Effect of bolt preload on bearing response of single-lap, countersunkcomposite bolted joints

-

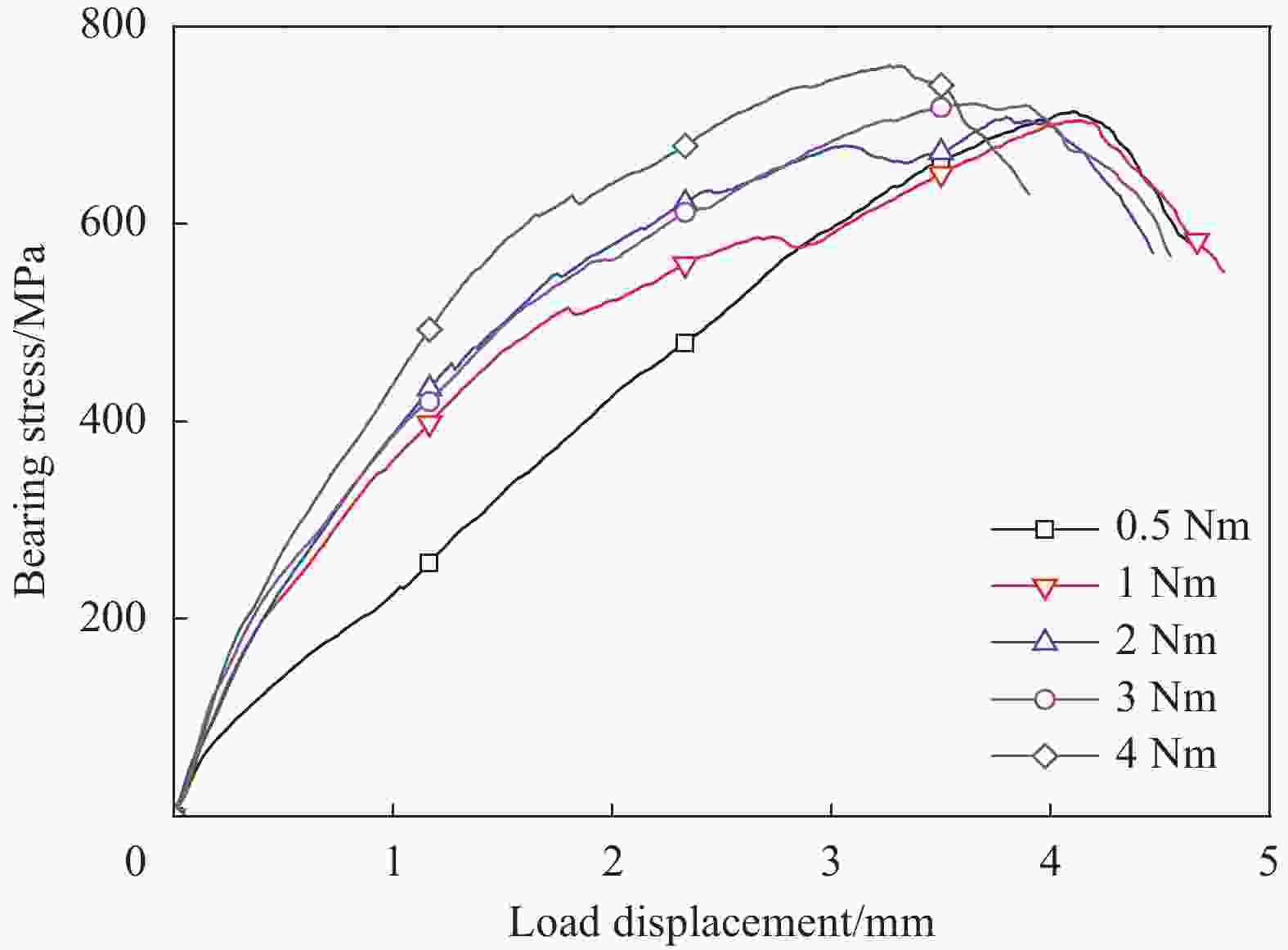

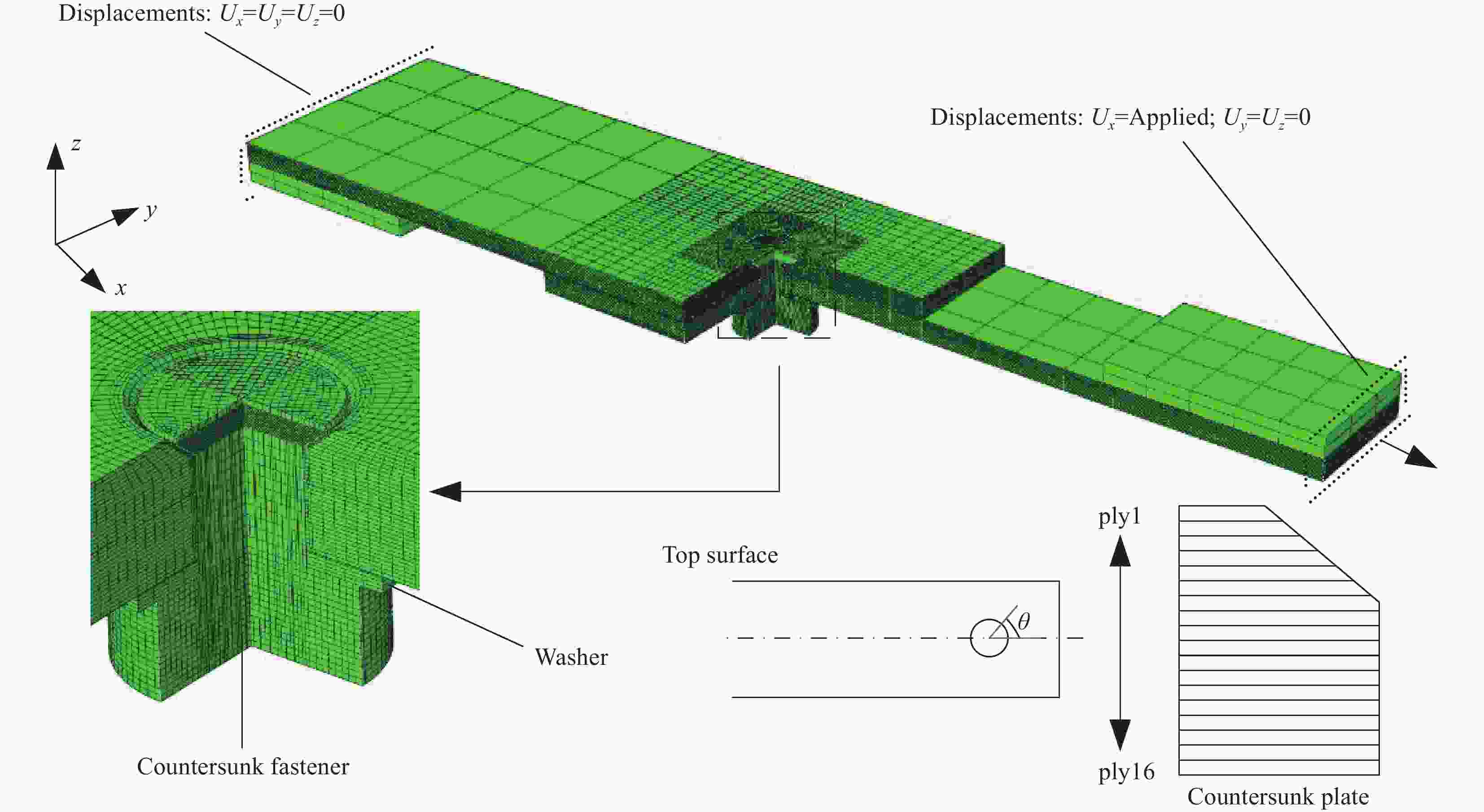

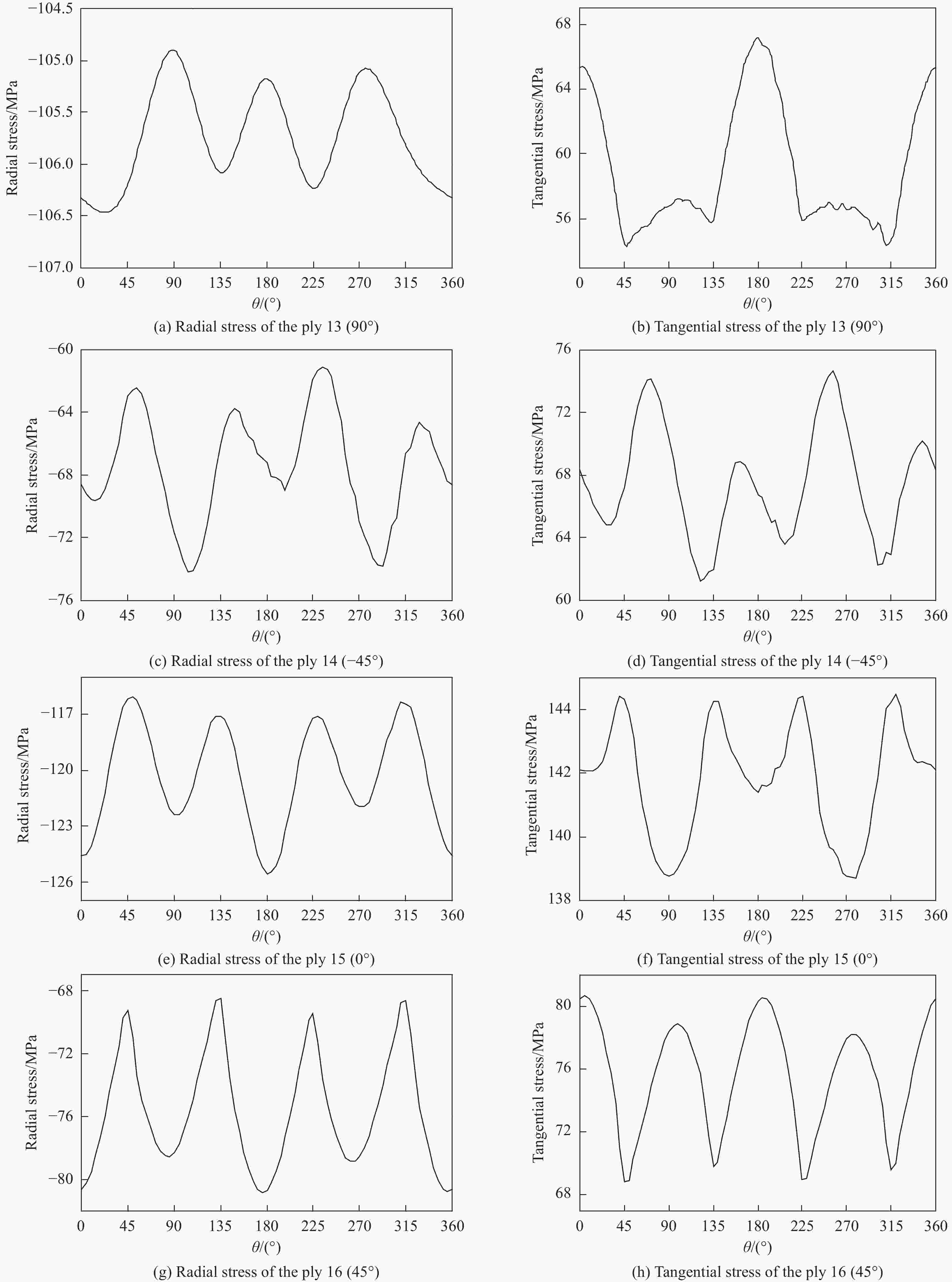

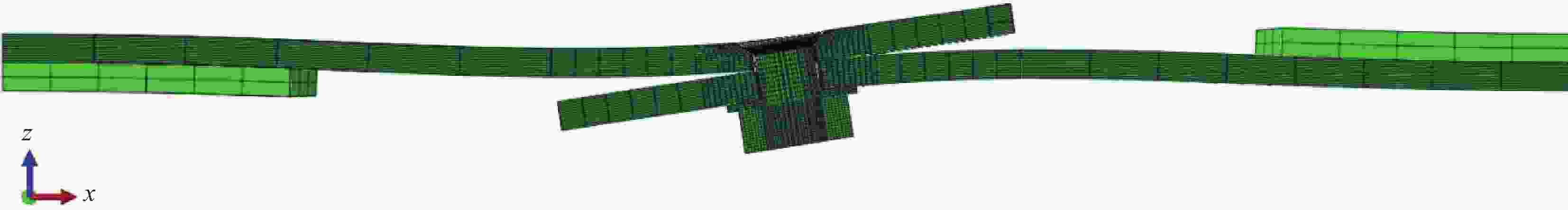

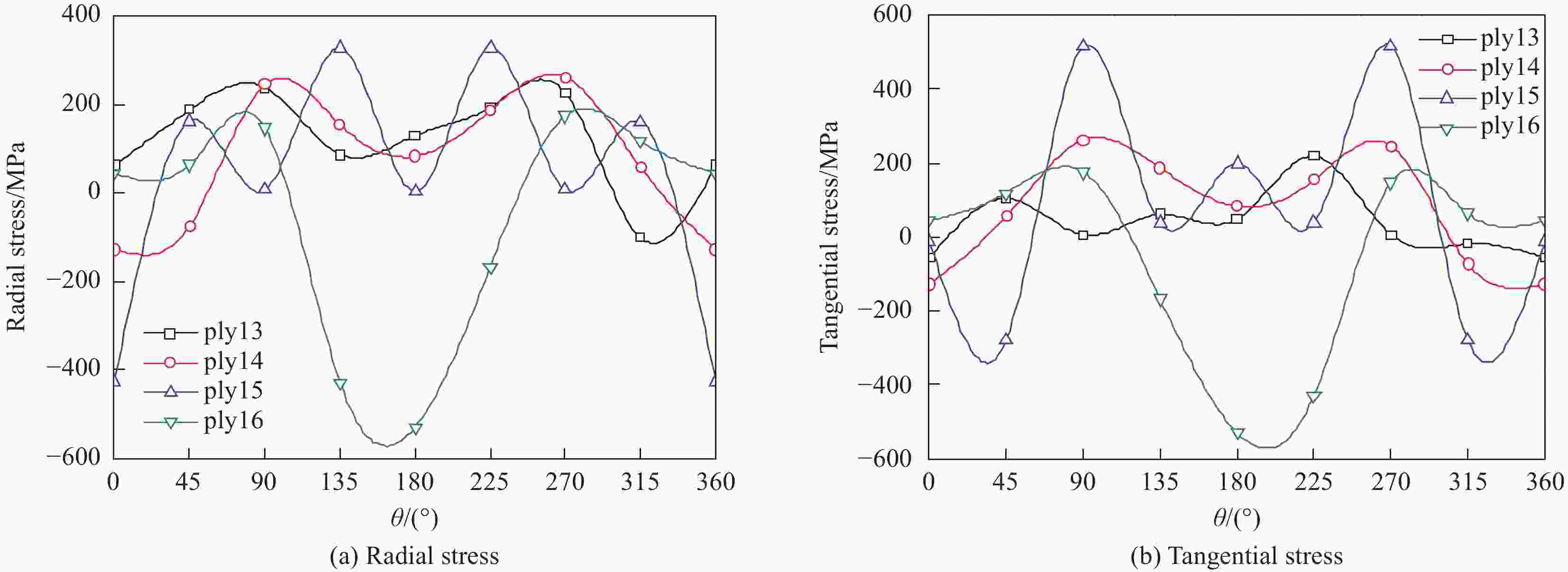

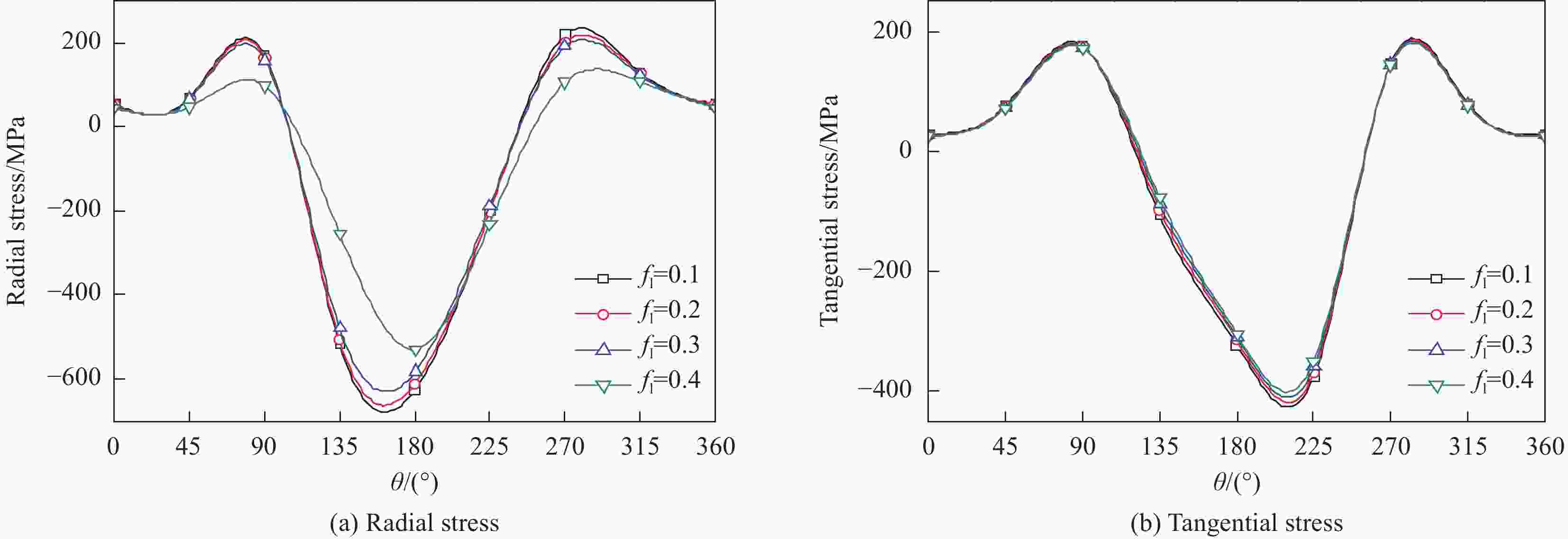

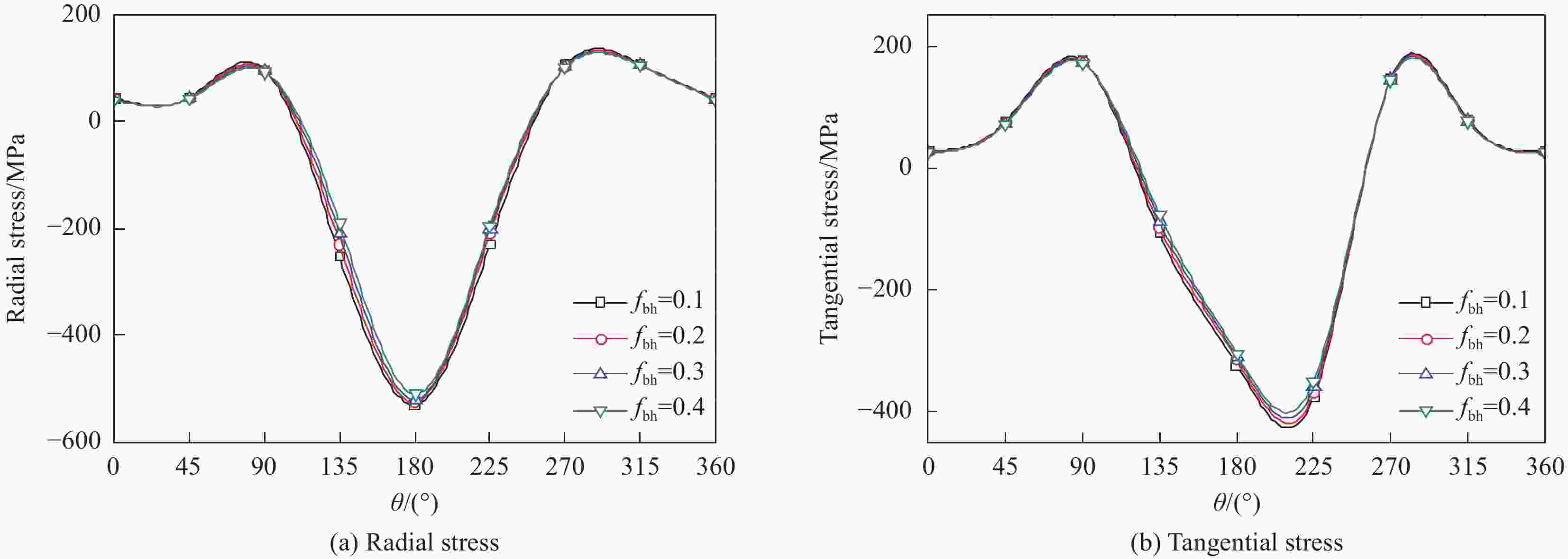

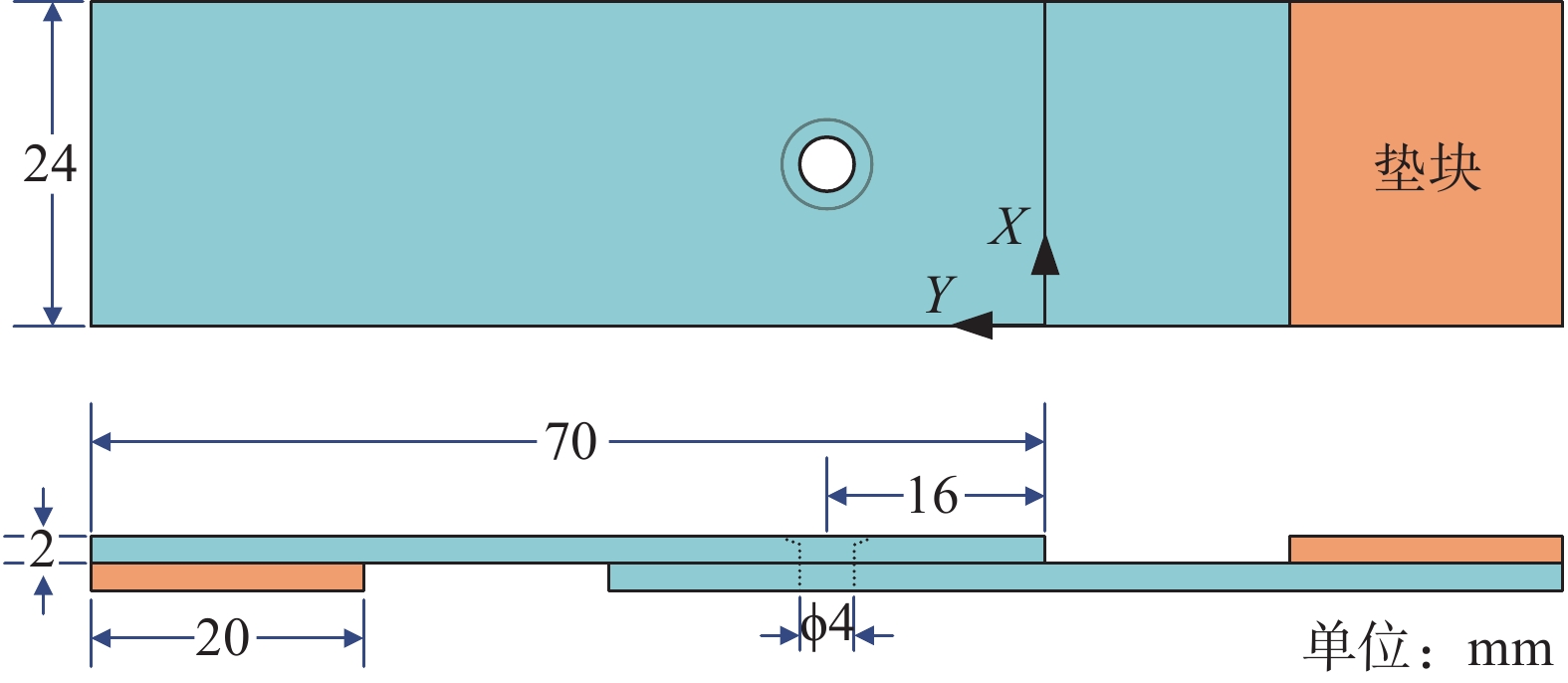

摘要: 根据ASTM 5961试验标准设计了复合材料单搭沉头螺栓接头试件,通过试验和仿真分析了螺栓预紧力水平对其静拉伸性能影响规律。试件为准各向同性铺层的碳纤维环氧树脂层合板,试验过程中利用非接触全场应变测量系统(2D DIC)对沉头板表面应变场数据进行了采集。基于ABAQUS/Standard隐式分析模块建立了复合材料单搭沉头螺栓接头的静拉伸三维有限元模型,分析了螺栓预紧力和摩擦系数对沉头孔周挤压应力的影响规律。结果表明:当接头承受拉伸载荷时,沉头孔周区域受螺栓挤压损伤最为严重;增加螺栓预紧力可提高螺栓孔2%变形的承载强度,但对接头极限承载强度的提升效果较小。有限元应力分析表明,增加螺栓预紧力或增大层合板之间的摩擦系数均有利于减轻孔周应力集中程度,提高复合材料单搭沉头螺栓接头的承载性能。Abstract: Experimental and numerical studies on the bearing response of single-lap, countersunk composite joints which were designed according to ASTM 5961 under various bolt preload were presented. The specimens were manufactured from carbon fiber/epoxy unitapes with quasi-isotropic lay-ups. To obtain a more accurate hole strain, 2D DIC measurement technique was used. Three-dimensional finite element model was constructed using ABAQUS/Standard and validated by comparing to the experiment. The validated model was used to provide a detailed stress analysis around the hole boundary considering various bolt preload and friction conditions. The results show that countersunk hole is the region where the severest damage occurs, and bolt preload could significantly improve the 2% hole deformation bearing strength but only slightly increase the ultimate bearing strength. Through stress analysis, increasing either bolt preload or friction between laminates are found to have an active effect on relieving stress concentration, and will make a better bearing performance of single-lap, single-bolt, countersunk composite joints.

-

Key words:

- single-lap /

- countersunk composite joints /

- bolt preload /

- bearing tests /

- 2D DIC /

- finite element analysis

-

Materials $ {E}_{11} $/GPa $ {E}_{22} $/GPa $ {E}_{33} $/GPa $ {G}_{12} $/GPa $ {G}_{13} $/GPa $ {G}_{23} $/GPa $ {\nu }_{12} $ $ {\nu }_{13} $ $ {\nu }_{32} $ Lamina 135 8.8 8.8 4.47 4.47 3.00 0.33 0.33 0.33 E/GPa ν Ti (bolt) 110 0.28 Steel (washer and nut) 210 0.3 表 2 DIC主要技术指标

Table 2. Main technical indicators of DIC

Displacement accuracy / pixel 0.02 Strain /με 200 Measurement resolution/pixel 4096×3000 Frames Per Second / Hz 9 Measurement range / mm 120*100 表 3 不同螺栓预紧力对复合材料单搭沉头螺栓接头挤压强度的影响

Table 3. Influence of varied bolt preload on bearing strength of single-lap, countersunk composite joints

Tightening torque /(N·m) 0.5 1 2 3 4 Ultimate bearing strength /MPa 714 705 708 722 758 Diff from 0.5 N·m - −1.26% +0.84% +1.12% +6.16% 2% offset bearing strength /MPa 108 172 170 190 201 Diff from 0.5 N·m - +59.3% +57.4% +75.9% +86.1% 表 4 摩擦系数

Table 4. Friction coefficients

Contact surface Friction coefficients Plate-bolt 0.1 Plate-plate 0.4 Plate-washer 0.3 Bolt-washer 0.1 -

[1] Park HJ. Effects of stacking sequence and clamping force on the bearing strengths of mechanically fastened joints in composite laminates[J]. Compos Struct, 2001, 53(2): 213-221. doi: 10.1016/S0263-8223(01)00005-8 [2] Quinn WJ, Matthews FL. The effect of stacking sequence on the pin-bearing strength in GFRP[J]. J Compos. Mater., 1987, 11: 139-145. [3] Aktas A, Dirikolu M H. The effect of stacking sequence of carbon epoxy composite laminates on pinned-joint strength[J]. Compos Struct, 2003, 62(1): 107-111. doi: 10.1016/S0263-8223(03)00096-5 [4] Cooper C, Turvey GJ. Effects of joint geometry and bolt torque on the structural performance of single bolt tension joints in pultruded GRP sheet material[J]. Composite Structures, 1995, 32(1-4): 217-226. doi: 10.1016/0263-8223(95)00071-2 [5] Kretsis G, Matthews FL. Strength of bolted joints in glass fibre/epoxy laminates[J]. Composites, 1985, 16(2): 92-102. doi: 10.1016/0010-4361(85)90615-9 [6] Chutima C, Blackie AP. Effect of pitch distance, row spacing, end distance and bolt diameter on multi-fastened composite joints[J]. Composites Part A:Applied Science Manufacturing, 1996, 27(2): 105-110. doi: 10.1016/1359-835X(95)00020-3 [7] Croxford AM, Davidson P, Waas AM. Influence of hole eccentricity on failure progression in a double shear bolted joint (DSBJ)[J]. Compos Sci Technol, 2018, 168: 179-187. doi: 10.1016/j.compscitech.2018.09.011 [8] Yang Y, Liu X, Wang Y, et al. An enhanced spring-mass model for stiffness prediction in single-lap composite joints with considering assembly gap and gap shimming[J]. Compos Struct, 2018, 187: 18-26. doi: 10.1016/j.compstruct.2017.12.041 [9] McCarthy M A, Lawlor V P, Stanley W F, et al. Bolt-hole clearance effects and strength criteria in single-bolt, single-lap, composite bolted joints[J]. Compos Sci Technol, 2002, 62(10): 1415-1431. [10] Kelly G, Hallström S. Bearing strength of carbon fibre/epoxy laminates: Effects of bolt-hole clearance[J]. Compos Part B:Eng, 2004, 35(4): 331-343. doi: 10.1016/j.compositesb.2003.11.001 [11] Lawlor V P, McCarthy M A, Stanley W F. An experimental study of bolt–hole clearance effects in double-lap, multi-bolt composite joints[J]. Compos Struct, 2005, 71(2): 176-190. doi: 10.1016/j.compstruct.2004.09.025 [12] McCarthy C T, McCarthy M A. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: Part II––effects of bolt-hole clearance[J]. Compos Struct, 2005, 71(2): 159-175. doi: 10.1016/j.compstruct.2004.09.023 [13] Wang H S, Hung C L, Chang F K. Bearing failure of bolted composite joints. Part I: experimental characterization[J]. J Compos Mater, 1996, 30(12): 1284-1313. doi: 10.1177/002199839603001201 [14] Giannopoulos IK, Doroni-Dawes D, Kourousis KI, et al. Effects of bolt torque tightening on the strength and fatigue life of airframe FRP laminate bolted joints[J]. Compos Part B:Eng, 2017, 125(15): 19-26. [15] J. S. Hu, S. Q. Mi, Z. Y. Yang, et al. An experimental investigation on bearing behavior and failure mechanism of bolted composite interference-fit joints under thermal effects[J]. Eng. Fail. Anal, 2022, 131: 105830. doi: 10.1016/j.engfailanal.2021.105830 [16] 肖睿恒, 王耀, 刘庆波等. 预紧力对复合材料单搭接接头疲劳性能的影响[J]. 机械制造与自动化, 2022, 51(05): 65-69.XIAO Ruiheng, WANG Yao, LIU Qingbo, et al. Effect of Preload on Fatigue Properties of Composite Single-lap Joints[J]. Machine Building & Automation, 2022, 51(05): 65-69(in Chinese). [17] 刘庆波, 安鲁陵, 杨浩然. 预紧力对复合材料单搭接接头拉伸性能的影响[J]. 机械制造与自动化, 2022, 51(03): 5-8.Liu Qingbo, AN Luling, YANG Haoran. Effect of Preload on Tensile Properties of Composite Single-lap Joints[J]. Machine Building & Automation, 2022, 51(03): 5-8(in Chinese). [18] 梅俊杰, 倪爱清, 王继辉. 复合材料螺栓连接渐近失效分析[J]. 玻璃钢/复合材料, 2017, 7: 40-44.MEI Junjie, NI Aiqing, WANG Jihui. PROGRESSIVE DAMAGE ANALYSIS OF COMPOSITE BOLTED JOINTS[J]. Fiber Reinforced Plastics. Composites, 2017, 7: 40-44(in Chinese). [19] 董慧民, 李小刚, 马绪强, 等. 聚合物基复合材料凸头螺栓连接研究进展[J]. 北京航空航天大学学报, 2023, 49(04): 745-760.DONG Huimin, LI Xiaogang, MA Xuqiang, et al. Research progress in mechanically fastened polymer-matrix composite joints with protruding-head bolts[J]. Journal of Beijing University of Aeronautics and Astronautics, 2023, 49(04): 745-760(in Chinese). [20] 宋广舒. 复合材料沉头螺栓连接强度分析与渐进损伤研究[D]. 郑州: 郑州大学, 2017.Guangshu Song. The Strength Analysis and Progressive Damage Research for Countersunk Composite Bolted Joints[D]. Zhengzhou: Zhengzhou University, 2017. (in Chinese) [21] 黄学优. 复合材料螺栓连接接头失效行为研究[D]. 太原: 中北大学, 2016.Xuyou Huang. Failure Behavior Study of Composite Bolted Joint[D]. Taiyuan: North University of China, 2016. (in Chinese) [22] 安子乾, 舒茂盛, 程羽佳, 等. 3钉带衬套复合材料/金属接头拉伸疲劳性能[J]. 材料工程, 2021, 49(12): 164-174.AN Ziqian, SHU Maosheng, CHENG Yujia, et al. Tensile fatigue properties of composite/metal bolted joints with 3-pin and sleeves[J]. Journal of Materials Engineering, 2021, 49(12): 164-174(in Chinese). [23] 安子乾, 舒茂盛, 程羽佳, 等. 3钉带衬套复合材料/金属接头拉伸疲劳性能试验研究[J]. 材料导报, 2021, 35(20): 20081-20086.AN Ziqian, SHU Maosheng, CHENG Yujia, et al. Experimental Study on Tensile fatigue properties of composite/metal bolted joints with 3-pin and sleeves[J]. MATERIALS REPORTS, 2021, 35(20): 20081-20086(in Chinese). [24] Ireman T. Three-dimensional stress analysis of bolted single-lap composite joints[J]. Compos Struct, 1998, 43(3): 195-216. doi: 10.1016/S0263-8223(98)00103-2 [25] Chishti M, Wang C H, Thomson R S, et al. Experimental investigation of damage progression and strength of countersunk composite joints[J]. Compos Struct, 2012, 94(3): 865-873. doi: 10.1016/j.compstruct.2011.10.011 [26] Mandal B, Chakrabarti A. Numerical failure assessment of multi-bolt FRP composite joints with varying sizes and preloads of bolts[J]. Compos Struct, 2018, 187: 169-178. doi: 10.1016/j.compstruct.2017.12.048 [27] Yoon D, Kim S, Kim J, et al. Study on bearing strength and failure mode of a carbon-epoxy composite laminate for designing bolted joint structures[J]. Compos Struct, 2020, 239: 112023. doi: 10.1016/j.compstruct.2020.112023 [28] Sun H T, Chang F K, Qing X. The response of composite joints with bolt-clamping loads, Part I: Model development[J]. J Compos Mater, 2002, 36(1): 47-67. doi: 10.1177/0021998302036001301 [29] 宋广舒, 郑艳萍, 赵江铭. 复合材料沉头搭接强度与渐进损伤研究[J]. 玻璃钢/复合材 料, 2017, (04): 5-10.SONG Guangshu, ZHENG Yanping, ZHAO Jiangming. STRENGTH AND PROGRESS FAILURE RESEARCH OF COUNTERSUNK COMPOSITE[J]. Fiber Reinforced Plastics. Composites, 2017, (04): 5-10(in Chinese). [30] 林炜彦. 单搭接单螺栓连接板的力学特性研究[D]. 南昌: 南昌航空大学, 2018.Lin Weiyan. Study on Mechanical Properties of Single-lapped and Single Bolted Joint Plate[D]. Nanchang: Nanchang Hangkong University, 2018. (in Chinese) [31] 刘豫霖. 树脂基复合材料机匣安装边连接强度分析与试验研究[D]. 南京: 南京航空航天大学, 2020.Liu Yulin. Analysis and Experimental Research on the Connection Strength of the Installation Edge of the Resin Matrix Composite Case[D]. Nanjing : Nanjing University of Aeronautics and Astronautics, 2020. (in Chinese) [32] Egan B, McCarthy C T, McCarthy M A, et al. Stress analysis of single-bolt, single-lap, countersunk composite joints with variable bolt-hole clearance[J]. Compos Struct, 2012, 94(3): 1038-1051. doi: 10.1016/j.compstruct.2011.10.004 [33] Egan B, McCarthy C T, McCarthy M A, et al. Modelling a single-bolt countersunk composite joint using implicit and explicit finite element analysis[J]. Comp Mater Sci, 2012, 64: 203-208. doi: 10.1016/j.commatsci.2012.02.008 [34] ASTM D5961: 2013. Standard test method for bearing response of polymer matrix composite laminates[S]. [35] Zhai Yunong, Li Dongsheng, Li Xiaoqiang, et al. An experimental study on the effect of bolt-hole clearance and bolt torque on single-lap, countersunk composite joints[J]. Compos Struct, 2015, 127: 411-419. doi: 10.1016/j.compstruct.2015.03.028 [36] 张振华, 应秉斌, 矫明. 螺栓拧紧力矩的确定方法及相关探讨[J]. 化学工程与装备, 2009, 8: 105-107.ZHANG Zhenhua, YING Bingbin, JIAO Ming. Discussions and Method for determining the bolt tightening torque[J]. Chemical Engineering & Equipment, 2009, 8: 105-107(in Chinese). -

下载:

下载: