Considering the influence of temperature and stress levels on the nonlinear creep model of GFRP in a water environment

-

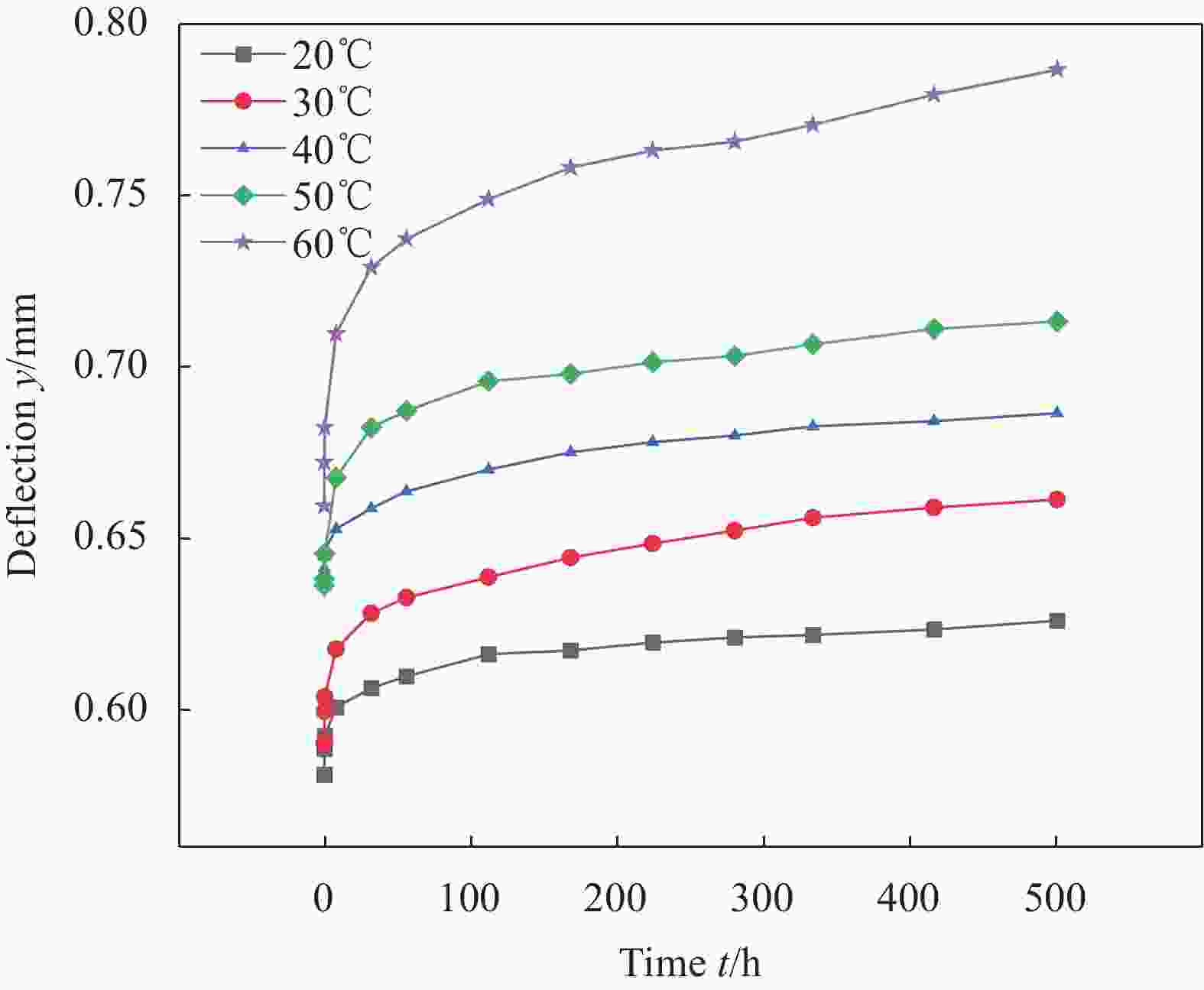

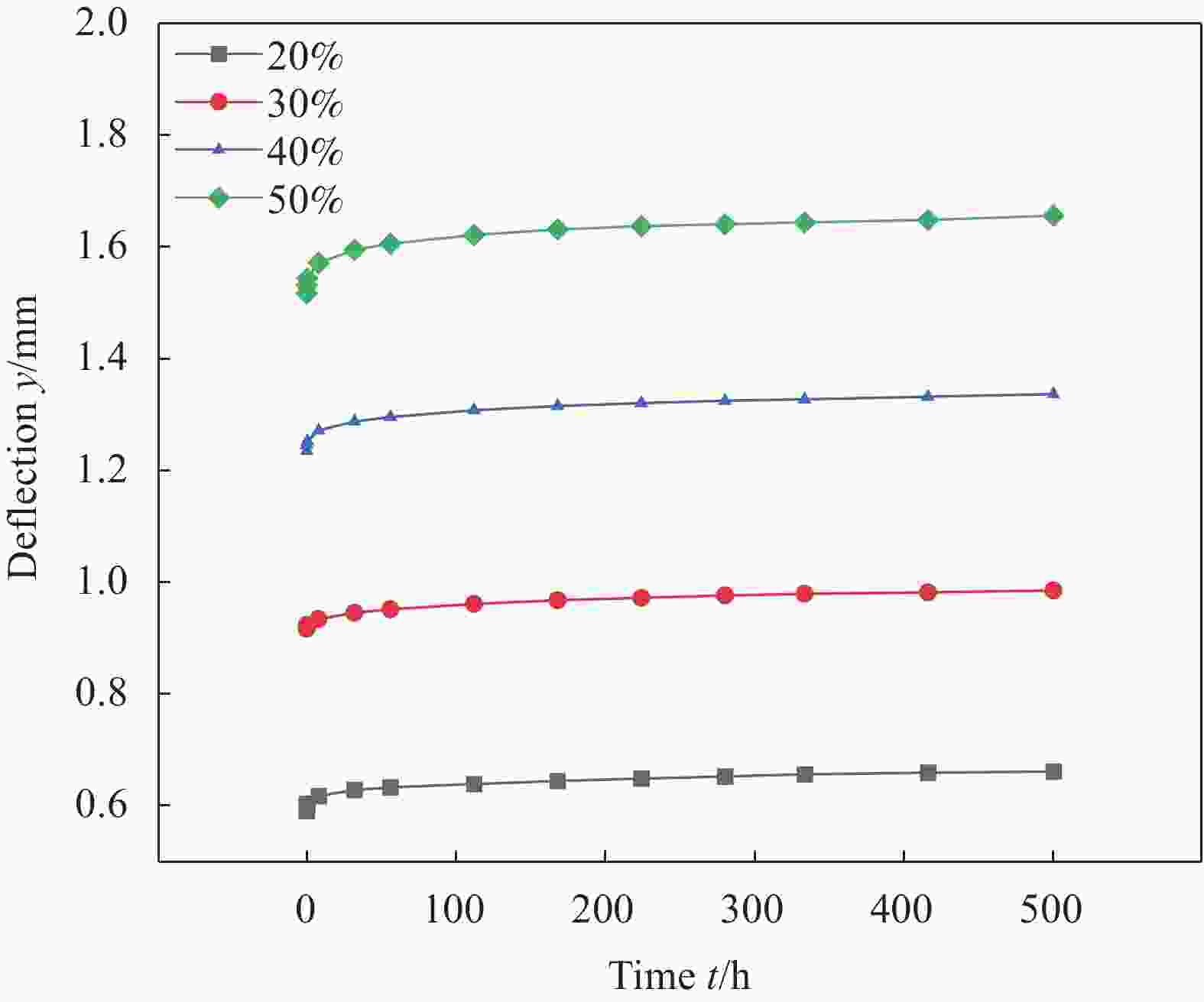

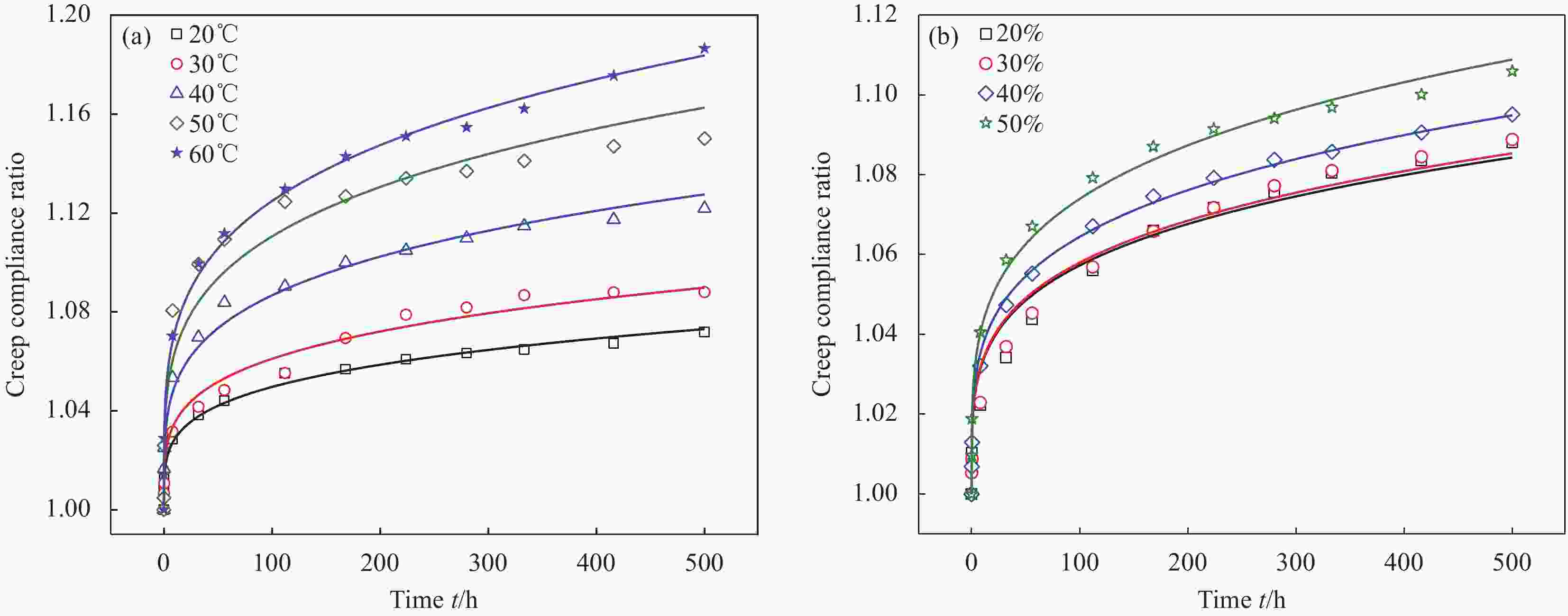

摘要: 针对去离子水环境中GFRP复合材料,研究了温度与应力水平对水环境中GFRP蠕变性能的影响。对试样用树脂封边处理后,采用恒载荷弯曲腐蚀试验机,进行了20%应力水平下,20℃、30℃、40℃、50℃、60℃条件下的长期蠕变实验,和30℃条件下,20%、30%、40%、50%等多种应力水平下的长期蠕变实验,分别研究了不同温度和不同应力水平对GFRP蠕变性能的影响,并量化了温度与应力水平对去离子水环境中GFRP的蠕变性能的综合影响,建立了改进Findley非线性蠕变模型。并通过短梁剪切法测试了去离子水环境对GFRP层间剪切强度的影响。结果表明,改进Findley非线性蠕变模型可描述GFRP在20~60℃、低于其蠕变断裂应力水平下的蠕变性能,适用范围广,准确性高,与实验结果吻合良好。根据此模型可预测GFRP在去离子水环境中不同温度不同应力水下的GFRP复合材料的长期蠕变性能,预测误差均在2%以内。去离子水对经过封边处理的GFRP试样的层间剪切强度影响甚小。本文所得结果为GFRP结构的设计提供依据。

-

关键词:

- 蠕变 /

- GFRP /

- 层间剪切 /

- 水环境 /

- 改进Findley模型

Abstract: This study investigates the influence of temperature and stress levels on the creep behavior of GFRP composite materials in deionized water environment. After treating the specimens with resin edge sealing, long-term creep tests were conducted at 20%, 30%, 40%, 50%, and 60% stress levels under 20°C, 30°C, 40°C, 50°C, and 60°C conditions using a constant load bending corrosion test machine. Furthermore, long-term creep tests were also performed at 20%, 30%, 40%, and 50% stress levels under 30°C conditions. The study separately examines the effects of different temperatures and stress levels on the creep performance of GFRP, quantifies the comprehensive impact of temperature and stress levels on the creep behavior of GFRP in deionized water environment, and establishes an improved Findley nonlinear creep model. Additionally, the study assesses the influence of deionized water environment on the interlaminar shear strength of GFRP using the short beam shear method. The results indicate that the improved Findley nonlinear creep model can accurately describe the creep performance of GFRP at temperatures ranging from 20°C to 60°C and below its creep fracture stress level, showing a broad applicability and high accuracy with good agreement with experimental results. Based on this model, the long-term creep performance of GFRP composite materials under different temperatures and stress levels in deionized water environment can be predicted, with prediction errors within 2%. Deionized water has minimal impact on the interlaminar shear strength of edge-sealed GFRP specimens. The findings of this study provide a basis for the design of GFRP structures.-

Key words:

- creep /

- GFRP /

- interlaminar shear /

- water environment /

- improving the Findley model

-

表 1 GFRP复合材料的弯曲性能

Table 1. Banding property of GFRP composites

σf Ef Mean value 568.8 MPa 20.14 GPa Standard deviation 65.58 3.17 Coefficient of variation 8.51% 15.76% Notes: σf -Flexural strength; Ef -Flexural modulus. 表 2 GFRP复合材料层间剪切强度

Table 2. Inter-laminar shear strength of GFRP composites

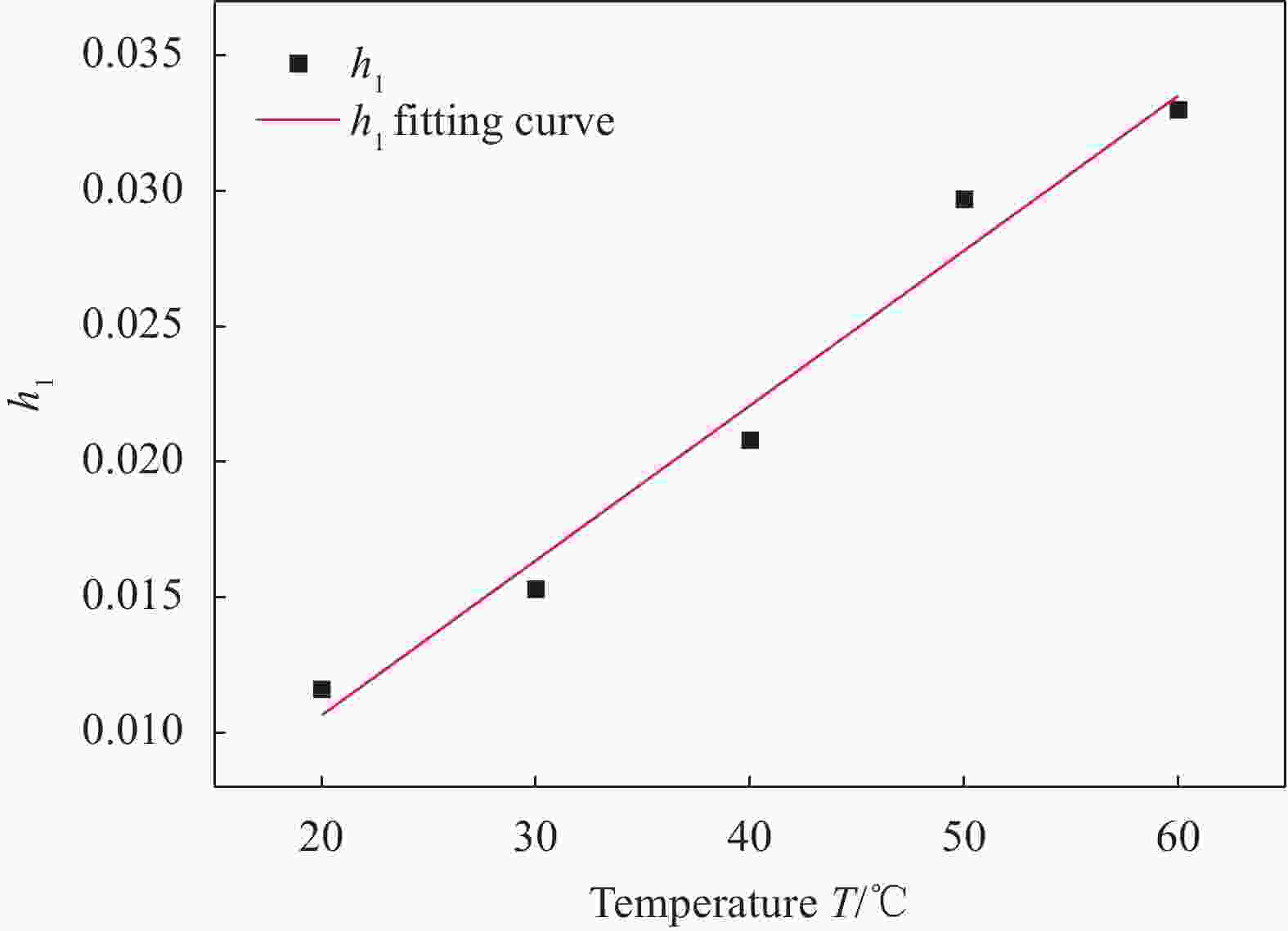

Group wt/% τs/MPa Loss of strength A - 49.72 - B 0.35 47.24 4.99% C 0.12 48.03 3.40% Notes: wt−Moisture content;τs−Interlaminar shear strength. 表 3 GFRP复合材料不同温度下的参数h1(T)

Table 3. Parameter h1(T) at different temperatures of GFRP composites

T/℃ 20 30 40 50 60 h1 0.0116 0.0153 0.0208 0.0297 0.0330 R2 0.9895 0.9755 0.9956 0.9650 0.9956 Notes: T-Temperature of the environment box; h1−Functions related to temperatures; R2−Goodness-of-fit. 表 4 GFRP复合材料不同应力水平下的参数h2(σ)

Table 4. Parameter h2(σ) at different stress levels of GFRP composites

Stress level 20% 30% 40% 50% h2 1.065 1.078 1.198 1.374 R2 0.9755 0.9791 0.9971 0.9960 Notes: h2−Functions related to stress level. 表 5 GFRP复合材料不同温度下的拟合优度R2

Table 5. Goodness of fit R2 of GFRP composites at different temperatures

T/℃ 20 30 40 50 60 R2 0.990 0.976 0.996 0.965 0.996 表 6 GFRP复合材料不同应力水平下的拟合优度R2

Table 6. Goodness of fit R2 of GFRP composites under different stress levels

Stress level 20% 30% 40% 50% R2 0.976 0.979 0.997 0.996 表 7 各工况下GFRP的蠕变柔量预测值与试验值对比

Table 7. Comparison between the predicted value and the experimental value of the creep compliance of GFRP

Test conditions 35℃-20%(500 h) 30℃-45%(500 h) 20℃-30%(500 h) 20℃-40%(1000 h) Creep compliance J0/10−11Pa-1 5.262 5.066 5.813 4.795 Improve Findley predictions 1.0975 1.0887 1.0585 1.1186 Creep compliance prediction /10-11Pa−1 5.775 5.515 6.153 5.364 Test creep compliance /10-11Pa−1 5.777 5.581 6.074 5.427 Deviations/% 0.034 1.183 1.300 1.161 -

[1] 薛忠民. 中国玻璃钢/复合材料发展回顾与展望[J]. 玻璃钢/复合材料, 2015(1): 5-12.XUE Z M. Retrospect and prospect of development of FRP / CM in China[J] Fiber Reinforced Plastics/ Composites, 2015(1): 5-12(in Chinese). [2] 叶国锐, 晏义伍, 曹海琳. 氧化石墨烯改性玄武岩纤维及其增强环氧树脂复合材料性能[J]. 复合材料学报, 2014, 31(6): 1402-1408.YE G R, YAN Y W, CAO H L. Basalt fiber modified with graphene oxide and properties of its reinforced epoxy composites[J]. Acta Materiae Compositae Sinica, 2014, 31(6): 1402-1408(in Chinese). [3] Rafiee R. On the mechanical performance of glass-fibre-reinforced thermosetting-resin pipes: A review[J]. Composite Structures, 2016, 143: 151-164. doi: 10.1016/j.compstruct.2016.02.037 [4] Rafiee R. Stochastic fatigue analysis of glass fiber reinforced polymer pipes[J]. Composite Structures, 2017, 167(1): 96-102. [5] Hollaway L C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties[J]. Construction and building materials, 2010, 24(12): 2419-2445. doi: 10.1016/j.conbuildmat.2010.04.062 [6] Mohammed A A, Manalo A C, Ferdous W, et al. State-of-the-art of prefabricated FRP composite jackets for structural repair[J]. Engineering Science and Technology, an International Journal, 2020, 23(5): 1244-1258. doi: 10.1016/j.jestch.2020.02.006 [7] Liu C, Fan X, Zhu M. Regulating the grinding performance of grindstones via using basalt fibers[J]. Tribology International, 2022, 173: 107611. doi: 10.1016/j.triboint.2022.107611 [8] Katouzian M, Vlase S, Marin M, et al. Modeling Study of the Creep Behavior of Carbon-Fiber-Reinforced Composites: A Review[J]. Polymers, 2023, 15(1): 00194. [9] 宋寅搏, 陈务军, 高成军, 等. 飞艇用织物膜材单轴拉伸蠕变强度试验与模型[J]. 复合材料学报, 2022, 39(10): 5041-5048.SONG Yinbo, CHEN Wujun, GAO Chengjun, et al. Uniaxial tensile creep experiment and creep model of fabric for airship structures[J]. ActaMateriae Compositae Sinica, 2022, 39(10): 5041-5048(in Chinese) [10] Li M, Xing F, Li T, et al. Multiscale interfacial enhancement of surface grown carbon nanotubes carbon fiber composites[J]. Polymer Composites, 2023, 44(5): 2766-2777. doi: 10.1002/pc.27278 [11] Tamrakar S, Ganesh R, Sockalingam S, et al. Strain rate-dependent large deformation inelastic behavior of an epoxy resin[J]. Journal of Composite Materials, 2020, 54(1): 71-87. doi: 10.1177/0021998319859054 [12] 梁娜, 朱四荣, 陈建中. 一种新的聚合物基复合材料应力松弛经验模型[J]. 复合材料学报, 2017, 34(10): 2205-2210.LIANG N, ZHU S R, CHEN J Z. A new empirical model for stress relaxation of polymer matrix[J]. Acta Materiae Compositae Sinica, 2017, 34(10): 2205-2210(in Chinese). [13] 贾彩霞, 王乾, 任荣, 等. 超高分子量聚乙烯(UHMWPE)纤维表面处理对UHMWPE/环氧树脂复合材料界面性能的影响机制[J]. 复合材料学报, 2020, 37(3): 573-580.JIA C X, WANG Q, REN R, et al. Influence mechanism of ultra high molecular weight polyethylene(UHMWPE) fiber surface modification on interfacial performance of UHMWPE/epoxy composites[J], Acta Materiae Compositae Sinica 2020, 37(3); 573-580 ( in Chinese). [14] 别依诺, 朱四荣, 贺攀, 等. 纳米SiO2-硅烷协同改性对玄武岩纤维/环氧树脂复合材料力学性能及蠕变性能的影响[J]. 复合材料学报, 2022, 39(8): 3723-3732.BIE Y N, ZHU S R, HE P, et al. Effect of nano-SiO2 particles-silane synergistic modification on mechanical properties and creep properties of basalt fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3723-3732(in Chinese). [15] 栗越, 张京发, 易顺民, 等. 改性芳纶纤维增强木粉/高密度聚乙烯复合材料的力学性能[J]. 复合材料学报, 2019, 36(3): 638-645.LI Y, ZHANG J F, YI S M, et al. Mechanical properties of modified aramid fiber reinforced wood flour/ high density polyethylene composites[J]. Acta Materiae Compositae Sinica, 2019, 36(3): 638-645(in Chinese) . [16] 张尧, 朱四荣, 陆士平, 等. 考虑界面效应的 GFRP 复合材料蠕变模型[J]. 复合材料学报, 2021, 38(11): 3682-3692.ZHANG Yao, ZHU Sirong, LU Shiping, et al. Creep model of GFRP composites considering interface effect[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3682-3692(in Chinese). [17] Bank, L. C. , Mosallam, A. S. Creep and failure of a full-size fiber-reinforced plastic pultruded frame. Composites Engineering, 1992, 2 (3), 213–227. [18] Sá M F, Gomes A M, Correia J R, et al. Creep behavior of pultruded GFRP elements–Part 2: Analytical study[J]. Composite structures, 2011, 93(9): 2409-2418. doi: 10.1016/j.compstruct.2011.04.001 [19] Sá M F, Gomes A M, Correia J R, et al. Creep behavior of pultruded GFRP elements–Part 1: Literature review and experimental study[J]. Composite Structures, 2011, 93(10): 2450-2459. doi: 10.1016/j.compstruct.2011.04.013 [20] Bai, Y. , Keller, T[J]. Time dependence of material properties of FRP composites in fire. Journal of Composite Materials, 2009, 43(21): 2469-2484. [21] Tomlins P E, Read B E. Creep and physical ageing of polypropylene: a comparison of models[J]. Polymer, 1998, 39(2): 355-367. doi: 10.1016/S0032-3861(97)00258-9 [22] Al-Rubaye M, Manalo A, Alajarmeh O, et al. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems[J]. Composite Structures, 2020, 236: 111836. doi: 10.1016/j.compstruct.2019.111836 [23] 中国国家标准化管理委员会. 玻璃纤维增强塑料树脂含量试验方法. GB/T 2577-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for resin content of glass fiber reinforced plastics: GB/T 2577-2005[S]. Beijing: China Standards Press, 2005(in Chinese) [24] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fibre-reinforced plastic composites-Determination of flexural properties: GB/T 1449-2005[S]. Beijing: China Standards Press, 2005(in Chinese). [25] 中华人民共和国工业和信息化部. 纤维增强塑料短梁法测定层间剪切强度. JC/T 773-2010 [S]. 北京: 中国标准出版社, 2010.Ministry of Industry and Information Technology of the People's Republic of China. Fibre-reinforced plastics composites-Determination of apparent interlaminar shear strength by short‘beam method. JC/T 773-2010 [S]. Beijing: China Standards Press, 2010(in Chinese). [26] The British Standards Institution. GRP tanks and vessels for use above ground-Part 3: Design and workmanship: EN 13121-3-2016 [S]. London: BSI Standards Limited, 2016. [27] 中国国家标准化管理委员会. 纤维增强塑料设备和管道工程技术规范. GB51160-2016 [S]. 北京: 中国标准出版社, 2016.Standardization Administration of the People’s Republic of China. Technical code for fibre reinforced plastics equipment and piping engineering: GB51160-2016 [S]. Beijing: China Standards Press, 2016(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 66

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: