Design, preparation and mechanical properties of microwave sintered TiB2-based ceramic tools with complex edge shape

-

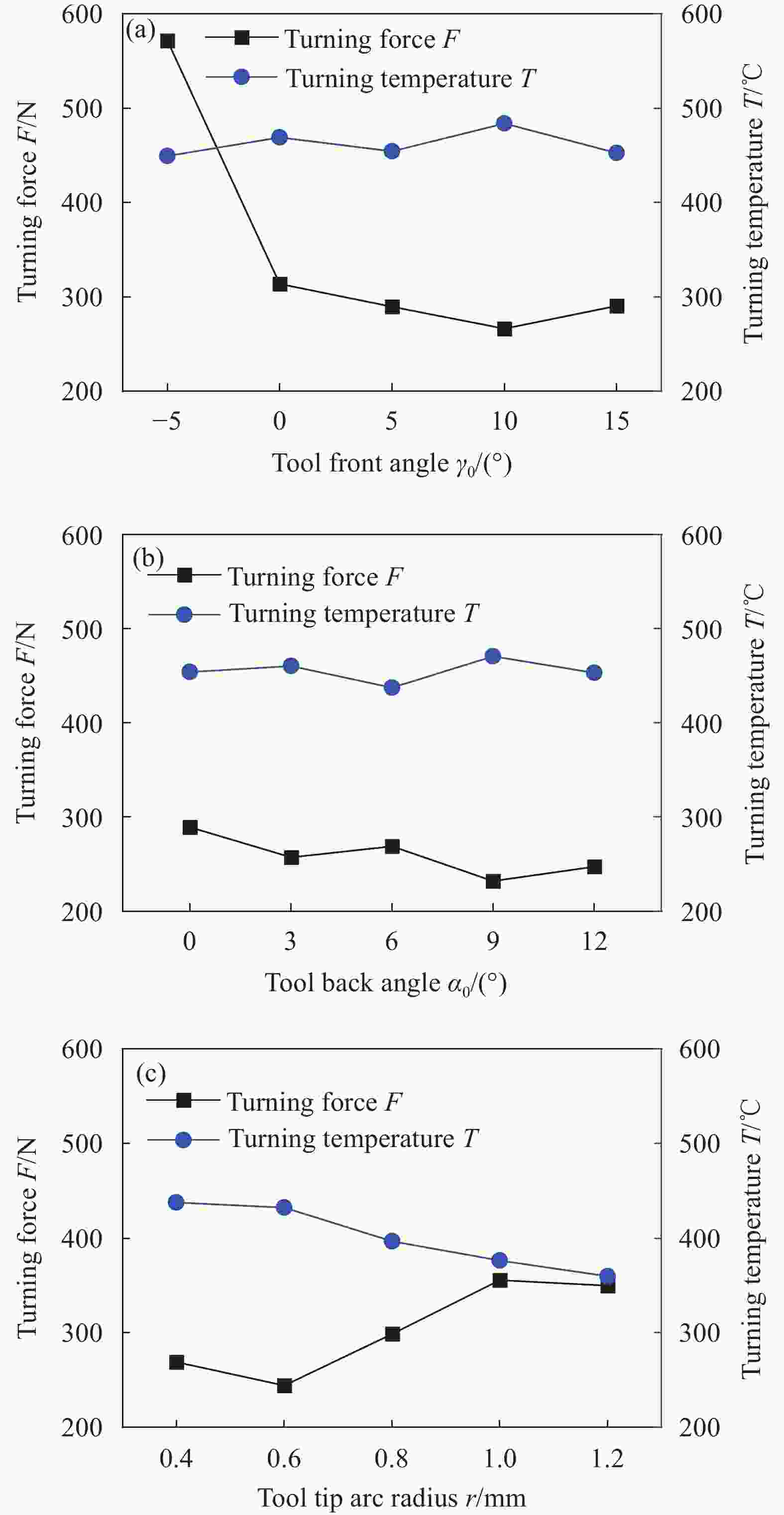

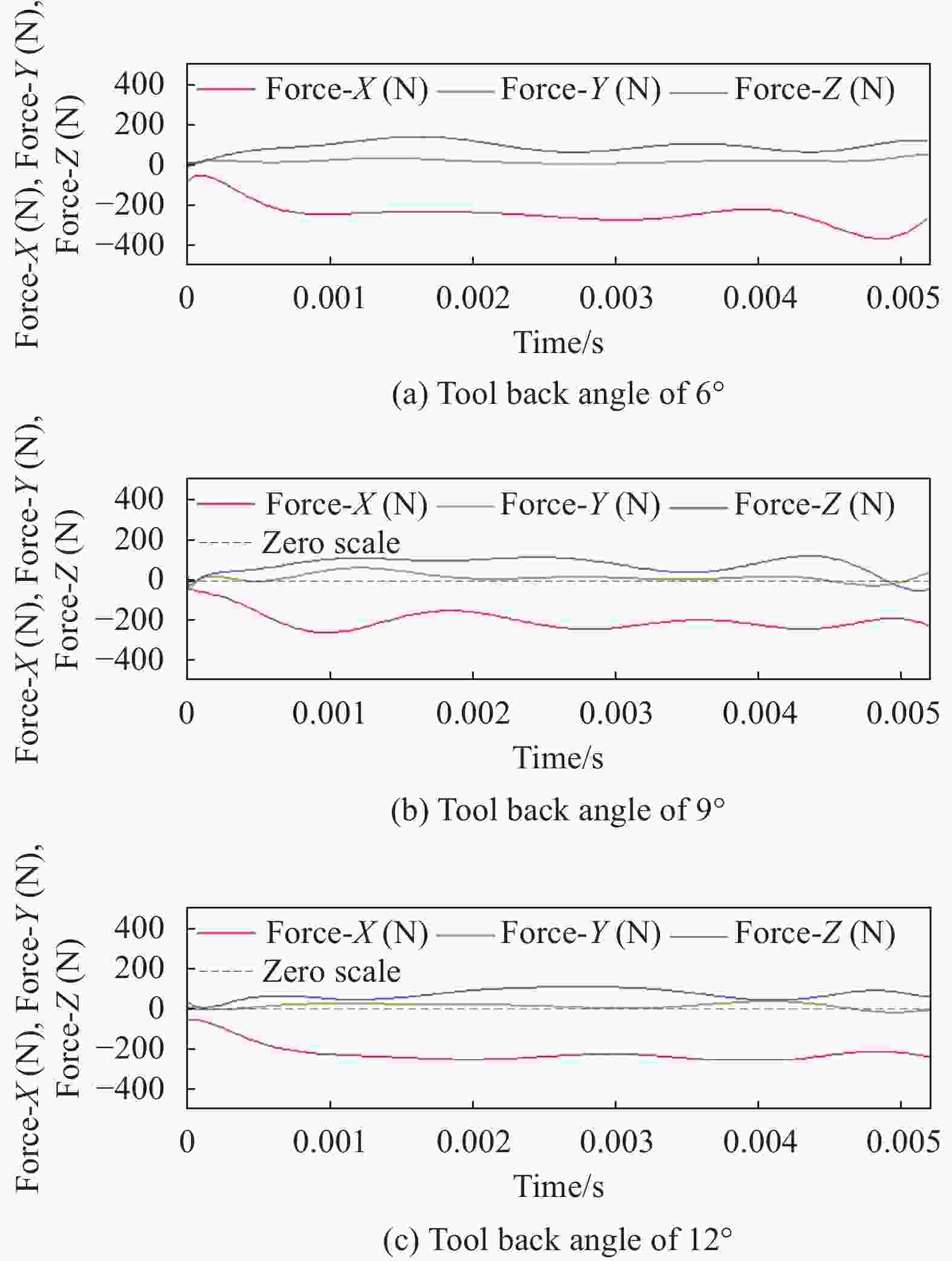

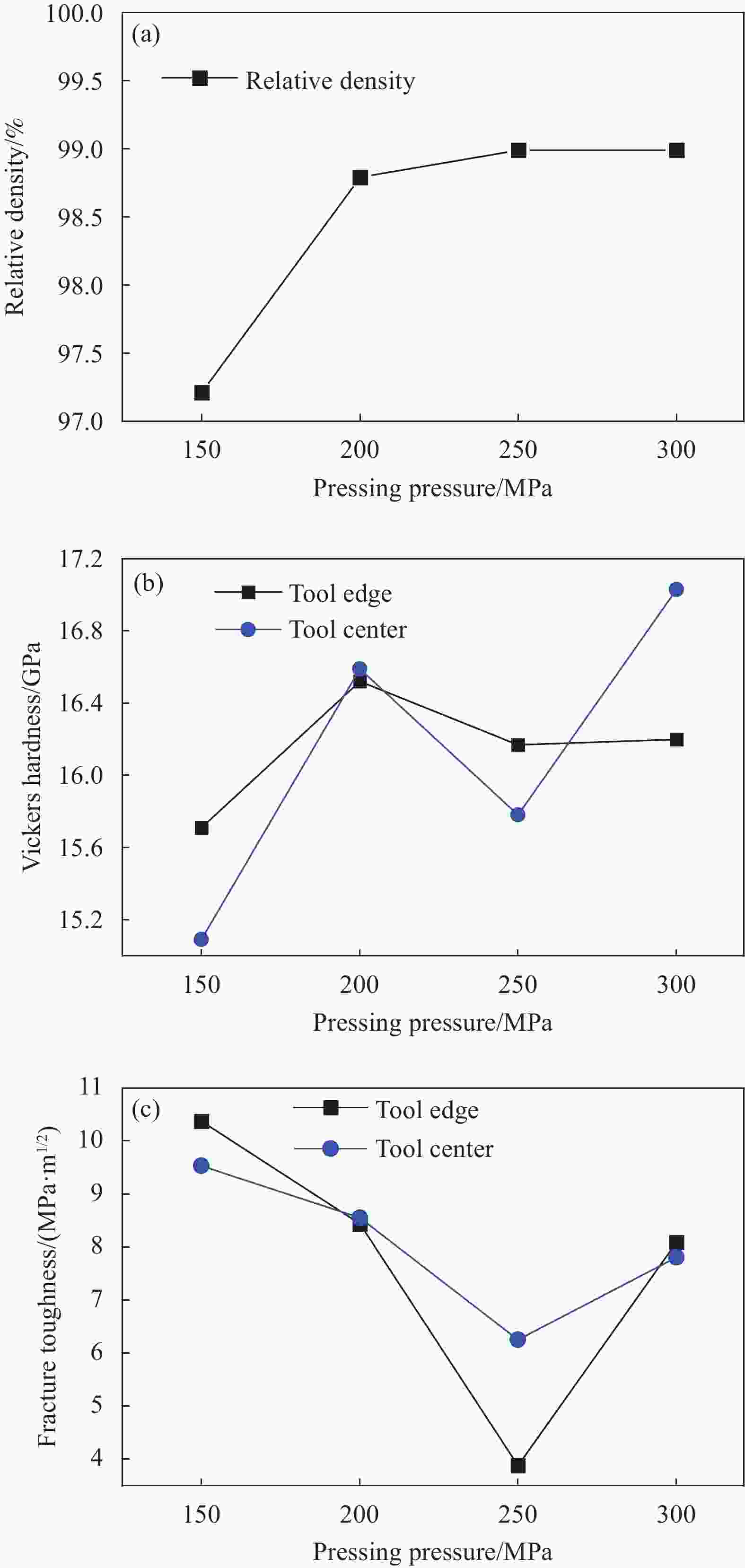

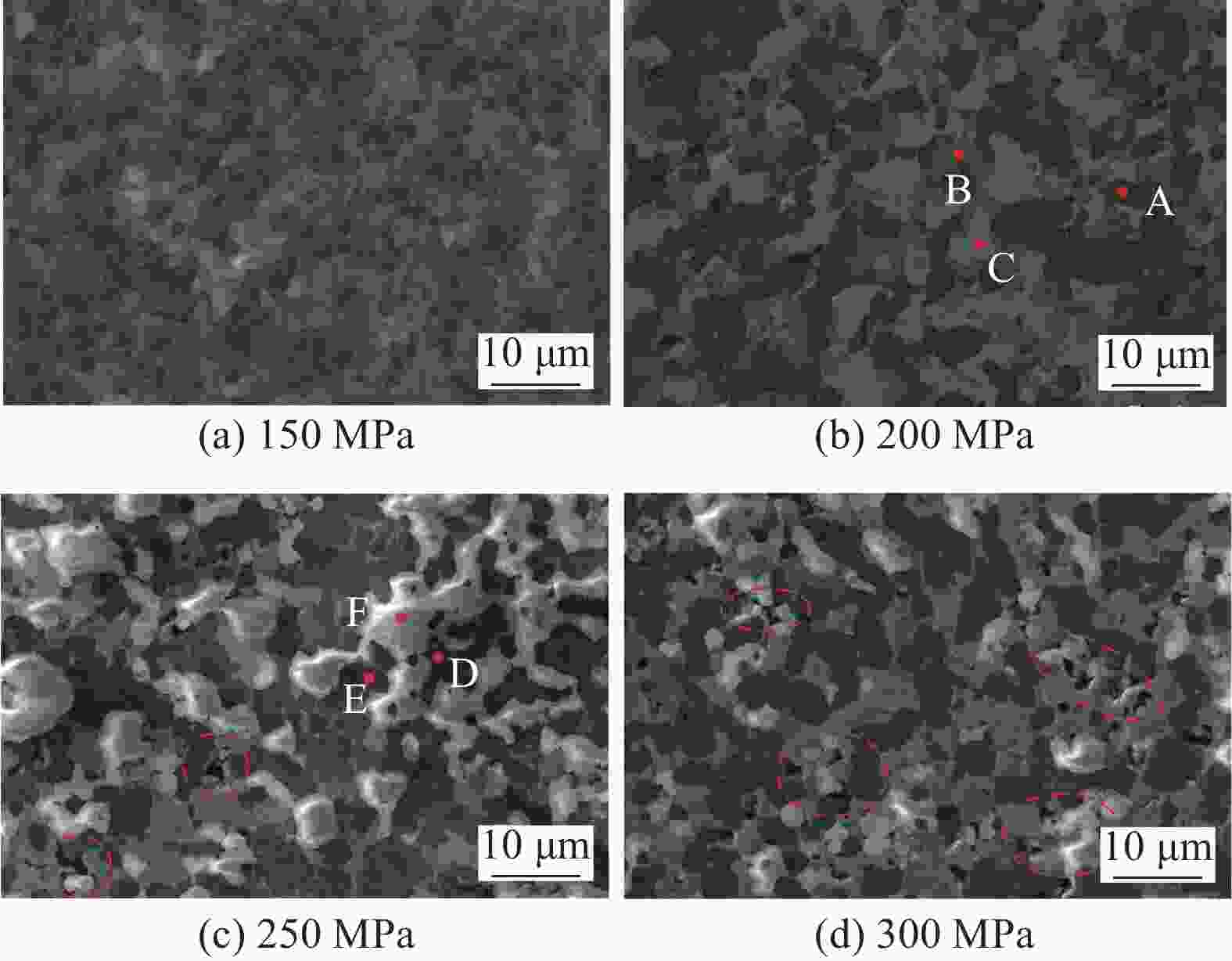

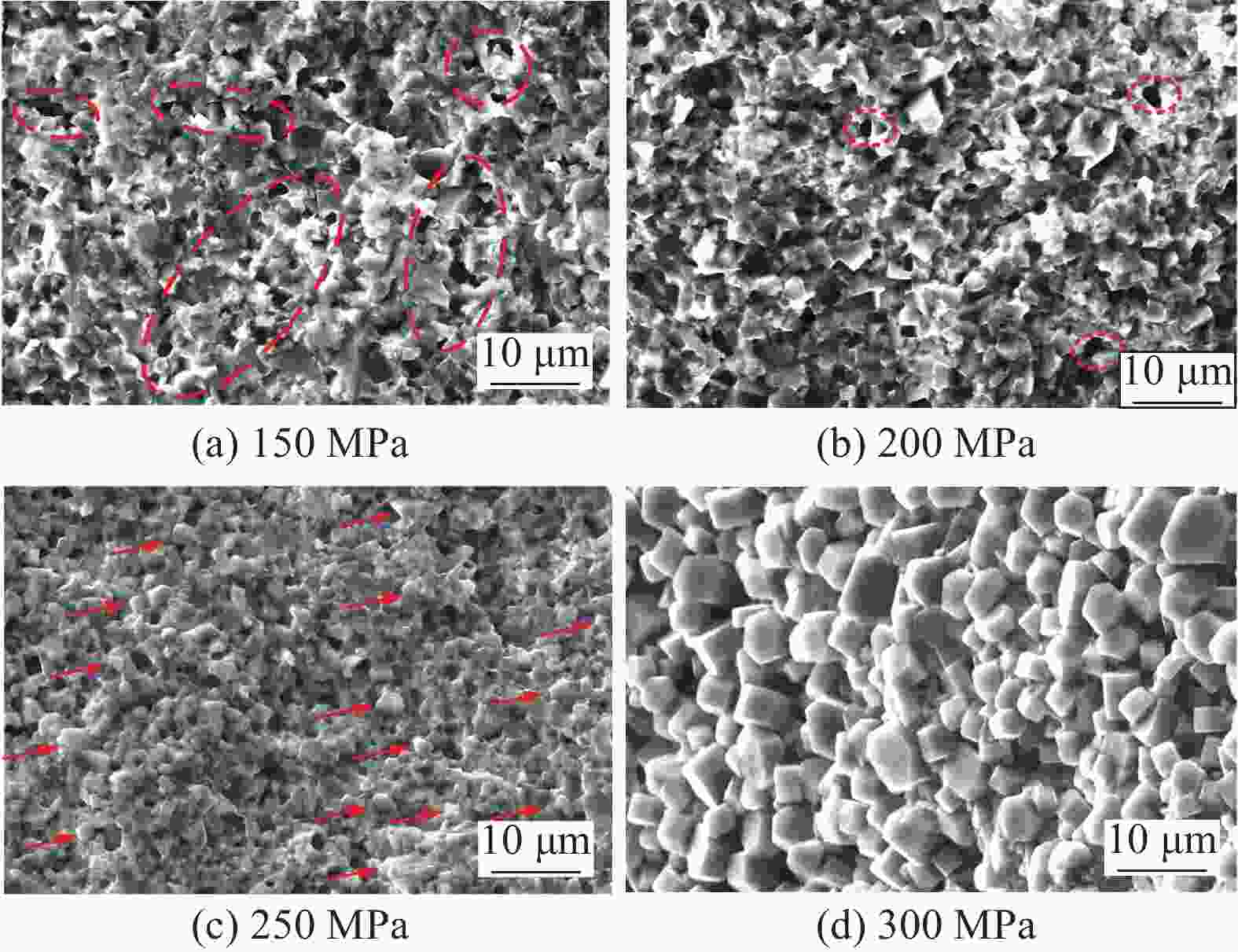

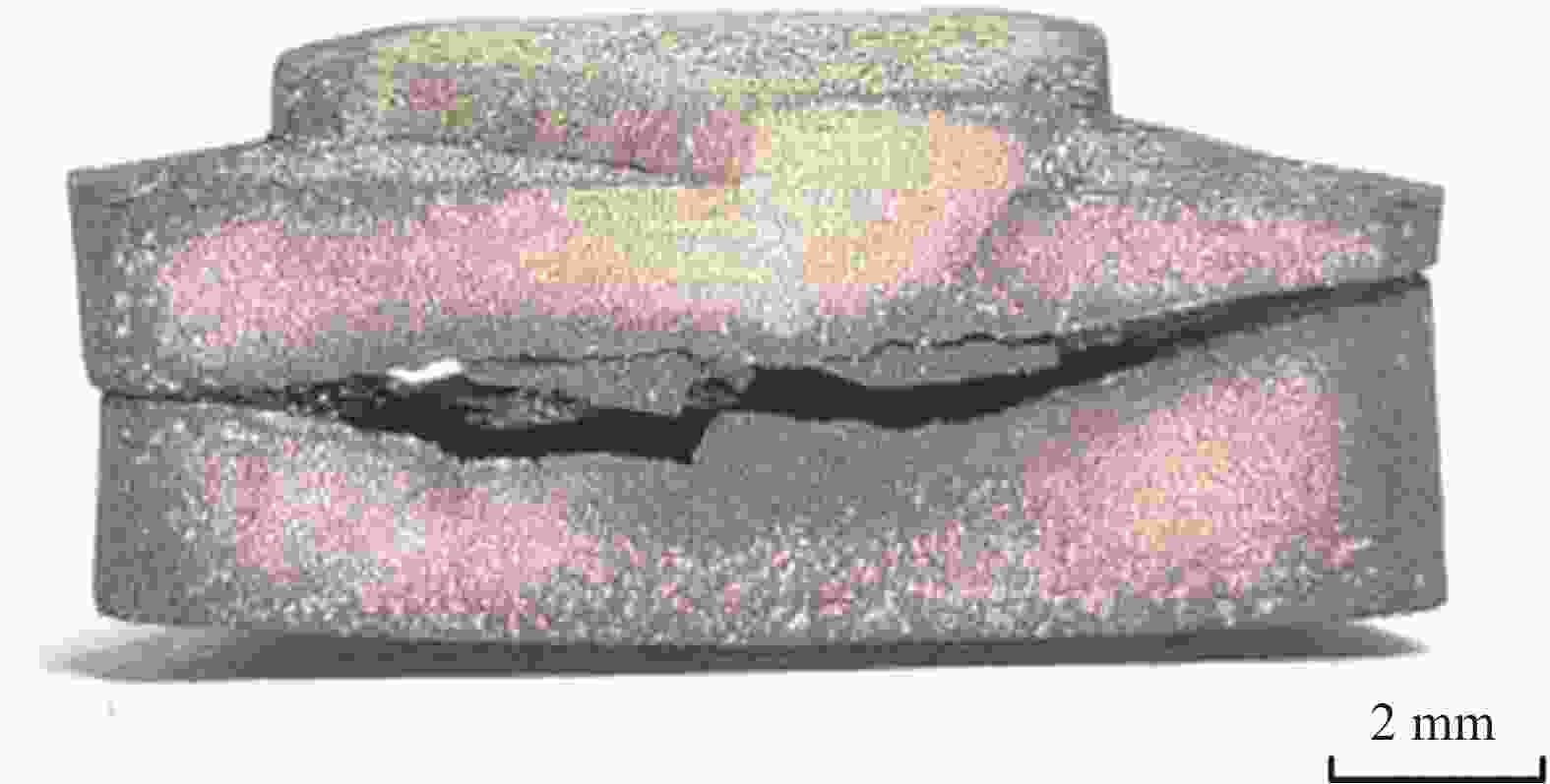

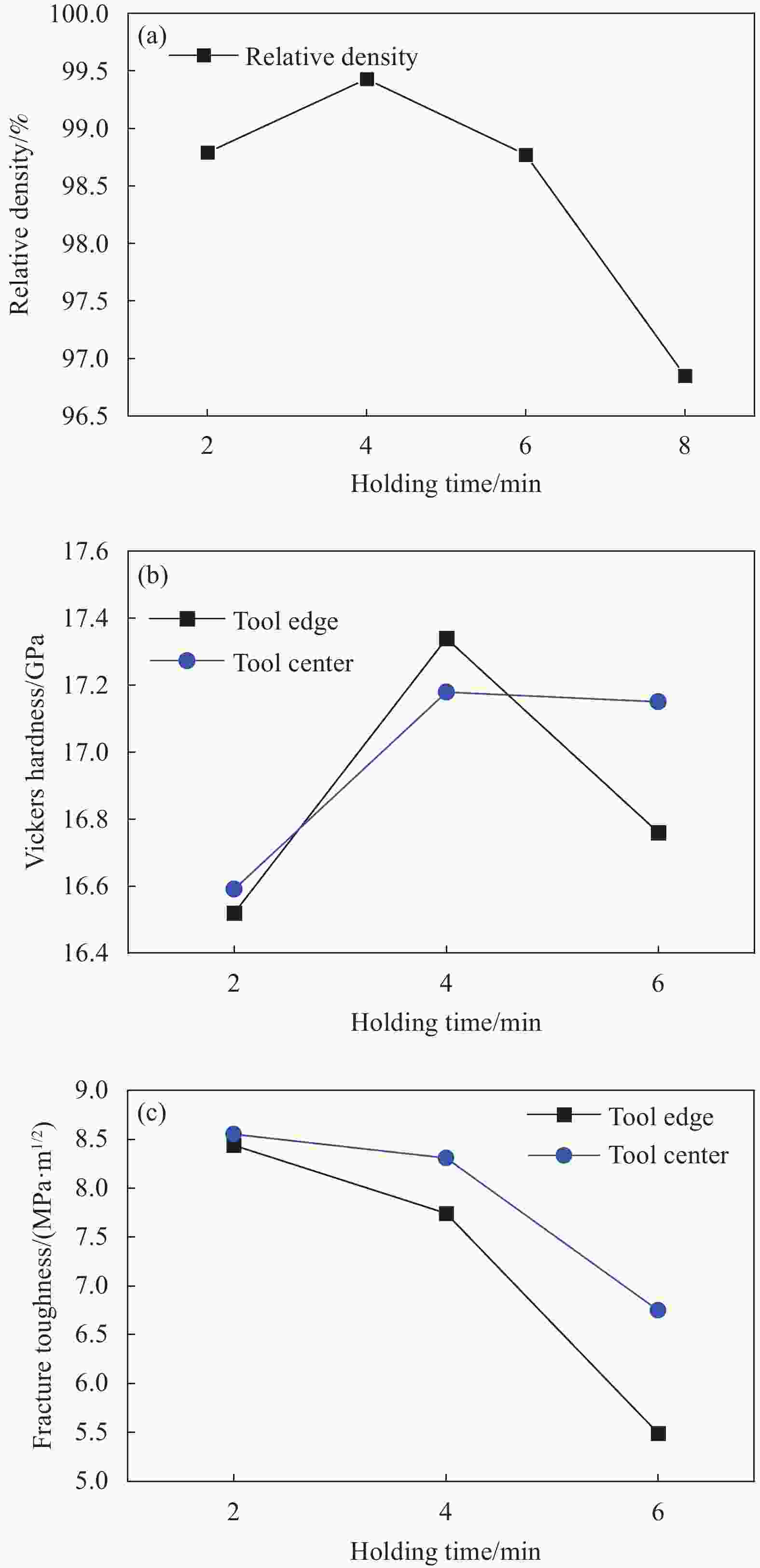

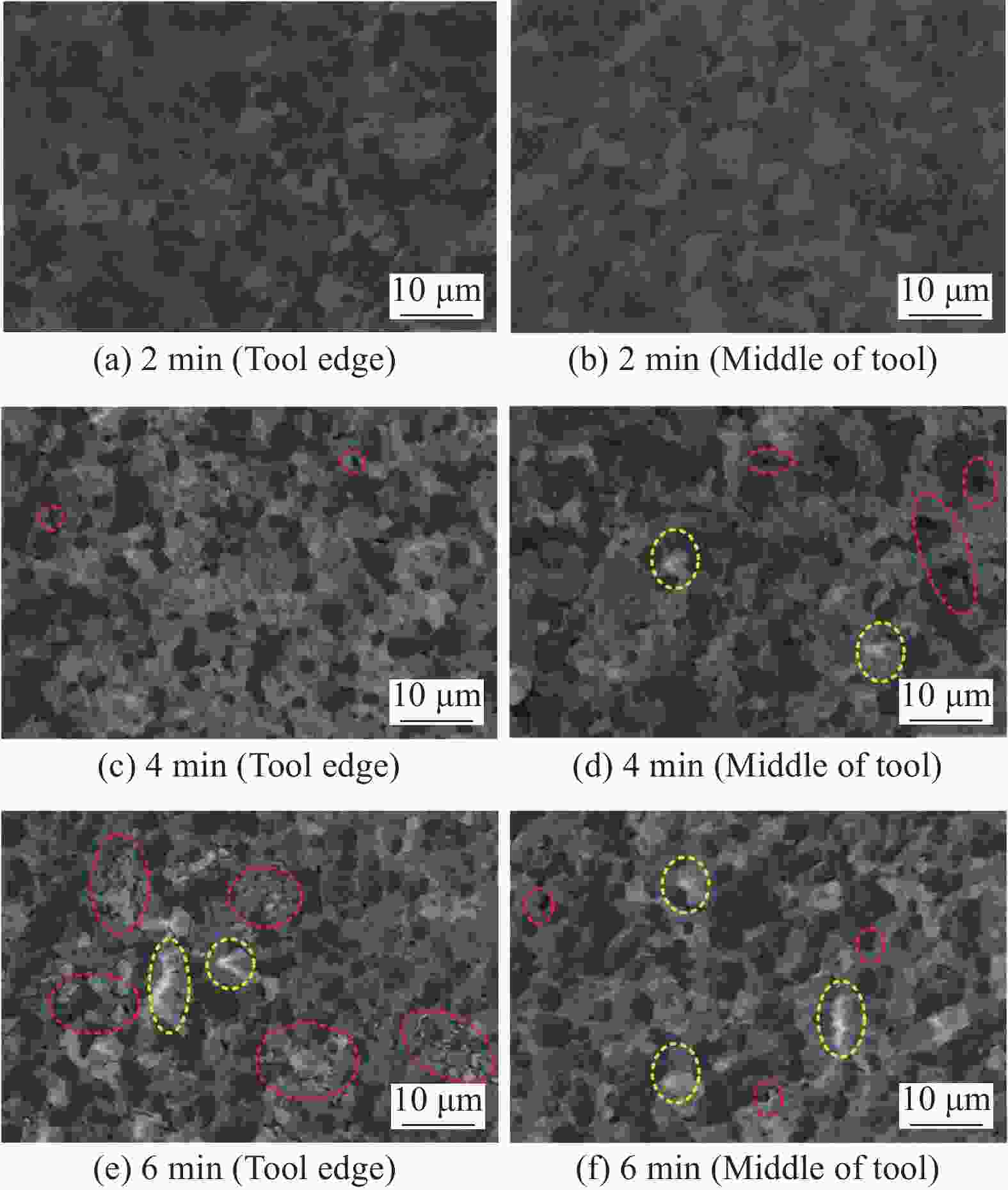

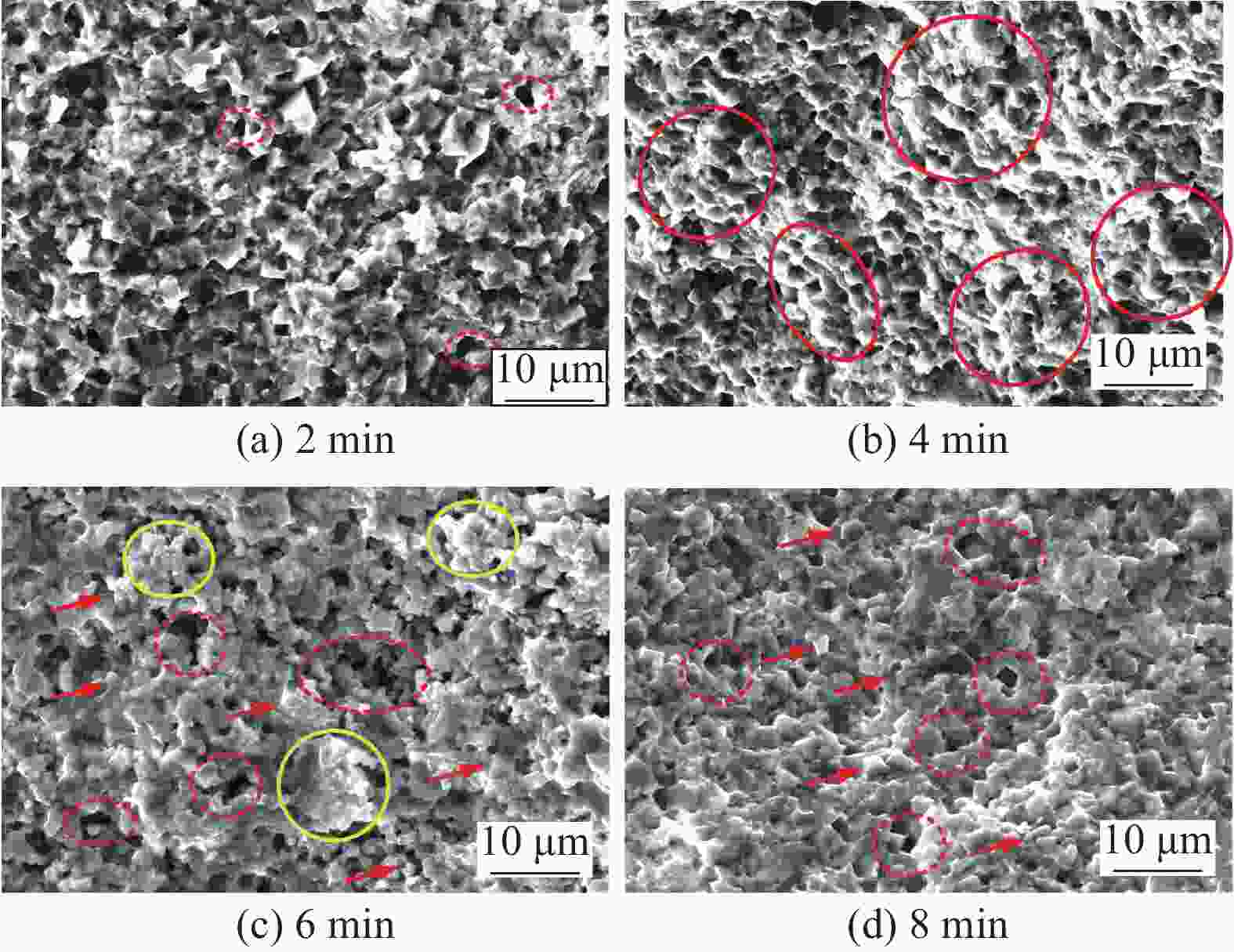

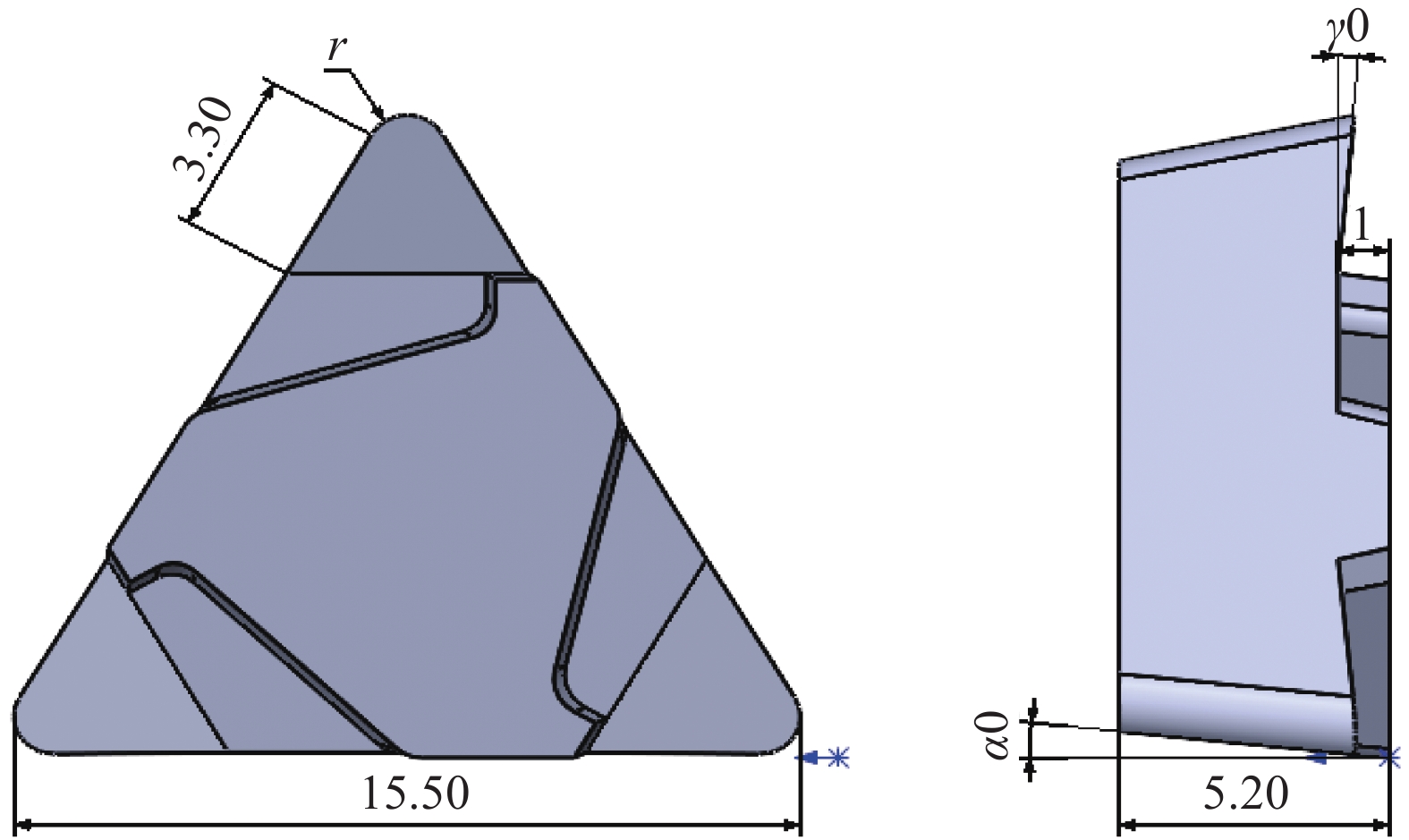

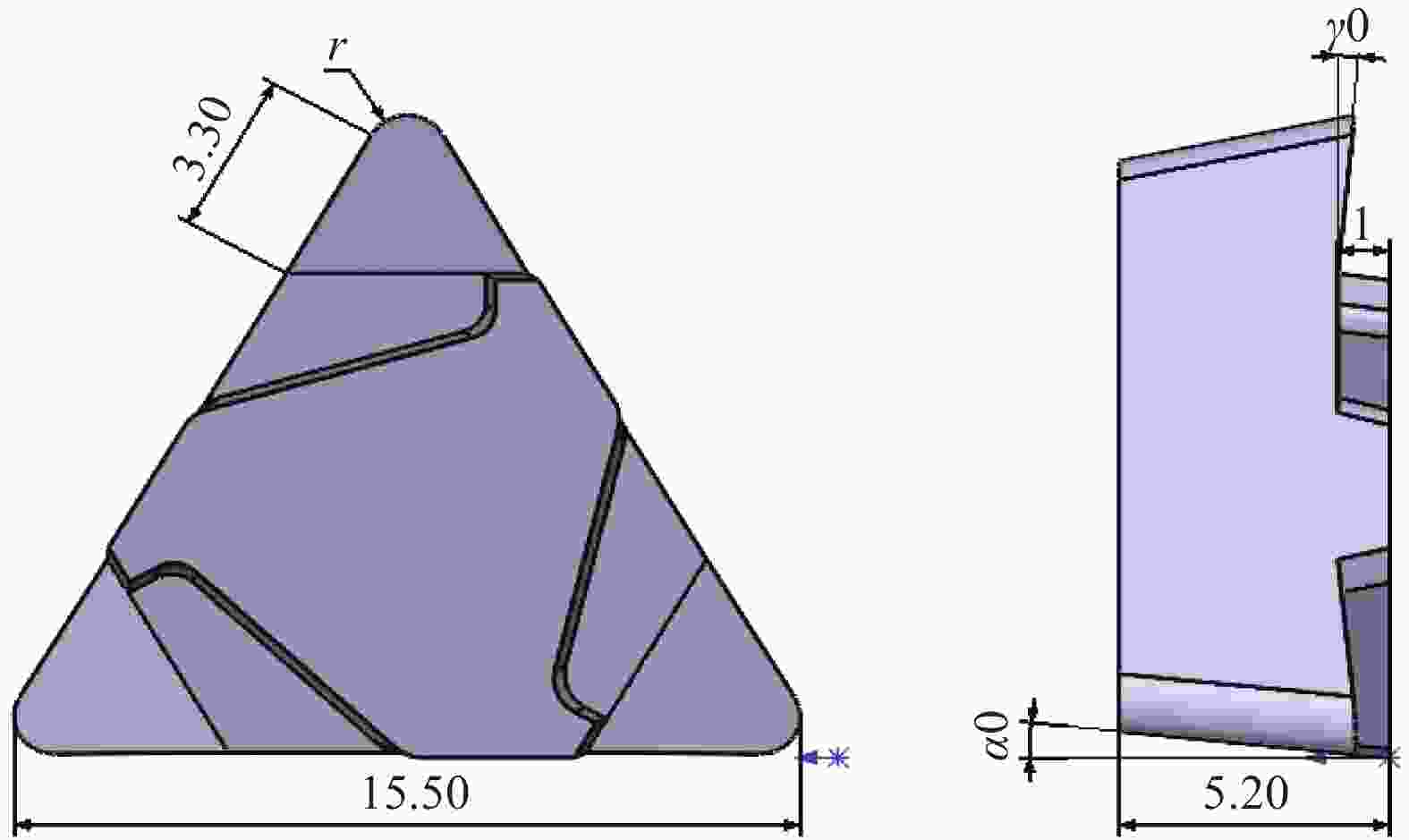

摘要: 基于微波烧结的特点,设计了复杂刃形TiB2基陶瓷刀具的结构参数。利用有限元仿真,研究了在车削球墨铸铁QT450时刀具结构参数对车削力和车削温度的影响。确定了复杂刃形TiB2基陶瓷刀具的最优刀具前角为5°、后角为6°、刀尖圆弧半径为0.8 mm。采用微波烧结技术制备了复杂刃形TiB2基陶瓷刀具,研究了压制压力和保压时间对复杂刃形TiB2基陶瓷刀具的相对密度、力学性能和微观组织的影响。结果表明,压制压力对晶粒的异常生长影响较大,合理的压制压力可以抑制晶粒的异常长大,改善刀具断裂模式,进而提高刀具性能。合理的保压时间可以使刀具表面的白色相分局均匀,防止聚集,这有利于刀具断裂韧度的提高。在压制压力为200 MPa,保压时间为4 min时,刀具各部位尺寸收缩率较为平均,成形精度较高,致密度最高,微观组织更加均匀,晶粒排列更加紧密,综合力学性能最优。Abstract: The structural parameters of TiB2-based ceramic tools with complex edge shapes were designed based on microwave sintering characteristics. The effect of tool design parameters on turning forces and temperatures when turning QT450 ductile cast iron was investigated using finite element simulation. For TiB2-based ceramic tools with complex cutting edges, the optimum tool front angle was found to be 5°, the optimum back angle was found to be 6° and the optimum tip radius was found to be 0.8mm. Complex edge-shaped TiB2-based ceramic tools were prepared by microwave sintering technology, and the effects of pressing pressure and holding time on the relative density, mechanical properties and microstructure of complex edge-shaped TiB2-based ceramic tools were investigated. The results show that the pressing pressure has a great influence on the abnormal growth of grains, and a reasonable pressing pressure can inhibit the abnormal growth of grains, improve the tool fracture mode, and then improve the tool performance. A reasonable holding time can make the white phase on the surface of the tool partition uniform and prevent aggregation, which is conducive to improving the fracture toughness of the tool. When the pressing pressure is 200MPa and the holding time is 4min, the dimensional shrinkage of each part of the tool is more average, the forming accuracy is higher, the densification is the highest, the microstructure is more uniform, the grain arrangement is more compact, and the overall mechanical properties are optimal.

-

Key words:

- tool structure /

- microwave sintering /

- pressing pressure /

- holding time /

- mechanical property

-

表 1 复杂刃形TiB2基陶瓷刀具车削仿真结构参数设计

Table 1. Structural parameter design for turning simulation of TiB2-based ceramic tools with complex edge shape

Research objective Tool front angle γ0/(°) Tool back angle α0/(°) Tool tip arc radius r/mm Design parameter −5, 0, 5, 10, 15 0, 3, 6, 9, 12 0.4, 0.6, 0.8, 1.0, 1.2 表 2 复杂刃形TiB2基陶瓷刀具原材料及特性

Table 2. Raw materials and characteristics of TiB2-based ceramic tools with complex cutting edges

Powder composition Densities/(g·cm−3) Particle size/μm Purity/% Manufacturer TiB2 4.502 0.5 99.9 Shanghai Chaowei TiC 4.930 0.5 99.9 Shanghai Chaowei HfC 12.700 0.1 99.9 Shanghai Chaowei Ni 8.902 0.6 99.9 Shanghai Chaowei Mo 10.200 0.5 99.9 Shanghai Chaowei 表 3 不同压制压力下复杂刃形TiB2基陶瓷刀具试样烧结前后尺寸和收缩率

Table 3. Dimensions and shrinkage of TiB2-based ceramic cutting tool samples before and after sinteringatdifferent press pressures

Blade sample Pre-sintering After sintering Percentage of

contraction/%Blade sample A(2 min、150 MPa) Knife blade/mm 3.30 2.80 15.15 Thickness/mm 5.70 4.80 15.79 Length of side/mm 15.50 12.70 18.06 volumetric/mm3 592.98 335.24 43.47 Blade sample B(2 min、200 MPa) Knife blade/mm 3.30 2.70 18.18 Thickness/mm 5.50 4.40 20.00 Length of side/mm 15.50 12.92 16.64 volumetric/mm3 572.17 318.04 44.42 Blade sample C(2 min、250 MPa) Knife blade/mm 3.30 2.80 15.15 Thickness/mm 5.50 4.52 17.82 Length of side/mm 15.50 12.90 16.77 volumetric/mm3 572.17 325.70 43.08 Blade sample D(2 min、300 MPa) Knife blade/mm 3.30 2.80 15.15 Thickness/mm 5.30 4.50 15.09 Length of side/mm 15.50 13.14 15.23 volumetric/mm3 551.37 336.44 38.98 表 4 不同压制压力下复杂刃形TiB2基陶瓷刀具试样烧结前后的结构尺寸及误差

Table 4. Structural dimensions and errors of TiB2-based ceramic tool specimens with complex cutting edges before and after sintering under different pressing pressures.

Blade sample Pre-sintering After sintering Errors/% Blade sample A (2 min、150 MPa) Rake angle/° 5.00 5.55 11.00 Tool tip arc radius/mm 0.80 0.61 23.75 Blade sample B (2 min、200 MPa) Rake angle/° 5.00 5.35 7.00 Tool tip arc radius/mm 0.80 0.68 15.00 Blade sample C (2 min、250 MPa) Rake angle/° 5.00 5.65 13.00 Tool tip arc radius/mm 0.80 0.66 17.50 Blade sample D (2 min、300 MPa) Rake angle/° 5.00 5.65 13.00 Tool tip arc radius/mm 0.80 0.64 20.00 表 5 图7中A~F各点位的EDS分析

Table 5. EDS analysis of each point from A to F in Figure 5

Test point Element/wt% B C Ti Hf Ni Mo A 54.46 39.86 3.49 0.91 1.24 0.05 B 60.84 21.42 15.39 1.11 1.25 0.00 C 21.84 32.16 32.73 13.24 0.02 0.01 D 54.44 37.53 7.80 0.01 0.03 0.19 E 25.39 42.18 24.16 1.39 6.86 0.01 F 10.85 38.55 10.24 40.36 0.01 0.00 表 6 不同保压时间下复杂刃形TiB2基陶瓷刀具试样烧结前后尺寸和收缩率

Table 6. Dimensions and shrinkage of TiB2-based ceramic cutting tool samples before and after sintering at different pressure holding times

Blade sample Pre-sintering After sintering Percentage of contraction/% Blade sample B1 (2 min、200 MPa) Knife blade/mm 3.30 2.70 18.18 Thickness/mm 5.50 4.40 20.00 Length of side/mm 15.50 12.92 16.64 volumetric/mm3 572.17 318.04 44.42 Blade sample B2 (4 min、200 MPa) Knife blade/mm 3.30 2.74 16.97 Thickness/mm 5.70 4.75 16.67 Length of side/mm 15.50 12.82 17.29 volumetric/mm3 592.98 338.04 42.99 Blade sample B3 (6 min、200 MPa) Knife blade/mm 3.30 2.80 15.15 Thickness/mm 5.40 4.43 17.96 Length of side/mm 15.50 12.85 17.10 volumetric/mm3 561.77 316.75 43.62 Blade sample B4 (8 min、200 MPa) Knife blade/mm 3.30 The specimen cracked in two parts and could not be tested Thickness/mm 5.30 Length of side/mm 15.50 volumetric/mm3 551.37 表 7 不同保压时间下复杂刃形TiB2基陶瓷刀具试样烧结前后的结构尺寸及误差

Table 7. Structural dimensions and errors of TiB2-based ceramic tool specimens with complex cutting edge shape before and after sintering at different pressure holding times

Blade sample Pre-sintering After sintering Error/% Blade sample B1(2 min、200 MPa) Rake angle/(°) 5.00 5.35 7.00 Tool tip arc radius/mm 0.80 0.68 15.00 Blade sample B2(4 min、200 MPa) Rake angle/(°) 5.00 5.37 7.40 Tool tip arc radius/mm 0.80 0.69 13.75 Blade sample B3(6 min、200 MPa) Rake angle/(°) 5.00 5.45 9.00 Tool tip arc radius/mm 0.80 0.69 13.75 Blade sample B4(8 min、200 MPa) Rake angle/(°) 5.00 3.5 30.00 Tool tip arc radius/mm 0.80 0.61 23.75 -

[1] 黄小晓, 涂赣峰, 王术新, 等. TiB2涂层的制备及其应用研究进展[J]. 稀有金属材料与工程, 2022, 51(3): 1087-1099.HUANG Xiaoxiao, TU Ganfeng, WANG Shuxin, et al. Research progress on preparation and application of TiB2 coating[J]. Rare Metal Materials and Engineering, 2022, 51(3): 1087-1099(in Chinese). [2] SHUSTER L S, FOX-RABINOVICH G S, CHERTOVSKIKH S V. Influence of cutting conditions on the wear resistance of tools with a TiB2 coating during titanium alloy machining[J]. Journal of Friction and Wear, 2021, 42(6): 466-472. doi: 10.3103/S1068366621060118 [3] 张剑平, 张萌, 艾云龙. TiB2在原位反应制备铜基复合材料中的应用现状[J]. 特种铸造及有色合金, 2008, (7): 544-547,490.ZHANG Jianping, ZHANG Meng, AI Yunlong, et ai. Application status of TiB2 in in-situ reaction preparation of copper matrix composites[J]. Special Casting & Nonferrous Alloys, 2008, (7): 544-547,490(in Chinese). [4] GONG F, ZHAO J, LIU G, et al. Design and fabrication of TiB2-TiC-Al2O3 gradient composite ceramic tool materials reinforced by VC/Cr3C2 additives[J]. Ceramics International, 2021, 47(14): 20341-20351. doi: 10.1016/j.ceramint.2021.04.042 [5] WU N, XUE F, YANG Q, et al. Microstructure and mechanical properties of TiB2-based composites with high volume fraction of Fe-Ni additives prepared by vacuum pressureless sintering[J]. Ceramics International, 2017, 43(1): 1394-1401. doi: 10.1016/j.ceramint.2016.10.100 [6] YAN S R, LV Z J. FANG L J. Effects of SiC amount and morphology on the properties of TiB2-based composites sintered by hot-pressing[J]. Ceramics International, 2020, 46(11): 18813-18825. doi: 10.1016/j.ceramint.2020.04.199 [7] 刘元会, 石少杰, 曹宇航, 等. 热压烧结制备碳纤维/氧化铝陶瓷复合材料的负介电行为[J]. 复合材料学报, 2022, 39(08): 4085-4092. doi: 10.13801/j.cnki.fhclxb.20211012.003LIU Yuanhui, SHI Shaojie, CAO Yuhang, et al. Negative dielectric behavior of carbon fiber/alumina ceramic composites prepared by hot press sintering[J]. Acta Materiae Compositae Sinica, 2022, 39(08): 4085-4092(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211012.003 [8] DING X, PAN K, LIU Z, et al. Effects of TiC particle size on microstructures and mechanical properties of B4C-TiB2 composites prepared by reactive hot-press sintering of TiC-B mixtures[J]. Ceramics International, 2020, 46(8): 10425-10430. doi: 10.1016/j.ceramint.2020.01.041 [9] CHEN D, ZHANG K, ZENG J, et al. High-strength TiB2-B4C composite ceramics sintered by spark plasma sintering[J]. International Journal of Applied Ceramic Technology, 2022, 19(4): 1949-1955. doi: 10.1111/ijac.14051 [10] 张新杰, 崔洪芝, 王明亮, 等. 放电等离子烧结Ni/TiB2-TiC复合材料微观组织及磨损性能[J]. 复合材料学报, 2018, 35(01): 158-167.ZHANG Xinjie, CUI Hongzhi, WANG Mingliang, et al. Microstructure and wear properties of Ni/TiB2-TiC composites prepared by spark plasma sintering[J]. Acta Materiae Compositae Sinica, 2018, 35(01): 158-167(in Chinese). [11] XU G F, ZHUANG H R, WU F Y, et al. Microwave reaction sintering of α-β-sialon composite ceramics - ScienceDirect[J]. Journal of the European Ceramic Society, 1997, 17(5): 675-680. doi: 10.1016/S0955-2219(96)00114-8 [12] SINGHAL C, MURTAZA Q, PARVEJ. Microwave sintering of advanced composites materials: A Review[J]. Materials Today:Proceedings, 2018, 5(11+3): 24287-24298. [13] RAMESH S, ZULKIFLI N, TAN C Y, et al. Comparison between microwave and conventional sintering on the properties and microstructural evolution of tetragonal zirconia[J]. Ceramics International, 2018, 44(8): 8922-8927. doi: 10.1016/j.ceramint.2018.02.086 [14] AGRAWAL D, RAGULYA A, DEMIRSKYI D. Tough ceramics by microwave sintering of nanocrystalline titanium diboride ceramics[J]. Ceramics International, 2014, 40(1B): 1303-1310. [15] DEMIRSKYI D, CHENG J, AGRAWAL D, et al. Densification and grain growth during microwave sintering of titanium diboride[J]. Scripta Materialia, 2013, 69(8): 610-613. doi: 10.1016/j.scriptamat.2013.07.012 [16] 方一航, 夏伶勤, 陈光, 等. 成型压力对Ti(C, N)基金属陶瓷微观组织结构和力学性能的影响[J]. 材料与冶金学报, 2023, 22(3): 249-255.FANG Yihang, XIA Lingqin, CHEN Guang, et al. Effect of molding pressure on microstructure and mechanical properties of Ti(C, N) matrix ceramics[J]. Journal of Materials and Metallurgy, 2023, 22(3): 249-255(in Chinese). [17] ZONG H, ZHANG C, RU H, et al. Effect of forming pressure on microstructure and mechanical properties of B4C-SiC-Si ceramic composites[J]. Key Engineering Materials, 2018, 768(1): 152-158. [18] SARAVANAMURUGAN S, SUNDAR B S, PRANAV R S, et al. Optimization of cutting tool geometry and machining parameters in turning process[J]. Materials Today:Proceedings, 2021, 38(5): 3351-3357. [19] JI Junhao, YANG Qi, CHEN Peng, et al. An improved mathematical model of cutting temperature in end milling Al7050 based on the influence of tool geometry parameters and milling parameters[J]. Mathematical Problems in Engineering, 2021, 2021: 1-10 [20] MANUEL N, BELTRãO D, GALVãO I, et al. Influence of tool geometry and process parameters on torque, temperature, and quality of friction stir welds in dissimilar al alloys[J]. Materials, 2021, 14(20): 6020. doi: 10.3390/ma14206020 [21] 胡波, 赵先锋, 史红艳, 等. 基于AdvantEdge切削工艺参数及刀具几何参数对切削力影响研究[J]. 组合机床与自动化加工技术, 2021, (7): 128-132. doi: 10.13462/j.cnki.mmtamt.2021.07.030HU Bo, ZHAO Xianfeng, SHI Hongyan, et al. Research on the influence of cutting process parameters and tool geometry parameters on cutting force based on AdvantEdge[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2021, (7): 128-132(in Chinese). doi: 10.13462/j.cnki.mmtamt.2021.07.030 [22] 殷增斌, 朱智勇, 王子祥, 等. 复杂刃形陶瓷刀具微波烧结技术研究[J]. 中国机械工程, 2022, 33(8): 899-907.YIN Zengbin, ZHU Zhiyong, WANG Zixiang, et al. Research on microwave sintering technology of complex blade ceramic cutte[J]. China Mechanical Engineering, 2022, 33(8): 899-907(in Chinese). [23] 洪东波, 殷增斌, 陈为友, 等. 微波烧结复杂刃形SiAlON陶瓷刀具铣削GH4169高温合金性能研究[J]. 中国机械工程, 2023, 34(7); 770-779, 788.HONG Dongbo, YIN Zengbin, CHEN Weiyou, et al. Study on milling performance of GH4169 superalloy with complex blade SiAlON ceramic tool by microwave sintering[J]. China Mechanical Engineering, 2023, 34(7); 770-779, 788(in Chinese). [24] 程德俊, 许丰, 张春燕, 等. 薄壁件铣削加工刀具几何参数优化[J]. 组合机床与自动化加工技术, 2020, (4): 130-3,8. doi: 10.13462/j.cnki.mmtamt.2020.04.030CHENG Dejun, XU Feng, ZHANG Chunyan, et al. Optimization of milling cutter parameters for machining thin-walled parts[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2020, (4): 130-3,8(in Chinese). doi: 10.13462/j.cnki.mmtamt.2020.04.030 [25] TOKTAŞ A. Determination of Vickers indentation fracture toughness of boronised alloyed ductile iron[J]. Transactions of the Institute of Metal Finishing, 2019, 97(5): 271-276. doi: 10.1080/00202967.2019.1646458 [26] 达丽梅, 周后明, 周金虎, 等. Al2O3颗粒增韧TiB2-Ti(C(0.5), N(0.5))复合陶瓷刀具的力学性能及微观结构[J]. 材料科学与工程学报, 2022, 40(05): 785-790.DA Limei, ZHOU Houming, ZHOU Jinhu, et al. Mechanical properties and microstructure of TiB2-Ti(C(0.5), N(0.5)) composite ceramic tools toughened with Al2O3 particles[J]. Journal of Materials Science and Engineering, 2022, 40(05): 785-790(in Chinese). [27] 张广森, 季文彬, 戴士杰, 等. 微波烧结Ti(C, N)-WC-Al2O3/Ti(C, N)-WC叠层陶瓷的微观结构和力学性能[J]. 硅酸盐学报, 2022, 50(12): 3212-3221.ZHANG Guangsen, JI Wenbin, DAI Shijie, et al. Structural Design And Mechanical Properties of Microwave Sintered Ti(C, N)-WC-Al2O3/Ti(C, N)-WC Laminated Ceramics[J]. Bulletin of the Chinese Ceramic Society, 2022, 50(12): 3212-3221(in Chinese). [28] 王波, 王杨, 董中奇, 等. 压制压力对机械合金化Cu20Fe80合金微波烧结组织及性能的影响[J]. 粉末冶金工业, 2018, 28(3): 24-8.WANG Bo, WANG Yang, DONG Zhongqi, et al. Effect of compaction pressure on microstructure and properties of mechanically alloyed Cu20Fe80 alloy during microwave sintering[J]. Powder Metallurgy Industry, 2018, 28(3): 24-8(in Chinese). [29] Natalia D. L, Wijanarko R, Angela I, et al. Influence of compaction pressure on density, bending strength, and microstructures of Al2O3-SiC-ZrO2 ceramic matrix composites with Nb2O5 additives[J]. Materials Science Forum, 2018, 923(1): 61-65. [30] 周后明, 陈皓月, 李神贵. 基于梯度结构的Al2O3/ZrO2陶瓷刀具材料的制备及其力学性能[J]. 中国机械工程, 2023, 34(10): 1199-1207. doi: 10.3969/j.issn.1004-132X.2023.10.009ZHOU Houming, CHEN Haoyue, LI Shengui. Preparation and mechanical properties of Al2O3/ZrO2 ceramic tool materials based on gradient structure[J]. China Mechanical Engineering, 2023, 34(10): 1199-1207(in Chinese). doi: 10.3969/j.issn.1004-132X.2023.10.009 -

下载:

下载: