Factors influencing interfacial shear strength between UHPC and concrete substrate

-

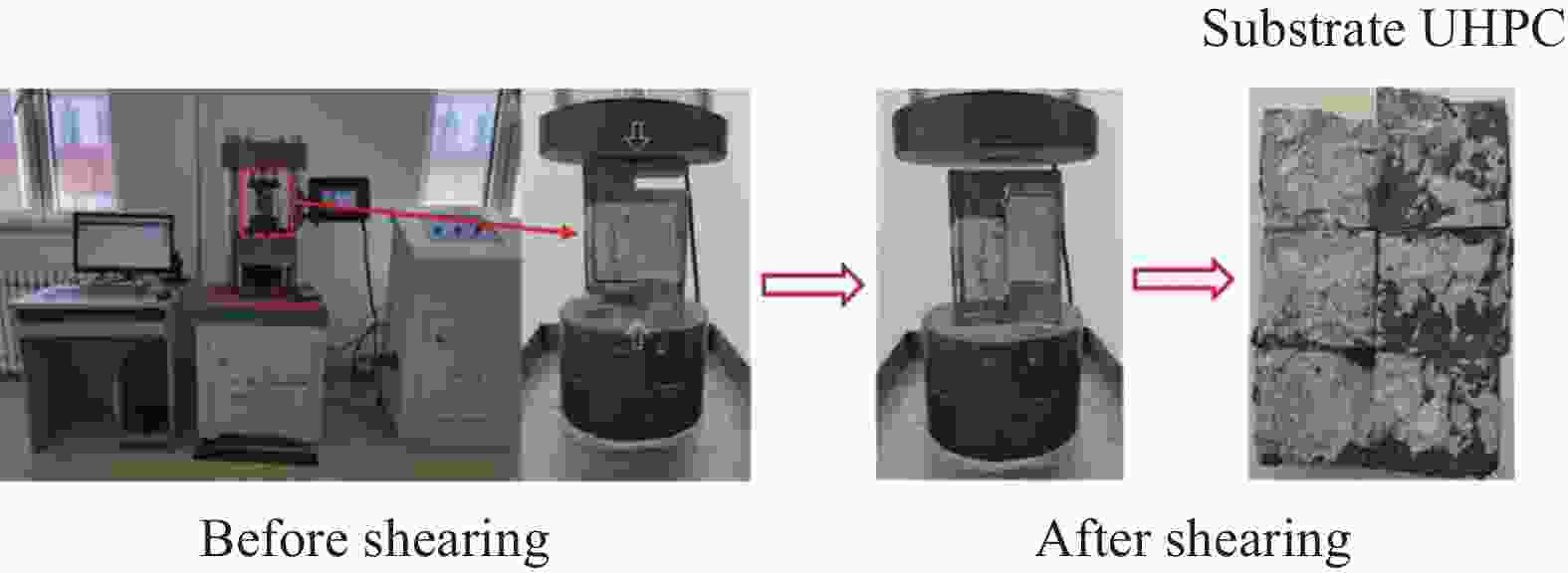

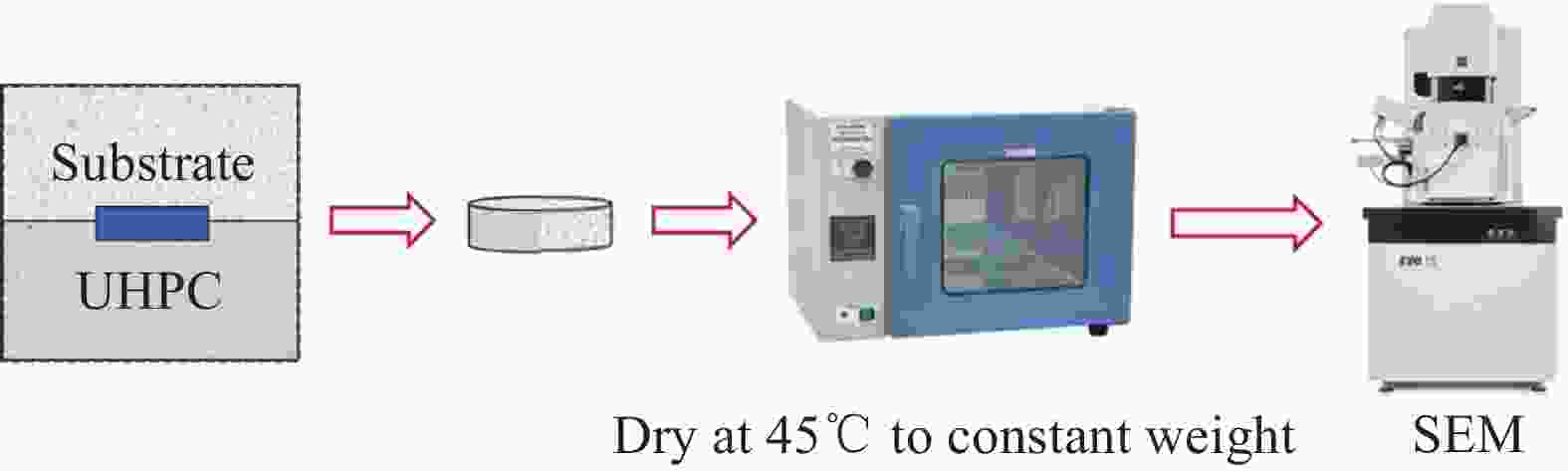

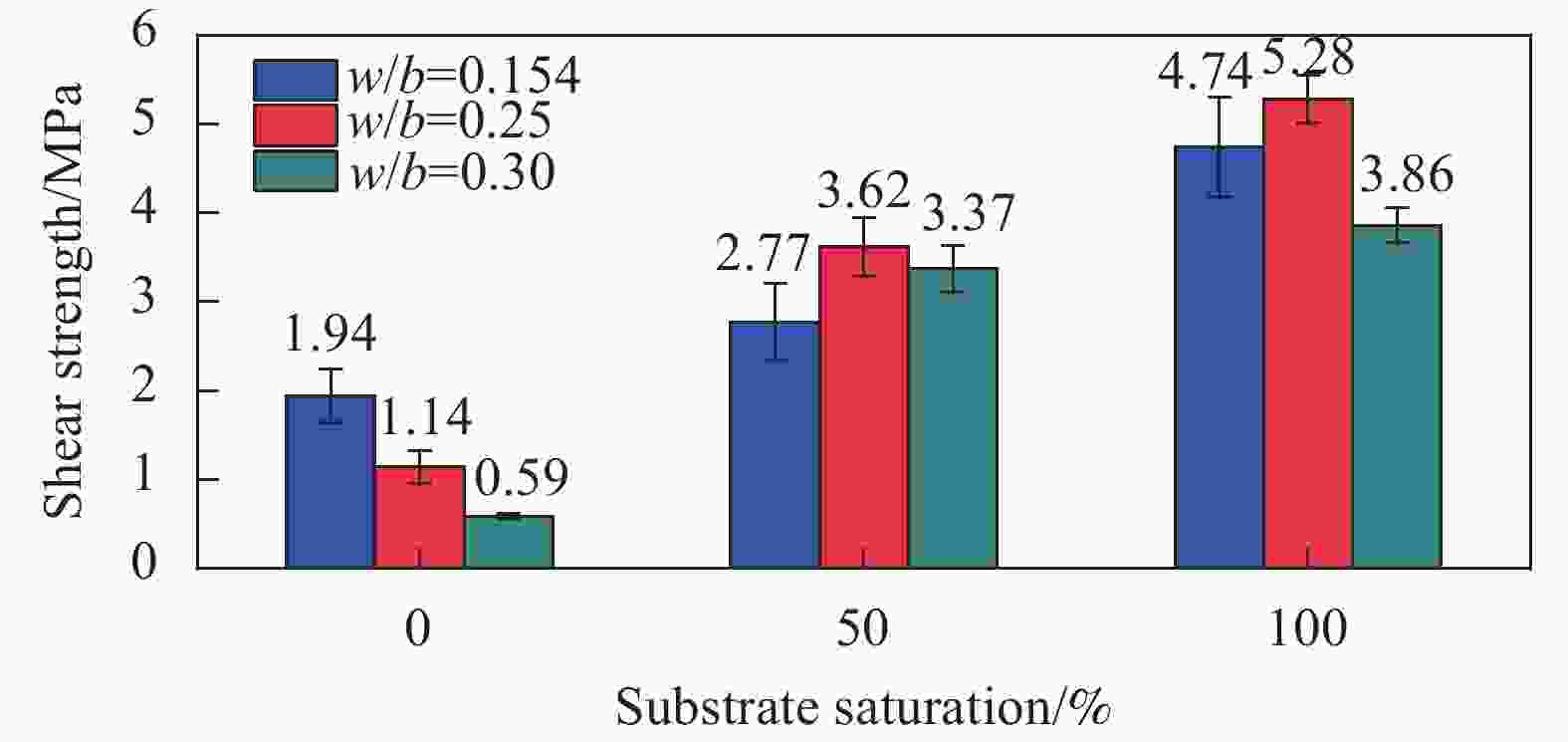

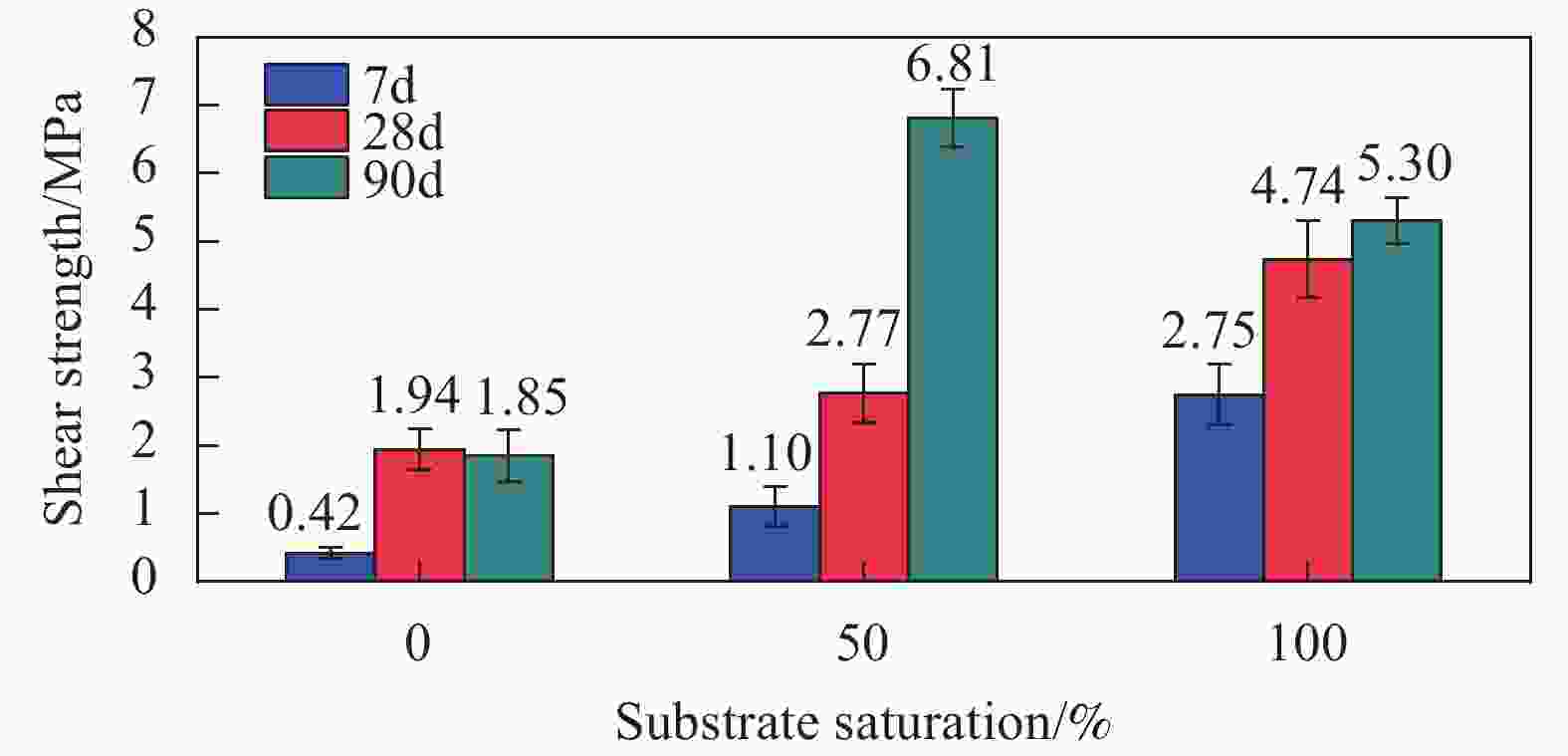

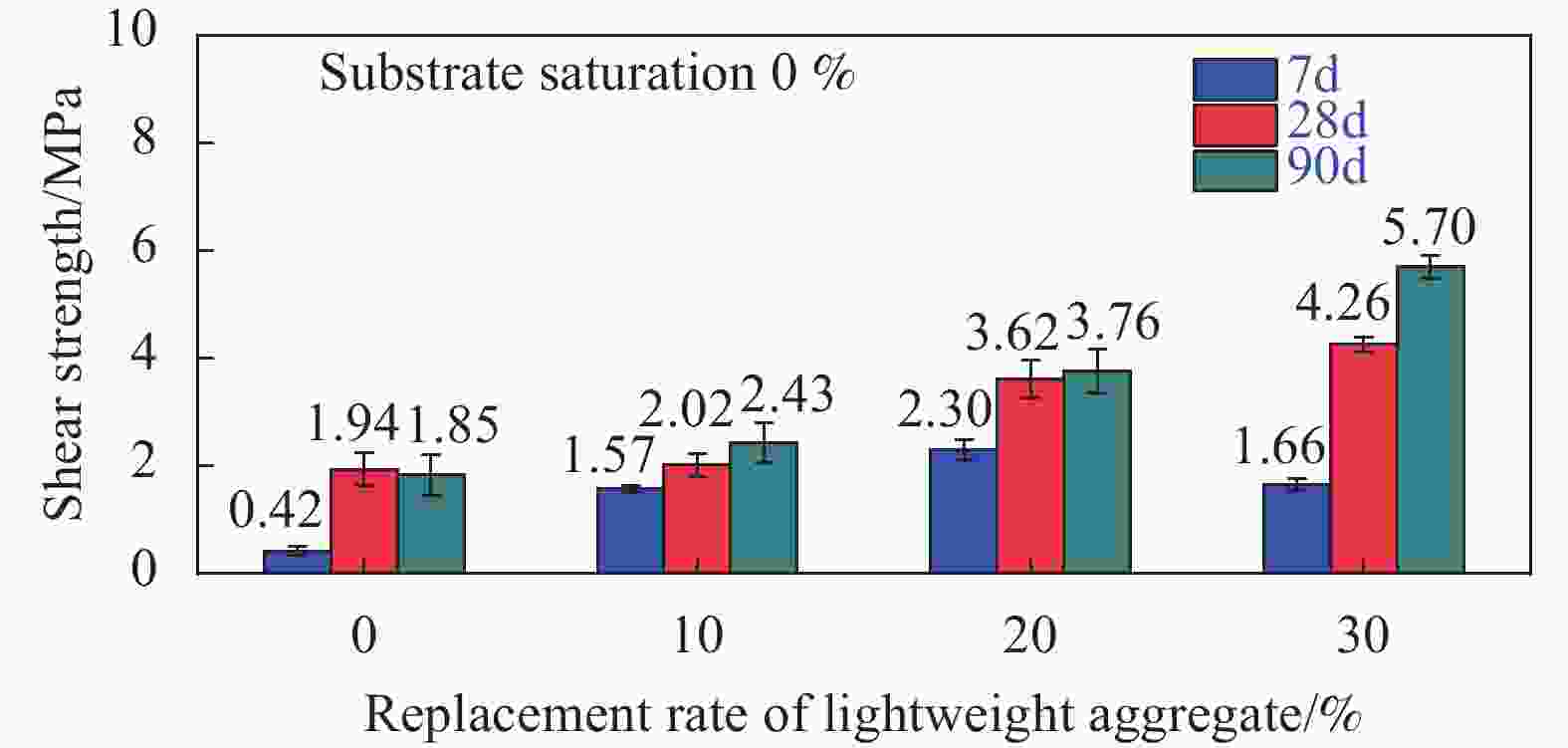

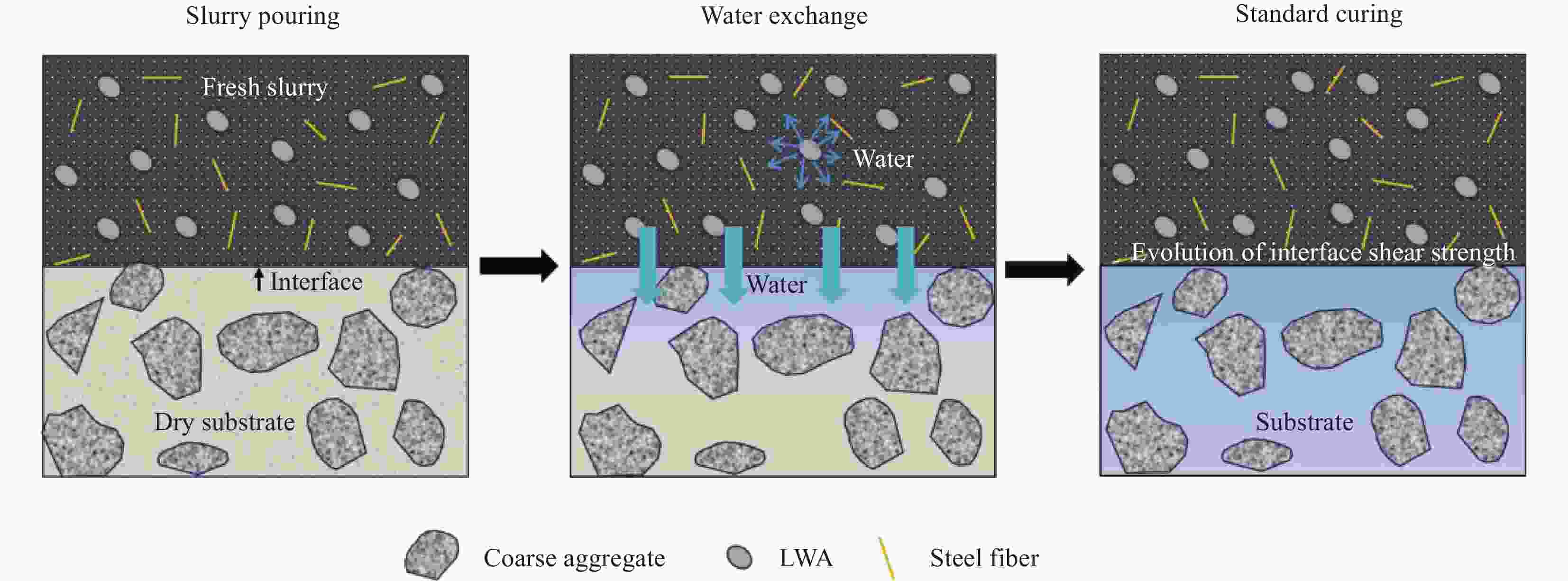

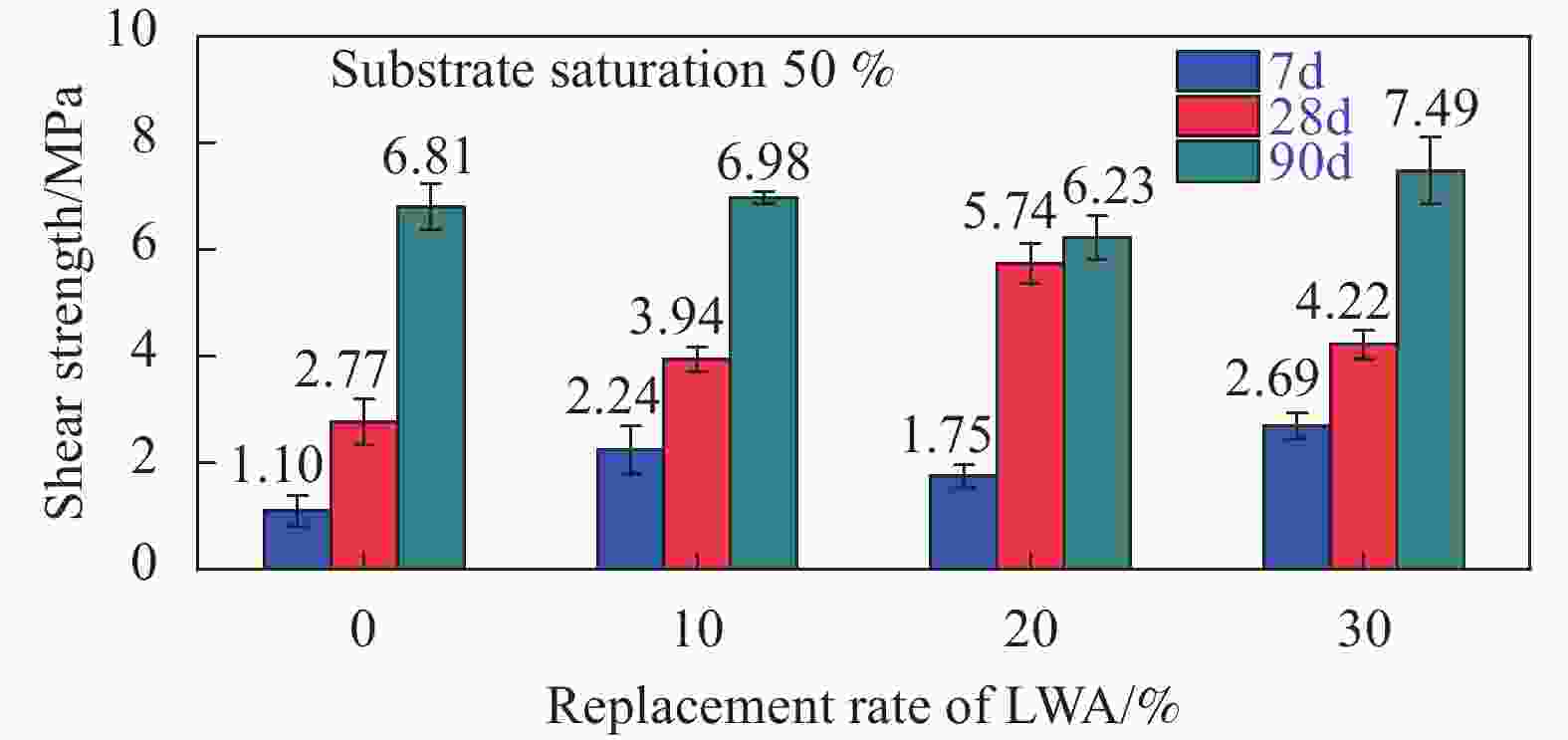

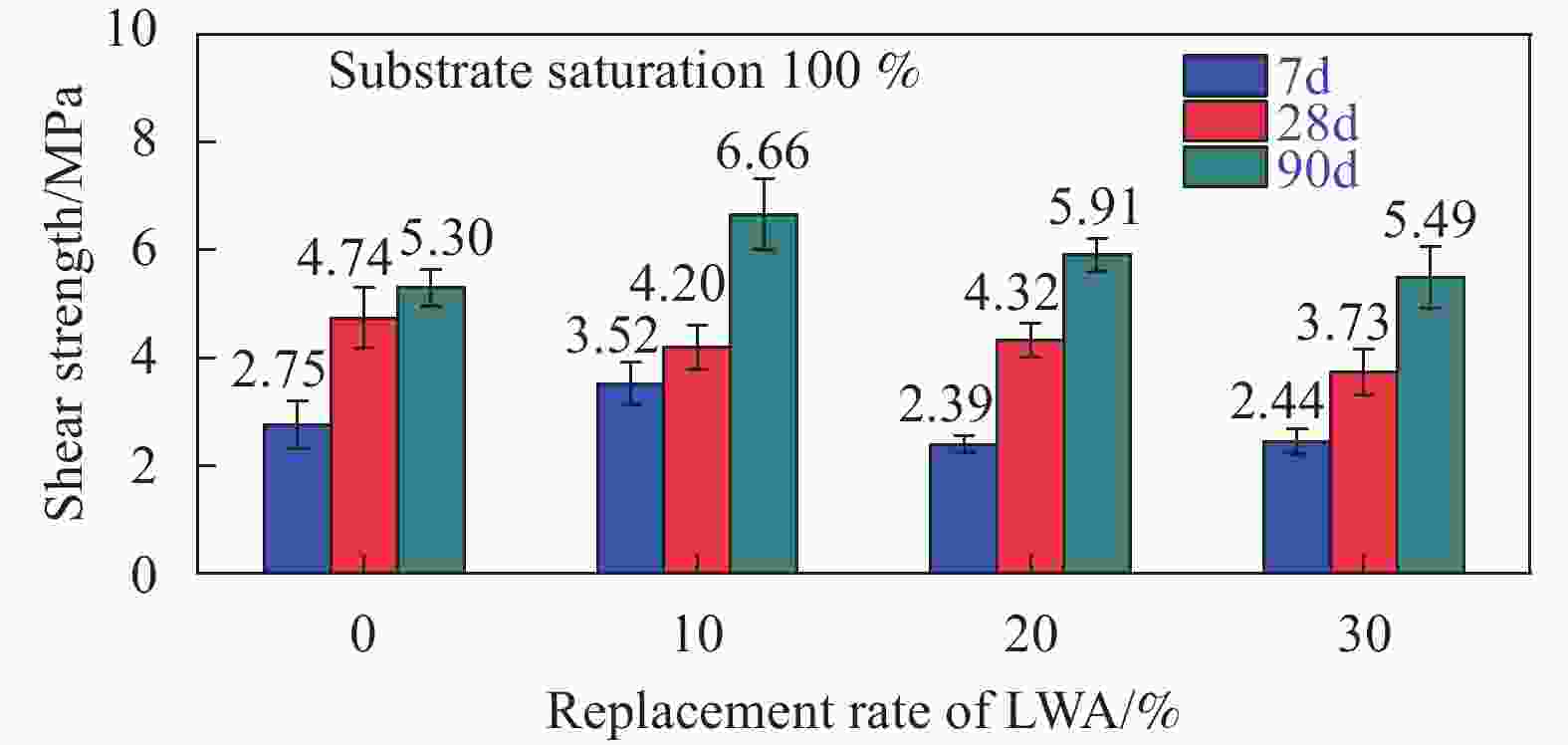

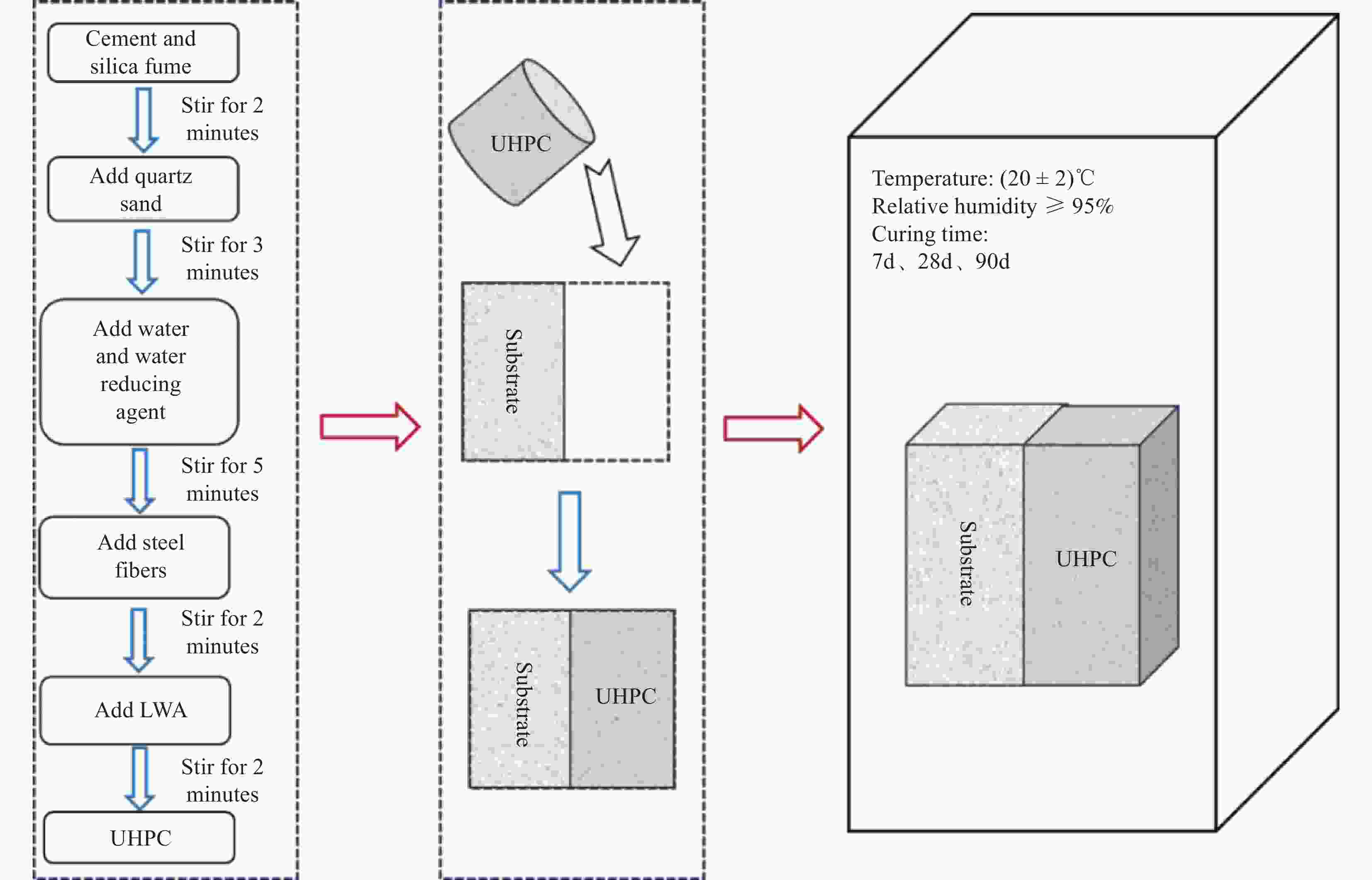

摘要: 超高性能混凝土(Ultra-high performance concrete, UHPC)具备优异的力学与抗渗性能,在混凝土结构补强加固工程中有着广阔的应用前景,如何提高UHPC与既有基体间的粘结性能成为土木工程领域普遍关心的重要课题。本文利用标准养护条件制备的试件开展试验研究,首先研究了UHPC水胶比与混凝土基体初始含水饱和度对二者间界面剪切强度的影响规律。此外,选取特定配合比的UHPC,研究了其与不同饱和度混凝土间界面剪切强度随龄期的演化规律。向UHPC中掺入预湿轻骨料以实现内养护,考虑UHPC中轻骨料取代率、混凝土基体含水饱和度的影响,研究了不同龄期养护后轻骨料UHPC与混凝土基体间界面剪切强度的演化规律。利用扫描电镜技术观测了UHPC与混凝土间界面的微结构。结果表明:(1)对于未掺轻骨料的UHPC:不论水胶比如何变化,其与饱水基体间的界面剪切强度最高,而与干燥基体间的界面剪切强度最低;其与干燥基体间的界面剪切强度随水胶比的升高而降低,与预湿基体间的界面剪切强度随水胶比的升高而先增长后降低。(2)水胶比为0.154的UHPC与不同饱和度基体间28 d时的界面剪切强度均较7 d时显著增长;90 d时,其仅与50%饱和度基体间的界面剪切强度进一步显著增长。(3)低轻骨料取代率能够提高UHPC与干燥基体间7 d时的界面剪切强度,而高轻骨料取代率能够显著提高UHPC与干燥基体间28 d和90 d时的界面剪切强度;28 d和90 d时,轻骨料UHPC与50%饱和度基体间的界面剪切强度显著高于干燥基体;7 d时,不同轻骨料取代率的UHPC与饱水基体间便可形成一定的界面剪切强度,且该强度在28 d和90 d时均进一步增长。Abstract: Ultra-high performance concrete (UHPC) has excellent mechanical and impermeability properties, and has a broad application prospect in the concrete structure reinforcement project. How to improve the bonding performance between UHPC and existing substrate has become an important topic of general concern in the field of civil engineering. In this paper, experimental studies were carried out using specimens prepared under standard curing conditions, and the effects of the water-binder ratio (w/b) of UHPC and the initial water saturation of the concrete substrate on the interfacial shear strength between them were first investigated. In addition, the evolution law of interfacial shear strength with age between the selected UHPC with a specific mix proportion and concrete with different saturation was investigated. Pre-wetted lightweight aggregate was incorporated into UHPC to achieve internal curing, and the evolution law of the interfacial shear strength between lightweight aggregate UHPC and concrete substrate after curing with different ages was investigated by taking into account the effects of the replacement rate of lightweight aggregate in UHPC, and the water saturation of concrete substrate. The microstructure of the interface between UHPC and concrete was observed using scanning electron microscopy. The results show that (1) for UHPC without lightweight aggregates, the interfacial shear strength between it and water-saturated substrate is the highest while the interfacial shear strength between it and dry substrate is the lowest irrespective of the change of the w/b of UHPC. The interfacial shear strength between UHPC and dry substrate decreases with the increase of w/b, and that between UHPC and pre-wetted substrate increases first and then decreases with the increase of the w/b. (2) The interfacial shear strengths between UHPC with a w/b of 0.154 and different saturated substrate all increase significantly at 28d compared to that at 7d. At 90d, only the interfacial shear strengths between it and 50% saturated substrate further increase significantly. (3) A low lightweight aggregate replacement rate can increase the interfacial shear strength between UHPC and dry substrate at 7d, while a high lightweight aggregate replacement rate can significantly increase the interfacial shear strength between UHPC and dry substrate at 28d and 90d. The interfacial shear strength between lightweight aggregate UHPC and 50% saturated substrate is significantly higher than that between lightweight aggregate UHPC and dry substrate at 28d and 90d. At 7d, a certain interfacial shear strength can be formed between UHPC with different lightweight replacement rates and water-saturated substrate, and the strength further increases at both 28d and 90d.

-

Key words:

- UHPC /

- substrate saturation /

- lightweight aggregate /

- interface shear strength /

- curing age

-

表 1 超高性能混凝土(UHPC)配合比(kg/m3)

Table 1. Mix proportion of ultra-high performance concrete (UHPC) (kg/m3)

Groups Cement Silica fume Quartz sand Water SP Steel fiber LWA UHPC-00 770 230 1000 154 42 156 0 UHPC-10 770 230 900 154 42 156 96 UHPC-20 770 230 800 154 42 156 192 UHPC-30 770 230 700 154 42 156 288 25-UHPC 770 230 1000 250 20 156 0 30-UHPC 770 230 1000 300 16 156 0 Notes: SP denotes superplasticizer. LWA represents lightweight aggregate. The UHPC group with a LWA replacement rate of 0%, 10%, 20% and 30% is designated as UHPC-00, UHPC-10, UHPC-20, UHPC-30. The UHPC group with a water-binder ratio (w/b) of 0.25 and 0.30 is designated as 25-UHPC and 30-UHPC, respectively. 表 2 混凝土基体配合比(kg/m3)

Table 2. Mix proportion of concrete substrate (Unit: kg/m3)

Cement Coarse aggregate Fine aggregate Water 375 1125 750 200 表 3 各组变量汇总表

Table 3. Summary table of variables for each group

Groups w/b Saturation of the substrate Replacement rate LWA Curing age UHPC-00 0.154 0%、50%、100% 0% 7 d、28 d、90 d 25-UHPC 0.25 0%、50%、100% 0% 28 d 30-UHPC 0.30 0%、50%、100% 0% 28 d UHPC-10 0.154 0%、50%、100% 10% 7 d、28 d、90 d UHPC-20 0.154 0%、50%、100% 20% 7 d、28 d、90 d UHPC-30 0.154 0%、50%、100% 30% 7 d、28 d、90 d Note: w/b refers to the water-binder ratio of UHPC. -

[1] C Li Victor, 张亚梅. 高延性纤维增强水泥基复合材料的研究进展及应用[J]. 硅酸盐学报. 2007, 35(4): 531-536.C Li Victor, Zhang Yamei Research progress and application of high ductility fiber-reinforced cement-based composites [J] Journal of Silicates 2007, 35 (4): 531-536(in Chinese). [2] 王少伟, 肖焰钰, 朱平华, 等. 高延性水泥基复合材料与既有混凝土结合面的抗溶蚀性[J]. 硅酸盐学报. 2022, 50(10): 2692-2700.Wang Shaowei, Xiao Yanyu, Zhu Pinghua, et al. Corrosion resistance of the interface between high ductility cement-based composite materials and existing concrete [J] Journal of Silicates 2022, 50 (10): 2692-2700(in Chinese). [3] Yu J, Zhang B, Chen W, et al. Multi-scale study on interfacial bond failure between normal concrete (NC) and ultra-high performance concrete (UHPC)[J]. Journal of Building Engineering, 2022, 57: 104808. doi: 10.1016/j.jobe.2022.104808 [4] 廖肇乾. UHPC-NC界面粘结强度试验研究[D]. 湖南大学, 2018.Liao Zhaoqian Experimental study on the bonding strength of UHPC-NC interface [D] Hunan University, 2018(in Chinese). [5] 饶欣频, 霍文斌, 胡智敏, 等. 超高性能混凝土与普通混凝土的界面抗剪性能试验研究[J]. 建筑结构. 2021, 51(14): 101-106.Rao Xinpin, Huo Wenbin, Hu Zhimin, et al. Experimental study on the interface shear resistance of ultra-high performance concrete and ordinary concrete [J] Building structure 2021, 51 (14): 101-106(in Chinese). [6] 阎培渝, 张增起. 复合胶凝材料的水化硬化机理[J]. 硅酸盐学报. 2017, 45(8): 1066-1072.Yan Peiyu, Zhang Zengqi The hydration hardening mechanism of composite cementitious materials [J] Journal of Silicates 2017, 45 (8): 1066-1072(in Chinese). [7] Li G. A new way to increase the long-term bond strength of new-to-old concrete by the use of fly ash[J]. Cement and Concrete Research, 2003, 33(6): 799-806. doi: 10.1016/S0008-8846(02)01064-5 [8] Behforouz B, Tavakoli D, Gharghani M, et al. Bond strength of the interface between concrete substrate and overlay concrete containing fly ash exposed to high temperature[J]. Structures, 2023, 49: 183-197. doi: 10.1016/j.istruc.2023.01.122 [9] Feng S, Xiao H, Li H. Comparative studies of the effect of ultrahigh-performance concrete and normal concrete as repair materials on interfacial bond properties and microstructure[J]. Engineering Structures, 2020, 222: 111122. doi: 10.1016/j.engstruct.2020.111122 [10] 李港来. UHPC中胶凝材料的后续水化及对其稳定性的影响[D]. 湖南大学, 2021.Li Ganglai. Subsequent hydration of cementitious materials in UHPC and its impact on their stability [D] Hunan University, 2021(in Chinese). [11] Beushausen H, Höhlig B, Talotti M. The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ[J]. Cement and Concrete Research, 2017, 92: 84-91. doi: 10.1016/j.cemconres.2016.11.017 [12] Zhang Y, Zhu P, Liao Z, et al. Interfacial bond properties between normal strength concrete substrate and ultra-high performance concrete as a repair material[J]. Construction and Building Materials, 2020, 235: 117431. doi: 10.1016/j.conbuildmat.2019.117431 [13] Bentz D P, De la Varga I, Muñoz J F, et al. Influence of substrate moisture state and roughness on interface microstructure and bond strength: Slant shear vs. pull-off testing[J]. Cement and Concrete Composites, 2018, 87: 63-72. doi: 10.1016/j.cemconcomp.2017.12.005 [14] Xiong G, Luo B, Wu X, et al. Influence of silane coupling agent on quality of interfacial transition zone between concrete substrate and repair materials[J]. Cement and Concrete Composites, 2006, 28(1): 97-101. doi: 10.1016/j.cemconcomp.2005.09.004 [15] Semendary A A, Svecova D. Factors affecting bond between precast concrete and cast in place ultra high performance concrete (UHPC)[J]. Engineering Structures, 2020, 216: 110746. doi: 10.1016/j.engstruct.2020.110746 [16] 吴琛, 储福玮, 龚明子, 等. 免蒸养超高性能混凝土-既有混凝土界面粘结性能试验研究[J]. 材料导报. 2023, 37(24): 163-170.Wu Chen, Chu Fuwei, Gong Mingzi, et al. Experimental study on the interfacial bonding performance between non steam cured ultra-high performance concrete and existing concrete [J] Material Guide 2023, 37 (24): 163-170(in Chinese). [17] 郭旗, 薛善彬, 荆蜂杰, 等. 新拌修补砂浆与基体水分交换行为及其对复合体性能的影响[J]. 硅酸盐学报. 2023, 51(5): 1115-1125.Guo Qi, Xue Shanbin, Jing Fengjie, et al. The water exchange behavior between freshly mixed repair mortar and matrix and its impact on the performance of the composite [J] Journal of Silicates 2023, 51 (5): 1115-1125(in Chinese). [18] Xue S, Zhang P, Lehmann E H, et al. Neutron radiography of water exchange across the interface between old and fresh mortar[J]. Measurement, 2021, 183: 109882. doi: 10.1016/j.measurement.2021.109882 [19] Xue S, Meng F, Zhang P, et al. Influence of substrate moisture conditions on microstructure of repair mortar and water imbibition in repair-old mortar composites[J]. Measurement, 2021, 183: 109769. doi: 10.1016/j.measurement.2021.109769 [20] 孟繁强. 新旧砂浆粘结性能及水分传输规律试验研究[D]. 青岛理工大学, 2021.Meng Fanqiang Experimental study on the bonding performance and water transfer law of new and old mortar [D] Qingdao University of Technology, 2021(in Chinese). [21] 张立卿, 潘延念, 胡文兵, 等. 废弃瓷砖粉对超高性能混凝土的抗压强度影响规律与机制[J]. 复合材料学报. 2023, 40(3): 1611-1623.Zhang Liqing, Pan Yannian, Hu Wenbing, et al. The influence and mechanism of waste ceramic tile powder on the compressive strength of ultra-high performance concrete [J] Journal of Composite Materials 2023, 40 (3): 1611-1623(in Chinese). [22] 杨正宏, 高双双, 于龙, 等. 养护温度对陶粒内水分向水泥浆体中迁移行为的影响[J]. 建筑材料学报. 2020, 23(1): 138-144.Yang Zhenghong, Gao Shuangshuang, Yu Long, etc The effect of curing temperature on the migration behavior of water inside ceramic particles into cement slurry [J] Journal of Building Materials 2020, 23 (1): 138-144(in Chinese). [23] Zhang G, Chen H, Yang J, et al. Relationship between chloride ion permeation resistance of ultra-high performance concrete and lightweight aggregate ratio[J]. Journal of Building Engineering, 2023, 76: 107360. doi: 10.1016/j.jobe.2023.107360 [24] Shen P, Lu J, Zheng H, et al. Expansive ultra-high performance concrete for concrete-filled steel tube applications[J]. Cement and Concrete Composites, 2020, 114: 103813. doi: 10.1016/j.cemconcomp.2020.103813 [25] 张媛媛, 毛倩瑾, 李松涛, 等. 高吸水树脂作为混凝土内养护材料的研究进展[J]. 硅酸盐学报. 2022, 50(11): 3009-3020.Zhang Yuanyuan, Mao Qianjin, Li Songtao, et al. Research progress on high water absorbent resin as an internal curing material for concrete [J] Journal of Silicates 2022, 50 (11): 3009-3020(in Chinese). [26] 于本田, 陈延飞, 王焕, 等. 大掺量高吸附性石粉高强机制砂混凝土收缩开裂抑制试验[J]. 复合材料学报. 2021, 38(8): 2737-2746.Yu Bentian, Chen Yanfei, Wang Huan, et al. Experimental Study on Shrinkage and Cracking Inhibition of High Strength Mechanized Sand Concrete with High Content and Adsorption of Stone Powder [J] Journal of Composite Materials 2021, 38 (8): 2737-2746(in Chinese). [27] Liu J, Wang M, Liu N, et al. Development of ultra-fine SAP powder for lower-shrinkage and higher-strength cement pastes made with ultra-low water-to-binder ratio[J]. Composites Part B:Engineering, 2023, 262: 110810. doi: 10.1016/j.compositesb.2023.110810 [28] 张高展, 王宇譞, 葛竞成, 等. 轻集料对超高性能混凝土工作和力学性能的影响[J]. 建筑材料学报. 2021, 24(3): 499-507.Zhang Gaozhan, Wang Yuqian, Ge Jingcheng, et al. The influence of lightweight aggregates on the workability and mechanical properties of ultra-high performance concrete [J] Journal of Building Materials 2021, 24 (3): 499-507(in Chinese). [29] 李春云, 薛善彬, 张鹏, 等. 轻骨料对砂浆力学与毛细吸水性能的影响[J]. 硅酸盐通报. 2022, 41(1): 41-50.Li Chunyun, Xue Shanbin, Zhang Peng, et al. The influence of lightweight aggregates on the mechanical and capillary water absorption properties of mortar [J] Silicate notification 2022, 41 (1): 41-50(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 40

- HTML全文浏览量: 21

- 被引次数: 0

下载:

下载: