Intelligent identification of micro components and defects of 3D braided C/C composites based on deep learning of X-ray CT images

-

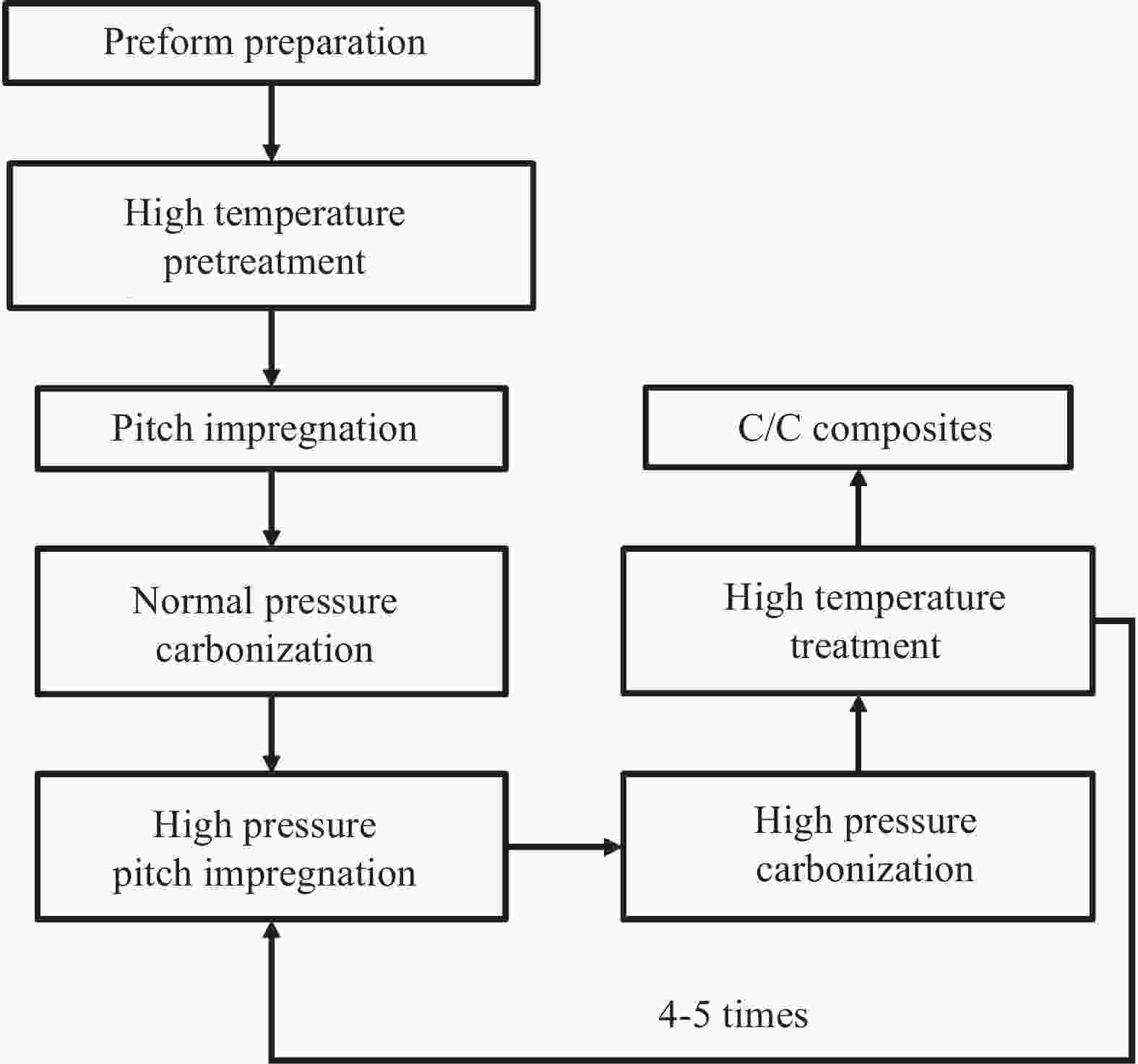

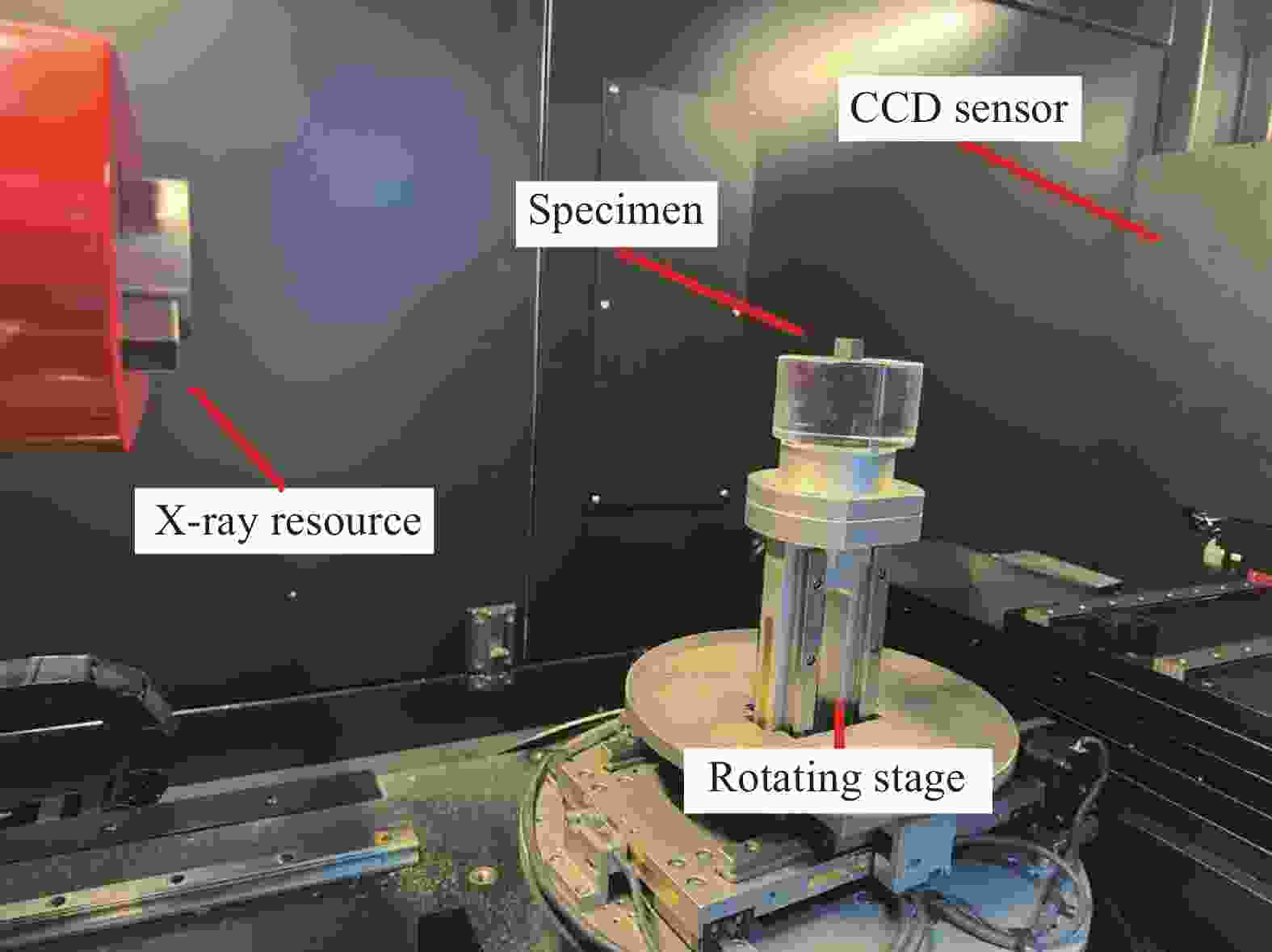

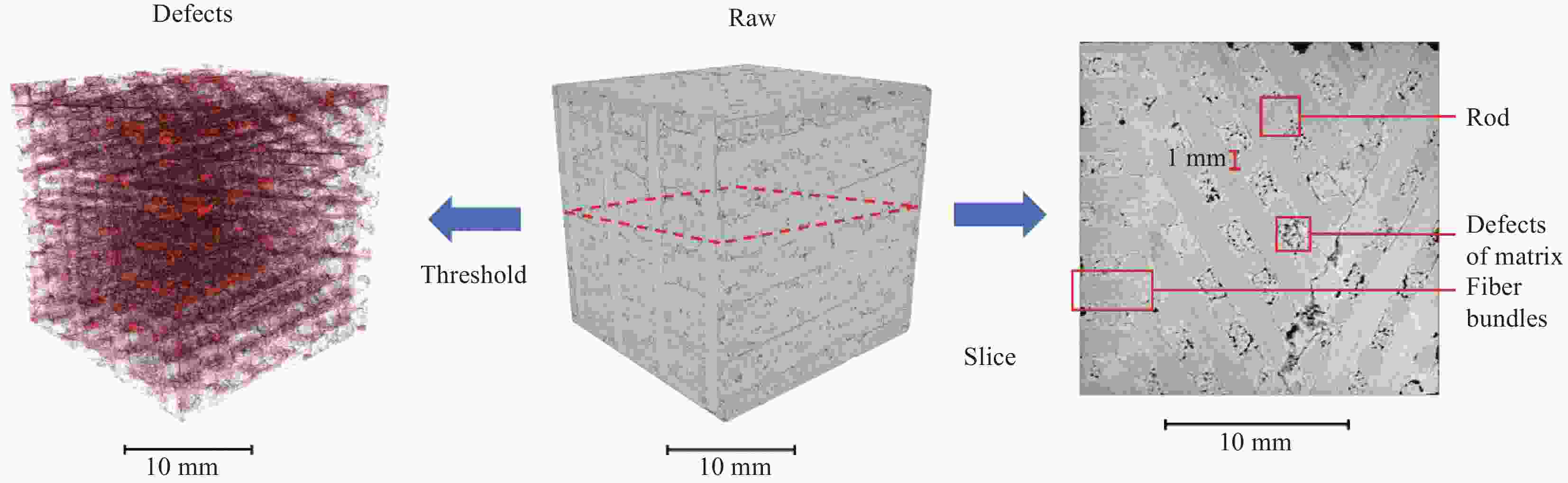

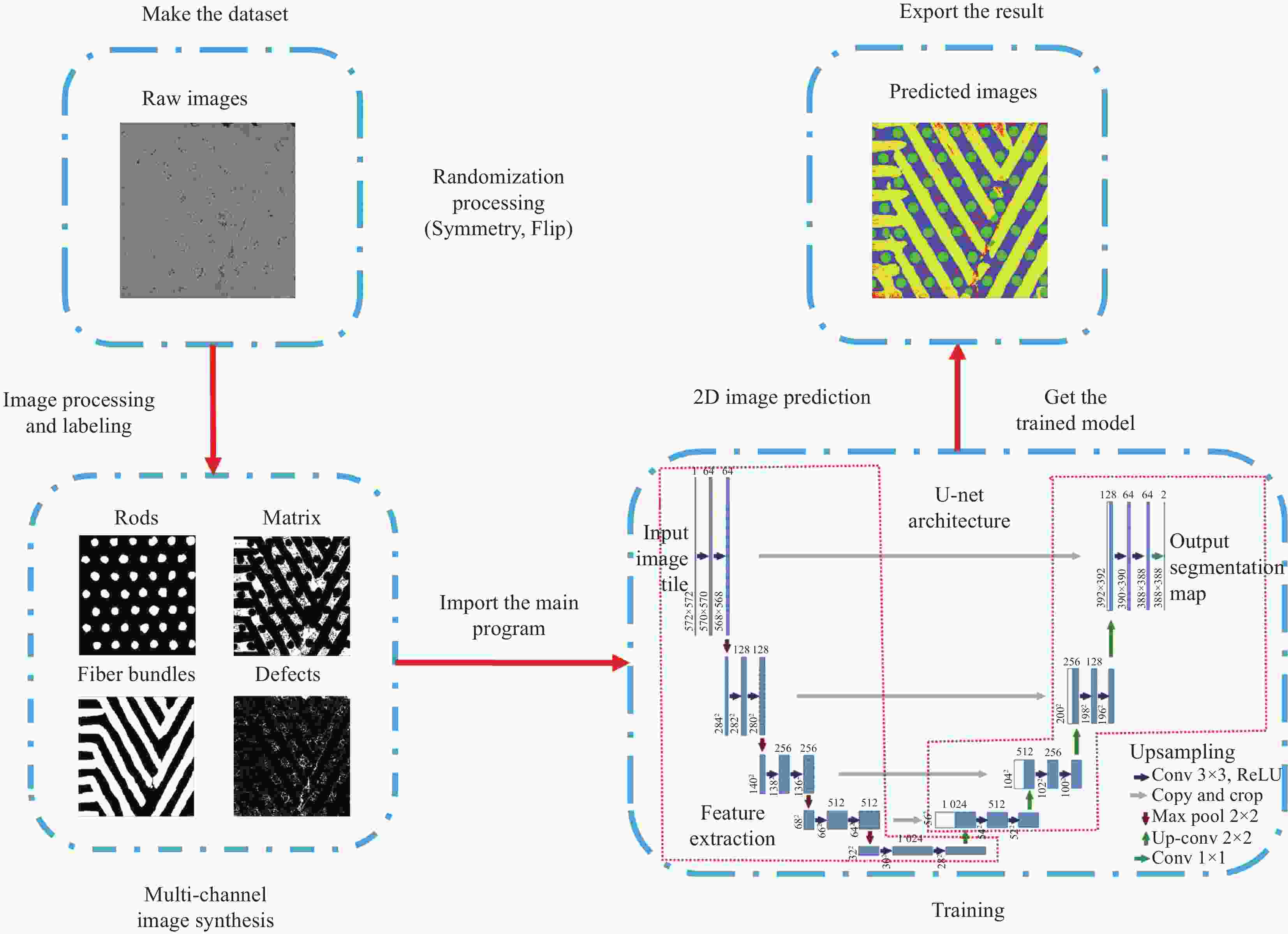

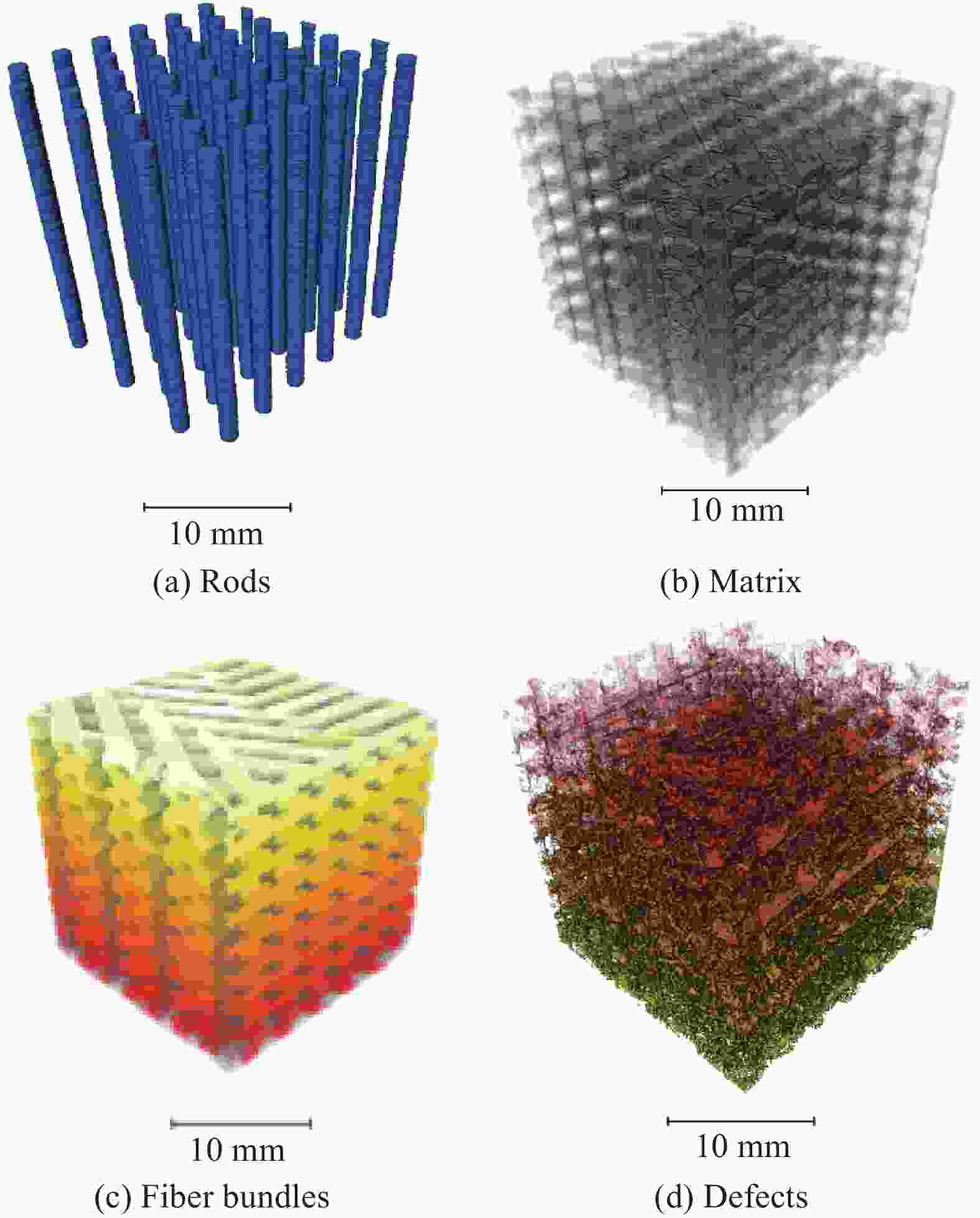

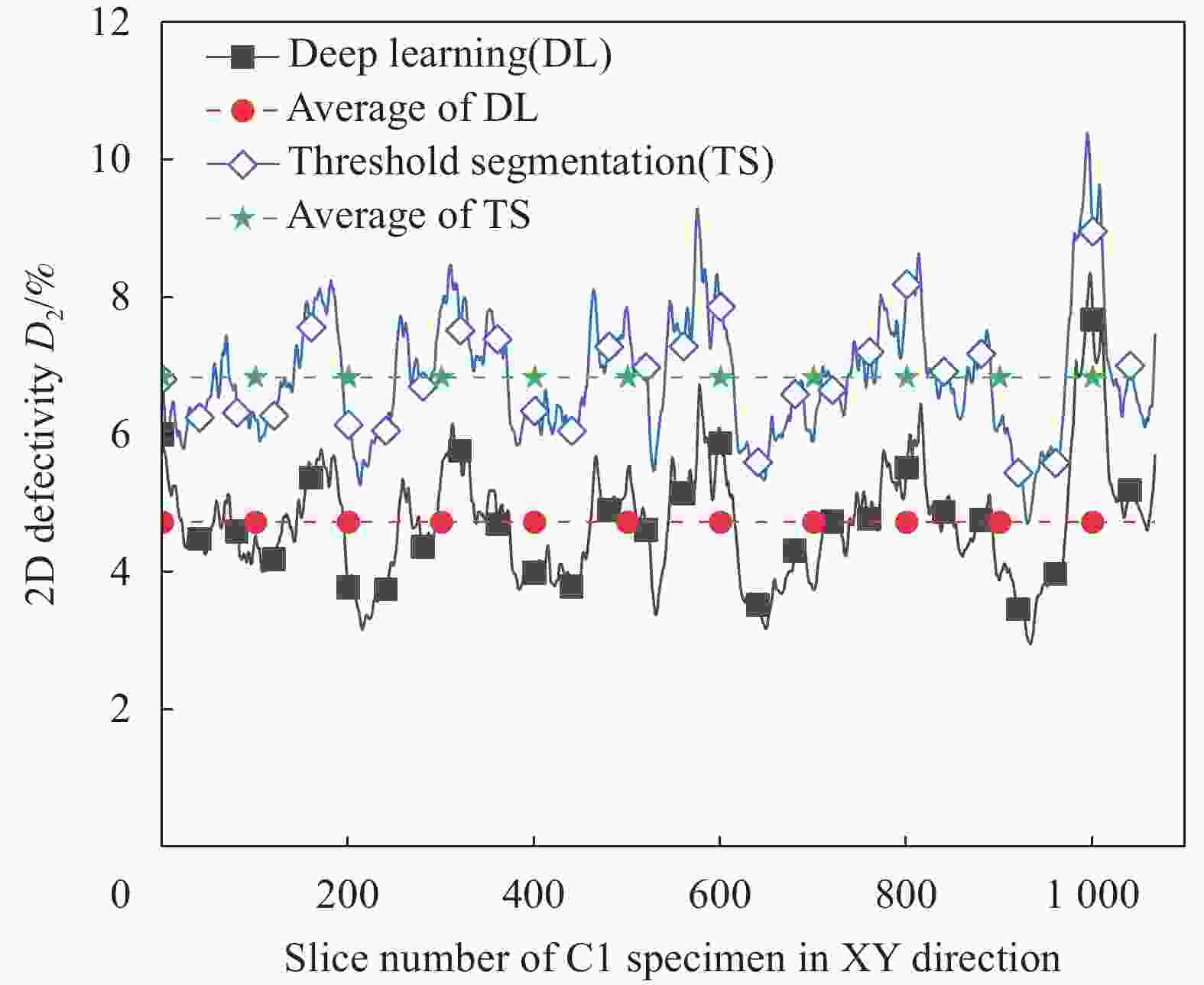

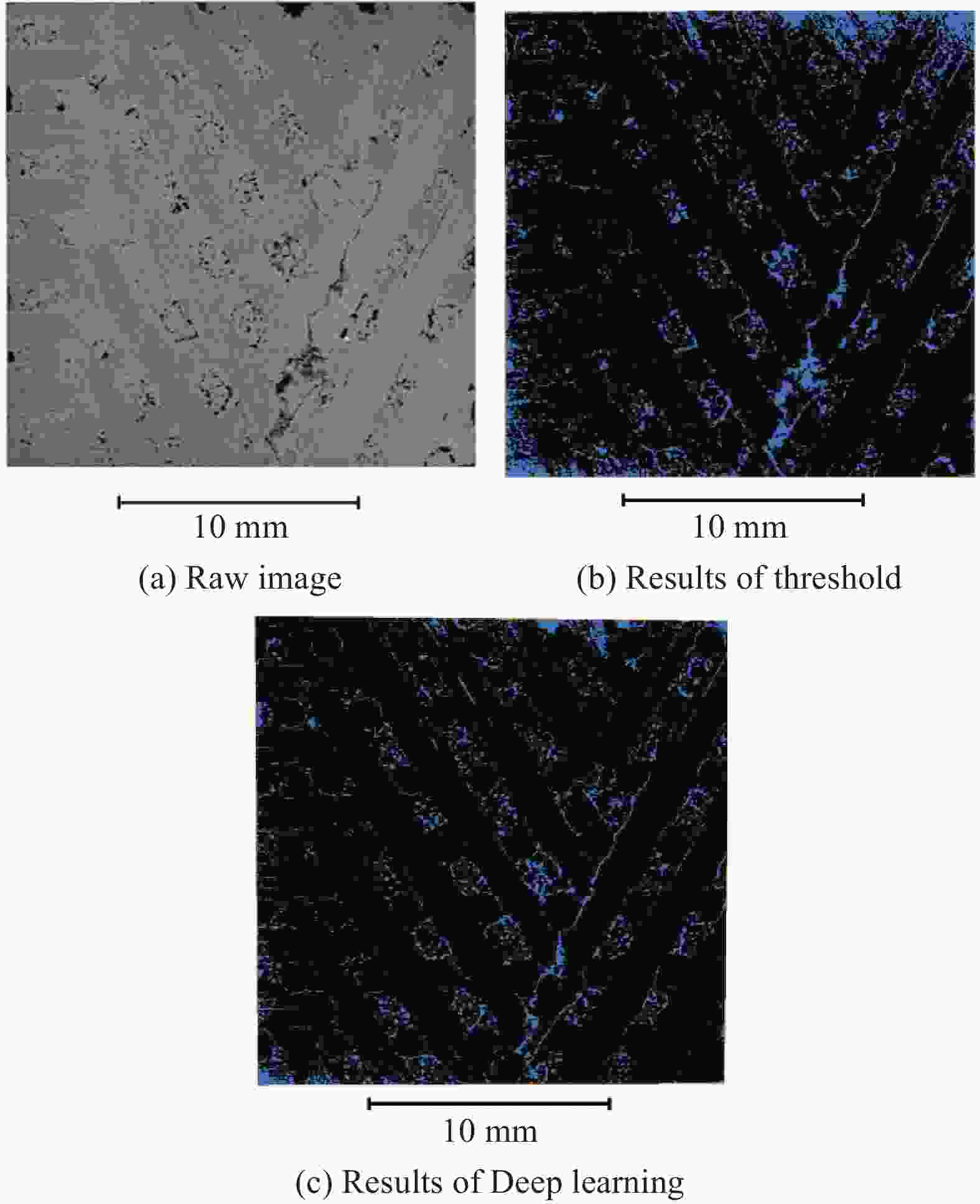

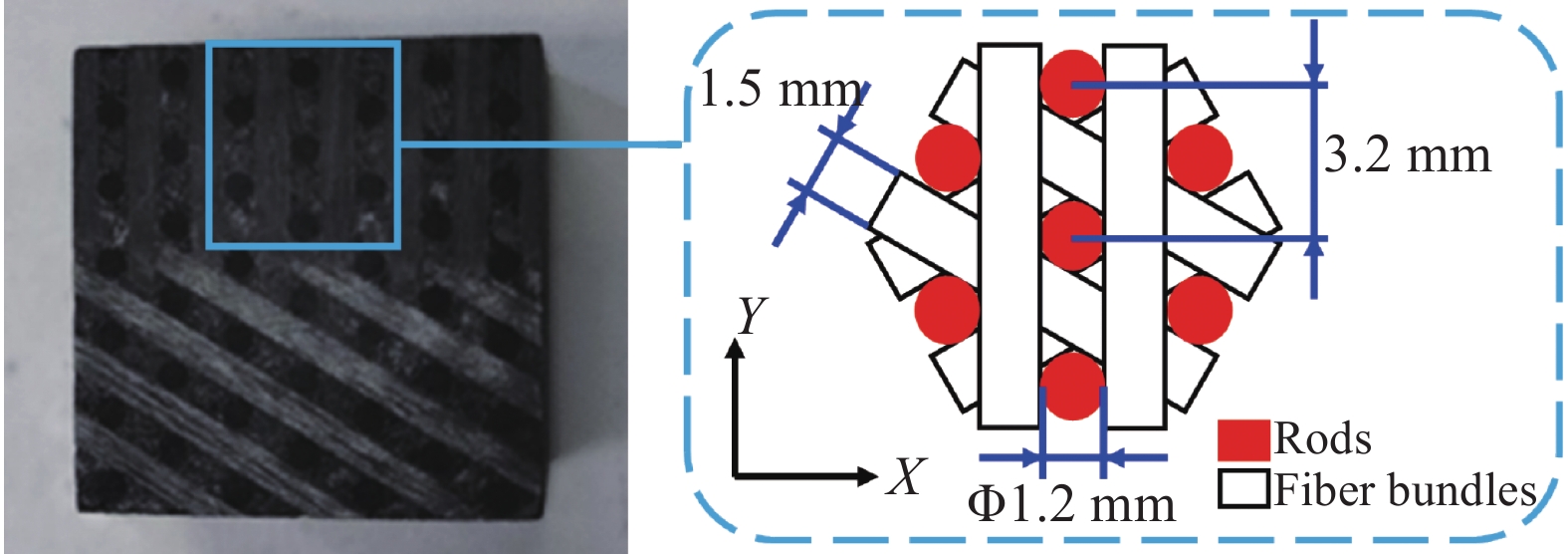

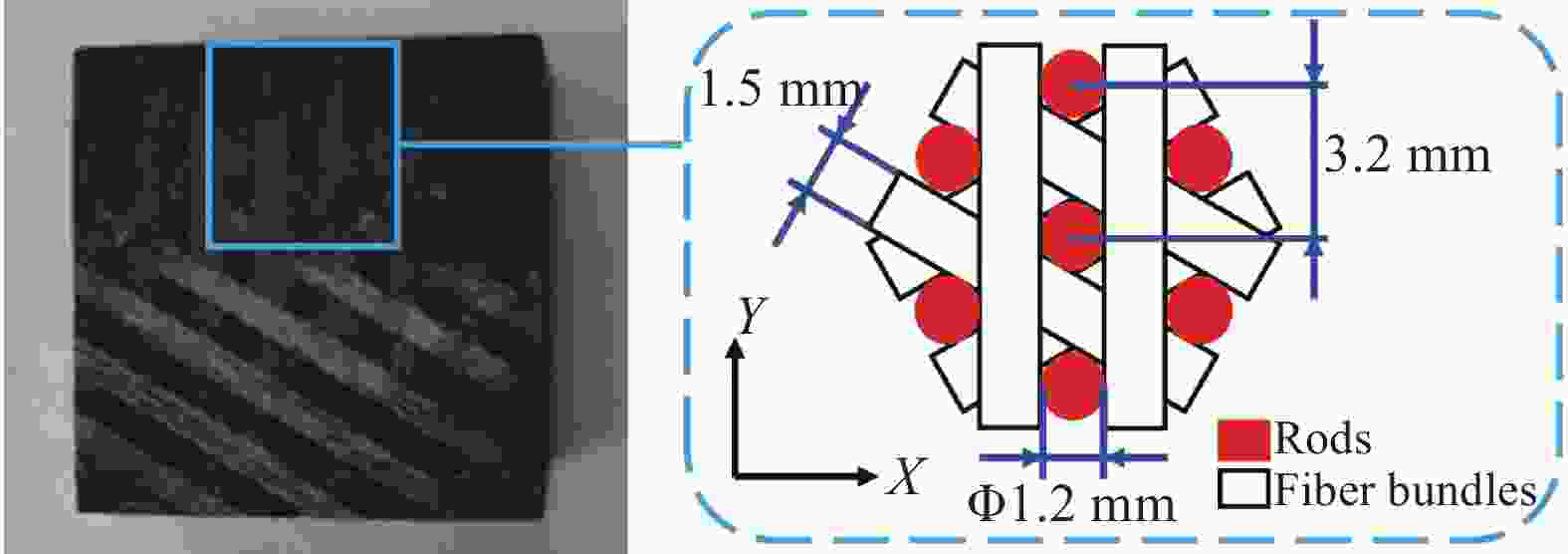

摘要: 首先采用微观X射线计算断层扫描(Micro X-ray computed tomography, XCT)对四枚20 mm立方体三维编织碳/碳(Carbon fiber reinforced carbon, C/C)复合材料试件进行扫描,获得精度为18 μm的内部微观结构图像;然后采用基于深度学习的语义分割算法,对大量二维XCT图像进行训练,实现对试件三维微观组分(碳棒、碳纤维束和基体)和缺陷(孔洞、分层和裂纹)的智能识别和分割。结果表明:(1) 微观XCT扫描能够高精度表征三维编织C/C复合材料内部组分和缺陷的分布和形态,主要缺陷为相邻纤维束层之间的分层;(2)由于C/C复合材料各微观组分均为碳材料,在CT图像中灰度值相同(或十分接近),难以采用传统阈值算法进行分割;深度学习算法能够有效过滤噪声与伪影并自动精准分割各组分和缺陷,且预测速度比人工图像标注高约两个数量级。本工作对三维编织C/C复合材料后续微细观建模和性能优化奠定了基础。Abstract: Four 20 mm cubic 3D braided carbon/carbon (C/C) composite specimens were scanned by micro X-ray computed tomography (XCT) to obtain internal microstructure images with a voxel resolution of 18 μm. A deep learning based semantic segmentation algorithm was then used to train a large number of 2D XCT images to achieve intelligent identification and segmentation of rods, fiber bundles, matrix, pores, delamination and cracks of these specimens. The results show that (1) the XCT scanning can characterize the distribution and morphology of the above components and defects with high resolutions, and the dominant defect is delamination between adjacent fiber bundle layers; (2) Since the grey values in the CT images of all micro components of C/C composites are very close, it is impossible for the traditional threshold segmentation method to segment the different components, whereas the deep learning based algorithm is able to effectively filter noise and artifacts and segment all the components and defects with high accuracy and at a prediction speed of about two orders faster than manual image labelling. This deep learning algorithm thus provides a promising tool to construct high-resolution numerical models for further studies such as performance optimization of C/C composites.

-

图 5 基于语义分割的深度学习流程 (左下掩膜图像中的白色为各组分或缺陷,黑色为背景;右上预测结果图像中绿色代表碳棒、蓝色代表碳基体、黄色代表碳纤维束、红色代表缺陷)

Figure 5. Process of deep learning based on semantic segmentation (The white areas in the lower left masks represent the components or defects and the black areas are the background; the green, blue, yellow and red areas represent rods, matrix, fiber bundles and defects in the upper rightpredicted results, respectively)

表 1 XCT扫描三维编织C/C复合材料试件和图像参数

Table 1. XCT scanned 3D braided C/C composite specimens and image parameters

Specimen SDim/mm SRes/μm VXY/Voxel VZ

/VoxelC1 20×20×20 18.27 1747×1743 1442 C2 20×20×20 18.27 1713×1709 1307 C3 20×20×20 18.27 1737×1698 1302 C4 20×20×20 18.27 1734×1703 1299 Notes: SDim is the dimension of specimen, SRes is the scanning resolution of specimen, VXY and VZ are the image sizes in XY directions slice and Z direction. 表 2 三维编织 C/C 复合材料试件深度学习预测结果

Table 2. Results of deep learning predication of 3D braided C/C composite specimens

Specimen VDef/vol% VRod/vol% VFBd/vol% VMat/vol% C1 4.72 12.02 50.14 33.12 C2 5.52 11.25 46.71 36.52 C3 5.31 11.69 49.51 33.49 C4 5.01 10.96 48.07 35.96 Average of predication 5.14 11.48 48.61 34.77 Design value - 11[6] - - Average of threshold 6.83 - - - Notes: VDef, VRod, VFBd, VMat represents volume fraction of defects, rods, fiber bundles and matrix, respectively. -

[1] 郭飞, 李彦斌, 张培伟, 等. C/C复合材料销钉准静态和动态剪切性能[J]. 复合材料学报, 2021, 38(05): 1604-1610. doi: 10.13801/j.cnki.fhclxb.20200722.001GUO Fei, LI Yanbin, ZHANG Peiwei, et al. Quasi-static and dynamic shear properties of C/C composite pins[J]. Acta Materiae Compositae Sinica, 2021, 38(05): 1604-1610(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200722.001 [2] LIU P, CAI Y L, DU C L, et al. An elastoplastic mechanical-thermal model for temperature rise simulation of two-dimensional triaxially braided composites under quasi-static loads[J]. Composite Structures, 2023, (306): 116559. [3] 林志远, 邢会华, 侯晓, 等. 针刺C/C复合材料高温力学性能试验及本构关系[J]. 固体火箭技术, 2019, 42(01): 98-104.LIN Zhiyuan, XING Huihua, HOU Xiao, et al. High-temperature mechanical properties testing and constitutive relation of needle-punched C/C composite[J]. Journal of Solid Rocket Technology, 2019, 42(01): 98-104(in Chinese). [4] 耿莉, 成溯, 付前刚, 等. 碳/碳复合材料的激光烧蚀行为与机制[J]. 复合材料学报, 2022, 39(9): 4337-4343.GENG Li, CHENG Su, FU Qian'gang, et al. Laser ablation behavior and mechanism of carbon/carbon composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4337-4343(in Chinese). [5] 翟兆阳, 曲雅静, 张延超, 等. 碳纤维增强碳基复合材料加工技术研究与探讨[J]. 复合材料学报, 2022, 39(5): 2014-2033.ZHAI Zhaoyang, QU Yajing, ZHANG Yanchao, et al. Research and discussion on processing technology of carbon fiber reinforced carbon matrix composites[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2014-2033(in Chinese). [6] 魏连锋, 崔红, 嵇阿琳, 等. 预制体结构对三维编织C/C复合材料本征性能影响研究[J]. 炭素, 2017, (01): 5-9.WEI Lianfeng, CUI Hong, JI Alin, et al. Effects of preform structure on mechanical properties of three-dimensional braided carbon/carbon composites[J]. Carbon, 2017, (01): 5-9(in Chinese). [7] ZHANG Y F, WU L Z, SUN Y G, et al. CCCs off-axial orientation sensitivity analysis in hole pin-bearing failure via hierarchical multiscale simulation framework[J]. Composite Structures, 2023, (310): 115759. [8] 魏坤龙, 史宏斌, 李江, 等. 考虑孔隙缺陷三维编织C/C复合材料渐进损伤及强度预测[J]. 固体火箭技术, 2020, 43(04): 447-457.WEI Kunlong, SHI Hongbin, LI Jiang, et al. Progressive damage simulation and tensile strength prediction of three-dimensional braided C/C composites considering void defects[J]. Journal of Solid Rocket Technology, 2020, 43(04): 447-457(in Chinese). [9] GUO J H, KE Y N, WU Y Y, et al. Effects of defect sizes at different locations on compressive behaviors of 3D braided composites[J]. Thin-Walled Structures, 2022, (179): 109653. [10] 罗忠兵, 曹欢庆, 林莉. 航空复合材料构件R区相控阵超声检测研究进展[J]. 航空制造技术, 2019, 62(14): 67-75.LUO Zhongbing, CAO Huanqing, LIN Li. Progress in study of phased array ultrasonic testing on CFRP Radii in aerospace component[J]. Aeronautical Manufacturing Technology, 2019, 62(14): 67-75(in Chinese). [11] YANG Z J, REN W Y, SHARMA R, et al. In-situ X-ray computed tomography characterisation of 3D fracture evolution and image-based numerical homogenisation of concrete[J]. Cement and Concrete Composites, 2017, (75): 74-83. [12] YANG Z J, QSYMAH A, PENG Y Z, et al. 4D characterisation of damage and fracture behaviour of UHPFRC by in-situ XCT tests[J]. Cement and Concrete Composites, 2020, (106): 103473. [13] ZHANG X, YANG Z J, PANG M, et al. Ex-situ micro X-ray computed tomography tests and image-based simulation of UHPFRC beams under bending[J]. Cement and Concrete Composites, 2021, (123): 104216. [14] SENCU R M, YANG Z J, WANG Y C, et al. Generation of micro-scale finite element models from synchrotron X-ray CT images for multidirectional carbon fibre reinforced composites[J]. Composites Part A:Applied Science and Manufacturing, 2016, (91): 85-95. [15] SINCHUK Y, SHISHKINA O, GUEGUEN M, et al. X-ray CT based multi-layer unit cell modeling of carbon fiber-reinforced textile composites: Segmentation, meshing and elastic property homogenization[J]. Composite Structures, 2022, (298): 116003. [16] 刘海龙, 张大旭, 祁荷音, 等. 基于X射线CT原位试验的平纹SiC/SiC复合材料拉伸损伤演化[J]. 上海交通大学学报, 2020, 54(10): 1074-1083. doi: 10.16183/j.cnki.jsjtu.2019.274LIU Hailong, ZHANG Daxu, QI Heyin, et al. Tensile damage evolution of plain weave SiC/SiC composites based on in-situ X-ray CT tests[J]. Journal of Shanghai Jiao Tong University, 2020, 54(10): 1074-1083(in Chinese). doi: 10.16183/j.cnki.jsjtu.2019.274 [17] 寇宝弘, 卢德宏, 龚文豪, 等. 构型参数及方式对 Al2O3p/高锰钢球形网络复合材料压缩性能的影响[J]. 复合材料学报, 2023, 40(1): 499-509.KOU Baohong, LU Dehong, GONG Wenhao, et al. Influence of architecture parameter and mode on compressive properties of an Al2O3p/high manganese steel spherical interpenetrating composite[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 499-509(in Chinese). [18] GENG J, LI Y, XIAO H, et al. Study fatigue crack initiation in TiB2/Al-Cu-Mg composite by in-situ SEM and X-ray microtomography[J]. International Journal of Fatigue, 2021, (142): 105976. [19] GARCEA S C, WANG Y, WITHERS P J. X-ray computed tomography of polymer composites[J]. Composites Science and Technology, 2018, (156): 305-319. [20] WANG G Q, ZHOU C W, YU J, et al. Mechanical model of needle-punched (NP) carbon/carbon (C/C) composites with isogeometric beams-extended springs at mesoscale[J]. Composite Structures, 2023, (318): 117038. [21] LI W D, JIAN Y J, ZHOU X G, et al. In situ tensile damage characterization of C/C composites through X-ray computed tomography and digital volume correlation[J]. Ceramics International, 2023, (49): 10471-10480. [22] KOPP R, JOSEPH J, NI X C, et al. Deep Learning Unlocks X-ray Microtomography Segmentation of Multiclass Microdamage in Heterogeneous Materials[J]. Advanced Materials, 2022, (34): 2107817. [23] BADRAN A, MARSHALL D, LEGAULT Z, et al. Automated segmentation of computed tomography images of fiber-reinforced composites by deep learning[J]. Journal of Materials Science, 2020, (55): 16273-16289. [24] GAO X Y, LEI B, ZHANG Y, et al. Identification of microstructures and damages in silicon carbide ceramic matrix composites by deep learning[J]. Materials Characterization, 2023, (196): 112608. [25] RONNEBERGER O, FISCHER P, BROX T. U-Net: convolutional networks for biomedical image segmentation [C]. International Conference on Medical Image Computing and Computer-Assisted Intervention. Munich, 2015: 234-241. [26] 候晓, 程文, 陈妮, 等. 轴炭棒法制备高性能炭/炭复合材料喉衬织物[J]. 新型炭材料, 2013, 28(05): 355-362. doi: 10.1016/S1872-5805(13)60088-8HOU Xiao, CHENG Wen, CHEN Ni, et al. Preparation of a high performance carbon/carbon composite throat insert woven with axial carbon rods[J]. New Carbon Materials, 2013, 28(05): 355-362(in Chinese). doi: 10.1016/S1872-5805(13)60088-8 [27] 曹翠微, 李贺军, 李照谦, 等. 一种三维四向碳/碳复合材料的微观结构与力学性能[J]. 南京理工大学学报(自然科学版), 2010, 34(05): 713-716.CAO Cuiwei, LI Hejun, LI Zhaoqian, et al. Microstructures and mechanical properties of 3D 4-directional carbon/carbon composites[J]. Journal of Nanjing University of Science and Technology (Natural Science), 2010, 34(05): 713-716(in Chinese). -

下载:

下载: