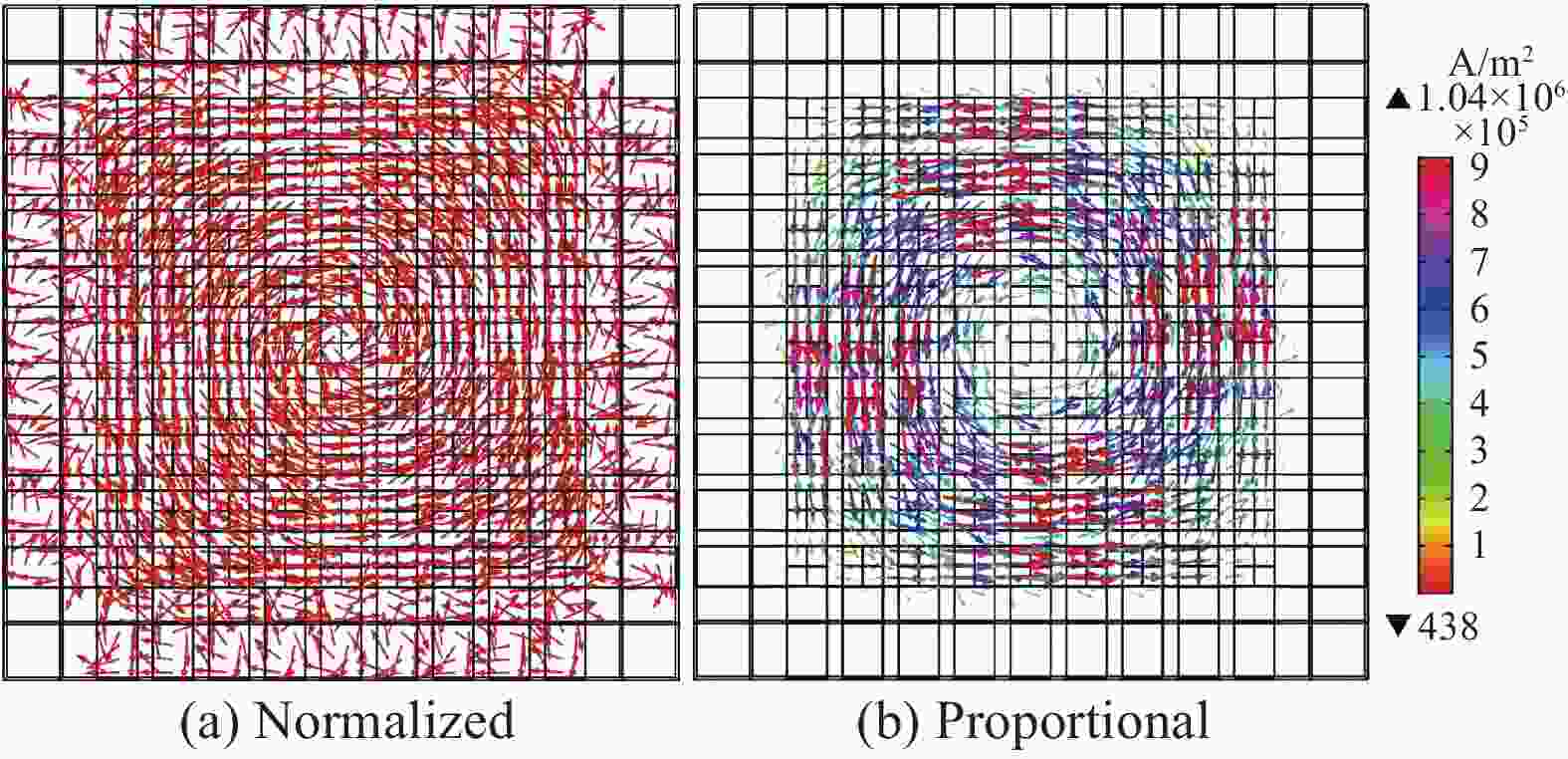

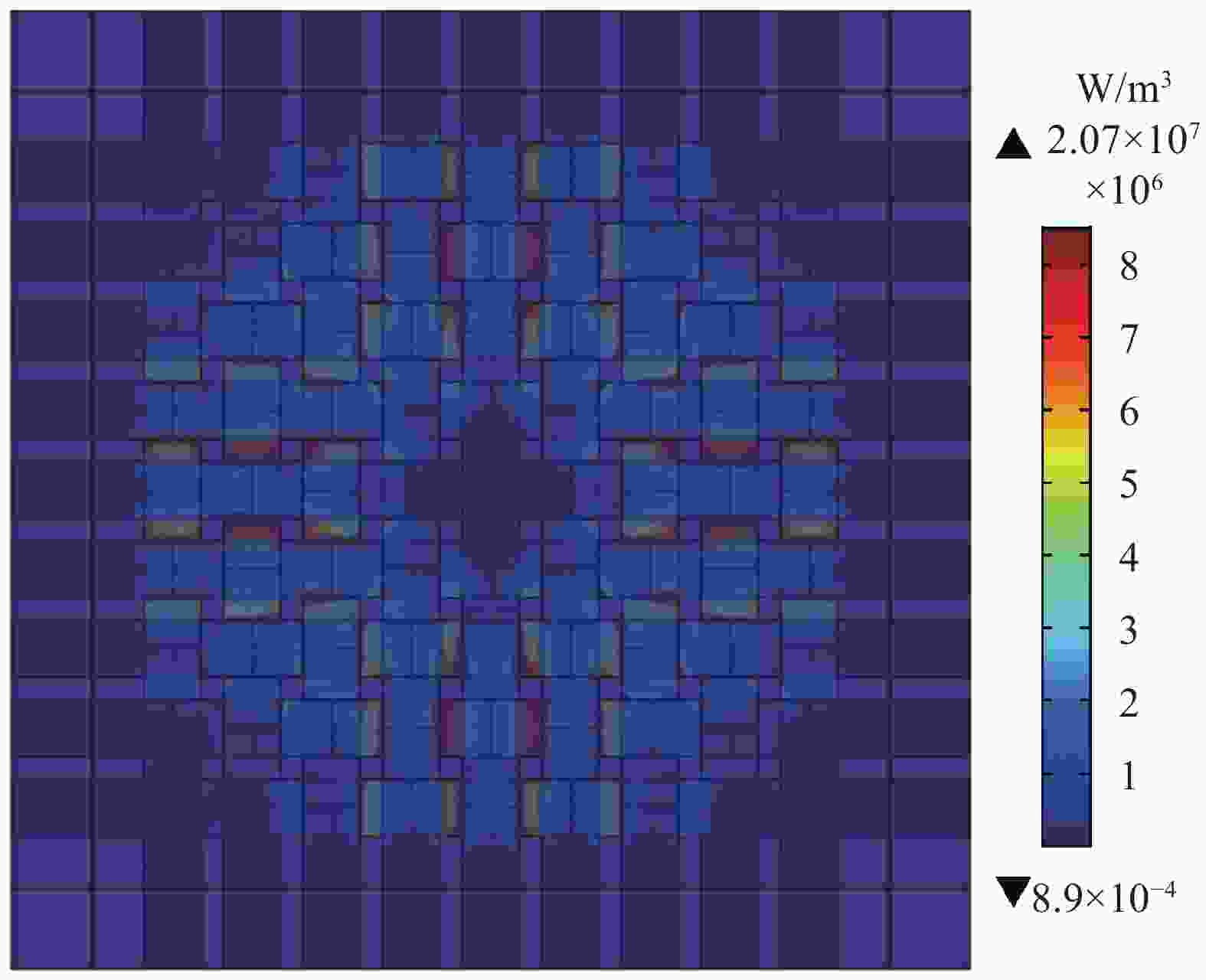

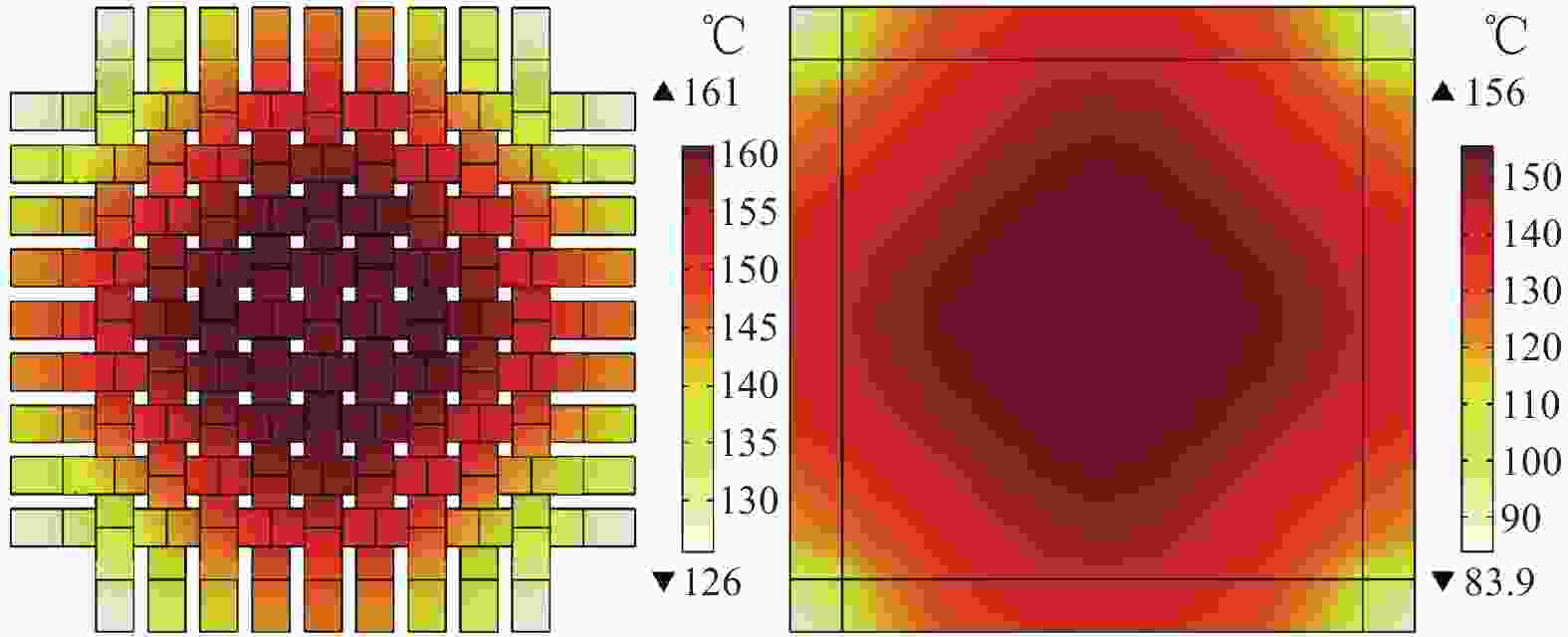

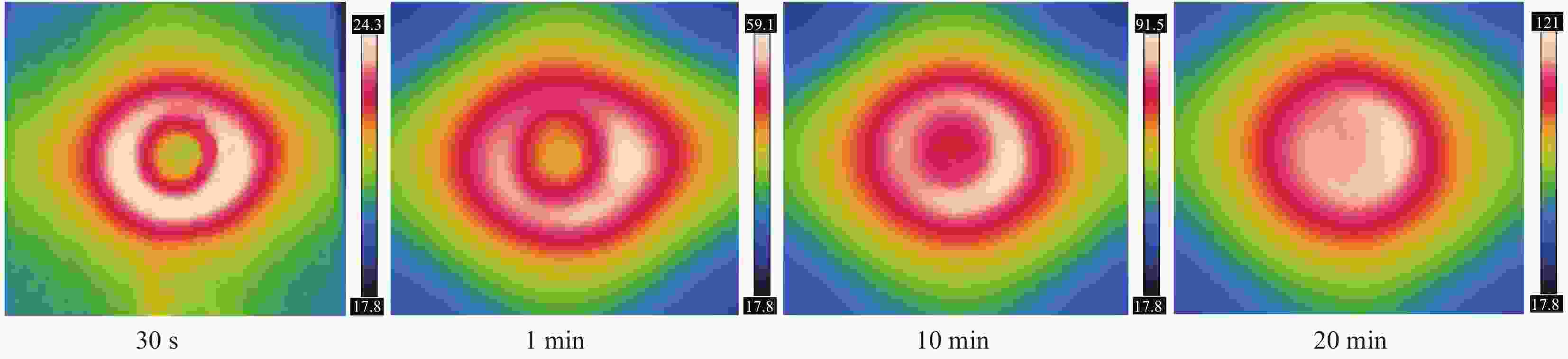

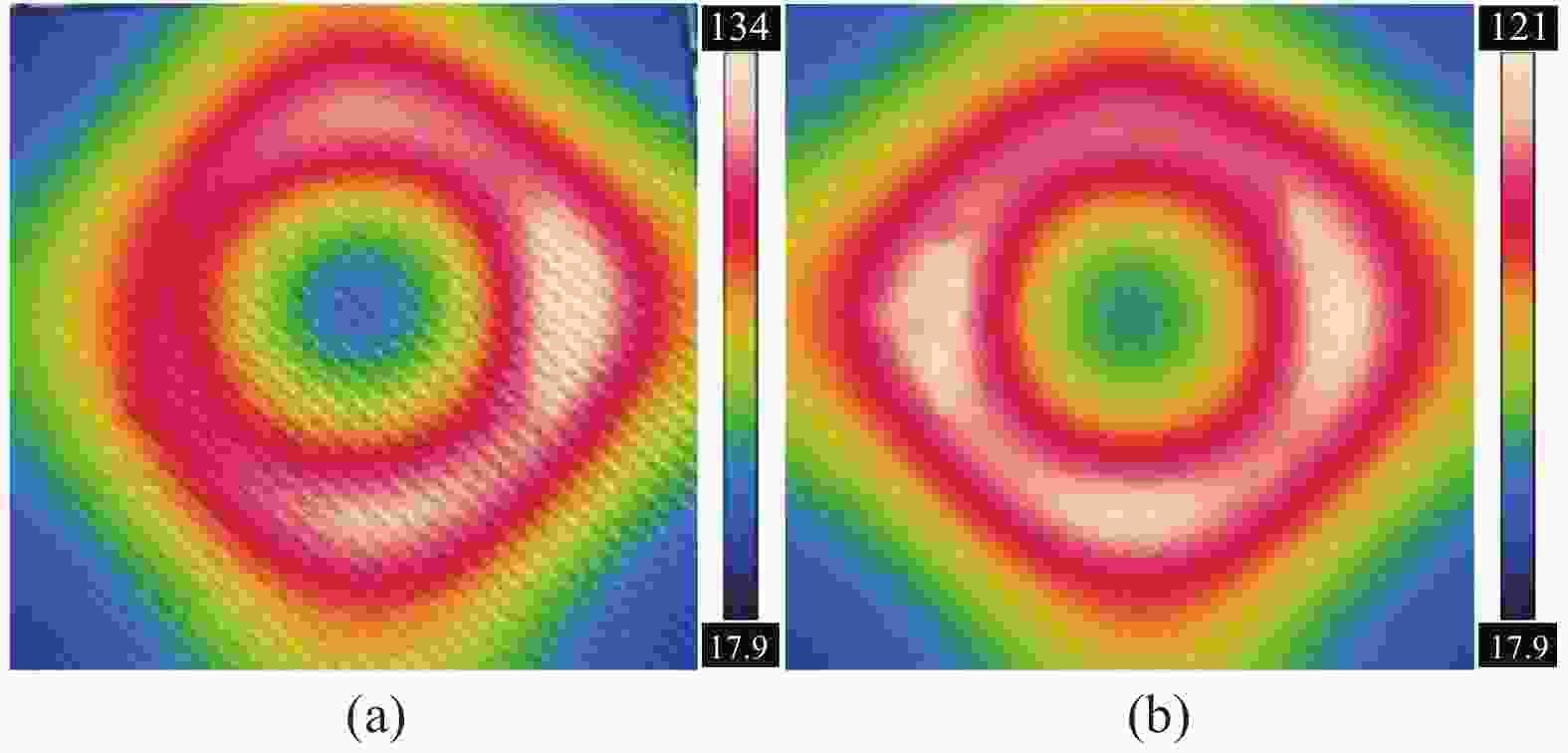

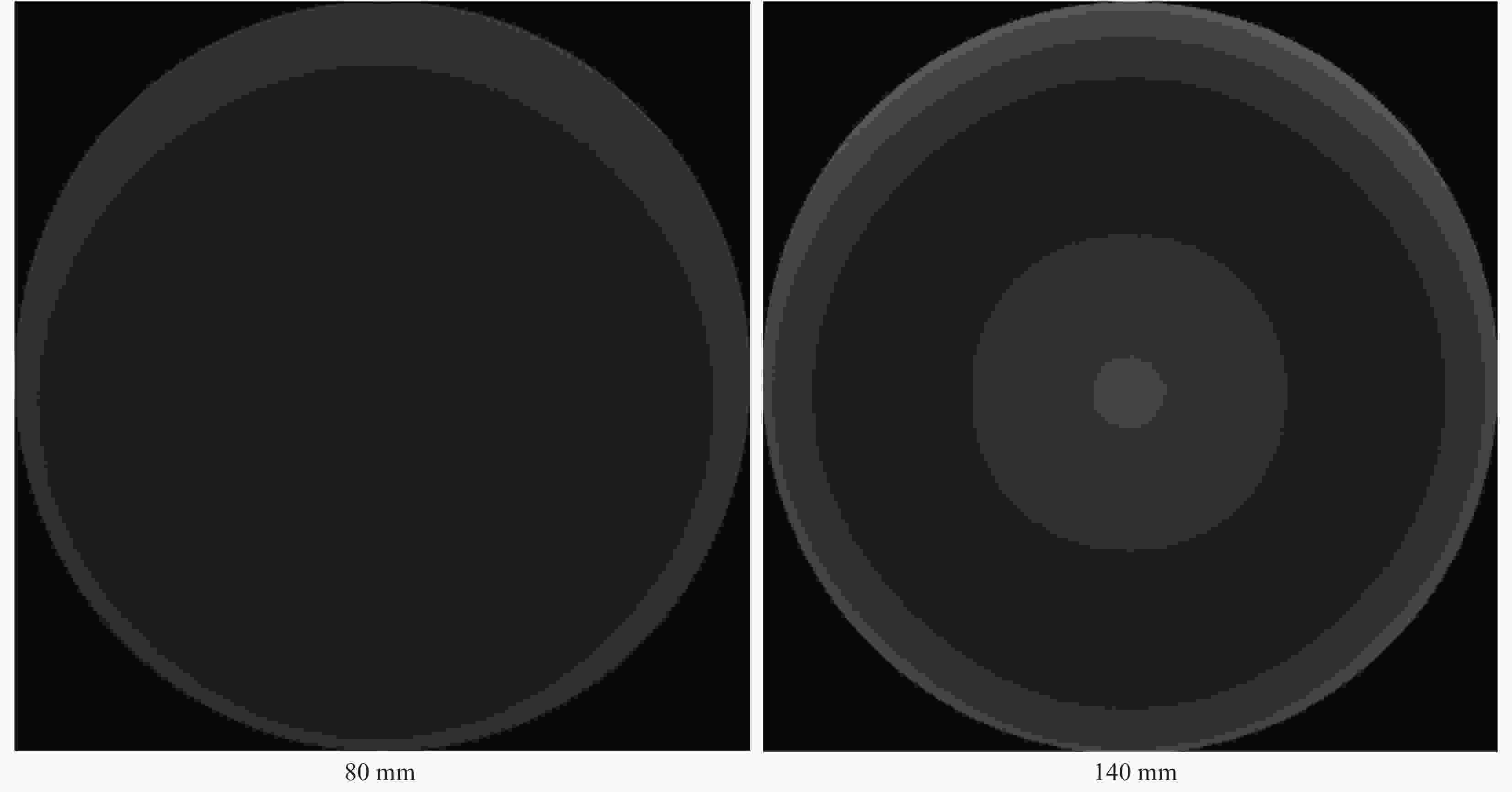

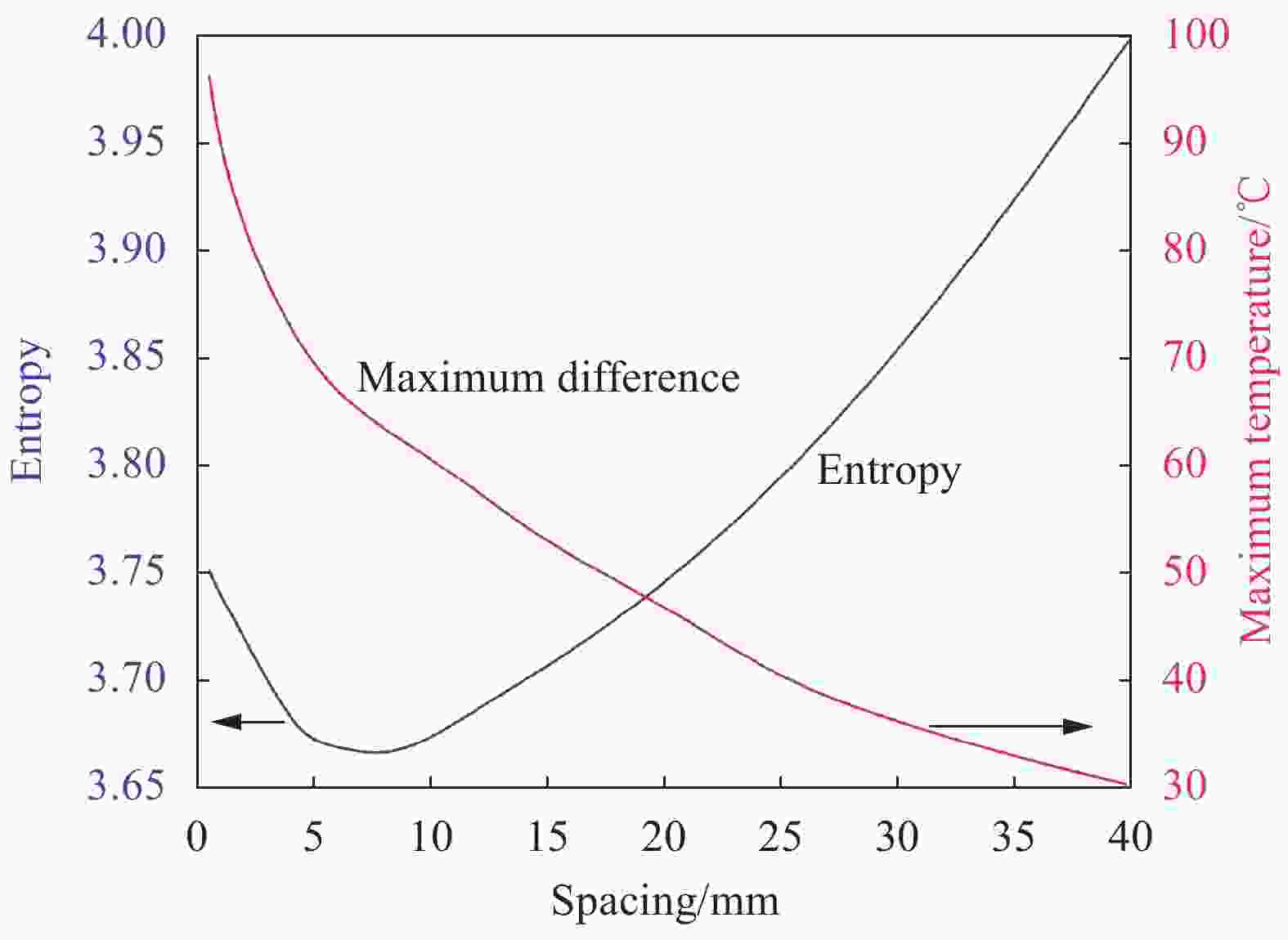

摘要: 感应加热技术是实现碳纤维增强树脂复合材料(CFRP)低能耗高效固化成型的有效方法,提高CFRP感应加热温度场均匀性是保证成型质量的关键,而线圈中心区域温度场均匀性是保证材料整体温度均匀性的关键。根据电磁加热原理建立了CFRP有限元多场耦合的分析模型,通过对模拟计算和实验过程的温度场升温及分布情况的对比分析,证明了本仿真可以准确模拟CFRP感应加热温度场分布。根据图像的熵值理论将温度场均匀性通过熵值大小进行表示,实现了CFRP感应加热温度场均匀性的量化分析,并通过有限元模型计算研究了线圈直径及线圈与材料间距对线圈中心区域温度场均匀性的影响,得到了中心区域温度场均匀性与线圈直径及材料间距之间的关系曲线,为组合式线圈均匀加热CFRP提供了线圈直径及材料间距大小选择的理论依据。Abstract: Induction heating technology is an effective method to achieve low energy consumption and efficient curing and molding of carbon fiber reinforced polymer (CFRP). Improving the uniformity of the CFRP induction heating temperature field is the key to ensure the molding quality. And the uniformity of the temperature field in the left of the coil is to ensure the overall temperature uniformity of the material key. According to the principle of electromagnetic heating, an analysis model of CFRP finite element multi-field coupling was established. The comparison and analysis of the temperature field heating and distribution of the simulation calculation and the experimental process proves that the simulation can accurately simulate the temperature field distribution of CFRP induction heating. According to the entropy theory of the image, the uniformity of the temperature field is expressed by the size of the entropy, and the quantitative analysis of the uniformity of the CFRP induction heating temperature field is realized. The coil diameter and the distance between the coil and the material are calculated and studied through the finite element model. The influence of the uniformity of the temperature field, the relationship curve between the uniformity of the temperature field in the left area and the coil diameter and material spacing is obtained, which provides a theoretical basis for the selection of coil diameter and material spacing for the combined coil to uniformly heat CFRP.

-

Key words:

- composite material /

- carbon fiber /

- plain weave /

- induction heating /

- temperature field

-

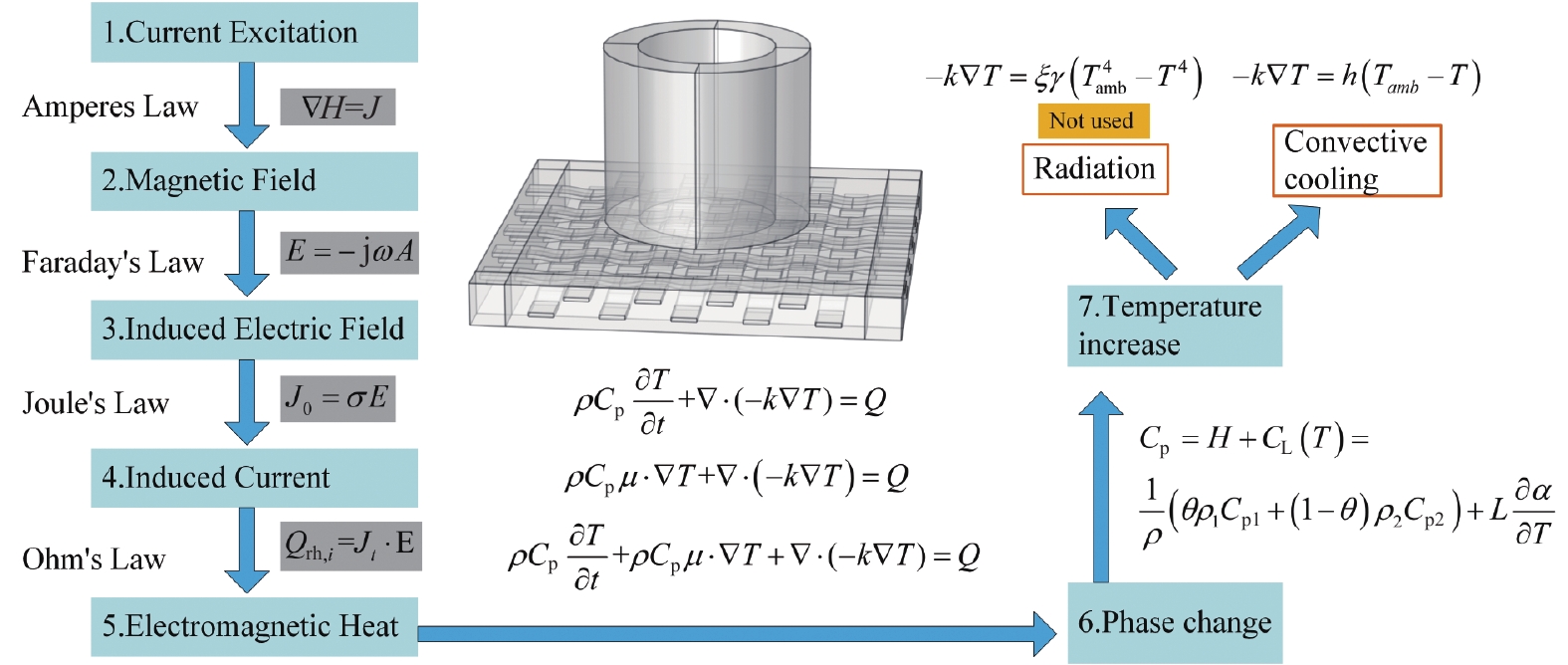

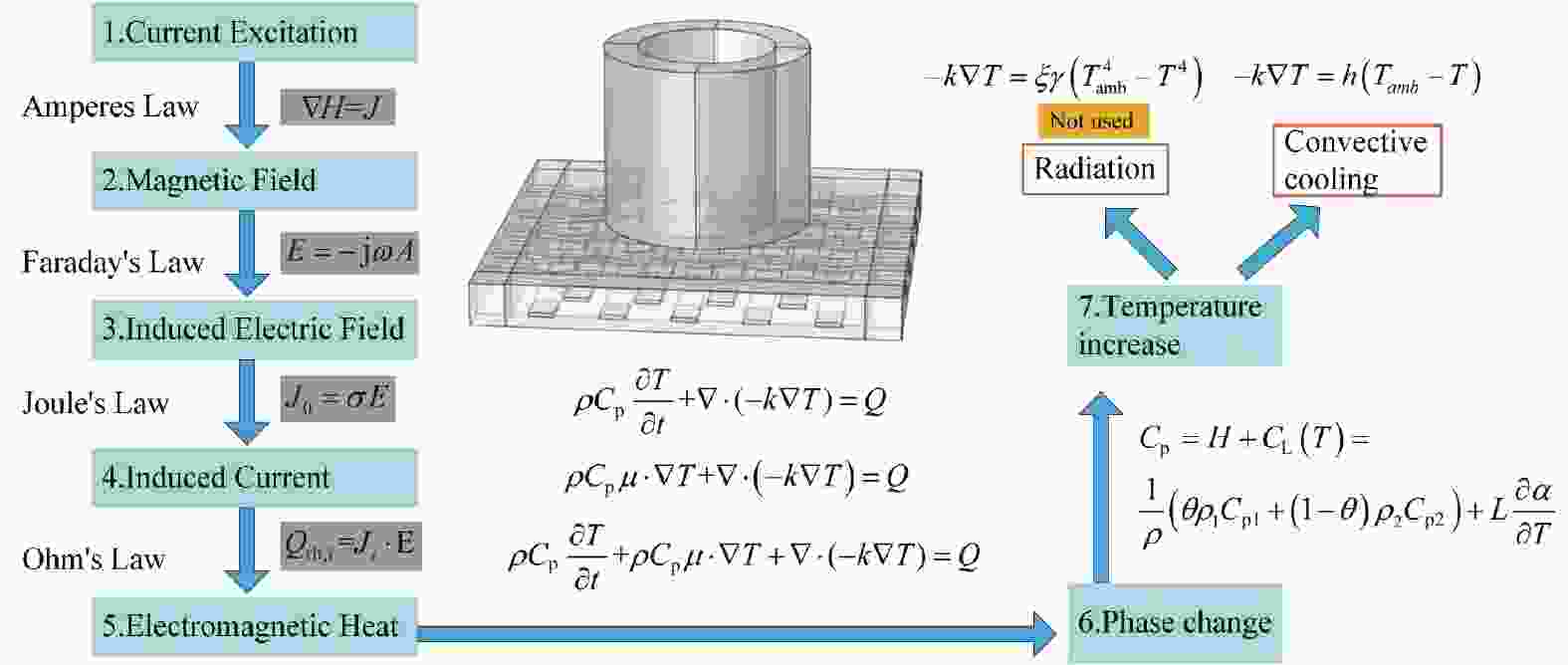

图 1 感应加热过程中多物理场耦合示意图

Figure 1. Multi-physical field coupling diagram in induction heating

H(A/m)—Magnetic field intensity vector; J(A/m2)—Current density in vector form; μ0—Vacuum permeability; μr—Relative permeability; A(Wb/m)—Magnetic vector potential; E(V/m)—Induced electric field; f(Hz)—Magnetic field frequency; Qrh(W/m3)—Heat source; ρ(kg/m3)—Density; Cp(J/(kg·K))—Specific heat capacity; k(W/(m·K))—Thermal conductivity; μ(m/s)—Flow rate of resin when heated; h(W/m2K)—Heat transfer coefficient determined by boundary type and surface properties; Tamb—Outside air temperature; T—Surface temperature of heated material

表 1 CFRP几何模型中各材料赋值的参数

Table 1. Simulation parameters used in the CFRP geometric model

Air Carbon fiber bundle Resin Coils Thermal conductivity/(W·(m·K)−1) — (20,4,4) 0.2 — Heat capacity/(J·(kg·K)−1) — 1000 1000 — Density/(kg·m−3) — 1500 1200 8960 Electrical conductivity/(S·m−1) 0 (4.8×104,0,0) 1×10−2 6×107 Relative permittivity 1 — 3.2 1 Relative permeability 1 1 1 1 Notes: Parameter acquisition. COMSOL built-in material library[24] and provided by the manufacturer. -

[1] BAYERL T, DUHOVIC M, MITSCHANG P, et al. The heating of polymer composites by electromagnetic induction—A review[J]. Composites Part A: Applied Science and Manufacturing,2014,57:27-40. doi: 10.1016/j.compositesa.2013.10.024 [2] SCHIELER O, BEIER U, MITSCHANG P. Control of the through thickness temperature distribution in carbon composite aerospace parts during induction welding[J]. Journal of Thermoplastic Composite Materials,2017,31(12):1587-1608. [3] 曹维宇, 杨学萍, 张藕生. 我国高性能高分子复合材料发展现状与展望[J]. 中国工程科学, 2020, 22(5):112-120.CAO Weiyu, YANG Xueping, ZHANG Ousheng. Development and prospect of high performance polymer compo-sites in China[J]. Strategic Study of CAE,2020,22(5):112-120(in Chinese). [4] 邢丽英, 冯志海, 包建文, 等. 碳纤维及复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). [5] 包建文, 蒋诗才, 张代军. 航空碳纤维树脂基复合材料的发展现状和趋势[J]. 科技导报, 2018, 36(19):52-63.BAO Jianwen, JIANG Shicai, ZHANG Daijun. Current status and trends of aeronautical resin matrix composites reinforced by carbon fiber[J]. Science & Technology Review,2018,36(19):52-63(in Chinese). [6] ABLIZ D, YUGANG D. Curing methods for advanced polymer composites-A review[J]. Polymers & Polymer Composites,2013,21(6):101-106. [7] SUN X F, MA S N, LIU H W. Research on properties of carbon fiber/epoxy resin composite material by microwave curing[J]. Rare Metal Materials and Engineering,2012,41:422-424. [8] 刘怡, 朱光明. 纤维增强树脂基复合材料固化工艺的发展[J]. 中国塑料, 2018, 32(6):1-9.LIU Yi, ZHU Guangming. Development of curing process for fiber-reinforced resin matrix composites[J]. China Plastics,2018,32(6):1-9(in Chinese). [9] RICCIO A, RUSSO A, RAIMONDO A, et al. A numerical/ experimental study on the induction heating of adhesives for composite materials bonding[J]. Materials Today Communications,2018,15:203-213. doi: 10.1016/j.mtcomm.2018.03.008 [10] SERGEANT P L, DUPRE L R, DEWULF M. Optimizing active and passive magnetic shields in induction heating by a genetic algorithm[J]. IEEE Transactions on Magnetics,2003,39(6):3486-3496. doi: 10.1109/TMAG.2003.819460 [11] HAN Y, WEN H Y, YU E L. Study on electromagnetic heating process of heavy-duty sprockets with circular coils and profile coils[J]. Applied Thermal Engineering,2016,100:861-868. doi: 10.1016/j.applthermaleng.2016.01.161 [12] MENANA H, FELIACHI M. An integro-differential model for 3D Eddy current computation in carbon fiber reinforced polymer composites[J]. IEEE Transactions on Magnetics,2011,47(4):756-763. doi: 10.1109/TMAG.2010.2102770 [13] RUDOLF R, MITSCHANG P, NEITZEL M. Induction heating of continuous carbon-fiber-reinforced thermoplastics[J]. Composites Part A: Applied Science and Manufacturing,2000,31:1191-1202. doi: 10.1016/S1359-835X(00)00094-4 [14] WASSELYNCK G, TRICHET D, RAMDANE B. Interaction between electromagnetic field and CFRP materials: A new multiscale homogenization approach[J]. IEEE Transactions on Magnetics,2010,46(8):3277-3280. doi: 10.1109/TMAG.2010.2045359 [15] WANG K F, CHANDRASEKAR S, YANG H T Y. Finite-element simulation of moving induction heat treatment[J]. Journal of Materials Engineering and Performance,1995,4(4):460-473. doi: 10.1007/BF02649308 [16] BOKOTA A, SAWOMIR I. Numerical analysis of phase transformations and residual stresses in steel cone-shaped elements hardened by induction and flame methods[J]. International Journal of Mechanical Sciences,1998,40(6):617-629. doi: 10.1016/S0020-7403(97)00084-2 [17] KIM H J, SHRIDHAR Y, JOHN W. A study on the induction heating of carbon fiber reinforced thermoplastic composites[J]. Advanced Composite Materials,2002,11(1):71-80. doi: 10.1163/156855102753613309 [18] LUNDSTRÖM F, FROGNER K, WIBERG O, et al. Induction heating of carbon fiber composites: Investigation of electrical and thermal properties[J]. International Journal of Applied Electromagnetics and Mechanics,2017,53:S21-S30. doi: 10.3233/JAE-162235 [19] WASSELYNCK G, TRICHET D, RAMDANE B. Microscopic and macroscopic electromagnetic and thermal modeling of carbon fiber reinforced polymer composites[J]. IEEE Transactions on Magnetics,2011,47:1114-1117. doi: 10.1109/TMAG.2010.2073456 [20] JUN C, JINHAO Q, TOSHIYUKI T. Numerical analysis of correlation between fibre orientation and eddy current testing signals of carbon-fibre reinforced polymer compo-sites[J]. International Journal of Applied Electromagne-tics and Mechanics,2012,39(1-4):251-259. doi: 10.3233/JAE-2012-1468 [21] MILLER A K, CHANG C, PAYNE A, et al. The nature of induction heating in graphite-fiber-polymer-matrix compo-site materials[J]. Sampe Journal,1990,26(4):37-54. [22] FRAUENHOFER M, KUNZ H, DILGER K. Fast curing of adhesives in the field of CFRP[J]. International Journal of Adhesion and Adhesives,2012,88(4-6):406-417. [23] TZENG J T, HSIEH K T. Electromagnetic analysis of composite structures subjected to transient magnetic fields[J]. Journal of Composite Materials,2019,54(6):745-752. [24] COMSOL Multiphysics Reference Manual Version: COMSOL 5.2a, 2016. -

下载:

下载: