Inter-laminar stress modeling and validation on multi-layer composite cylinders under thermal loading

-

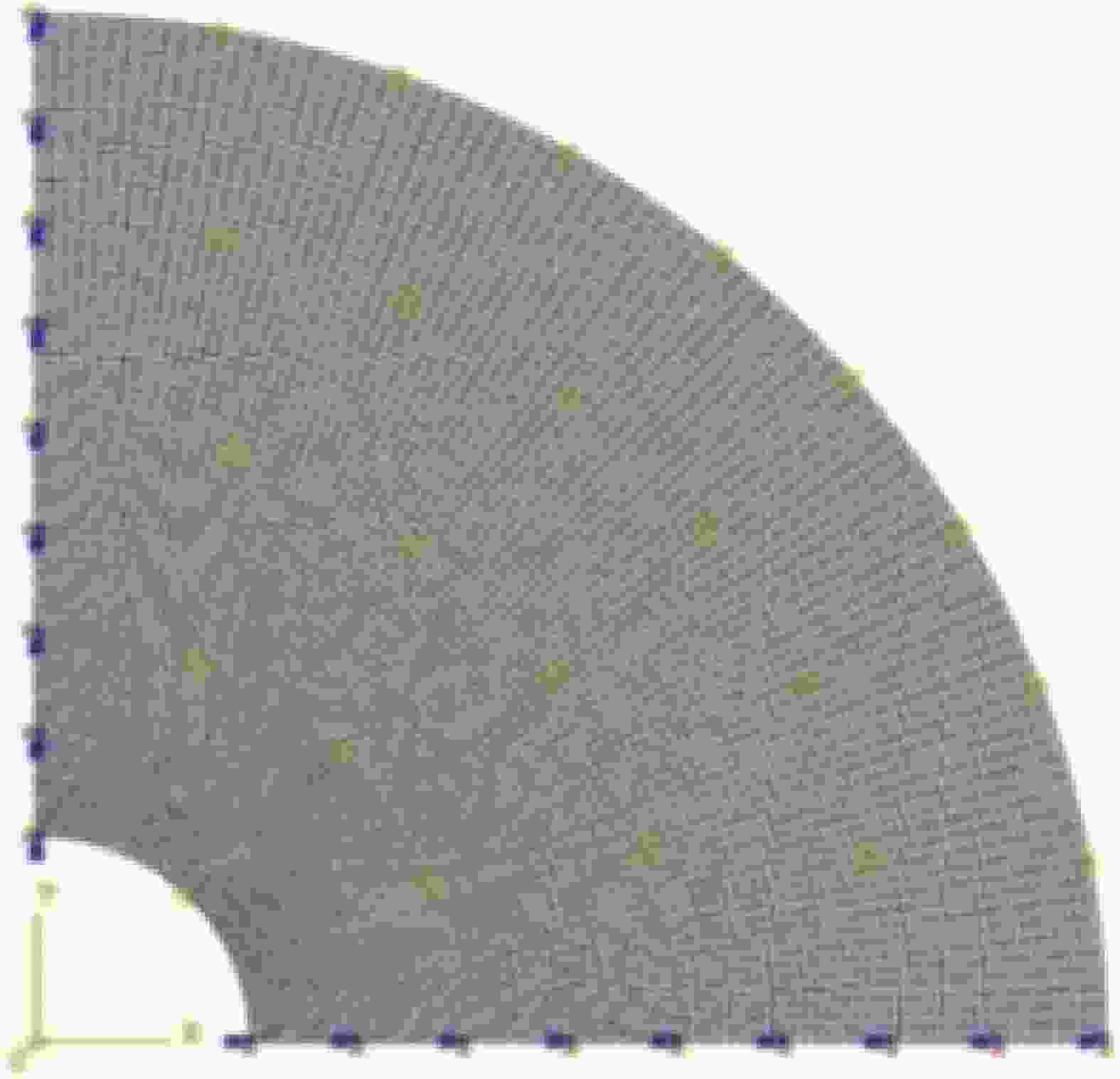

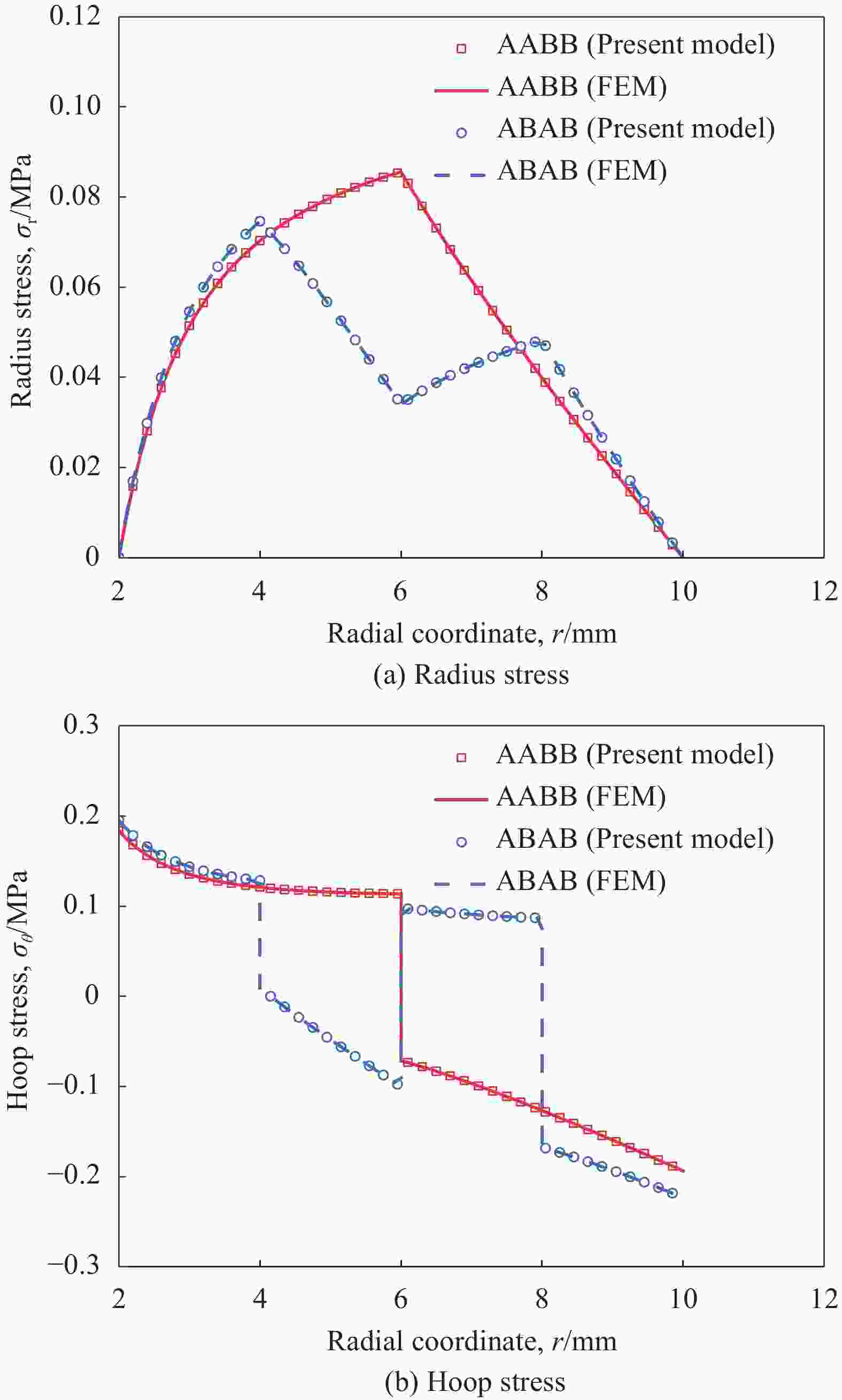

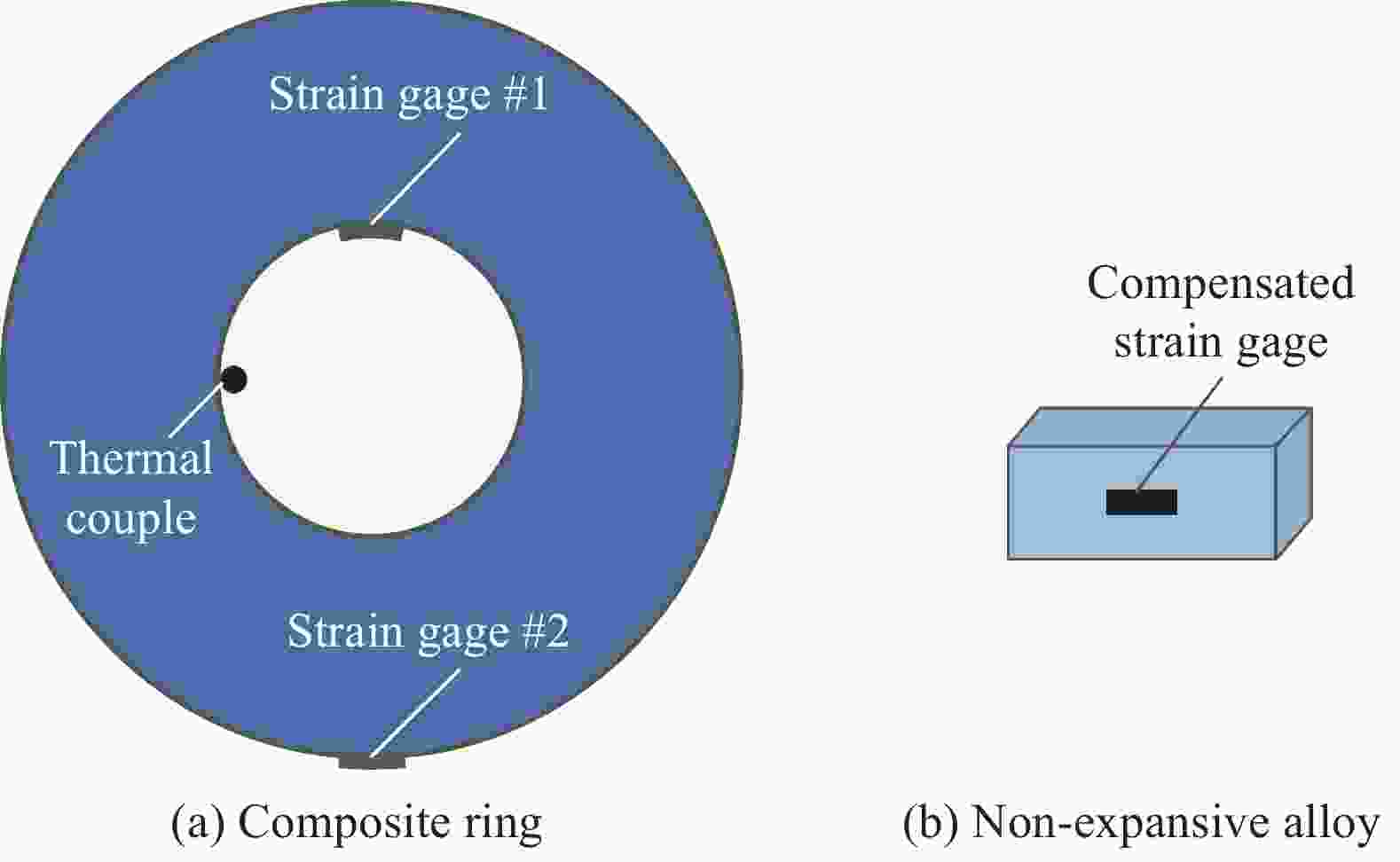

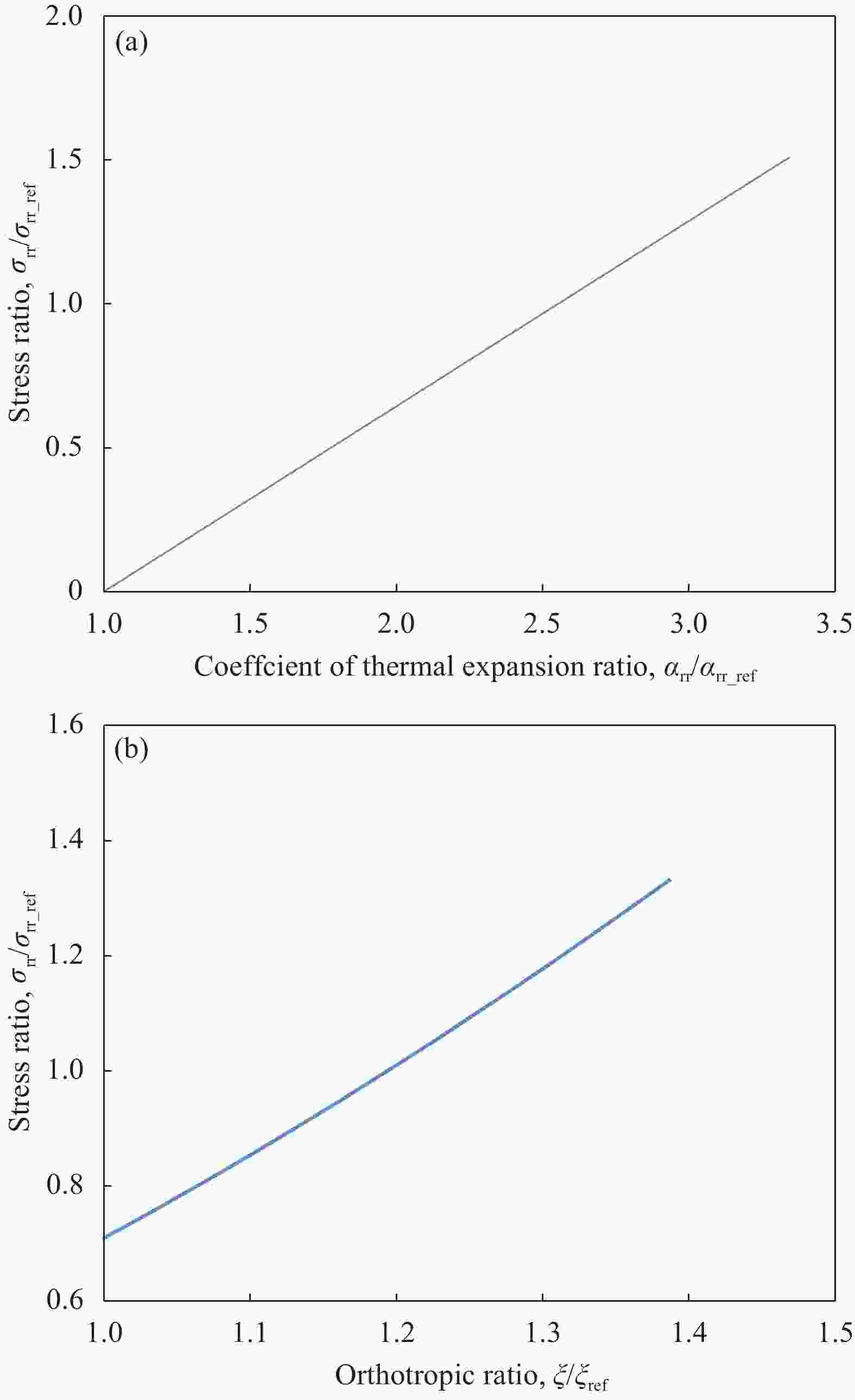

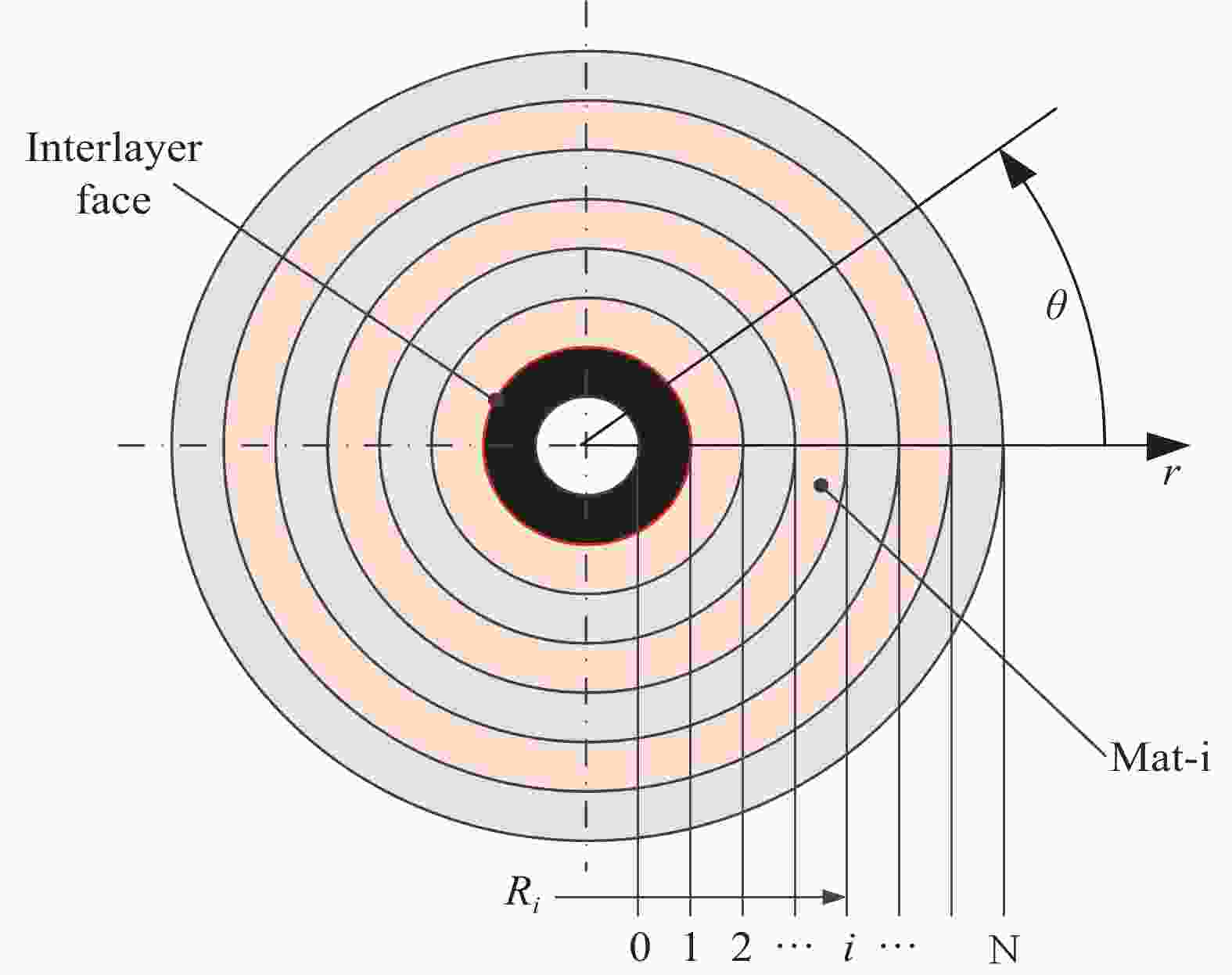

摘要: 多层复合材料筒状结构的残余应力可造成内部分层、结构失稳等,有必要结合理论和实验等研究其内部应力形成机制。基于各向异性线弹性本构和平面应力假设,建立了温度载荷作用下多层复合材料筒状结构内部应力的预测模型,并通过有限元仿真和热膨胀变形测试对模型有效性进行了校核和验证。结果表明,筒状结构环向的热膨胀变形从内层到外层逐渐增大,其中内层附近环向热膨胀系数低于面内热膨胀系数、外层附近环向热膨胀系数则高于面内热膨胀系数。在此基础上,结合模型理论分析揭示了层间应力对多层复合材料筒状结构的热膨胀变形行为的影响机制。在筒状结构形式下,温度加载引起的层间应力由一个涉及热膨胀系数和弹性参数的热力耦合项决定;由于多层复合材料面内与面外热膨胀系数存在差异,该应力耦合项不为零,从而在温度加载下形成了层间应力并影响了环向膨胀变形行为。基于上述认识,提出了调控多层复合材料筒状结构层间应力的有效措施。本研究对揭示多层复合材料筒状结构的层间开裂物理机制、优化其热力匹配设计等具有重要意义。Abstract: The inter-laminar stress in multi-layer composite cylindrical structures can cause internal delamination, structural instability, etc. It is necessary to study the internal stress formation mechanism. An analytical model for prediction of the inter-laminar stress in multi-layer composite cylinders subjected to thermal loading was developed based on an anisotropic constitutive model and the plane stress assumption. The analytical model was validated by means of finite element analyses and a thermal expansion experiment performed on a composite cylinder. Using this validated model, the inter-laminar stress between layers and the thermal expansion behavior were investigated. Results show that the special geometric constraint of the cylinder itself plays an important role in the residual stress development. The thermal expansion behavior in the cylinders is much different compared to that in planer laminated composites. Due to the difference of modulus and coefficient of thermal expansion along hoop and radial direction, a significant inter-laminar tensile stress will generate during cooling down process. Furthermore, the hoop thermal expansion deformation shows an evident increasing trend from the inner layer to the outer layer. The hoop thermal expansion deformation in the inner layer is much smaller than that of the composite. With the increment of the cylinder thickness, the inter-laminar tensile stress, and the difference in coefficient of thermal expansion between inner layer and outermost layer increase. The developed model could be useful to disclose the stress-induced inter-laminar crack and optimize stress distribution in multi-layer composite cylinders.

-

表 1 材料参数

Table 1. Material properties

Property Mat-a Mat-b In-plane Young modulus Er/MPa 2000 3000 Out-of-plane Young modulus Eθ/MPa 2500 12000 Poisson ratio${\mu _{r\theta }}$ 0.2 0.075 In-plane coefficient of thermal expansion(CTE) ${\alpha _r}$/(10−6·℃−1) 50 50 Out-of-plane coefficient of thermal expansion(CTE) ${\alpha _\theta }$/(10−6·℃−1) 50 5 表 2 多层缠绕复合材料结构材料性能

Table 2. Material properties of multi-layer composite laminate

Property Value Standard In-plane Young modulus ${{{E_r}} \mathord{\left/ {\vphantom {{{E_r}} {\rm{MPa}}}} \right. } {\rm{MPa}}}$ 4623 ASTM D3039[18] Out-of-plane Young modulus ${{{E_\theta }} \mathord{\left/ {\vphantom {{{E_\theta }} {\rm{MPa}}}} \right. } {\rm{MPa}}}$ 3243 ASTM D3039[18] Poisson ratio ${\mu _{r\theta }}$ 0.36 ASTM D3039[18] In-plane coefficient of thermal expansion(CTE) ${\alpha _\theta }$/(10−6·℃−1) 38 ASTM E831[19] Out-of-plane coefficient of thermal expansion(CTE) ${\alpha _r}$/(10−6·℃−1) 97 ASTM E831[19] 表 3 多层复合材料筒状结构不同位置热膨胀系数模型校核结果

Table 3. Validation of the analytical model on coefficient of thermal expansion for different positions in a multi-layer composite cylinder

Position Coefficient of thermal expansion

α/(10−6·℃−1)Experiment Prediction Error Inner-most layer(#1) 18.54 20.58 11.1% Outer-most layer(#2) 49.95 50.44 1.0% -

[1] 王青于, 杨熙, 彭宗仁, 等. 应用三维电磁-热-流固耦合场分析方法计算换流变压器干式套管的温度场分布[J]. 中国电机工程学报, 2016, 36(22): 6269-6275.WANG Q Y, YANG X, PENG Z R, et al. 3D coupled electromagnetic-thermal-fluid method for computation of temperature field of converter transformer RIP bushings[J]. Proceedings of the CSEE, 2016, 36(22): 6269-6275(in Chinese). [2] KIM Y K, WHITE S R. Cure-dependent viscoelastic residual stress analysis of filament-wound composite cylinders[J]. Mechanics of Composite Materials and Structures, 1998, 5: 327-354. doi: 10.1080/10759419808945905 [3] VOYIADJIS G Z, HARTLEY C S. Residual-stress determination of concentric layers of cylindrically orthotropic materials[J]. Experimental Mechanics, 1987: 290-297. [4] KANG C, LIU Z, SHIRINZADEH, B, et al. Multiparametric sensitivity analysis of multilayered filament-wound cylinder under internal pressure[J]. Mechanics of Advanced Materials and Structures, 2022, 29(8): 1172-1183. doi: 10.1080/15376494.2020.1811435 [5] 郭凯特, 文利华, 校金友, 等. 多角度纤维缠绕复合材料圆筒张力设计[J]. 固体火箭技术, 2020, 43(4): 458-467.GUO K T, WEN L H, XIAO J Y, et al. Tension design for composite cylinder with multi-angle layers[J]. Journal of Solid Rocket Technology, 2020, 43(4): 458-467(in Chinese). [6] EDULJEE R F, GILLESPIE JR J W. Elastic response of post- and in situ consolidated laminated cylinders[J]. Composites:Part A, 1996, 27A: 437-446. [7] VEDELD K, SOLLUND H A. Stresses in heated pressurized multi-layer cylinders in generalized plane strain conditions[J]. International Journal of Pressure Vessels and Piping, 2014, 120-121: 27-35. doi: 10.1016/j.ijpvp.2014.04.002 [8] SOLLUNDH A, VEDELD K, HELLESLAND J. Efficient analytical solutions for heated and pressurized multi-layer cylinders[J]. Ocean Engineering, 2014, 92: 285-295. doi: 10.1016/j.oceaneng.2014.10.003 [9] YEO W H, PURBOLAKSONO J, ALIABADI M H, et al. Exact solution for stress/displacements in a multilayered hollow cylinder under thermo-mechanical loading[J]. International Journal of Pressure Vessels and Piping, 2017, 151: 45-53. doi: 10.1016/j.ijpvp.2017.01.003 [10] KANG C, SHI Y, DENG B, et al. Determination of residual stress and design of process parameters for composite cylinder in filament winding[J]. Advances in Materials Science and Engineering, 2018: 1-11. [11] 李博, 熊超, 殷军辉, 等. 多角度交替缠绕复合圆筒的剩余应力算法及水压试验[J]. 复合材料学报, 2018, 35(6): 1452-1463.LI B, XIONG C, YIN J H, et al. Residual stress algorithm for composite cylinder with alternate multi-angle winding layers and water-pressure test[J]. Acta MateriaeCompositaeSinica, 2018, 35(6): 1452-1463 (in Chinese). [12] 郭章新, 韩小平, 李金强, 等. 纤维缠绕复合材料固化过程残余应力/应变的三维数值模拟[J]. 复合材料学报, 2014, 31(4): 1006-1012.GUO Z X, HAN X P, LI J Q, et al. Three-dimensional numerical simulation of residual stress/strain for filament-wound composites during process[J]. Acta MateriaeCompositaeSinica, 2014, 31(4): 1006-1012(in Chinese). [13] TZENG, CHIEN L S. Viscoelastic analysis of thick-walled filament-wound composite cylinders with elevated temperatures[J]. AIAA Journal, 1996, 34(7): 1526-1529. doi: 10.2514/3.13264 [14] CALIUS E P, LEE S Y, SPRINGER G S. Filament winding cylinders: I. Process Model[J]. Journal of Composite Materials, 1990, 24: 1270-1298. doi: 10.1177/002199839002401202 [15] CALIUS E P, LEE S Y, SPRINGER G S. Filament winding cylinders: II. Validation of the Process Model[J]. Journal of Composite Materials, 1990, 24: 1299-1343. doi: 10.1177/002199839002401203 [16] KRYSIAK P, BLACHUT A, KALETA J. Theoretical and experimental analysis of inter-layer stresses in filament-wound cylindrical composite structures[J]. Materials, 2021, 14,7037: 1-25. [17] BOWER A F. Applied mechanics of solids[M]. Taylor & Francis: CRC Press, 2009. [18] ASTM International. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039[S]. West Conshohocken: ASTM International, , 2014. [19] ASTM International. Standard test method for linear thermal expansion of solid materials by thermomechanical analysis: ASTM E831 [S]. West Conshohocken: ASTM International, 2019. [20] TANG K, SHA L, LI Y J, et al. Measurement of thermal expansion at low temperatures using the strain gage method[J]. Journal of Zhejiang University-SCIENCE A (Applied Physics & Engineering), 2014, 15(5): 323-330. -

点击查看大图

点击查看大图

计量

- 文章访问数: 67

- HTML全文浏览量: 49

- 被引次数: 0

下载:

下载: