Interface characteristics and mechanical properties of reactive melt infiltrated C/C-SiC-ZrC matrix composites

-

摘要: C/C-ZrC-SiC复合材料作为一种极具前景的热防护材料,在航空航天领域均有广泛应用。但是反应熔渗法(Reactive melt infiltration,RMI)制备的C/C-ZrC-SiC复合材料却存在力学性能偏低的缺点,成为制约其发展应用的主要因素。为了改善 C/C- SiC-ZrC 基复合材料的纤维损伤和力学性能,通过化学气相沉积(Chemical vapor deposition, CVD)在碳纤维针刺坯体中引入了300 nm厚的热解碳(Pyrolysis carbon,PyC)界面、300 nm厚的PyC/SiC双层界面和100 nm、300 nm、800 nm厚的(PyC+SiC)共沉积界面,再采用RMI制备出C/C-SiC-ZrC复合材料。采用XRD、SEM、EPMA和TEM等分析手段研究了C/C-SiC-ZrC复合材料的物相、微观形貌、元素分布以及RMI后C/C-SiC-ZrC复合材料的界面损伤情况,并利用三点弯曲试验评估了RMI后试样的弯曲性能。结果表明:界面的引入不仅起到了对纤维的保护作用,同时也改善了纤维和基体间的结合状态,极大的避免了反应熔渗对碳纤维的侵蚀;PyC界面对纤维的保护作用有限,而PyC/SiC双层界面的保护作用最好;界面类型和界面厚度对复合材料力学性能产生重要影响,当界面厚度相同时,含(PyC+SiC)共沉积界面复合材料和含PyC/SiC双层界面复合材料的抗弯强度分别为162.80 MPa和208.58 MPa,均优于含PyC界面的复合材料;随(PyC+SiC)共沉积界面厚度的增大,复合材料的力学性能呈现先上升后下降的趋势。

-

关键词:

- C/C-SiC-ZrC复合材料 /

- 界面 /

- 反应熔渗 /

- 界面损伤 /

- 弯曲强度

Abstract: C/C-ZrC-SiC matrix composites are widely used in aerospace field as a kind of promising thermal protection materials. But C/C-ZrC-SiC matrix composites prepared by reactive melt infiltration (RMI) have the disadvantage of low mechanical properties, which is the main factor restricting its development and application. In order to improve the fiber damage and mechanical properties of the C/C- SiC-ZrC matrix composites, 300 nm pyrolysis carbon(PyC) interface, 300 nm PyC/SiC double-layer interface, and 100 nm, 300 nm, and 800 nm (PyC+SiC) co-deposited interfaces were introduced into carbon fiber needled preform by chemical vapor deposition(CVD); and then the C/C-SiC-ZrC matrix composites were prepared by RMI. The phase composition, micro-morphology, element distribution and interface damage were investigated by XRD, SEM, EPMA and TEM, and the mechanical properties of the composites after RMI were evaluated by three-point bending tests. The results show that the introduction of the interfaces not only protect the fibers, but also improve the bonding state between the fibers and the matrix, which greatly avoids the erosion of the carbon fibers by RMI. The PyC interface provided limited protection to the fibers, while the PyC/SiC double-layer interface provided the best protection. The interface type and interface thickness have an important effect on the mechanical properties of the composites. When the interface thickness is the same, the flexural strength of the composites with (PyC+SiC) co-deposited interface and the composites with PyC/SiC double-layer interface are 162.80 MPa and 208.58 MPa, respectively, which are superior to those of the composites containing the PyC interface; the mechanical properties of the composites show a first increase in the thickness of the interface with the increase in the thickness of the interface with the increase in the thickness of the interface. With the increase of (PyC+SiC) co-deposited interface thickness, the mechanical properties of the composites show the trend of increasing and then decreasing. -

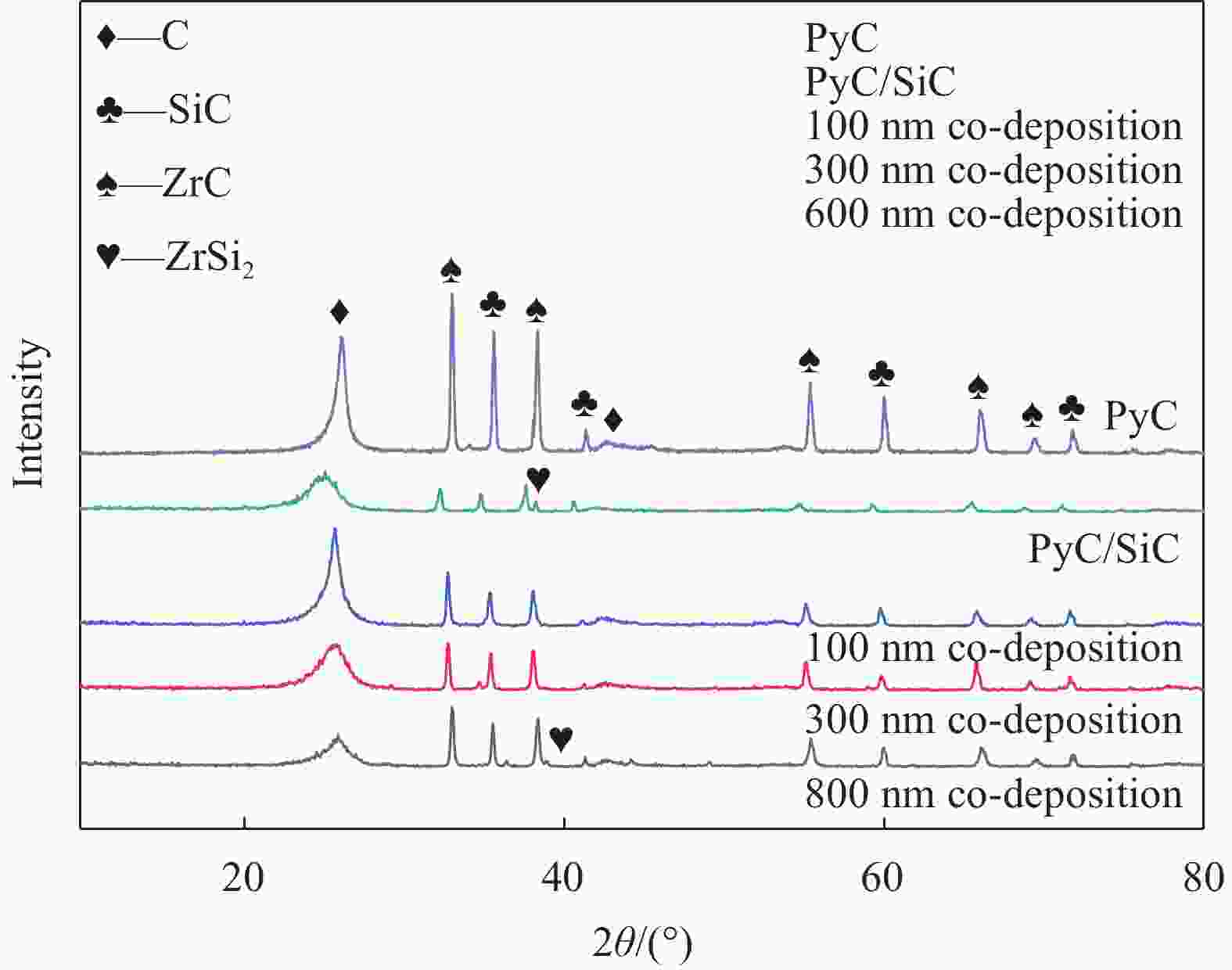

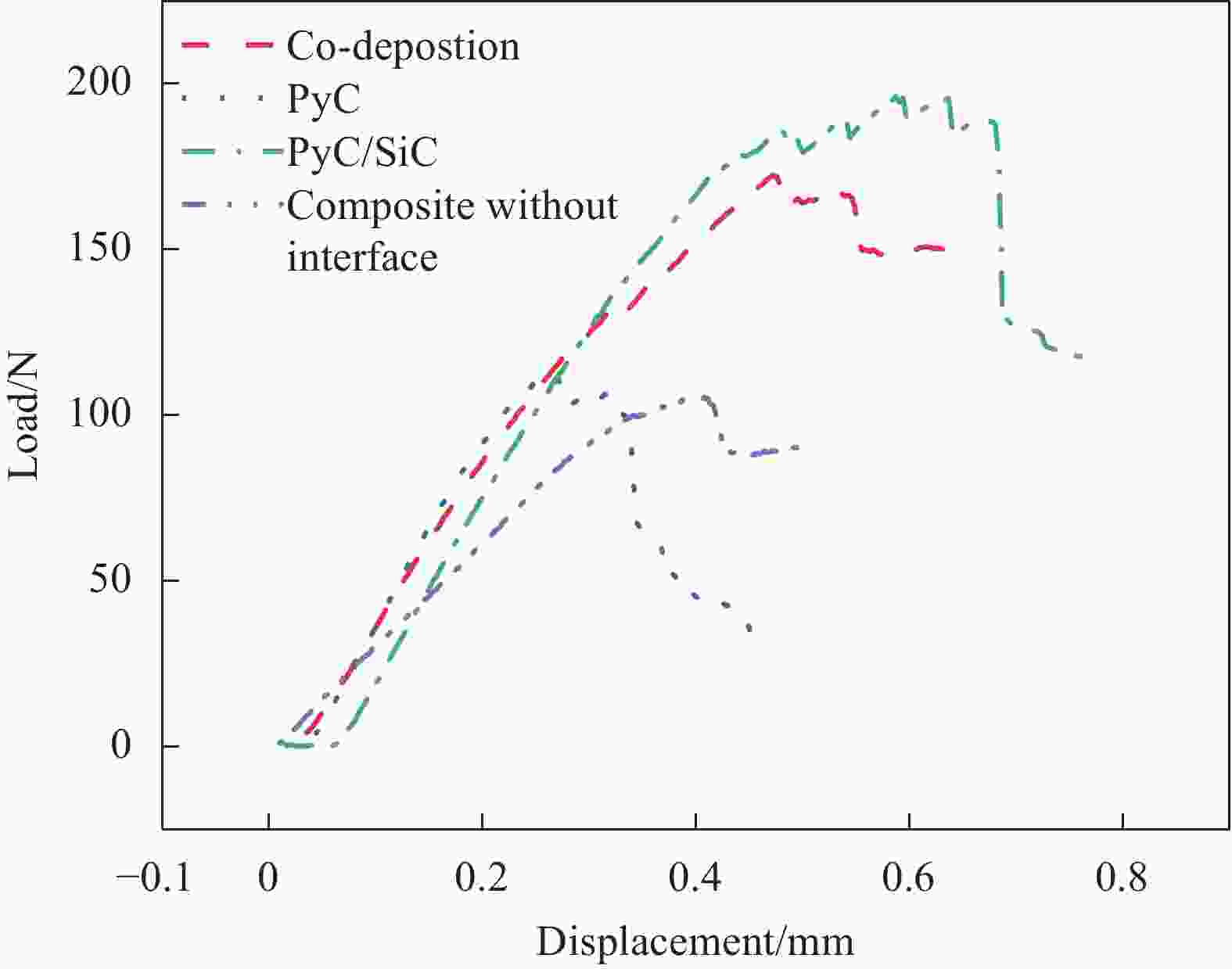

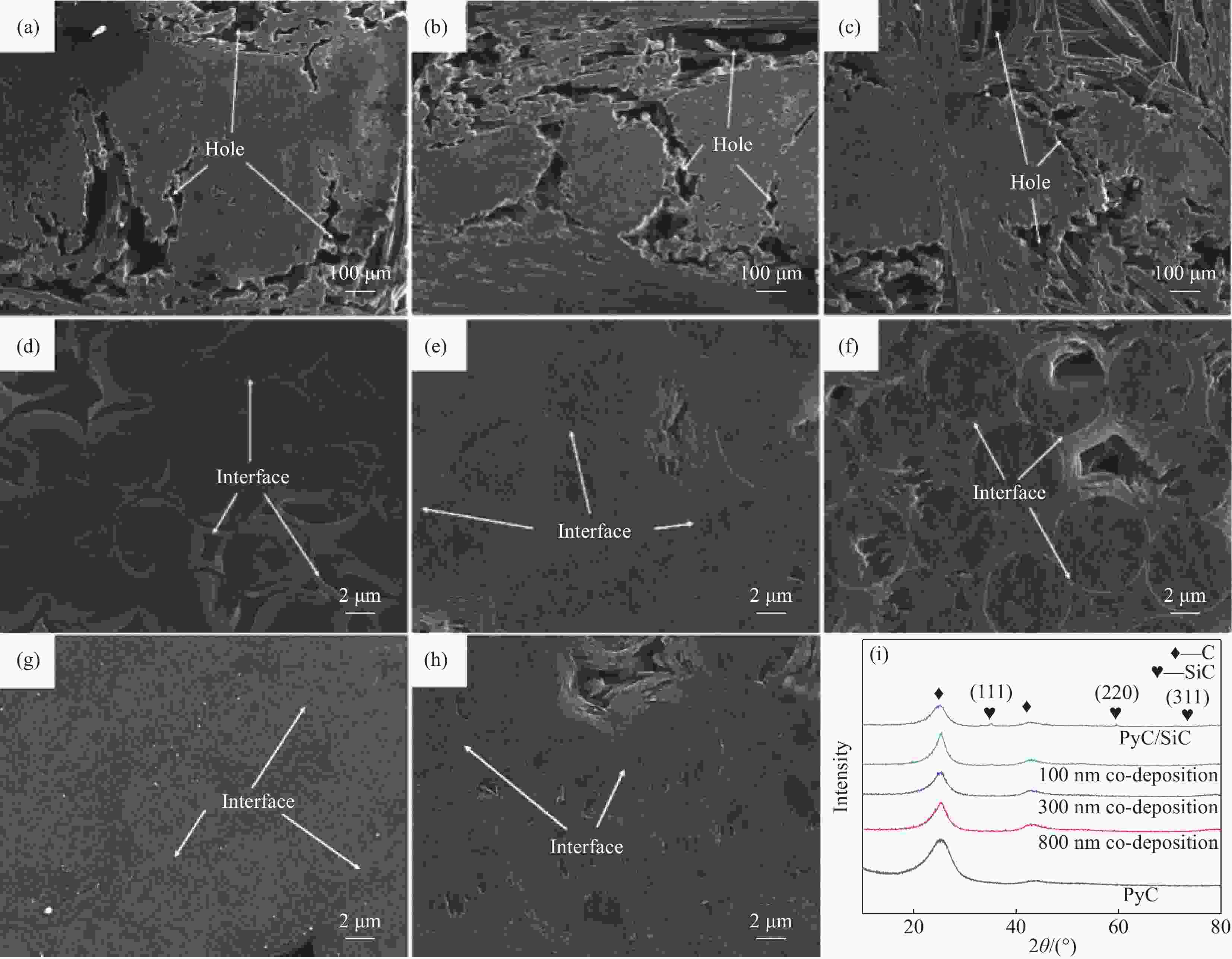

图 1 含不同界面低密度C/C坯体微观形貌及X射线衍射

(a)(d)PyC界面;(b)(e) 300 nm共沉积界面;(c)(f)PyC/SiC双层界面;(g)100 nm共沉积界面;(i)800 nm共沉积界面; (h) C/C坯体X射线衍射

Figure 1. Microstructures and X-ray diffraction of low-density C/C preforms with different interfaces (a)(d) PyC interface; (b)(e) 300 nm codeposition interface; (c)(f) PyC/SiC double-layer interface; (g)100 nm codeposition interface; (i)800 nm codeposition interface; (h) C/C body X-ray diffraction

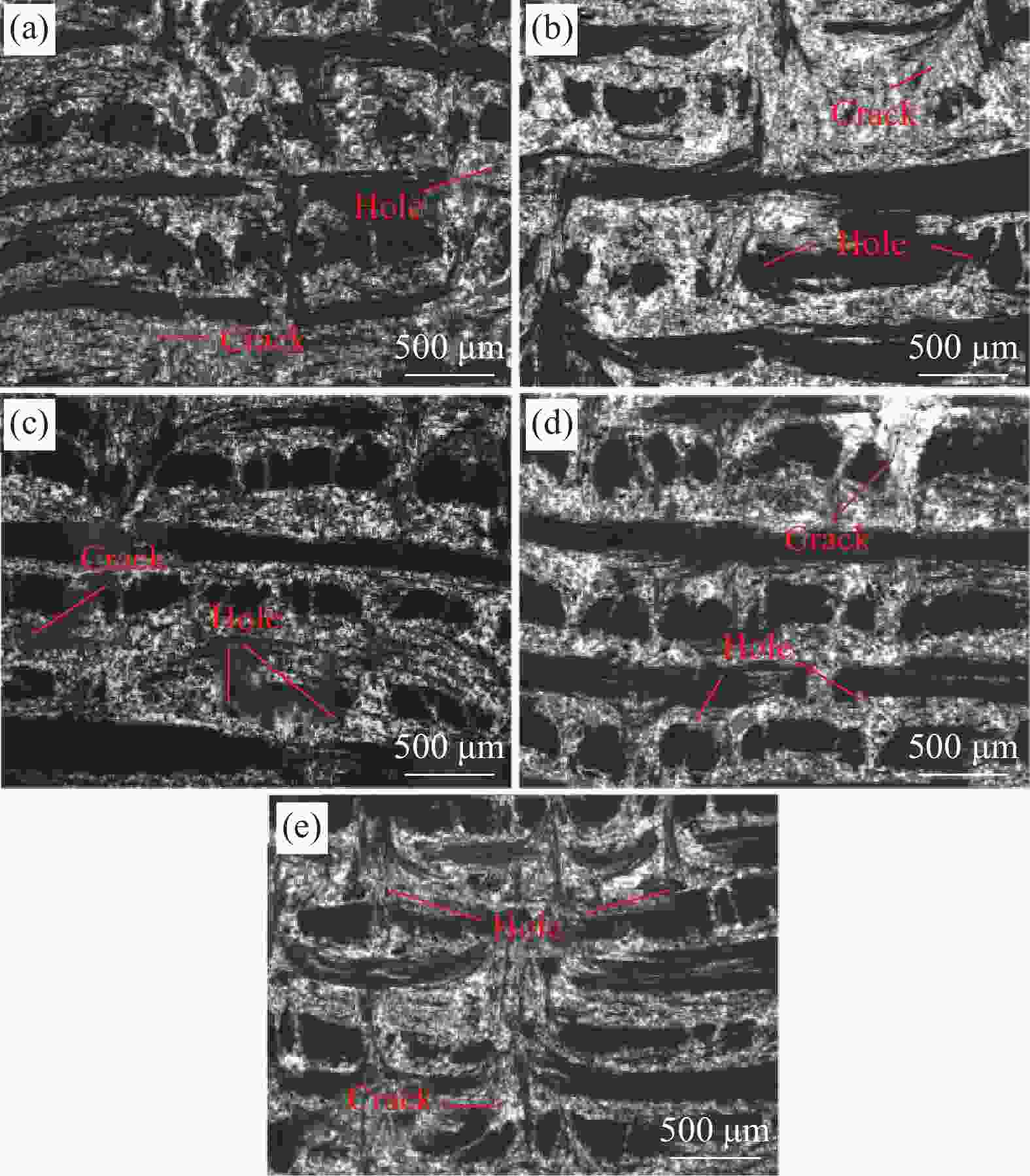

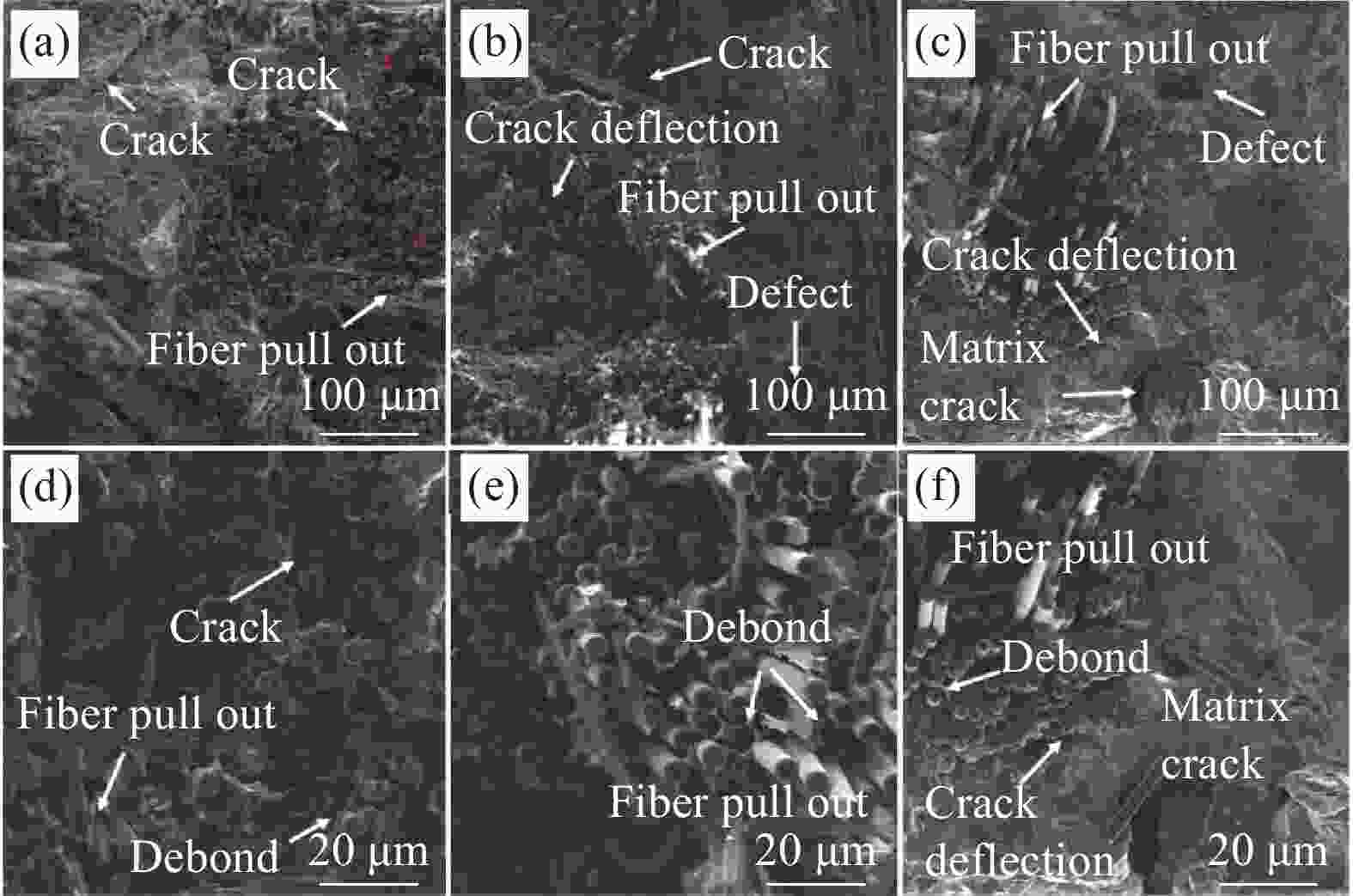

图 3 含不同界面C/C-SiC-ZrC复合材料低倍数SEM图像

(a) 热解碳(PyC)界面; (b) 100 nm(PyC+SiC)共沉积界面; (c) 300 nm(PyC+SiC)共沉积界面; (d) 800 nm(PyC+SiC)共沉积界面;(e) PyC/SiC双层界面

Figure 3. Low magnification SEM images of C/C-SiC-ZrC composites with different interfaces

(a) Pyrolysis carbon (PyC) interface; (b) 100 nm(PyC+SiC) co-deposition interface; (c) 300 nm(PyC+SiC) co-deposition interface; (d) 800 nm(PyC+SiC) codeposition interface; (e) PyC/SiC double-layer interface

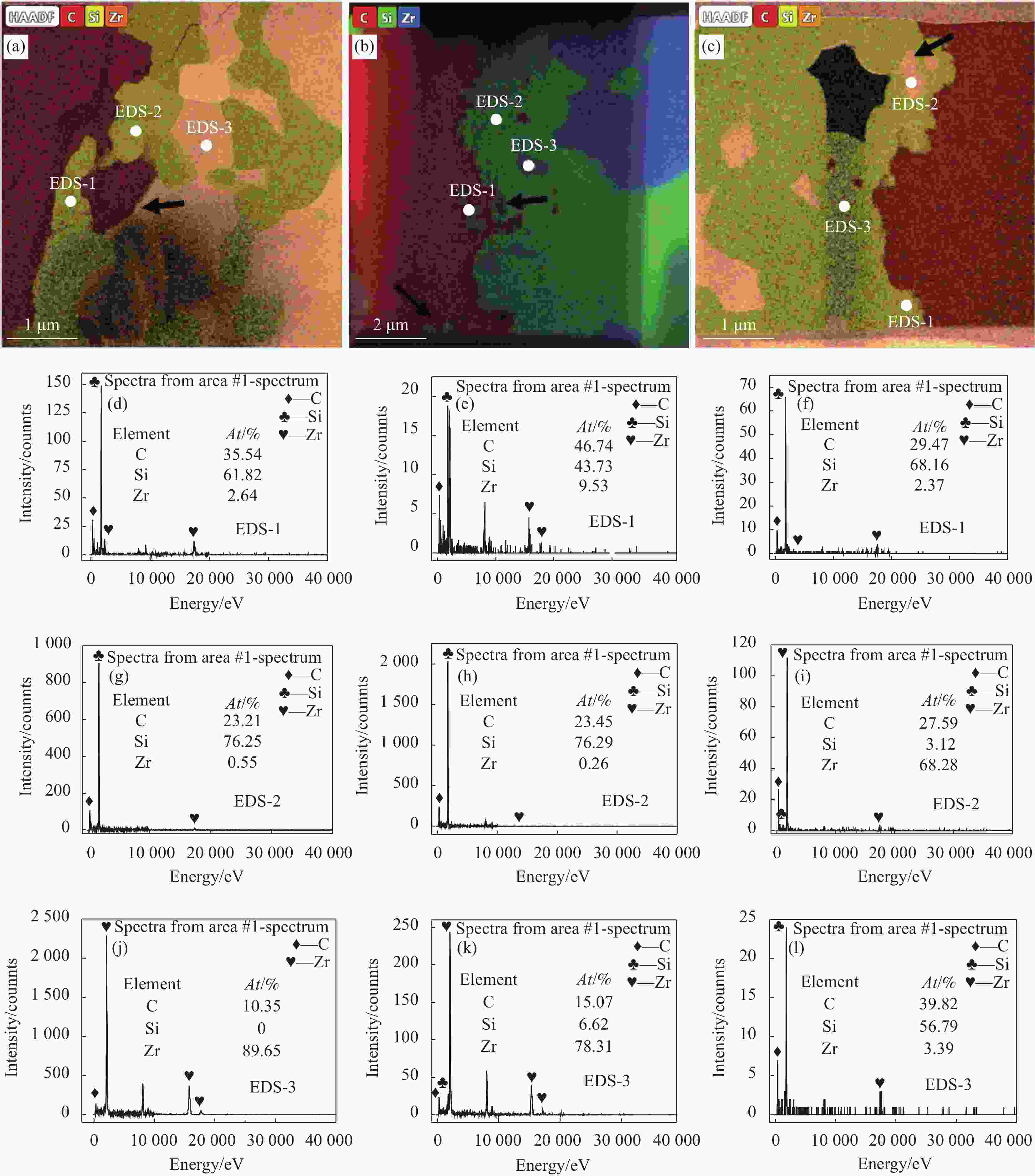

图 4 含PyC/SiC双层界面的C/C-SiC-ZrC复合材料内部微观结构及EDS分析

(a) 低倍数SEM图像; (b) 高倍数SEM图像; (c) (d) (e) EDS元素分析

Figure 4. EDS analysis of internal microstructure and elemental composition of C/C-SiC-ZrC composites with PyC/SiC double-layer interface

(a) low-magnification SEM images; (b) high-magnification SEM images; (c) (d) (e) EDS elemental analysis

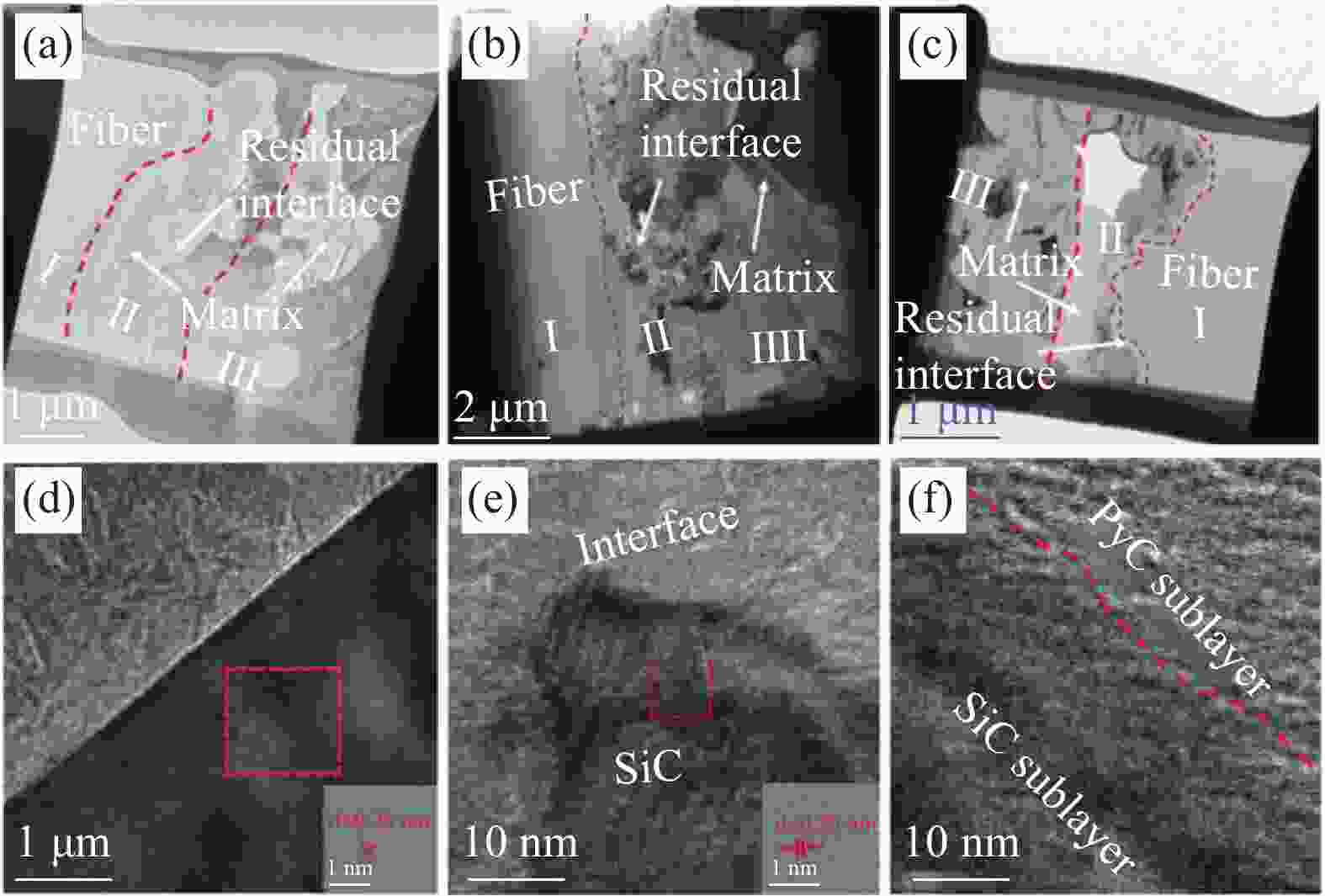

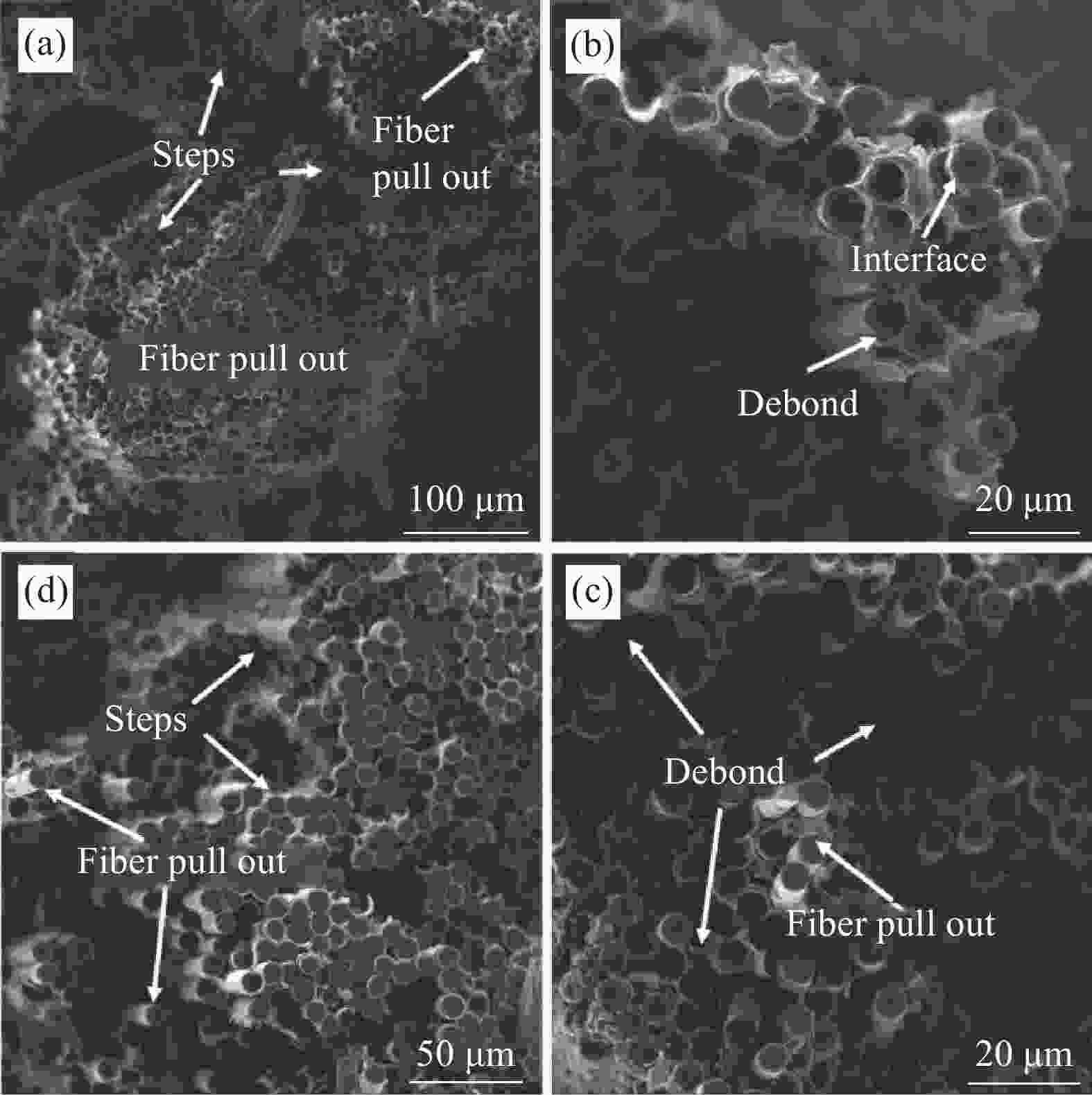

图 7 不同界面纤维与陶瓷相分界面及残余界面TEM图像

(a)(d) PyC界面; (b) (e) (PyC+SiC)共沉积界面; (c) (f) PyC/SiC双层界面

Figure 7. TEM images of the interface and residual interface between fibers and ceramic phases at different interfaces

(a)(d) PyC interface; (b) (e) (PyC+SiC) codeposition interface; (c) (f) PyC/SiC double-layer interface

表 1 含不同类型、不同厚度界面的低密度碳纤维坯体的性能特征

Table 1. Parameters of low-density carbon fiber preforms with different type and thickness of interfaces

Sample Type of interface Thickness of interface/nm Density/(g·cm−3) Porosity/% P PyC 300 1.29 28.6 PS100 (PyC+SiC) co-deposition 100 1.31 29.3 PS300 300 1.40 24.1 PS800 800 1.39 26.3 PC PyC/SiC 300/300 1.31 28.4 表 2 含不同厚度(PyC+SiC)共沉积界面复合材料抗弯性能

Table 2. Mechanical properties of co-deposited interface composites with different thicknesses

Sample Type of interface Thiceness of interface/nm Flexural strength/MPa PS100 (PyC+SiC) co-deposition 100 139.68 PS300 300 162.80 PS800 800 128.95 -

[1] 梁伟, 金华, 孟松鹤, 等. 高超声速飞行器新型热防护机制研究进展[J]. 宇航学报, 2021, 42(4): 409-424. doi: 10.3873/j.issn.1000-1328.2021.04.002LIANG Wei, JIN Hua, MENG Songhe, et al. Research progress on new thermal protection mechanism of hypersonic vehicles[J]. Journal of Astronautics, 2021, 42(4): 409-424(in Chinese). doi: 10.3873/j.issn.1000-1328.2021.04.002 [2] JACKSON L R, DIXON S C, TENNEY D R, et al. Hypersonic structures and materials - a progress report[J]. Aerospace America, 1987, (25): 722-736. [3] YANG X F, GUI Y W, TANG W, et al. Surface chemical effects on hypersonic nonequilibrium aeroheating in dissociated carbon-oxygen mixture[J]. Journal of Spacecraft and Rockets, 2018, 55(3): 687-697. doi: 10.2514/1.A34079 [4] CAMPBELL I E, SHERWOOD E M. High-temperature materials and technology[J]. Journal of the Electrochemical Society, 1967, 115(4): 108-115. [5] UPADHYA K Y, YANG J M, HOFFMAN W P. Materials for ultra-high temperatures structural applications[J]. American Ceramic Society Bulletin, 1997, 76(12): 51-56. [6] SALUTE J, BULL J, RASKY D, et al. SHARP-B2: flight test objectives, project implementation and initial results [C]//2nd Annual Conference on Composites, Materials and Structures, 2001: 118-137. [7] WILLIAM, B, JOHNSON, et al. Kinetics of formation of a platelet-reinforced ceramic composite prepared by the directed reaction of zirconium with boron carbide[J]. Journal of the American Ceramic Society, 1991, 74(9): 2093-2101. doi: 10.1111/j.1151-2916.1991.tb08265.x [8] HE Q C, LI H J, LU J H, et al. Oxidation behavior of co-deposited ZrC modified C/C composites prepared by chemical liquid-vapor infiltration process[J]. Vacuum, 2017, 142: 154-163. doi: 10.1016/j.vacuum.2017.05.019 [9] YAO J J, PANG S Y, HU C L, et al. Mechanical, oxidation and ablation properties of C/(C-SiC)(CVI)-(ZrC-SiC)(PIP) composites[J]. Corrosion Science, 2020, 162: 27-39. [10] TANG S, HU C. Design, Preparation and Properties of Carbon Fiber Reinforced Ultra-High Temperature Ceramic Composites for Aerospace Applications: A Review[J]. Journal of Materials Science & Technology, 2017, 33(2): 117-130. [11] FENG L, FAHRENHOLTZ W G, HILMAS G E, et al. Synthesis of single-phase high-entropy carbide powders[J]. Scripta Materialia, 2019, 162: 90-93. doi: 10.1016/j.scriptamat.2018.10.049 [12] NI D, CHENG Y, ZHANG J, et al. Advances in ultra-high temperature ceramics, composites, and coatings[J]. Journal of Advanced Ceramics, 2022, 11(1): 1-56. doi: 10.1007/s40145-021-0550-6 [13] 朱强强, 范金娟, 邬冠华. Cf/SiC复合材料的氧化及抗氧化技术研究进展[J]. 失效分析与预防, 2018, 13(1): 54-59.ZHU Qiangqiang, FAN Jinjuan, WU Guanhua. Research progress of oxidation and oxidation resistance of Cf /SiC composites[J]. Failure Analysis and Prevention, 2018, 13(1): 54-59(in Chinese). [14] WANG Y G, ZHU X J, ZHANG L T, et al. Reaction kinetics and ablation properties of C/C-ZrC composites fabricated by reactive melt infiltration[J]. Ceramics International, 2011, 37(4): 1277-1283. doi: 10.1016/j.ceramint.2010.12.002 [15] ZOU L H, WALI N, YANG J M, et al. Microstructural development of a C-f/ZrC composite manufactured by reactive melt infiltration[J]. Journal of the European Ceramic Society, 2010, 30(6): 1527-1535. doi: 10.1016/j.jeurceramsoc.2009.10.016 [16] YANG X, SU Z A, HUANG Q Z, Microstructure and mechanical properties of C/C-ZrC-SiC composites fabricated by reactive melt infiltration with Zr, Si mixed powders[J]. Journal of Materials Science & Technology, 2013, 29(08): 702-710. [17] 侯旭初, 郝振华, 舒永春, 等. 反应熔渗法制备耐烧蚀陶瓷改性C/C复合材料的研究进展[J]. 中南大学学报(自然科学版), 2020, 51(11): 3032-3043.HOU Xuchu, HAO Zhenhua, SHU Yongchun, et al. Research progress on preparation of ablative ceramic modified C/C composites by reactive infiltration[J]. Journal of Central South University (Science and Technology), 2020, 51(11): 3032-3043(in Chinese). [18] 易近人, 杨鑫, 黄启忠, 等. PyC/SiC界面改性C/C-SiC-ZrC复合材料的等离子烧蚀性能研究[J]. 炭素技术, 2021, 40(2): 22-26.Yi Jinren, Yang Xin, Huang Qizhong, et al. Ablation property of PyC/SiC interface modified C/C-SiC-ZrC composites under plasma flame[J]. Carbon Techniques, 2021, 40(2): 22-26(in Chinese). [19] WANG D K, DONG S M, ZHOU H J, et al. Effect of pyrolytic carbon interface on the properties of 3D C/ZrC-SiC composites fabricated by reactive melt infiltration[J]. Ceramics International, 2016, 42(8): 10272-10278. doi: 10.1016/j.ceramint.2016.03.155 [20] CHENG Y, LIU C, HU P, et al. Using PyC coated short chopped carbon fiber to tackle the dilemma between tit toughness and strength of ZrC-SiC[J]. Ceramics International, 2019, 45(1): 503-509. doi: 10.1016/j.ceramint.2018.09.196 [21] HU P, CHENG Y, GUO X, et al. Architectural engineering inspired method of preparing C-f/ZrC-SiC with graceful mechanical responses[J]. Journal of the American Ceramic Society, 2019, 102(1): 70-78. doi: 10.1111/jace.16018 [22] DU B H, CHENG Y, XUN L C, et al. Using PyC modified 3D carbon fiber to reinforce UHTC under low temperature sintering without pressure[J]. Journal of Advanced Ceramics, 2021, 10(4): 871-884. doi: 10.1007/s40145-021-0495-9 [23] 杨晓辉, 李克智, 白龙腾, 等. PyC界面层厚度对三维针刺C/ZrC-SiC复合材料力学性能影响规律[J]. 宇航材料工艺, 2021, 51(2): 38-46.YANG Xiaohui, LI Kezhi, BAI Longteng, et al. Effects of PyC interface thickness on the mechanical properties of 3D needled C/ZrC-SiC composites[J]. Aerospace Materials & Technology, 2021, 51(2): 38-46(in Chinese). [24] 中国国家标准化管理委员会(标准制定单位). 陶瓷材料抗弯曲强度试验方法: GB/T 4741-1999[S]. 北京: 中国标准出版社, 1999.Standardization Administration of the People’s Republic of China. Standard test method for bending strength of ceramic materials: GB/T 4741-1999[S]. Beijing: China Standards Press, 1999(in Chinese). [25] WANG D K, DONG S M, ZHOU H J, et al. Fabrication and microstructure of 3D C-f /ZrC-SiC composites: through RMI method with ZrO2 powders as pore-making agent[J]. Ceramics International, 2016, 42(6): 6720-6727. doi: 10.1016/j.ceramint.2016.01.041 -

点击查看大图

点击查看大图

计量

- 文章访问数: 69

- HTML全文浏览量: 41

- 被引次数: 0

下载:

下载: