Research progress on wood-based porous materials for dye wastewater treatment

-

摘要: 染料广泛应用于纺织、皮革、塑料、造纸、化妆品等行业,已经成为当今水体污染的主要来源之一。染料废水成分复杂,具有高毒性、有机污染物含量高、重金属超标等特性,对生态环境造成极大危害,因此实现水体中水溶性有机染料的去除成为当前废水处理面临的重要挑战。木材是一种可再生、可生物降解的环境友好型天然材料,具有构造有序、层次分明的多尺度分级结构和丰富的孔隙构造,这种层级多孔结构为新型染料去除材料和装置的开发创造了天然条件。通过在木材内部管腔表面负载石墨烯、MOF、贵金属纳米颗粒(Ag、Au、Pd)和多氧金属酸盐等活性物质,可促进木质基复合材料对染料的物理化学吸附与催化降解,进而实现废水中染料的有效去除。本文首先对染料废水的特性及其危害进行了概述,并详细介绍了木材的特殊微观结构及其在染料废水处理中的优势;随后,综述了负载活性物质的木基多孔材料用于染料废水的吸附和催化降解两种处理方式的原理和研究现状,并对木基多孔材料处理染料废水的发展前景进行展望和总结。Abstract: Dyes are extensively utilized in various industries, such as textiles, leather, plastics, and paper, and are currently one of the major sources of water pollution. Dye wastewater is characterized by its complex composition, high toxicity, and significant amounts of organic pollutants and heavy metals, which poses a serious threat to the ecological environment. Consequently, the removal of water-soluble organic dyes from water bodies has become a crucial challenge in wastewater treatment. Wood is a renewable, biodegradable, and environmentally friendly natural material that possesses a well-structured and hierarchically organized multiscale structure, as well as abundant pore structures. This porous hierarchical structure serves as a natural basis for the creation of new materials and devices intended for removing dyes. The physicochemical adsorption and catalytic degradation of dyes by wood-based composites can be promoted by loading active substances such as graphene, MOF, noble metal nanoparticles (Ag, Au, Pd) and polyoxometalates on the surface of the internal lumen of the wood, which can lead to the effective removal of dyes from wastewater. In this paper, the characteristics of dye wastewater and its hazards are firstly outlined, and the special microstructure of wood and its advantages in dye wastewater treatment are introduced in detail. Subsequently, the principles and research status of wood-based porous materials loaded with active substances for the two treatments of adsorption and catalytic degradation of dye wastewater are overviewed, and the future development prospects of wood-based porous materials for the treatment of dye wastewater are also prospected and summarized.

-

Key words:

- wood /

- dye wastewater /

- porous structure /

- adsorption /

- degradation

-

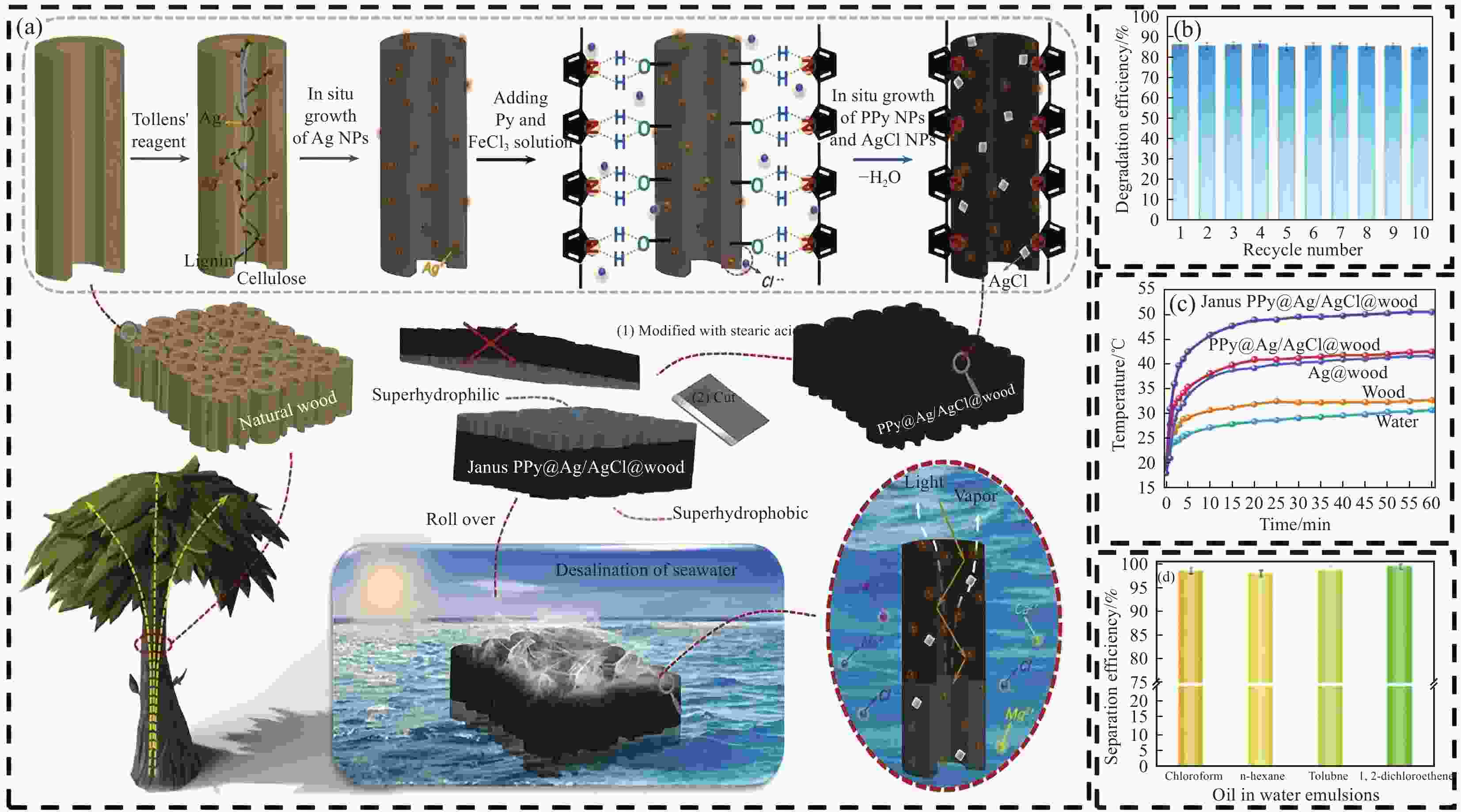

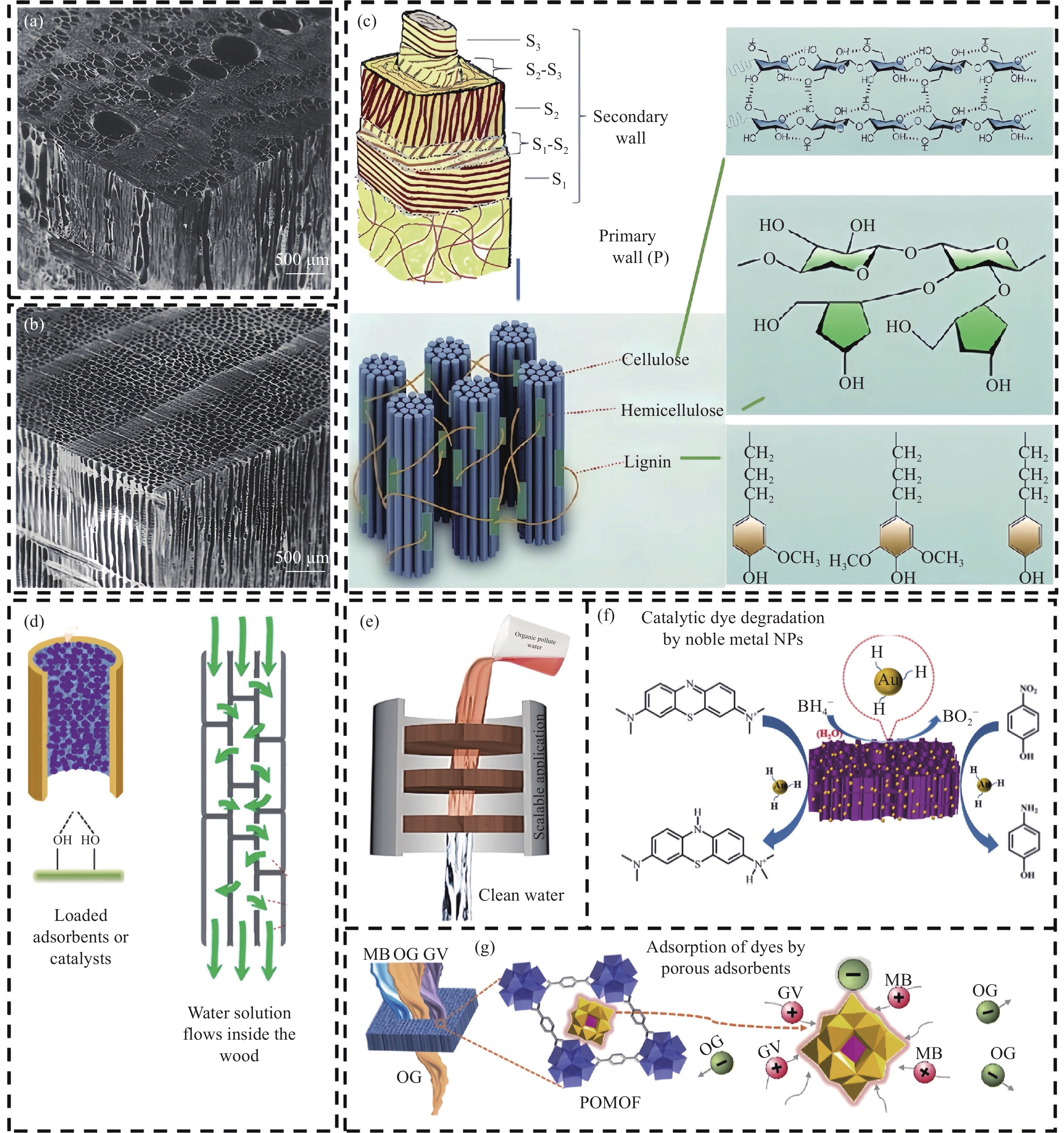

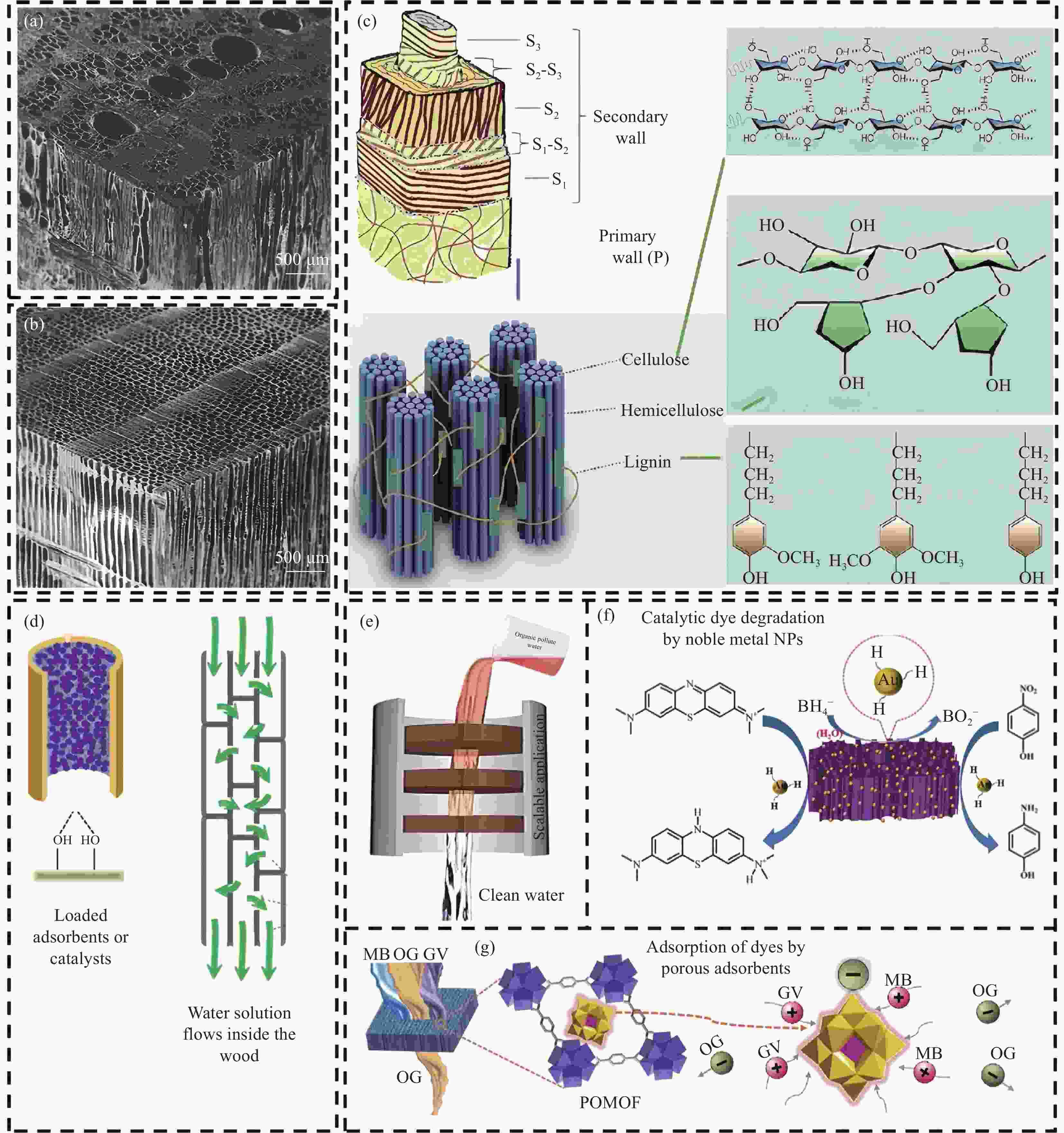

图 1 (a) 阔叶材微观图像[29];(b) 针叶材微观图像[29];(c) 木材细胞壁的分层结构及主要化学组成[32-33];(d) 活性物质附着于木材内部示意图[35];(e) 木材作为过滤基材图[36];(f) 降解法处理废水[37];(g) 吸附法处理废水[38]

NPs—Nanoparticles; MB—Methylene blue; OG—Orange G; GV—Gentian violet; POMOFs—Polyoxometalate-based metal-organic frameworks

Figure 1. (a) Microscopic image of hardwood[29]; (b) Microscopic image of softwood[29]; (c) Hierarchical structure and main chemical composition of wood cell walls[32-33]; (d) Schematic diagram of active substances attached to the interior of wood[35]; (e) Diagram of wood as a filtration substrate[36]; (f) Treatment of wastewater by degradation[37]; (g) Treatment of wastewater by adsorption[38]

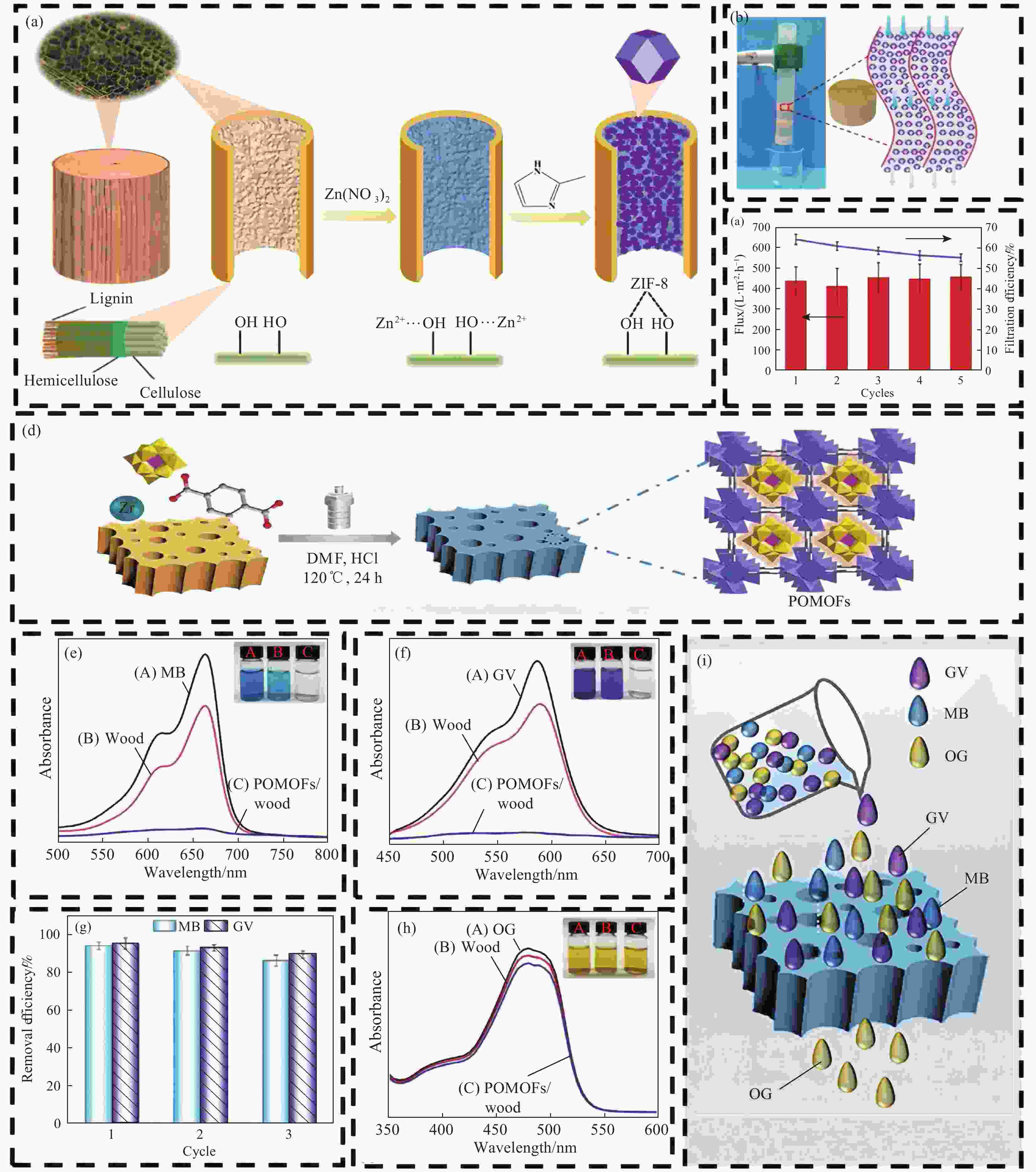

图 2 (a) 沸石咪唑酯骨架材料(ZIF-8)@wood复合材料的制备示意图;(b) 一体化过滤器的实验设置;(c) 3层ZIF-8复合材料5次循环去除Cu2+的通量与分离效率[35];(d) 多氧金属酸盐的金属有机框架(POMOFs)/wood材料的制备示意图;(e) 天然木材和 POMOFs/wood对亚甲基蓝(MB)的去除效率(8 mg/L);(f) 天然木材和 POMOFs/木材对龙胆紫(GV)的去除效率(8 mg/L);(g) 3个循环后GV和MB的去除效率;(h) 天然木材和POMOFs/wood对橙黄G (OG)的去除效率(8 mg/L);(i) POMOFs/wood选择性吸附示意图[38]

Figure 2. (a) Schematic of the preparation of zeolitic imidazolate framework-8 (ZIF-8)/wood composites; (b) Experimental setup of integrated filter; (c) Flux and separation efficiency of three-layer ZIF-8 composites for Cu2+ removal in five cycles[35]; (d) Schematic of the preparation of POMOFs/wood materials; (f) Removal efficiency of natural wood and POMOFs/wood for MB (8 mg/L); (g) Removal efficiency of natural wood and POMOFs/wood for GV (8 mg/L); (g) Removal efficiencies of GV and MB after three cycles; (h) Removal efficiencies of natural wood and POMOFs/wood for OG (8 mg/L); (i) Schematic of the selective adsorption of POMOFs/wood[38]

DMF—N, N-dimethylformamide

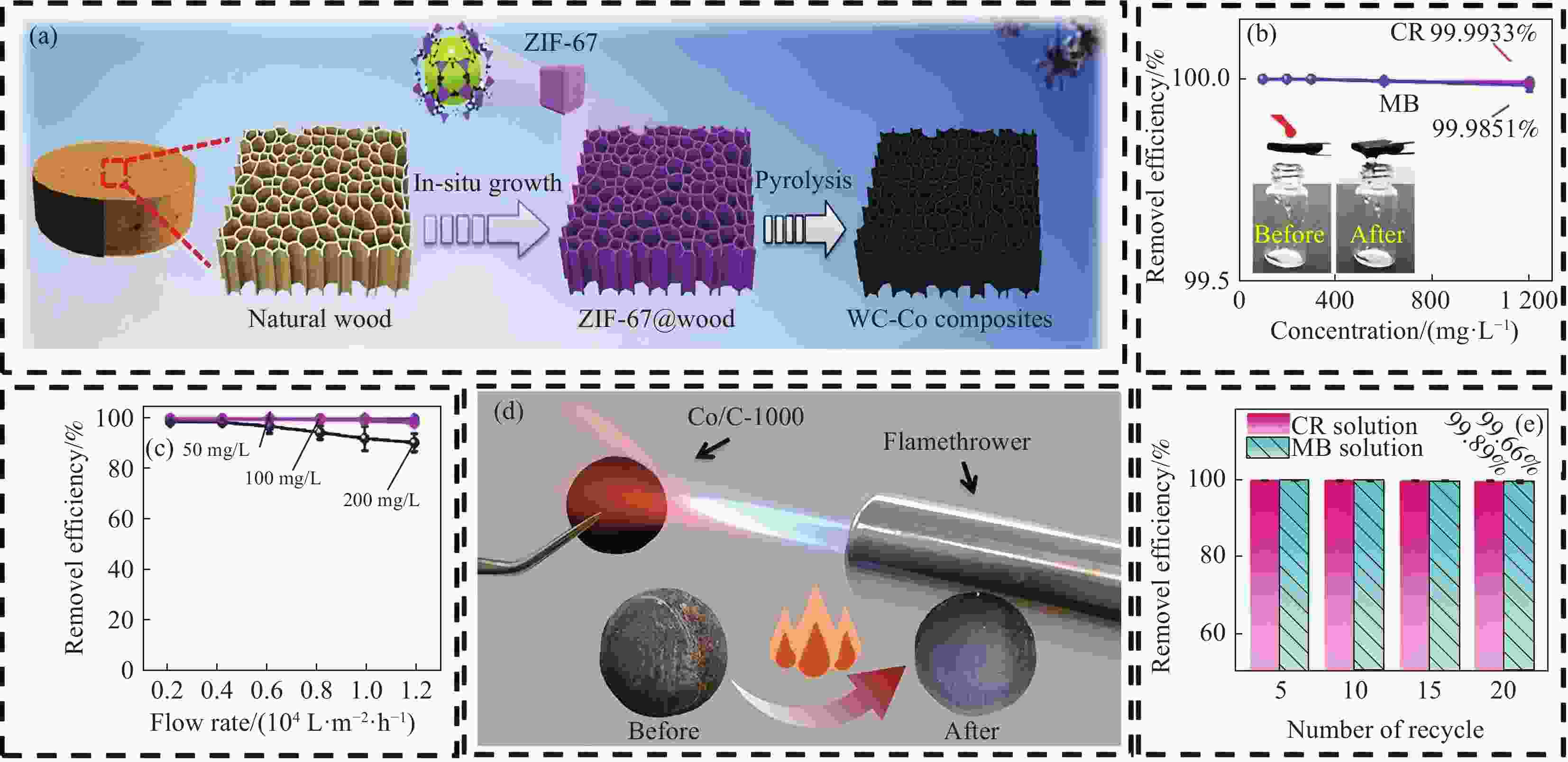

图 3 (a) 磁性WC-Co复合材料的制备示意图;(b) Co/C-1000过滤器对不同刚果红(CR)和MB浓度的去除效率;(c) Co/C-1000在不同通量下的CR溶液的去除效率;(d) Co/C-1000过滤器的回收方法演示;(e) 连续再生循环的去除效率变化[43]

Figure 3. (a) Schematic of the preparation of magnetic WC-Co composites; (b) Removal efficiencies of Co/C-1000 filters for different Congo red (CR) and MB concentrations; (c) Removal efficiencies of Co/C-1000 at different fluxes of CR solution; (d) Demonstration of recycling method of Co/C-1000 filters; (e) Variation of the removal efficiencies for successive regeneration cycles[43]

ZIF-67—Cobalt 2-methylimidazole

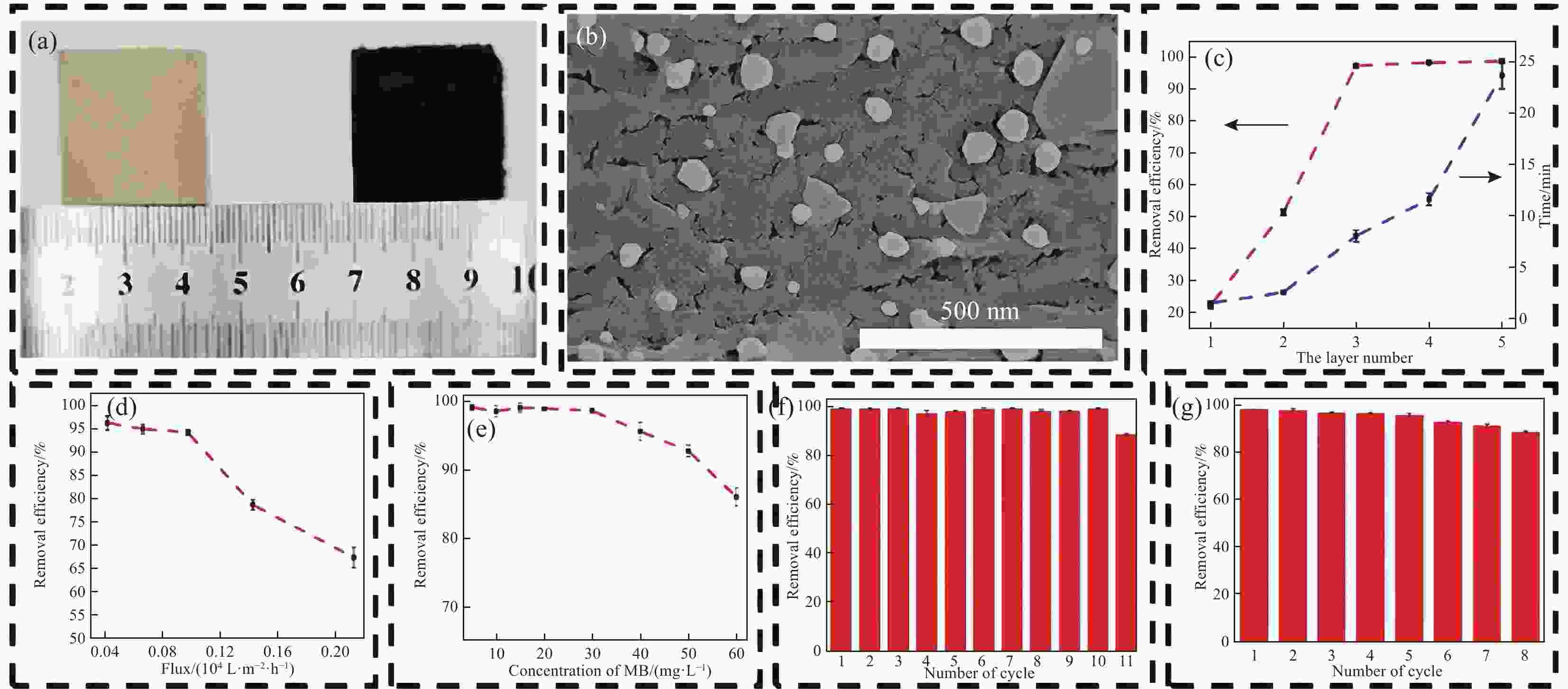

图 4 (a) 木材和Au纳米颗粒(NPs)/木材的数码照片;(b) Au NPs在木材上分布的SEM图像;(c) Au NPs/wood 的层数对去除效率和过滤时间的影响;(d) 分离效率与水通量之间的相关性;(e) 分离效率与MB浓度的关系;Au NPs/wood 催化还原MB (f) 和4-硝基酚(4-NP) (g)的可回收性[37]

Figure 4. (a) Digital photos of wood and Au NPs/wood; (b) SEM image of the distribution of Au NPs on wood; (c) Effect of the number of layers of Au NPs/wood on the removal efficiency and filtration time; (d) Correlation between the separation efficiency and the water flux; (e) Separation efficiency versus the concentration of MB; Recyclability of the Au NPs/wood for catalytic reduction of MB (f) and 4-NP (g)[37]

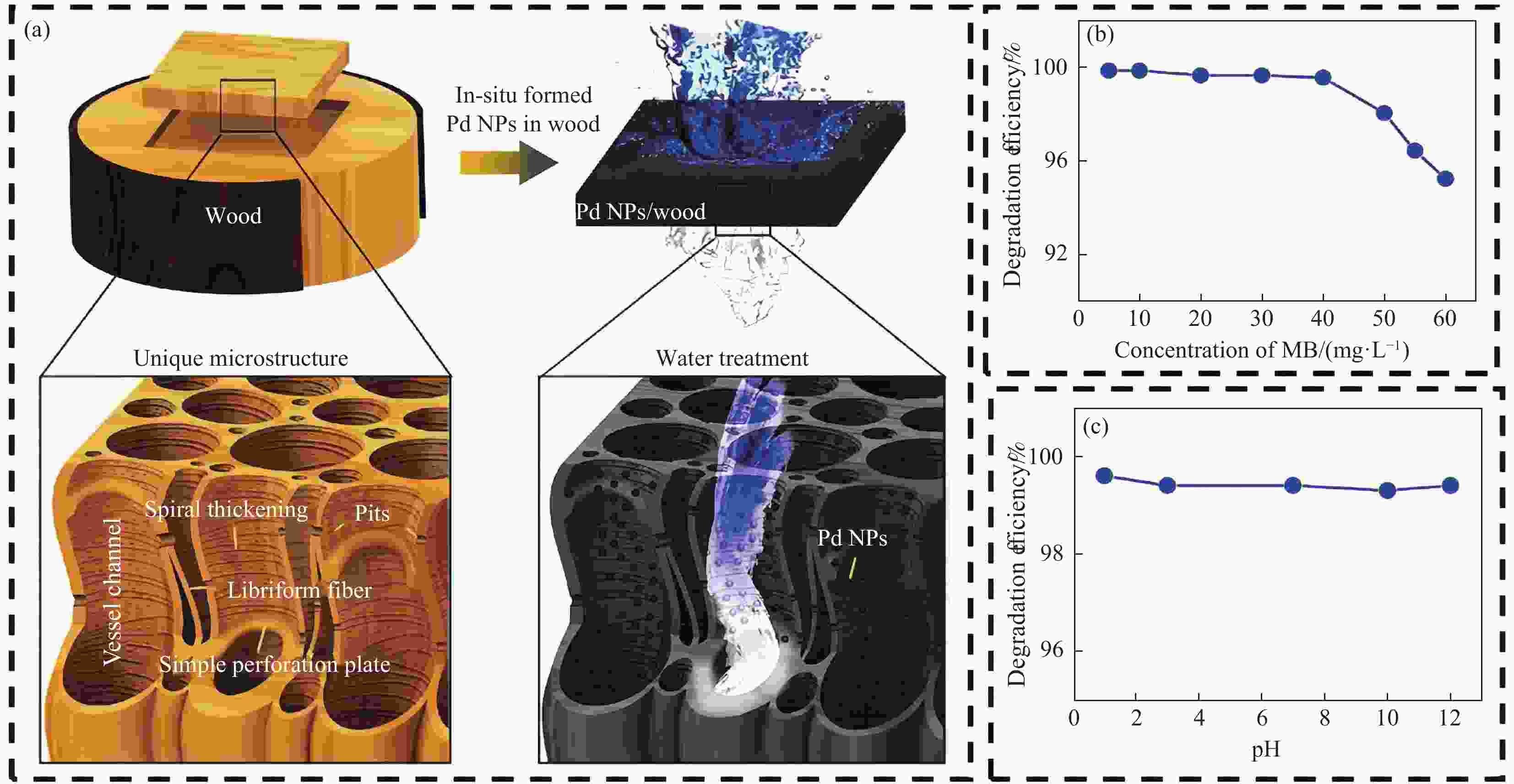

图 6 (a) Ag/木质复合过滤器制备及用于水处理示意图; (b) 不同pH值下使用Ag/木质过滤器的MB去除效率;(c) 不同浓度MB下使用Ag/木质过滤器的去除效率;(d) 不同Ag NPs含量的Ag/木质过滤器的大肠杆菌去除率[47]

Figure 6. (a) Schematic diagram of Ag/wood composite filters prepared and used for water treatment; (b) MB removal efficiencies using Ag/wood filters at different pH values; (c) Removal efficiencies using Ag/wood filters at different concentrations of MB; (d) E. coli removal by Ag/wood filters at different Ag NPs contents[47]

图 7 (a) 用于海水淡化的Janus介孔木质膜的制备示意图; (b) Janus介孔木质膜10次循环过滤MB的去除效率;(c) 5个蒸发系统的表面温度变化;(d) 各种水包油乳液相应的分离效率[50]

Figure 7. (a) Schematic of the preparation of Janus mesoporous lignocellulose membranes for seawater desalination; (b) Removal efficiencies of Janus mesoporous lignocellulose membranes for filtration of MB over 10 cycles; (c) Surface temperature variations of five evaporation systems; (d) Corresponding separation efficiencies for various oil-in-water emulsions[50]

PPy—Polypyrrole

-

[1] 袁思杰, 张芮铭. 染料废水处理技术研究进展[J]. 染料与染色, 2022, 59(4): 55-62.YUAN Sijie, ZHANG Ruiming. Research progress of dye wastewater treatment technology[J]. Dyestuffs and Coloration, 2022, 59(4): 55-62(in Chinese). [2] SELATILE M K, RAY S S, OJIJO V, et al. Recent developments in polymeric electrospun nanofibrous membranes for seawater desalination[J]. RSC Advances, 2018, 8(66): 37915-37938. doi: 10.1039/C8RA07489E [3] DASSANAYAKE R S, ACHARYA S, ABIDI N. Recent advances in biopolymer-based dye removal technologies[J]. Molecules, 2021, 26(15): 4697. doi: 10.3390/molecules26154697 [4] 王晓媛, 马迁, 崔玉, 等. 改性石墨毡阴极电Fenton氧化法处理印染废水[J]. 化工环保, 2023, 43(6): 767-772.WANG Xiaoyuan, MA Qian, CUI Yu, et al. Treatment of printing and dyeing wastewater by electro-Fenton oxidation process with modified graphite felt cathode[J]. Environmental Protection of Chemical Industry, 2023, 43(6): 767-772(in Chinese). [5] 宣晓旭. 皮草染色废水深度处理与回用研究解析[J]. 环境与发展, 2020, 32(1): 39-40.XUAN Xiaoxu. Advanced treatment and reuse of fur dyeing wastewater[J]. Environment and Development, 2020, 32(1): 39-40(in Chinese). [6] 林金钩, 陈燕贵, 吕碧洪, 等. 三维电催化氧化法处理高浓度有机废水[J]. 环境工程学报, 2023, 17(10): 3325-3332.LIN Jingou, CHEN Yangui, LYU Bihong, et al. Three-dimensional electrocatalytic oxidation for treatment of highly concentrated organic wastewater[J]. Chinese Journal of Environmental Engineering, 2023, 17(10): 3325-3332(in Chinese). [7] CHEN C, KUANG Y, ZHU S, et al. Structure–property–function relationships of natural and engineered wood[J]. Nature Reviews Materials, 2020, 5(9): 642-666. doi: 10.1038/s41578-020-0195-z [8] ZHU H, LUO W, CIESIELSKI P N, et al. Wood-derived materials for green electronics, biological devices, and energy applications[J]. Chemical Reviews, 2016, 116(16): 9305-9374. doi: 10.1021/acs.chemrev.6b00225 [9] WIMMERS G. Wood: A construction material for tall buildings[J]. Nature Reviews Materials, 2017, 2(12): 17051. doi: 10.1038/natrevmats.2017.51 [10] SJOSTROM E. Wood chemistry: Fundamentals and applications[M]. Elsevier, Netherlands, 2013: 1-23. [11] LING S, KAPLAN D L, BUEHLER M J. Nanofibrils in nature and materials engineering[J]. Nature Reviews Materials, 2018, 3(4): 18016. [12] 金枝, 李伯涛, 尹江苹, 等. 木材孔隙连通性评价研究进展[J]. 林业科学, 2022, 58(5): 177-186.JIN Zhi, LI Botao, YIN Jiangping, et al. Research progress for the evaluation of wood pore connectivity[J]. Scientia Silvae Sinicae, 2022, 58(5): 177-186(in Chinese). [13] KATAKI S, CHATTERJEE S, VAIRALE M G, et al. Concerns and strategies for wastewater treatment during COVID-19 pandemic to stop plausible transmission[J]. Resources, Conservation and Recycling, 2021, 164: 105156. doi: 10.1016/j.resconrec.2020.105156 [14] 王宝山, 陈晓杰, 赵培宇, 等. 基于三维生物膜电极的难生化有机化工废水处理研究进展[J/OL]. 化工进展: 1-20[2024-03-23]. https://doi.org/10.16085/j.issn.1000-6613.2023-1079.WANG Baoshan, CHEN Xiaojie, ZHAO Peiyu, et al. Research progress on the treatment of refractory organic chemical wastewater using three-dimensional biofilm electrodes[J]. Chemical Industry and Engineering Progress, 2023: 1-20[2024-03-23]. https://doi.org/10.16085/j.issn.1000-6613.2023-1079(in Chinese). [15] 姚继明, 张维, 穆玉广, 等. 电化学参数对硫化黑染色废水絮凝效果的影响[J]. 印染, 2023, 49(10): 12-17.YAO Jiming, ZHANG Wei, MU Yuguang, et al. Influence of electrochemical system parameters on the flocculation effect of sulfide black dyeing wastewater[J]. China Dyeing & Finishing, 2023, 49(10): 12-17(in Chinese). [16] 陈潮军, 王丹青, 韩伟. 化工染料废水处理技术的应用[J]. 化工管理, 2020(30): 102-103.CHEN Chaojun, WANG Danqing, HAN Wei. Application of chemical dye wastewater treatment technology[J]. Chemical Engineering Management, 2020(30): 102-103(in Chinese). [17] 薛飞华, 朱宝玉. 染料废水处理技术方法的研究[J]. 环境与发展, 2019, 31(7): 91, 93.XUE Feihua, ZHU Baoyu. Study on the treatment technology of dye wastewater[J]. Environment and Development, 2019, 31(7): 91, 93(in Chinese). [18] ZARE E N, MOTAHARI A, SILLANPÄÄ M. Nanoadsorbents based on conducting polymer nanocomposites with main focus on polyaniline and its derivatives for removal of heavy metal ions/dyes: A review[J]. Environmental Research, 2018, 162: 173-195. doi: 10.1016/j.envres.2017.12.025 [19] 王永奎, 程紫琳. 活性炭吸附法处理印染废水研究进展[J]. 湖北理工学院学报, 2020, 36(5): 15-19.WANG Yongkui, CHENG Zilin. Research progress of dyeing wastewater treatment by activated carbon adsorption[J]. Journal of Hubei Polytechnic University, 2020, 36(5): 15-19(in Chinese). [20] ZEYAD M T, KUMAR M, MALIK A. Mutagenicity, genotoxicity and oxidative stress induced by pesticide industry wastewater using bacterial and plant bioassays[J]. Biotechnology Reports, 2019, 24: e00389. doi: 10.1016/j.btre.2019.e00389 [21] BILAL M, ASGHER M. Sandal reactive dyes decolorization and cytotoxicity reduction using manganese peroxidase immobilized onto polyvinyl alcohol-alginate beads[J]. Chemistry Central Journal, 2015, 9(1): 47. doi: 10.1186/s13065-015-0125-0 [22] BILAL M, IQBAL M, HU H, et al. Mutagenicity and cytotoxicity assessment of biodegraded textile effluent by Ca-alginate encapsulated manganese peroxidase[J]. Biochemical Engineering Journal, 2016, 109: 153-161. doi: 10.1016/j.bej.2016.01.020 [23] SONG J, CHEN C, ZHU S, et al. Processing bulk natural wood into a high-performance structural material[J]. Nature, 2018, 554(7691): 224-228. [24] CHANG S S, QUIGNARD F, ALMÉRAS T, et al. Mesoporosity changes from cambium to mature tension wood: A new step toward the understanding of maturation stress generation in trees[J]. New Phytologist, 2015, 205(3): 1277-1287. [25] CHEN C, SONG J, ZHU S, et al. Scalable and sustainable approach toward highly compressible, anisotropic, lamellar carbon sponge[J]. Chem, 2018, 4(3): 544-554. [26] 彭荣富, 朱新锋, 王军宁, 等. MOFs耦合木材复合材料在环境修复方面应用研究进展[J/OL]. 工程科学与技术, 2023: 1-18[2024-03-23]. https://doi.org/10.15961/j.jsuese.202300393.PENG Rongfu, ZHU Xinfeng, WANG Junning, et al. Research progress in the application of MOFs coupled wood composites in environmental remediation[J/OL]. Advanced Engineering Sciences, 2023: 1-18[2024-03-23]. https://doi.org/10.15961/j.jsuese.202300393(in Chinese). [27] 粟婉婷, 李鹏辉, 王欢, 等. 木质素基多孔碳材料的制备与应用的研究进展[J]. 中国造纸, 2023, 42(7): 130-140.SU Wanting, LI Penghui, WANG Huan, et al. Research progress in preparation and application of lignin-based porous carbon materials[J]. China Pulp & Paper, 2023, 42(7): 130-140(in Chinese). [28] 卿彦, 廖宇, 刘婧祎, 等. 木基储能材料研究新进展[J]. 林业工程学报, 2021, 6(5): 1-13.QING Yan, LIAO Yu, LIU Jingyi, et al. Research progress of wood-derived energy storage materials[J]. Journal of Forestry Engineering, 2021, 6(5): 1-13(in Chinese). [29] THOMAS R. Wood: Structure and chemical composition[M]// ACS Symposium Series American ChemicalSociety. New York: ACS Publications, 1977: 1-23. [30] 程志泳. 负载纳米Ag木质过滤材料的制备及其废水处理性能研究[D]. 北京: 中国林业科学研究院, 2020.CHENG Zhiyong. Fabrication of wood-based filter loaded with Ag nanoparticles and its performance in wastewater treatment[D]. Beijing: Research Institute of Forest Chinese Academy of Forestry, 2020(in Chinese). [31] 姜晓峰, 于维钊, 王继乾. 油水分离用天然材料表面化学研究进展[J]. 化学通报, 2021, 84(4): 290-304, 321.JIANG Xiaofeng, YU Weizhao, WANG Jiqian. The surface chemistry of natural materials for oil-water separation[J]. Chemistry, 2021, 84(4): 290-304, 321(in Chinese). [32] 吴义强. 木材科学与技术研究新进展[J]. 中南林业科技大学学报, 2021, 41(1): 1-28.WU Yiqiang. Newly advances in wood science and technology[J]. Journal of Central South University of Forestry & Technology, 2021, 41(1): 1-28(in Chinese). [33] SALMÉN L. Wood cell wall structure and organisation in relation to mechanics[M]//Plant Biomechanics: From Structure to Function at Multiple Scales. Berlin: Springer, 2018: 3-19. [34] JIANG F, LI T, LI Y, et al. Wood-based nanotechnologies toward sustainability[J]. Advanced Materials, 2018, 30(1): 1703453. doi: 10.1002/adma.201703453 [35] ZHANG X F, WANG Z, SONG L, et al. In situ growth of ZIF-8 within wood channels for water pollutants removal[J]. Separation and Purification Technology, 2021, 266: 118527. doi: 10.1016/j.seppur.2021.118527 [36] GUO R, CAI X, LIU H, et al . In situ growth of metal-organic frameworks in three-dimensional aligned lumen arrays of wood for rapid and highly efficient organic pollutant removal[J]. Environmental Science and Technology,2019 ,53 (5 ):2705 -2712 .GUO R, CAI X, LIU H, et al. In situ growth of metal-organic frameworks in three-dimensional aligned lumen arrays of wood for rapid and highly efficient organic pollutant removal[J]. Environmental Science and Technology, 2019, 53(5): 2705-2712.[37] YU Y, ZHANG Q, CHI M, et al. Porous wood decorated with gold nanoparticles as flow-through membrane reactor for catalytic hydrogenation of methylene blue and 4-nitrophenol[J]. Cellulose, 2021, 28: 7283-7294. doi: 10.1007/s10570-021-03934-3 [38] CUI Z, WU J, XU Y, et al. In-situ growth of polyoxometalate-based metal-organic frameworks on wood as a promising dual-function filter for effective hazardous dye and iodine capture[J]. Chemical Engineering Journal, 2023, 451: 138371. doi: 10.1016/j.cej.2022.138371 [39] 卜岩斌, 康松, 李丽颖. 吸附法去除废水中染料罗丹明B的研究[J]. 供水技术, 2023, 17(3): 46-51.BU Yanbin, KANG Song, LI Liying. Study on the adsorption of dye rhodamine B in wastewater[J]. Water Technology, 2023, 17(3): 46-51(in Chinese). [40] GOODMAN S M, BURA R, DICHIARA A B. Facile impregnation of graphene into porous wood filters for the dynamic removal and recovery of dyes from aqueous solutions[J]. ACS Applied Nano Materials, 2018, 1(10): 5682-5690. doi: 10.1021/acsanm.8b01275 [41] 张旭鹏, 朱刚, 邓书端, 等. 新型MOF@木材复合材料的制备及其染料吸附和阻燃性能研究[J]. 功能材料, 2023, 54(1): 1208-1214, 1236.ZHANG Xupeng, ZHU Gang, DENG Shuduan, et al. Preparation of a novel MOF@wood composites and their dye adsorption and flame retardant properties[J]. Journal of Functional Materials, 2023, 54(1): 1208-1214, 1236(in Chinese). [42] ZHU T T, ZHANG Z M, CHEN W L, et al. Encapsulation of tungstophosphoric acid into harmless MIL-101(Fe) for effectively removing cationic dye from aqueous solution[J]. RSC Advances, 2016, 6(85): 81622-81630. doi: 10.1039/C6RA16716K [43] MA X, ZHAO S, TIAN Z, et al. MOFs meet wood: Reusable magnetic hydrophilic composites toward efficient water treatment with super-high dye adsorption capacity at high dye concentration[J]. Chemical Engineering Journal, 2022, 446: 136851. doi: 10.1016/j.cej.2022.136851 [44] JIAO M L, YAO Y G, CHEN C J, et al. Highly efficient water treatment via a wood-based and reusable filter[J]. ACS Materials Letters, 2020, 2(4): 430-437. doi: 10.1021/acsmaterialslett.9b00488 [45] HE X, KIM H, DONG T G, et al. Green synthesis of Ag/lignin nanoparticle-loaded cellulose aerogel for catalytic degradation and antimicrobial applications[J]. Cellulose, 2022, 29(17): 9341-9360. doi: 10.1007/s10570-022-04848-4 [46] CHEN F, GONG A S, ZHU M, et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment[J]. ACS Nano, 2017, 11(4): 4275-4282. doi: 10.1021/acsnano.7b01350 [47] CHE W, XIAO Z, WANG Z, et al. Wood-based mesoporous filter decorated with silver nanoparticles for water purification[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(5): 5134-5141. [48] LYU Y, LI Q, HOU Y, et al. Facile preparation of an asymmetric wettability Janus cellulose membrane for switchable emulsions' separation and antibacterial property[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(17): 15002-15011. [49] YANG H C, HOU J, CHEN V, et al. Janus membranes: Exploring duality for advanced separation[J]. Angewandte Chemie International Edition, 2016, 55(43): 13398-13407. doi: 10.1002/anie.201601589 [50] ZHANG M, SHI L, DU X, et al. Janus mesoporous wood-based membrane for simultaneous oil/water separation, aromatic dyes removal, and seawater desalination[J]. Industrial Crops and Products, 2022, 188: 115643. doi: 10.1016/j.indcrop.2022.115643 -

下载:

下载: