Influencing factors of rheological properties and prediction of rheological behavior of fresh low water-to-cement ratio cement pastes

-

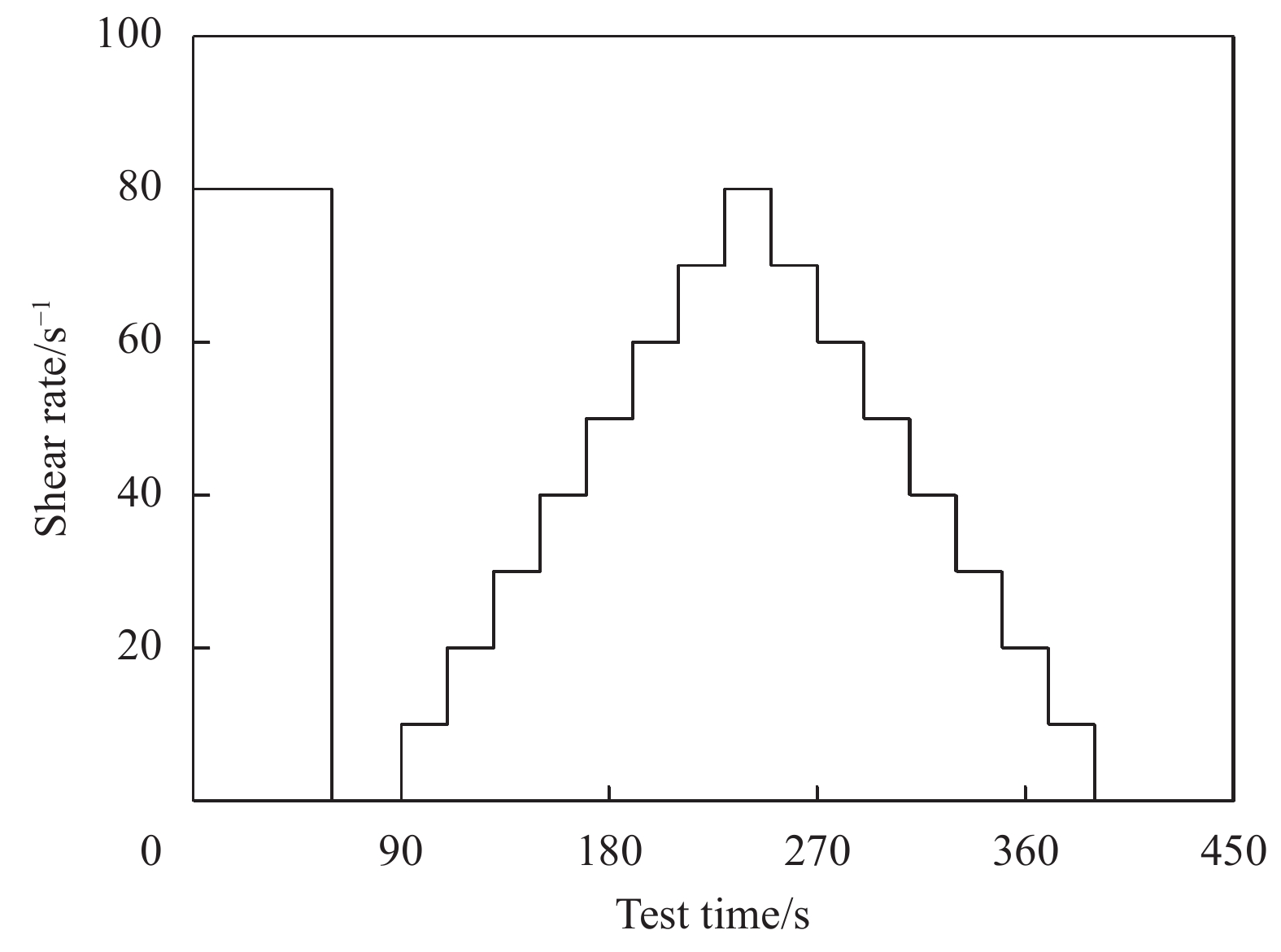

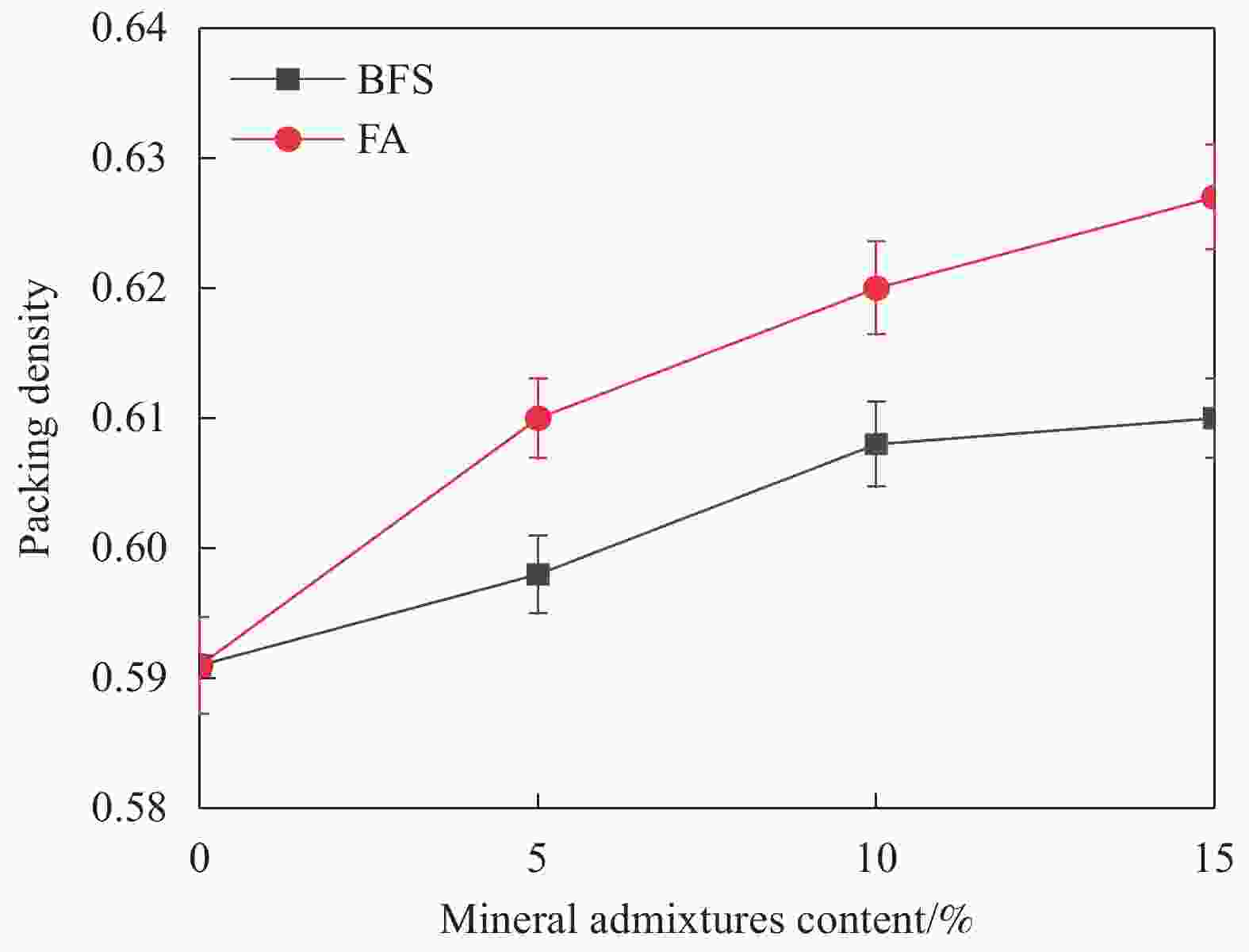

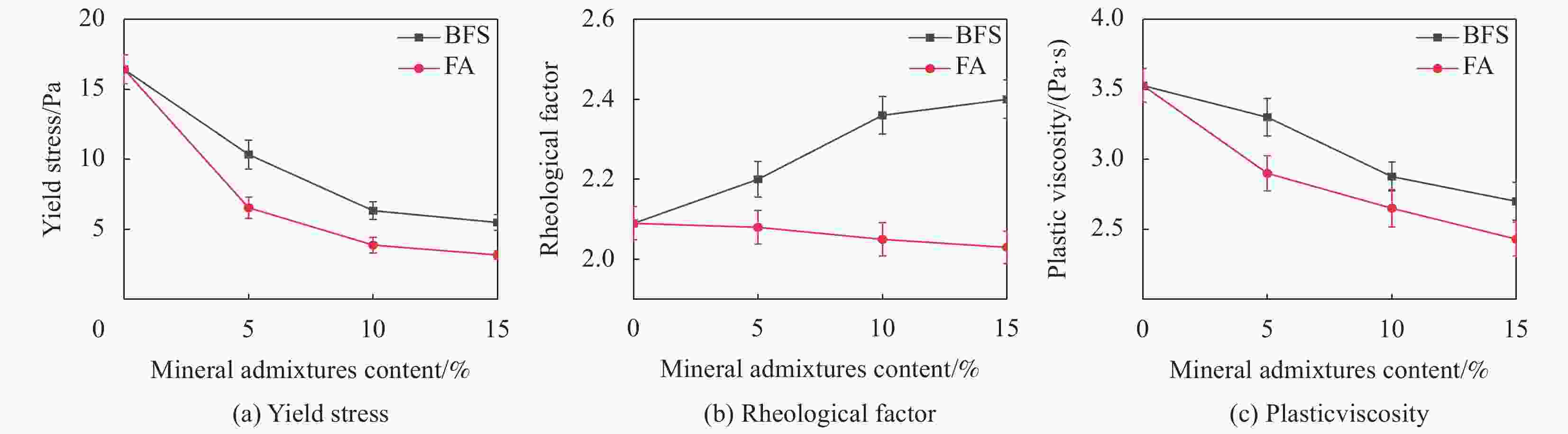

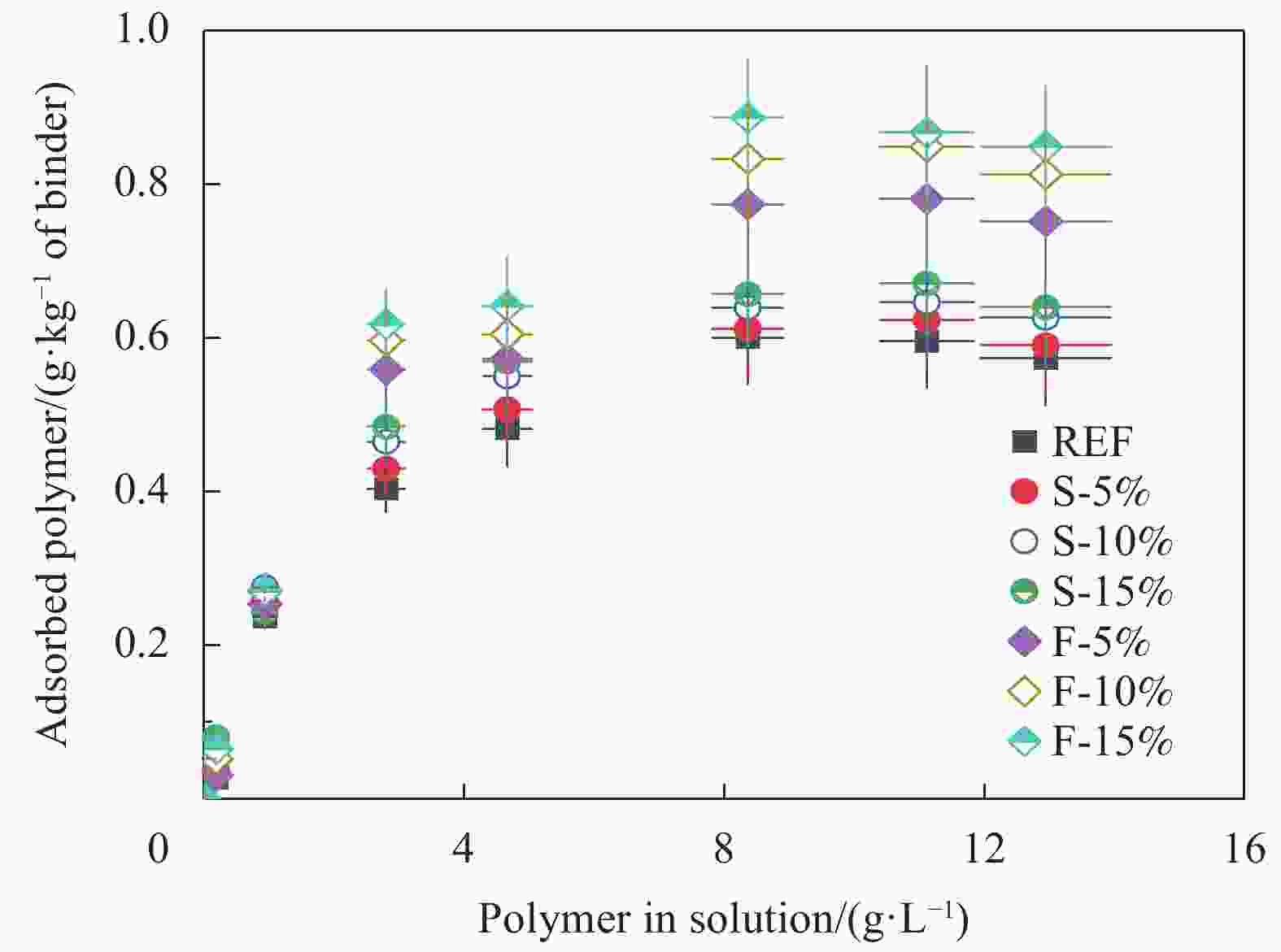

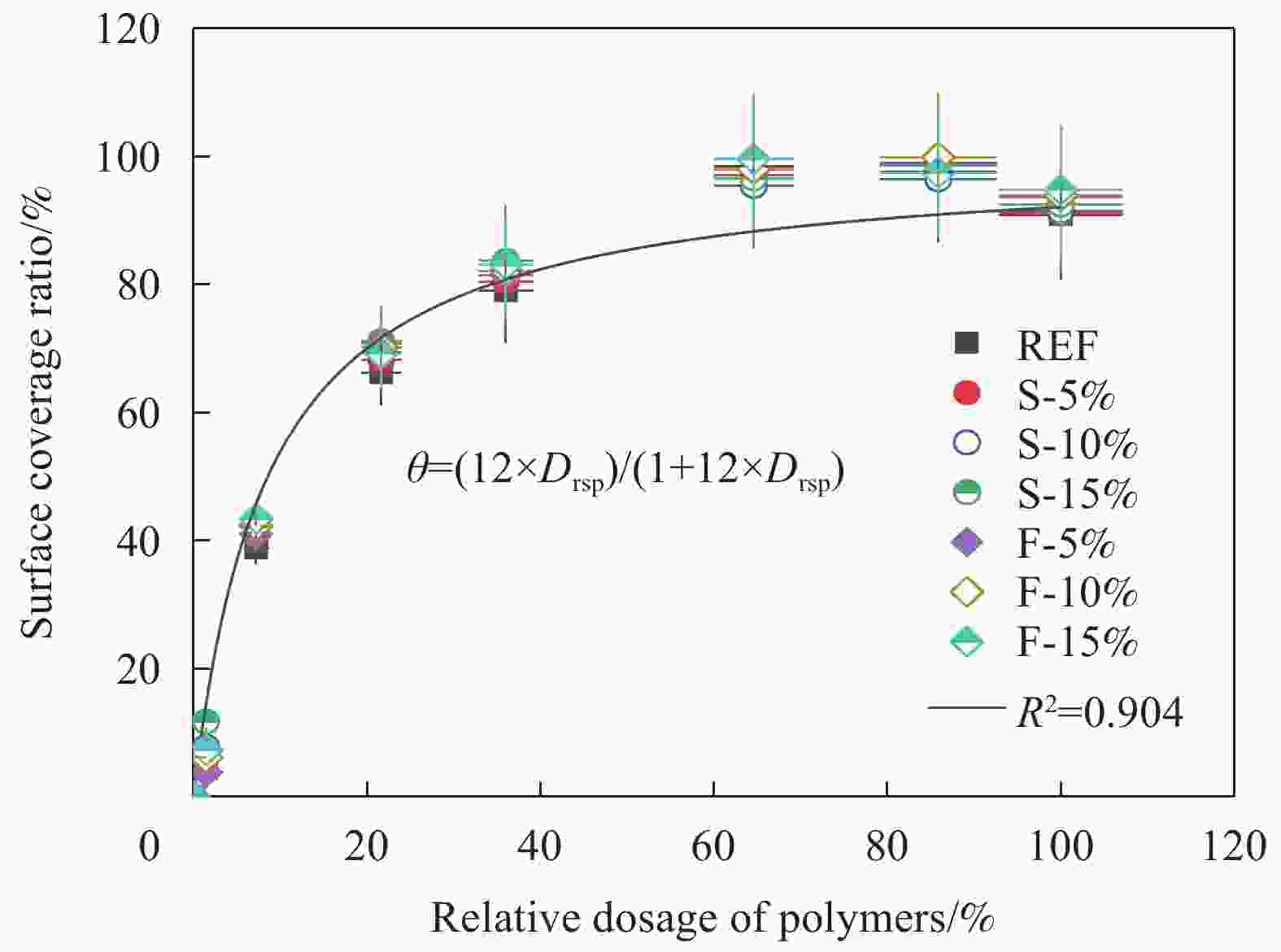

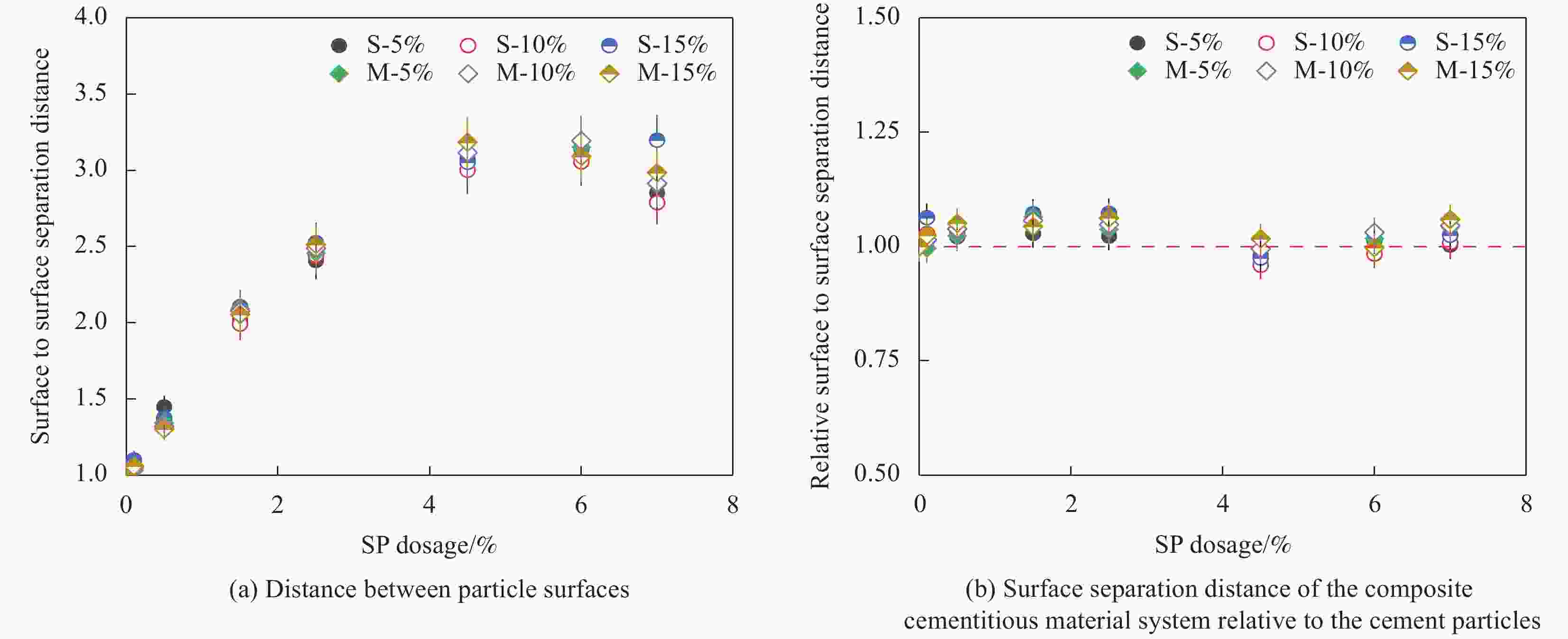

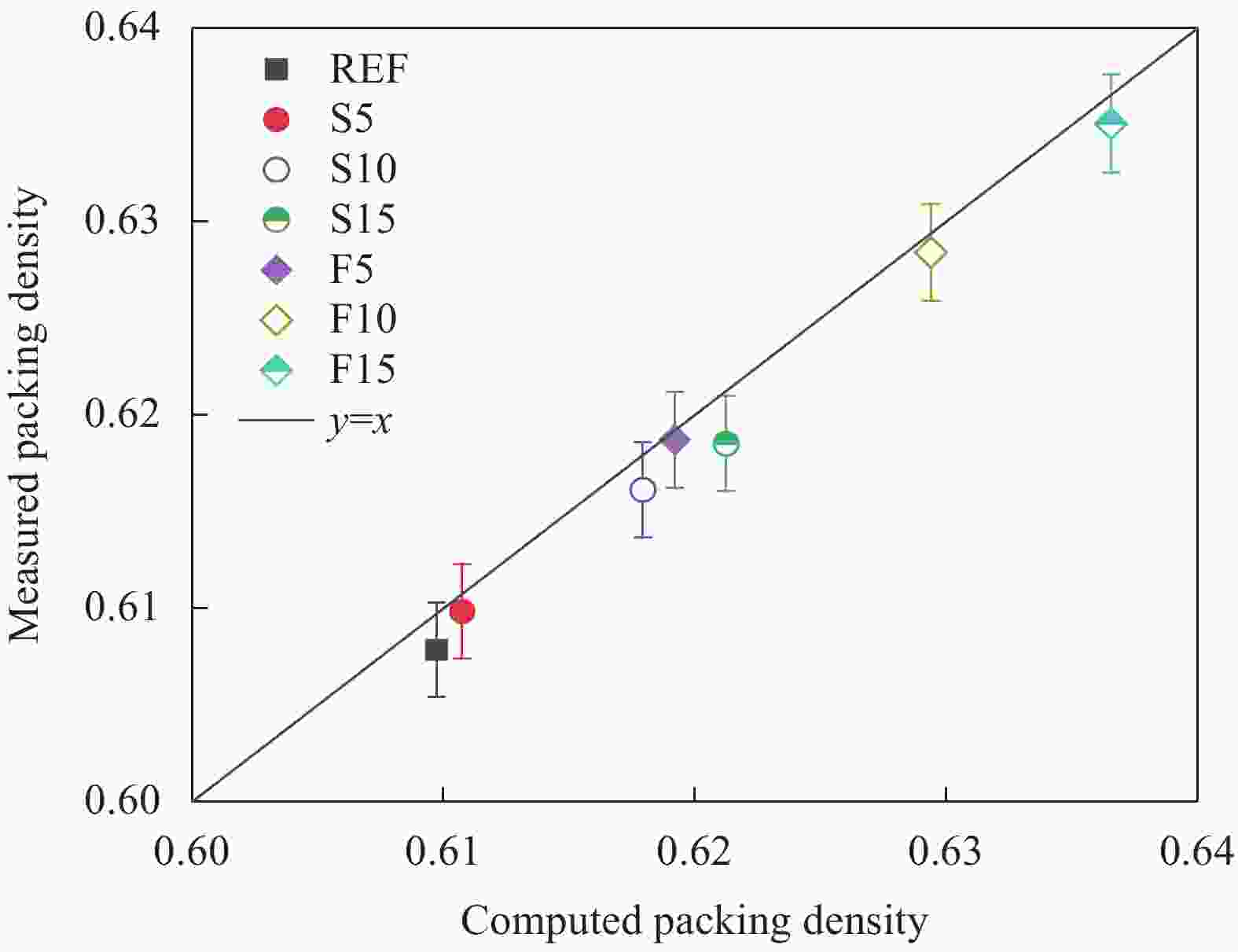

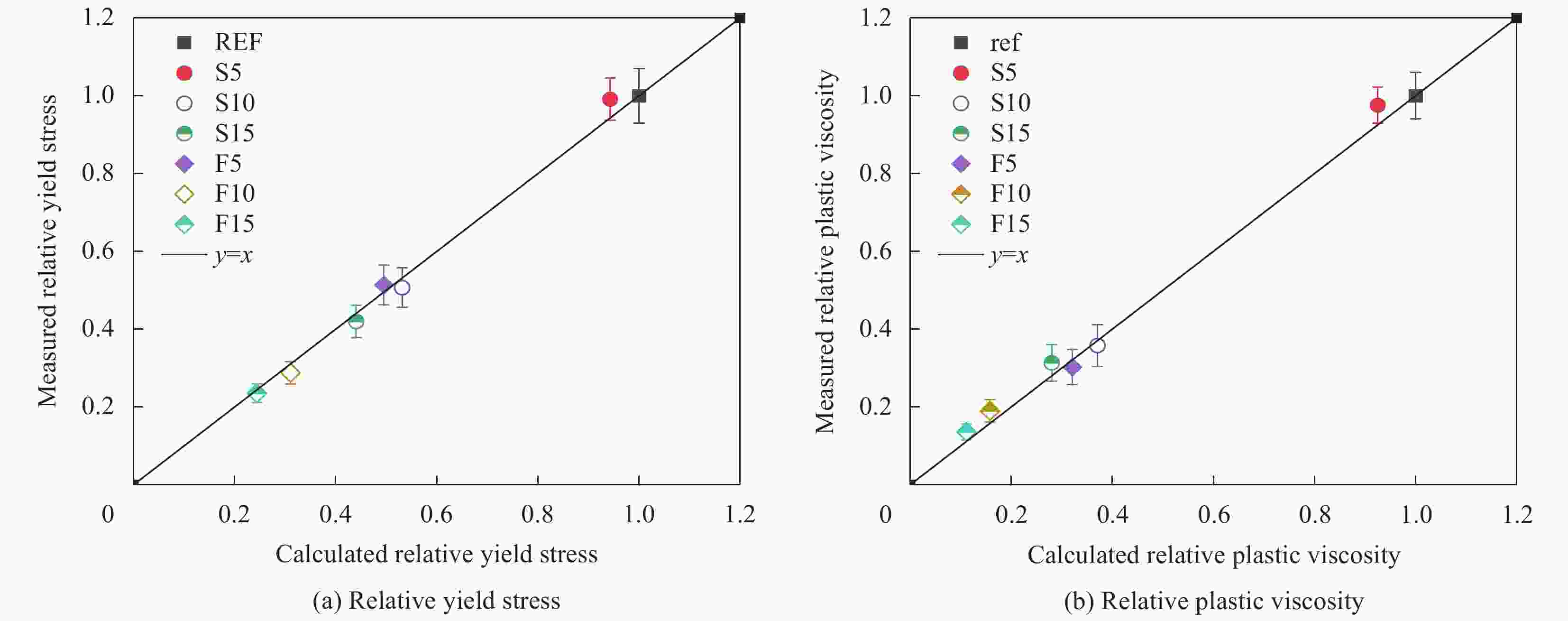

摘要: 高性能混凝土流变性能较差的稳定性以及较为复杂的调控方法,是影响其在土木工程建设中推广应用的重要因素之一。基于堆积密度试验、流变试验和总有机碳吸附试验,研究了矿粉和粉煤灰掺量对低水胶比水泥浆体流变参数的影响规律。结果表明:当矿粉和粉煤灰体积掺量在0%~15%之间时,随着掺量的增加,复合胶凝材料体系的堆积密度提高,水泥浆体的屈服应力和塑性粘度降低,并且上述规律随着减水剂掺量和矿物掺合料取代量的增加更加明显。胶凝材料表面的吸附-脱附平衡速率常数只与减水剂性质有关,对于本试验所用的减水剂拟合值为12。通过颗粒堆积理论和经典流变模型分析得到,矿粉和粉煤灰主要通过影响复合胶凝材料体系的凝胶作用力和相对堆积密实度,影响水泥浆体的流变性能。基于此提出了适用于水泥-矿粉和水泥-粉煤灰体系的低水胶比水泥浆体流变性能预测及优化方法。Abstract: The poor stability and complex control methods of rheological properties of high performance concrete are one of the important factors that affect its popularization and application in civil engineering construction. Based on the measurements of packing density, rheological properties, and total organic carbon adsorption, the influence and mechanism of the content of mineral additives on the rheological properties of cement paste with low water-to-cement ratio were investigated. The results show that, when the volume content of mineral powder and fly ash is between 0% and 15%, with the increase of the volume, the packing density of the composite cementing material system will be increased, and the yield stress and plastic viscosity of the cement slurry will be reduced. Moreover, the above rheological parameters increase with the increase in PCE dosage and the replacement ratio of mineral additives. Through adopting the particle packing model and recently developed rheological models, the adsorption-desorption equilibrium rate constant on the surface of the cementitious material is only related to the nature of the water reducing agent, and the fitted value is 12 for the water reducing agent used in this test. It is concluded that the change in rheological properties by blending mineral additives is mainly due to the changes in the colloidal interactions and relative packing density of the cementitious particles. Based on the above findings, an approach for predicting and optimizing the rheological properties of low water-to-cement ratio cement paste applicable to the cement-slag and the cement-fly ash microbeads system is proposed.

-

Key words:

- adsorption isotherms /

- packing density /

- yield stress /

- plastic viscosity /

- rheological model

-

表 1 胶凝材料的化学组成(wt%)

Table 1. Chemical composition of cementitious material(wt%)

Material SiO2 Al2O3 CaO MgO Fe2O3 SO3 K2O Others OPC 21.26 5.53 62.42 3.24 2.89 2.83 1.12 0.71 BFS 33.18 12.59 38.16 11.24 2.67 1.14 0.36 0.66 FA 61.12 20.14 8.34 1.03 7.16 0 1.37 0.84 Notes: OPC is ordinary Portland cement. BFS is blast furnace slag. FA is fly ash. 表 2 水泥净浆配合比

Table 2. Mix proportion of cement pastes

Sample Mix proportion/(kg·m−3) Water/

binder ratioOPC FA BFS SP REF 1899.5 0 0 58.9 0.21 F-5% 1804.5 73.6 0 58.2 0.21 F-10% 1709.5 147.3 0 57.6 0.21 F-15% 1614.6 220.9 0 56.9 0.21 S-5% 1804.5 0 87.2 58.6 0.21 S-10% 1709.5 0 174.3 58.4 0.21 S-15% 1614.6 0 261.5 58.2 0.21 Notes: REF is the control group of pure cement system; Numbers after F and S are the volume ratios to cement; F is blast furnace slag; S is fly ash. 表 3 减水剂在不同胶凝材料体系中的饱和掺量Dsat

Table 3. Saturated dosage of Dsat SP in different cementitious material systems

Sample Dsat REF 0.61 S-5% 0.79 S-10% 0.85 S-15% 0.89 F-5% 0.63 F-10% 0.67 F-15% 0.68 -

[1] 闫昊起. 基于绿色低碳发展的干寒腐蚀地区干硬性混凝土性能演变及寿命预测 [D]. 兰州: 兰州交通大学, 2023.YAN Haoqi. Performance evolution and life prediction of stiff concrete in drycold corrosion area based on green and low-carbon development [D]. Lanzhou: Lanzhou University of Technology, 2023. [2] ZUO Wenqiang, SHE Wei, LI Wei, et al. Effects of fineness and substitution ratio of limestone powder on yield stress of cement suspensions[J]. Materials and Structures, 2019, 52(4): 11−14. [3] BENTZ D P, ERRARIS C F, JONES S Z, et al. Limestone and silica powder replacements for cement: Early-age performance[J]. Cement and Concrete Composites, 2017, 78: 433−56. doi: 10.1016/j.cemconcomp.2017.01.001 [4] MUELLER F V, WALLEVIK O H, KHAYAT K H,. Linking solid particle packing of Eco-SCC to material performance[J]. Cement and Concrete Composites, 2014, 54: 1177−125. doi: 10.1016/j.cemconcomp.2014.04.001 [5] ZUO Wenqiang, LIU Jiaping, TIAN Qian, et al. Norm method to define and evaluate robustness of self-compacting concrete due to component quantity variations[J]. Construction and Building Materials, 2018, 161(10): 2466−253. [6] 刘宇, 黎梦圆, 阎培渝. 矿物掺合料对胶凝材料浆体流变性能和触变性的影响[J]. 硅酸盐学报, 2019, 47(5): 594−601.LIU Yu, LI Mengyuan, YAN Peiyu. J Chin Ceram Soc, 2019, 47(5): 594−601. (in Chinese). [7] 熊蓉蓉, 龙广成, 谢友均, 等. 矿物掺合料对蒸养高强浆体抗压强度及孔结构的影响[J]. 硅酸盐学报, 2017, 45(2): 175−181.XIONG Rongrong, LONG Guangcheng, XIE Youjun, et al. J Chin Ceram Soc. 2017, 45(2): 175−181. (in Chinese). [8] 褚洪岩, 蒋金洋, 李荷, 等. 环保型细集料对超高性能混凝土力学性能的影响[J]. 材料导报, 2020, 34(24): 5.CHU Hongyan, JIANG Jinyang, LI He, et al. Materials Reports, 2020, 34(24): 5. (in Chinese). [9] 李传习, 王圣杰, 夏雨航, 等. 硅烷改性超高性能混凝土的流变性和强度[J]. 硅酸盐学报, 2023, 51(11): 2914−2923.LI Chuanxi, WANG Shengjie, XIA Yuhang, et al. J Chin Ceram Soc. 2023, 51(11): 2914−2923. (in Chinese). [10] WANG Dehui, SHI Caijun, WU Zemei, et al. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties[J]. Construction and Building Materials, 2015, 96: 3688−377. doi: 10.1016/j.conbuildmat.2015.08.095 [11] SHANAHAN Natallia, TRAN Victor, WILLIAMS Andrew, et al. Effect of SCM combinations on paste rheology and its relationship to particle characteristics of the mixture[J]. Construction and Building Materials, 2016, 123: 7455−753. doi: 10.1016/j.conbuildmat.2016.07.094 [12] WANG Penggang, FU Hua, ZUO Wenqiang, et al. Effect of n-C-S-H-PCE and slag powder on the autogenous shrinkage of high-strength steam-free pipe pile concrete[J]. Construction and Building Materials, 2022, 325: 126815. doi: 10.1016/j.conbuildmat.2022.126815 [13] HAN Xiaofeng, FU Hua, LI Gege, et al. Volume Deformation of Steam-Cured Concrete with Slag during and after Steam Curing[J]. Materials, 2021, 14(7): 1647. doi: 10.3390/ma14071647 [14] AHMADAH Oumayma, BESSAIES-BAY Hela, YAHIA Ammar, et al. A new mix design method for low-environmental-impact blended cementitious materials: Optimization of the physical characteristics of powders for better rheological and mechanical properties[J]. Cement and Concrete Composites, 2022, (128): 104437. [15] JOHN V M, DAMINELI B L, QUATTRONE M, et al. Fillers in cementitious materials — Experience, recent advances and future potential[J]. Cement and Concrete Research, 2018, 114: 655−78. doi: 10.1016/j.cemconres.2017.09.013 [16] DAMINELI B L , JOHN V M , LAGERBLAD B , et al. Viscosity prediction of cement-filler suspensions using interference model: A route for binder efficiency enhancement[J]. Cement and Concrete Research, 2016, 84: 8−19. [17] ZUO Wenqiang, WEI Luansu, DU Zhenxing, et al. Design of robust Self-Compacting concrete based on analysis of component properties[J]. Construction and Building Materials, 2021, 301: 124063. doi: 10.1016/j.conbuildmat.2021.124063 [18] FEYS D, KHAYAT K H. , KHATIB R. How do concrete rheology, tribology, flow rate and pipe radius influence pumping pressure?[J]. Cement and Concrete Composites 2016, 66: 38−46. [19] DE FRANCA M S, CAZACLIU B, CARDOSO F A, et al. Influence of mixing process on mortars rheological behavior through rotational rheometry[J]. Construction and Building Materials, 2019, 223: 811−90. doi: 10.1016/j.conbuildmat.2019.06.213 [20] HAFID H, OVARLEZ G, TOUSSAINT F, et al. Effect of particle morphological parameters on sand grains packing properties and rheology of model mortars[J]. Cement and Concrete Research, 2016, 80: 444−51. doi: 10.1016/j.cemconres.2015.11.002 [21] WONG H H C, KWAN A K H. Packing density of cementitious materials: part 1-measurement using a wet packing method[J]. Materials and Structures, 2008, 41: 6899−701. doi: 10.1617/s11527-007-9274-5 [22] VANCE K, DAKHANE A, SANT G, et al. Observations on the rheological response of alkali activated fly ash suspensions: the role of activator type and concentration[J]. Rheologica Acta, 2014, 53(10): 9433−855. [23] 汪玺玥. 超高性能水泥基材料流变行为及机理研究 [D]. 南京: 东南大学, 2020.WANG Xiyue. Study on rheological behavior and mechanism of ultra high performance cement-based materials [D]. Nanjing: Southeast University, 2020. [24] HOT Julie, BESSAIES-BEY Hela, BRUMAUD Coralie, et al. Adsorbing polymers and viscosity of cement pastes[J]. Cement and Concrete Research, 2014, 63: 122−19. doi: 10.1016/j.cemconres.2014.04.005 [25] PERROT A, LECOMPTE T, KHELIFI H, et al. Yield stress and bleeding of fresh cement pastes[J]. Cement and Concrete Research, 2012, 42(7): 9377−944. doi: 10.1016/j.cemconres.2012.03.015 [26] 王莉, 张颖. 建筑用混凝土中掺入粉煤灰后的滚珠效应与润滑性对比分析[J]. 科技通报, 2017, 33(1): 1544−158.WANG Li; ZHANG Ying. The Ball Effect and Lubricity Contrast Analysis of Concrete Mixed with Fly Ash[J]. Bulletin of Science and Technology, 2017, 33(1): 1544−158(in Chinese). [27] 左文强. 自密实混凝土鲁棒性与收缩性能研究 [D]. 南京: 东南大学, 2020.ZUO Wenqiang. Investigation of robustness and shrinkageof self-compacting concrete [D]. Nanjing: Southeast University, 2020. [28] ZUO Wenqiang, BESSAIES-BEY Hela, TIAN Qian, et al. Robustness of cement-based materials: From dosage variations to yield stress fluctuations[J]. Cement and Concrete Research, 2021, 139: 106260. doi: 10.1016/j.cemconres.2020.106260 [29] KWAN A K H, CHAN K W, WONG V. A 3-parameter particle packing model incorporating the wedging effect[J]. Powder Technology, 2013, 237(3): 1722−179. [30] WONG V, KWAN A K H. A 3-parameter model for packing density prediction of ternary mixes of spherical particles[J]. Powder Technology, 2014, 268(1): 3577−367. [31] DE L F. Concrete Mixture Proportioning: A Scientific Approach [M]. London: CRC Press, 1999. [32] ZUO Wenqiang, LIU Jiaping, TIAN Qian, et al. Optimum design of low-binder Self-Compacting Concrete based on particle packing theories[J]. Construction and Building Materials, 2017, 163: 9388−948. [33] FLATT R J, BOWEN P. Yodel: A Yield Stress Model for Suspensions[J]. Journal of the American Ceramic Society, 2006, 89(4): 12444−1256. doi: 10.1111/j.1551-2916.2005.00888.x [34] ROUSSEL N, LEMAITRE A, FLATT R J, et al. Steady state flow of cement suspensions: A micromechanical state of the art[J]. Cement and Concrete Research, 2010, 40(1): 777−84. doi: 10.1016/j.cemconres.2009.08.026 [35] UKRAINCZYK N, THIEDEITZ M, KRANKEL T, et al. Modeling SAOS Yield Stress of Cement Suspensions: Microstructure-Based Computational Approach[J]. Materials, 2020, 13(12): 2769. doi: 10.3390/ma13122769 [36] ZUO Wenqiang, ZHANG Lizhi, WANG Penggang, et al. A multi-scale approach for assessing the robustness of cement-based materials from a yield stress perspective[J]. Construction and Building Materials, 2021, 300: 123998. doi: 10.1016/j.conbuildmat.2021.123998 [37] ZUO Wenqiang, ZHANG Lizhi, DU Zhenxing, et al. Design of cement-based materials with robust viscosity: from polymer solution scale to concrete scale[J]. Materials and Structures, 2022, 55(7): 188. doi: 10.1617/s11527-022-02028-1 -

点击查看大图

点击查看大图

计量

- 文章访问数: 34

- HTML全文浏览量: 29

- 被引次数: 0

下载:

下载: