Discrete element simulation of foam concrete under uniaxial compression considering non-spherical pores

-

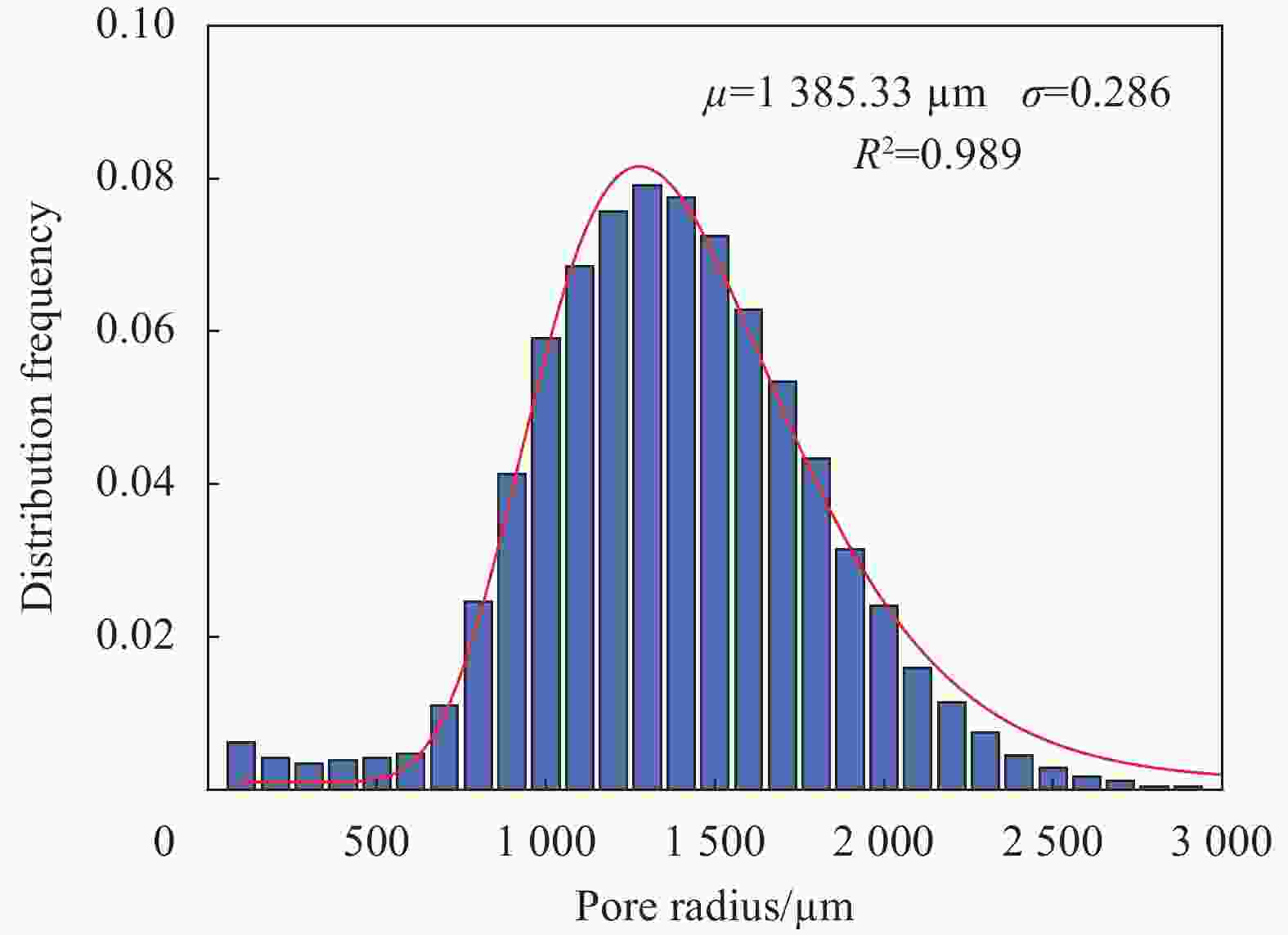

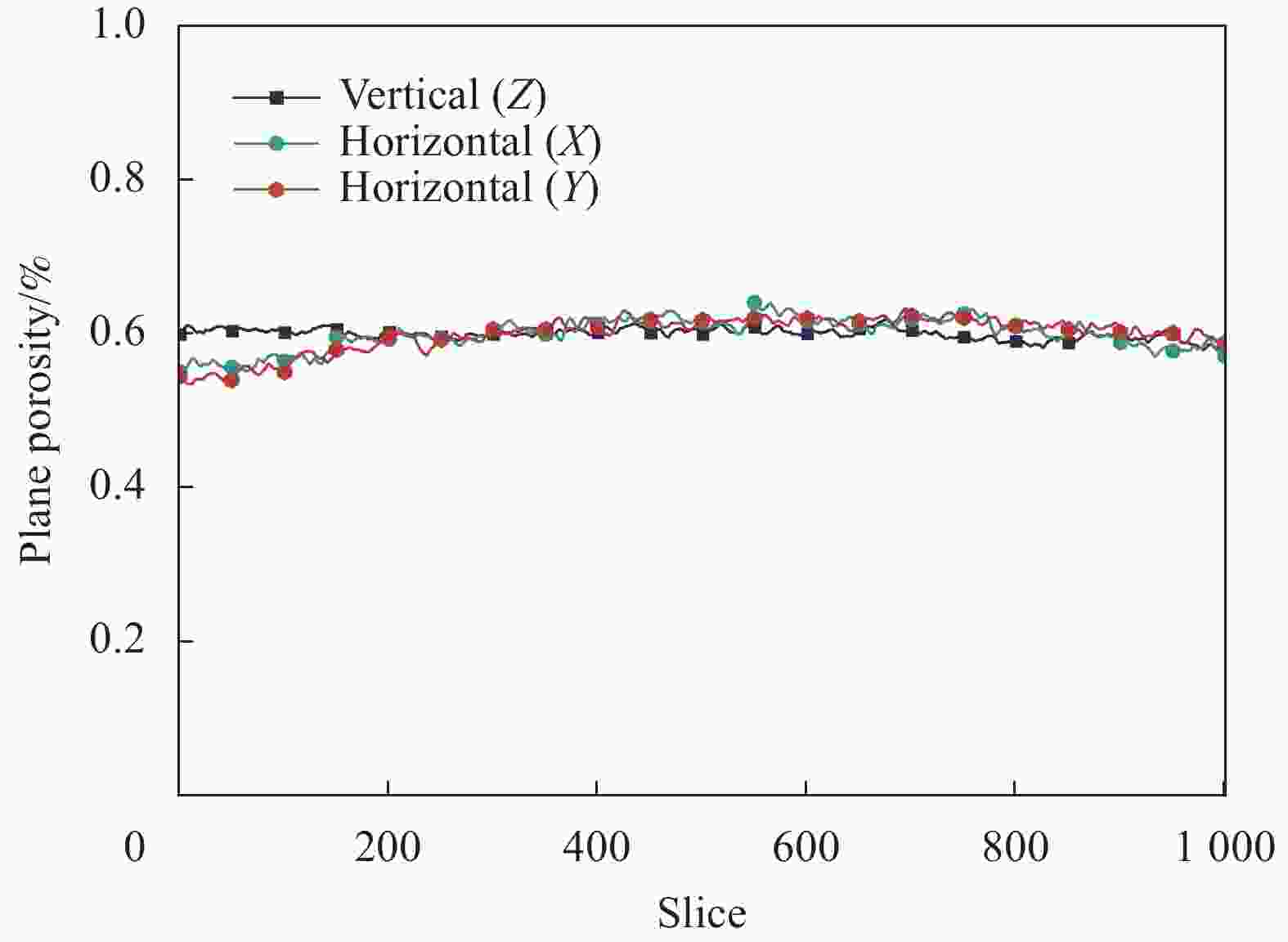

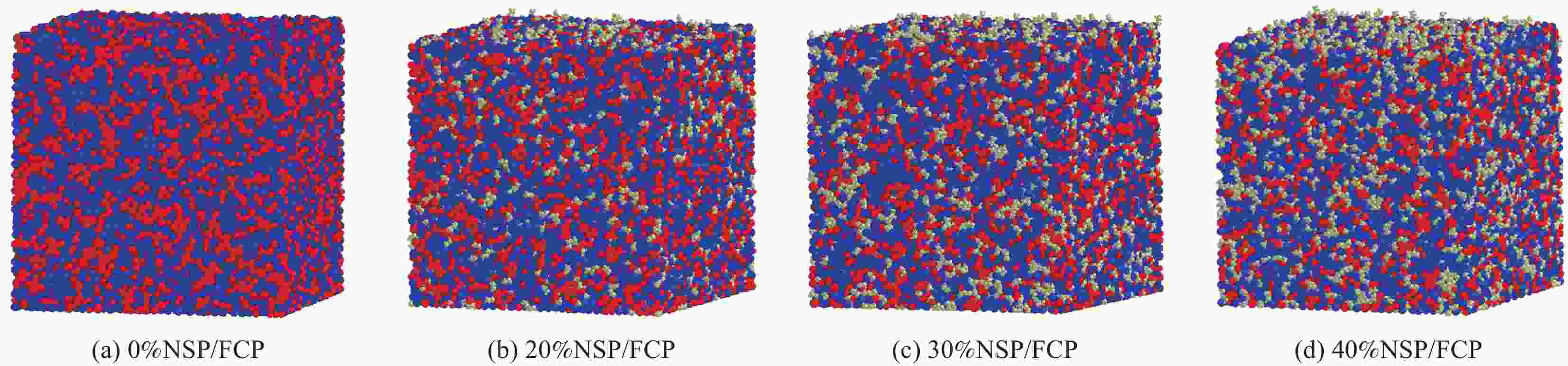

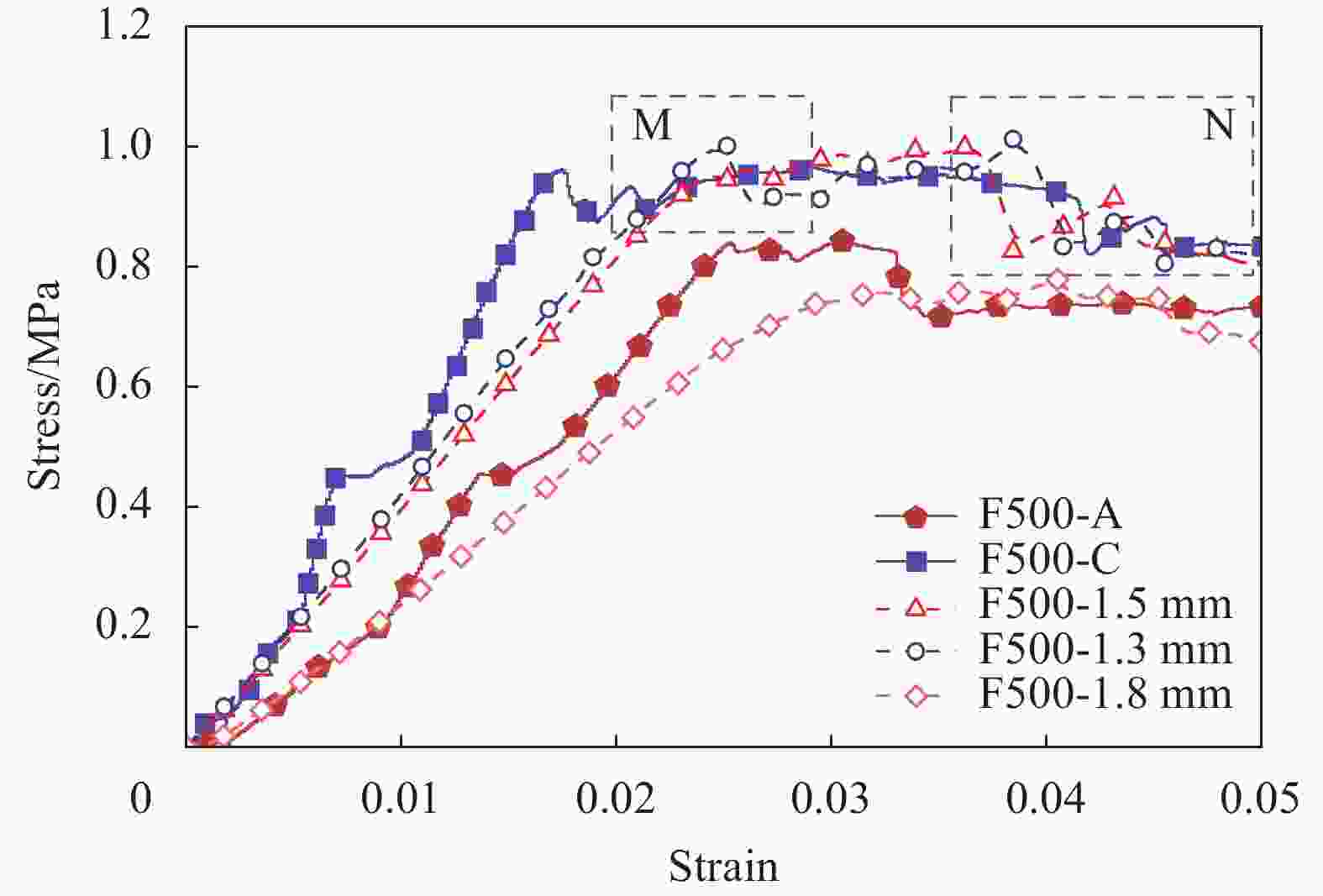

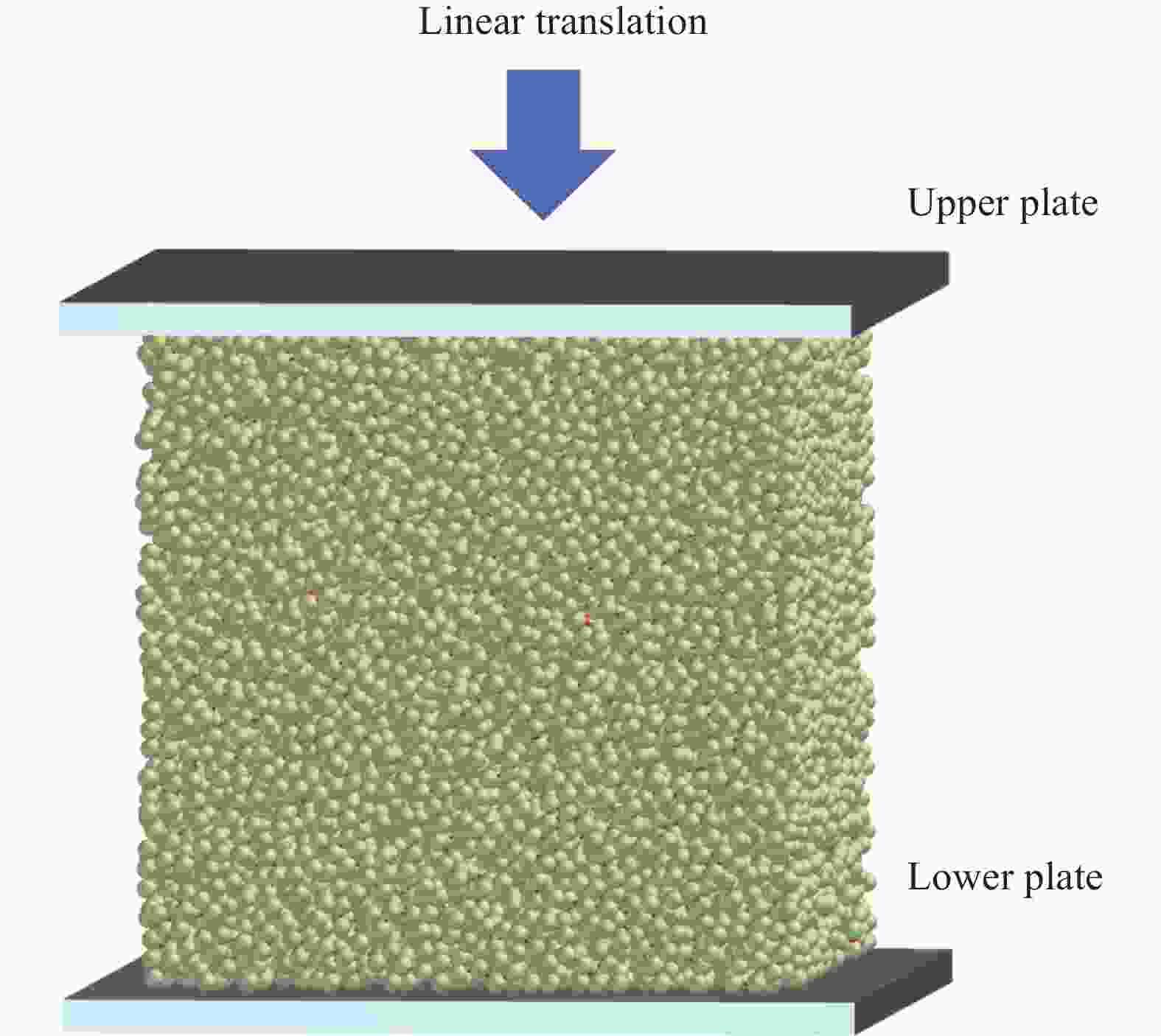

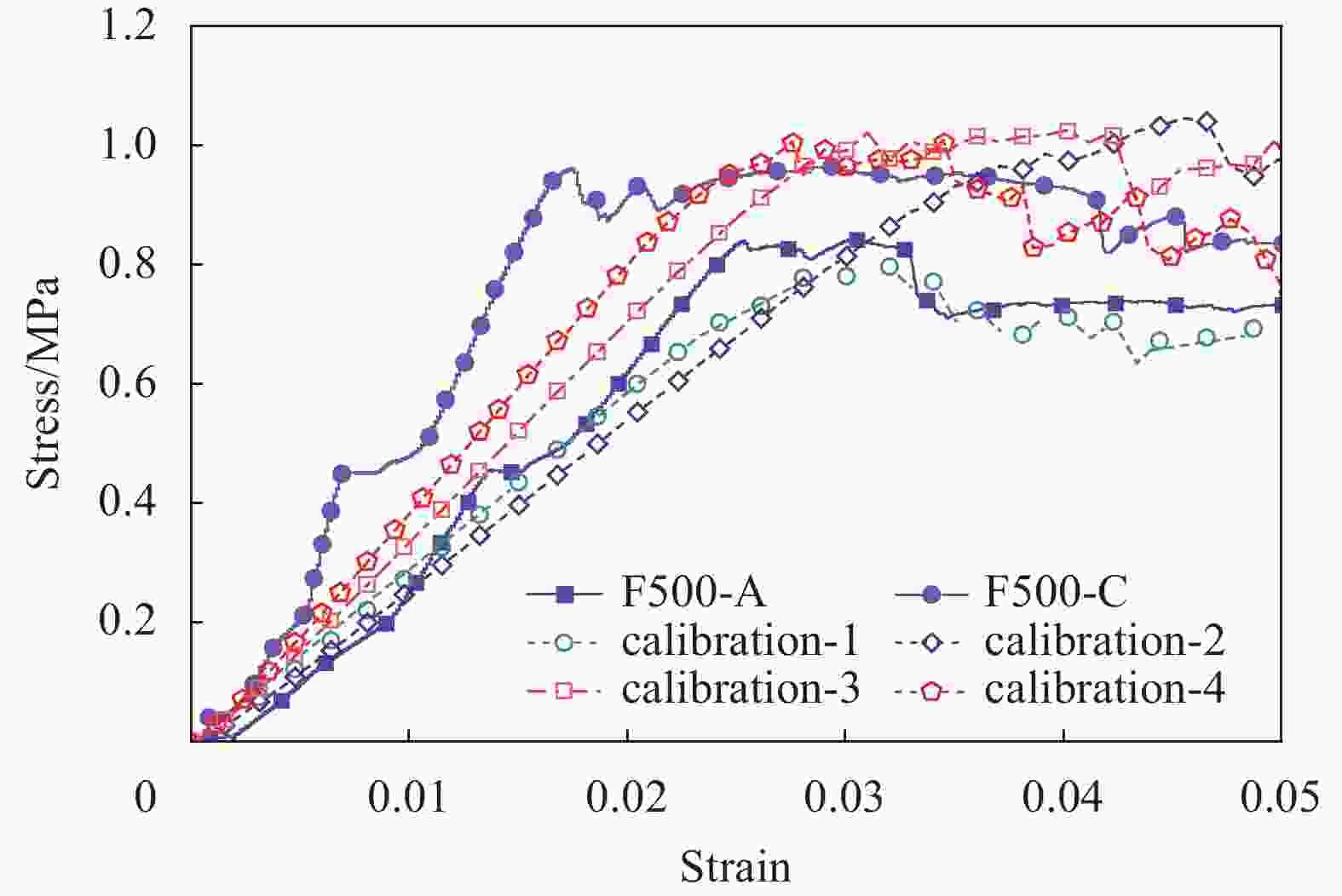

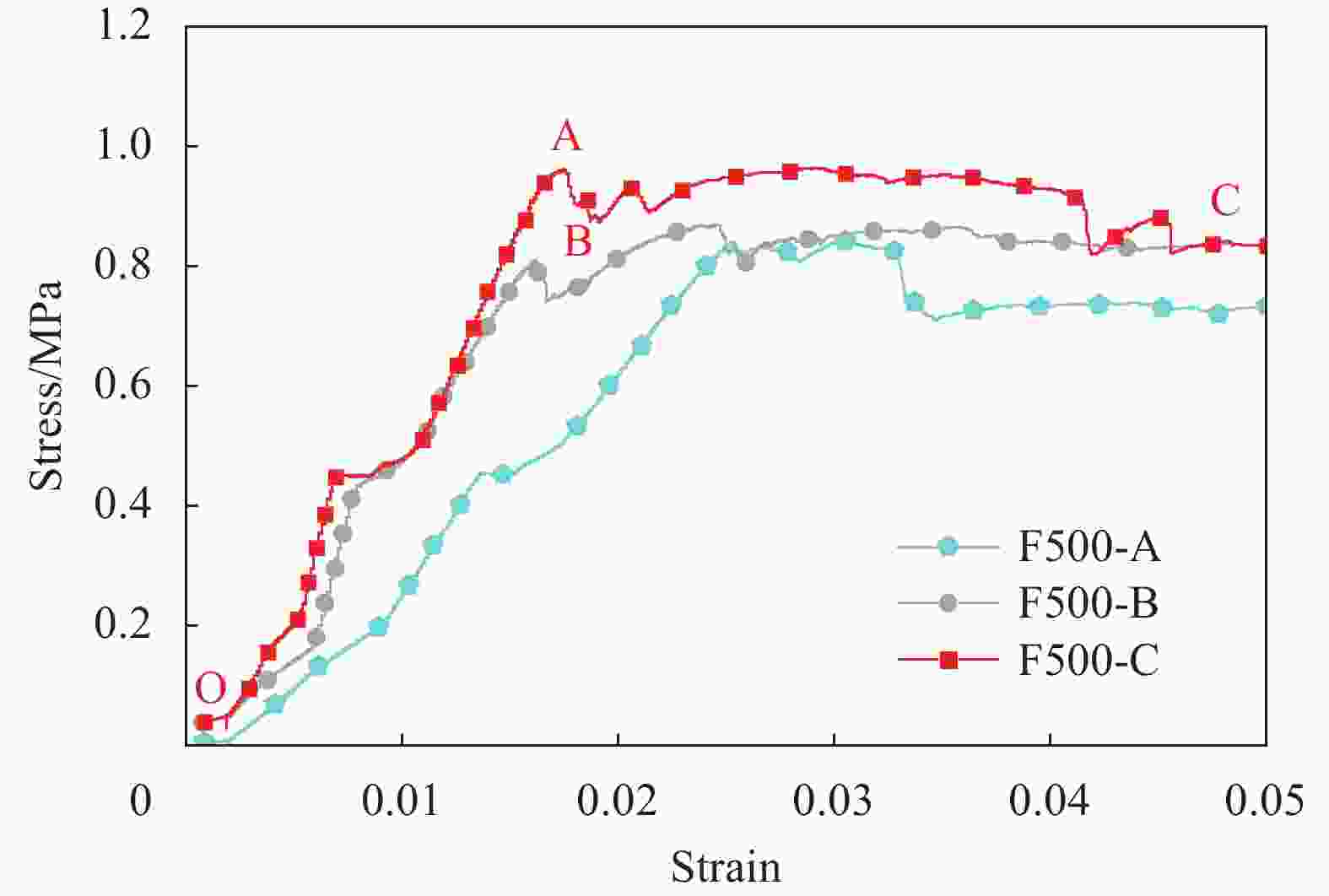

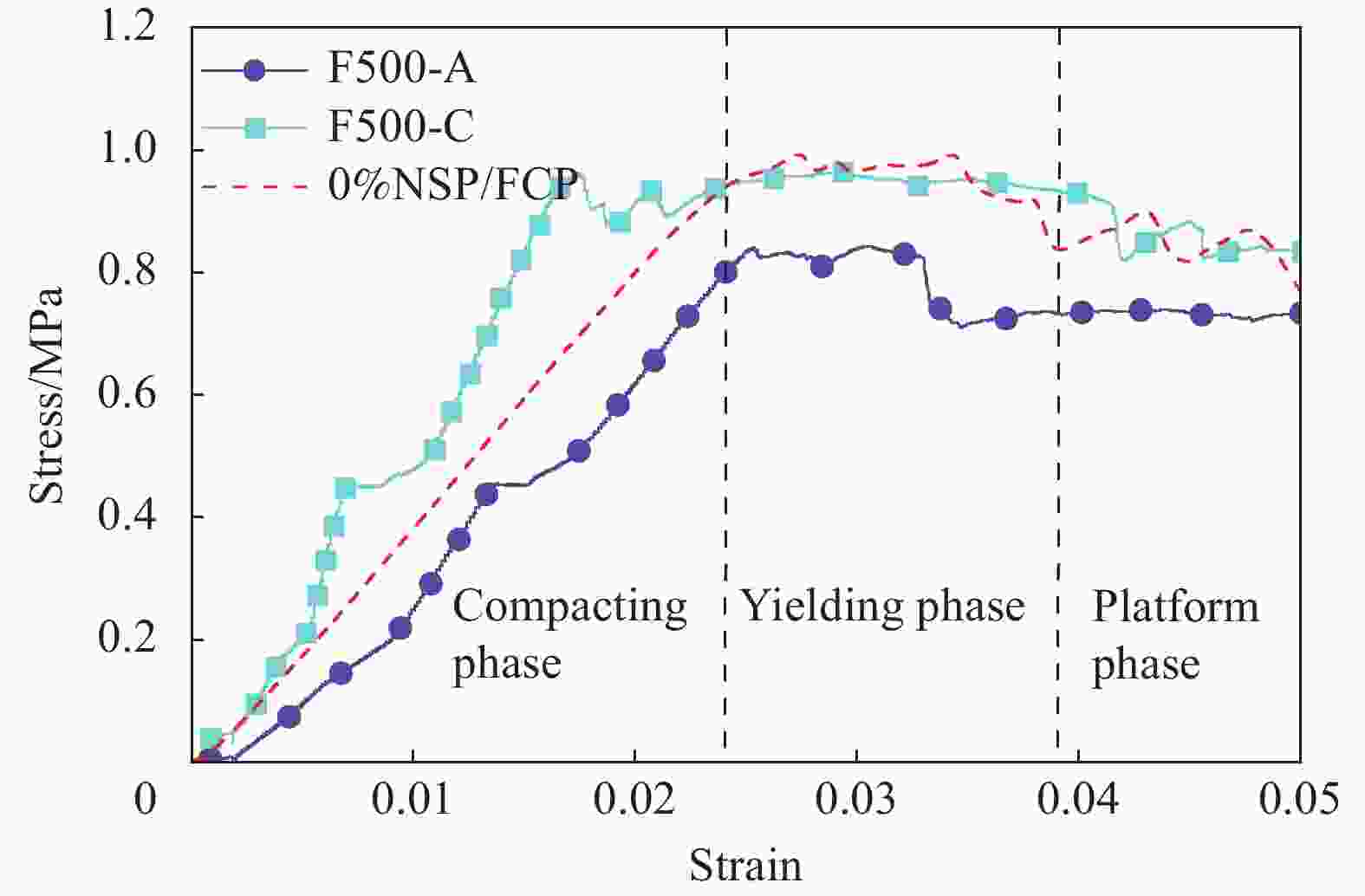

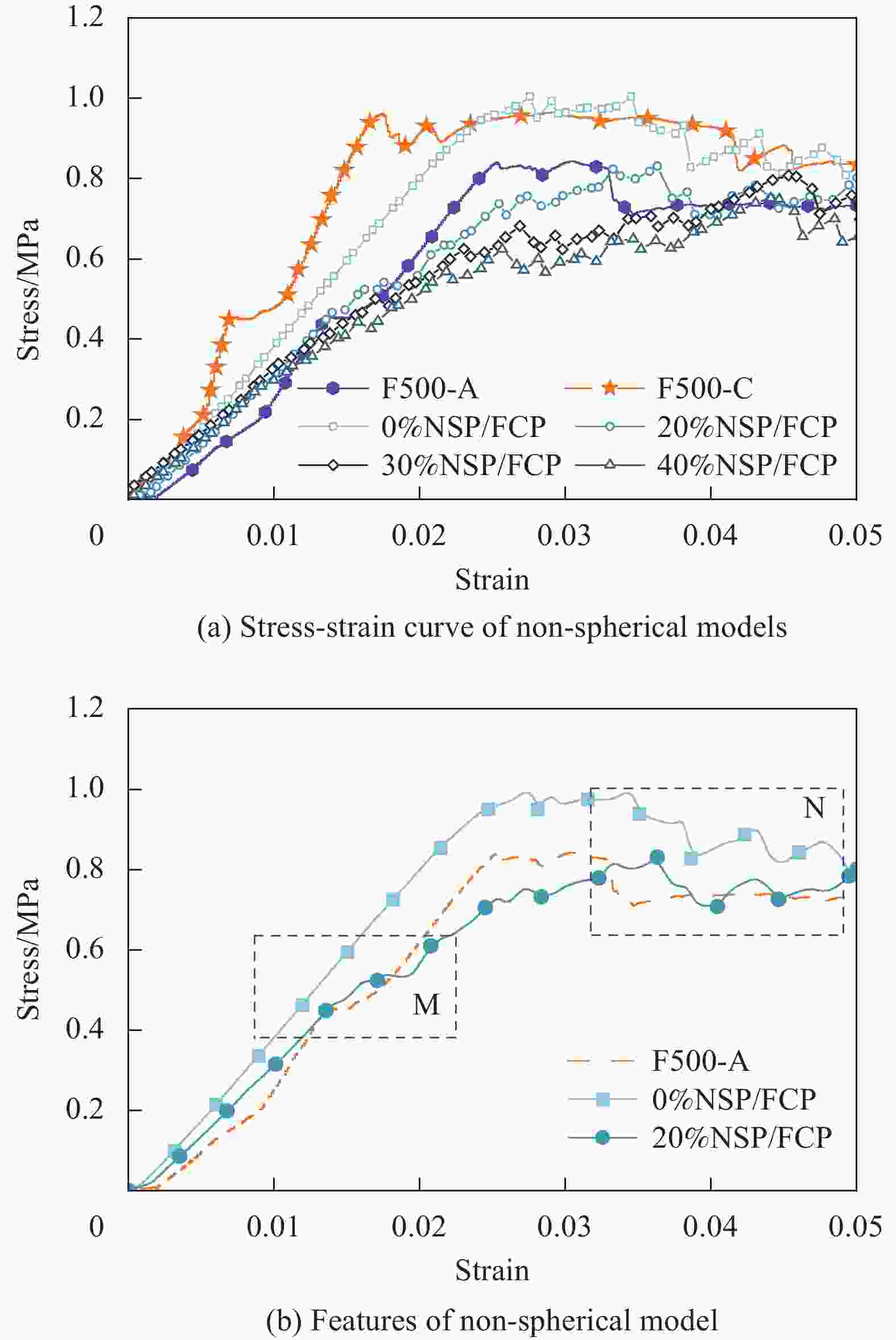

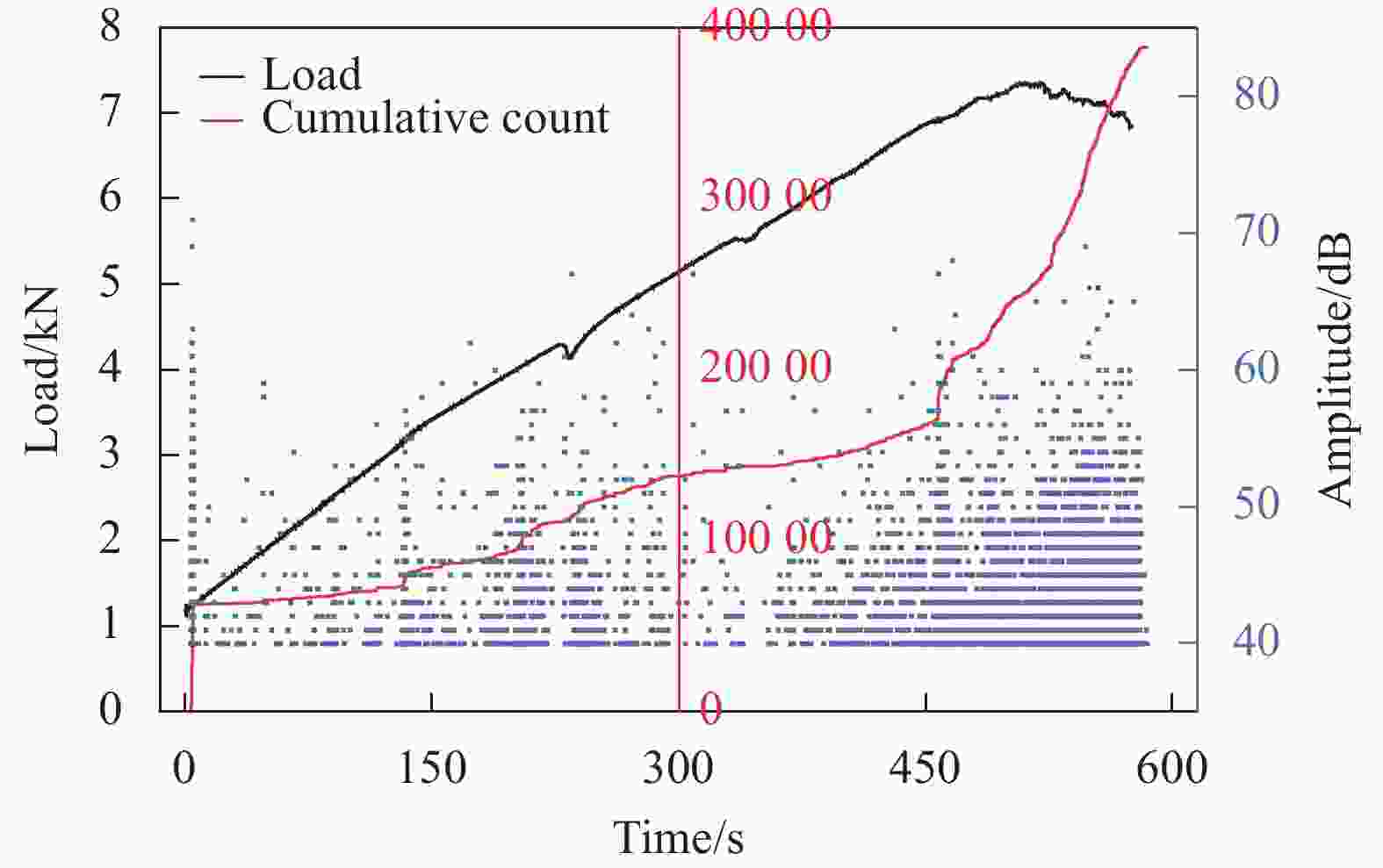

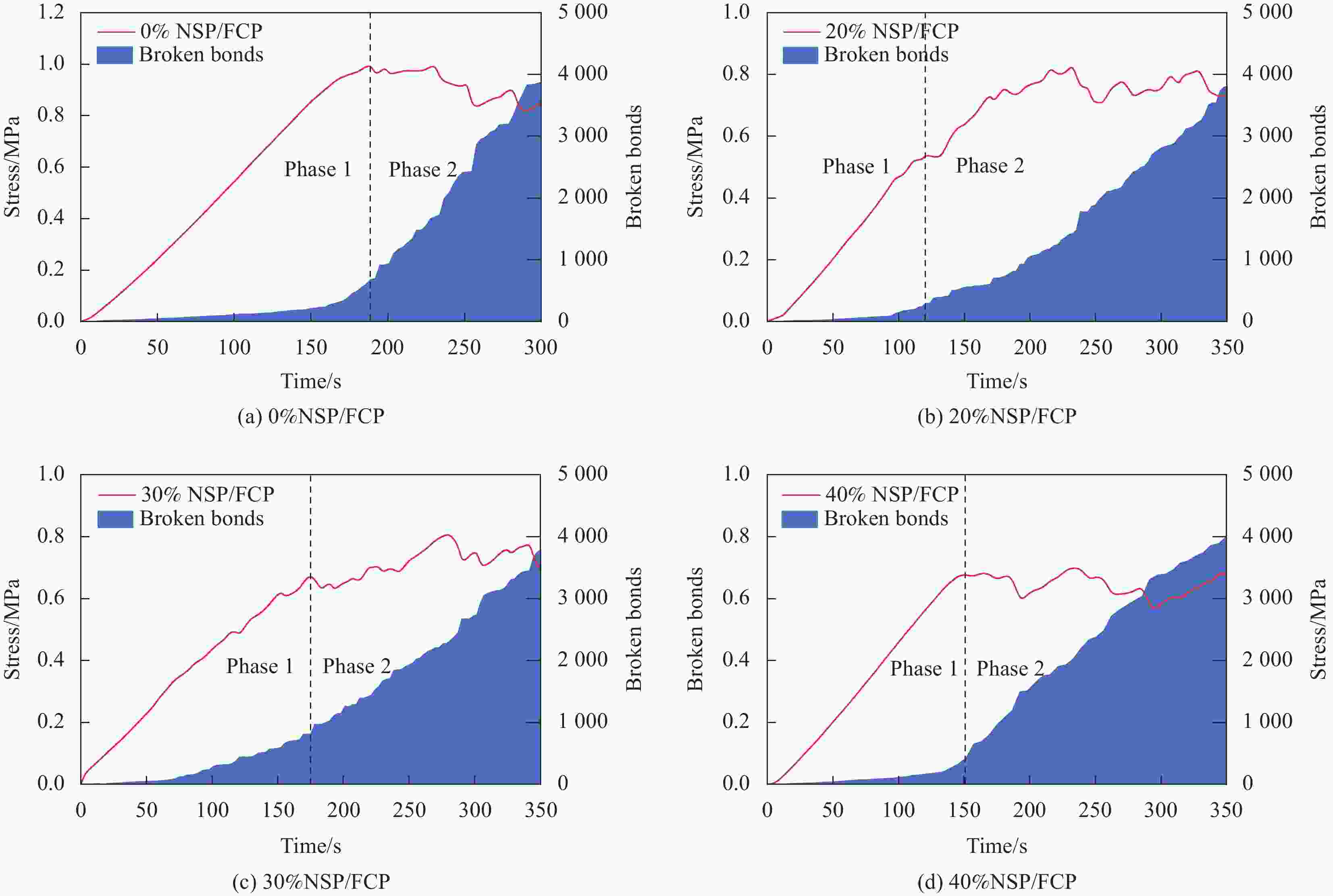

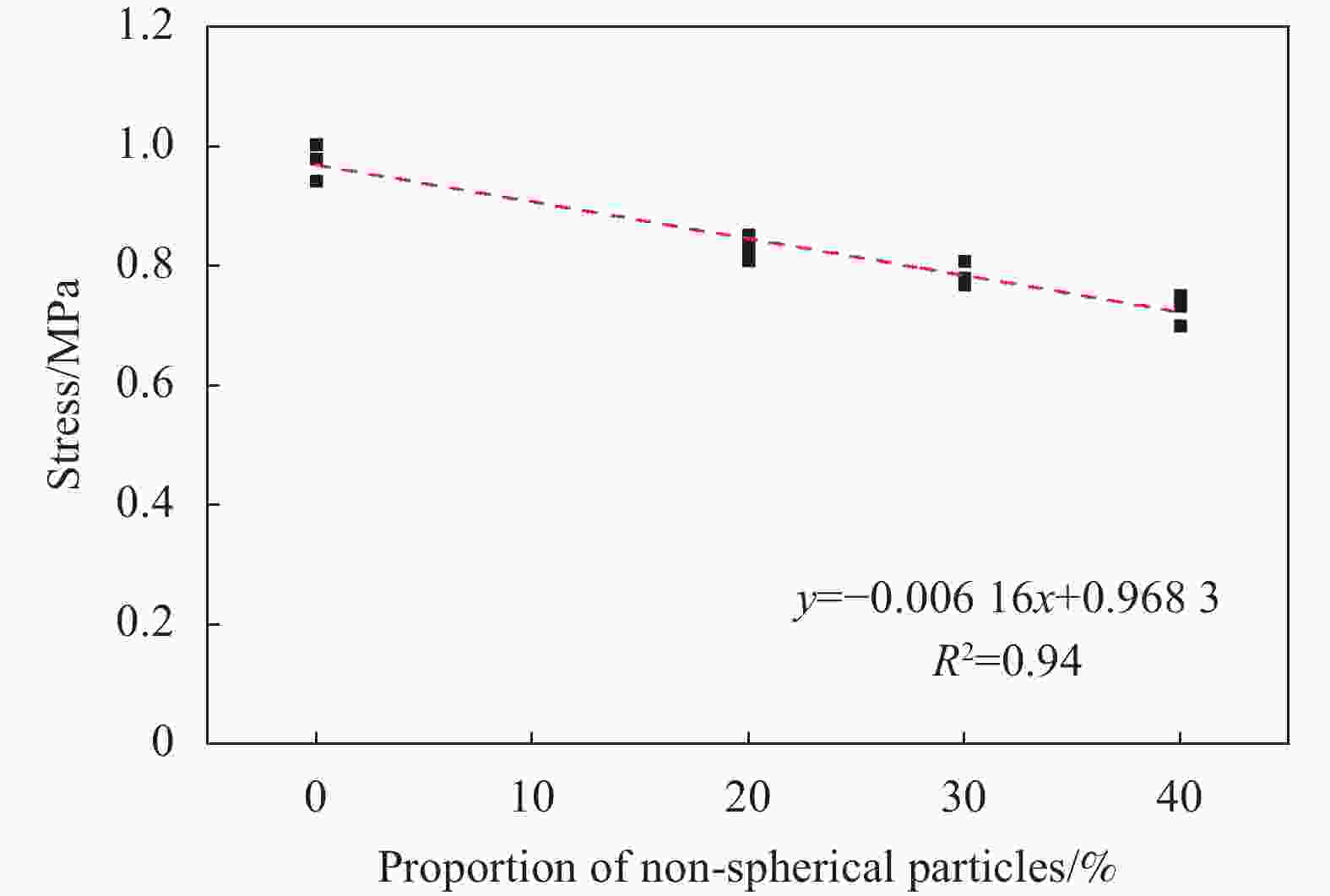

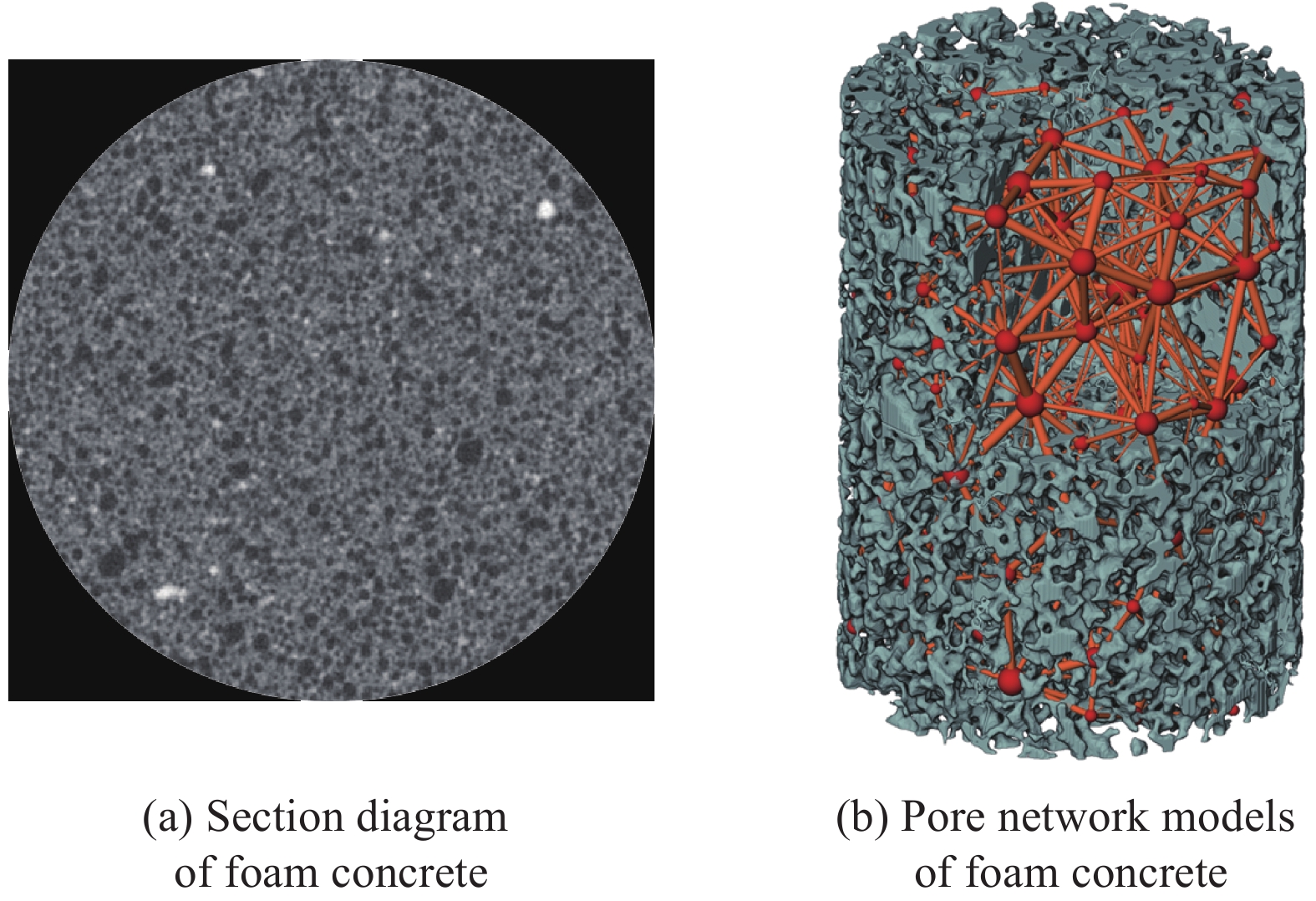

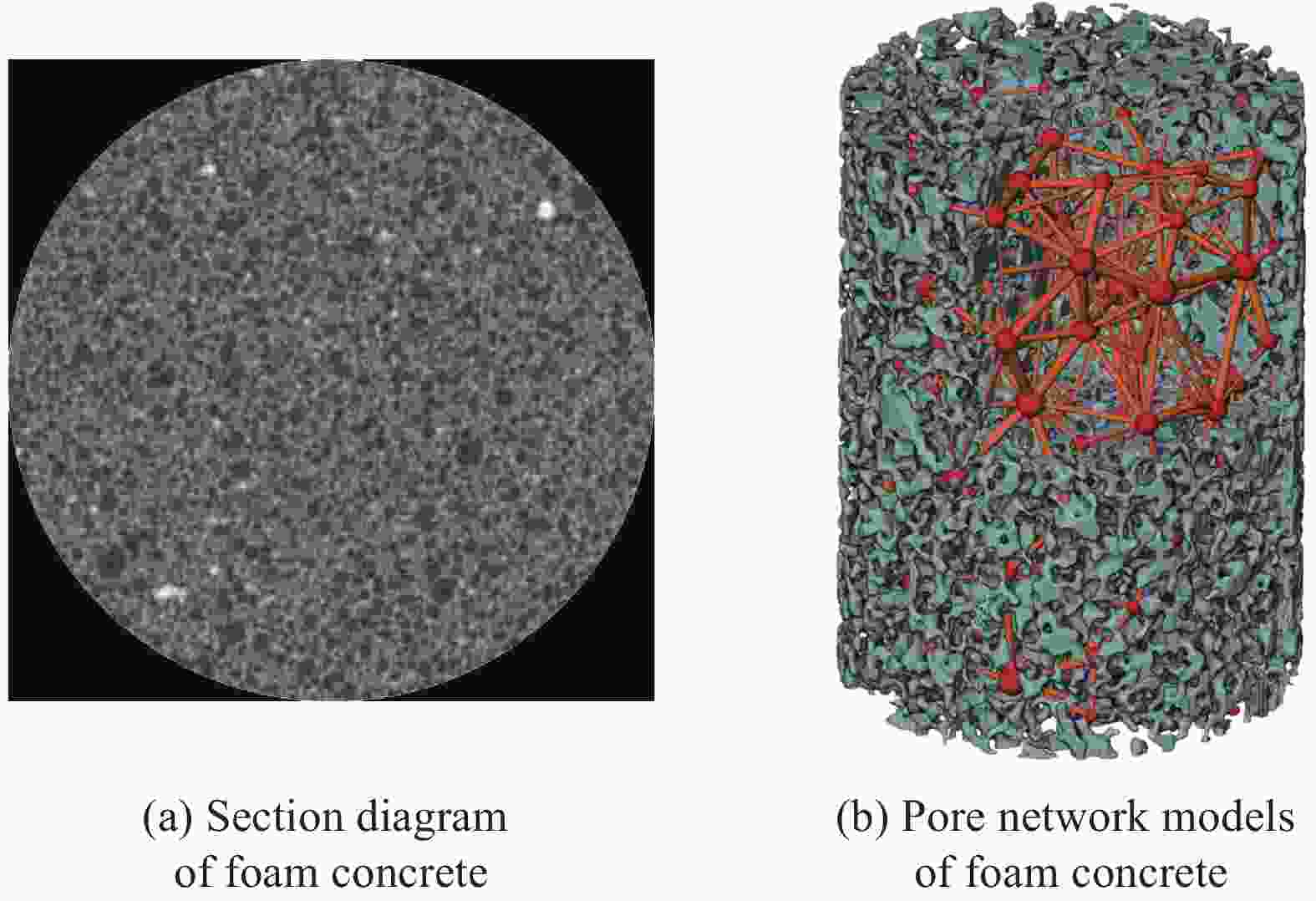

摘要: 为了研究异形孔隙对泡沫混凝土单轴压缩特性的影响,本文对密度等级500 kg/m3的泡沫混凝土开展了X-CT试验及单轴压缩-声发射联合试验,基于实测孔结构特征建立了不同非球形颗粒占比的三维细观离散元模型并模拟了单轴压缩过程。结果表明:离散元模型模拟的单轴压缩损伤过程与声发射试验结果基本一致,具有明显的阶段特征;异形颗粒离散元模型能表征初步密实阶段应力-应变曲线的震荡,模拟出应力消散阶段基质的剪切和互锁,在建立泡沫混凝土离散元模型时,应考虑孔隙形状的影响;离散元模型的抗压强度随模型中孔隙非球形率的提高而线性衰减,相关系数达0.94。Abstract: In order to study the fitness of discrete element method (DEM) in the simulation of mechanical properties of foam concrete and the influence of non-spherical pores on the uniaxial compression characteristics of foam concrete, X-CT test and uniaxial compression-acoustic emission joint test were carried out on foamed concrete with density of 500 kg/m3. Based on the measured pore structure characteristics, a series of three-dimensional mesoscopic DEM models with different non-spherical particle proportions were established and the uniaxial compression process was simulated. The results show that the uniaxial compression damage process of the model is basically consistent with the acoustic emission test results, which has obvious stage characteristics. The non-spherical particle discrete element model can characterize the oscillation of the stress-strain curve in the initial compaction stage, and simulate the shear and interlocking of the matrix in the stress dissipation stage. When establishing the discrete element model of foam concrete, the influence of pore shape should be considered. The compressive strength of the DEM model decreases linearly with the increase of the non-spherical rate of the pores in the model while the correlation coefficient is 0.94.

-

表 1 泡沫混凝土配合比

Table 1. Mix proportion of foam concrete

Sample No. Mix proportion/(kg·m−3) Wet density/(kg·m−3) Dry density/(kg·m−3) Cement Water Foam agent F500-A 310 186 0.59 523 398 F500-B 310 186 0.59 528 408 F500-C 310 186 0.59 530 415 Notes: The specimen number as F500-A, where F500 represents the wet density level of the specimen, and A represents the specimen number. 表 2 非球形颗粒基本参数

Table 2. Basic parameters of non-spherical particle

Particle Number Coordinate/mm Radius/mm X Y Z A 1 0 2 2 0.5 2 0 0.82 3 0.5 3 0 0.82 2 1 4 0.71 0 2 0.5 5 0 0 0.61 1 6 0 0.82 0 0.5 7 −1.2 −0.3 0.25 0.5 表 3 泡沫混凝土离散元模型颗粒统计

Table 3. Particle statistics of DEM model of foam concrete

Sample

No.Spherical particle volume/mm3 Non-spherical particle volume/mm3 Cement particle volume/mm3 Degree of compaction Porosity Deviation from experimental value 0%NSP/FCP 399271.10 - 274190.35 67.35% 0.593 2.47% 20%NSP/FCP 325290.65 86204.16 283082.63 69.46% 0.592 2.47% 30%NSP/FCP 283944.50 120768.48 285881.79 69.06% 0.586 3.62% 40%NSP/FCP 248534.41 164424.96 283280.55 69.62% 0.593 2.47% Notes: The specimen number as 20%NSP/FCP-1, where 20%NSP/FCP represents the volume ratio of non-spherical pore particles in all pore particles of DEM model of foam concrete, and 1 represents the specimen number. 表 4 泡沫混凝土离散元模型细观参数

Table 4. Mesoscopic parameters of DEM model of foam concrete

Contact parameters of Hertz-Mindlin model Mesoscopic parameters of Bonding model parameters Values parameters Values Coefficient of restitution 0.2 Normal stiffness per unit area (N/m3) 1.55×1010 Coefficient of static friction 0.4 Shear stiffness per unit area (N/m3) 1.32×1010 Coefficient of rolling friction 0.04 Critical normal stress (Pa) 4.8×106 Poisson’s ratio 0.35 Critical shear stress (Pa) 4.6×106 -

[1] 宋强, 张鹏, 鲍玖文, 等. 泡沫混凝土的研究进展与应用[J]. 硅酸盐学报, 2021, 49(2): 398-410. doi: 10.14062/j.issn.0454-5648.20200316SONG Q, ZHANG P, BAO J W, et al. Research progress and application of foam concrete[J]. Journal of the Chinese Ceramic Society, 2021, 49(2): 398-410(in Chinese). doi: 10.14062/j.issn.0454-5648.20200316 [2] 李升涛, 陈徐东, 张锦华, 等. 不同密度等级泡沫混凝土的单轴压缩破坏特征[J]. 建筑材料学报, 2021, 24(6): 1146-1153. doi: 10.3969/j.issn.1007-9629.2021.06.004LI S T, CHEN X D, ZHANG J H, et al. Failure characteristics of foam concrete with different density under uniaxial compression[J]. Journal of Building Materials, 2021, 24(6): 1146-1153(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.06.004 [3] Li T, HUANG F, ZHU J, et al. Effect of foaming gas and cement type on the thermal conductivity of foamed concrete[J]. Construction and Building materials, 2020, 231: 117197. doi: 10.1016/j.conbuildmat.2019.117197 [4] NAMBIAR E K, RAMAMURTHY K. Air-void characterisation of foam concrete[J]. Cement and Concrete Research, 2007, 37(2): 221-30. doi: 10.1016/j.cemconres.2006.10.009 [5] 周程涛, 陈波, 高志涵. 冻融环境下泡沫混凝土的单轴压缩特性[J]. 硅酸盐通报, 2023, 42(4): 1233-1241. doi: 10.3969/j.issn.1001-1625.2023.4.gsytb202304011ZHOU C T, CHEN B, GAO Z H. Uniaxial Compression Characteristics of Foamed Concrete under Freeze-thaw Environment[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(4): 1233-1241(in Chinese). doi: 10.3969/j.issn.1001-1625.2023.4.gsytb202304011 [6] 庞超明, 王少华. 泡沫混凝土孔结构的表征及其对性能的影响[J]. 建筑材料学报, 2017, 20(1): 93-98.PANG C M, WANG S H, Void characterization and effect on properties of foam concrete[J]. Journal of Building Materials, 2017, 20(1): 93-98(in Chinese). [7] SHE W, CHEN Y Q, ZHANG Y S, et al. Characterization and simulation of microstructure and thermal properties of foamed concrete[J]. Construction and Building materials, 2013, 47: 1278-1291. doi: 10.1016/j.conbuildmat.2013.06.027 [8] 朱兴一, 张启帆, 于越, 等. 基于离散元的EMAS泡沫混凝土贯入力学性能研究[J]. 建筑材料学报, 2023, 26(2): 122-128. doi: 10.3969/j.issn.1007-9629.2023.02.002ZHU X Y, ZHANG Q F, YU Y, et al. Penetration mechanical properties of EMAS foam concrete based on Discrete Element Simulation[J]. Journal of Building Materials, 2023, 26(2): 122-128(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.02.002 [9] SUCHORZEWSKI J, TEJCHMAN J, NITKA M. Discrete element method simulations of fracture in concrete under uniaxial compression based on its real internal structure[J]. International Journal of Damage Mechanics, 2018, 27(4): 578-607. doi: 10.1177/1056789517690915 [10] CHEN C H, GU J Y, PENG Z S, et al. Discrete element modeling of particles sphericity effect on sand direct shear performance[J]. Scientific Reports, 2022, 12(1). [11] NGUYENA T T, BUI H H, NGO T D, et al. A micromechanical investigation for the effects of pore size and its distribution on geopolymer foam concrete under uniaxial compression[J]. Engineering Fracture Mechanics, 2019, 209: 228-244. doi: 10.1016/j.engfracmech.2019.01.033 [12] NGUYEN T T, BUI H H, NGO T D, et al. Experimental and numerical investigation of influence of air-voids on the compressive behaviour of foamed concrete[J]. Materials & Design, 2017, 130: 103-119. [13] ZHU X Y, LEI P. A novel prediction model for failure mechanism of foamed concr ete[J]. Construction and Building materials, 2023, 370: 130625. doi: 10.1016/j.conbuildmat.2023.130625 [14] 袁志颖, 陈波, 陈家林, 等. 泡沫混凝土孔结构表征及其对力学性能的影响[J]. 复合材料学报, 2023, 40(7): 4117-4127.YUAN Z Y, CHEN B, CHEN J L, et al. Characterization of pore structure of foamed concrete and its influence on performance[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 4117-4127(in Chinese). [15] 高志涵, 陈波, 陈家林, 等. 基于X-CT的泡沫混凝土孔隙结构与导热性能[J]. 建筑材料学报, 2023, 26(7): 723-730. doi: 10.3969/j.issn.1007-9629.2023.07.004GAO Z H, CHEN B, CHEN J L, et al. Pore Structure and Thermal Conductivity of Foam Concrete Based on X-CT[J]. Journal of Building Materials, 2023, 26(7): 723-730(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.07.004 [16] GUO Y Z, CHEN X D, CHEN B, et al. Analysis of foamed concrete pore structure of railway roadbed based on X-ray computed tomography[J]. Construction and Building materials, 2021, 273: 121773. doi: 10.1016/j.conbuildmat.2020.121773 [17] 中华人民共和国住房和城乡建设部. 泡沫混凝土: JG/T266−2011[S]. 北京: 中国标准出版社, 2011.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Foamed concrete: JG/T266−2011[S]. Beijing: Standards Press of China, 2011(in Chinese). [18] 中华人民共和国国家质量监督检验检疫总局. 无损检测 声发射检测 总则: GB/T 26644-2011[S]. 2011.General Administration of Quality Supervision, Inspection and Quarantine of the People 's Republic of China. General principles of acoustic emission testing for non-destructive testing: GB/T 26644-2011 [S]. 2011(in Chinese). [19] Mindlin R D, Deresiewicz H. Elastic spheres in contact under varying oblique forces ASME[J]. Journal of Applied Mechanics, 1953, 20(3): 327-344. doi: 10.1115/1.4010702 [20] TSUJI Y, TANAKA T, LSHIDA T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe[J]. Powder Technology, 1992, 71(3): 239-250. doi: 10.1016/0032-5910(92)88030-L [21] SAKAGUCHI H, OZAKI E, LGARASHI T. Plugging of the Flow of Granular Materials during the Discharge from a Silo[J]. International Journal of Modern Physics B, 1993, 07(09n10): 1949-1963. doi: 10.1142/S0217979293002705 [22] 崔溦, 魏杰, 李国栋. 考虑粗骨料破碎的混凝土力学特性细观模拟[J]. 东南大学学报(自然科学版), 2022, 52(1): 50-56. doi: 10.3969/j.issn.1001-0505.2022.01.007CUI W, WEI J, LI G D. Meso-simulation of mechanical properties of concrete considering coarse aggregate crushing[J]. Journal of southeast university (Natural Science Edition), 2022, 52(1): 50-56(in Chinese). doi: 10.3969/j.issn.1001-0505.2022.01.007 [23] MA G G, SUN Z J MA H, et al. Calibration of Contact Parameters for Moist Bulk of Shotcrete Based on EDEM [J] Advances in Materials Science and Engineering, 2022, 14: 6072303. [24] 侯英伟, 曹东. 基于EDEM的混凝土板桩静压贯入过程三维颗粒流数值模拟[J]. 水利水电技术, 2020, 51(04): 123-131. doi: 10.13928/j.cnki.wrahe.2020.04.014HOU Y W, CAO D. EDEM-based 3D numerical simulation of particle flow during static pressure penetration of concrete sheet pile[J]. Water Resources and Hydropower Engineering, 2020, 51(04): 123-131(in Chinese). doi: 10.13928/j.cnki.wrahe.2020.04.014 [25] 牛子豪, 朱珍德, 阙相成, 等. 基于三维多晶离散元柱状节理岩体压缩特性研究[J]. 岩石力学与工程学报, 2022, 41(9): 1874-1887.NIU Z H, ZHU Z D, QUE X C, et al. Study on compression characteristics of columnar jointed rock mass by 3D Voronoi-based discrete element model[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(9): 1874-1887(in Chinese). [26] CHEN B, CHEN J, CHEN X, et al. Experimental study on compressive strength and frost resistance of steam cured concrete with mineral admixtures[J]. Construction and Building Materials, 2022, 325: 126725. doi: 10.1016/j.conbuildmat.2022.126725 -

下载:

下载: