Tensile and compressive properties and crack characteristics of rice husk ash and crumb rubber particles modified engineered cementitious composites

-

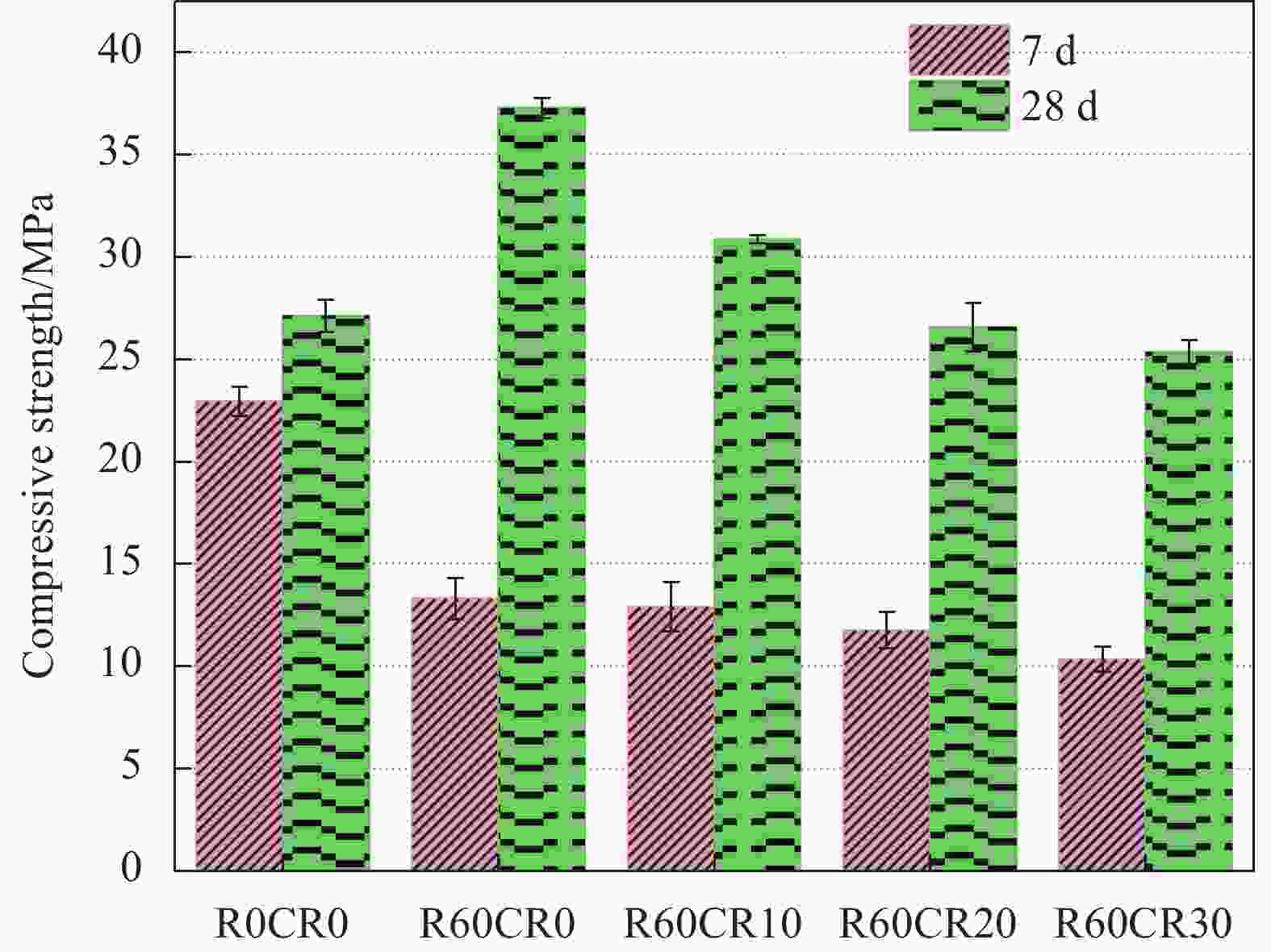

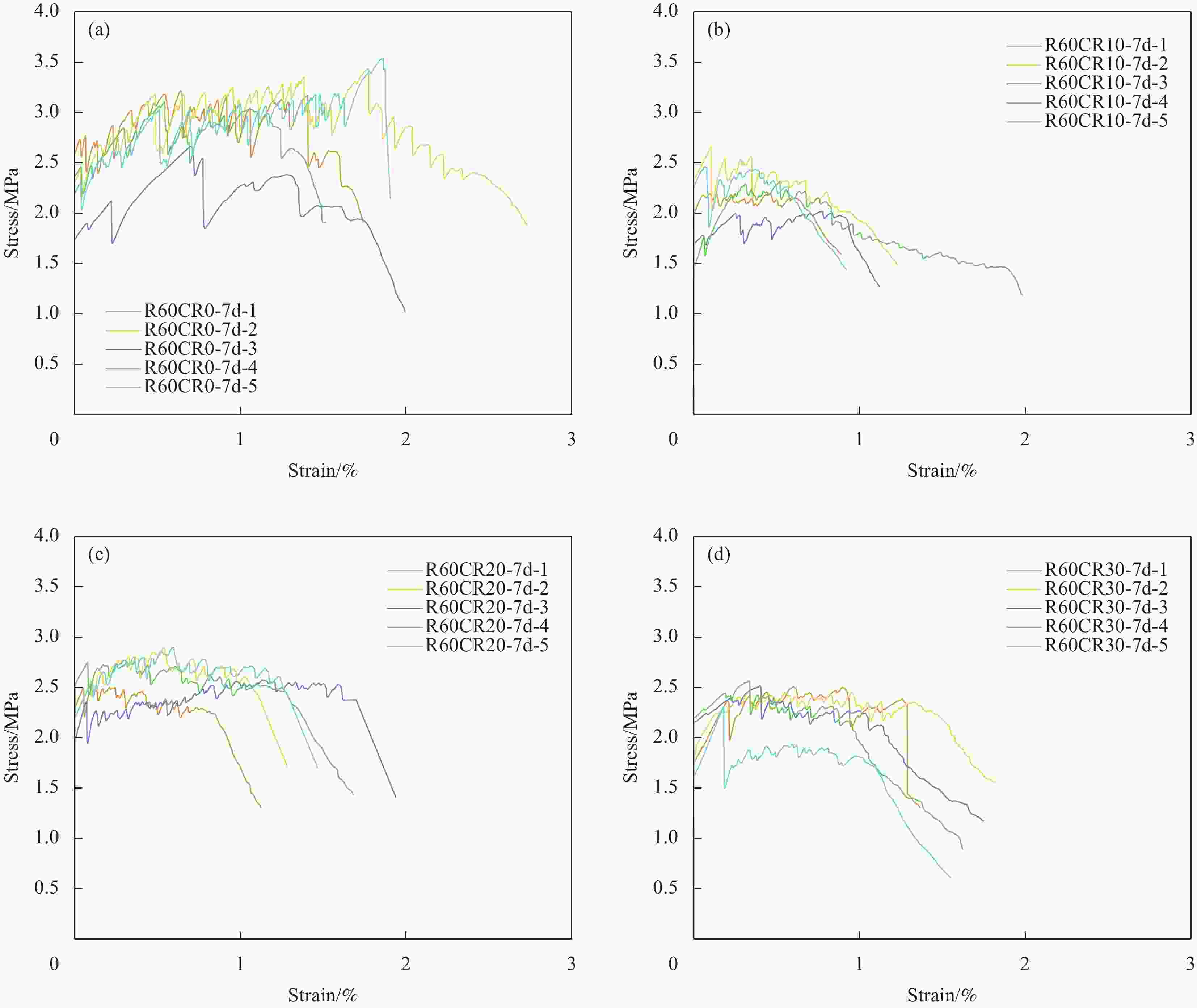

摘要: 采用稻壳灰为主要胶凝材料并掺入橡胶颗粒作为人工缺陷,制备低碳环保型的高延性水泥基复合材料(Rice Husk Ash and Crumb Rubbers Engineered Cementitious Composites, CR-RHA/ECC)。通过宏观力学性能与微观实验,研究不同养护龄期下(7 d和28 d)橡胶掺入量(0, 10%, 20%, 30%)对CR-RHA/ECC延性和开裂特性的影响。结果表明:随着龄期的增长,CR-RHA/ECC的延性存在较大差异,CR替代10%河砂使CR-RHA/ECC的7 d龄期延性削弱了54%,而使CR-RHA/ECC的28d龄期增长了67%,随着龄期增长(28d龄期),CR替代30%河砂可使CR-RHA/ECC的延性达6%,此时CR-RHA/ECC相较于无CR替代河砂组CR-RHA/ECC的拉伸裂缝宽度减小了53%。

-

关键词:

- 高延性水泥基复合材料 /

- 稻壳灰 /

- 橡胶 /

- 延性 /

- 裂缝宽度

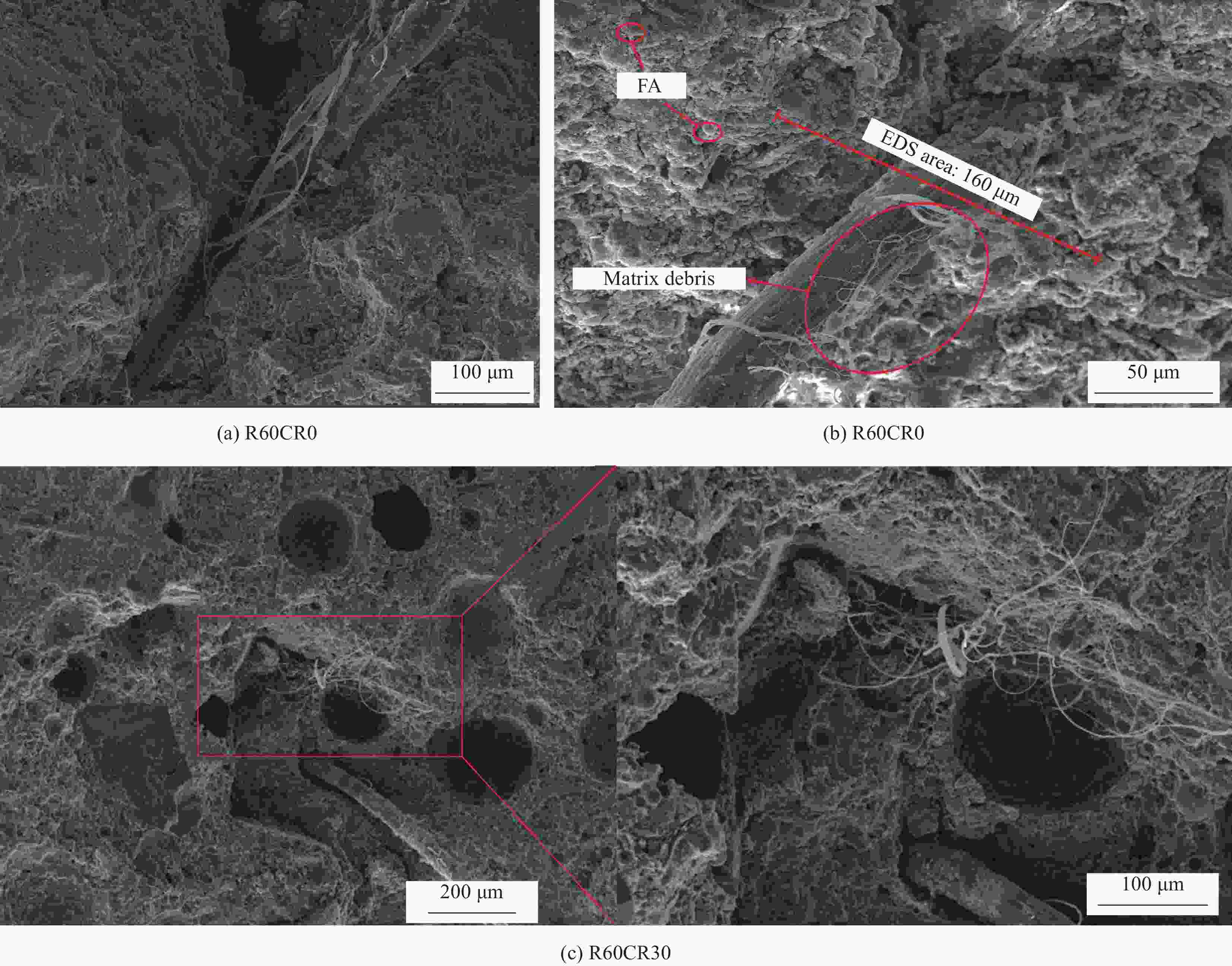

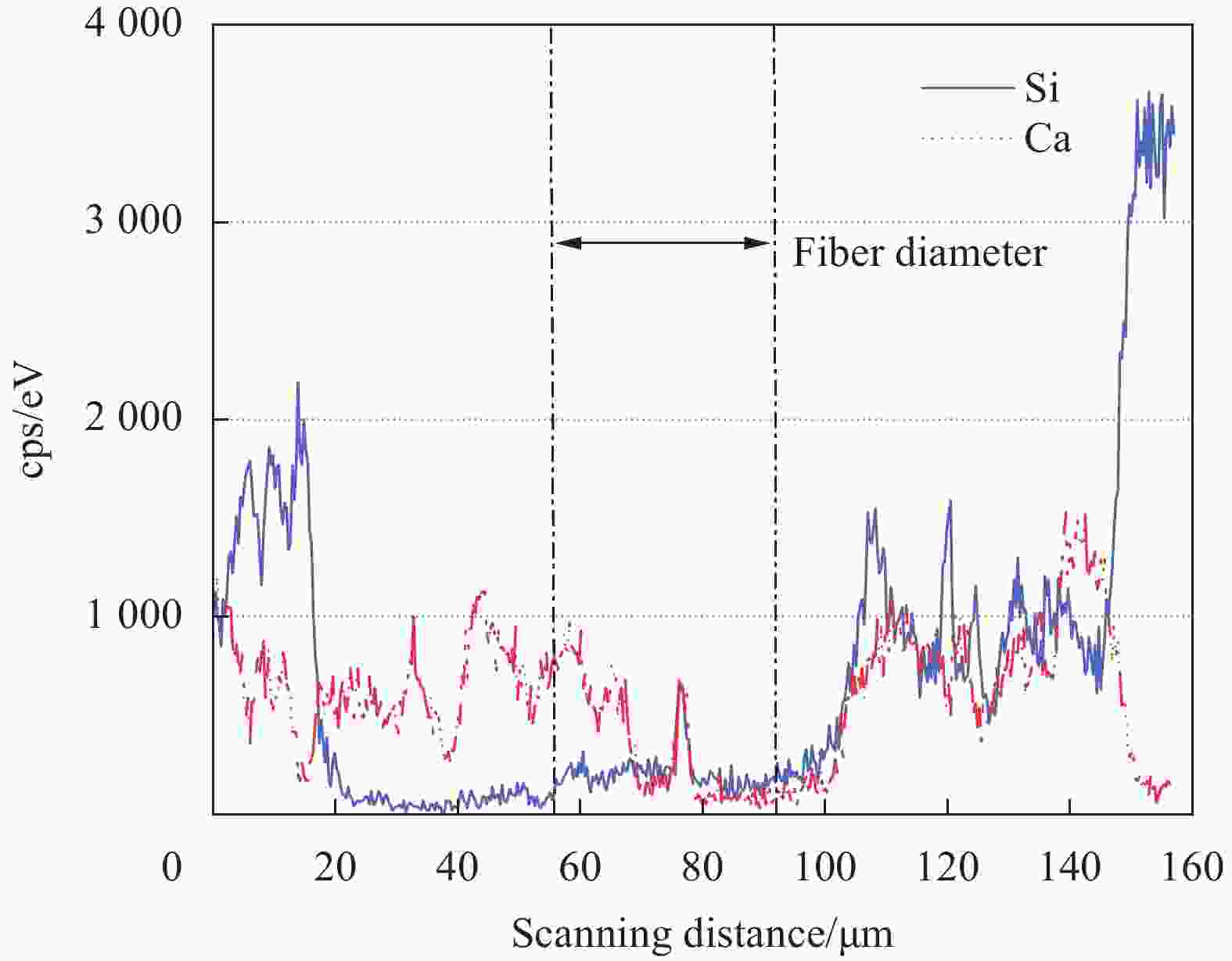

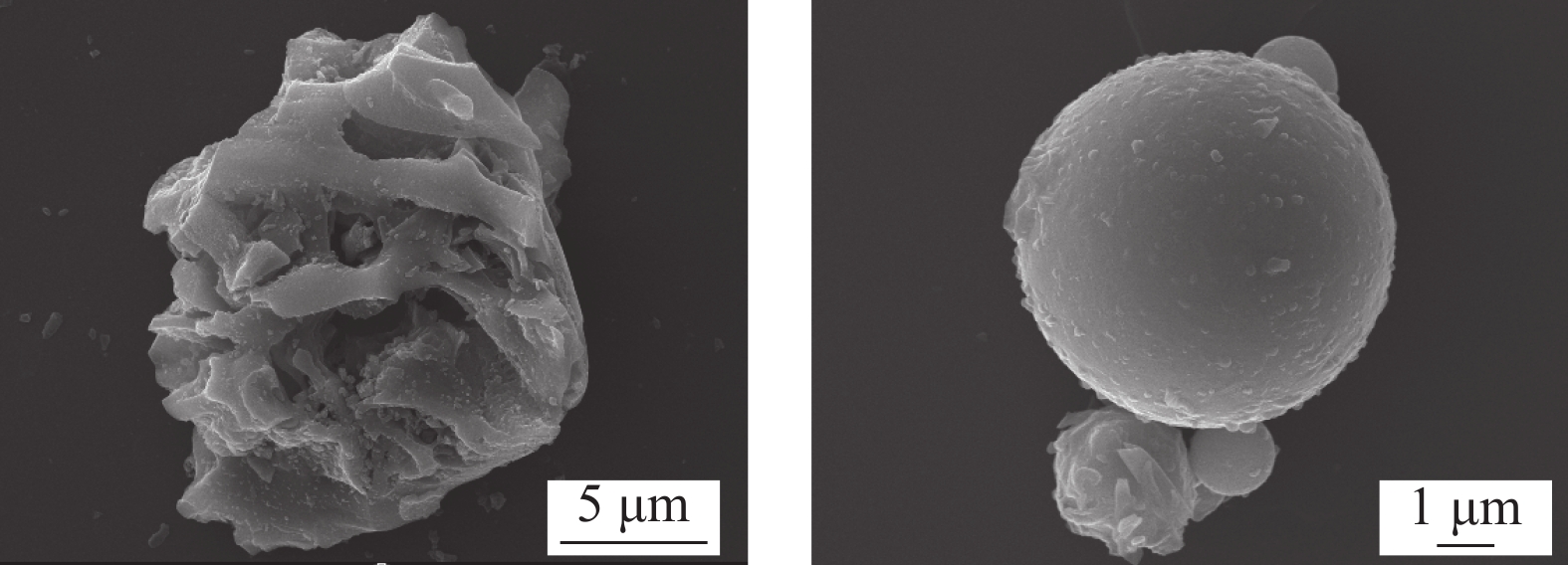

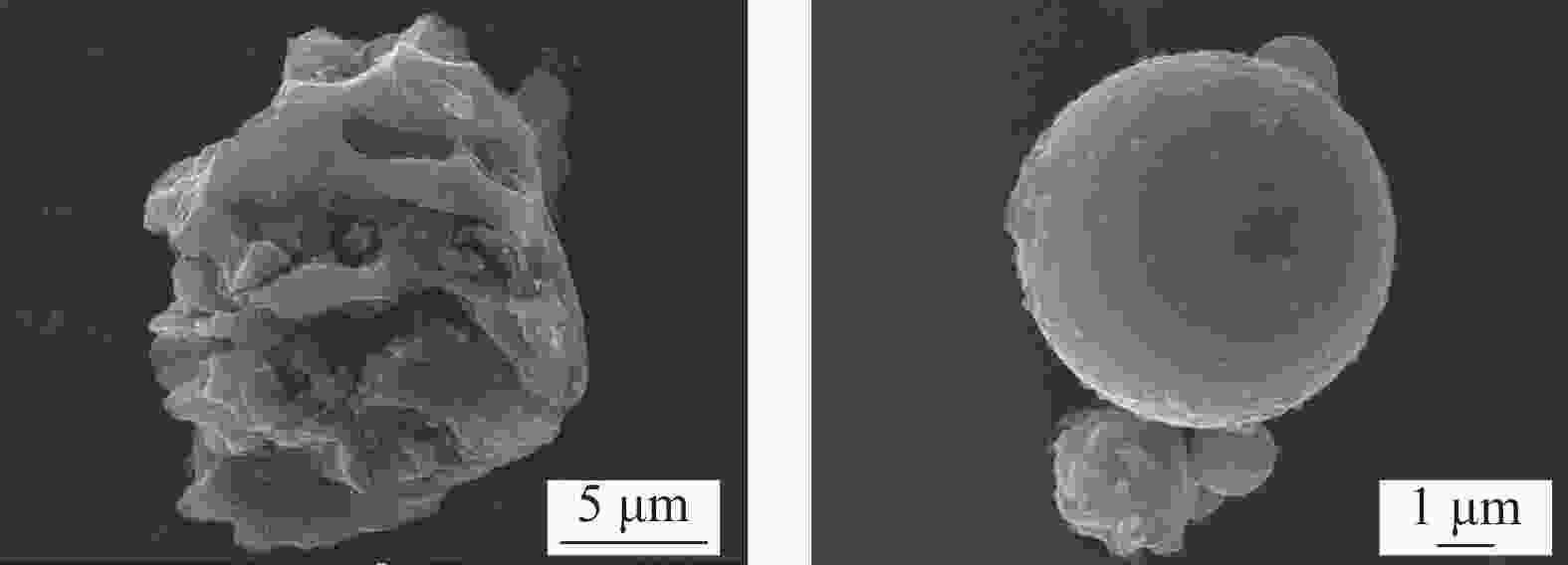

Abstract: Rice husk ash is the primary supplementary cementitious material, with rubber particles injected as artificial flaws. CR-RHA/ECC (Rice Husk Ash and Crumb Rubbers Engineered Cementitious Composites) are low carbon, ecologically friendly cementitious composites with good ductility. The effects of rubber content (0, 10%, 20%, 30%) on the ductility and cracking characteristics of CR-RHA/ECC at each curing ages (7 d and 28 d) were explored employing macroscopic mechanical properties and microscopic investigations. The results show that: With the increase of age, there is a great difference in the ductility of CR-RHA/ECC. The replacement of 10% river sand by CR weakens the ductility of CR-RHA/ECC at 7 days by 54% and increases the ductility of CR-RHA/ECC at 28 days by 67%. With the increase of age (28 days), When CR replaces 30% river sand, the ductility of CR-RHA/ECC can reach 6%, and the tensile fracture width of CR-RHA/ECC decreases by 53% compared with that of CR-RHA/ECC without CR replacement.-

Key words:

- high ductility cementitious composites /

- rice husk ash /

- crumb rubber /

- ductility /

- crack wide

-

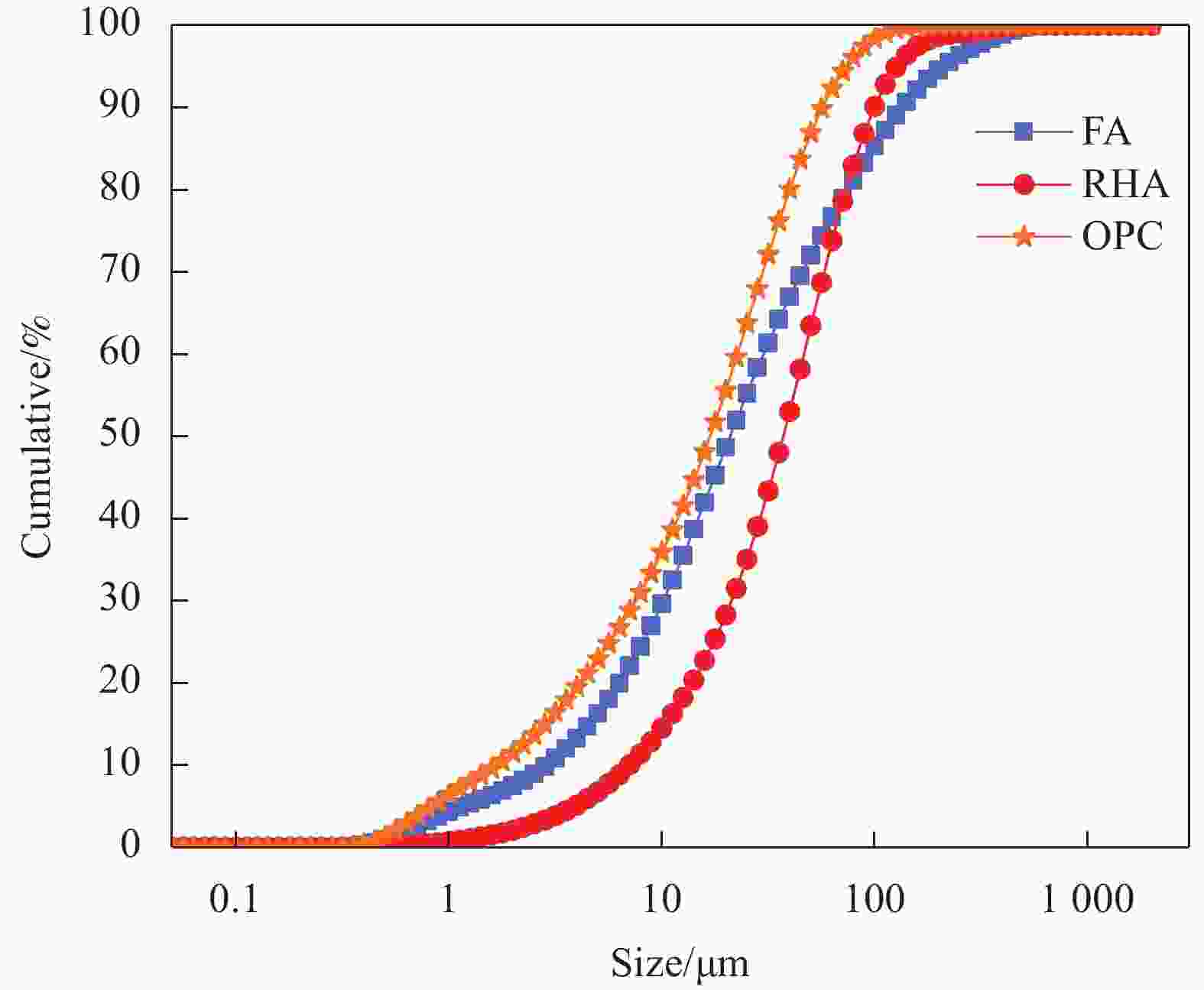

表 1 胶凝材料化学成分含量(wt%)

Table 1. Chemical composition of cementitious materials(wt%)

SiO2 K2O CaO P2O5 Al2O3 MgO Fe2O3 SO3 Na2O RHA 85.90 3.43 1.11 0.75 0.55 0.46 0.37 0.19 0.11 FA 50.80 1.44 2.29 0.38 31.95 0.62 3.34 0.67 0.54 OPC 22.00 0.56 62.20 0.12 6.02 0.85 4.23 3.16 0.17 Notes: RHA, FA and OPC stand for rice husk ash, fly ash and ordinary Portland cement. 表 2 CR-RHA/ECC配合比方案(wt%)

Table 2. Mix design of CR-RHA/ECC (wt%)

Mixtures OPC FA RHA River sand CR Water HRWRA

/wt%PVA

/vol%R60CR0 1.00 0.88 0.76 1.15 0 0.80 7.00 2.00 R60CR10 1.00 0.88 0.76 1.04 0.03 0.80 7.00 2.00 R60CR20 1.00 0.88 0.76 0.92 0.05 0.80 7.00 2.00 R60CR30 1.00 0.88 0.76 0.81 0.08 0.80 7.00 2.00 R0 CR0 1.00 2.20 0.00 1.15 0.00 0.80 2.00 2.00 Notes: HRWRA is the liquid superplasticizer. OPC, FA and RHA stand for ordinary portland cement, fly ash and rice husk ash. R represent RHA, CR represent crumbs rubber; In RiCRj, i represents the volume fraction of rice husk ash to FA; j represents the volume ratio of crumb rubber to river sand. 表 3 开裂与极限应力及其比值

Table 3. Cracking and ultimate strength and their ratio

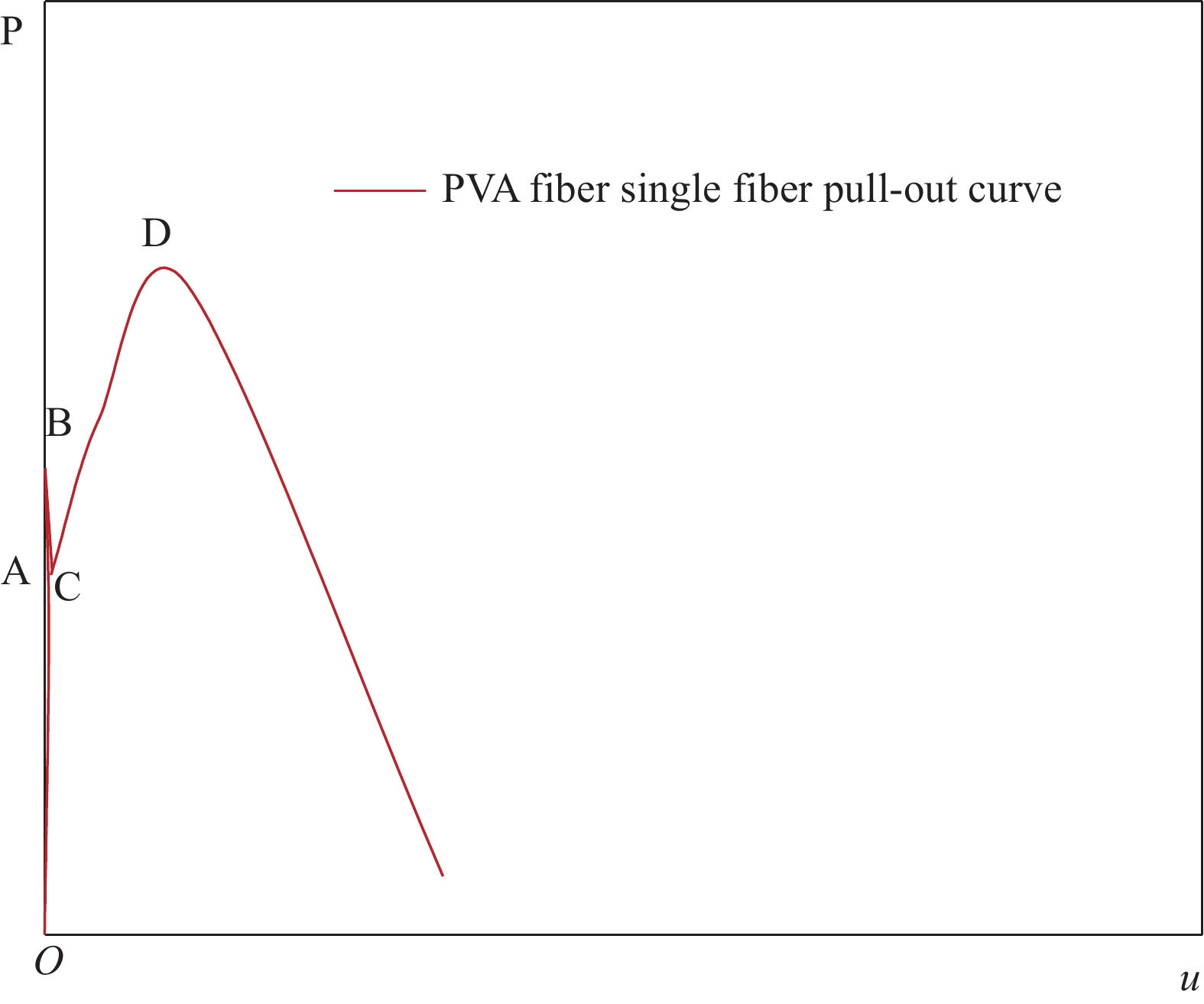

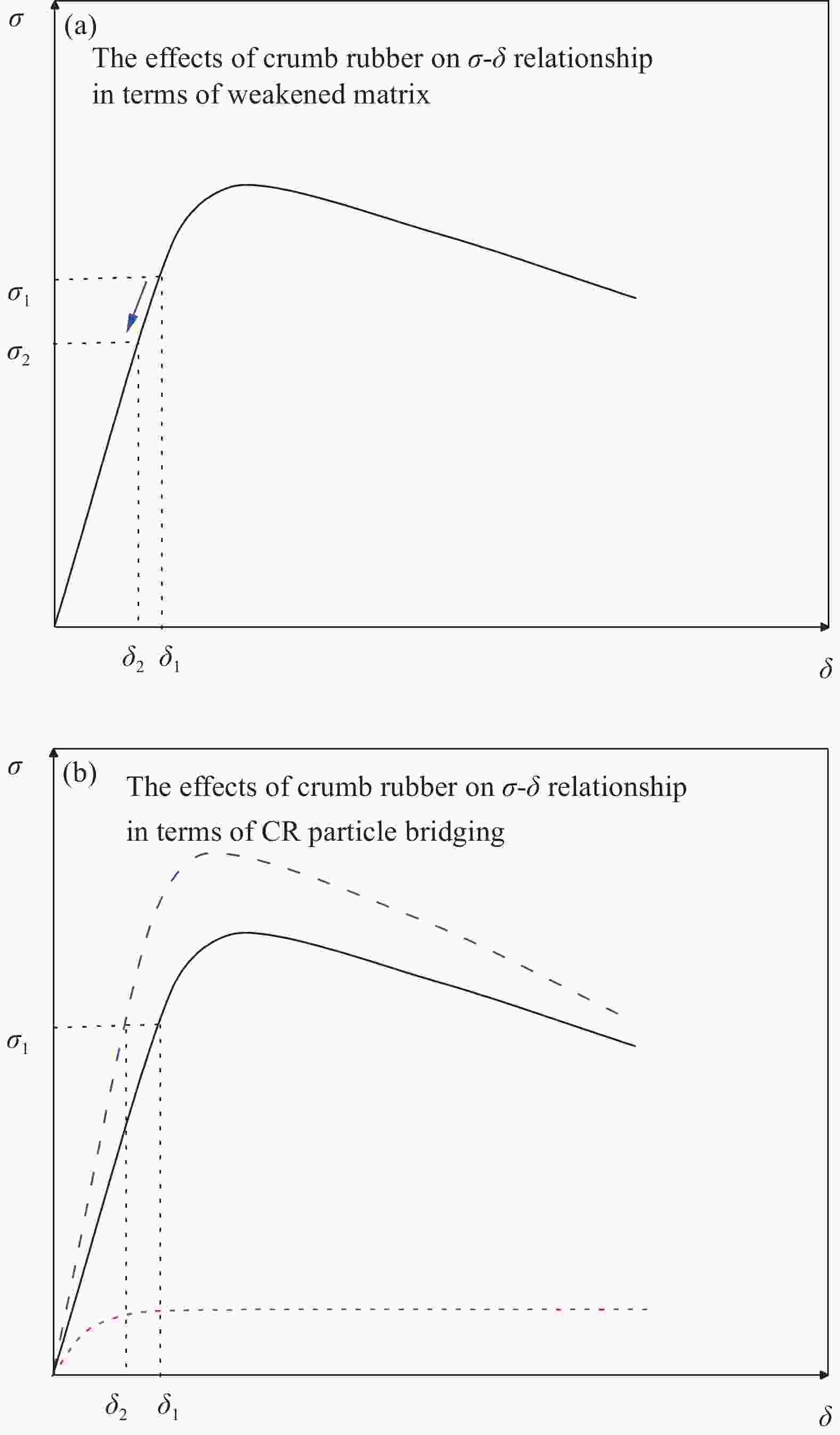

Mixture Cracking strength $ {\sigma }_{\mathrm{s}\mathrm{s}} $ Ultimate strength $ {\sigma }_{\mathrm{c}} $ $ {\sigma }_{\mathrm{c}}/{\sigma }_{\mathrm{s}\mathrm{s}} $ 7 d (MPa) 28 d(MPa) 7 d (MPa) 28 d(MPa) 7 d (MPa) 28 d(MPa) R60CR0 2.47 2.82 3.47 4.36 1.44 1.55 R60CR10 2.49 2.61 2.51 4.33 1.09 1.66 R60CR20 2.24 2.36 2.49 3.89 1.00 1.65 R60CR30 2.23 2.52 2.45 4.11 1.17 1.63 表 4 28 d裂缝参数统计

Table 4. Statistical of crack parameters

Mixture Crack numbers Crack width/μm Mixture Crack numbers Crack width/μm R60CR0 12 197 R60CR10 37 96 R60CR20 47 104 R60CR30 48 93 -

[1] Li V C, Wang S X, Wu C. Tensile strain-hardening behavior or polyvinyl alcohol engineered cementitious composite (PVA-ECC)[J]. Aci Materials Journal, 2001, 98(6): 483-92. [2] 徐世烺, 蔡向荣, 张英华. 超高韧性水泥基复合材料单轴受压应力-应变全曲线试验测定与分析[J]. 土木工程学报, 2009, 42(11): 79-85. doi: 10.3321/j.issn:1000-131X.2009.11.011XU Shilang, CAI Xiangrong, ZHANG Yinghua. Determination and analysis of full stress-strain curves of ultra-high toughness cement-based composites under Uniaxial Compression[J]. Journal of Civil Engineering, 2009, 42(11): 79-85(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.11.011 [3] 高淑玲, 徐世烺. PVA纤维增强水泥基复合材料拉伸特性试验研究[J]. 大连理工大学学报, 2007, (02): 233-239. doi: 10.3321/j.issn:1000-8608.2007.02.016GAO Shuling, XU Shilang. Experimental study on tensile properties of PVA fiber reinforced cement-based composites[J]. Journal of Dalian University of Technology, 2007, (02): 233-239(in Chinese). doi: 10.3321/j.issn:1000-8608.2007.02.016 [4] Yu J, Li H, Leung C K Y, et al. Matrix design for waterproof engineered cementitious composites (ECCs)[J]. Construction and Building Materials, 2017, 139: 438-446. doi: 10.1016/j.conbuildmat.2017.02.076 [5] 杨珊, 彭林欣, 滕晓丹. 高温后PVA纤维增强水泥基复合材料力学性能试验研究[J]. 混凝土与水泥制品, 2021, (04): 49-54.YANG Shan, PENG Linxin, TENG Xia-dan. Experimental study on Mechanical properties of PVA fiber-reinforced cement-based composites at high temperature[J]. Concrete and Cement Products, 2021, (04): 49-54(in Chinese). [6] WANG J, XIAO J, ZHANG Z, et al. Action mechanism of rice husk ash and the effect on main performances of cement-based materials: a review[J]. Construction and Building Materials, 2021, (288): 123068. [7] 李丽华, 韩琦培, 杨星, 等. 稻壳灰-水泥固化淤泥土力学特性及微观机理研究[J/OL]. 土木工程学报: 1-122023-03-29]. LI Lihua, HAN Qipei, YANG Xing, et al. Rice husk ash and cement solidification silt soil mechanics properties and microscopic mechanism research [J/OL]. Journal of civil engineering: 1-12 [2023-03-29] (in Chinese). [8] He, Z. H. , Li, L. , Du, S. Creep analysis of concrete containing rice husk ash[J]. Cement Concr. Compos. 2017, 80: 190–199. [9] Huang, H, Gao X, Wang H, et al. Influence of rice husk ash on strength and permeability of ultra-high performance concrete[J]. Construct. Build. Mater., 2017, 149: 621-628. doi: 10.1016/j.conbuildmat.2017.05.155 [10] Zhang Z, Fan Y, Liu J C. Shuping Wang, Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash[J]. Cem. Concr. Res, 2020, 137: 106200. doi: 10.1016/j.cemconres.2020.106200 [11] F. B. P. da Costa, D. P. Righi, A. G. Graeff, et al. Experimental study of some durability properties of ECC with a more environmentally sustainable rice husk ash and high tenacity polypropylene fibers[J]. Constr. Build. Mater., 2019, 213: 505-513. doi: 10.1016/j.conbuildmat.2019.04.092 [12] Zhang Z, Yuvaraj A, Di J, et al. Matrix design of light weight, high strength, high ductility ECC[J]. Construction and Building Materials, 2019, 210: 188-197. doi: 10.1016/j.conbuildmat.2019.03.159 [13] Abdulkadir I, Mohammed B S, Liew M S, et al. A review of the effect of waste tire rubber on the properties of ECC[J]. Intern. J. Adv. Appl. Sci, 2020, 7: 105-116. [14] Abdulkadir I, Mohammed B S, Liew M S, et al. A review of the effect of waste tire rubber on the properties of ECC[J]. Intern. J. Adv. Appl. Sci, 2020, 7: 105-116. [15] Zhang Z, Ma H, Qian S. Investigation on properties of ECC incorporating crumb rubber of different sizes[J]. Journal of Advanced Concrete Technology, 2015, 13(5): 241-251. doi: 10.3151/jact.13.241 [16] 陈爱玖, 王静, 马莹. 钢纤维橡胶再生混凝土的抗冻性试验[J]. 复合材料学报, 2015, 32(4): 933-941.CHEN Aijiu, WANG Jing, MA Ying. Rubber steel fiber recycled concrete frost resistance test[J]. Journal of composite materials, 2015, 32(4): 933-941(in Chinese). [17] Ismail MK, Sherir MA, Siad H, et al. Properties of self-consolidating engineered cementitious composite modified with rubber[J]. Journal of Materials in Civil Engineering, 2018, 30(4): 04018031. doi: 10.1061/(ASCE)MT.1943-5533.0002219 [18] Zhang Z, Yuvaraj A, Di J, et al. Matrix design of light weight, high strength, high ductility ECC[J]. Construction and Building Materials, 2019, 210: 188-197. doi: 10.1016/j.conbuildmat.2019.03.159 [19] Ma H, Qian S, Zhang Z, et al. Tailoring engineered cementitious composites with local ingredients[J]. Construction and Building Materials, 2015, 101: 584-595. doi: 10.1016/j.conbuildmat.2015.10.146 [20] S. Ramanathan, H. Moon, M. Croly, et al. Suraneni, Predicting the degree of reaction of supplementary cementitious materials in cementitious pastes using a pozzolanic test[J]. Constr. Build. Mater. , 2019, 204: 621–630. [21] M. Hou, D. Zhang, V. C. Li. Crack Width Control and Mechanical Properties of Low 681 Carbon Engineered Cementitious Composites (ECC)[J]. Constr. Build. Mater. , 2022: 348. [22] P. Suraneni, J. Weiss. Examining the pozzolanicity of supplementary cementitious materials using isothermal calorimetry and thermogravimetric analysis[J]. Cem. Concr. Compos., 2017, 83: 273-278. doi: 10.1016/j.cemconcomp.2017.07.009 [23] P. T. Durdziński, M. B. Haha, S. A. Bernal, et al. , Outcomes of the RILEM round robin on degree of reaction of slag and fly ash in blended cements[J]. Mater. Struct. , 2017, 50 (2): 135. [24] Wang J, Guo Z, Yuan Q, et al. Effects of ages on the ITZ microstructure of crumb rubber concrete[J]. Construction and Building Materials, 2020, 254: 119329. doi: 10.1016/j.conbuildmat.2020.119329 [25] Ma H, Qian S, Zhang Z, et al. Tailoring engineered cementitious composites with local ingredients[J]. Construction and building materials, 2015, 101: 584-595. doi: 10.1016/j.conbuildmat.2015.10.146 [26] Yang E H, Wang S, Yang Y, et al. Fiber-bridging constitutive law of engineered cementitious composites[J]. Journal of advanced concrete technology, 2008, 6(1): 181-193. doi: 10.3151/jact.6.181 [27] 滕晓丹, 郭健鸣, 孙辉煌. 基于深度学习的高延性水泥基复合材料单轴拉伸裂缝检查与特征定量化识别[J/OL]. 硅酸盐学报: 1-102023-03-29]. TENG Xiaodan, GUO Jianming, SUN Huihuang. Deep learning based uniaxial tensile crack inspection and feature quantification identification of high ductility cement-based composites [J/OL]. Journal of silicate: 1-10. [2023-03-29] (in Chinese). [28] 阚黎黎, 朱嘉伦, 王飞等. 聚乙烯纤维增强赤泥-碱矿渣复合材料的力学性能[J]. 复合材料学报, 2022, 33(11): 5367-5374.KAN Lili, ZHU Jialun, WANG Fei, et al. Polyethylene fiber reinforced mechanical properties of red mud - alkali slag composites[J]. Journal of composite materials, 2022, 33(11): 5367-5374(in Chinese). [29] Redon C, Li V C, Wu C, et al. Measuring and modifying interface properties of PVA fibers in ECC matrix[J]. Journal of materials in civil engineering, 2001, 13(6): 399-406. doi: 10.1061/(ASCE)0899-1561(2001)13:6(399) -

下载:

下载: