Experimental investigation on discreteness of quasi-static and dynamic compressive strength of recycled aggregate concrete

-

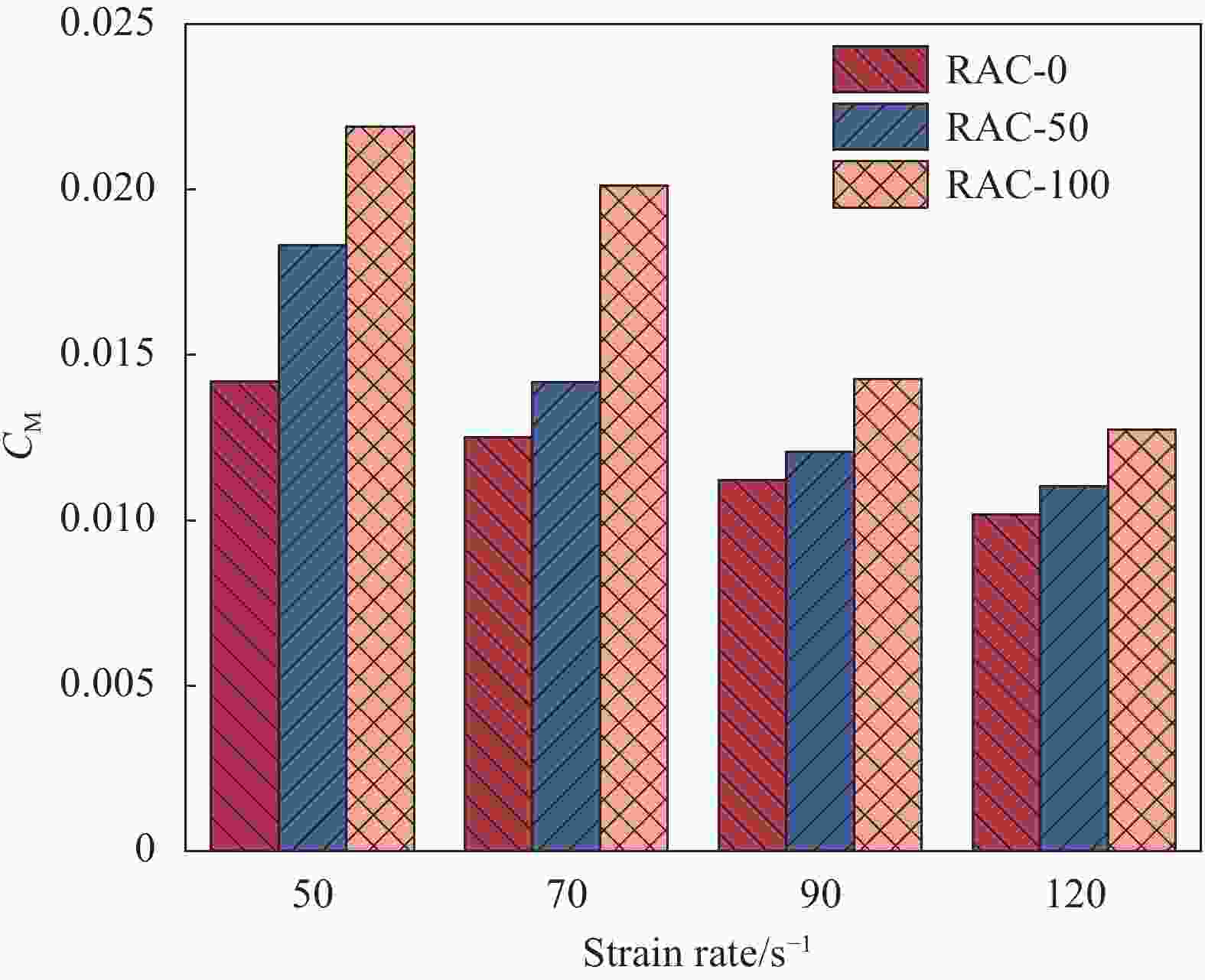

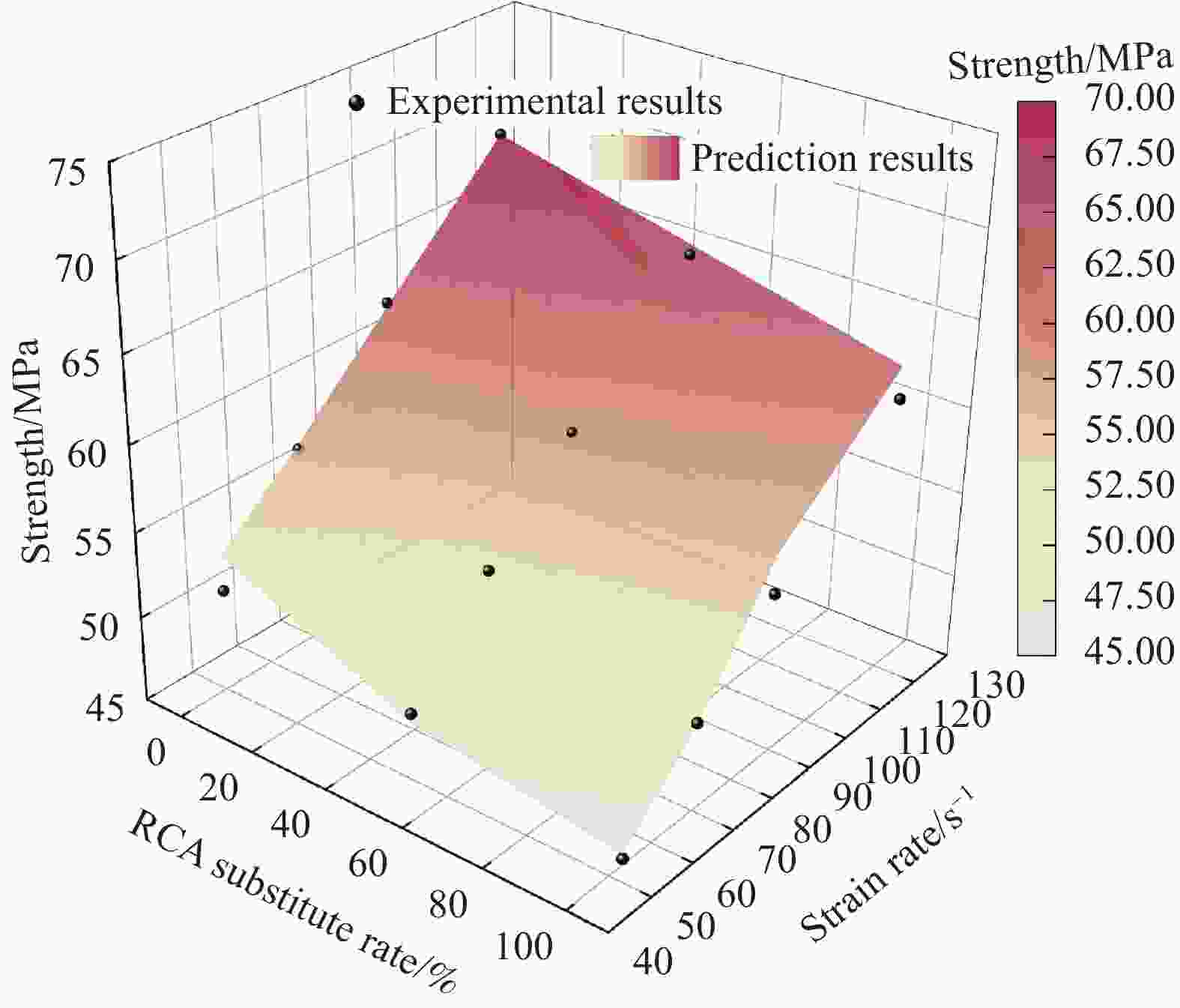

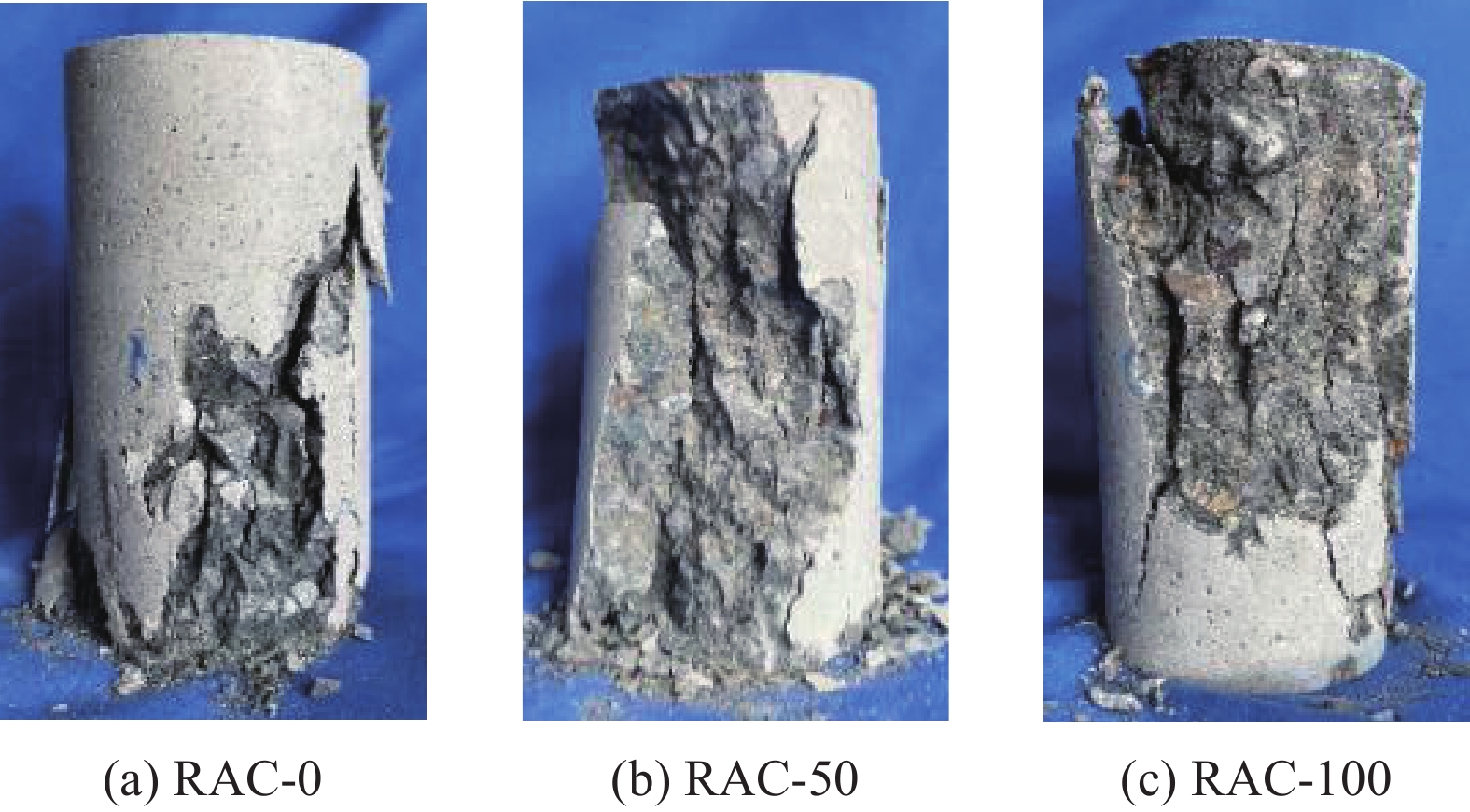

摘要: 为研究再生粗骨料(RCA)替代率和应变率对再生粗骨料混凝土(RAC)抗压强度离散性的影响,制备了3种不同RCA替代率的RAC (0%、50%、100%),分别进行准静态压缩及霍普金森压杆(SHPB)试验,于概率统计分析理论,对RAC抗压强度结果进行分析讨论。结果表明:准静态压缩下,RAC抗压强度离散程度随RCA替代率增加变化不显著,但表现出先增加后减小的趋势;SHPB试验应变率为50~120 s−1时,受RCA替代率和应变率的共同影响,同一应变率下RAC动态抗压强度离散程度随RCA替代率增加而增加,同一RCA替代率下RAC动态抗压强度离散程度随应变率增加逐渐减小。此外,对传统Weibull分布模型引入替代率和应变率参数进行修正,考虑到抗压强度离散性可能影响结构设计的安全性,提出了在任意保证率下具有不同RCA替代率的RAC动态抗压强度预测公式。Abstract: To explore the influence of the substitute rate of recycled coarse aggregate (RCA) and strain rate on the discreteness of the compressive strength of recycled aggregate concrete (RAC), RAC specimens with three different RCA substitute rates were prepared for both quasi-static compression and split Hopkinson pressure bar (SHPB) tests. The test results show that despite the limited change in the discreteness of compressive strength of RAC with increasing RCA substitution rate, it still tends to initially increase and then decrease as the RCA substitution rate increases. The results of the SHPB test indicate that both the RCA substitute rate and the strain rate exert a significant influence on the variability of the dynamic compressive strength of RAC. The dynamic compressive strength discreteness of RAC with the same RCA substitute rate gradually decreases with increasing strain rate, while it increases with increasing RCA substitute rate under the same strain rate. In addition, the traditional Weibull distribution model was modified by introducing the parameters of RCA substitute rate and strain rate, and a dynamic compressive strength prediction formula for RAC with different RCA substitute rates at any given probability level was proposed.

-

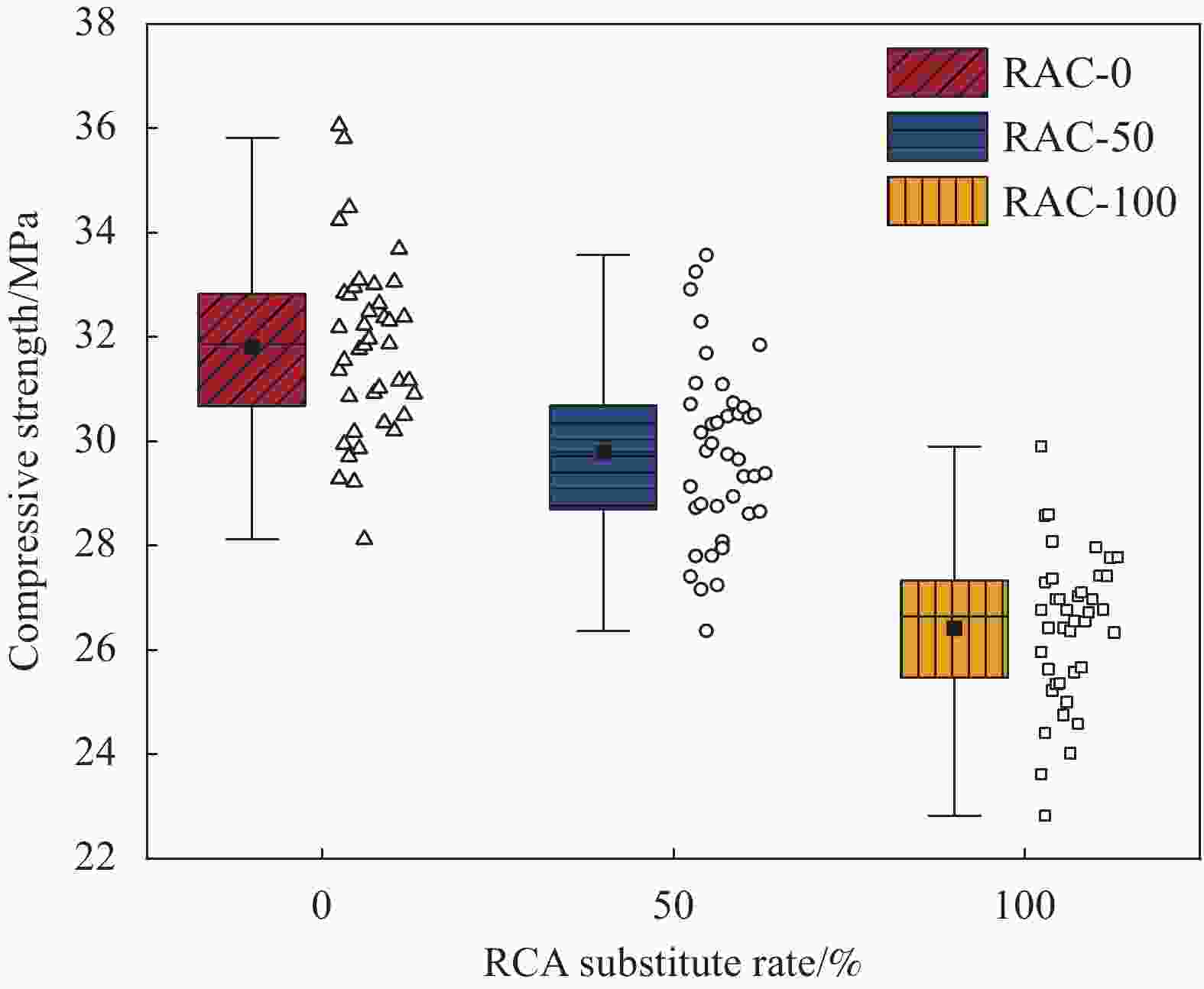

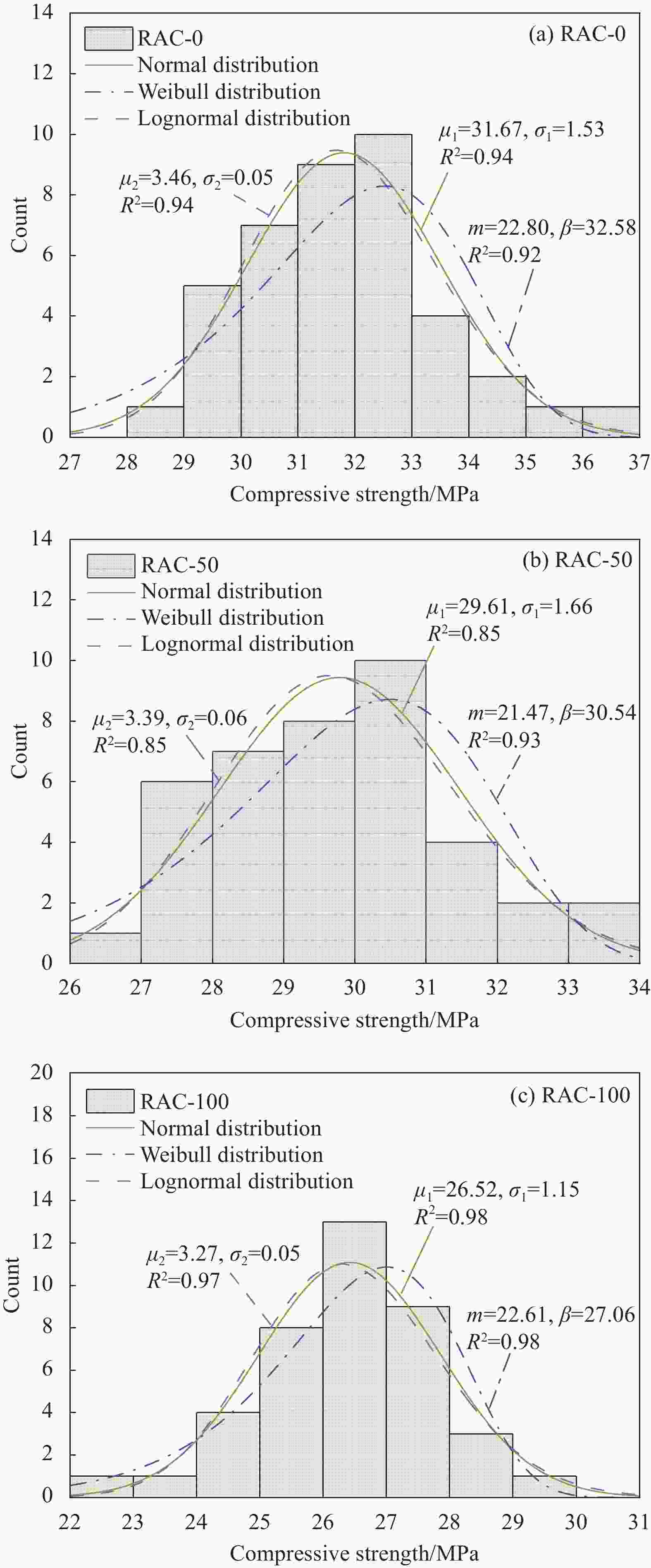

图 5 准静态压缩试验下RAC抗压强度分布图

Figure 5. Distribution of compressive strength of RAC under quasi-static compression

μ1, σ1—Mean and standard deviation of the normal distribution; m, β—Shape and scale parameters of the Weibull distribution; μ2, σ2—Location and scale parameters of the lognormal distribution; R2—Goodness of fit

表 1 普通硅酸盐水泥 P·O 42.5的矿物成分

Table 1. Mineral components of ordinary Portland cement P·O 42.5

Al2O3/wt% SiO2/wt% Fe2O3/wt% CaO/wt% SO3/wt% R2O/wt% MgO/wt% Other/wt% 4.42 21.65 2.61 62.93 2.27 0.83 2.92 2.37 Note: R2O—Basic oxide ( Na2O, K2O). 表 2 粗骨料性能指标

Table 2. Performance index of coarse aggregates

Aggregate type Gradation/mm Apparent density/(kg·m−3) Crush index/% Mortar content/% Water absorption/% NCA 5-12.5 2814 8.8 0 0.40 RCA 5-12.5 2640 17.7 34 3.85 Notes: NCA—Natural coarse aggregate; RCA—Recycled coarse aggregate. 表 3 试验配合比 (kg/m3)

Table 3. Mix design proportions of tests (kg/m3)

Specimen Cement Sand NCA RCA Water Extra water RAC-0 462.5 596.09 1156.41 0 185 0 RAC-50 462.5 596.09 578.21 578.21 185 17.35 RAC-100 462.5 596.09 0 1156.41 185 34.69 Notes: RAC-0, RAC-50, RAC-100—Recycled aggregate concrete (RAC) with 0%, 50%, 100% substitute rate of recycled coarse aggregate, respectively. 表 4 准静态压缩下RAC抗压强度Weibull参数

Table 4. Weibull parameters for compressive strength of RAC under quasi-static compression

Specimen Linear fitting equation

Y=aX+bWeibull parameter E(σ)/MPa S/MPa C K-S

goodness-of-testa b R2 m β Dn Dnα RAC-0 22.80 79.43 0.92 22.80 32.58 31.817 1.737 0.054 0.103 0.215 RAC-50 21.47 73.41 0.93 21.47 30.54 29.783 1.723 0.058 0.104 RAC-100 22.61 74.55 0.98 22.61 27.06 26.415 1.454 0.055 0.069 Notes: E(σ)—Mathematical expectation; S—Variance; C—Dispersion coefficient; K-S—Kolmogorov-Smirnov; a, b—Slope and intercept of the linear fitting equation; Dn—Maximum deviation; Dnα—Critical values for n data at a confidence level of α. 表 5 不同保证率下的RAC抗压强度

Table 5. Compressive strength of RAC at different levels of reliability

Specimen σmean/MPa σ0.75/MPa σ0.85/MPa σ0.95/MPa RAC-0 31.82 30.85 30.09 28.60 RAC-50 29.78 28.82 28.06 25.47 RAC-100 26.42 25.61 24.97 22.77 Notes: σmean—Mean compressive strength; σ0.75, σ0.85, σ0.95—Compressive strength with a guarantee of 0.75, 0.85, 0.95, respectively. 表 6 SHPB试验下RAC抗压强度修正Weibull参数

Table 6. Modified Weibull parameters for compressive strength of RAC in SHPB test

Specimen Strain

rate/s−1Fitting curve Modified Weibull parameter R2 EM(σ)/

MPaSM/

MPaCM K-S goodness-of-test Dn Dnα m β η δ RAC-0 50.4 Y=10.62X−42.67 10.62 13.53 −3.79 1.5 0.92 52.20 0.74 0.014 0.099 0.215 68.0 Y=11.05X−45.18 11.05 13.89 −3.82 0.97 57.06 0.71 0.012 0.111 89.1 Y=11.46X−47.85 11.46 14.37 −3.85 0.98 62.11 0.70 0.011 0.095 117.3 Y=12.08X−51.68 12.07 15.48 −3.90 0.98 69.20 0.70 0.010 0.094 RAC-50 50.8 Y=8.34X−32.79 8.34 13.05 −2.94 0.94 49.23 0.85 0.018 0.135 68.7 Y=10.15X−40.66 10.15 13.36 −3.43 0.97 53.13 0.75 0.014 0.123 88.6 Y=10.88X−44.93 10.88 14.30 −3.62 0.92 60.70 0.73 0.012 0.087 118.2 Y=11.86X−50.07 11.86 15.43 −3.72 0.96 66.03 0.73 0.011 0.134 RAC-100 53.2 Y=7.19X−27.95 7.19 12.66 −2.53 0.96 45.37 0.96 0.022 0.119 70.5 Y=8.12X−32.24 8.12 13.99 −2.62 0.94 49.47 1.00 0.020 0.095 89.2 Y=10.55X−43.06 10.55 14.73 −3.35 0.97 56.23 0.80 0.014 0.142 121.3 Y=11.24X−47.02 11.24 15.84 −3.42 0.98 62.86 0.80 0.013 0.073 Notes: EM(σ), SM, and CM—Mathematical expectation, variance, and dispersion coefficient based on the modified model; η—Strain rate effect parameter; δ—Substitute rate parameter. -

[1] 杜修力, 韩亚强, 金浏, 等. 骨料空间分布对混凝土压缩强度及软化曲线影响统计分析[J]. 水利学报, 2015, 46(6): 631-639.DU Xiuli, HAN Yaqiang, JIN Liu, et al. Statistical investigation on effects of aggregate distribution on concrete compression strength and the descending part of stress-strain curve[J]. Journal of Hydraulic Engineering, 2015, 46(6): 631-639(in Chinese). [2] GUNEYISI E, GESOGLU M, KAREEM Q, et al. Effect of different substitution of natural aggregate by recycled aggregate on performance characteristics of pervious concrete[J]. Materials and Structures, 2016, 49(1-2): 521-536. doi: 10.1617/s11527-014-0517-y [3] 王俊辉, 黄悦, 杨国涛, 等. 再生混凝土抗压性能研究进展[J]. 材料导报, 2022, 36(S1): 278-286.WANG Junhui, HUANG Yue, YANG Guotao, et al. Research progress on compressive properties of recycled aggregate concrete[J]. Materials Reports, 2022, 36(S1): 278-286(in Chinese). [4] 商效瑀, 杨经纬, 李江山. 基于CT图像的再生混凝土细观破坏裂纹分形特征[J]. 复合材料学报, 2020, 37(7): 1774-1784.SHANG Xiaoyu, YANG Jingwei, LI Jiangshan. Fractal characteristics of meso-failure crack in recycled coarse aggregate concrete based on CT image[J]. Acta Materiae Compositae Sinica, 2020, 37(7): 1774-1784(in Chinese). [5] XIAO J Z. Recycled aggregate concrete structures[M]. Berlin: Springer-Verlag, 2018: 144-146. [6] GUO J L, CHEN Q J, CHEN W S, et al. Tests and numerical studies on strain-rate effect on compressive strength of recycled aggregate concrete[J]. Journal of Materials in Civil Engineering, 2019, 31(11): 04019281. doi: 10.1061/(ASCE)MT.1943-5533.0002937 [7] LU Y B, CHEN X, TENG X, et al. Dynamic compressive behavior of recycled aggregate concrete based on split Hopkinson pressure bar tests[J]. Latin American Journal of Solids and Structures, 2014, 11(1): 131-141. doi: 10.1590/S1679-78252014000100008 [8] XIAO J Z, LI L, SHEN L M, et al. Compressive behaviour of recycled aggregate concrete under impact loading[J]. Cement and Concrete Research, 2015, 71: 46-55. doi: 10.1016/j.cemconres.2015.01.014 [9] 陈海霞, 宋学庆. 再生骨料混凝土强度离散性试验研究[J]. 西安科技大学学报, 2021, 41(2): 290-297. doi: 10.13800/j.cnki.xakjdxxb.2021.0213CHEN Haixia, SONG Xueqing. Experimental study on the strength dispersion of recycled aggregates concrete[J]. Journal of Xi'an University of Science and Technology, 2021, 41(2): 290-297(in Chinese). doi: 10.13800/j.cnki.xakjdxxb.2021.0213 [10] 赵雨, 刘元珍, 王文婧, 等. 再生粗骨料取代率对再生保温混凝土抗压强度离散性影响[J]. 科学技术与工程, 2017, 17(13): 275-279. doi: 10.3969/j.issn.1671-1815.2017.13.051ZHAO Yu, LIU Yuanzhen, WANG Wenjing, et al. Influence of recycled coare aggregate replacement rate on the discreteness of the compressire strength of recycled aggregate thermal insulation concrete[J]. Science Technology and Engineering, 2017, 17(13): 275-279(in Chinese). doi: 10.3969/j.issn.1671-1815.2017.13.051 [11] 全国混凝土标准化技术委员会. 混凝土用再生粗骨料: GB/T 25177—2010[S]. 北京: 中国标准出版社, 2010.National Technical Committee 458 on Concrete of Standardization Administration of China. Recycled coarse aggregate for concrete: GB/T 25177—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [12] 鲍玖文, 李树国, 张鹏, 等. 再生粗骨料硅烷浸渍处理对混凝土介质传输性能的影响[J]. 复合材料学报, 2020, 37(10): 2602-2609. doi: 10.13801/j.cnki.fhclxb.20200316.002BAO Jiuwen, LI Shuguo, ZHANG Peng, et al. Effect of recycled coarse aggregate after strengthening by silane impregnation on mass transport of concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(10): 2602-2609(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200316.002 [13] 王礼立. 应力波基础[M]. 北京: 国防工业出版社, 2005: 52-54.WANG Lili. Foundation of stess waves[M]. Beijing: National Defense Industry Press, 2005: 52-54(in Chinese). [14] 王兴国, 姜茂林, 陈旭, 等. 不同预浸骨料-PVA纤维对再生混凝土力学性能的影响[J]. 复合材料学报, 2022, 39(3): 1205-1214.WANG Xingguo, JIANG Maolin, CHEN Xu, et al. Effect of different pre-soaked aggregate-PVA fiber on the mechanical properties of recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1205-1214(in Chinese). [15] 李为民, 许金余, 沈刘军, 等. 玄武岩纤维混凝土的动态力学性能[J]. 复合材料学报, 2008(2): 135-142. doi: 10.3321/j.issn:1000-3851.2008.02.023LI Weimin, XU Jinyu, SHEN Liujun, et al. Dynamic mechanical properties of basalt fiber reinforced concrete using a split Hopkinson pressure bar[J]. Acta Materiae Compositae Sinica, 2008(2): 135-142(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.023 [16] ZHOU H Y, ZHOU H Z, WANG X J, et al. Static size effect of recycled coarse aggregate concrete: Experimental study, meso-scale simulation, and theoretical analysis[J]. Structures, 2021, 34: 2996-3012. doi: 10.1016/j.istruc.2021.09.050 [17] PAJAK M, JANISZEWSKI J. Influence of aggregate and recycled steel fibres on the strain rate sensitivity of mortar and concrete[J]. Construction and Building Materials, 2023, 363: 129855. doi: 10.1016/j.conbuildmat.2022.129855 [18] 谢友均, 王猛, 马昆林, 等. 不同养护温度下蒸养混凝土的冲击性能[J]. 建筑材料学报, 2020, 23(3): 521-528, 536.XIE Youjun, WANG Meng, MA Kunlin, et al. Impact mechanical characteristics of steam cured concrete under different curing temperatures[J]. Journal of Building Materials, 2020, 23(3): 521-528, 536(in Chinese). [19] 王国盛, 路德春, 杜修力. 混凝土材料真实动态强度及率效应机理研究[J]. 工程力学, 2018, 35(6): 58-67.WANG Guosheng, LU Dechun, DU Xiuli, et al. Research on the actual dynamic strength and the rate effect mechanisms for concrete materials[J]. Engineering Mechanics, 2018, 35(6): 58-67. [20] 王海龙, 李庆斌. 不同加载速率下饱和混凝土的劈拉试验研究及强度变化机理[J]. 工程力学, 2007, 24(2): 105-109. doi: 10.3969/j.issn.1000-4750.2007.02.018WANG Hailong, LI Qingbin. Experiments on saturated concrete under different splitting tensile rate and mechanism on strength change[J]. Engineering Mechanics, 2007, 24(2): 105-109(in Chinese). doi: 10.3969/j.issn.1000-4750.2007.02.018 [21] LU D C, DU X L, WANG G S, et al. A three-dimensional elastoplastic constitutive model for concrete[J]. Computers & Structures, 2016, 163(8): 41-55. [22] 白卫峰, 李思蕾, 管俊峰, 等. 再生混凝土的单轴压缩动态力学性能[J]. 建筑材料学报, 2022, 25(5): 498-508. doi: 10.3969/j.issn.1007-9629.2022.05.009BAI Weifeng, LI Silei, GUAN Junfeng, et al. Dynamic mechanical properties of recycled concrete in uniaxial compression[J]. Journal of Building Materials, 2022, 25(5): 498-508(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.05.009 [23] 金浏, 韩亚强, 杜修力. 混凝土单轴动态拉伸强度随机性的统计特性分析[J]. 振动与冲击, 2016, 35(24): 6-13, 26.JIN Liu, HAN Yaqiang, DU Xiuli. Statistical investigationon the randomness of uniaxial dynamic tensile strengths of concrete[J]. Journal of Vibration and Shock, 2016, 35(24): 6-13, 26(in Chinese). [24] 李佳彬, 肖建庄, 黄健. 再生粗骨料取代率对混凝土抗压强度的影响[J]. 建筑材料学报, 2006, 9(3): 297-301. doi: 10.3969/j.issn.1007-9629.2006.03.008LI Jiabin, XIAO Jianzhuang, HUANG Jian. Influence of recycled coarse aggregate replacement percentages on compressive strength of concrete[J]. Journal of Building Materials, 2006, 9(3): 297-301(in Chinese). doi: 10.3969/j.issn.1007-9629.2006.03.008 [25] 孔祥清, 何文昌, 邢丽丽, 等. 钢纤维-聚丙烯纤维混杂对再生混凝土抗冲击性能的影响[J]. 复合材料学报, 2020, 37(7): 1763-1773.KONG Xiangqing, HE Wenchang, XING Lili, et al. Effect of steel fiber-polypropylene fiber hybrid additon on impact resistance of recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2020, 37(7): 1763-1773(in Chinese). [26] 韩旭旭, 张程煜, 陈博, 等. 2D-SiCf/SiC复合材料抗拉强度统计分布规律[J]. 复合材料学报, 2019, 36(2): 434-440.HAN Xuxu, ZHANG Chengyu, CHEN Bo, et al. Statistical distribution of tensile strength of a 2D-SiCf/SiC composite[J]. Acta Materiae Compositae Sinica, 2019, 36(2): 434-440(in Chinese). [27] VU C C, HO N K, PHAM T A. Weibull statistical analysis and experimental investigation of size effects on the compressive strength of concrete-building materials[J]. Case Studies in Construction Materials, 2022, 17: e01231. doi: 10.1016/j.cscm.2022.e01231 [28] PETTITT A N, STEPHENS M A. The Kolmogorov-Smirnov goodness-of-fit statistic with discrete and grouped data[J]. Technometrics, 1977, 19(2): 205-210. doi: 10.1080/00401706.1977.10489529 [29] XU J S, HE X X. Size effect on the strength of a concrete member[J]. Engineering Fracture Mechanics, 1990, 35(4-5): 687-695. doi: 10.1016/0013-7944(90)90151-6 [30] 肖建庄, 雷斌, 袁飚. 不同来源再生混凝土抗压强度分布特征研究[J]. 建筑结构学报, 2008(5): 94-100. doi: 10.3321/j.issn:1000-6869.2008.05.012XIAO Jianzhuang, LEI Bin, YUAN Biao. Compressive strength distribution of recycled aggregate concrete derived from different origins[J]. Journal of Building Structures, 2008(5): 94-100(in Chinese). doi: 10.3321/j.issn:1000-6869.2008.05.012 [31] CHEN X D, WU S X, ZHOU J K. Compressive strength of concrete cores under high strain rates[J]. Journal of Performance of Constructed Facilities, 2015, 29(1): 06014005. doi: 10.1061/(ASCE)CF.1943-5509.0000586 [32] 骆开静. 高性能再生混凝土动态力学特性及应变率效应研究[D]. 北京: 中国矿业大学(北京), 2018.LUO Kaijing. The research on dynamic mechanical characteristics of high performance recycled concrete and strain rate effect[D]. Beijing: China University of Mining and Technology (Beijing), 2018(in Chinese). -

下载:

下载: