“Forming-bending” coupling numerical model for the carbon fiber reinforced polypropylene composite tube

-

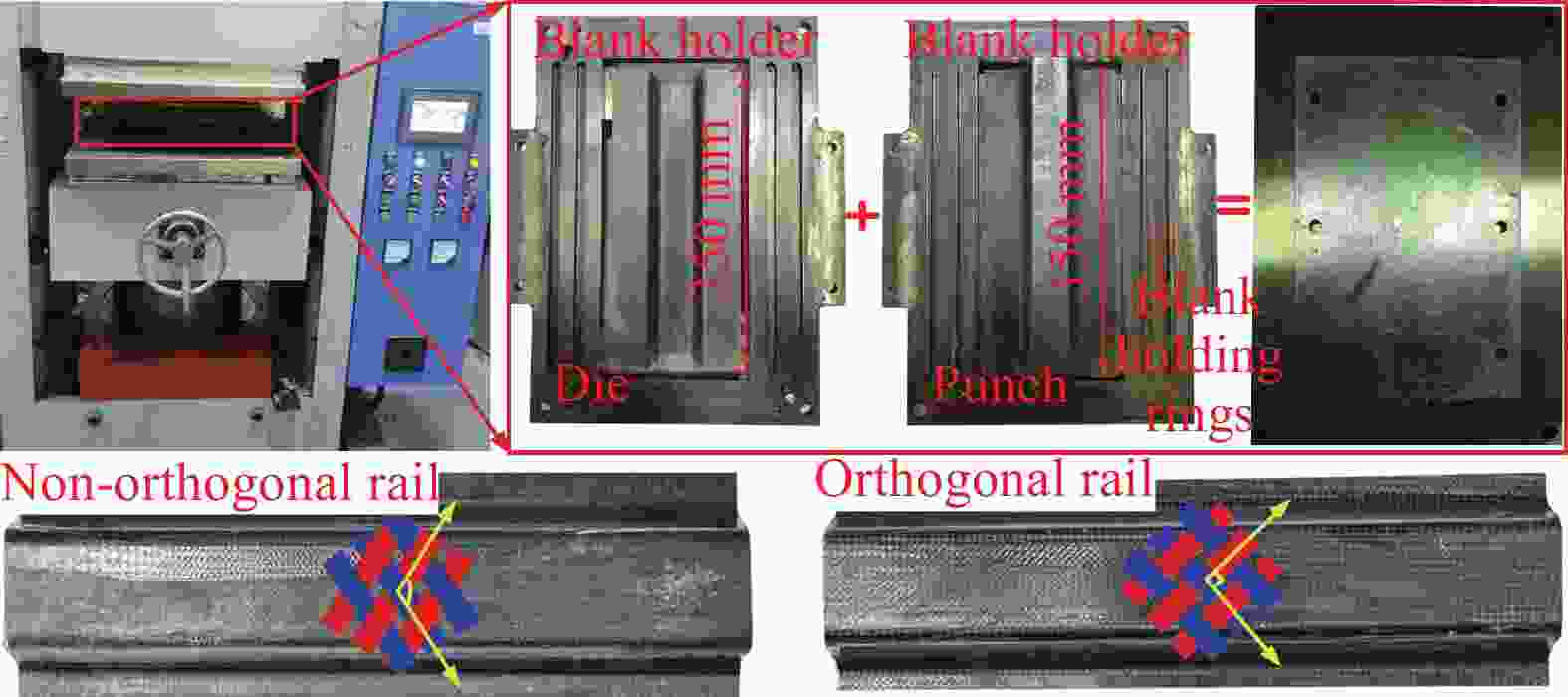

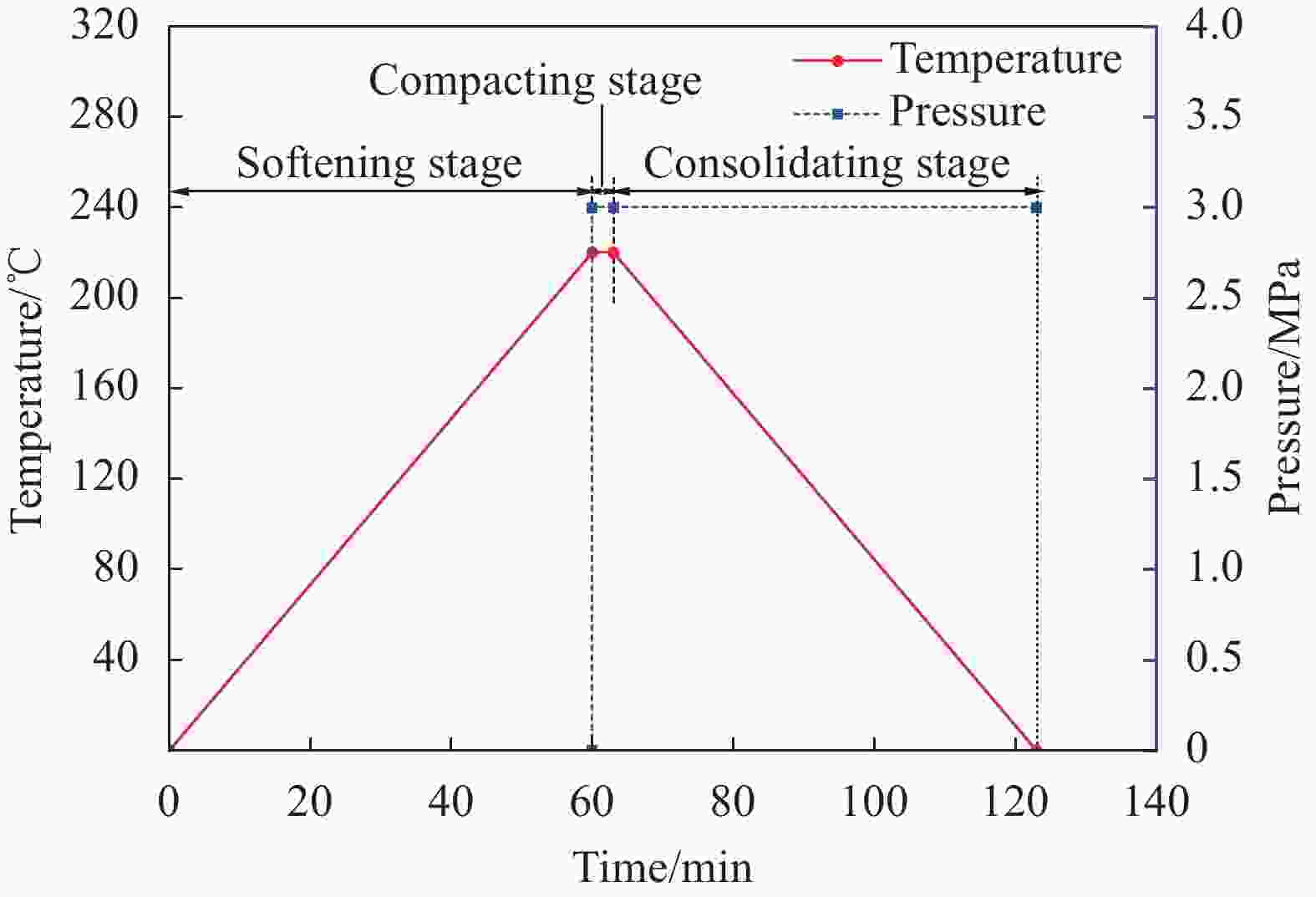

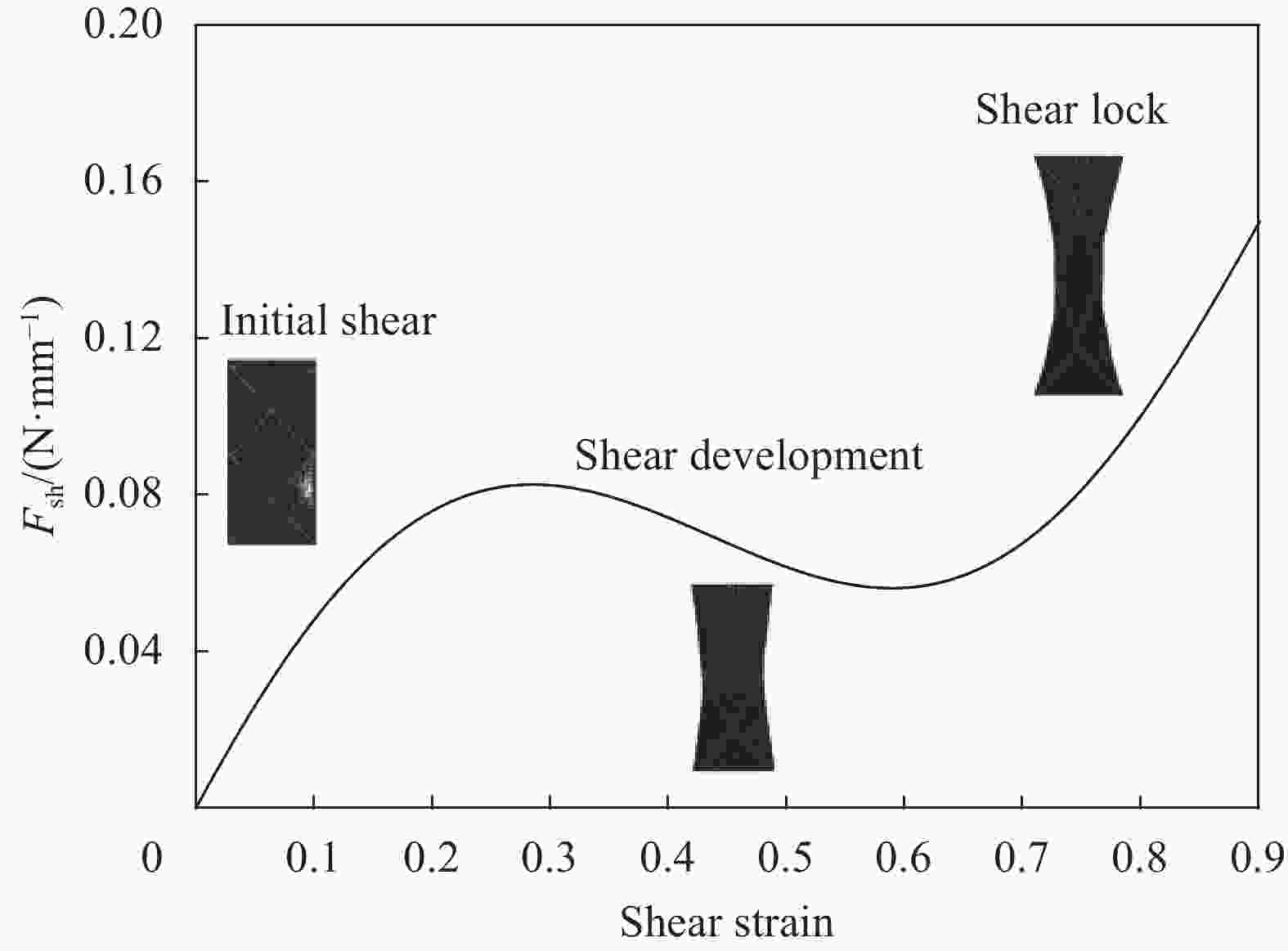

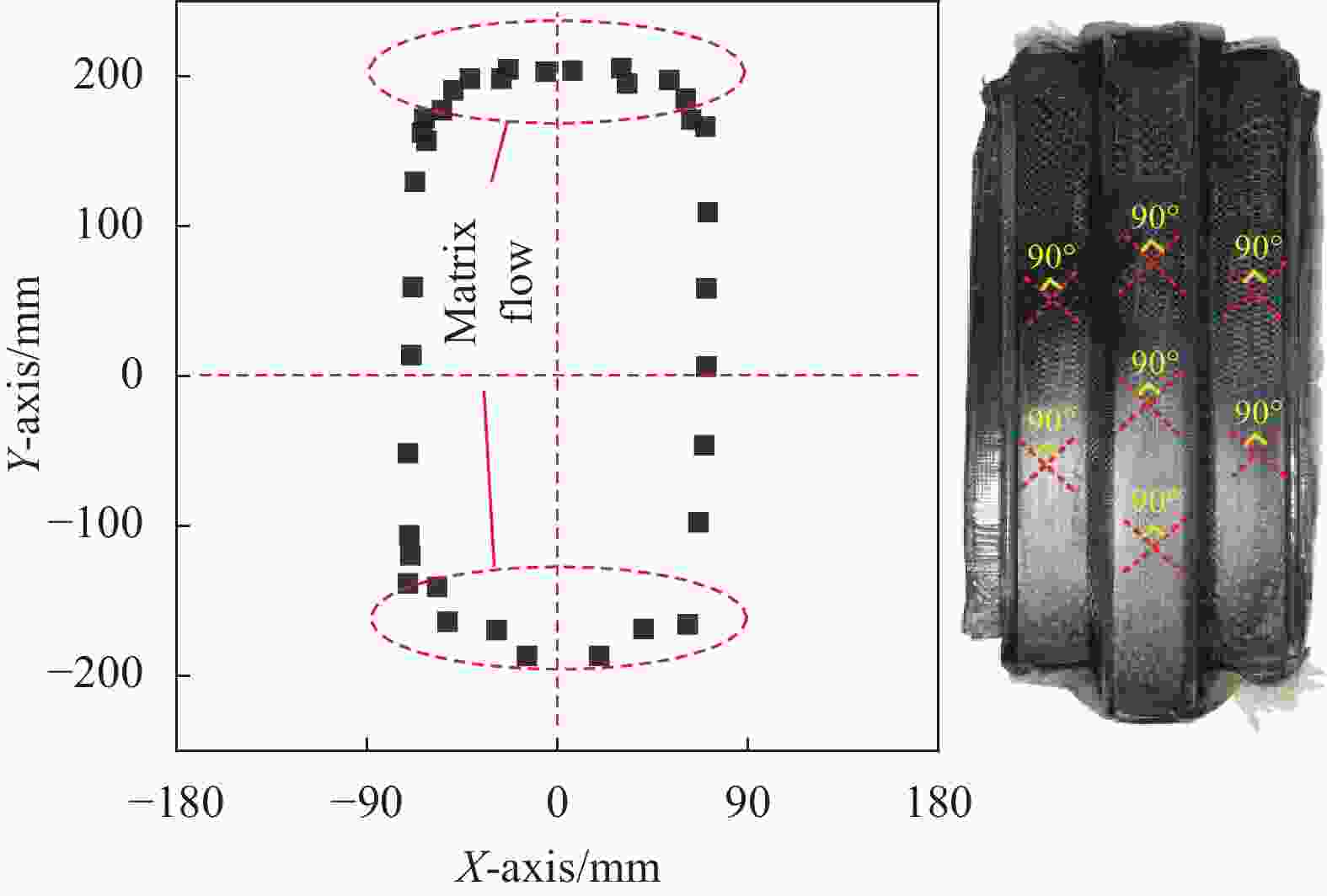

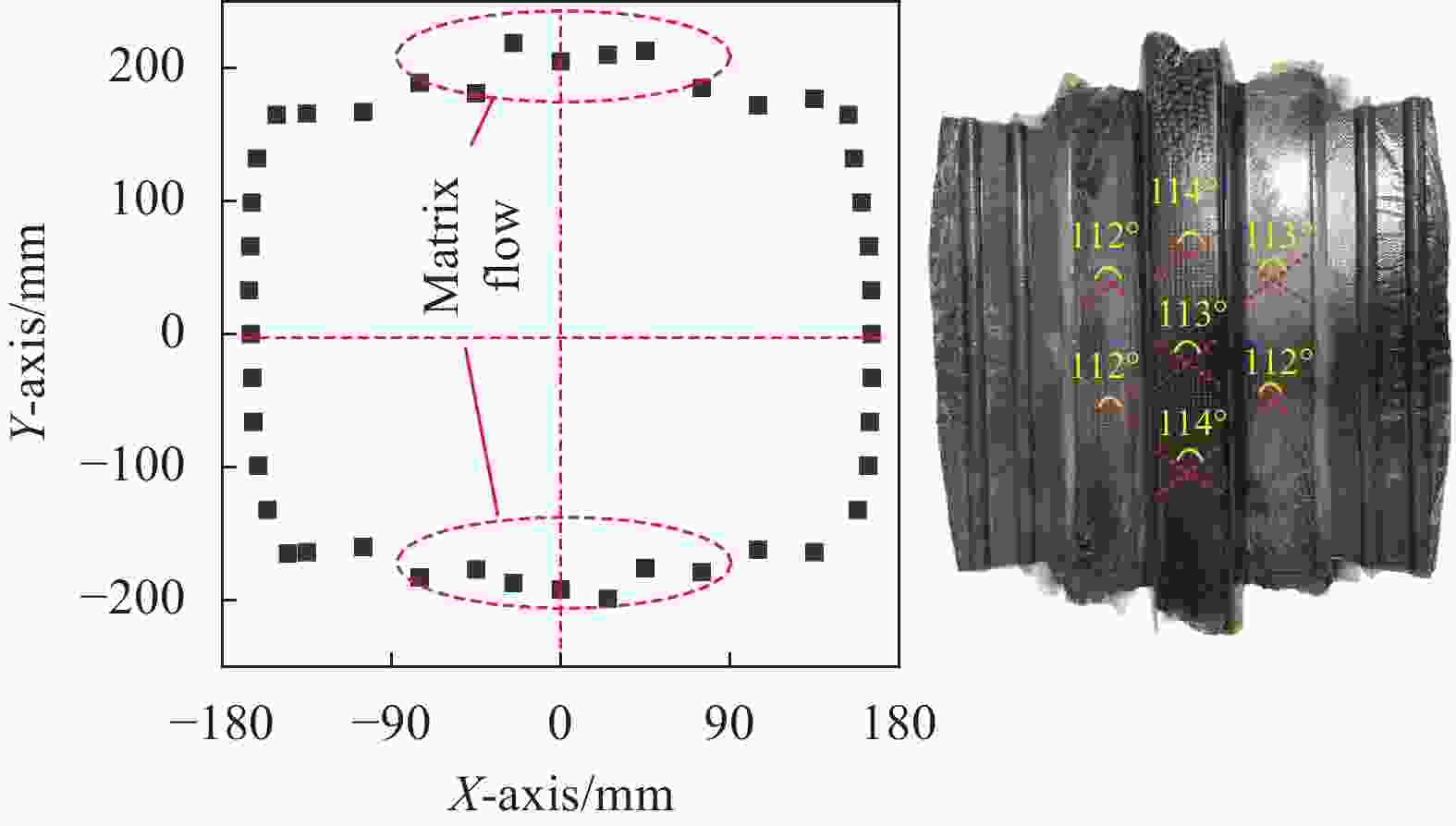

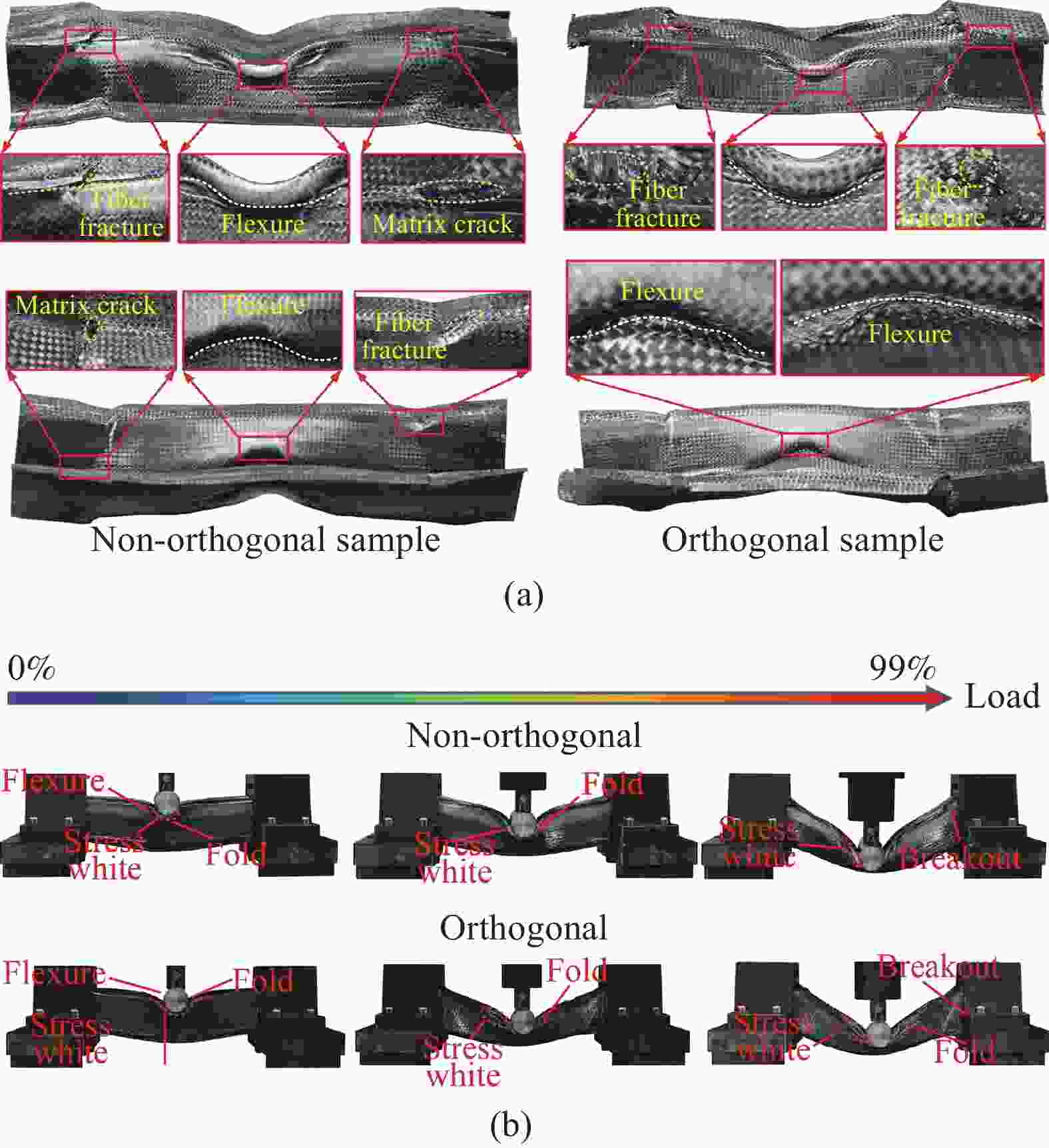

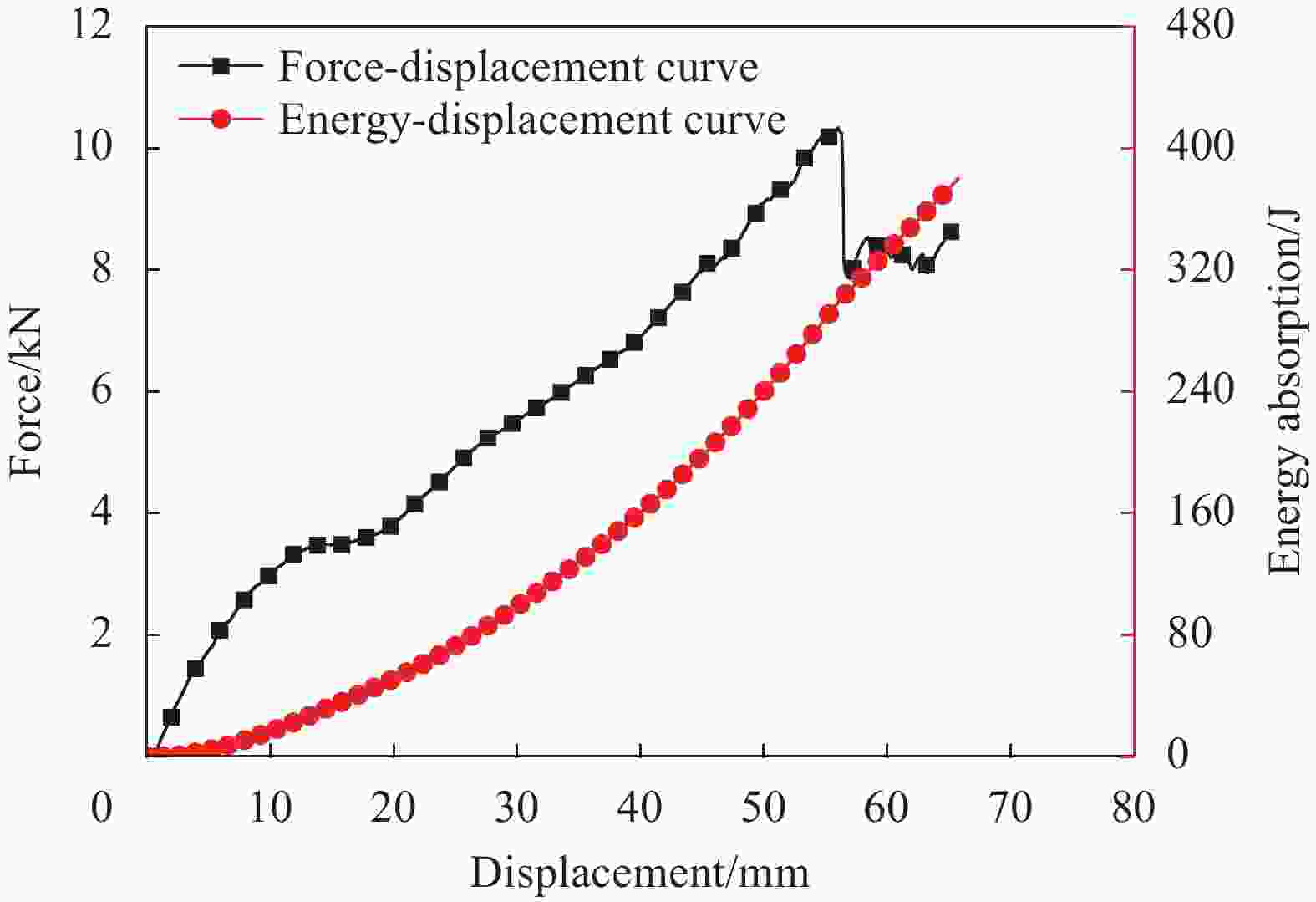

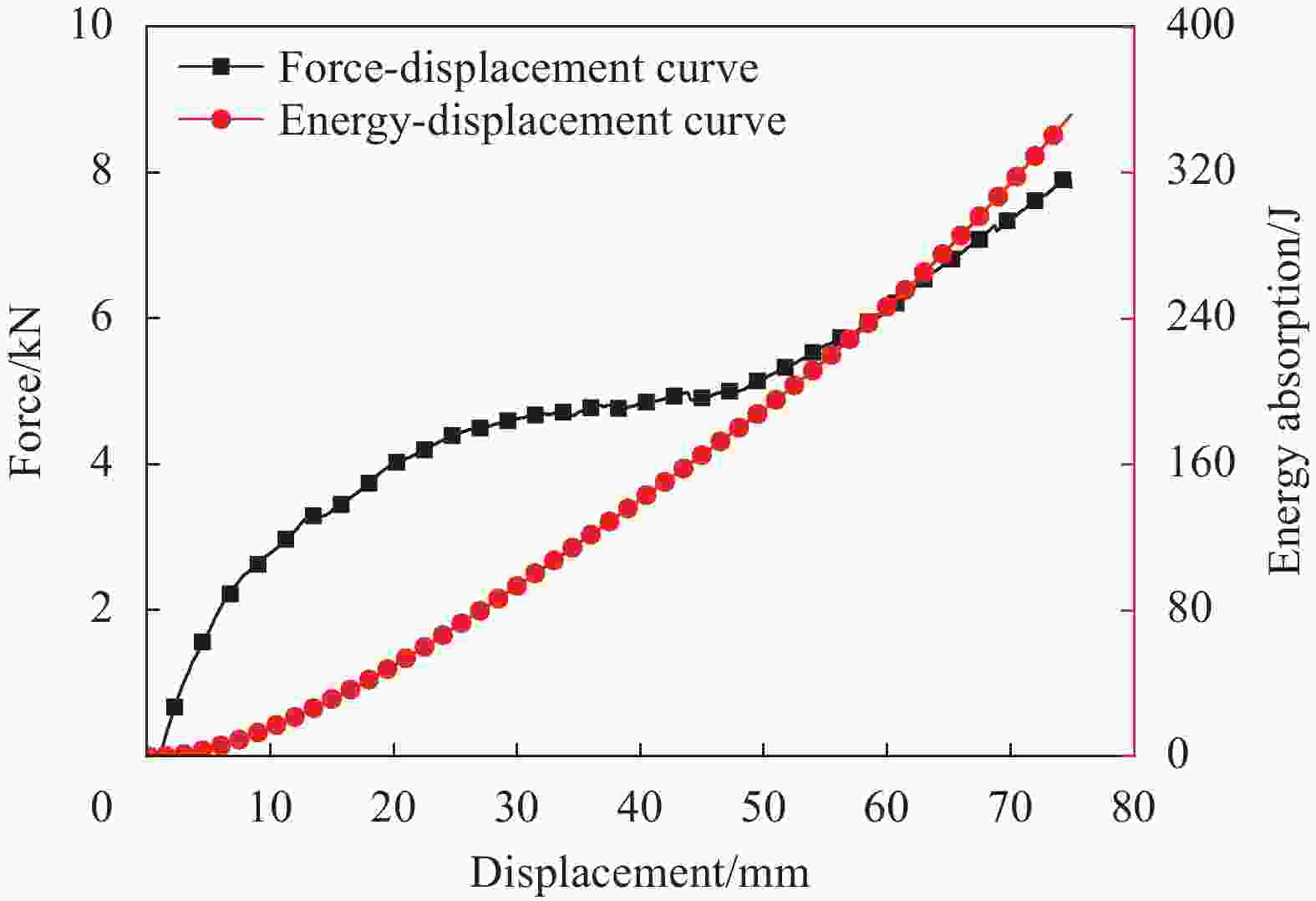

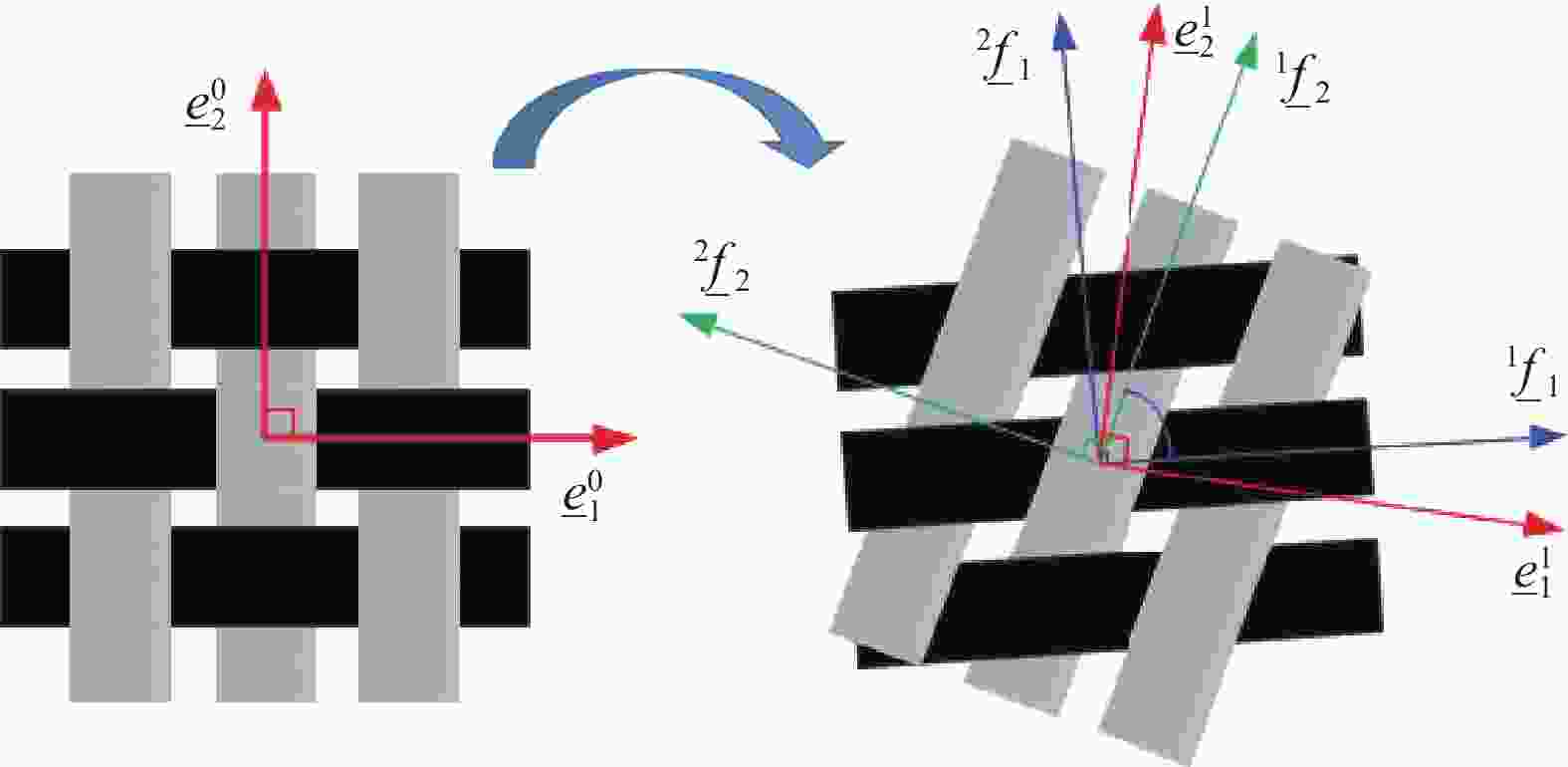

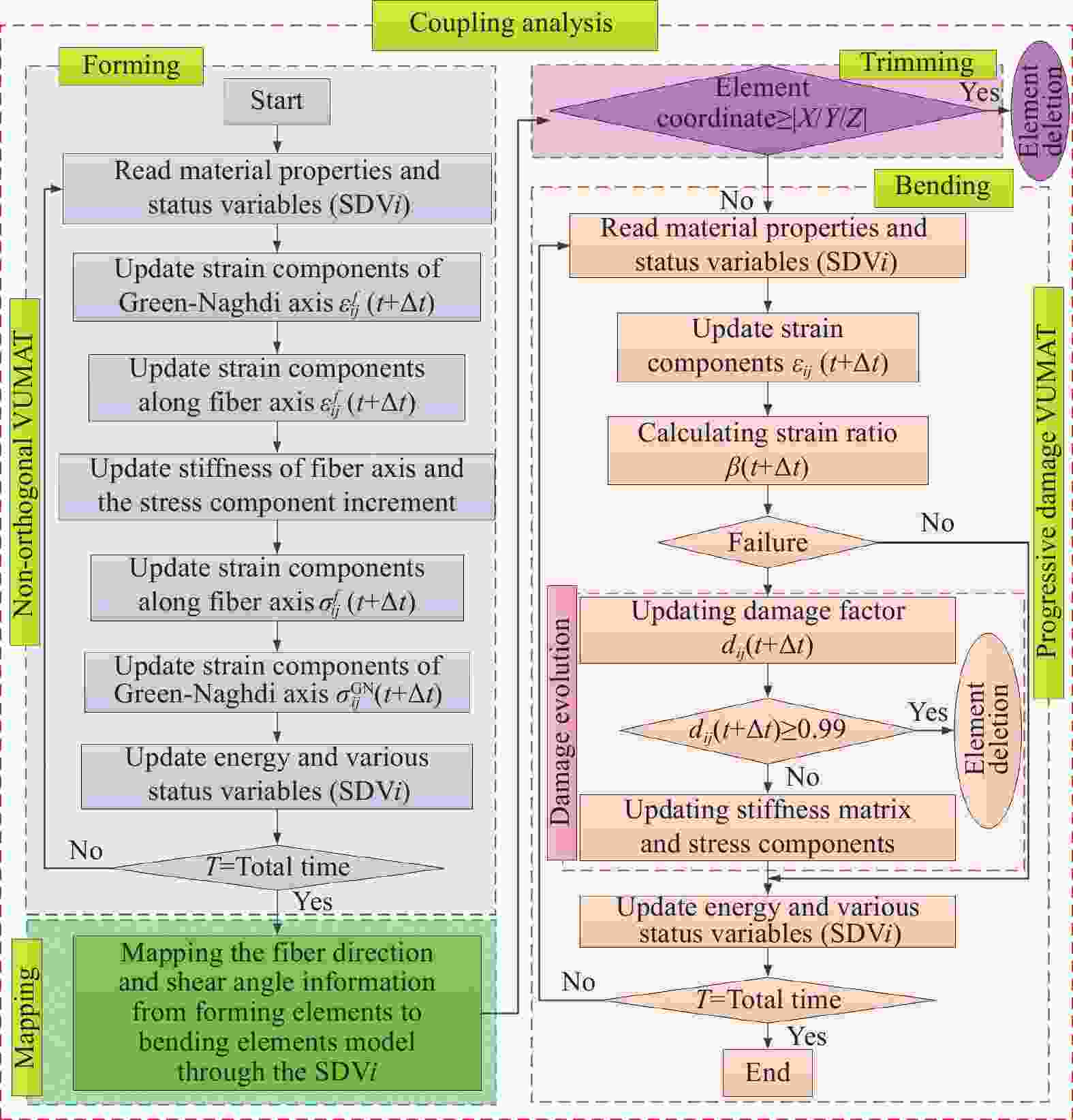

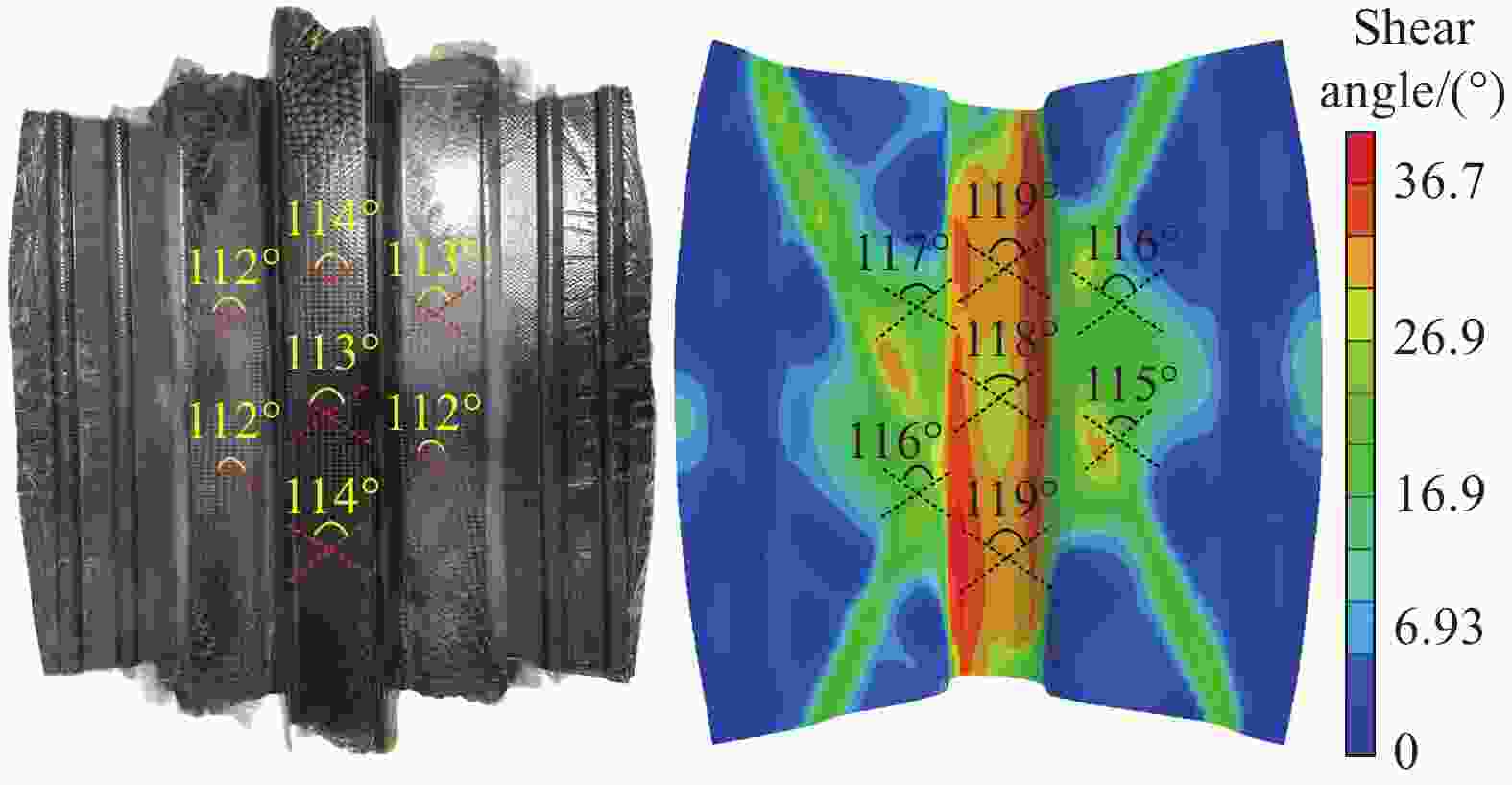

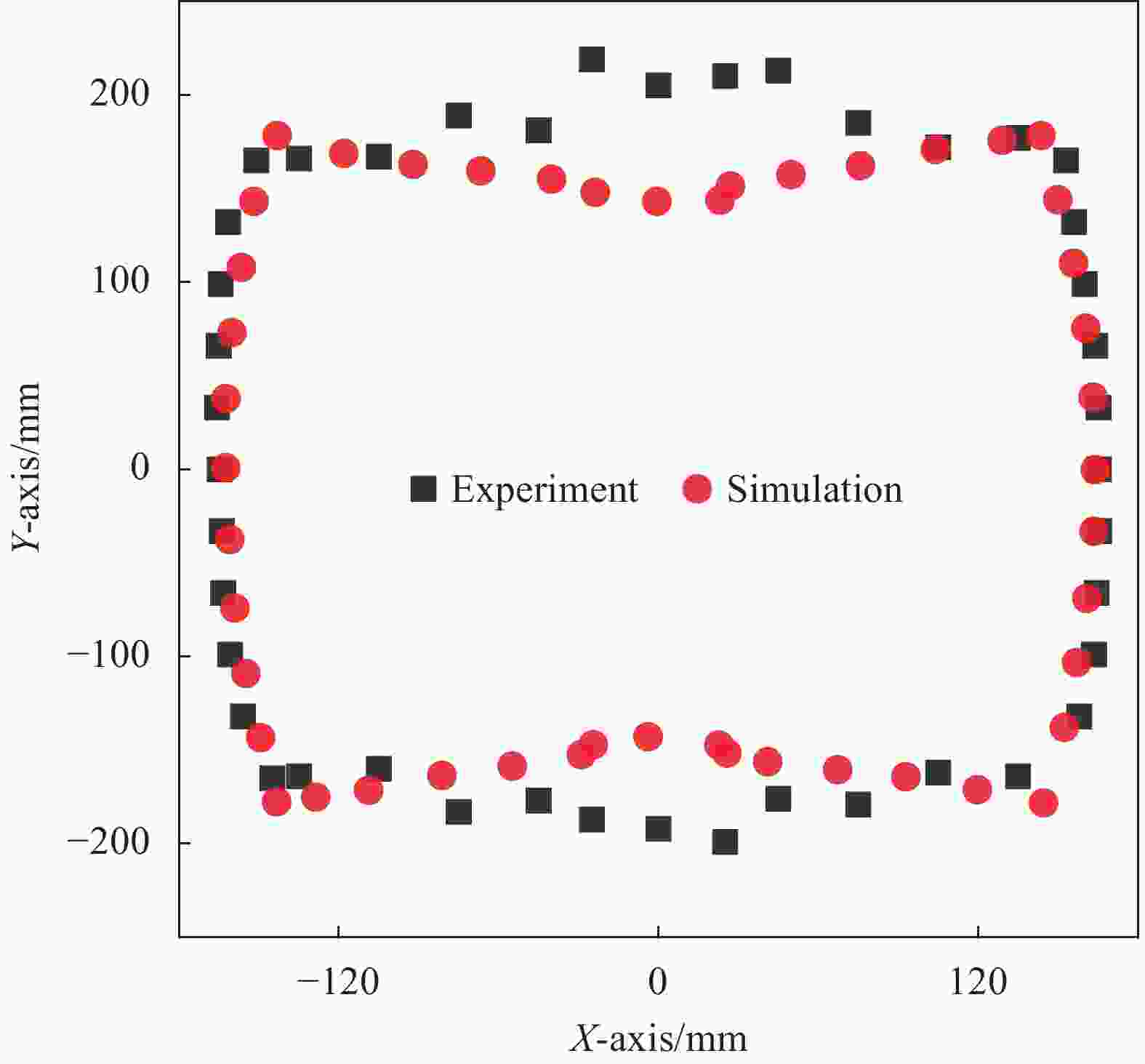

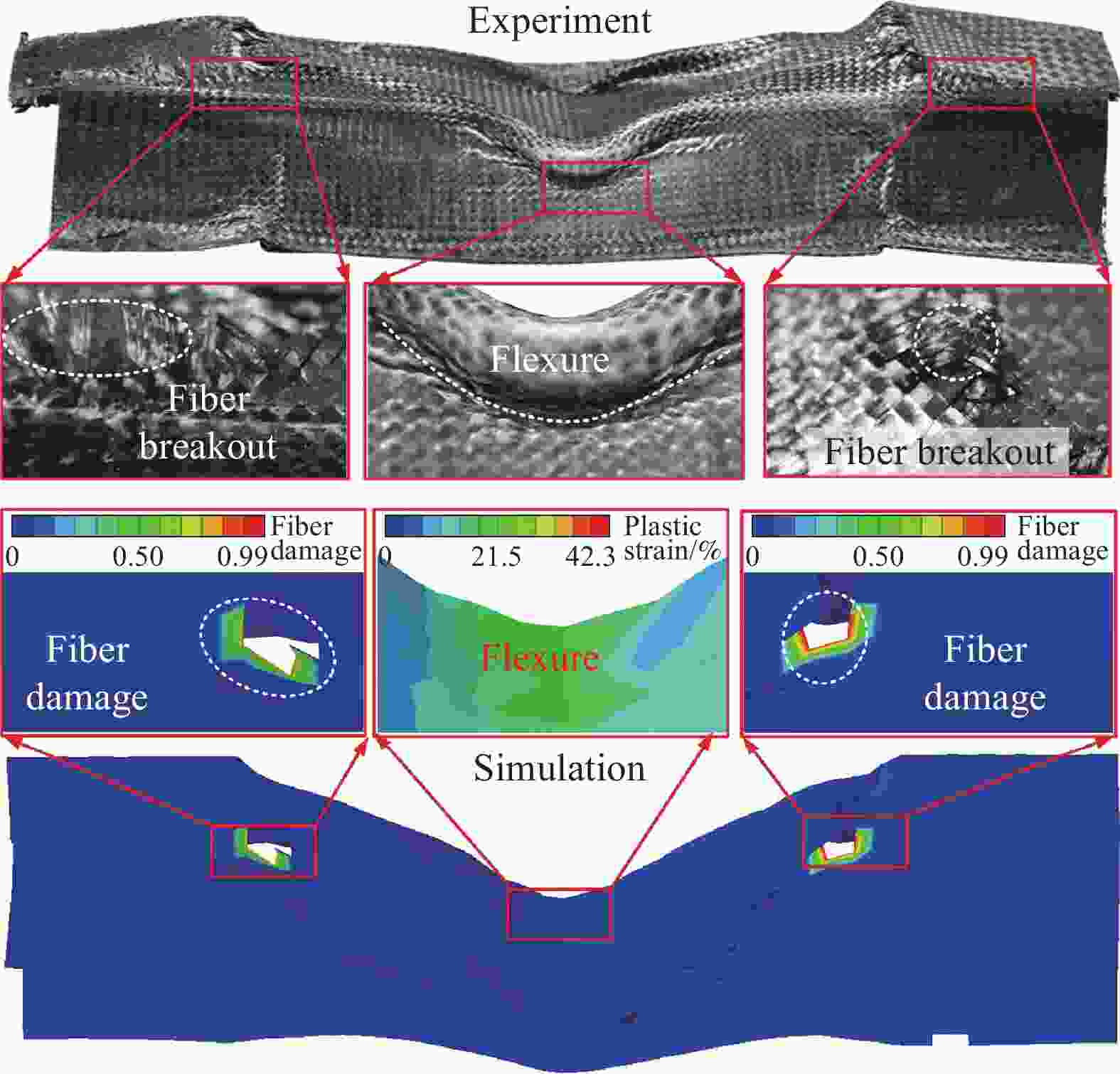

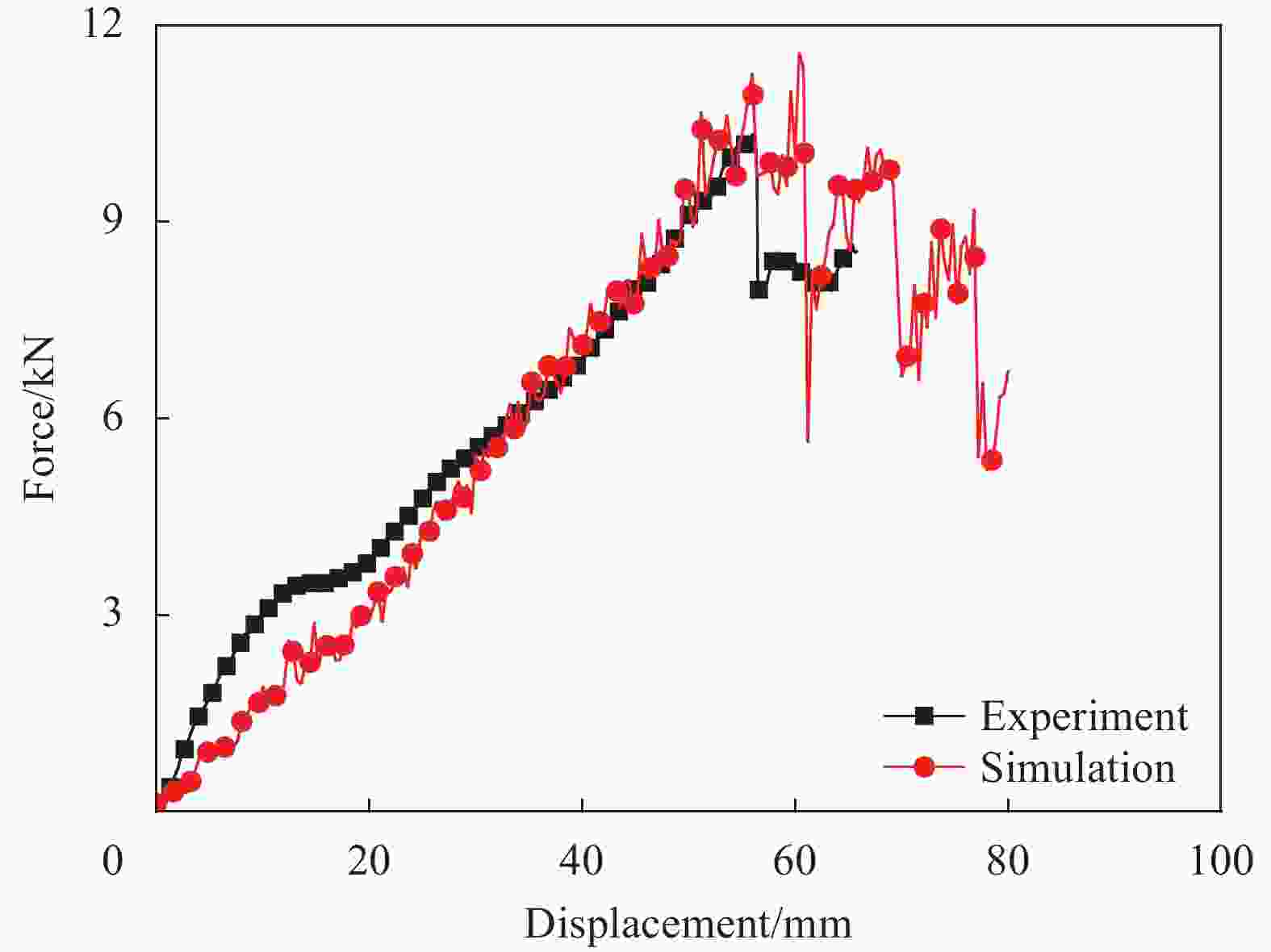

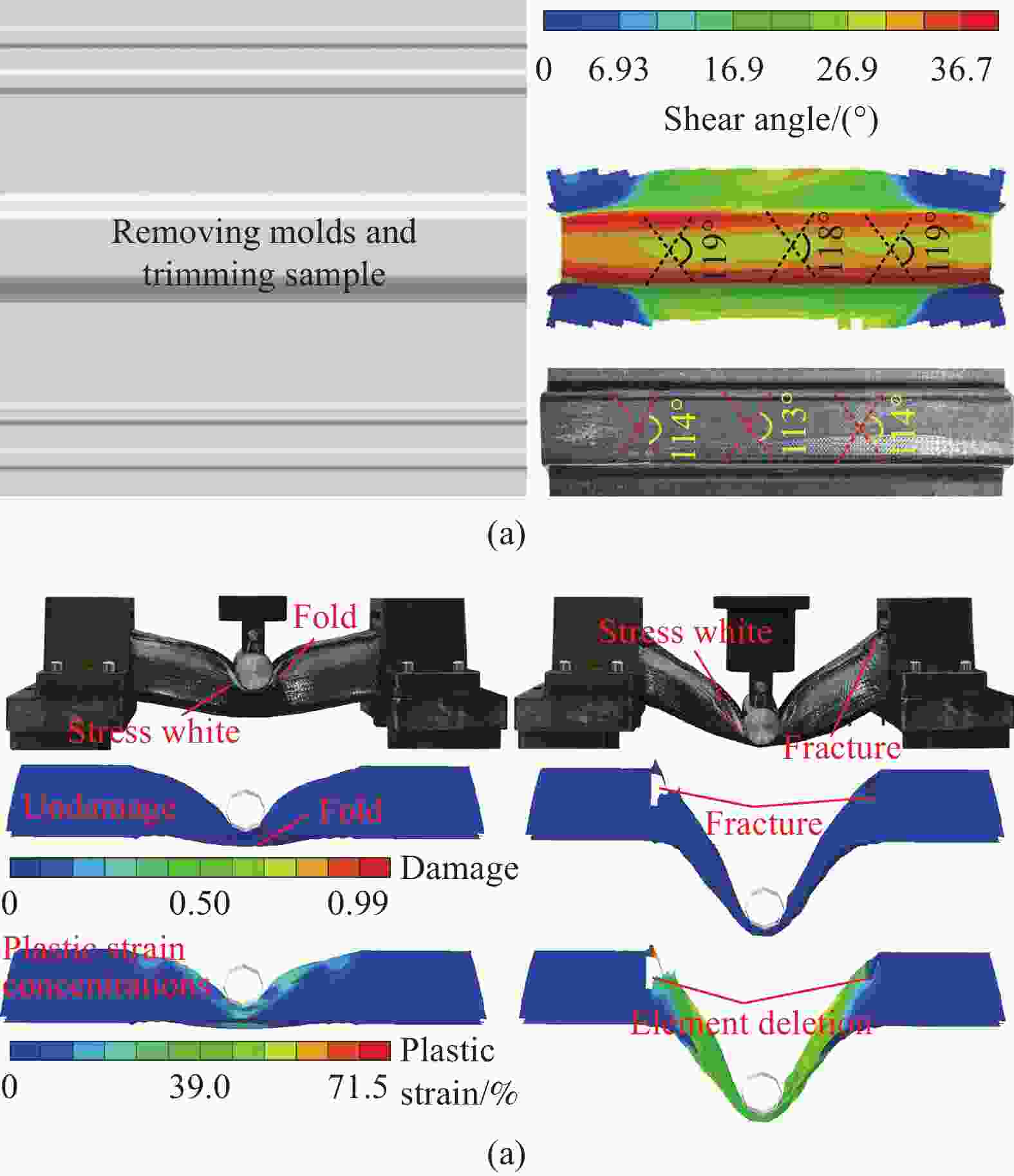

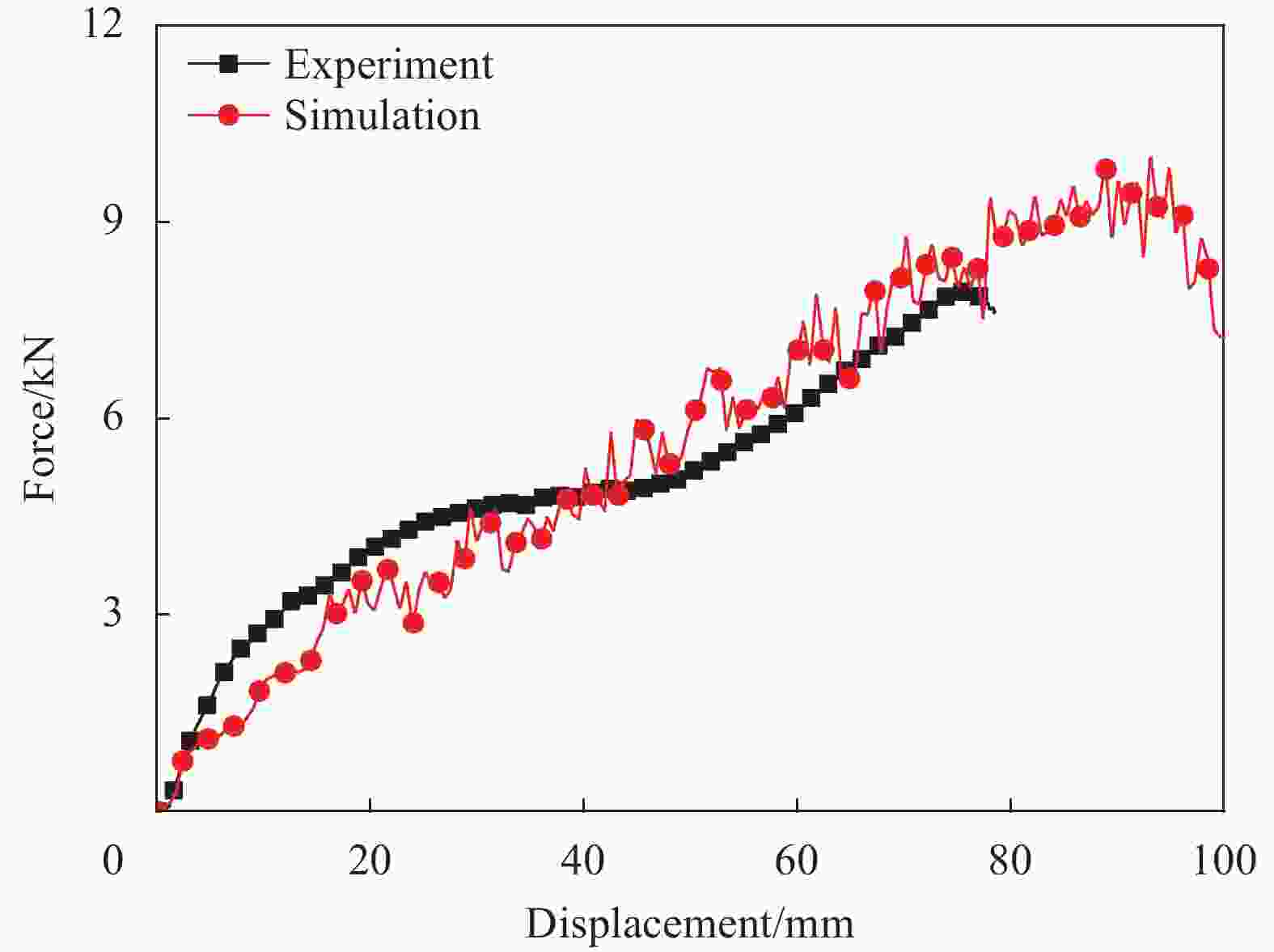

摘要: 当前复合材料车身零部件在研发过程中依然面临着制造工艺与结构性能孤立分析的难题,开发平纹织物纤维增强热塑性复合材料(Woven fabric reinforced thermoplastics, WFRTPs)的“成形-性能”耦合数值模型,对于促进WFRTPs在新能源汽车领域的产业化应用意义重大。本研究通过热模压工艺制备了两种不同纤维夹角的碳纤维增强聚丙烯(Carbon fiber reinforced polypropylene, CF/PP)薄壁管件,并对CF/PP预浸料和CF/PP层合板进行了准静态偏轴拉伸实验,对CF/PP管件进行了准静态弯曲测试,实验结果表明,由成形工艺引发的织物纤维夹角增加将导致CF/PP层合板剪切强度降低和失效应变增加,进一步造成CF/PP管件在弯曲工况下峰值载荷减小和失效位移增加。开发了CF/PP预浸料的次弹性成形本构模型、层合板的渐进损伤弯曲本构模型以及管件的“成形-弯曲”耦合本构模型并验证了上述本构模型的准确性,仿真结果表明,在压边力约束下制备的非正交CF/PP管件的剪切塑性应变比无压边力制备的正交试样高69%,纤维夹角的增加将显著增加CF/PP材料的塑性剪切应变,进而导致非正交CF/PP管件的弯曲失效位移显著增加。

-

关键词:

- 热塑性复合材料 /

- 碳纤维增强聚丙烯复合材料 /

- 管件 /

- 成形 /

- 三点弯曲 /

- "成形-弯曲"耦合模型

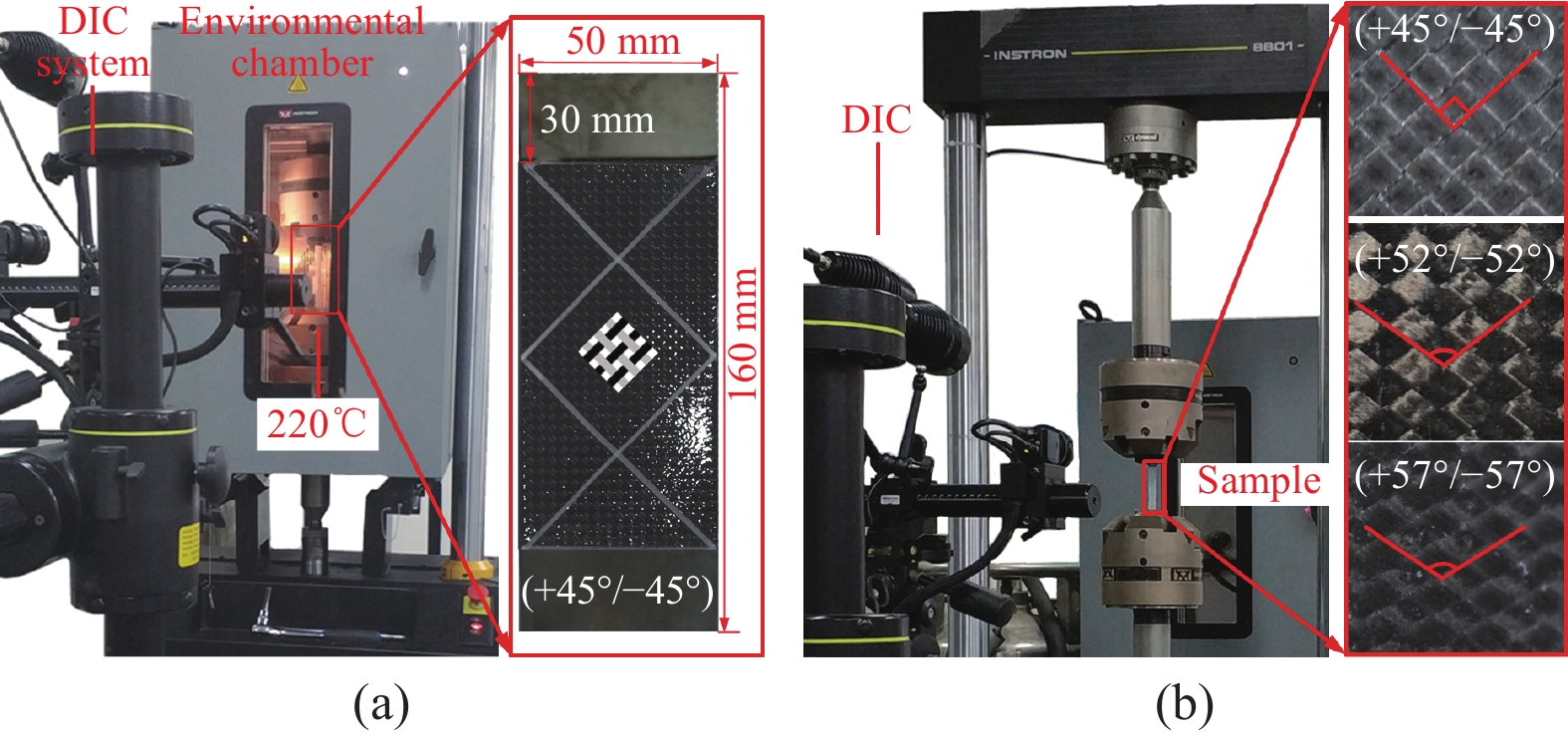

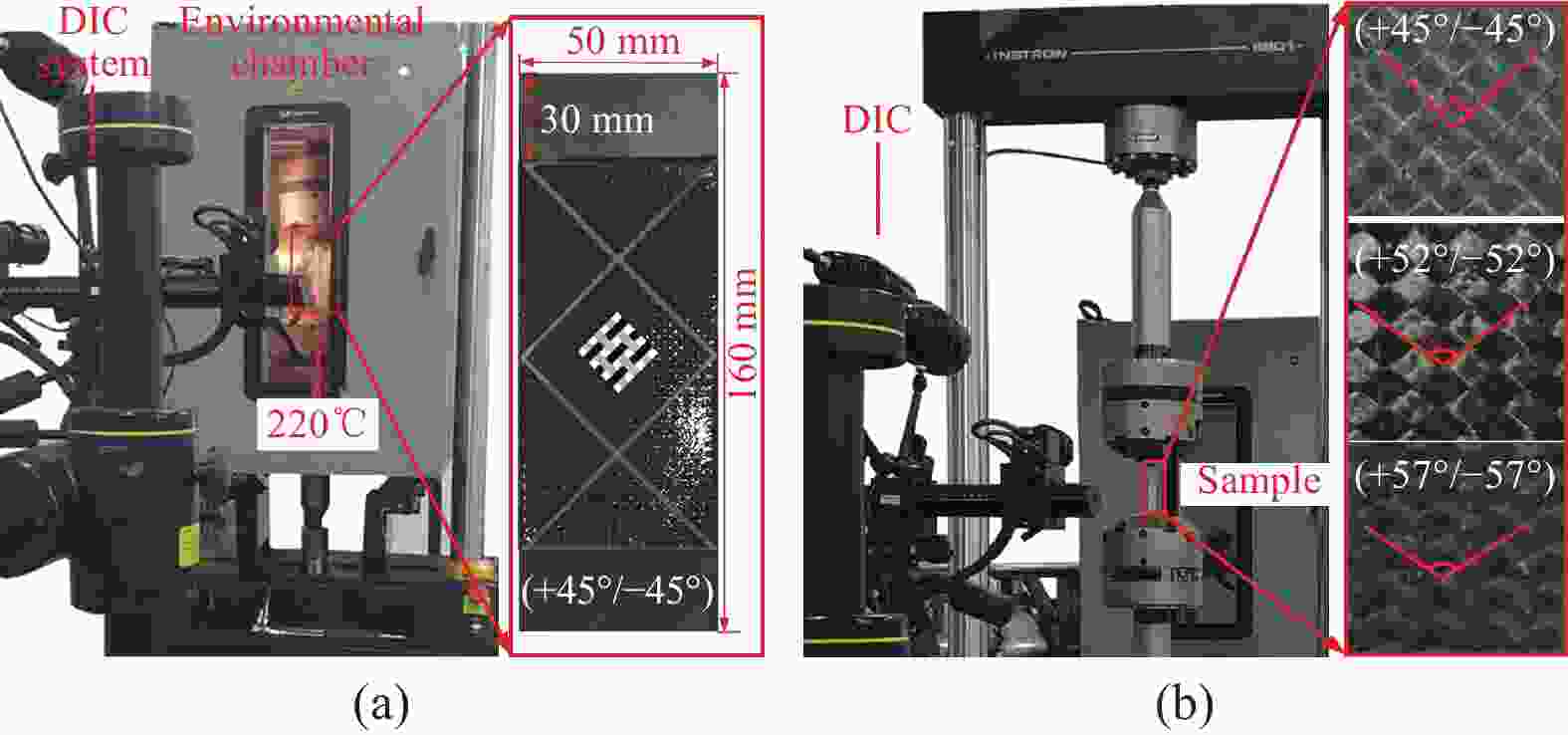

Abstract: Currently, composite automotive body components still face the challenge of isolated analysis of manufacturing process and structural performance in the research and development process, developing the “forming-performance” coupling model for woven fabric reinforced thermoplastics (WFRTPs) shows great significances to promote the industrial application of WFRTPs in the field of new energy vehicles. In this study, using the carbon fiber reinforced polypropylene (CF/PP) prepregs as the raw materials, two kinds of thin-walled CF/PP tubes with different fiber angles were manufactured by hot molding process, and the quasi-static bias-extension tests for CF/PP prepregs and CF/PP laminates, and the three-point bending tests for CF/PP tubes were preformed, and experimental results show that the increase in fabric fiber angle caused by the forming process leads to the decrease in shear strength and the increase in failure strain of the CF/PP laminates, which further results in the reduction in peak force and the increase in failure displacement of CF/PP tubes. Then, the hypoelastic forming constitutive model for CF/PP prepreg, the progressive damage bending constitutive model for CF/PP laminate and the“forming-bending” coupling constitutive model for CF/PP tube were developed and validated. The numerical results indicate that the shear plastic strain of the non-orthogonal CF/PP tube manufactured with restraints of blank holding force is 69% higher than that of the orthogonal sample without blank holding force, and the increase in fiber angle results in the significant increase in shear plastic strain, which further significantly increases the bending failure displacement of the non-orthogonal CF/PP tube. -

表 1 CF/PP层合板的力学性能

Table 1. Mechanical properties of CF/PP laminates

Sample Strength/MPa Modulus/MPa Failure strain/% Yield strength/MPa (+45°/-45°)6 41 550 79.1 11.0 (+52°/-52°)6 22 475 98.5 9.5 (+57°/-57°)6 9 435 105.6 6.5 表 2 正交试件和非正交CF/PP试件的弯曲指标对比

Table 2. Comparisons in bending indicators between orthogonal and non-orthogonal CF/PP specimens

Specimen EA/J ESA/(g·J-1) FPC/kN Orthogonal 311.97 3.22 9.77 Non-orthogonal 307.92 3.14 7.82 Notes: EA—Energy absorption; ESA—Specific energy absorption; FPC—Peak force. -

[1] 刘腾飞, 田小永, 朱伟军, 等. 连续碳纤维增强聚乳酸复合材料3D打印及回收再利用机理与性能[J]. 机械工程学报, 2019, 55(7): 128-134. doi: 10.3901/JME.2019.07.128LIU Tengfei, TIAN Xiaoyong, ZHU Weijun, et al. Mechanism and performance of 3D printing and recycling for continuous carbon fiber reinforced PLA composites[J]. Journal of Mechanical Engineering, 2019, 55(7): 128-134(in Chinese). doi: 10.3901/JME.2019.07.128 [2] 肇研, 孙铭辰, 张思益, 等. 连续碳纤维增强高性能热塑性复合材料的研究进展[J]. 复合材料学报, 2022, 39(9): 4274-4285.ZHAO Yan, SUN Mingchen, ZHANG Siyi, et al. Advance in continuous carbon fiber reinforced high performance thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4274-4285 (in Chinese). [3] LIANG B, BOISSE P. A review of numerical analyses and experimental characterization methods for forming of textile reinforcements[J]. Chinese Journal of Aeronautics, 2021, 34(8):143-163. [4] GONG Y K, SONG Z R, NING H M, et al. A comprehensive review of characterization and simulation methods for thermo-stamping of 2D woven fabric reinforced thermoplastics[J]. Composites Part B: Engineering, 2020, 203: 108462. [5] 王振, 朱国华. Al-碳纤维增强聚丙烯混合帽型梁的热模压成形特性及三点弯曲特性[J]. 复合材料学报, 2022, 39(12): 6096-6108.WANG Zhen, ZHU Guohua. Hot press molding characteristics and three-point bending characteristics of Al-carbon fiber reinforced polypropylene hybrid hat-shaped rail[J]. Acta Materiae Compositae Sinica, 2022, 39(12): 6096-6108 (in Chinese). [6] 王振, 曹悉奥, 梅轩, 等. 铝合金-碳纤维增强聚丙烯混合帽型梁热成形数值模拟[J]. 复合材料学报, 2024, 41(3): 1581-1591.WANG Zhen, CAO Xi’ao, MEI Xuan, et al. Numerical simulation of hot forming of aluminum-carbon fiber reinforced polypropylene hybrid hat-shaped rail[J]. Acta Materiae Compositae Sinica, 2024, 41(3): 1581-1591 (in Chinese). [7] 王健, 于跃, 朱伟, 等. 玻璃纤维/聚丙烯复合材料层合板拉深成型性[J]. 复合材料学报, 2018, 35(10): 2640-2650.WANG Jian, YU Yue, ZHU Wei, et al. Deep drawing formability of glass fiber/polypropylene composite laminates[J]. Acta Materiae Compositae Sinica, 2018, 35(10): 2640-2650 (in Chinese). [8] 梅鸣, 周珺晗, 韦凯. 纤维增强复合材料自动化成型中织物变形研究进展[J]. 复合材料学报, 2023, 40(5): 2507-2524.MEI Ming, ZHOU Junhan, WEI Kai. Advance of fabric deformation in automated forming of fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2507-2524 (in Chinese). [9] 李宏福, 姚瑞娟, 王会平, 等. 碳纤维/尼龙6预浸料的制备及盒体的热冲压成型工艺[J]. 复合材料学报, 2019, 36(1): 51-59.LI Hongfu, YAO Ruijuan, WANG Huiping, et al. Preparation of continuous carbon fiber/polyamide 6 prepreg and rectangular box forming by hot stamping[J]. Acta Materiae Compositae Sinica, 2019, 36(1): 51-59(in Chinese). [10] 张衡, 严飙, 龚友坤, 等. 碳纤维机织物增强热塑性树脂复合材料热冲压叠层模型[J]. 复合材料学报, 2017, 34(12): 2741-2746.ZHANG Heng, YAN Biao, GONG Youkun, et al. A lamination model for thermostamping of carbon woven fabric reinforced thermoplastic resin composites[J]. Acta Materiae Compositae Sinica, 2017, 34(12): 2741-2746(in Chinese). [11] CHEN S, HARPER L T, ENDRUWEIT A, et al. Formability optimisation of fabric preforms by controlling material draw-in through in-plane constraints[J]. Composites Part A: Applied Science and Manufacturing, 2015, 76: 10-19. doi: 10.1016/j.compositesa.2015.05.006 [12] 彭雄奇, 堵同亮, 郭早阳. 机织复合材料各向异性超弹性本构模型[J]. 机械工程学报, 2012, 48(20): 48-53. doi: 10.3901/JME.2012.20.045PENG Xiongqi, DU Tongliang, GUO Zaoyang. Anisotropic hyperelastic constitutive model for woven composite fabrics under large deformation[J]. Journal of Mechanical Engineering, 2012, 48(20): 48-53 (in Chinese). doi: 10.3901/JME.2012.20.045 [13] 鲍益东, 何瑞, 宋云鹤, 等. 二维编织碳纤维增强树脂复合材料一步法铺层展开[J]. 复合材料学报, 2022, 39(7): 3144-3155.BAO Yidong, HE Rui, SONG Yunhe, et al. One-step spreading for 2D woven carbon fiber reinforced plastics[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3144-3155(in Chinese). [14] 孔令国, 王继辉, 陈宏达, 等. 压边力对非平衡平纹机织物预制体成型作用规律[J]. 复合材料学报, 2022, 39(4): 1798-1812.KONG Lingguo, WANG Jihui, CHEN Hongda, et al. Influence of blank-holder force on the draping process of unbalanced plain woven fabric preform[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1798-1812 (in Chinese). [15] 吕柄熠, 王时玉, 校金友, 等. 基于非正交本构模型的热塑性机织物预浸料宽温域赋形褶皱缺陷仿真方法[J]. 复合材料学报, 2023, 40(4): 2355-2364.LYU Bingyi, WANG Shiyu, XIAO Jinyou, et al. A simulation method of forming wrinkle defects in thermoplastic woven fabric prepregs in a wide temperature range based on non-orthogonal constitutive model[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2355-2364 (in Chinese). [16] BORIA S, SCATTINA A, BELINGARDI G. Impact behavior of a fully thermoplastic composite[J]. Composite Structures, 2017, 167: 63-75. doi: 10.1016/j.compstruct.2017.01.083 [17] PRIEM C, OTHMAN R, ROZYCKI P, et al. Experimental investigation of the crash energy absorption of 2.5D-braided thermoplastic composite tubes[J]. Composite Structures, 2014, 116: 814-826. doi: 10.1016/j.compstruct.2014.05.037 [18] BORIA S, SCATTINA A, BELINGARDI G. Axial crushing of metal-composite hybrid tubes: Experimental analysis[J]. Procedia Structural Integrity, 2018, 8: 102-117. doi: 10.1016/j.prostr.2017.12.012 [19] 肖杰, 施涵, 余许多, 等. 碳纤维增强环氧树脂基复合材料轴管的低速冲击失效机制及剩余压缩性能[J]. 复合材料学报, 2021, 38(11):3640-3651.XIAO Jie, SHI Han, YU Xuduo, et al. Failure mechanisms and residual compression performance of carbon fiber reinforced epoxy composite shaft tubessubjected to low velocity impact[J]. Acta Materiae Compositae Sinica, 2021, 38(11):3640-3651(in Chinese). [20] 沈勇, 柯俊, 吴震宇. 不同编织角碳纤维增强聚合物复合材料-Al方管的吸能特性[J]. 复合材料学报, 2020, 37(3): 591-600.SHEN Yong, KE Jun, WU Zhenyu. Energy-absorbing characteristics of carbon fiber reinforced polymer composite-Al square tubes with different braiding angles[J]. Acta Materiae Compositae Sinica, 2020, 37(3): 591-600(in Chinese). [21] NAJAFI A, RAIS-ROHANI M. Sequential coupled process-performance simulation and multi-objective optimization of thin-walled tubes[J]. Materials & Design, 2012, 41: 89-98. [22] NAJAFI A, ACAR E, RAIS-ROHANI M. Multi-objective robust design of energy-absorbing components using coupled process–performance simulations[J]. Engineering Optimization, 2014, 46(2): 146-164. doi: 10.1080/0305215X.2012.753437 [23] KÄRGER L, BERNATH A, FRITZ F, et al. Development and validation of a CAE chain for unidirectional fibre reinforced composite components[J]. Composite Structures, 2015, 132: 350-358. doi: 10.1016/j.compstruct.2015.05.047 [24] CAO J, AKKERMAN R, BOISSE P, et al. Characterization of mechanical behavior of woven fabrics: Experimental methods and benchmark results[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(6): 1037-1053. doi: 10.1016/j.compositesa.2008.02.016 [25] 朱国华, 成艾国, 王振, 等. 电动车轻量化复合材料车身骨架多尺度分析[J]. 机械工程学报, 2016, 52(6): 145-152. doi: 10.3901/JME.2016.06.145ZHU Guohua, CHENG Aiguo, WANG Zhen, et al. Analysis of lightweight composite body structure for electrical vehicle using the multiscale approach[J]. Journal of Mechanical Engineering, 2016, 52(6): 145-152(in Chinese). doi: 10.3901/JME.2016.06.145 [26] 宋凯, 王振, 朱国华, 等. 单向碳纤维复合材料锥管轴向吸能特性研究[J]. 振动与冲击, 2018, 37(7): 172-178.SONG Kai, WANG Zhen, ZHU Guohua, et al. Axial energy absorption characteristics of unidirectional carbon-fiber composite cone tubes[J]. Journal of Vibration and Shock, 2018, 37(7): 172-178(in Chinese). [27] WANG Z, XIE H, LUO Q T, et al. Optimizaition for formability of plain woven carbon fiber fabrics[J]. International Journal of Mechanical Sciences, 2021, 197: 106318. doi: 10.1016/j.ijmecsci.2021.106318 [28] WANG Z, ZHANG W W, LUO Q T, et al. A novel failure criterion based upon forming limit curve for thermoplastic composites[J]. Composites Part B: Engineering, 2020, 202: 108320. doi: 10.1016/j.compositesb.2020.108320 [29] XIAO J R, GAMA B A, GILLESPIE J W. Progressive damage and delamination in plain weave S-2 glass/SC-15 composites under quasi-static punch-shear loading[J]. Composite Structures, 2007, 78(2): 182-196. doi: 10.1016/j.compstruct.2005.09.001 [30] KIM N H. Introduction to nonlinear finite element analysis[M]. New York: Springer New York, 2014: -

下载:

下载: