Effect of temperature on mechanical properties of metal-compositehybrid multi-bolt joint

-

摘要: 以铝合金-碳纤维/双马来酰亚胺(BMI)树脂复合材料多螺栓双搭接结构为研究对象,结合数字图像相关(DIC)技术开展了不同温度环境下(−100℃、25℃、150℃)的准静态拉伸试验,并采用金属弹塑性模型和复合材料渐进损伤模型进行数值模拟分析,同时开发考虑温度影响的UMAT子程序预测复合材料损伤,研究了温度对金属-复合材料混合多螺栓连接结构承载能力、破坏模式、损伤演化和钉载分配的影响规律。结果表明:相比25℃室温环境,150℃和−100℃环境下结构的极限载荷分别降低4.46%和2.06%;不同温度环境下的破坏模式均为复合材料孔边拉伸断裂,同时高温环境下孔边分层与挤压现象更为严重,而低温环境下纤维与基体结合紧密,孔边挤压与分层现象更弱;150℃环境下复合材料孔边损伤不均匀性相比常温环境有所减弱,而−100℃环境下不均匀性有所增强;由于热膨胀不匹配性,高温和低温环境下三组螺栓钉载分配规律也表现出明显差异。

-

关键词:

- 碳纤维/BMI树脂复合材料 /

- 螺栓连接结构 /

- 渐进损伤分析 /

- 高/低温力学性能 /

- 钉载分配

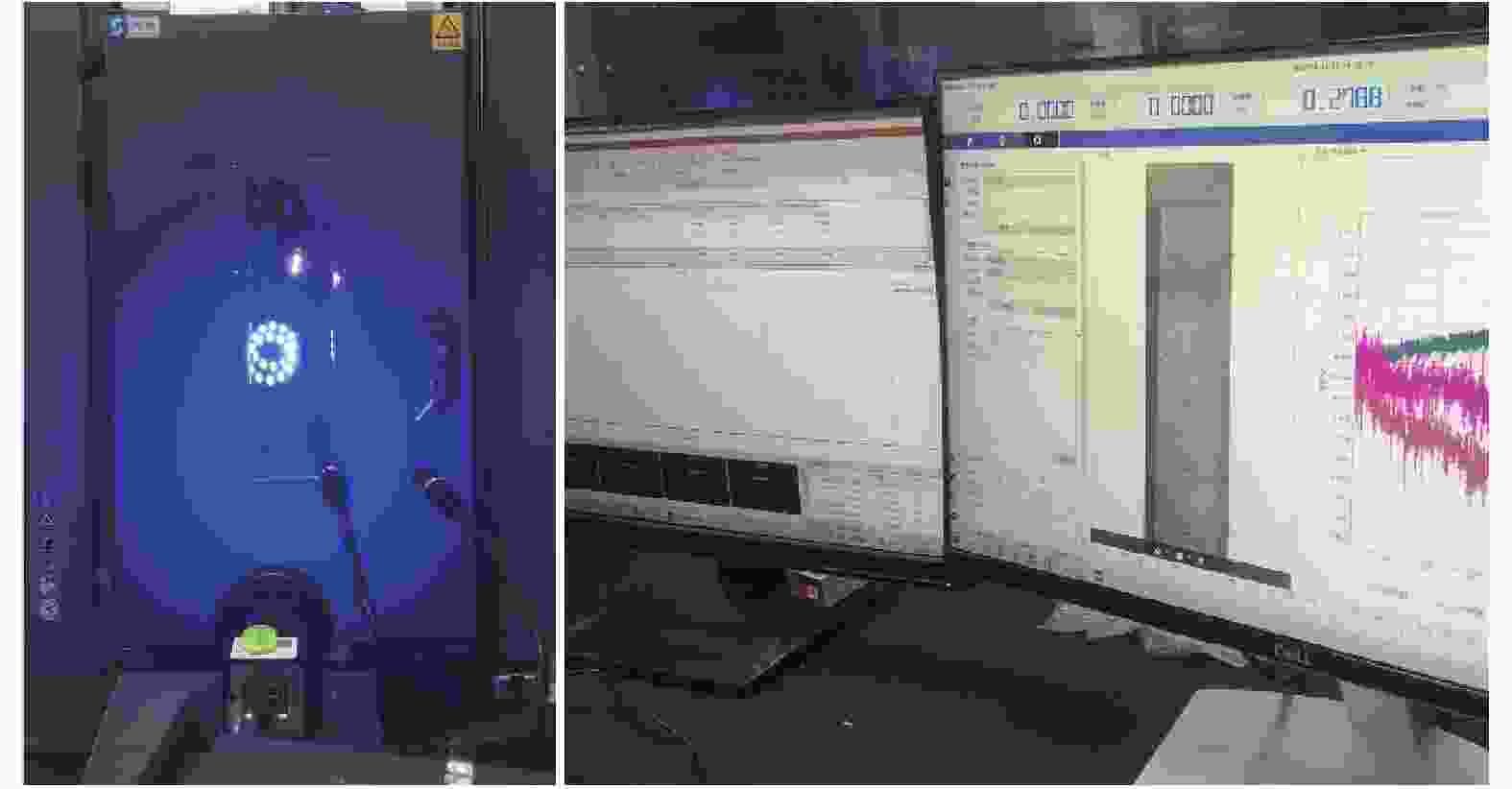

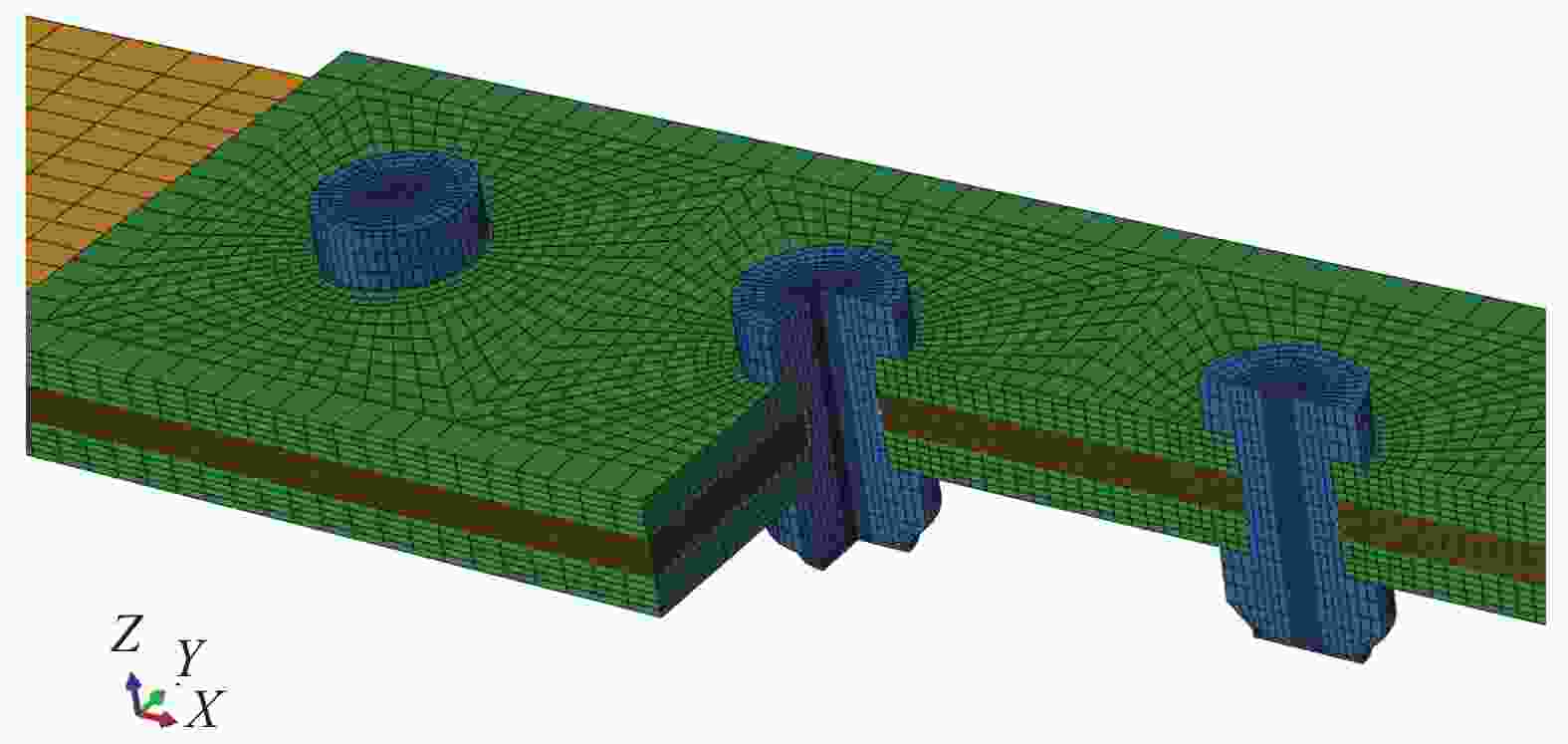

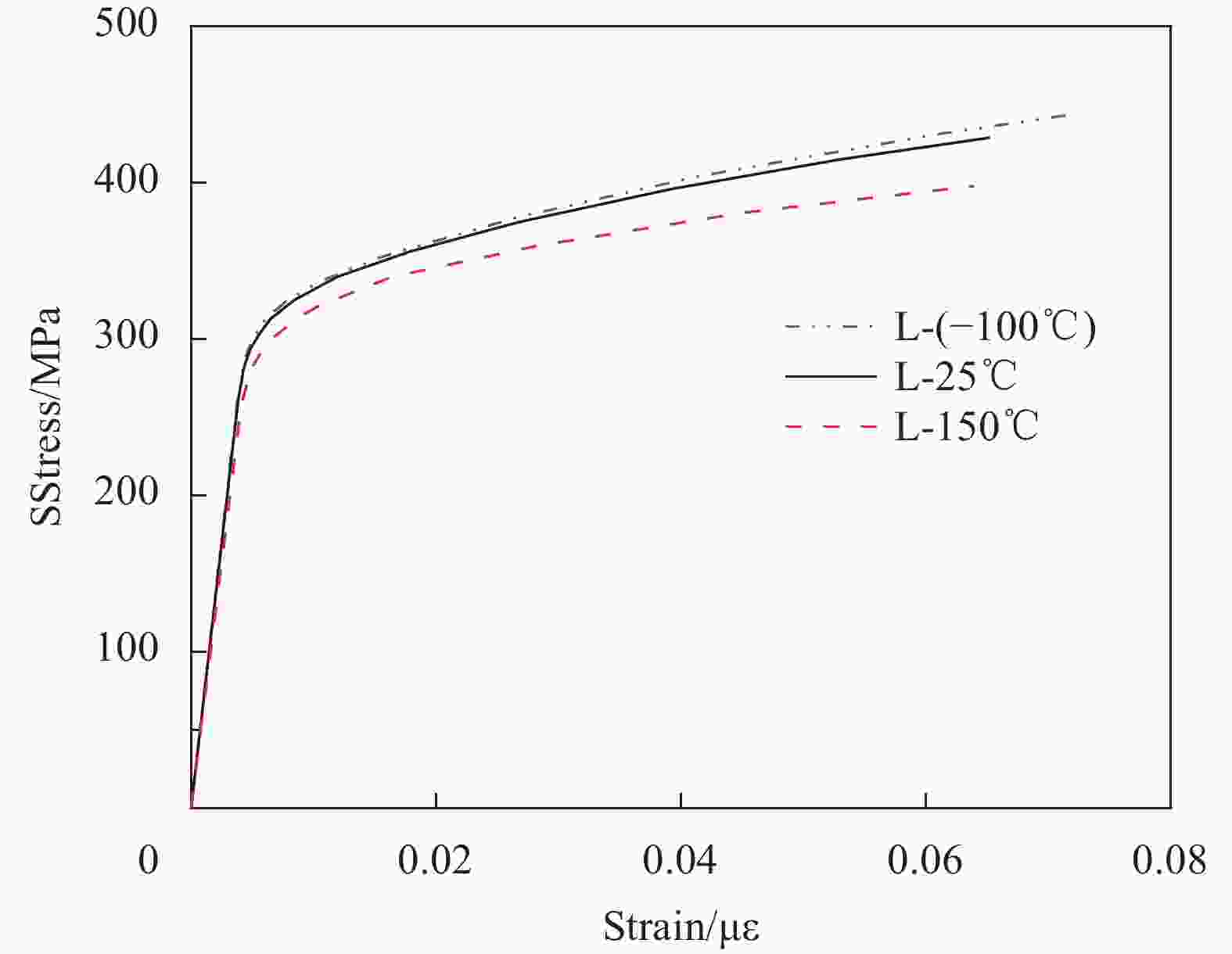

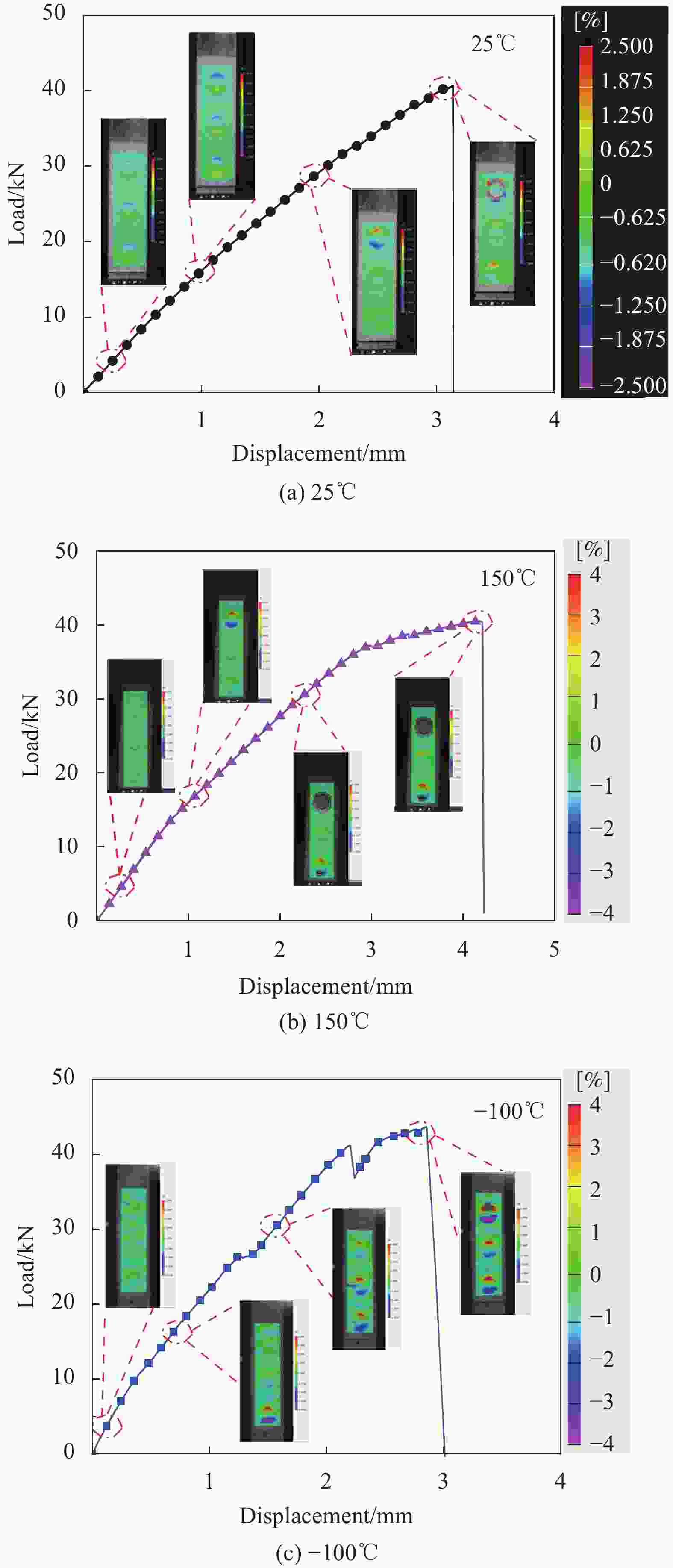

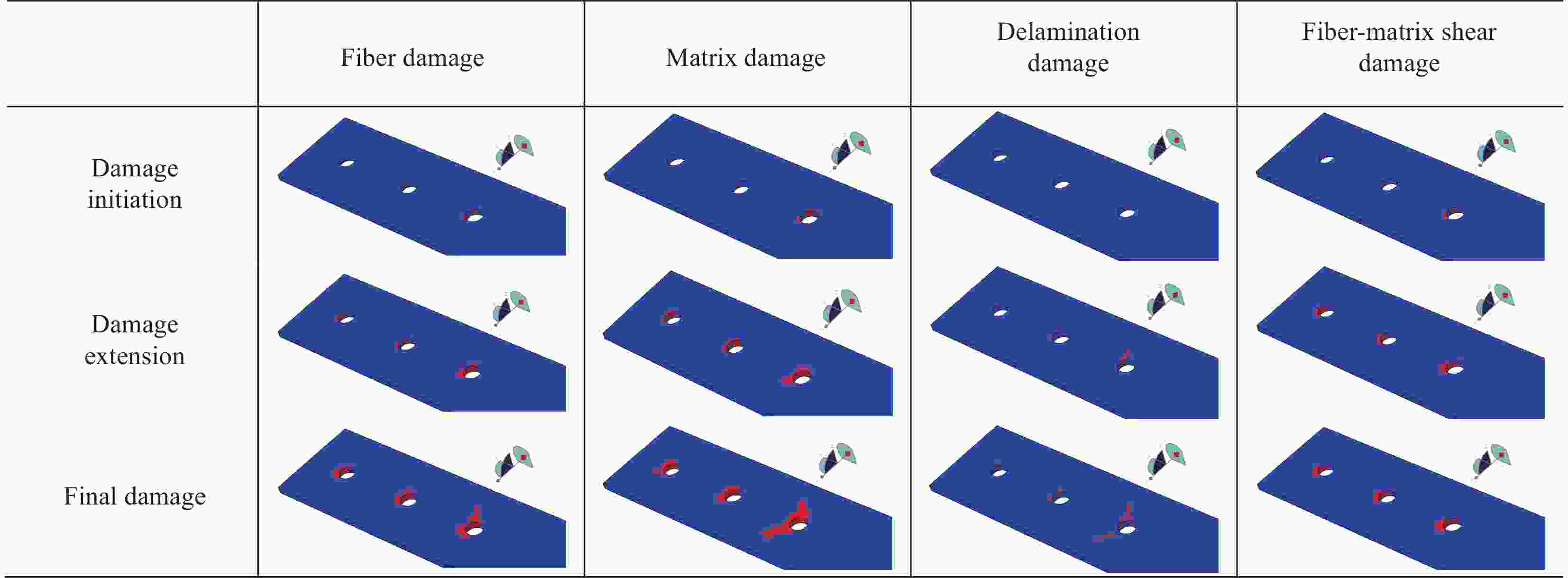

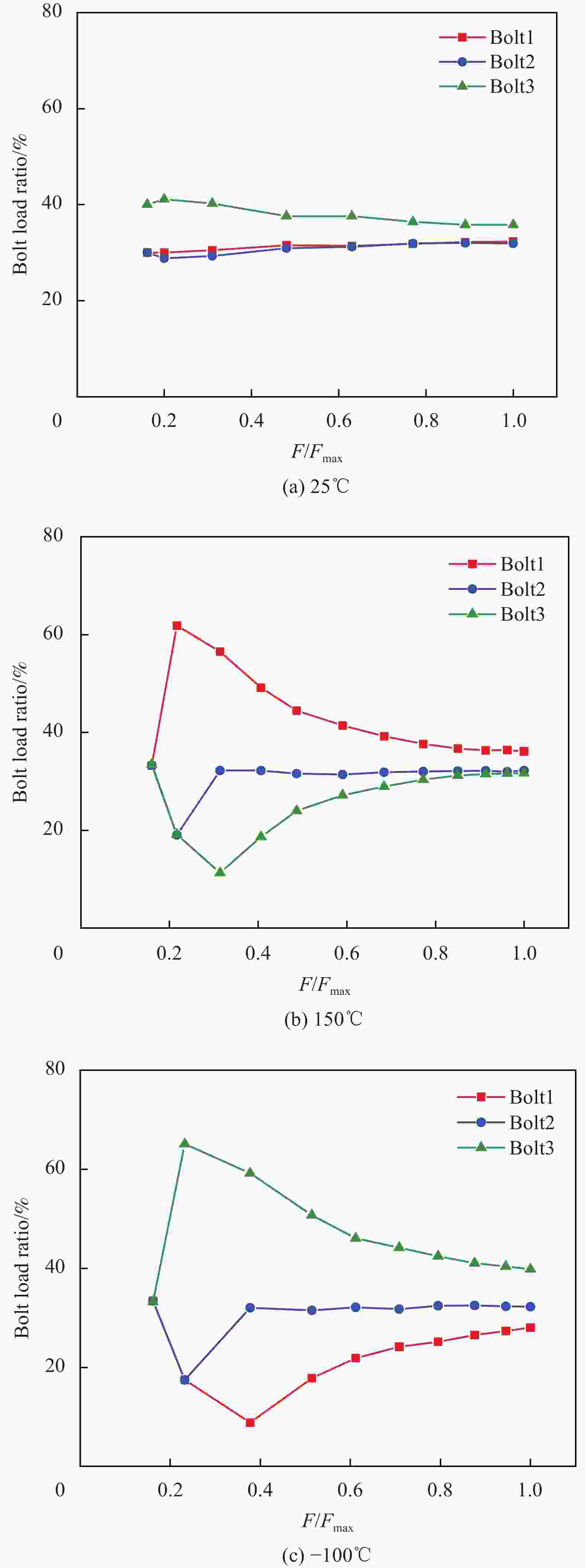

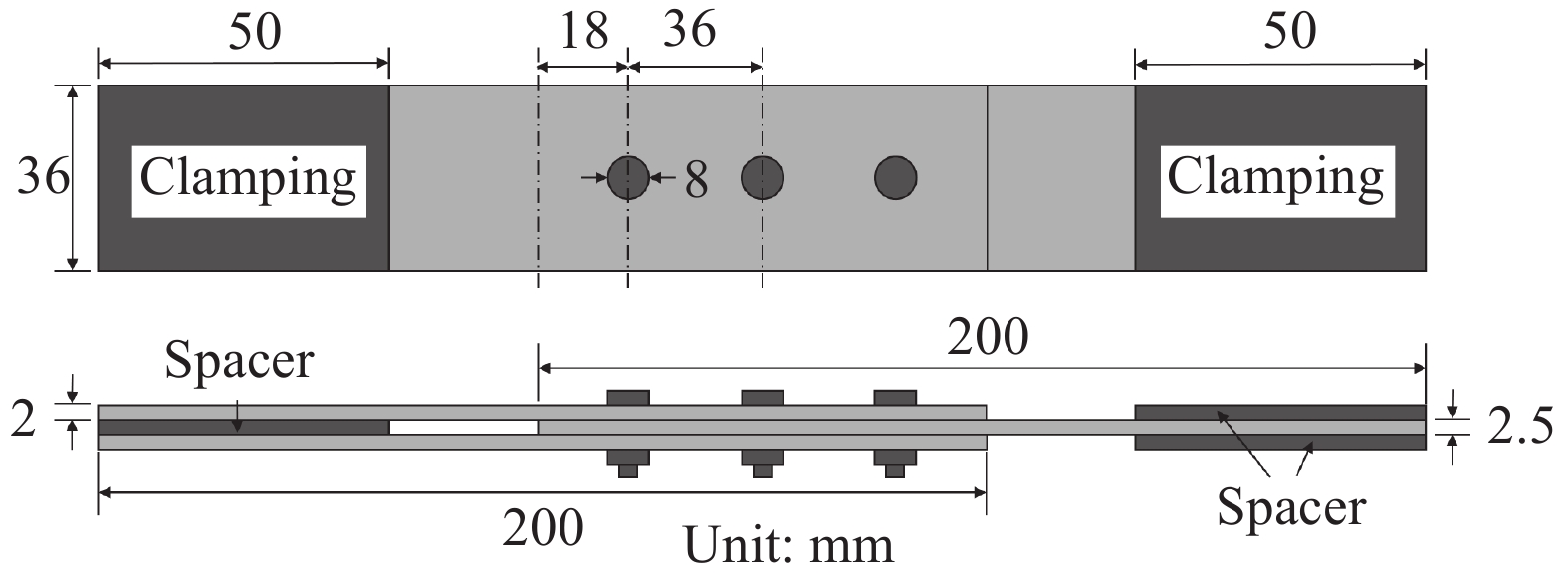

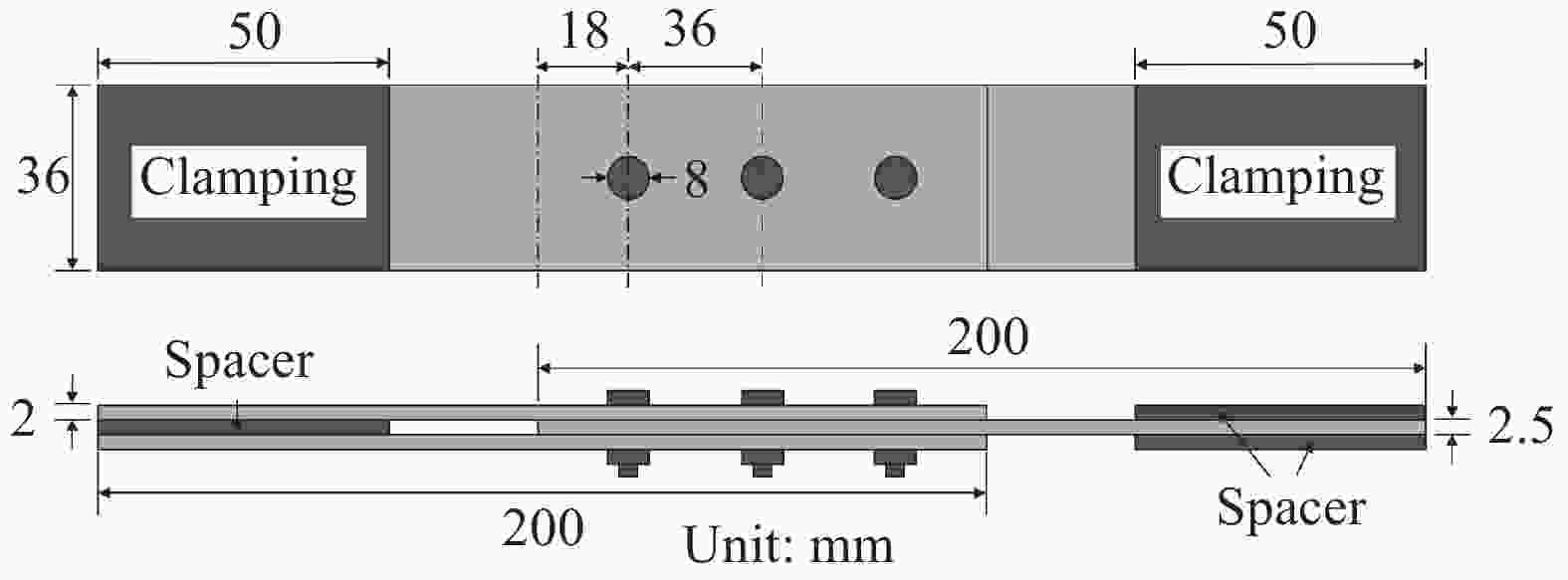

Abstract: Taking the aluminum alloy-carbon fiber/bismaleimide (BMI) resin composite multi-bolt double-lap structure as the research object, combined with digital image correlation (DIC) technology, quasi-static tensile tests under different temperature environments (−100°C, 25°C, 150°C) were carried out. The elastic-plastic model of metal and the progressive damage model of composite were used for numerical simulation. A UMAT subroutine considering the influence of temperature was developed to predict the damage of composite materials. The influence of temperature on load-bearing capacity, failure mode, damage evolution and bolt-load distribution of metal-composite hybrid multi-bolt joint structure was studied. The results show that the maximum load of the structure in the environment of 150°C and −100°C is reduced by 4.46% and 2.06% compared with the room temperature environment of 25°C, respectively. The failure modes of three temperature environments are all tensile fracture of the hole edge of the composite. The delamination and extrusion phenomenon of the hole edge are more serious at the high temperature, but the fiber and the matrix are tightly bonded and the extrusion and delamination of the hole edge are weaker in the cryogenic temperature environment. The unevenness of the multi-bolt hole edge damage is weakened at 150°C and is enhanced at −100°C, compared with at the room temperature. Due to the difference in thermal expansion between metal and composite, the bolt load distribution of the three bolts at high and cryogenic temperatures is different. -

表 1 碳纤维/BMI树脂基复合材料属性参数[14, 24]

Table 1. Attribute parameters of carbon fiber/BMI resin composite[14, 24]

${E_{11}}/{\text{MPa}} $ ${E}_{22}、{E}_{33}/\text{MPa} $ ${G}_{12}、{G}_{13}/\text{MPa} $ $ {G_{23}}/{\text{MPa}} $ $ {\nu }_{12}、{\nu }_{13} $ ${\nu _{23}} $ 150℃ 123000 9106 5250 3133 0.33 0.42 25℃ 125000 9370 5450 3373 0.3 0.4 −100℃ 129000 9980 5660 3521 0.28 0.38 ${X_{\text{t}}}/{\text{MPa}} $ $ {Y}_{\text{t}}、{Z}_{\text{t}}/\text{MPa} $ ${X_{\text{c}}}/{\text{MPa}} $ $ {Y}_{\text{c}}、{Z}_{\text{c}}/\text{MPa} $ $ {S}_{12}、{S}_{13}/\text{MPa} $ ${S_{23}}/{\text{MPa}} $ 150℃ 2180 1365 70 235 148 87 25℃ 2424 1430 74 248 159 95 −100℃ 2298 1510 68 260 167 90 Notes: $ {E_{11}},{E_{22}},{E_{33}} $−Elastic modulus in directions 1, 2 and 3; ${G_{12}},{G_{13}},{G_{23}} $−Shear modulus in directions 12, 13 and 23; ${\nu }_{12},{\nu }_{13},{\nu }_{23} $−Poisson's ratio in directions 12, 13 and 23, ${X_{\text{t}}},{Y_{\text{t}}},{Z_{\text{t}}} $−Tensile strength in directions x, y and z; ${X_{\text{c}}},{Y_{\text{c}}},{Z_{\text{c}}} $−Compressive strength in directions x, y and z; $ {S}_{12},{S}_{13},{S}_{23} $−Shear strength in directions 12, 13 and 23. Material Aluminum alloy TC4 Composite

(Fiber direction)Composite

(Matrix direction)Thermal expansivity/(10−6K−1) 25 8.1 0.25 32.6 表 3 混合连接结构极限载荷Fmax试验值与仿真值对比

Table 3. Comparison between test value and simulation value of maximum load of hybrid joint structures

Temperature Maximum load average/kN Dispersion coefficient/% Simulate maximum load/kN Error/% 150℃ 40.51 2.94 39.45 2.6 25℃ 42.74 0.92 40.81 4.5 −100℃ 41.87 6.37 39.84 4.8 -

[1] 翟月, 徐海萍, 代秀娟, 等. 先进复合材料的发展及应用[J]. 应用化工, 2018, 47(8): 1719-1722. doi: 10.3969/j.issn.1671-3206.2018.08.038ZHAI Yue, XU Haiping, DAI Xiujuan, et al. The development and state of advanced composited materials[J]. Applied Chemical Industry, 2018, 47(8): 1719-1722(in Chinese). doi: 10.3969/j.issn.1671-3206.2018.08.038 [2] 高禹, 王钊, 陆春, 等. 高性能树脂基复合材料典型空天环境下动态力学行为研究现状[J]. 材料工程, 2015, 43(3): 106-112. doi: 10.11868/j.issn.1001-4381.2015.03.018GAO Yu, WANG Zhao, LU Chun, et al. State of arts of the dynamic mechanical behaviors of high performance polymer composites in typical aerospace environments[J]. Journal of Materials Engineering, 2015, 43(3): 106-112(in Chinese). doi: 10.11868/j.issn.1001-4381.2015.03.018 [3] SZIROCZAK D, SMITH H. A review of design issues specific to hypersonic flight vehicles[J]. Progress in Aerospace Sciences, 2016, 84: 1-28. doi: 10.1016/j.paerosci.2016.04.001 [4] 湛永钟, 张国定. 低地球轨道环境对材料的影响[J]. 宇航材料工艺, 2003, 33(1): 1-5, 23. doi: 10.3969/j.issn.1007-2330.2003.01.001ZHAN Yongzhong, ZHANG Guoding. Low earth orbit environmental effects on materials[J]. Aerospace Materials & Technology, 2003, 33(1): 1-5, 23(in Chinese). doi: 10.3969/j.issn.1007-2330.2003.01.001 [5] FENG J M, GUO Z S. Effects of temperature and frequency on dynamic mechanical properties of glass/epoxy composites[J]. Journal of Materials Science, 2016, 51(5): 2747-2758. doi: 10.1007/s10853-015-9589-5 [6] SHINDO Y, TAKEDA T, NARITA F. Mechanical response of nonwoven polyester fabric/epoxy composites at cryogenic temperatures[J]. Cryogenics, 2012, 52(10): 564-568. doi: 10.1016/j.cryogenics.2012.07.008 [7] MCCARTHY C T, MCCARTHY M A, LAWLOR V P. Progressive damage analysis of multi-bolt composite joints with variable bolt–hole clearances[J]. Composites Part B: Engineering, 2005, 36(4): 290-305. doi: 10.1016/j.compositesb.2004.11.003 [8] MCCARTHY M A, MCCARTHY C T, PADHI G S. A simple method for determining the effects of bolt-hole clearance on load distribution in single-column multi-bolt composite joints[J]. Composite Structures, 2006, 73(1): 78-87. doi: 10.1016/j.compstruct.2005.01.028 [9] 赵丽滨, 秦田亮, 山美娟, 等. 基于渐进损伤分析的复合材料螺栓连接强度包线法研究[J]. 复合材料学报, 2015, 32(3): 823-830. doi: 10.13801/j.cnki.fhclxb.20150609.001ZHAO Libin, QIN Tianliang, SHAN Meijuan. Progressive damage analysis based strength envelope method research for composite bolted joints[J]. Acta Materiae Compositae Sinica, 2015, 32(3): 823-830(in Chinese). doi: 10.13801/j.cnki.fhclxb.20150609.001 [10] ZHOU Y H, YAZDANI NEZHAD H, HOU C, et al. A three dimensional implicit finite element damage model and its application to single-lap multi-bolt composite joints with variable clearance[J]. Composite Structures, 2015, 131:1060-1072. [11] 唐玉玲, 任煜赫, 张峻霞, 等. 胶层对复合材料多螺栓连接力学性能及钉载分配的影响[J]. 复合材料学报, 2023, 40(6): 3601-3612. doi: 10.13801/j.cnki.fhclxb.20220809.002TANG Yuling, REN Yuhe, ZHANG Junxia, et al. Effect of the adhesive layer on mechanical properties and load distribution in multi-bolt composite joints[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3601-3612(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220809.002 [12] TURVEY G J, SANA A. Pultruded GFRP double-lap single-bolt tension joints-Temperature effects on mean and characteristic failure stresses and knock-down factors[J]. Composite Structures, 2016, 153:624-631. [13] ZU S M, ZHOU Z G, ZHAO Y, et al. Effect of temperature and geometrical parameters on mechanical properties of pin-loaded fiber metal laminate joints[J]. Journal of Composite Materials, 2017, 51(22): 3163-3173. doi: 10.1177/0021998316687029 [14] 杨白凤. 碳纤维/双马树脂基复合材料及其连接结构在空天环境温度下的力学行为[D]. 西安: 西北工业大学, 2018.YANG Baifeng. Mechanical behaviour of carbon fiber/BMI composites and joints at space environment temperature[D]. XI’AN: Northwestern Polytechnical University, 2018(in Chinese). [15] ABDUS S, CHENG X Q, HUANG W J, et al. Bearing failure and influence factors analysis of metal-to-composite bolted joints at high temperature[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2019, 41(7):298. [16] 朱梓珣. 飞机复合材料层合板与金属连接结构热效应分析[D]. 哈尔滨: 哈尔滨工业大学, 2019.ZHU Zixun. Thermal effect analysis of aircraft composite laminate and metal joint structure[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [17] 蔡启阳, 赵琪. 环境温度和间隙对复合材料-金属混合结构机械连接钉载分配的影响[J]. 复合材料学报, 2021, 38(12): 4228-4238. doi: 10.13801/j.cnki.fhclxb.20210301.005CAI Qiyang, ZHAO Qi. Effects of temperature and clearance fit on the load distribution of composite-metal hybrid structures[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4228-4238(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210301.005 [18] ASTM. Standard test method for bearing response of polymer matrix composite laminates: ASTM D5961/D5961M-17[S]. ASTM International, 2017 [19] 金属材料拉伸试验 第2部分: 高温试验方法: GB/T 228.2—2015[S]. 2015.Tensile tests of metallic materials - Part 2: High temperature test methods: GB/T 228.2—2015[S]. 2015(in Chinese). [20] ABDUS S, CHENG X Q, HUANG W J, et al. Bearing failure and influence factors analysis of metal-to-composite bolted joints at high temperature[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2019, 41(7): 298. doi: 10.1007/s40430-019-1797-5 [21] CHENG X Q, YANG M M, ZHANG J, et al. Thermal behavior and tensile properties of composite joints with bonded embedded metal plate under thermal circumstance[J]. Composites Part B: Engineering, 2016, 99:340-347. [22] ABAQUS. ABAQUS Version 2020, Dassault Systemes[M]. Providence: ABAQUS, 2020. [23] 倪凯强. 复材/金属混合结构紧固件柔度与连接强度分析[D]. 西安: 西北工业大学, 2019.NI Kaiqiang. Analysis of fastener flexibility and strength for composite/metallic hybrid joints[D]. Xi’an, Northwestern Polytechnical University, 2019(in Chinese). [24] 陈龙. 复合材料-钛合金混合结构多钉连接分析与试验研究[D]. 南京: 南京航空航天大学, 2020.CHEN Long. Testing and numerical analysis of composite-to-titanium hybrid structure with multiple-bolted joints[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020(in Chinese). -

下载:

下载: