Flexible capacitive pressure sensor based on carbon black/barium titanate/polyurethane

-

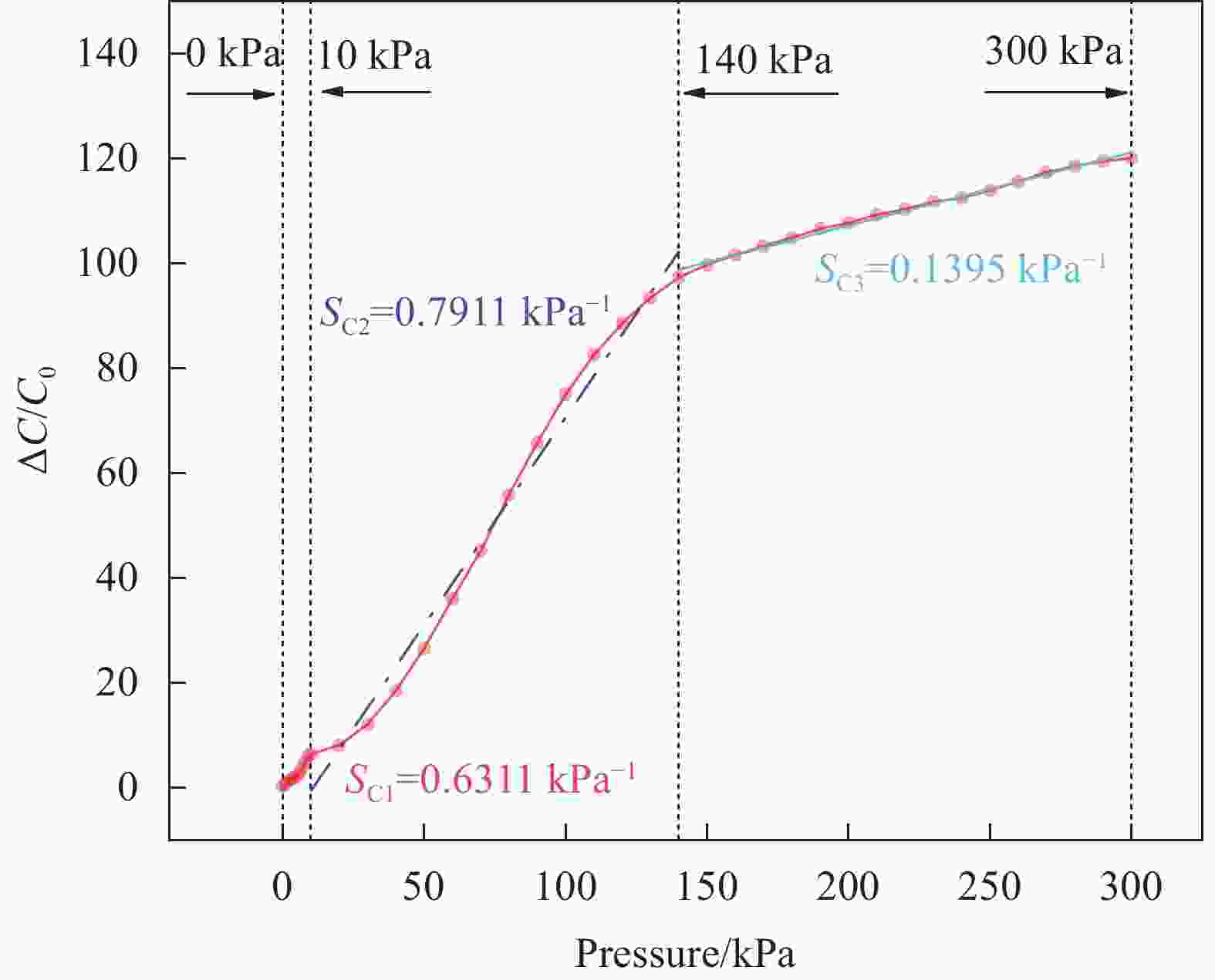

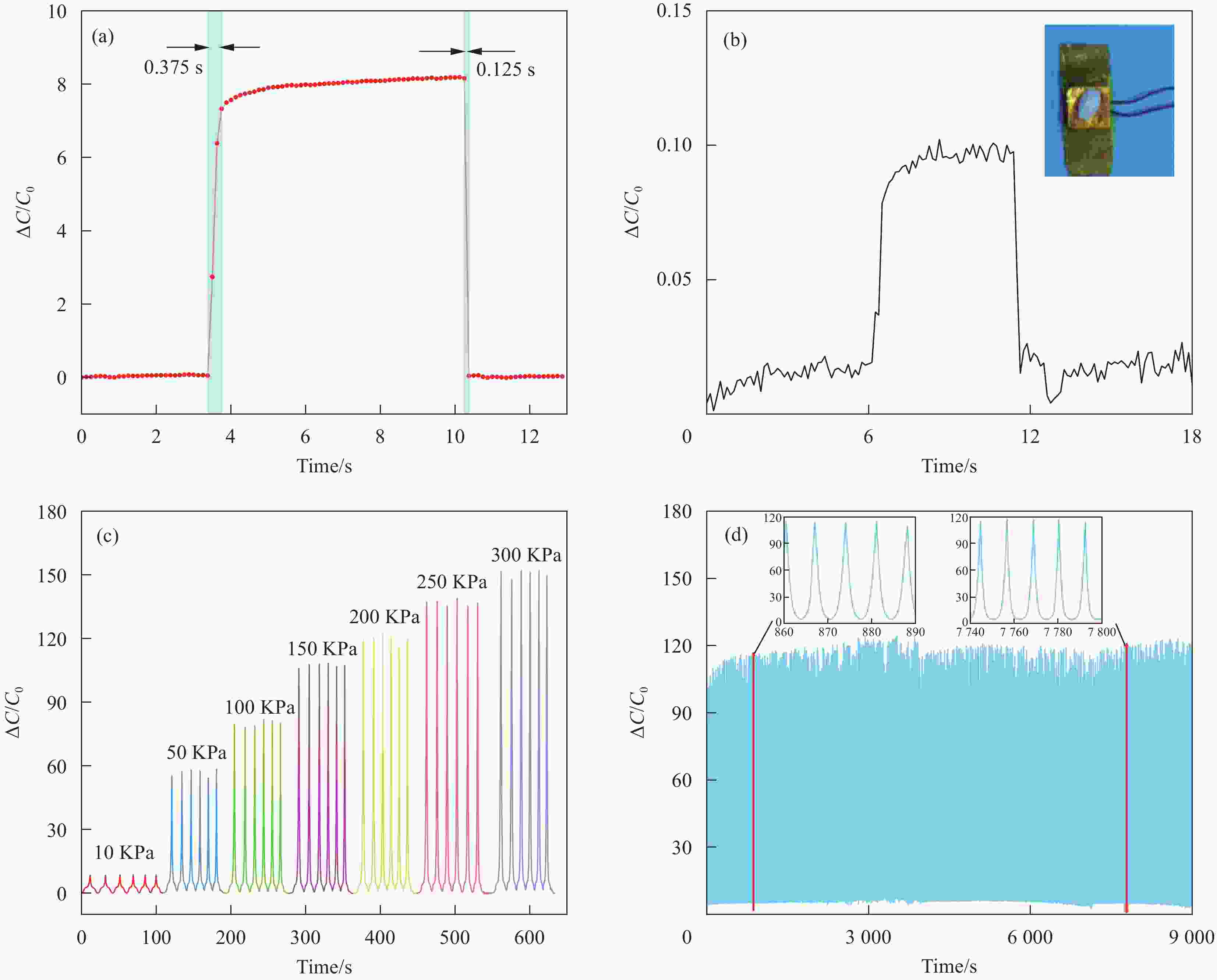

摘要: 随着智能可穿戴柔性电子技术在生物医疗、电子皮肤、人机交互等领域的快速发展和应用,兼具高灵敏度和宽检测范围的柔性压力传感器的研究需求被提上日程。本文采用聚氨酯海绵(PU)作为基底,通过超声浸渍涂覆的方法将炭黑-钛酸钡(CB-BTO)复合材料结合在聚氨酯海绵上,制备出了CB-BTO/PU海绵柔性电容式压力传感器。经测试,传感器兼具了高灵敏度(~0.7911 kPa−1)和宽的检测范围(0~300 kPa)等特性。同时,并对传感器的响应时间、最低检测限及稳定性等进行研究。此外,还对传感器进行了四个不同压力量程范围的应用测试,验证了传感器在高灵敏度和宽检测范围的应用潜力,为低成本、大规模制备高性能柔性传感器提供了新的可能性方案。Abstract: With the rapid development and application of smart wearable flexible electronic technology in biomedicine, electronic skin, human-computer interaction and other fields, the research demand of flexible pressure sensors with high sensitivity and wide detection range has been put on the agenda. In this paper, a CB-BTO/PU flexible capacitive pressure sensor was prepared by using the polyurethane sponge (PU) as the base and combining CB-BTO/ BTO composite material on the polyurethane sponge by ultrasonic dipping coating. After testing, the sensor combines high sensitivity (~0.7911 kPa−1) and wide detection range (0~300 kPa). At the same time, the response time, the minimum detection limit and the stability of the sensor are studied. In addition, the sensor has been tested in four different pressure ranges, which verifies the potential of the sensor in high sensitivity and wide detection range, and provides a new possibility for low-cost and large-scale fabrication of high-performance flexible sensors.

-

图 2 CB-BTO/PU海绵的形貌与结构表征:(a)是浸渍前后PU海绵实物图;(b)、(c)分别是PU海绵压缩的初始状态和压缩状态图;(d)、(e)、(f)是PU海绵断面SEM图像;(g)、(h)、(i)分别是Ba元素、Ti元素、C元素的EDS分布图(电子版为彩图)

Figure 2. Morphology and structure characterization of CB-BTO / PU sponge. (a) is the physical diagram of PU sponge before and after impregnation; (b) and (c) are the initial compression state and compression state diagrams of PU sponge respectively; (d), (e) and (f) are SEM images of PU sponge sections; (g), (h) and (i) are the EDS distribution diagrams of Ba element, Ti element and C element respectively (the electronic version is a color diagram).

图 6 CB-BTO/PU海绵压力传感器在各种变形信号监测中的应用:(a)手指点击鼠标上传感器的响应(0~5 kPa);(b)指关节弯曲的传感器响应(0~7 kPa);(c)抓取不同质量玻璃杯的传感器响应(0~40 kPa);(d)足底压力和步态监测的传感器响应(0~110 kPa)

Figure 6. Application of CB-BTO/PU sponge pressure sensor in monitoring various deformation signals: (a) Response of sensor when finger clicks the mouse(0~5 kPa); (b) Sensor response of knuckle bending(0~7 kPa); (c) Sensor responses for grabbing glasses with different qualities(0~40 kPa); (d) Sensor response of plantar pressure and gait monitoring(0~110 kPa).

表 1 CB-BTO/PU传感器与文献报道性能比较

Table 1. Performance comparison between CB-BTO / PU sensor and literature report

Materials Sensitivity Detection range Reference TiO2@PU 0.93 kPa−1 (0~0.37 kPa)

0.079 kPa−1 (0.37~2.83 kPa)

0.02 kPa−1 (2.83~10 kPa)0~10 kPa [33] CCTO@PU

0.73 kPa−1(0~1.6 kPa)

0.135 kPa−1(1.6~22.8 kPa)

0.026 kPa−1(22.8~100 kPa)0~100 kPa [34]

GO/CNTs@TPU

0.05777 kPa−1 (0~5 kPa)

0.33213 kPa−1 (5~60 kPa)0~60 kPa [35]

GNPs/MWCNTs/SR/PS

0.062 kPa−1 (0~0.3 kPa)

0.033 kPa−1 (0.3~4.5 kPa)0~4.5 kPa [36] CB-BTO/PU

0.6311 kPa−1(0~10 kPa)

0.7911 kPa−1(10~140 kPa)

0.1395 kPa−1(140~300 kPa)0~300 kPa This work Notes: TiO2-Titanium Dioxide; CCTO-Calcium copper titanate; GO-Graphene Oxide; CNTs- Carbon Nanotube; TPU-Thermoplastic Polyurethane; GNPs-Graphene nanosheets; MWCNTs-carboxyl-functionalized multiwalled carbon nanotubes; SR-Silicone rubber; PS-commercial polyurethane sponge. -

[1] MOHANKUMAR P, AJAYAN J, MOHANRAJ T, et al. Recent developments in biosensors for healthcare and biomedical applications: A review[J]. Measurement, 2021, 167: 108293. doi: 10.1016/j.measurement.2020.108293 [2] WANG L, XU T, ZHANG X. Multifunctional conductive hydrogel-based flexible wearable sensors[J]. TrAC Trends in Analytical Chemistry, 2021, 134: 116130. doi: 10.1016/j.trac.2020.116130 [3] LI R, ZHOU Q, BI Y, et al. Research progress of flexible capacitive pressure sensor for sensitivity enhancement approaches[J]. Sensors and Actuators A:Physical, 2021, 321: 112425. doi: 10.1016/j.sna.2020.112425 [4] LIU X, MIAO J, FAN Q, et al. Recent progress on smart fiber and textile based wearable strain sensors: materials, fabrications and applications[J]. Advanced Fiber Materials, 2022, 4(3): 361-389. doi: 10.1007/s42765-021-00126-3 [5] WANG X, LIU X, SCHUBERT D W. Highly sensitive ultrathin flexible thermoplastic polyurethane/carbon black fibrous film strain sensor with adjustable scaffold networks[J]. Nano-micro letters, 2021, 13: 1-19. doi: 10.1007/s40820-020-00525-y [6] QIN J, YIN L J, HAO Y N, et al. Flexible and stretchable capacitive sensors with different microstructures[J]. Advanced Materials, 2021, 33(34): 2008267. doi: 10.1002/adma.202008267 [7] YI Z, LIU Z, LI W, et al. Piezoelectric dynamics of arterial pulse for wearable continuous blood pressure monitoring[J]. Advanced Materials, 2022, 34(16): 2110291. doi: 10.1002/adma.202110291 [8] SHI Y, LI H, FU X, et al. Self-powered difunctional sensors based on sliding contact-electrification and tribovoltaic effects for pneumatic monitoring and controlling[J]. Nano Energy, 2023, 110: 108339. doi: 10.1016/j.nanoen.2023.108339 [9] ZHANG Y, HOWVER R, GOGOI B, et al. A High-Sensitive Ultra-Thin MEMS Capacitive Pressure Sensor[J]. 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference IEEE, 2011, 112-115 [10] WU Z, HUANG T, HOU C, et al. A flexible triaxial force capacitive sensor with microstructure electrode and orthogonal microstructure[C]//2021 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO). IEEE, 2021: 319-323. [11] GAO Y H, BI Y Q, LANG J H, et al. Insights into theoretical and practical characteristics of capacitive flexible tactile sensor based on spherical surface plate[J]. Journal of Materials Science: Materials in Electronics, 2021, 32(13). [12] WAN Y, QIU Z, HONG Y, et al. A highly sensitive flexible capacitive tactile sensor with sparse and high-aspect-ratio microstructures[J]. Advanced Electronic Materials, 2018, 4(4): 1700586. doi: 10.1002/aelm.201700586 [13] LI J, CHEN S, ZHOU J, et al. Flexible BaTiO 3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding[J]. Polymers, 2023, 15(15): 3292. doi: 10.3390/polym15153292 [14] 王振国. 仿人皮肤感受器的柔性多功能传感器3D/4D打印研究[D]. 吉林大学, 2023. DOI: 10.27162/d.cnki.gjlin.2023.007144.WANG Zhenguo. Research on 3D/4D printing of flexible multi-functional sensor mimicking human skin receptor [D]. Jilin university, 2023. DOI: 10.27162 /, dc nki. Gjlin. 2023.007144.(in Chinese) [15] LI H, GAO G, XU Z, et al. Recent progress in bionic skin based on conductive polymer gels[J]. Macromolecular Rapid Communications, 2021, 42(22): 2100480. doi: 10.1002/marc.202100480 [16] ZHANG Z, LI J, YU B, et al. Low-cost, flexible annular interdigital capacitive sensor (Faics) with carbon black-pdms sensitive layer for proximity and pressure sensing[C]//2022 IEEE 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS). IEEE, 2022: 35-38. [17] GUO Z, MO L, DING Y, et al. Printed and flexible capacitive pressure sensor with carbon nanotubes based composite dielectric layer[J]. Micromachines, 2019, 10(11): 715. doi: 10.3390/mi10110715 [18] LI Y, WEI Z, HUANG J. An LC-type flexible wireless humidity sensor with electrospun isolation layer[C]//2021 IEEE Sensors. IEEE, 2021: 1-4. [19] LIU Q, LIU Z, LI C, et al. Highly transparent and flexible iontronic pressure sensors based on an opaque to transparent transition[J]. Advanced Science, 2020, 7(10): 2000348. doi: 10.1002/advs.202000348 [20] NIE L, ZHANG L, DI X, et al. Assembly of highly-sensitive capacitive flexible pressure sensor based on BTO NWs-TPU porous composites film[J]. Vacuum, 2022, 205: 111423. doi: 10.1016/j.vacuum.2022.111423 [21] WANG J, SUZUKI R, SHAO M, et al. Capacitive pressure sensor with wide-range, bendable, and high sensitivity based on the bionic komochi konbu structure and Cu/Ni nanofiber network[J]. ACS applied materials & interfaces, 2019, 11(12): 11928-11935. [22] 田玉玉, 何韧, 吴菊英等. 电容式柔性压力传感器的性能优化原理及研究进展[J]. 材料导报, 2023, 37(16): 13-26.TIAN Yuyu, HE Ren, WU Juying, et al. Performance Optimization Principle and Research progress of Capacitive Flexible Pressure Sensor[J]. Materials Review, 2023, 37(16): 13-26(in Chinese). [23] ZHANG F T, XUE Z, et al. Recent progress in three-dimensional flexible physical sensors[J]. International Journal of Smart and Nano Materials, 2022, 13(1): 17-41. doi: 10.1080/19475411.2022.2047827 [24] ALI A A, ELTABEY M M, ABDELBARY B M, et al. MWCNTs/carbon nano fibril composite papers for fuel cell and super capacitor applications[J]. Journal of Electrostatics, 2015, 73: 12-18. doi: 10.1016/j.elstat.2014.10.012 [25] LU D, LIAO S, WEI Q, et al. Comparative study of different carbon materials for the preparation of knitted fabric sensors[J]. Cellulose, 2022, 29(13): 7431-7444. doi: 10.1007/s10570-022-04722-3 [26] XU Z, ZHAO S, LV X, et al. Highly Sensitive and Low Detection Limit Flexible Pressure Sensor Based on Modified TiO 2 Cocooned Elastic Sponge for Wearable Applications[J]. IEEE Sensors Journal, 2022, 22(23): 22479-22486. doi: 10.1109/JSEN.2022.3217086 [27] CHEN Y, LU B, CHEN Y, et al. Ultra-thin and ultra-flexible temperature/strain sensor with CNT nanostrips[C]//2016 IEEE International Conference on Electron Devices and Solid-State Circuits (EDSSC). IEEE, 2016: 70-73. [28] 张东光, 王鑫鑫, 杨嘉怡等. 液态金属泡沫柔性压力传感器设计及试验[J]. 振动. 测试与诊断, 2023, 43(1): 119-125+201-202. doi: 10.16450/j.cnki.issn.1004-6801.2023.01.018ZHANG Dong guang, WANG Xin xin, YANG Jia yi, et al. Design and test of liquid metal foam flexible pres-sure sensor[J]. Vibration, test and diagnosis, 2023, 43(1): 119-125+201-202. DOI: 10.16450/j.cnki.issn.1000. (in Chinese) [29] ZANG Y, ZHANG F, DI C, et al. Advances of flexible pressure sensors toward artificial intelligence and health care applications[J]. Materials Horizons, 2015, 2(2): 140-156. doi: 10.1039/C4MH00147H [30] DING H, WU Z, WANG H, et al. An ultrastretchable, high-performance, and crosstalk-free proximity and pressure bimodal sensor based on ionic hydrogel fibers for human-machine interfaces[J]. Materials Horizons, 2022, 9(7): 1935-1946. doi: 10.1039/D2MH00281G [31] YAN T, WU Y, TANG J, et al. Flexible strain sensors fabricated using aligned carbon nanofiber membranes with cross-stacked structure for extensive applications[J]. International Journal of Smart and Nano Materials, 2022, 13(3): 432-446. doi: 10.1080/19475411.2022.2091059 [32] HE Q, ZHONG Q, SUN Z, et al. Highly stretchable, repeatable, and easy-to-prepare ionogel based on polyvinyl chloride for wearable strain sensors[J]. Nano Energy, 2023, 113: 108535. doi: 10.1016/j.nanoen.2023.108535 [33] XU Z, ZHAO S, LV X, et al. Highly Sensitive and Low Detection Limit Flexible Pressure Sensor Based on Modified TiO 2 Cocooned Elastic Sponge for Wearable Applications[J]. IEEE Sensors Journal, 2022, 22(23): 22479-22486. doi: 10.1109/JSEN.2022.3217086 [34] CHHETRY A, SHARMA S, YOON H, et al. Enhanced sensitivity of capacitive pressure and strain sensor based on CaCu3Ti4O12 wrapped hybrid sponge for wearable applications[J]. Advanced Functional Materials, 2020, 30(31): 1910020. doi: 10.1002/adfm.201910020 [35] 刘秋雨, 叶秉泽, 王梓菡等. 基于电容-电阻转换原理的柔性压力传感器[J]. 测控技术2022, 41(06): 10-DOI: 10.19708/j.ckjs.2022.06.002.LIU Qiuyu, YE Bingze, WANG Zihan, et al. Flexible pressure sensor based on capacitance-resistance conversion principle[J]. Measurement and control technology 2022, 41 (06): 10-.(in Chinese) [36] QIU J, GUO X, CHU R, et al. Rapid-response, low detection limit, and high-sensitivity capacitive flexible tactile sensor based on three-dimensional porous dielectric layer for wearable electronic skin[J]. ACS applied materials & interfaces, 2019, 11(43): 40716-40725. -

点击查看大图

点击查看大图

计量

- 文章访问数: 83

- HTML全文浏览量: 47

- 被引次数: 0

下载:

下载: