Sizes effect on the tensile behaviors of H65-IF-H65 laminated metal composites

-

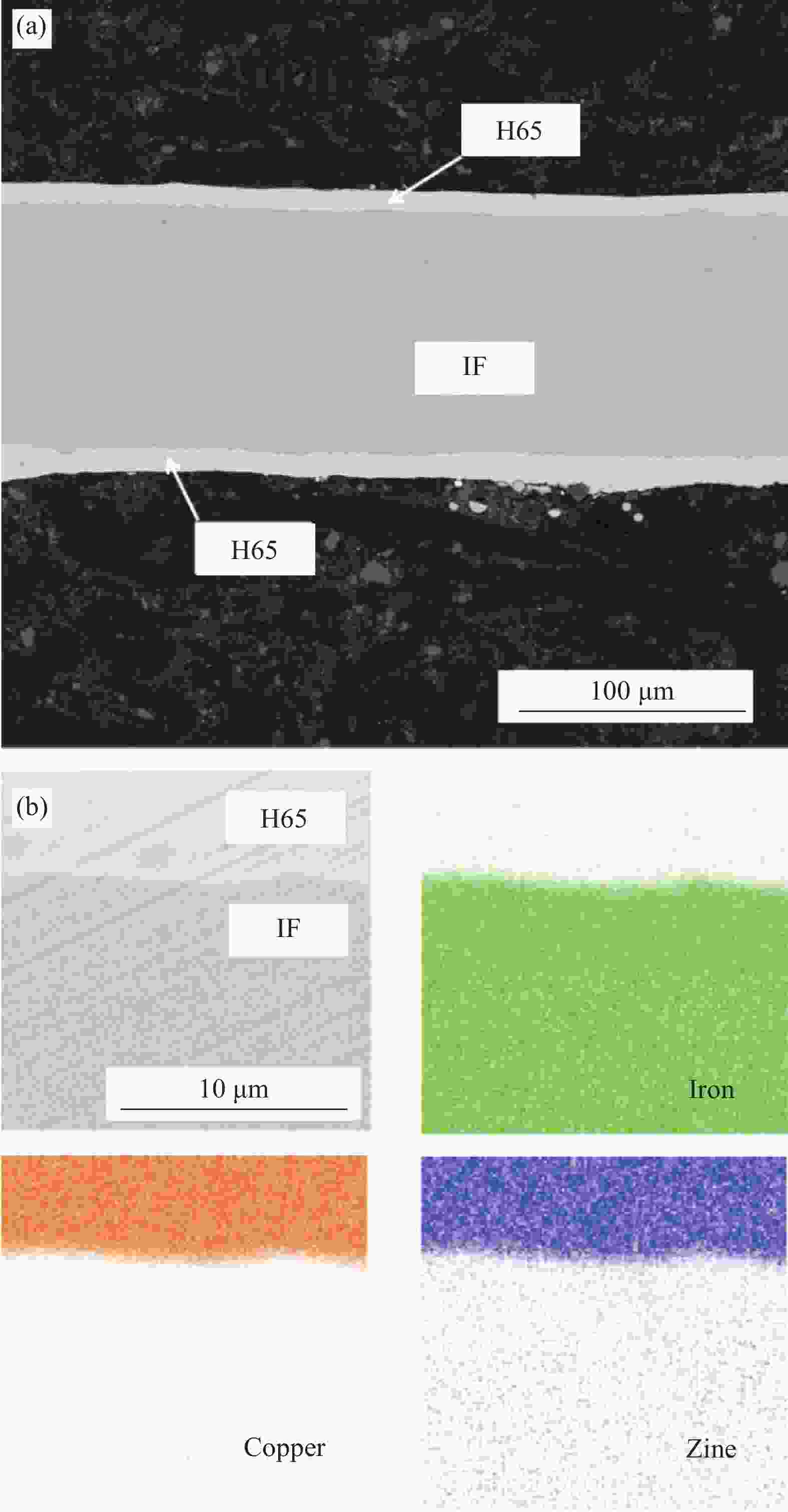

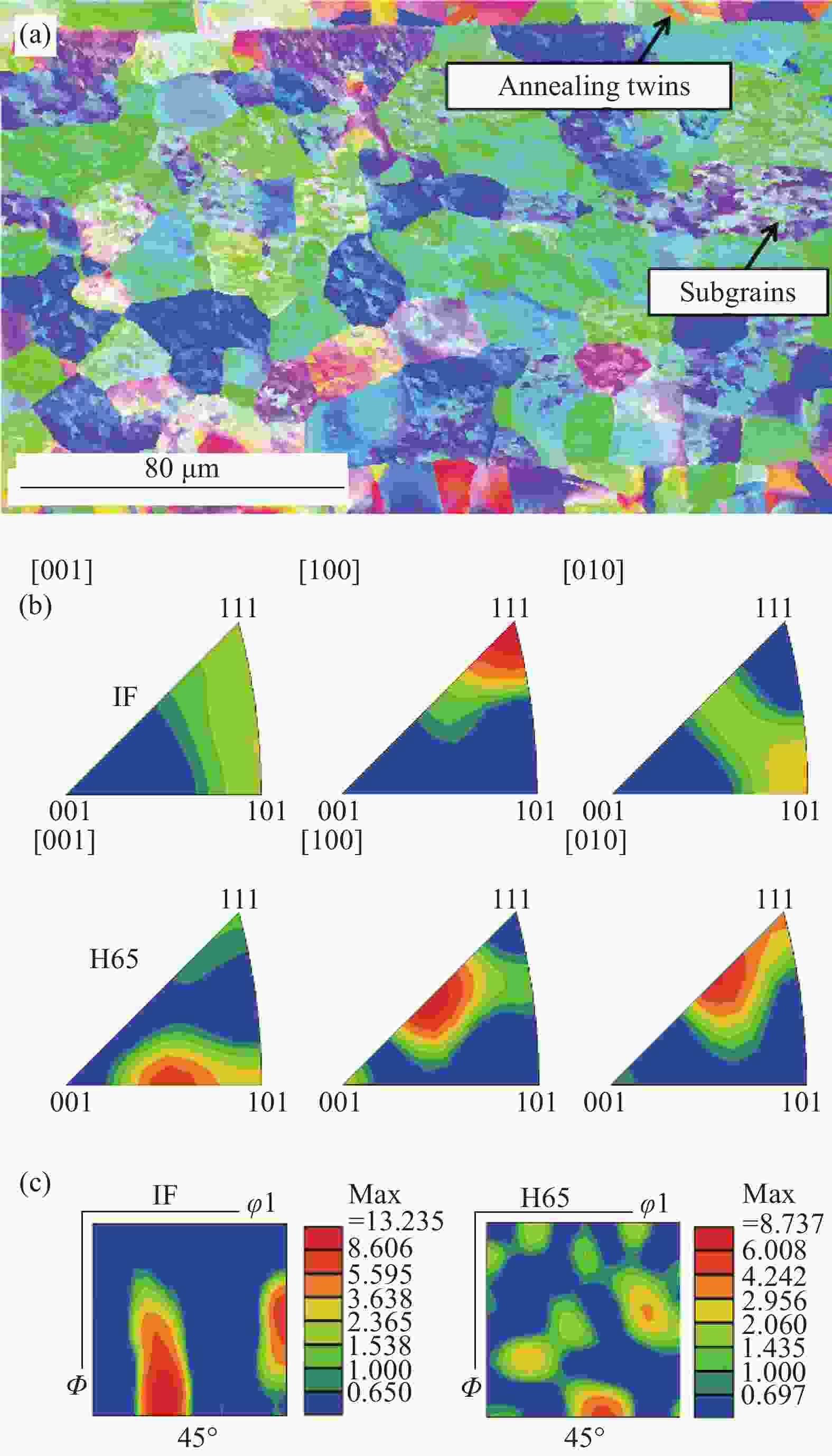

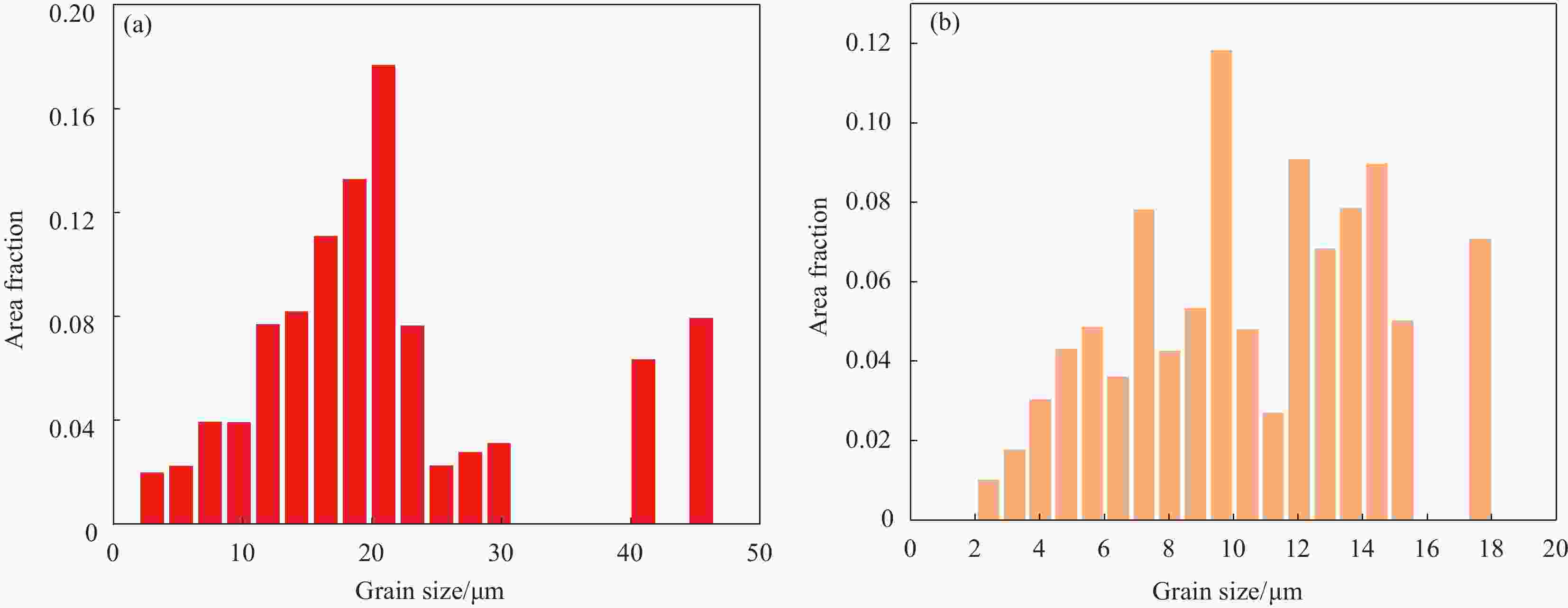

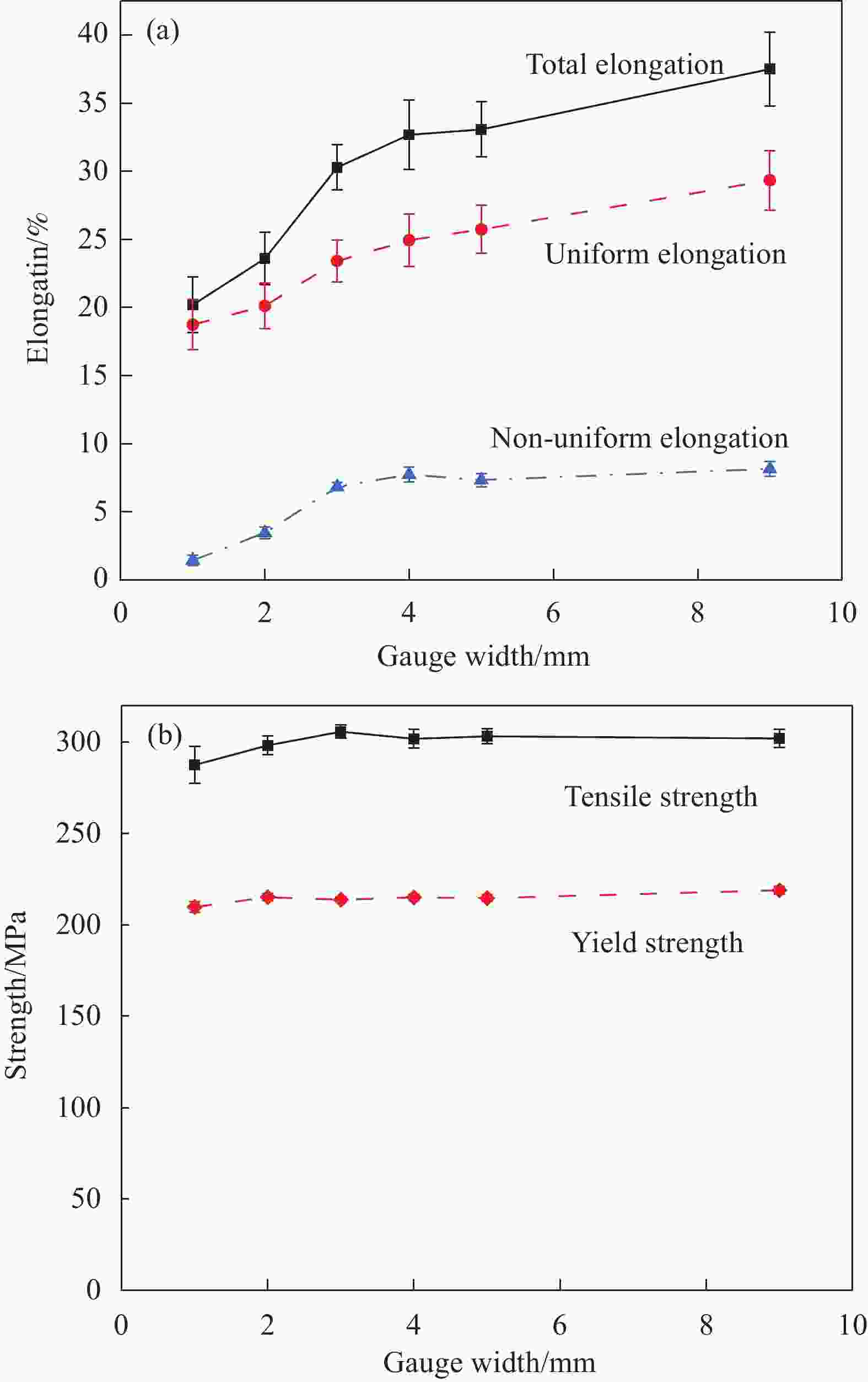

摘要: 采用轧制结合退火的方式制备了厚度为0.12 mm、标距宽度为1~9 mm的H65-IF-H65层状复合材料,并借助EBSD、DIC技术、常规拉伸、原位拉伸和SEM等手段分析了试样宽度对复合材料的力学行为的影响。研究结果表明:层状复合材料中的H65-IF界面在退火过程中未发生元素扩散,界面结合方式为机械结合。随着标距宽度由9 mm 逐渐降低至1 mm,材料的抗拉强度、屈服强度基本保持不变,但总延伸率、均匀延伸率和不均匀延伸率分别由30.3%、23.4% 和6.9%下降至20.3%、18.8%和1.5%,加工硬化能力迅速减弱。与此同时,材料的应变集中程度逐渐加剧,拉伸断口上的韧窝带宽度变小且带内的韧窝数量和尺寸也明显减小,呈现出显著的尺寸效应。H65-IF-H65层状复合材料的尺寸效应主要源于剪切应力的交互作用随着标距宽度的降低而被抑制,裂纹更易沿单道剪切带快速扩展而导致塑性下降。Abstract: The H65-IF-H65 laminated metal composites (LMCs) of 0.12 mm thickness and 1-9 mm gauge widths were prepared by rolling combined with annealing. The EBSD, digital image correlation technology, conventional tensile testing, in-situ tensile testing and SEM were used to analysis the effect of specimen width on the mechanical behavior of the H65-IF-H65 LMC. The results show that the H65-IF interface is mechanical bonded without elements diffusion during the annealing process. As the gauge width gradually reduced from 9 mm to 1 mm, the tensile strength and yield strength remain basically unchanged, meanwhile the total, the uniform, and the non-uniform elongations decrease from 30.3%, 23.4% and 6.9% to 20.3%, 18.8% and 1.5% respectively. The work hardening ability also decreases rapidly. Moreover, the strain of the H65-IF-H65 LMCs is gradually concentrated. On the tensile fracture, the width of the dimple band and the number and size of dimples within it also decrease significantly, which indicates a significant size effect. The main reason of sample sizes effect on the tensile behaviors of H65-IF-H65 LMCs is that the interaction of shear stress is inhibited with the decrease of the gauge width. The cracks are more likely to spread rapidly in the single shear band and result in a decreased ductility.

-

Key words:

- laminated metal composites /

- size effect /

- tensile fracture /

- in-situ tension /

- crack propagation

-

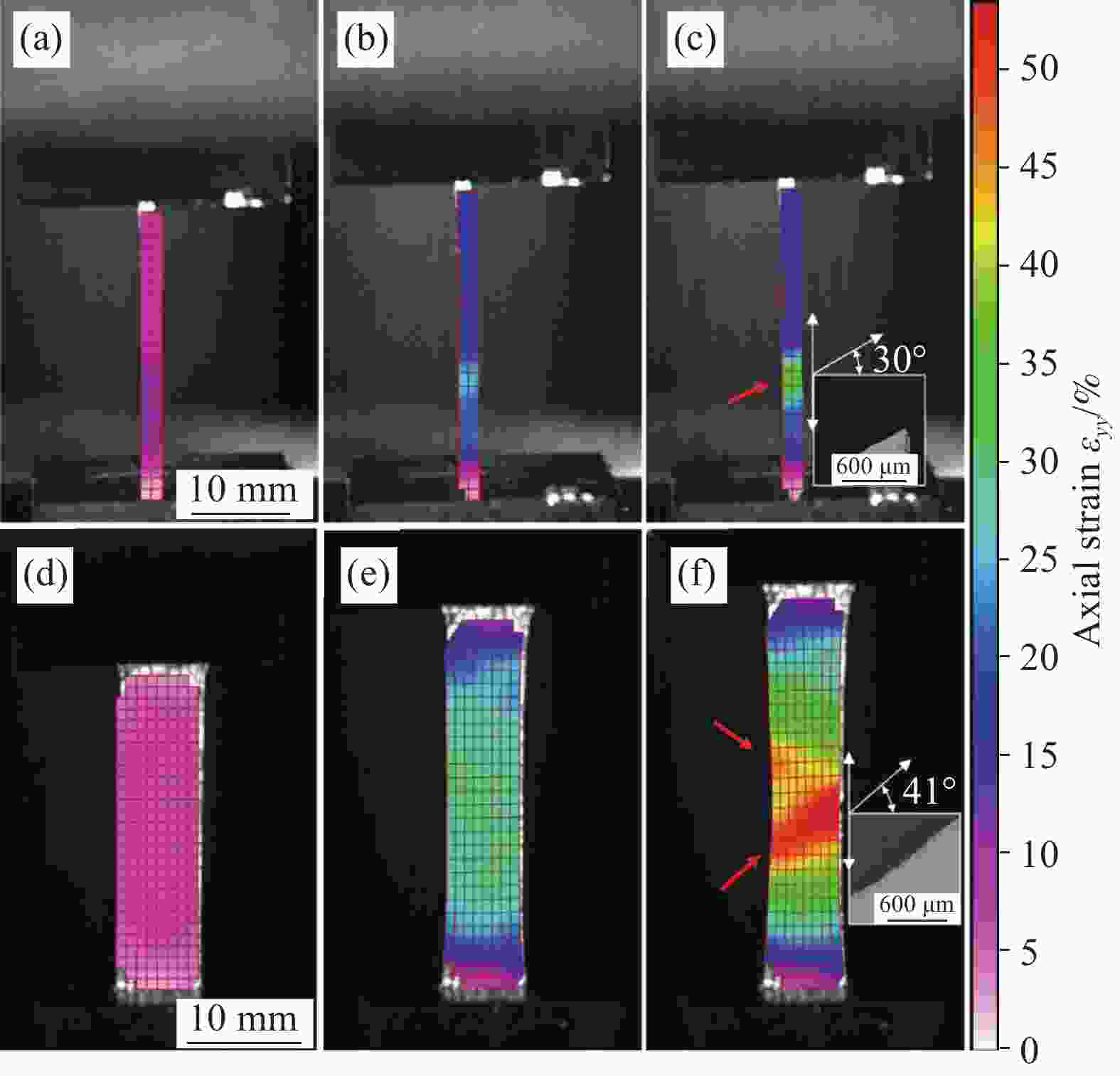

图 7 (a)~(c)标距宽度为1 mm的H65-IF-H65层状复合材料试样拉伸至工程应变约为10%、18.8%(颈缩点)和20%(即将断裂)的应变分布图;(d)~(f)标距宽度为9 mm试样拉伸至工程应变约为10%、29.3%(颈缩点)和37.3%(即将断裂)的应变分布图

Figure 7. Strain distributions of the H65-IF-H65 LMCs specimens with gauge width of 1 mm at the strains of 10%, 18.8% (necking point) and 20% (about to break) ((a)-(c)), and 9 mm at the strains of 10%, 29.3% (necking point) and 37.3% (about to break) ((d)-(f)), respectively

图 9 标距宽度为1 mm((a)~ (d))和9 mm((e)~ (h))的H65-IF-H65层状复合材料试样在裂纹扩展过程中的侧面SEM观察((i)和(j)为(f)中裂纹前端放大图与EDS分析,(k)和(l)分别为(f)和(h)在电镜下拍摄的宏观照片)

Figure 9. Side SEM observations during the crack growth of the H65-IF-H65 LMCs samples with gauge widths of 1 mm ((a)-(d)) and 9 mm ((e)-(h)) ((i) and (j) are the enlarged image and EDS analysis of the crack front in (f). (k) and (l) are the macroscopic photographs of (f) and (h) under electron microscope)

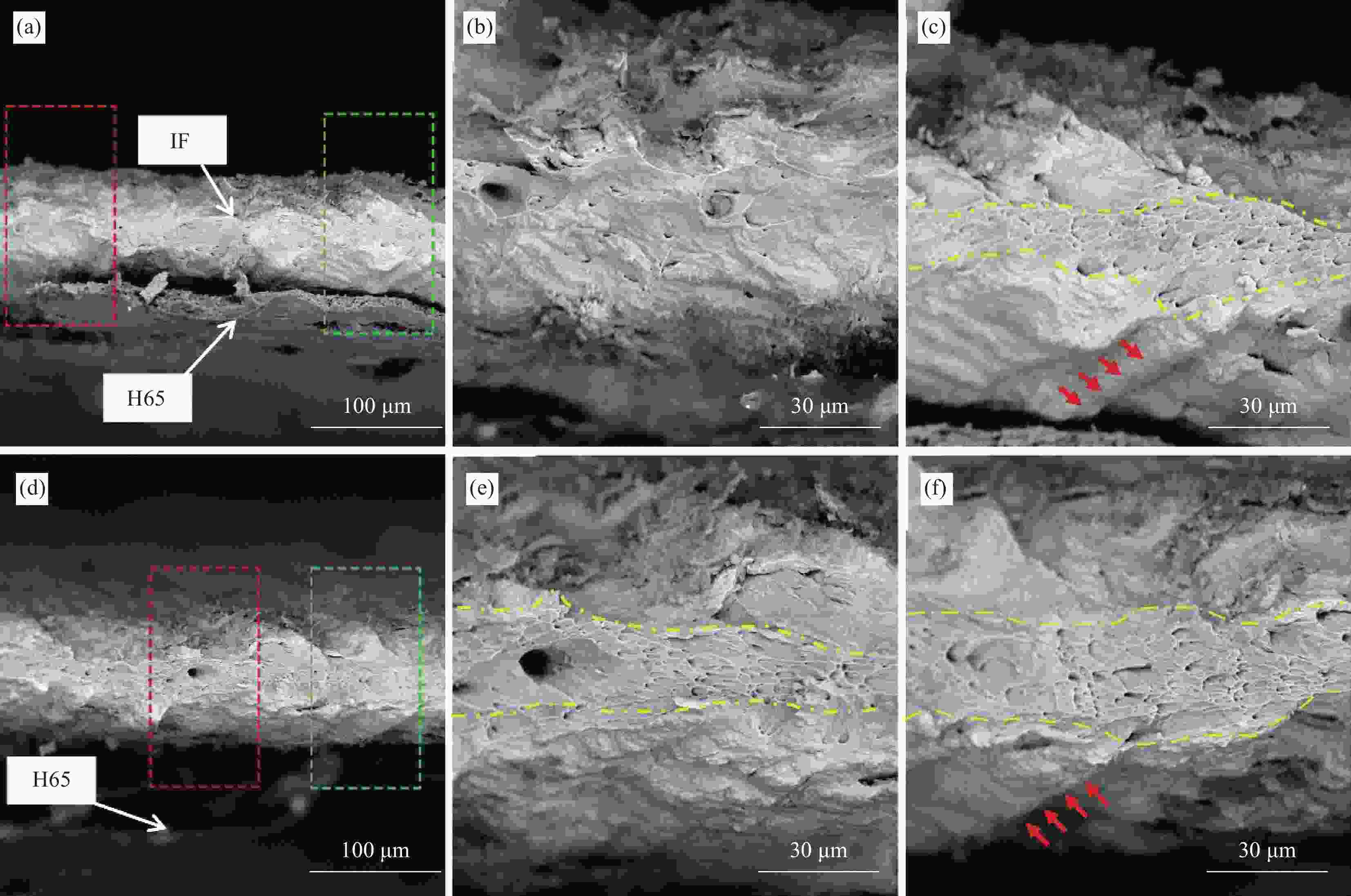

图 10 标距宽度1 mm(a)和9 mm(d)的H65-IF-H65层状复合材料试样断口正面SEM图像:(b)和(c)分别为(a)中红色和绿色框位置放大图;(e)和(f)分别为(d)中红色和绿色框位置放大图

Figure 10. SEM images of the front side of the H65-IF-H65 LMCs specimen with gauge width of 1 mm (a) and 9 mm (d): (b) and (c) are the enlarged images of the red and green frames in (a); (e) and (f) are the enlarged images of the red and green frames in (d)

表 1 H65黄铜-IF钢-H65黄铜(H65-IF-H65)层状复合材料中H65黄铜和IF钢成分(wt%)

Table 1. Compositions of H65 brass and IF steel in the H65-IF-H65 laminated metal composites (LMCs) (wt%)

Material Elements H65 Cu Zn P Fe Impurities 64.524% Bal. ≤0.01% 0.016% <0.2% IF Fe C Mn Cu Ni Cr P S Bal. 0.003% 0.18% 0.01% 0.01% 0.01% 0.03% 0.004% -

[1] 张志娟, 张兵, 赵田丽, 等. 轧制三金属复合材料研究进展[J]. 精密成形工程, 2021, 13: 23-34.ZHANG Zhijuan, ZHANG Bing, ZHAO Tian-li, et al. Research Progress of Tri-Metal Composites Prepared by Rolling Process[J]. Journal of Netshape Forming Engineering, 2021, 13: 23-34(in Chinese). [2] MA X, HUANG C, MOERING J, et al. Mechanical properties of copper/bronze laminates: Role of interfaces[J]. Acta Materialia, 2016, 116: 43-52. doi: 10.1016/j.actamat.2016.06.023 [3] 梅瑞斌, 史现利, 包立, 等. 多道次热辊轧制Al/Mg层状复合板材结合面特性[J]. 复合材料学报, 2022, 39: 3485-97.MEI Ruibin, SHI Xianli, BAO Li, et al. Interface characteristics study of Al/Mg laminated composite sheets by multi-passes RHR[J]. Acta Materiae Compositae Sinica, 2022, 39: 3485-97(in Chinese). [4] 常海, 徐超, 胡小石. 累积叠轧纯Mg/ZK60镁合金层状金属复合材料的组织与性能[J]. 复合材料学报, 2019, 36: 178-85.CHANG Hai, XU Chao, XU Xiaoshi. Microstructure evolution and mechanical properties of Mg/ZK60 laminated composite fabricated by accumulated roll-bonding[J]. Acta Materiae Compositae Sinica, 2019, 36: 178-185 (in Chinese). [5] D R, M T, HASHEMI R, et al. Microstructure and Mechanical Properties of Al/Cu/Mg Laminated Composite Sheets Produced by the ARB Process[J]. International Journal of Minerals, Metallurgy, and Materials, 2018, 25: 564-72. doi: 10.1007/s12613-018-1603-x [6] ZHANG XB, YU YB, LIU B, et al. Mechanical Properties and Tensile Fracture Mechanism Investigation of Al/Cu/Ti/Cu/Al Laminated omposites Fabricated by Rolling[J]. Journal of Alloys and Compounds, 2019, 805: 338-45. doi: 10.1016/j.jallcom.2019.07.064 [7] 郝平菊;王振华;刘元铭. 退火温度对铜/铝/铜复合板结合性能的影响[J]. 热加工工艺, 2018, 47: 159-62.HAO Pingju, WANG Zhenhua, LIU Yuanming. Effect of Annealing Temperature on Bonding Properties of Cu/Al/Cu Clad Sheet[J]. Hot Working Technology, 2018, 47: 159-162 (in Chinese). [8] WANG PJ, HUANG HT, LIU JJ, et al. Microstructure and Mechanical Properties of Ti6Al4V/AA6061/AZ31 Laminated Metal Composites (LMCs) Fabricated by Hot Roll Bonding[J]. Journal of Alloys and Compounds, 2021, 861: 157943. doi: 10.1016/j.jallcom.2020.157943 [9] ENGEL U, ECKSTEIN R. Microforming-from basic research to its realization[J]. Journal of Materials Processing Technology, 2002, 125-126: 35-44. doi: 10.1016/S0924-0136(02)00415-6 [10] 赵祥帅, 刘粤, Charlie K, 等. 异步轧制与退火铜箔的厚度尺寸效应研究[J]. 塑性工程学报, 2021, 28: 126-33.ZHAO Xiangshuai, LIU Yue, KONG Charlie, et al. Research on thickness size effect of asymmetric rolled and annealed copper foils[J]. Journal of Plasticity Engineering, 2021, 28: 126-33 (in Chinese). [11] ZHAO Y, GUO Y, WEI Q, et al. Influence of specimen dimensions on the tensile behavior of ultrafine-grained Cu[J]. Scripta Materialia, 2008, 59: 627-30. doi: 10.1016/j.scriptamat.2008.05.031 [12] 赵阳, 李文锦, 孙艳姣, 等. IF钢在轧制极薄带过程中的力学性能尺寸效应研究[J]. 四川冶金, 2022, 44: 6-10.ZHAO Yang, LI Wenjin, SUN Yanjiao, et al. Research on size effect of mechanical properties of IF steel during the process of preparing foil by cold rolling[J]. Sichuan Metallurgy, 2022, 44: 6-10 (in Chinese). [13] LI YP, ZHU XF, TAN J, et al. Comparative investigation of strength and plastic instability in Cu/Au and Cu/Cr multilayers by indentation[J]. Journal of Materials Research, 2009, 24: 728-35. doi: 10.1557/jmr.2009.0092 [14] CHEN W, HE W, LUO N, et al. Effect of layer thickness on the enhanced strength and ductility of laminated Ti/Al composite[J]. Materials Science and Engineering:A, 2022, 859: 144230. doi: 10.1016/j.msea.2022.144230 [15] XIA Y, WU H, MIAO K, et al. Effects of the layer thickness ratio on the enhanced ductility of laminated aluminum[J]. Journal of Materials Science & Technology, 2022, 111: 256-67. [16] GUO W, JäGLE E, YAO J, et al. Intrinsic and extrinsic size effects in the deformation of amorphous CuZr/nanocrystalline Cu nanolaminates[J]. Acta Materialia, 2014, 80: 94-106. doi: 10.1016/j.actamat.2014.07.027 [17] WANG K, Wei AP, Shi ZM, et al. The preparation and performance of grain size gradient TWIP steel fabricated by laser heat treatment[J]. Materials Science and Engineering:A, 2019, 743: 294-300. doi: 10.1016/j.msea.2018.11.074 [18] 赵志毅, 张晓君, 薛润东, 等. 不同热连轧工艺Ti-IF钢板中析出相及织构的研究[J]. 材料热处理技术, 2009, 38: 25-8.ZHAO Zhiyi, ZHANG Xiaojun, XUE Rundong, et al. Research on Precipitates and Texture in Ti-IF Steel Sheets Produced by Different Hot-rolling Process[J]. Material & Heat Treatment, 2009, 38: 25-28 (in Chinese). [19] 杜柳青. 铜合金薄板的微塑性成形尺寸效应研究[D]. 东北大学, 2022.DU Liuqing. Research on Size Effect of Microplastic Forming of Copper Alloy Sheet[D]. Northeastern University, 2022 (in Chinese). [20] 李文锦. IF钢极薄带微观结构及力学性能尺寸效应研究[D]. 辽宁工程技术大学, 2022.LI Wenjing. Study on size effect on the microstructure andmechanical properties of lF steel ultra thin strip[D]. Liaoning Technical University, 2022 (in Chinese). [21] DINI G, NAJAFIZADEH A, UEJI R, et al. Tensile deformation behavior of high manganese austenitic steel: The role of grain size[J]. Materials & Design, 2010, 31: 3395-402. [22] MOLOTNIKOV A, LAPOVOK R, GU CF, et al. Size effects in micro cup drawing[J]. Materials Science and Engineering:A, 2012, 550: 312-9. doi: 10.1016/j.msea.2012.04.079 [23] WANG Y, DONG PL, XU ZY, et al. A constitutive model for thin sheet metal in micro-forming considering first order size effects[J]. Materials & Design, 2010, 31: 1010-4. [24] GEIGER M, VOLLERTSEN F, KALS R. Fundamentals on the Manufacturing of Sheet Metal Microparts[J]. CIRP Annals, 1996, 45: 277-82. doi: 10.1016/S0007-8506(07)63063-7 [25] ZHAO Z, RADOVITZKY R, CUITIñO A. A study of surface roughening in fcc metals using direct numerical simulation[J]. Acta Materialia, 2004, 52: 5791-804. doi: 10.1016/j.actamat.2004.08.037 [26] SOLHJOO S, HALBERTSMA PJ, VELDHUIS M, et al. Effects of loading conditions on free surface roughening of AISI 420 martensitic stainless steel[J]. Journal of Materials Processing Technology, 2020, 275: 116311. doi: 10.1016/j.jmatprotec.2019.116311 [27] AL-QURESHI HA, KLEIN AN, FREDEL MC. Grain size and surface roughness effect on the instability strains in sheet metal stretching[J]. Journal of Materials Processing Technology, 2005, 170: 204-10. doi: 10.1016/j.jmatprotec.2005.04.116 [28] ZHENG PF, CHEN R, LIU HT, et al. On the standards and practices for miniaturized tensile test – A review[J]. Fusion Engineering and Design, 2020, 161: 112006. doi: 10.1016/j.fusengdes.2020.112006 [29] ZHAO YH, GUO YZ, WEI Q, et al. Influence of specimen dimensions and strain measurement methods on tensile stress–strain curves[J]. Materials Science and Engineering:A, 2009, 525: 68-77. doi: 10.1016/j.msea.2009.06.031 [30] DODD B, BAI Y. Adiabatic Shear Localization[M] . Elsevier, London: Frontiers and Advances, 2012. [31] 崔约贤, 王长利. 金属断口分析 [M]. 哈尔滨: 哈尔滨工业大学出版社, 1998.CUI Yuexian, WANG Changli. Analysis of metal fracture[M]. Harbin: Harbin Institute of Technology Press, 1998 (in Chinese). [32] 梁伟, 杨晓翔. 黄铜薄板单向拉伸第Ⅱ类尺寸效应[J]. 塑性工程学报, 2013, 20: 100-7.LIANG Wei, YANG Xiao-xiang. Second class size effects on brass sheet in tensile test[J]. Journal of Plasticity Engineering, 2013;20: 100-107 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 38

- HTML全文浏览量: 20

- 被引次数: 0

下载:

下载: