Cyclic compression test and stress-strain constitutive relationship of polypropylene fiber coral seawater concrete

-

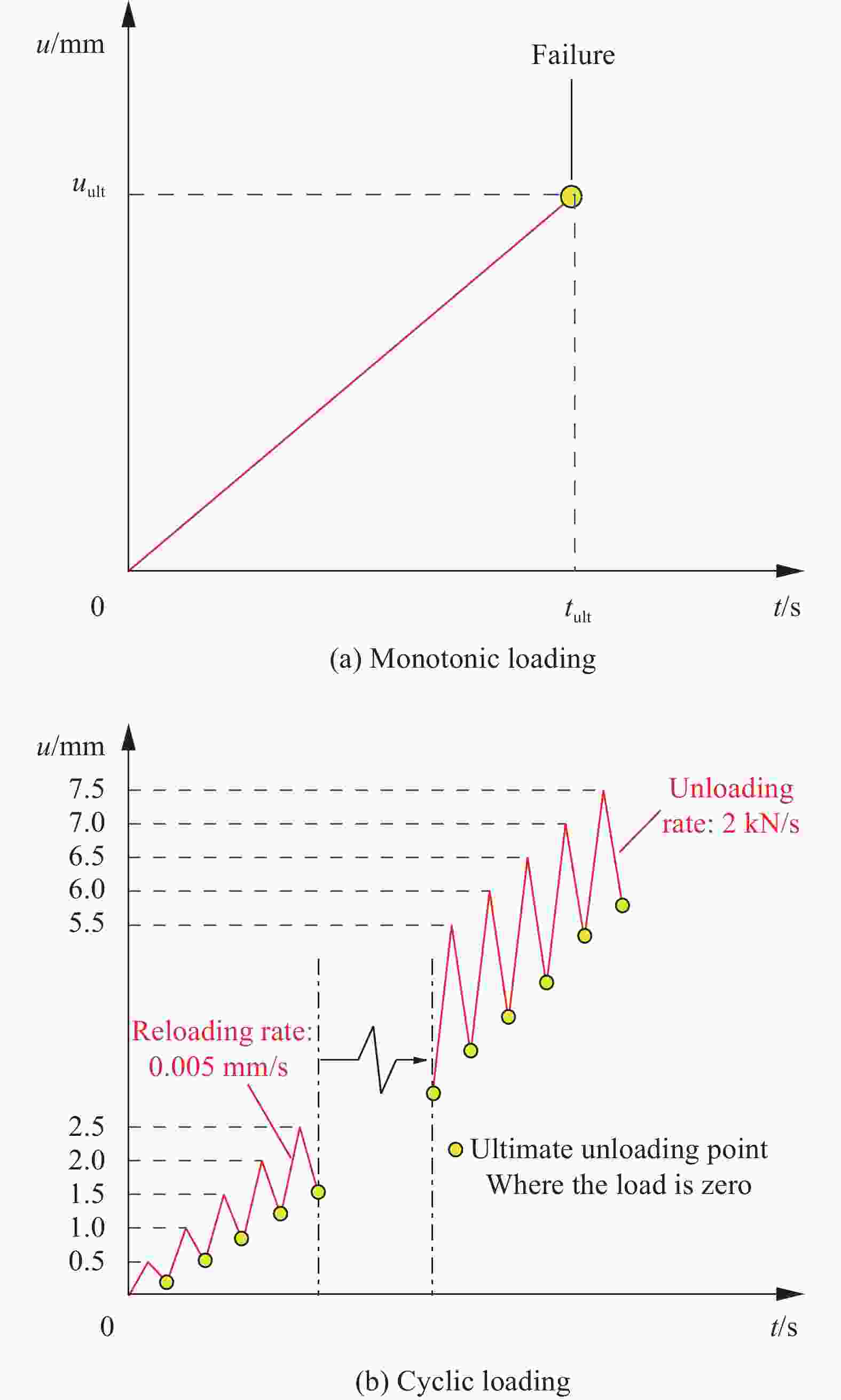

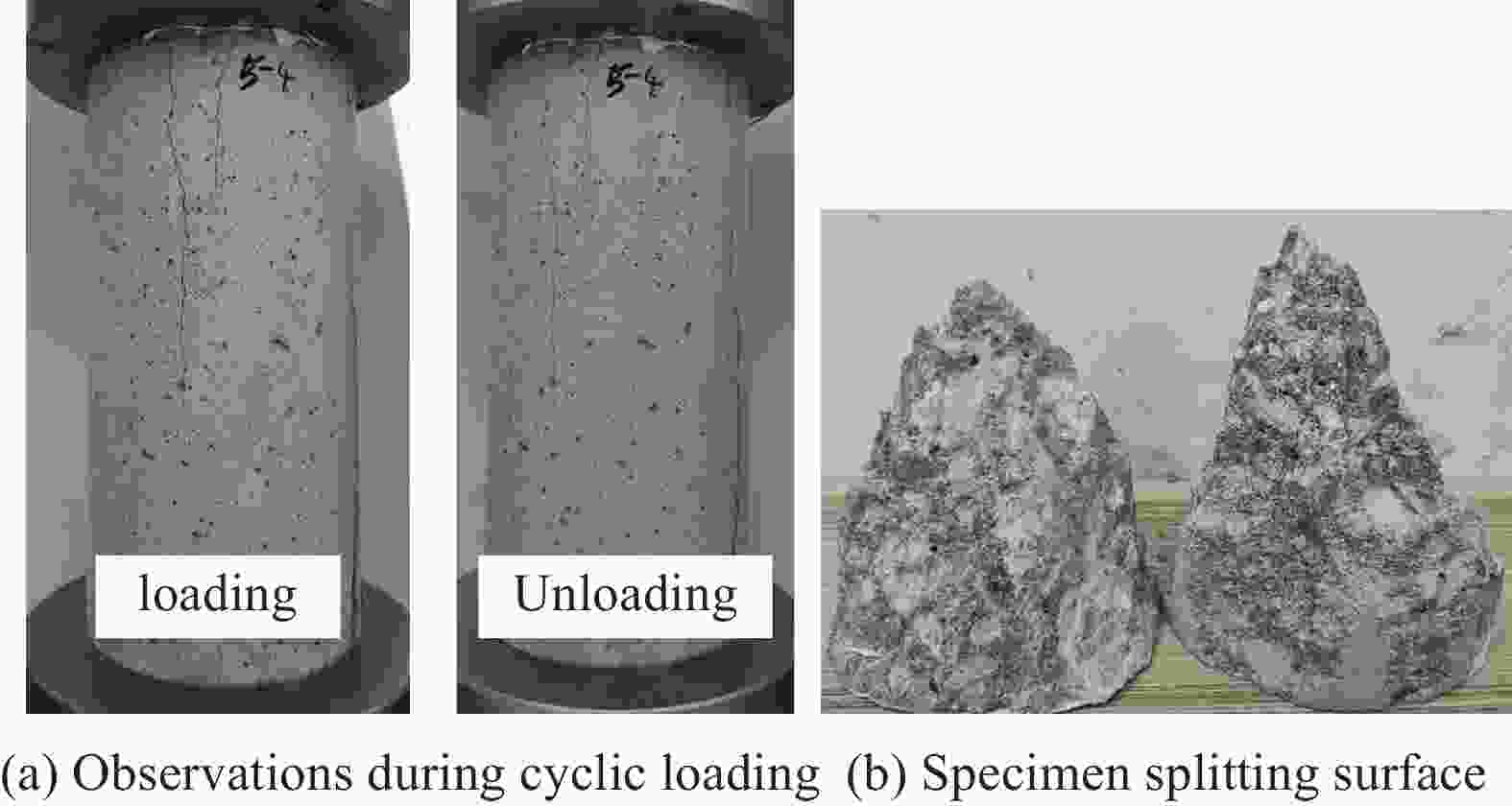

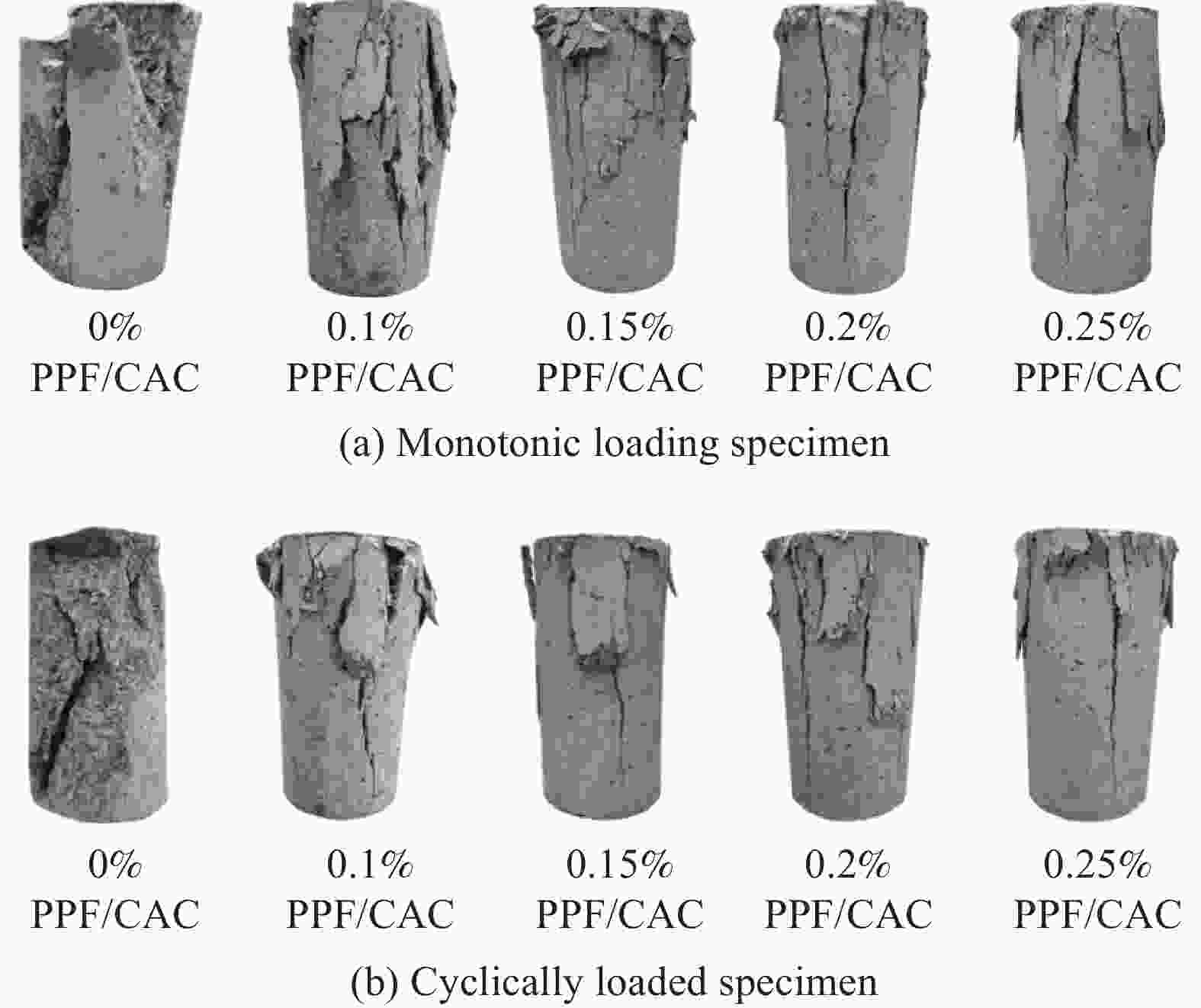

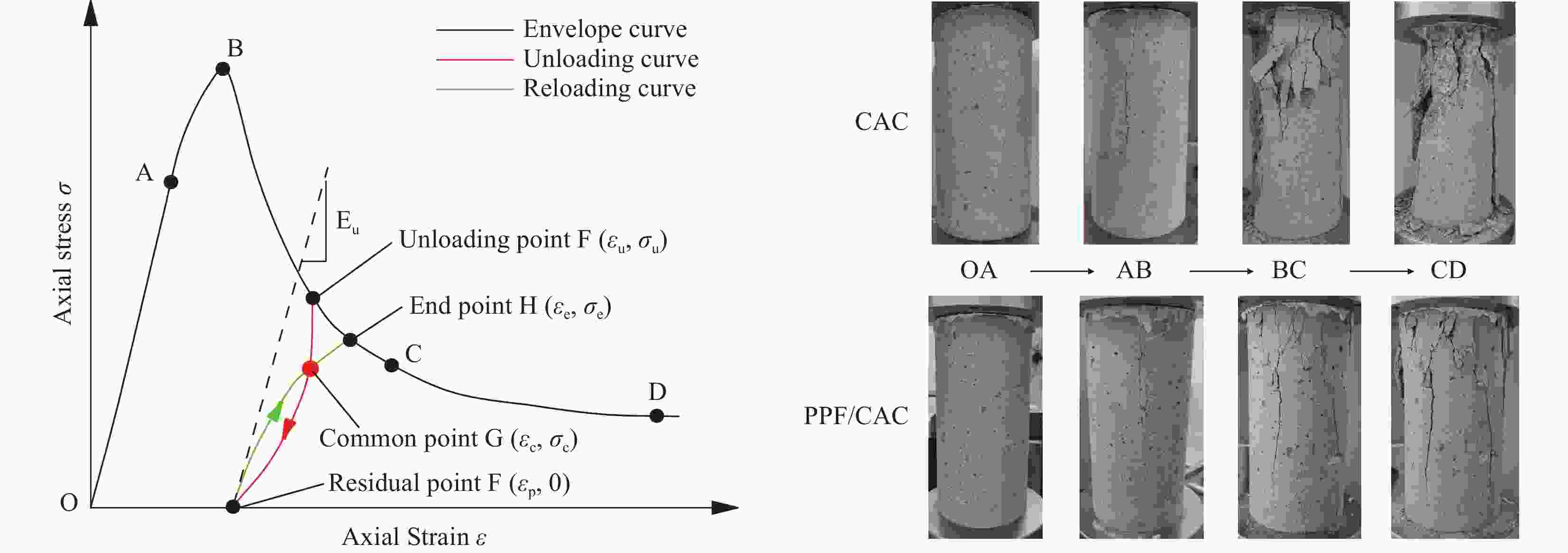

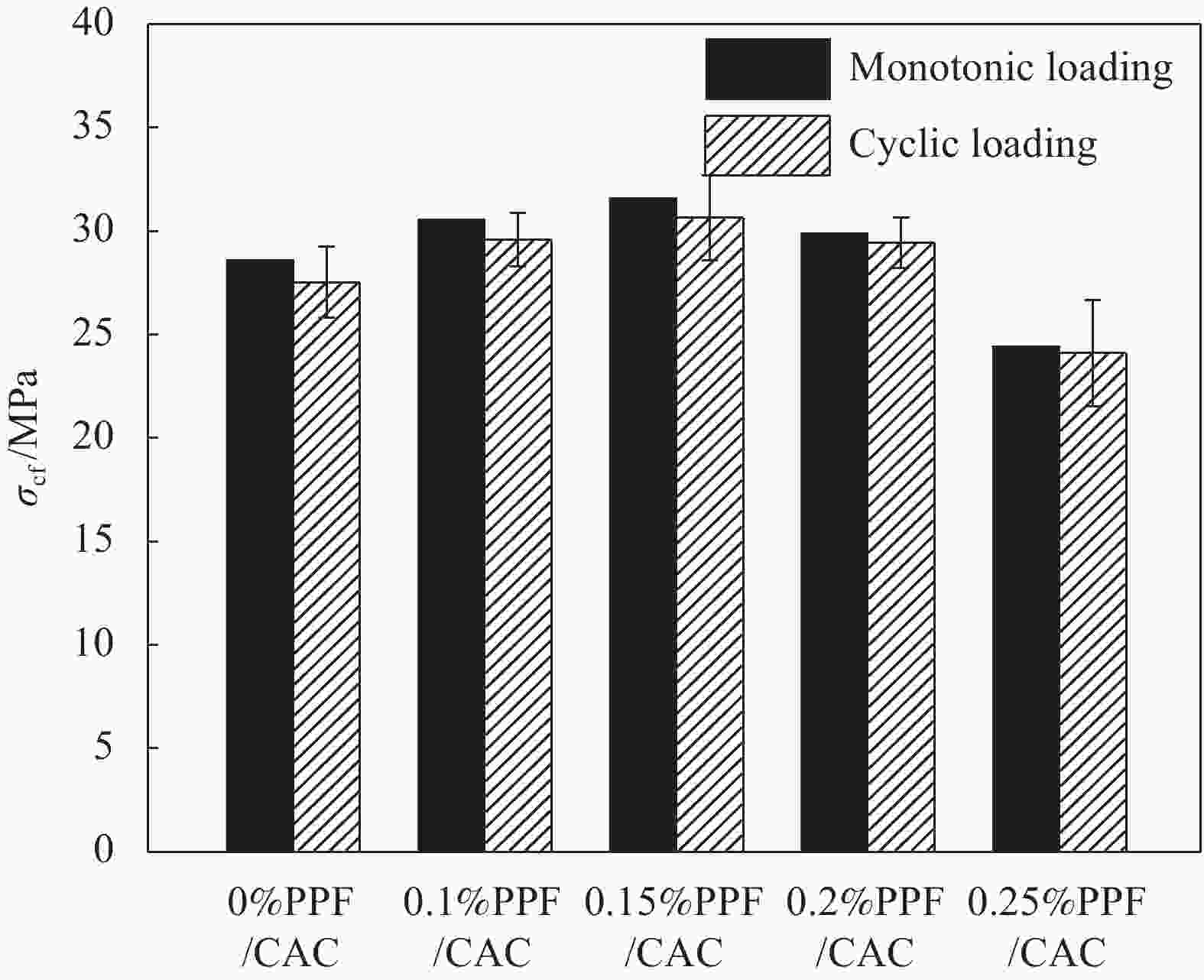

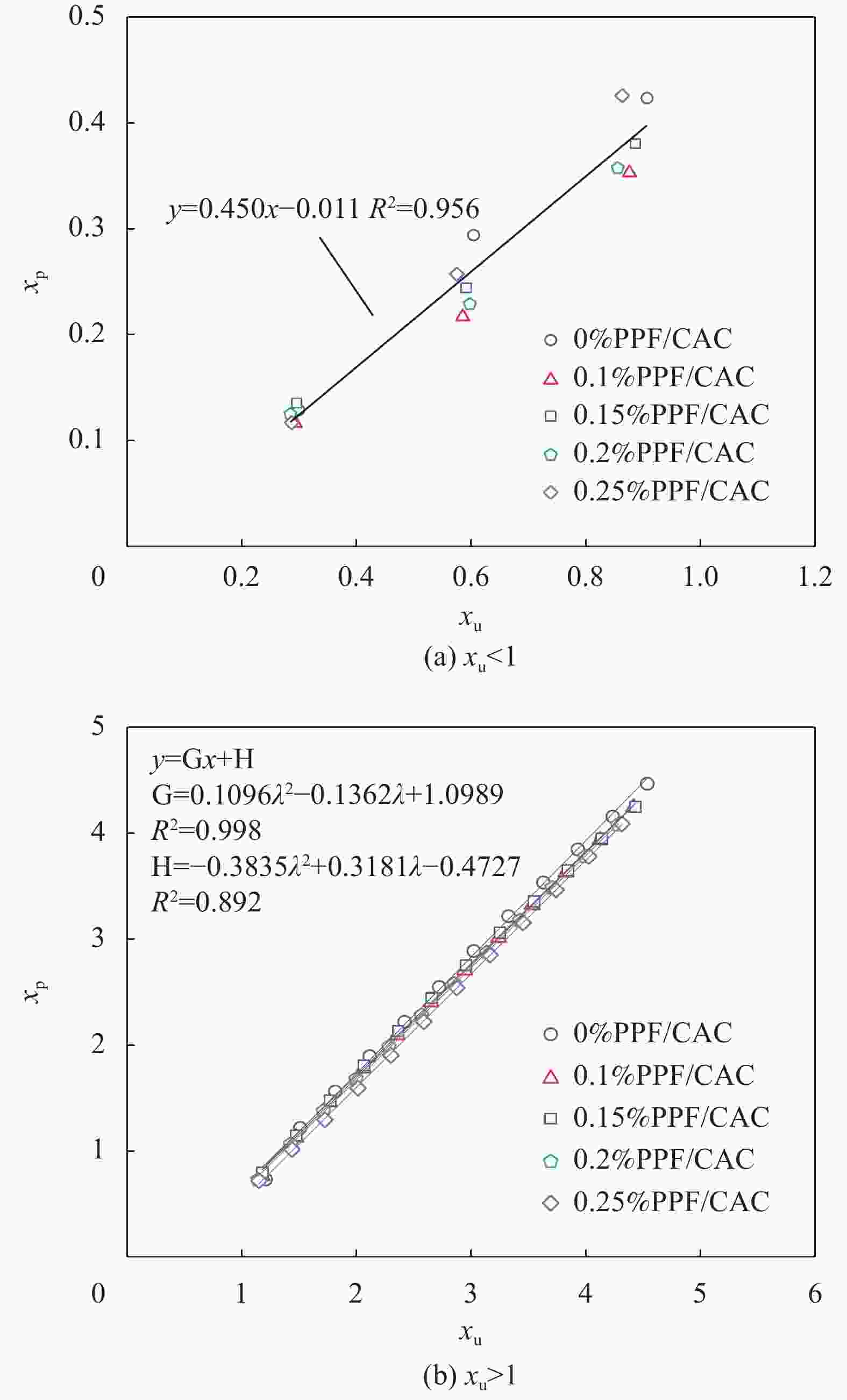

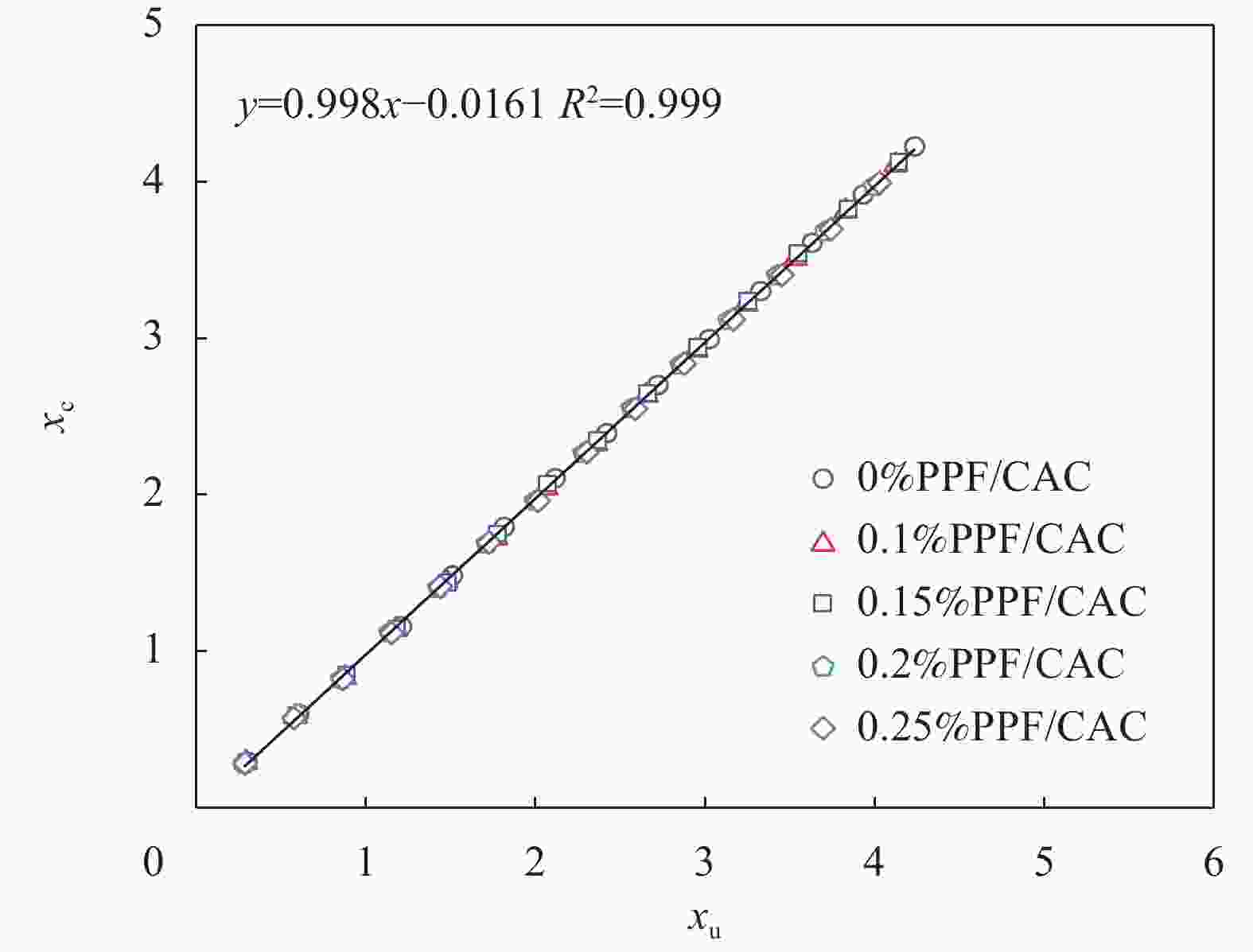

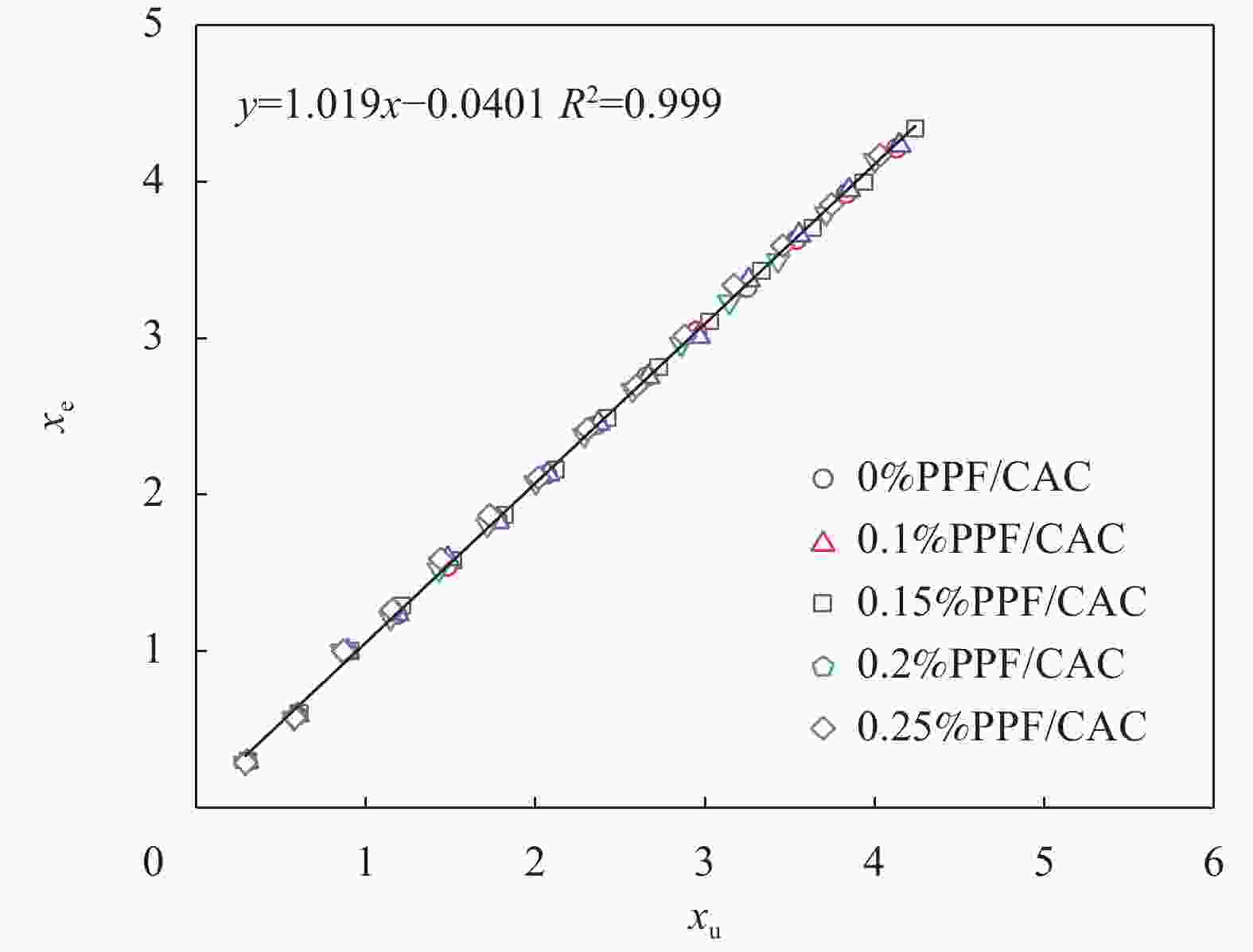

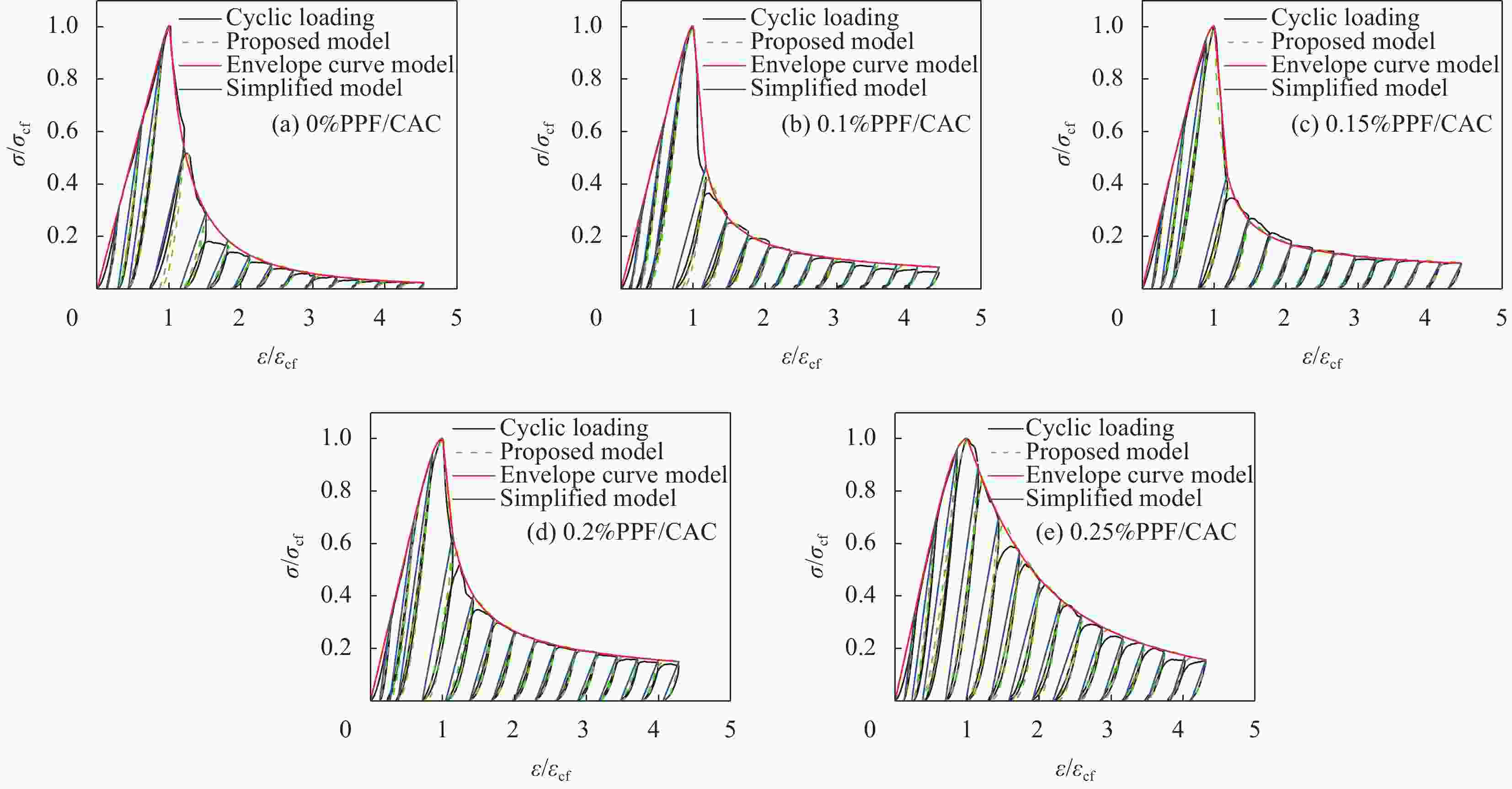

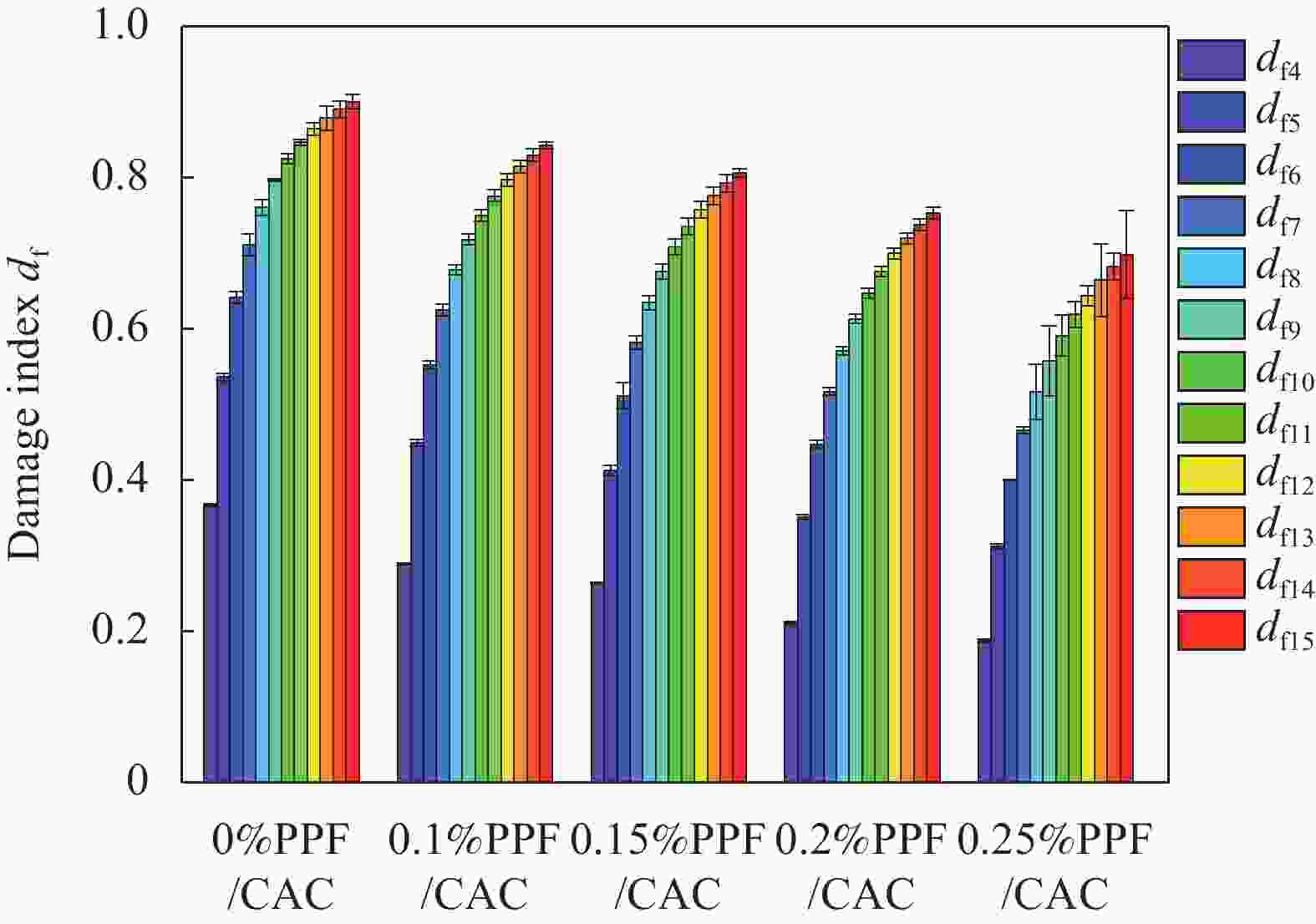

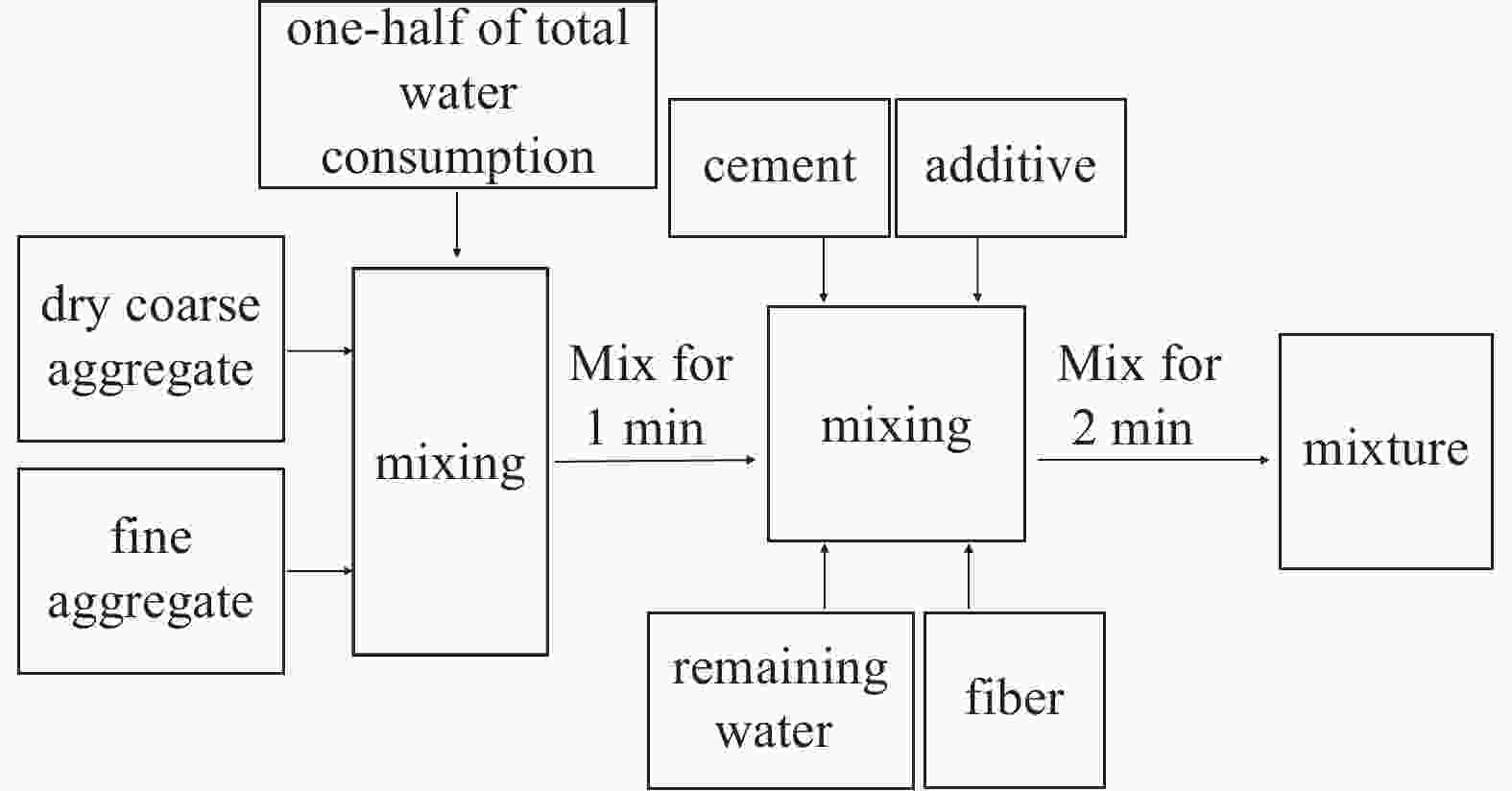

摘要: 为研究聚丙烯纤维珊瑚海水混凝土(PPF/CAC)在循环受压荷载作用下的力学行为,以聚丙烯纤维体积分数和加载方式为变化参数,设计了20个圆柱体试件进行单轴受压以及单轴循环受压试验。试验观察了PPF/CAC的破坏形态,获取了应力-应变全曲线及峰值应力应变、塑性应变等重要指标,深入分析了PPF/CAC在单轴循环受压作用下的应力-应变行为和损伤演化。结果表明:与单调加载相比,循环加载试件的强度退化了1.21%~3.67%,聚丙烯纤维能有效延缓强度退化;聚丙烯纤维体积分数为0.15%时珊瑚混凝土的峰值应力和峰值应变增幅最大,分别为10.45%和6.45%,改性效果最好;此外,聚丙烯纤维体积分数的增加可显著降低塑性应变的积累,提高弹性刚度比。本文根据试验结果定义了滞回曲线的四个特征点:卸载点、公共点、残余点和终点,并建立了残余应变、公共点应变和终点应变与卸载应变的关系。最后,提出了PPF/CAC在循环荷载作用下的应力-应变本构方程和损伤本构模型,且基于损伤演化规律简化后的应力-应变本构方程可以有效地预测其在循环荷载作用下的应力-应变行为。Abstract: The stress-strain characteristics and damage evolution of polypropylene fiber coral seawater concrete (PPF/CAC) under uniaxial cyclic compression were studied. A total of 20 samples with different fiber volume fractions were tested. The failure form of PPF/CAC was observed in the test, and the stress-strain curve, peak stress-strain, plastic strain and other important indexes were obtained. The results show that the strength of specimens under cyclic loading is reduces by 1.21%-3.67% compared with that under monochrome loading, and the degradation can be slowed down with the increase of fiber content. The peak stress and peak strain increases are the largest when the polypropylene fiber volume fraction is 0.15%, which are 10.45% and 6.45%, respectively. In addition, the increase of PPF volume fraction can significantly reduce the accumulation of plastic strain and increase the elastic stiffness ratio. According to the test results, four characteristic points of hysteresis curve are defined: unloading point, common point, residual point and end point. And the relationship between residual strain, common point strain and end point strain and unloading strain is established. Finally, the stress-strain constitutive equation and damage constitutive model of PPF/CAC under cyclic load are proposed, and the simplified stress-strain constitutive equation based on the damage evolution law can effectively predict the stress-strain behavior of PPF/CAC under cyclic load.

-

Key words:

- polypropylene fiber /

- coral sea concrete /

- cyclic compression /

- stress-strain /

- constitutive equation

-

表 1 试件配合比及设计参数(kg/m3)

Table 1. Sample fit ratio and design parameters

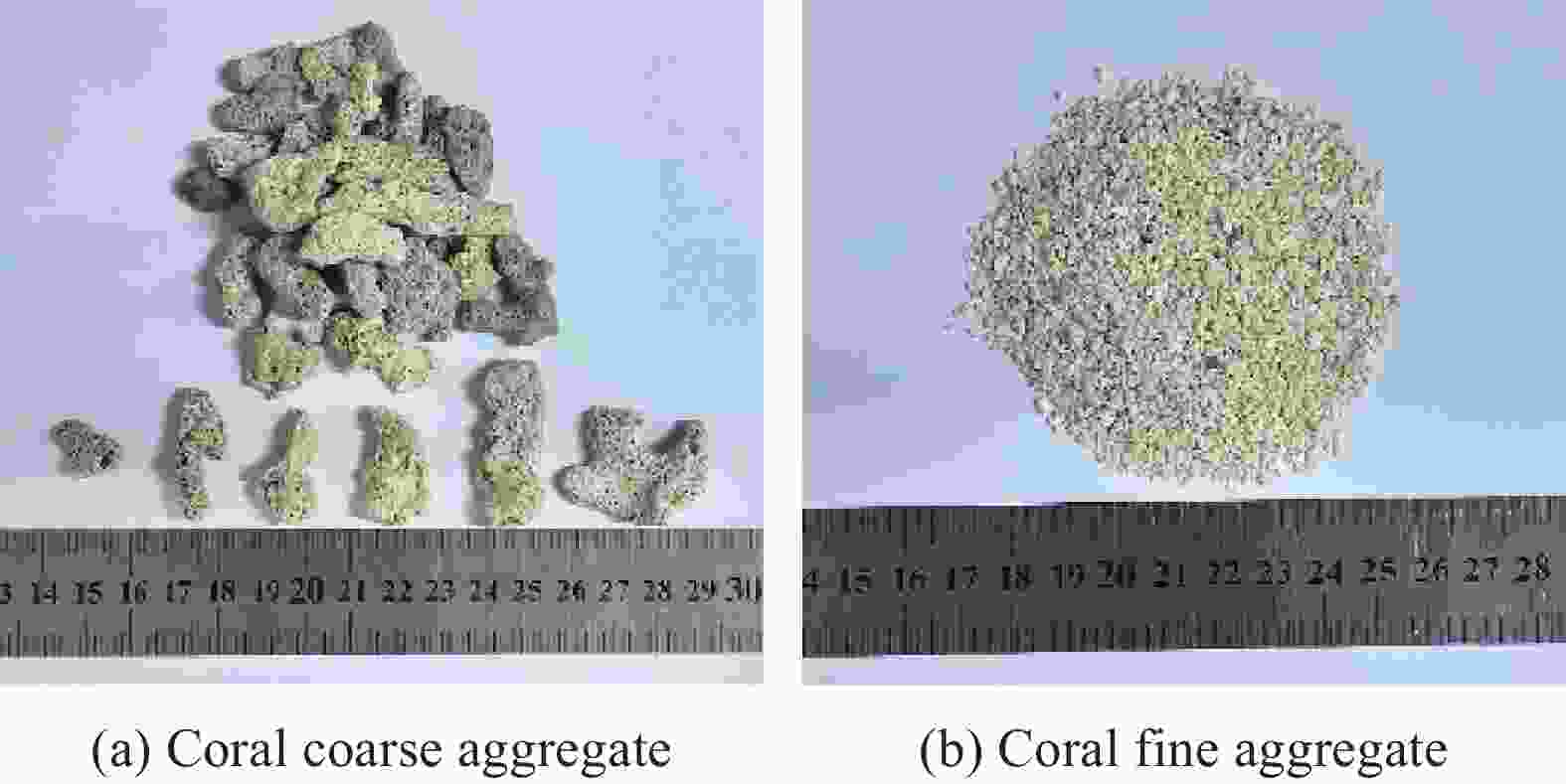

Specimen number Cement Coarse aggregate Fine aggregate Water water reducer VPPF/% 0%PPF/CAC 530 672 753 252 10.6 - 0.1%PPF/CAC 530 672 753 252 10.6 0.10 0.15%PPF/CAC 530 672 753 252 10.6 0.15 0.2%PPF/CAC 530 672 753 252 10.6 0.20 0.25%PPF/CAC 530 672 753 252 10.6 0.25 Notes: VPPF—Polypropylene fiber volume content. 表 2 珊瑚骨料的物理性能

Table 2. Mechanical and physical parameters of coral aggregate

Coral aggregate Bulk density /(kg·m−3) Performance density/(kg·m−3) Water content/% Water absorption/% 1 h 24 h Coarse aggregate 878 1846 2.3 8.5 9.6 Fine aggregate 1285 2701 2.4 3.45 3.70 表 3 聚丙烯纤维基本物理性能

Table 3. Basic physical properties of polypropylene fibers

Physical property PPF Fiber appearance d/mm 0.048

l/mm 19 Tensile strength/MPa >550 Density/(g·cm−3) 0.91 Elasticity modulus/GPa 6.5 Elongation at break/% 15 Notes: d—Diameter of fiber; l—Length of fiber. 表 4 经典混凝土残余应变计算公式

Table 4. Residual strain calculation formula of classical concrete

Constitutive model name Residual strain formula Karsan[27] model $ {x_{\text{p}}} = 0.145 x_{\text{u}}^2 + 0.127{x_{\text{u}}} $ Bahn and Hsu[28] model $ {x_{\text{p}}} = {c_{\text{p}}}{({x_{\text{u}}})^{{n_{\text{p}}}}} $ Biao Li[16] Linear function model $ {x_{\text{p}}} = G{x_{\text{u}}} + H $ Notes: xp—Remanent strain; xu—Unloading strain; cp, np, G and H—Model parameter. 表 5 第i次循环荷载下PPF/CAC试件的损伤指数

Table 5. Damage index of PPF/CAC specimens under i cycle load

Specimen df4 df5 df6 df7 df8 df9 df10 df11 df12 df13 df14 df15 0%PPF/CAC 0.350 0.556 0.645 0.723 0.759 0.796 0.815 0.834 0.856 0.867 0.881 0.892 0.1%PPF/CAC 0.310 0.471 0.568 0.642 0.671 0.739 0.761 0.784 0.802 0.811 0.825 0.821 0.15%PPF/CAC 0.287 0.416 0.526 0.597 0.637 0.671 0.710 0.725 0.746 0.759 0.774 0.789 0.2%PPF/CAC 0.243 0.364 0.468 0.544 0.576 0.624 0.655 0.667 0.686 0.714 0.725 0.736 0.25%PPF/CAC 0.184 0.302 0.390 0.446 0.513 0.570 0.627 0.656 0.667 0.700 0.703 0.704 Notes: The data in the table are the average values of the three specimens in each group, dfi—Damage index under i cycle load. -

[1] Yang S, Yang C, Huang M, et al. Study on bond performance between FRP bars and seawater coral aggregate concrete[J]. Construction and Building Materials, 2018, 173: 272-288. doi: 10.1016/j.conbuildmat.2018.04.015 [2] Wang Q, Li P, Tian Y, et al. Mechanical properties and microstructure of Portland cement concrete prepared with coral reef sand[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2016, 31(5): 996-1001. doi: 10.1007/s11595-016-1481-x [3] Zhou W, Feng P, Lin H. Constitutive relations of coral aggregate concrete under uniaxial and triaxial compression[J]. Construction and Building Materials, 2020, 251: 118957. doi: 10.1016/j.conbuildmat.2020.118957 [4] Wang Y, Shui Z, Gao X, et al. Utilizing coral waste and metakaolin to produce eco-friendly marine mortar: Hydration, mechanical properties and durability[J]. Journal of Cleaner Production, 2019, 219: 763-774. doi: 10.1016/j.jclepro.2019.02.147 [5] 蔡新光, 赵青, 陈惠苏. 珊瑚混凝土研究现状[J]. 硅酸盐学报, 2021, 49(08): 1753-1764. doi: 10.14062/j.issn.0454-5648.20200951Cai X G, Zhao Q, Chen H. Research status of coral concrete[J]. Journal of the Chinese Ceramic Society, 2021, 49(08): 1753-1764 (in Chinese). doi: 10.14062/j.issn.0454-5648.20200951 [6] Arumugam R A, Ramamurthy K. Study of compressive strength characteristics of coral aggregate concrete[J]. Magazine of Concrete Research, 1996, 48(176): 141-148. doi: 10.1680/macr.1996.48.176.141 [7] Liu B , Guo J , Wen X , et al. Study on flexural behavior of carbon fibers reinforced coral concrete using digital image correlation[J]. Construction and Building Materials, 2020, 242: 117968. [8] Yoo D Y, Banthia N. Impact resistance of fiber-reinforced concrete–A review[J]. Cement and Concrete Composites, 2019, 104: 103389. doi: 10.1016/j.cemconcomp.2019.103389 [9] Huang Y, Li X, Lu Y, et al. Effect of mix component on the mechanical properties of coral concrete under axial compression[J]. Construction and Building Materials, 2019, 223: 736-754. doi: 10.1016/j.conbuildmat.2019.07.015 [10] 陈宗平, 周济, 陈宇良, 等. 珊瑚粗骨料海水混凝土力学性能试验研究[J]. 应用力学学报, 2020, 37(05): 1999-2006+2319-2320. doi: 10.11776/cjam.37.05.B090Chen Z P, Zhou J, Chen Y L, et al. Experimental Study on Mechanical Properties of seawater concrete with coarse coral aggregate[J]. Chinese Journal of Applied Mechanics, 2020, 37(05): 1999-2006+2319-2320(in Chinese). doi: 10.11776/cjam.37.05.B090 [11] 熊祖菁. 掺入聚丙烯纤维珊瑚混凝土的力学性能及微观结构研究[D]. 广西: 桂林理工大学, 2014.Xiong Z Q. Study on Mechanical Properties and Microstructure of coral Concrete Mixed with polypropylene fiber [D]. Guangxi: Guilin University of Technology, 2014. [12] 王磊, 熊祖菁, 刘存鹏, 等. 掺入聚丙烯纤维珊瑚混凝土的力学性能研究[J]. 混凝土, 2014, (07): 96-99. doi: 10.3969/j.issn.1002-3550.2014.07.026Wang L, Xiong Z Q, Liu C P, et al. Study on Mechanical Properties of coral Concrete Mixed with polypropylene fiber[J]. Concrete, 2014, (07): 96-99(in Chinese). doi: 10.3969/j.issn.1002-3550.2014.07.026 [13] 易金, 刘超, 王磊. 聚丙烯纤维增强珊瑚混凝土抗冲击性能试验研究[J]. 科学技术与工程, 2019, 19(04): 244-248. doi: 10.3969/j.issn.1671-1815.2019.04.039Yi J, Liu C, Wang L. Experimental study on impact resistance of polypropylene fiber reinforced coral concrete[J]. Science Technology and Engineering, 2019, 19(04): 244-248(in Chinese). doi: 10.3969/j.issn.1671-1815.2019.04.039 [14] Deng F, Chi Y, Xu L, et al. Constitutive behavior of hybrid fiber reinforced concrete subject to uniaxial cyclic tension: Experimental study and analytical modeling[J]. Construction and Building Materials, 2021, 295: 123650. doi: 10.1016/j.conbuildmat.2021.123650 [15] Bahn B Y, Hsu C T T. Stress-strain behavior of concrete under cyclic loading[J]. Materials Journal, 1998, 95(2): 178-193. [16] Li B, Xu L, Chi Y, et al. Experimental investigation on the stress-strain behavior of steel fiber reinforced concrete subjected to uniaxial cyclic compression[J]. Construction and Building Materials, 2017, 140: 109-118. doi: 10.1016/j.conbuildmat.2017.02.094 [17] 徐礼华, 李长宁, 李彪, 等. 循环受压状态下钢纤维混凝土一维弹塑性损伤本构模型研究[J]. 土木工程学报, 2018, 51(11): 77-87. doi: 10.15951/j.tmgcxb.2018.11.006Xu L H, Li C N, Li B, et al. One-dimensional elastoplastic damage constitutive model of steel fiber reinforced concrete under cyclic compression[J]. China Civil Engineering Journal, 2018, 51(11): 77-87 (in Chinese). doi: 10.15951/j.tmgcxb.2018.11.006 [18] Xu L, Li B, Ding X, et al. Experimental investigation on damage behavior of polypropylene fiber reinforced concrete under compression[J]. International Journal of Concrete Structures and Materials, 2018, 12(1): 1-20. doi: 10.1186/s40069-018-0237-8 [19] T/CECS 694-2020, 珊瑚骨料混凝土应用技术规程[S]. 北京: 中国计划出版社, 2020.T/CECS 694-2020, Technical specification for coral aggregate concrete[S]. Beijing: China Planning Press, 2020 (in Chinese). [20] GB/T 17431.2-2010, 轻集料及其试验方法 第2部分: 轻集料试验方法[S]. (in ChineseLightweight aggregates and its test methods. Part 2: Test methods for Lightweight aggregates[S]. (in Chinese) [21] 陈宇良, 王琦, 梁鑫, 等. 多组合混杂纤维改性再生混凝土循环受压性能试验[J]. 复合材料学报, 2023, 40(08): 4745-4756.Chen Y L, Wang Q, Liang X, et al. Cyclic compression Performance Test of multi-combination hybrid fiber modified recycled concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(08): 4745-4756 (in Chinese). [22] Hu X, Lu Q, Xu Z, et al. Compressive stress-strain relation of recycled aggregate concrete under cyclic loading[J]. Construction and Building Materials, 2018, 193: 72-83. doi: 10.1016/j.conbuildmat.2018.10.137 [23] Yan H, Sun W, Chen H. The effect of silica fume and steel fiber on the dynamic mechanical performance of high-strength concrete[J]. Cement and Concrete Research, 1999, 29(3): 423-426. doi: 10.1016/S0008-8846(98)00235-X [24] Fallah S, Nematzadeh M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume[J]. Construction and building materials, 2017, 132: 170-187. doi: 10.1016/j.conbuildmat.2016.11.100 [25] Das C S, Dey T, Dandapat R, et al. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete[J]. Construction and Building Materials, 2018, 189: 649-659. doi: 10.1016/j.conbuildmat.2018.09.036 [26] Carreira D J, Chu K H. Stress-strain relationship for plain concrete in compression[C]//Journal Proceedings. 1985, 82(6): 797-804. [27] Karsan I D, Jirsa J O. Behavior of concrete under compressive loadings[J]. Journal of the Structural Division, 1969, 95(12): 2543-2564. doi: 10.1061/JSDEAG.0002424 [28] Bahn B Y, Hsu C T T. Stress-strain behavior of concrete under cyclic loading[J]. Materials Journal, 1998, 95(2): 178-193. [29] Lemaitre J, Chaboche J L. Mechanics of solid materials[M]. Cambridge university press, 1994. [30] Krahl P A, Gidrão G M S, Carrazedo R. Cyclic behavior of UHPFRC under compression[J]. Cement and Concrete Composites, 2019, 104: 103363. doi: 10.1016/j.cemconcomp.2019.103363 -

点击查看大图

点击查看大图

计量

- 文章访问数: 124

- HTML全文浏览量: 50

- 被引次数: 0

下载:

下载: