Damage accumulation simulation and residual performance evaluation of ceramic ballistic plate under the multi-hit strikes

-

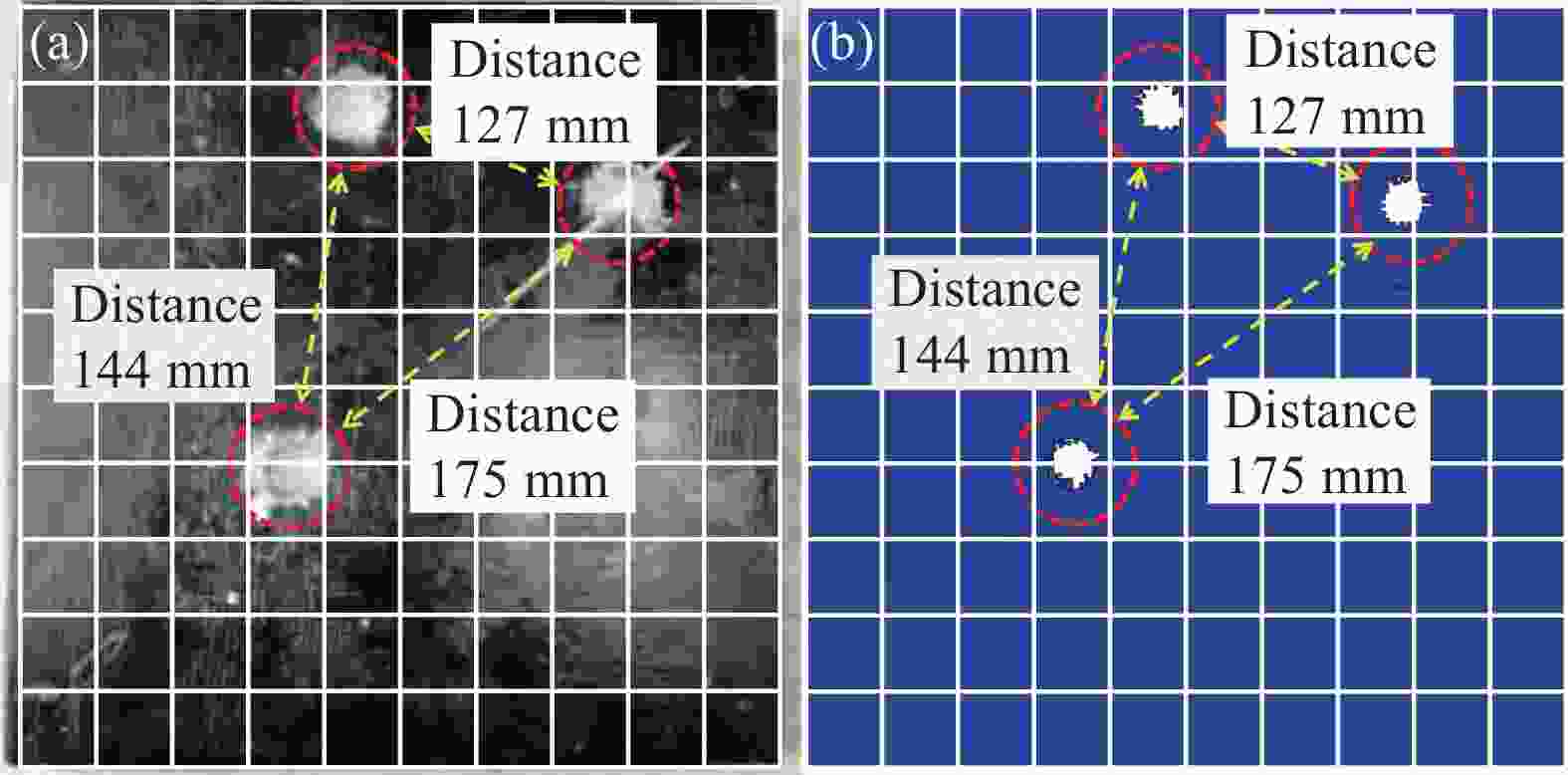

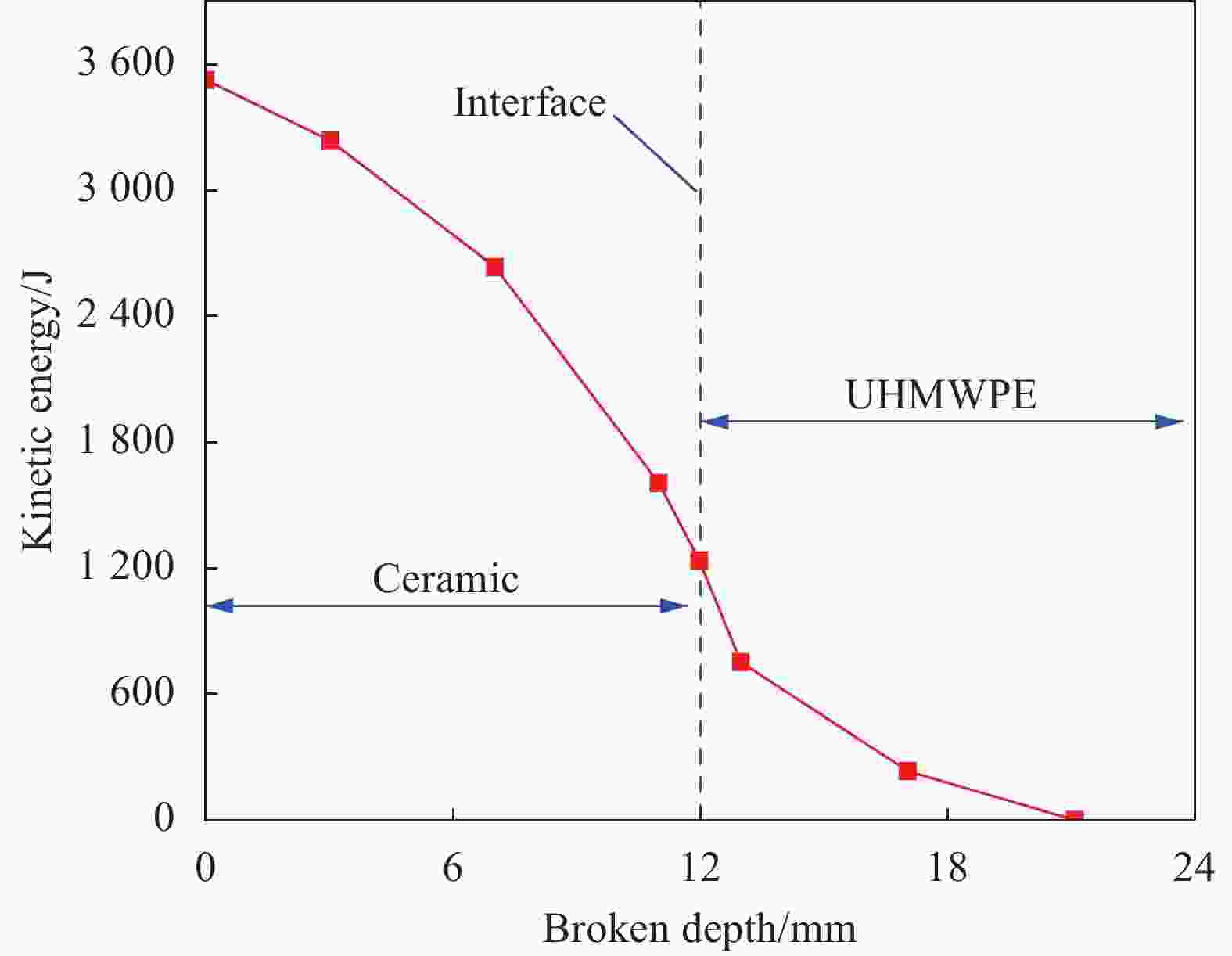

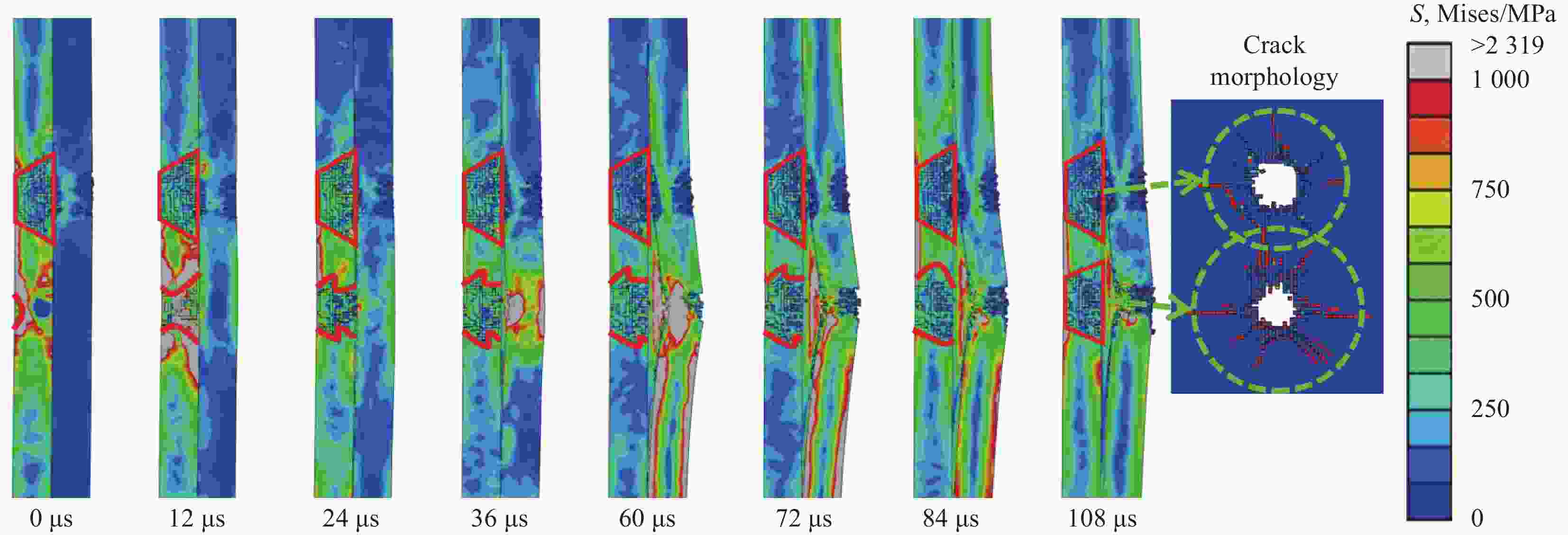

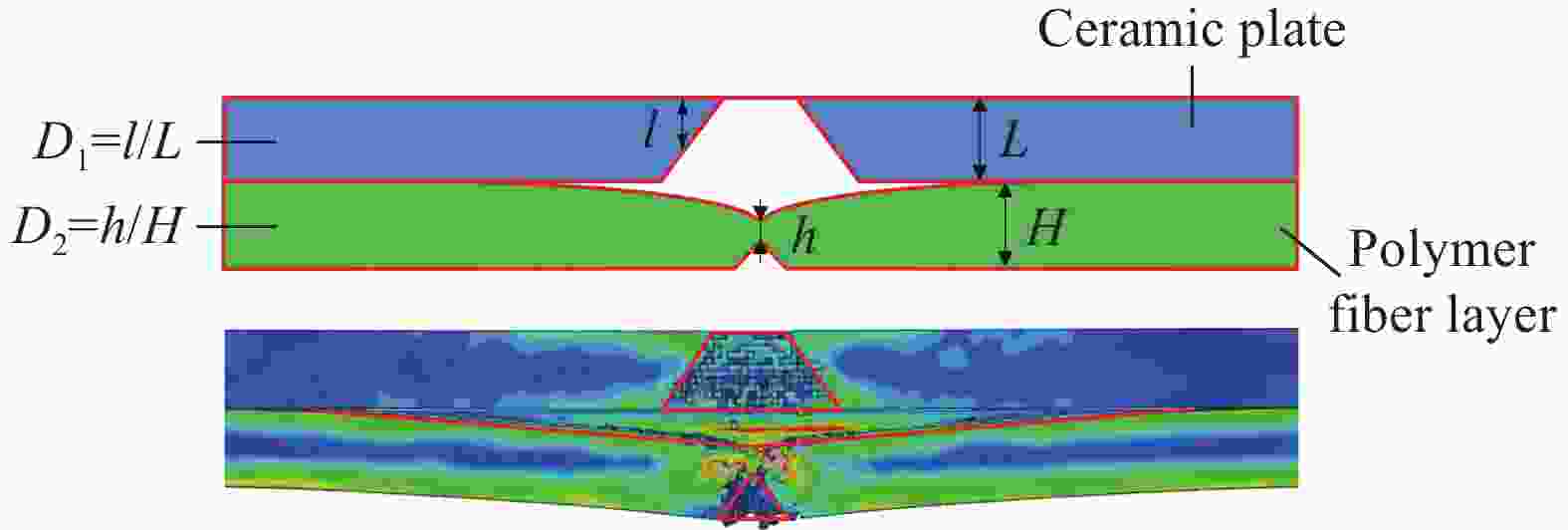

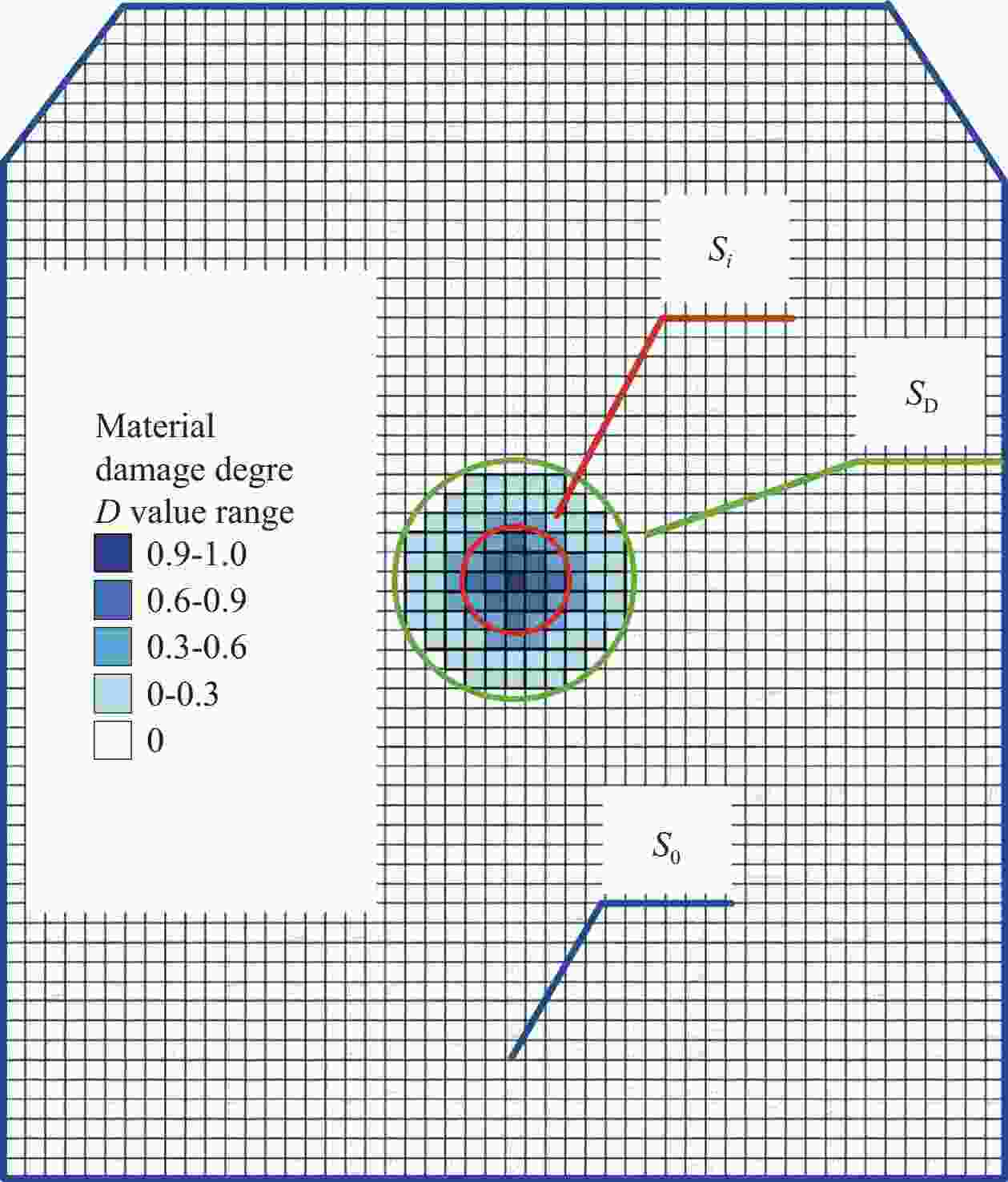

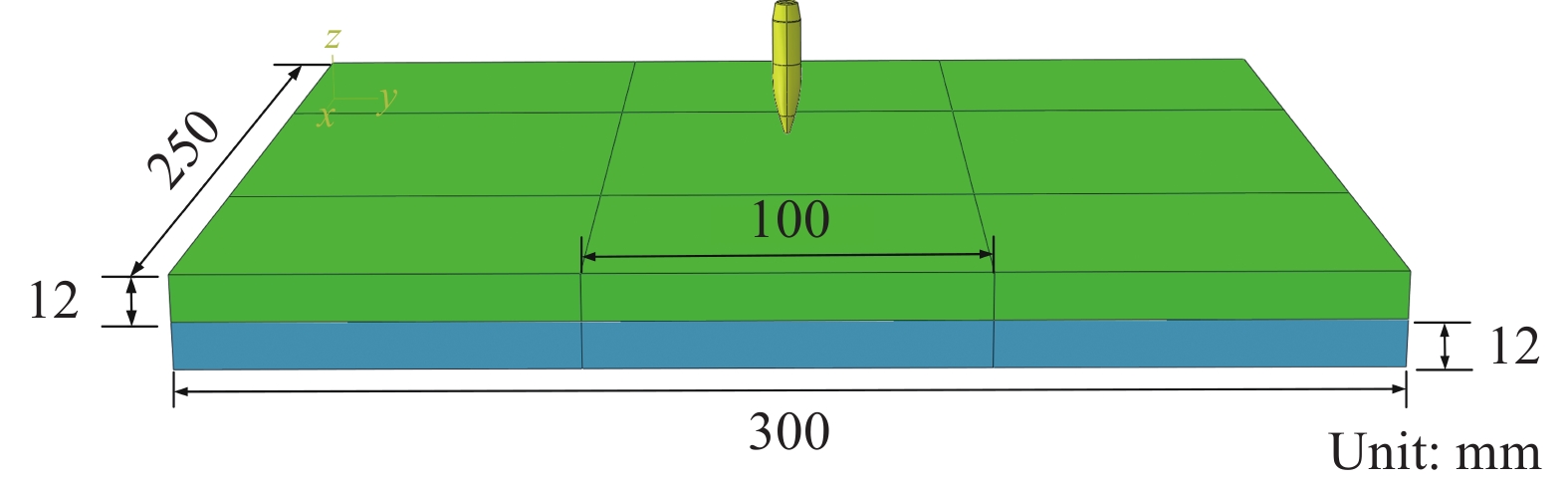

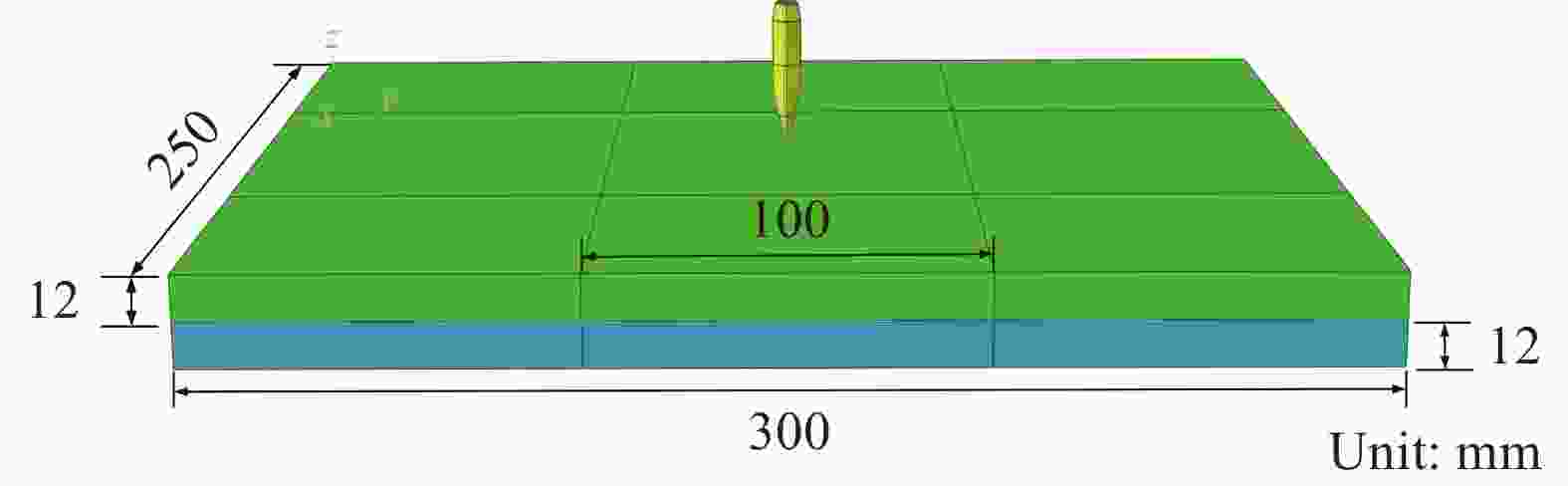

摘要: 陶瓷/纤维材料复合防弹板广泛应用于单兵防护装备,研究其抗多发冲击性能对于减少士兵伤亡有重要意义。基于53式7.62 mm穿燃弹冲击 SiC/UHMWPE 防弹板工况,利用数值模拟方法对多次冲击下防弹板的破坏分布和残余抗弹性能进行分析。利用陶瓷、纤维破坏及粘结面剥离程度表征整板损伤,并建立不同损伤区域下防弹板残余性能的分布规律。结果表明:第一次冲击下,防弹板损伤半径(R)为30 mm,当R<15 mm时,损伤(D)大于0.6,靶板无法抵御第二发子弹冲击;两次冲击下,两发子弹间距(ΔL)小于50 mm时,中间破坏区损伤有明显累加现象,当ΔL>50 mm时,损伤累加效应不显著。将防弹板以5 mm×5 mm网格离散,得到不同损伤面积占比,得出在两次冲击下整板穿透概率为0.94%。三次冲击下的整板穿透概率与第二次冲击位置有关,且当ΔL=20 mm时,三次冲击下整板穿透概率达到1.94%。Abstract: The ceramic/fibre composite ballistic panels are widely used in personal protection equipment, and the performance of the ballistic plate under multiple impact loadings are important to keep soldiers safe. The numerical simulation was used to analyze the failure distribution and residual ballistic performance of ballistic panels subjected to multiple impacting, and specifically focusing on the operating condition of 53-type 7.62 mm armor-piercing bullet impacting SiC/UHMWPE ballistic panels. The damage of the ballistic plate was characterized by the ceramic failure, fiber deformation and bond surface stripping, and the residual properties of the bulletproof plate with different damage were established. The results show that the damage radius (R) of ballistic panels is 30 mm under the first impact, and the damage (D) is greater than 0.6 when R<15 mm, and the target can't resist the second bullet impacting. Under two impacts, the damage in the middle zone becomes seriously when the distance between two bullets (ΔL) is less than 50 mm, and the cumulative effect of damage is not significant when ΔL>50 mm. Ballistic panels are discretized with 5 mm×5 mm grid, and the proportions of different damage areas are obtained. The penetration probability of the integral ballistic plate is 0.94% under the two impacts' loadings. The penetration probability of the integral ballistic plate under the third impacting is decided by the striking distance of the first two impacts, and the penetration probability by the third impacting is 1.94% when ΔL=20 mm.

-

Key words:

- ceramic composite armor /

- failure characteristics /

- finite element analysis /

- impact point /

- multi-hit

-

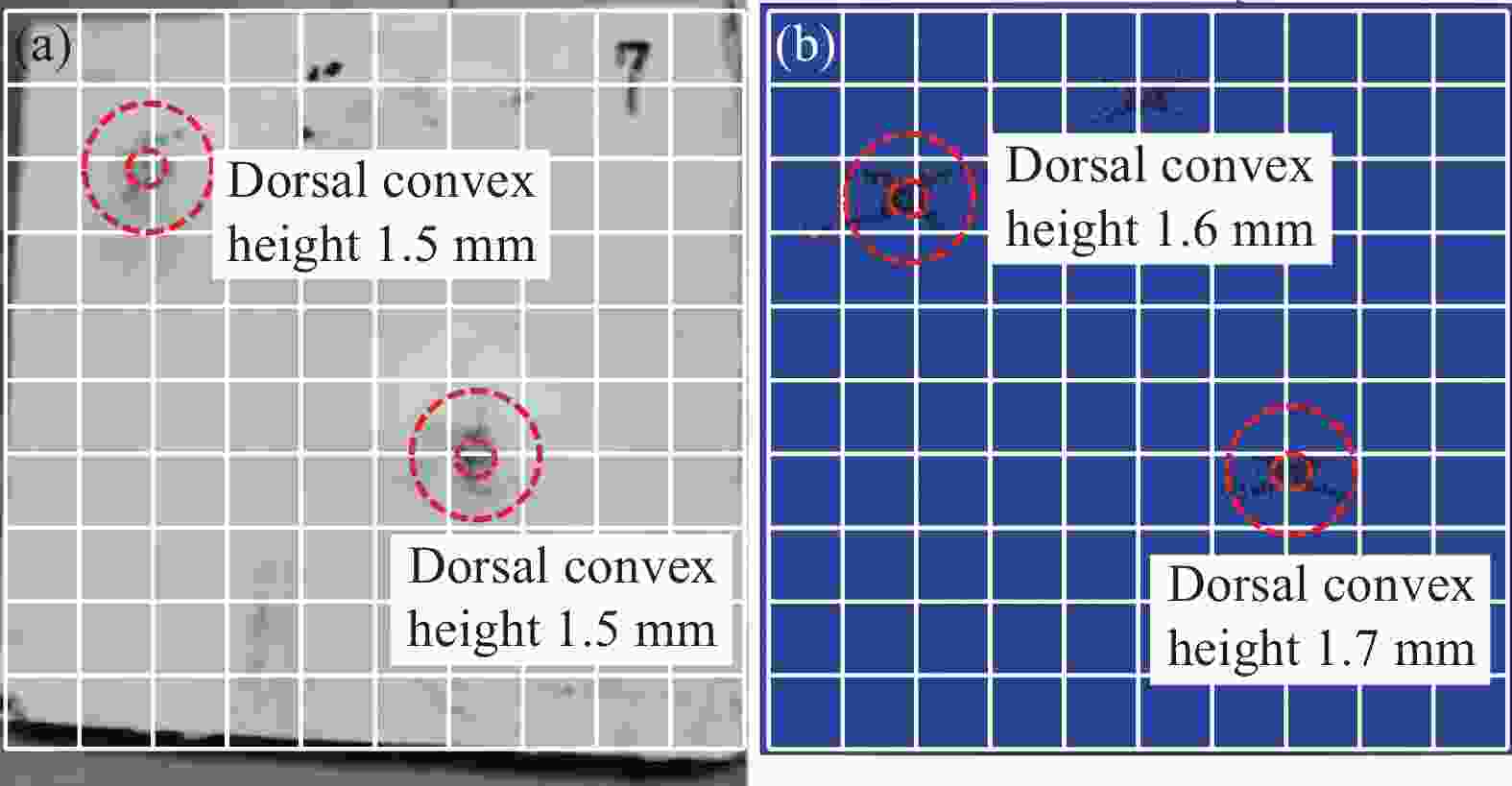

Parameter ρ/(g·cm−3) G/GPa A/GPa B/GPa n C $\dot \varepsilon _0^{}{\text{ /} }{ {\text{s} }^{ {{ - 1} } } }$ m Steel 7.85 206 1900 1100 0.065 0.05 1.0 1.0 Copper 8.96 124 90 292 0.31 0.025 1.0 1.09 Parameter t0/K tm/K D1 D2 D3 D4 D5 Steel 300 1800 0.2 — — — — Copper 300 1356 0.54 4.89 -3.03 0.014 1.12 Notes: ρ−Density; G−Shear modulus; A−Static yield strength; B−Strain hardening coefficient; n−Strain hardening exponent; C−Strain rate coefficient; ${\varepsilon }_{0}^{\dot{} }\text{ }$−Reference Strain rate; m−Thermal softening exponent; t0−Reference temperature; tm−Melting temperature; D−Damage constant. Parameter E1/GPa E2=E3/GPa ν12=ν31 ν23 G12/GPa G13/GPa G23/GPa UHMWPE 153 11.3 0.3 0.4 6 6 3.6 Parameter Xc/MPa Xt/MPa Yc/MPa Yt/MPa Zc/MPa Zt/MPa UHMWPE 2537 1580 2537 1580 340 180 Notes:E1, E2, E3−Elastic modulus in x, y and z directions, respectively; v12, v13, v23−Poisson's ratios; G12, G23, G13−Shear modulus; XC, XT, YC, YT, ZC, ZT−Compressive and tensile strengths in x, y, z directions. Parameter ρ/(g·cm−3) G/GPa A B C M N T/GPa SiC 3.125 193 0.96 0.35 0.009 1.0 0.65 0.75 Parameter PHEL/GPa D1 D2 β K1/GPa K2/GPa K3/GPa SiC 5.13 0.48 0.48 1.0 220 361 0 Notes:ρ−Density; G−Shear modulus; A−Intact strength coefficient; B−Fracture strength coefficient; C−Strain rate coefficient; M−Fracture strength exponent; N−Intact strength exponent; T−Maximum tensile pressure strength; PHEL−Pressure at HEL; D1−Damage coefficient; D2−Damage coefficient; K1−Bulk modulus; K2−Pressure coefficient. Parameter Numeric value K/(MPa·mm−1) 106 N/MPa 30 S/MPa 80 T/MPa 80 GI/(kJ·mm−2 ) 0.31 GI/(kJ·mm−2 ) 0.63 GIII/(kJ·mm−2 ) 0.63 Notes:K−Initial stiffness; N, S, T−Corresponding normal and shear strengths; GI, GII and GIII−Critical energy release rates of Model I, II and III. 表 5 子弹冲击SiC/UHMWPE实验结果与数值模拟结果比对

Table 5. Comparison between experimental results of bullet impact SiC/UHMWPE with numerical simulation results

Bullet velocity

/(m·s-1)Depth of penetration/mm Dorsal convex height/mm Mean to diameter

/mmCitations 808 6.7 1.5 25.5 Numerical simulation 808 7 1.6 23.67 表 6 第二发子弹穿透SiC/UHMWPE板概率

Table 6. Probability of the second bullet penetrate the SiC/UHMWPE plate

Penetration conditions Probability/% Ps2 3.77 Pp2 25.00 P02 0.94 Notes:Ps3−Probability that the second bullet will hit the damaged area; Pp3−Probability of a second bullet penetrating the damaged area; P03−Probability of the second bullet penetrating. 表 7 第三发子弹穿透SiC/UHMWPE板概率

Table 7. Probability of the third bullet penetrate the SiC/UHMWPE plate

Penetration

conditionsΔL/mm 15 20 35 50 80 Ps3 5.92% 7.40% 7.42% 8.9% 9.2% Pp3 26.07% 26.24% 25.53% 21.18% 20.49% P03 1.54% 1.94% 1.89% 1.89% 1.89% Notes:Ps3−Probability of the third bullet hitting the damage area of the second bullet; Pp3−Probability of the third bullet penetrating the damage area of the second bullet; P03−Probability of penetration of the third bullet. -

[1] 程时雨, 李忠盛, 郭峰, 等. 碳化硼陶瓷插板抗多发弹性能研究[J]. 兵器装备工程学报, 2022, 43(8): 146-151.CHEN Shiyu, LI Zhongsheng, GUO Feng, et al. Study on multiple elastic resistance of boron carbide ceramic insert[J]. Journal of Ordnance Equipment Engineering, 2022, 43(8): 146-151(in Chinese). [2] 贾楠, 焦亚男, 周庆, 等. 碳化硼陶瓷/超高分子量聚乙烯复合装甲板抗12.7 mm穿甲弹侵彻过程中陶瓷的碎裂行为[J]. 复合材料学报, 2023, 40(6): 3571-3582.JIA Nan, JIAO Yanan, ZHOU Qing, et al. Ceramic fragmentation behavior of B4C ceramic/ultra-high molecular weight polyethylene composite armor plate impacted by 12.7 mm armor piercing projectile[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3571-3582(in Chinese). [3] 陈智勇, 徐颖强, 李妙玲, 等. 陶瓷复合装甲优化设计及弹击后剩余弯曲强度[J]. 复合材料学报, 2023, 40(1): 577-589.CHEN Zhiyong, XU Yingqiang, LI Miaoling, et al. Optimum design of ceramic composite armor and residual bending strength after projectile impact[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 577-589(in Chinese). [4] 王晓宏, 张丰发, 刘长喜, 等. 陶瓷/纤维层间混杂复合材料设计制作及抗弹体冲击性能测试[J]. 复合材料学报, 2021, 38(8): 2684-2693.WANG Xiaohong, ZHANG Fengfa, LIU Changxi, et al. Design and fabrication of ceramic/fiber interlayer hybrid composites and test of projectile impact resistance[J]. Acta Materiae Compositae Sinica, 2021, 38(8): 2684-2693(in Chinese). [5] 肖文莹, 崔进, 王璐. B4C陶瓷/UHMWPE复合材料防护性能数值模拟分析[J]. 兵器材料科学与工程, 2021, 44(5): 103-110.XIAO Wenying, CUI Jin, WANG Lu. Simulation and analysis of protective performance of B4C/UHMWPE composite[J]. Ordnance Material Science and Engineering, 2021, 44(5): 103-110(in Chinese). [6] 王长利, 周刚, 马坤, 等. 爆炸成型弹丸对陶瓷材料的侵彻实验研究[J]. 兵器材料科学与工程, 2017, 40(3): 94-98.WANG Changli, ZHOU Gang, MA Kun, et al. Experimental study of EFP penetrating ceramic armor[J]. Ordnance Material Science and Engineering, 2017, 40(3): 94-98(in Chinese). [7] 贾楠, 焦亚男, 周庆, 等. 碳化硅-超高分子量聚乙烯纤维增强树脂基复合材料复合装甲板的抗穿甲弹侵彻性能及其损伤机制[J]. 复合材料学报, 2022, 39(10): 4908-4917.JIA Nan, JIAO Yanan, ZHOU Qing, et al. Anti-penetration performance of SiC-ultra-high molecular weight polyethylene fiber reinforced resin matrix composite armor plate against armor piercing projectile and its damage mechanism[J]. Acta Materiae Compositae Sinica, 2022, 39(10): 4908-4917(in Chinese). [8] DRESCH A B, VENTURINI J, ARCARO S, et al. Ballistic ceramics and analysis of their mechanical properties for armour applications: A review[J]. Ceramics International, 2021, 47(7): 8743-8761. [9] 韩永要, 赵国志, 杜忠华. 长管体斜侵彻有限厚均质靶板简化模型[J]. 力学与实践, 2007, 29(1): 53-57. doi: 10.1136/inpract.29.1.53HAN Yongyao, ZHAO Guozhi, DU Zhonghua. A simplified model for long tubular penetration into oblique finite homogeneous target[J]. Mechanics in Engineering, 2007, 29(1): 53-57(in Chinese). doi: 10.1136/inpract.29.1.53 [10] YU Y, WANG W Q, CHEN K G, et al. Controllable fracture in shocked ceramics: Shielding one region from severely fractured state with the sacrifice of another region[J]. International Journal of Solids and Structures, 2018, 135:137-147. [11] MIRKHALAF M, SUNESARA A, ASHRAFI B, et al. Toughness by segmentation: Fabrication, testing and micromechanics of architectured ceramic panels for impact applications[J]. International Journal of Solids and Structures, 2019, 158:52-65. [12] LAHIRI S K, SHAW A, RAMACHANDRA L S. On performance of different material models in predicting response of ceramics under high velocity impact[J]. International Journal of Solids and Structures, 2019, 176-177:96-107. [13] SHEN Z W, HU D A, YANG G, et al. Ballistic reliability study on SiC/UHMWPE composite armor against armor-piercing bullet[J]. Composite Structures, 2019, 213:209-219. [14] 杨姝, 于晨, 康玉彪, 等. N形装甲板抗穿甲弹侵彻性能数值模拟[J]. 振动与冲击, 2021, 40(16): 1-9.YANG Shu, YU Cheng, KANG Yubiao, et al. Numerical simulation of anti-penetration performance of an N-shaped armor plate against armor-piercing projectiles[J]. Journal of Vibration and Shock, 2021, 40(16): 1-9 (in Chinese). [15] HOLMQUIST T J, JOHNSON G R. Response of boron carbide subjected to high-velocity impact[J]. International Journal of Impact Engineering, 2008, 35(8): 742-752. doi: 10.1016/j.ijimpeng.2007.08.003 [16] JOHNSON G R, HOLMQUIST T J. An improved computational constitutive model for brittle materials[J]. AIP Conference Proceedings, 1994, 309(1): 981-984. [17] JOHNSON G R, HOLMQUIST T J, BEISSEL S R. Response of aluminum nitride (including a phase change) to large strains, high strain rates, and high pressures[J]. Journal of Applied Physics, 2003, 94(3): 1639-1646. doi: 10.1063/1.1589177 [18] DUCHET J, LEGRAS R, DEMOUSTIER-CHAMPAGNE S. Chemical synthesis of polypyrrole: Structure-properties relationship[J]. Synthetic Metals, 1998, 98(2): 113-122. doi: 10.1016/S0379-6779(98)00180-5 [19] LAHIRI S K, SHAW A, RAMACHANDRA L S. On performance of different material models in predicting response of ceramics under high velocity impact[J]. International Journal of Solids and Structures, 2019, 176-177: 96-107. [20] 罗小豪, 温垚珂, 闫文敏, 等. 基于ABAQUS二次开发的球形破片侵彻UHMWPE软质防弹衣数值模拟[J]. 复合材料学报, 2021, 38(10): 3373-3386.LUO Xiaohao, WEN Yaoke, YAN Wenming, et al. Numerical simulation of spherical fragment penetrating UHMWPE soft body armor based on ABAQUS[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3373-3386(in Chinese). [21] HAN Q G, LI H M, CHEN X H, et al. Impact resistant basalt fiber-reinforced aluminum laminate with Janus helical structures inspired by lobster and mantis shrimp [J], Composite Structures, 291 (2022), 115551. [22] 公共安全行业标准[S]. 警用防弹衣通用技术条件标准 GA 141-2001.Public safety industry standard [S]. General technical conditions for police body armour GA 141-2001(in Chinese). [23] 孔晓鹏. 陶瓷复合装甲脱粘机理和抗多发打击研究[D]. 长沙: 国防科学技术大学, 2010: 55-57.KONG Xiaopeng. Study on the debonding mechanism and the protection capability of ceramic composite armors against multi-hit [D]. Changsha: National University of Defense Technology, 2010: 55-57(in Chinese). [24] 黄浩杰, 梁森, 周越松. 陶瓷/UHMWPE异形复合材料靶板抗侵彻性能研究[J]. 复合材料科学与工程, 2022, (11): 49-53, 62.HUANG Haojie, LIANG Sheng, ZHOU Yuesong. Study on penetration resistance of ceramic/UHMWPE composite target plates with different shapes[J]. Acta Materiae Compositae Sinica, 2022, (11): 49-53, 62(in Chinese). [25] 江怡, 黄健, 陈威, 等. 防弹复合结构抗侵彻性能分析[J]. 计算机仿真, 2019, 36(12): 10-14, 30.JIANG Yi, HUANG Jian, CHEN Wei, et al. Research on the ballistic performance of the bullet-proof composite structures[J]. Computer Simulation, 2019, 36(12): 10-14, 30(in Chinese). -

下载:

下载: