Preparation and properties of thermally conductive grapheme nanoplates/(polyetherketone cardo-epoxy) composites with double percolation structures

-

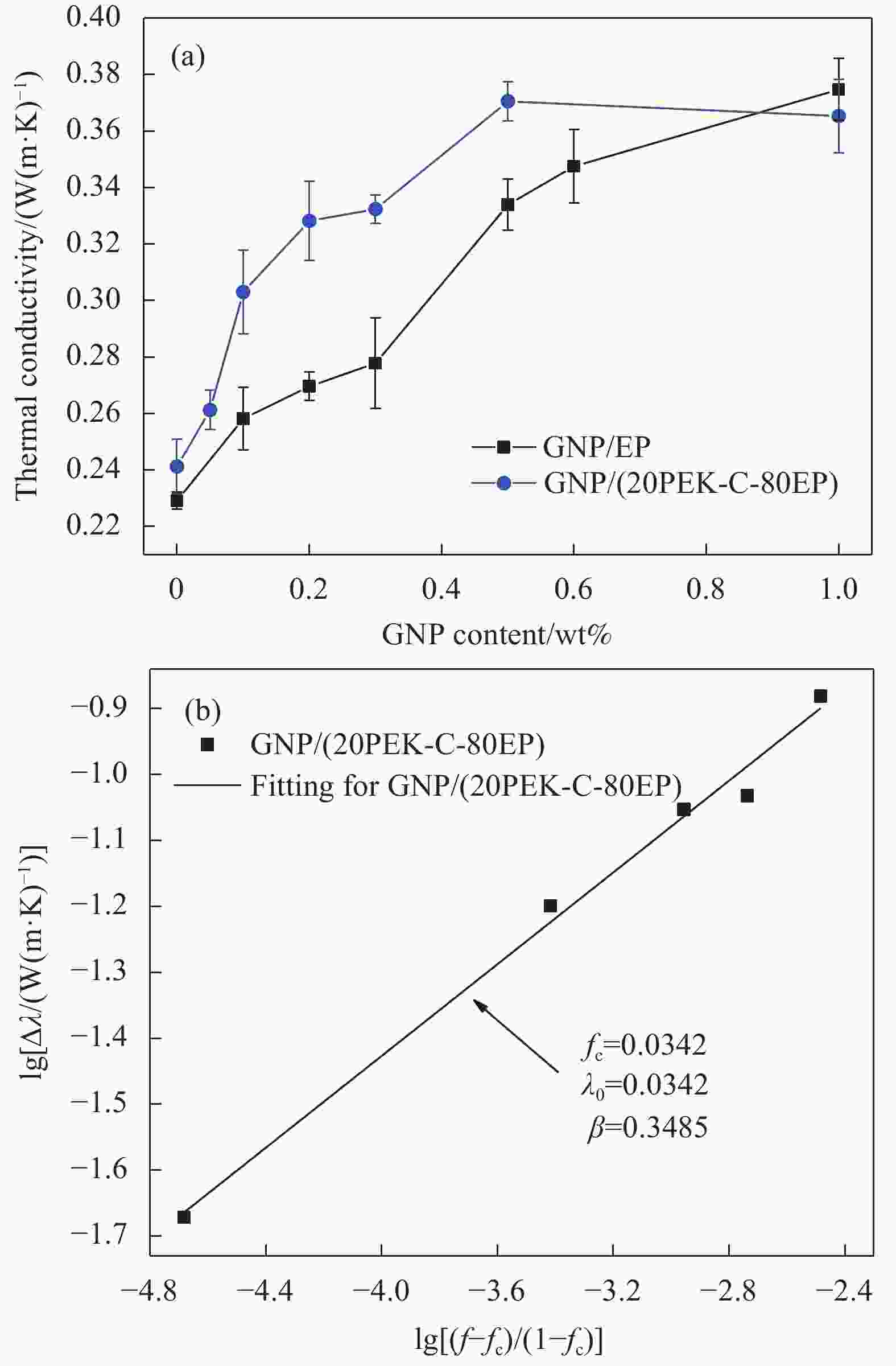

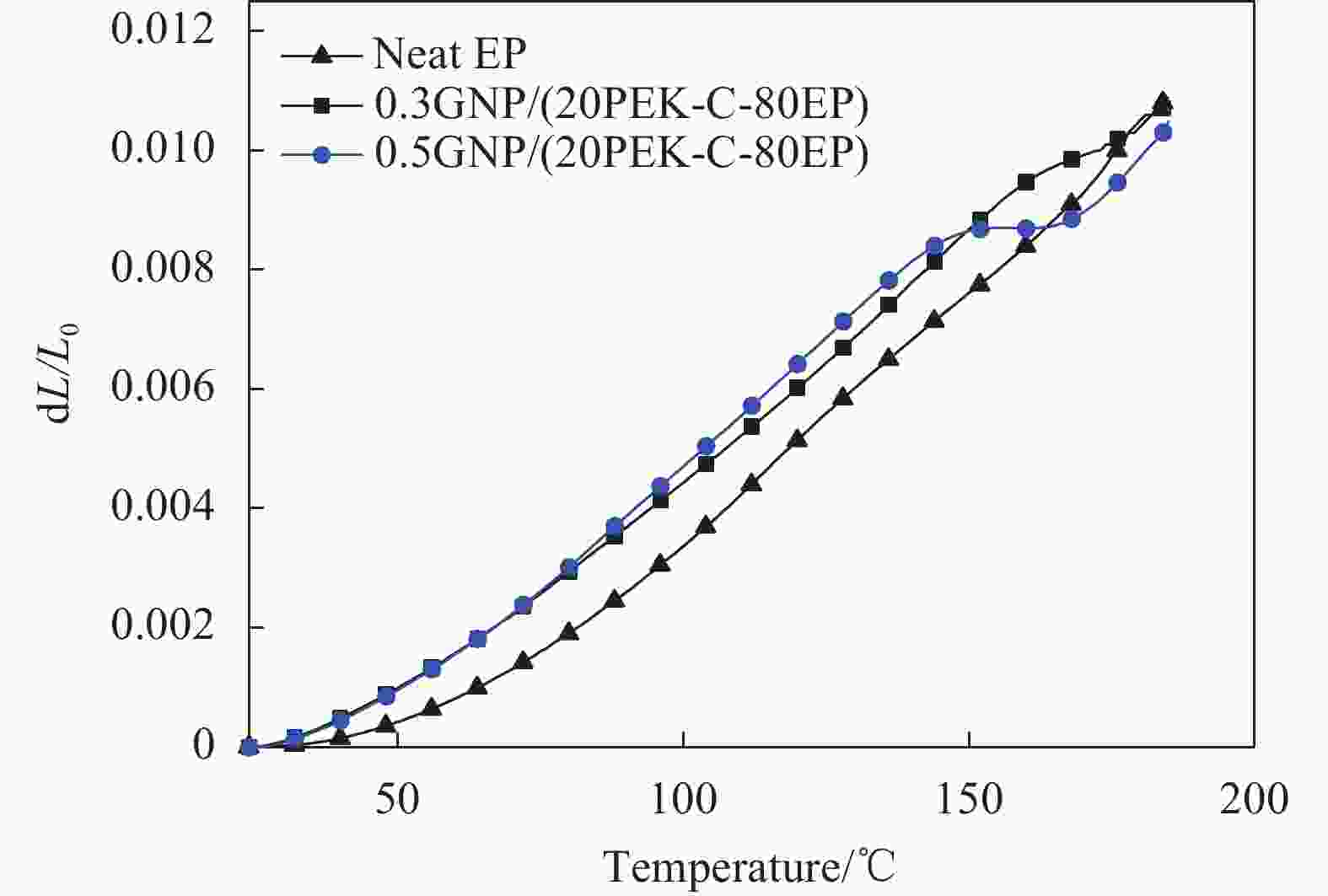

摘要: 为在较低的导热填料含量下提高环氧树脂(EP)的热导率,通过溶液法制备了石墨烯纳米片/(酚酞聚芳醚酮-EP) (GNP/(PEK-C-EP))复合材料。基于接触角测量计算并预测了GNP的选择性分布,并通过SEM和激光闪光法研究了GNP和PEK-C含量对GNP/(PEK-C-EP)复合材料的微观结构和热导率的影响。结果表明,当PEK-C的含量为20wt%时,GNP选择性分布在PEK-C中,形成了双逾渗结构的GNP/(PEK-C-EP)复合材料,从而构建了连续导热通道。当GNP含量为1wt%时,GNP/EP复合材料导热率最高达0.375 W(m·K)−1。当GNP含量为0.5wt%时,GNP/(PEK-C-EP)复合材料导热率最高达0.371 W(m·K)−1,较GNP含量为0.5wt%的GNP/EP复合材料热导率高48%,与GNP含量为1wt%的GNP/EP复合材料的热导率基本相同。表明GNP/(PEK-C-EP)复合材料的填料量减少了50%,利用双逾渗效应可以有效减少导热填料用量。此外,比较了纯EP和GNP/(PEK-C-EP)复合材料的玻璃化转变温度、热稳定性和热膨胀系数,结果表明,GNP/(PEK-C-EP)复合材料的热性能优于纯EP。Abstract: To improve the thermal conductivity of epoxy (EP) with a lower thermally conductive filler content, graphene nanoplates/(polyetherketone cardo-EP) (GNP/(PEK-C-EP)) composites were prepared by the solution method. The selective distribution of GNP was predicted by calculation based on contact angle measurements, and the effects of GNP and PEK-C contents on the microstructures and thermal conductivities of GNP/(PEK-C-EP) composites were investigated by SEM and laser flash method. The results show that double percolation structures are formed in GNP/(PEK-C-EP) composites as the content of PEK-C reaches 20wt%, where GNPs are selectively distributed in PEK-C to build continuous heat conduction paths. For GNP/EP composites, it reaches the highest thermal conductivity of 0.375 W(m·K)−1 at 1wt% GNP. While for GNP/(PEK-C-EP) composites, the content of 0.5wt% GNP reaches highest thermal conductivity of 0.371 W(m·K)−1, which is 48% higher than that of GNP/EP composites at 0.5wt% GNP content and basically the same as that of GNP/EP composites at 1wt% GNP. It indicates that the filler content of GNP/(PEK-C-EP) composites is reduced by 50% owing to the double percolation effect. In addition, the glass transition temperatures, thermal stability and coefficients of thermal expansion of pure EP and GNP/(PEK-C-EP) composites were compared. The results show that the GNP/(PEK-C-EP) composites are superior to pure EP in thermal properties.

-

Key words:

- double percolation effect /

- epoxy /

- polyetherketone cardo /

- graphene nanoplates /

- thermal conductivity

-

图 4 不同GNP含量的GNP/EP和GNP/(PEK-C-EP)复合材料热导率(a)及热逾渗幂律方程对GNP/(PEK-C-EP)复合材料热导率的拟合曲线(b)

Figure 4. Thermal conductivities of GNP/EP and GNP/(PEK-C-EP) composites with different GNP contents (a) and fitting curve of thermal conductivity of GNP/(PEK-C-EP) composites by thermal percolation power law equation (b)

表 1 试剂表面张力及其色散和极性分量[12]

Table 1. Surface tensions, dispersive and polarcomponents of chemical reagents

Reagent $\gamma $/(mN·m–1) ${\gamma ^{\rm{d}}}$/(mN·m–1) ${\gamma ^{\rm{p}}}$/(mN·m–1) Ethylene glycol 47.5 31.2 16.3 Deionized water 71.5 28.2 43.3 Notes: $\gamma $—Surface tension; ${\gamma ^{\rm{d}}}$, ${\gamma ^{\rm{p}}}$—Dispersive and polar components of surface tension, respectively. 表 2 EP、PEK-C和石墨烯纳米片(GNP)的表面张力

Table 2. Surface tensions of EP, PEK-C and graphene nanoplate (GNP)

Component Harmonic Geometric Ref. $\gamma $/(mN·m–1) ${\gamma ^{\rm{d}}}$/(mN·m–1) ${\gamma ^{\rm{p}}}$/(mN·m–1) $\gamma $/(mN·m–1) ${\gamma ^{\rm{d}}}$/(mN·m–1) ${\gamma ^{\rm{p}}}$/(mN·m–1) EP 43.07 10.35 32.72 40.49 7.71 32.78 Tested PEK-C 33.84 11.46 22.38 30.04 15.41 14.63 Tested GNP 23.20 10.80 12.40 22.76 19.49 3.27 [12] Notes: “Harmonic” indicates that the surface tensions can be obtained from the equation (6); “Geometric” indicates that the surface tensions can be obtained from the equation (7). 表 3 EP、PEK-C和GNP之间的界面张力

Table 3. Interfacial tensions of EP, PEK-C and GNP

Component couple ${\gamma _{1 - 2}}$/(mN·m−1) Geometric-Geometric Geometric-Harmonic Harmonic-Geometric Harmonic-Harmonic EP-PEK-C 4.93 1.01 9.51 1.99 EP-GNP 18.11 4.84 29.37 9.16 PEK-C-GNP 4.34 1.47 7.75 2.88 Notes: “Geometric-Geometric” and other similar marks indicate “the formula for the surface tension data source (equation (6) or equation (7))-the formula for calculating the interface tension (equation (4) or equation (5))”. 表 4 GNP/(PEK-C-EP)复合材料的润湿系数

${\omega _\alpha }$ Table 4. Wetting coefficient ωα of GNP/(PEK-C-EP) composites

${\omega _\alpha }$ calculated from

Geometric-Geometric${\omega _\alpha }$ calculated from

Geometric-Harmonic${\omega _\alpha }$ calculated from

Harmonic-Geometric${\omega _\alpha }$ calculated from

Harmonic-HarmonicLocation of GNP 2.79 3.35 2.27 3.15 PEK-C 表 5 EP和0.5GNP/(20PEK-C-80EP)复合材料的热失重5%的温度(T5%)、热失重10%的温度(T10% )和残炭率(Rw)

Table 5. Temperature of 5% mass loss (T5%), temperature of 10% mass loss (T10%) and residual carbon ratios (Rw) of EP and 0.5GNP/(20PEK-C-80EP) composite

Sample T5%/℃ T10%/℃ Rw/% EP 322.7 352.6 24.2 0.5GNP/

(20PEK-C-80EP)320.1 354.9 30.5 -

[1] LIU S, CHEVALI V S, XU Z G, et al. A review of extending performance of epoxy resins using carbon nanomaterials[J]. Composites Part B: Engineering,2018,136:197-214. doi: 10.1016/j.compositesb.2017.08.020 [2] GUO Y Q, RUAN K P, SHI X T, et al. Factors affecting thermal conductivities of the polymers and polymer composites: A review[J]. Composites Science and Technology,2020,193:108134. doi: 10.1016/j.compscitech.2020.108134 [3] CHEN H, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science,2016,59:41-85. doi: 10.1016/j.progpolymsci.2016.03.001 [4] ZHANG R H, SHI X T, TANG L, et al. Thermally conductive and insulating epoxy composites by synchronously incorporating Si-sol functionalized glass fibers and boron nitride fillers[J]. Chinese Journal of Polymer Science,2020,38(7):730-739. doi: 10.1007/s10118-020-2391-0 [5] 钟洨, 孟旭东, 张睿涵, 等. 改性纳米BN/甲基乙烯基硅橡胶导热复合材料的制备[J]. 复合材料学报, 2019, 36(11):2644-2650.ZHONG Xiao, MENG Xudong, ZHANG Ruihan, et al. Preparation of functionalized nano BN/methyl vinyl silicone rubber thermally conductive composites[J]. Acta Materiae Compositae Sinica,2019,36(11):2644-2650(in Chinese). [6] LEE E S, LEE S M, SHANEFIELD D J, et al. Enhanced thermal conductivity of polymer matrix composite via high solids loading of aluminum nitride in epoxy resin[J]. Journal of the American Ceramic Society,2008,91(4):1169-1174. doi: 10.1111/j.1551-2916.2008.02247.x [7] SUMITA M, SAKATA K, ASAI S, et al. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black[J]. Polymer Bulletin,1991,25(2):265-271. doi: 10.1007/BF00310802 [8] BONNET P, SIREUDE D, GARNIER B, et al. Thermal properties and percolation in carbon nanotube-polymer composites[J]. Applied Physics Letters,2007,91(20):201910. [9] CHEN J, CUI X, SUI K, et al. Balance the electrical properties and mechanical properties of carbon black filled immiscible polymer blends with a double percolation structure[J]. Composites Science and Technology,2017,140:99-105. doi: 10.1016/j.compscitech.2016.12.029 [10] LIU W, YANG Y, NIE M. Constructing a double-percolated conductive network in a carbon nanotube/polymer-based flexible semiconducting composite[J]. Composites Science and Technology,2018,154:45-52. doi: 10.1016/j.compscitech.2017.11.003 [11] QI X Y, YAN D, JIANG Z, et al. Enhanced electrical conductivity in polystyrene nanocomposites at ultra-low graphene content[J]. ACS Applied Materials & Interfaces,2011,3(8):3130-3133. doi: 10.1021/am200628c [12] HUANG J, ZHU Y, XU L, et al. Massive enhancement in the thermal conductivity of polymer composites by trapping graphene at the interface of a polymer blend[J]. Composites Science and Technology,2016,129:160-165. doi: 10.1016/j.compscitech.2016.04.029 [13] MA C G, XI D Y, LIU M. Epoxy resin/polyetherimide/carbon black conductive polymer composites with a double percolation structure by reaction-induced phase separation[J]. Journal of Composite Materials,2013,47(9):1153-1160. doi: 10.1177/0021998312446180 [14] ZHANG Y, CHEN F, LI Z, et al. Ubiquitous nature of the three-layered structure formation in the asymmetric phase separation of the epoxy/thermoplastic blends[J]. Polymer,2012,53(2):588-594. doi: 10.1016/j.polymer.2011.11.051 [15] ZHANG J, GUO Q, FOX B L. Study on thermoplastic-modified multifunctional epoxies: Influence of heating rate on cure behaviour and phase separation[J]. Composites Science and Technology,2009,69(7-8):1172-1179. doi: 10.1016/j.compscitech.2009.02.016 [16] ASTM International. Standard test method for thermal diffusivity of solids by the flash method: ASTM E1461—01[S]. West Conshohocken: ASTM International, 2001. [17] YANG X T, LIANG C B, MA T B, et al. A review on thermally conductive polymeric composites: Classification, measurement, model and equations, mechanism and fabrication methods[J]. Advanced Composites and Hybrid Materials,2018,1(2):207-230. doi: 10.1007/s42114-018-0031-8 [18] CUI L, ZHANG Y, ZHANG Y, et al. Electrical properties and conductive mechanisms of immiscible polypropylene/Novolac blends filled with carbon black[J]. European Polymer Journal,2007,43(12):5097-5106. doi: 10.1016/j.eurpolymj.2007.08.023 [19] WU S. Polymer interface and adhesion[M]. New York: CRC Press, 1982. [20] ZHANG J, NIU H, ZHOU J, et al. Synergistic effects of PEK-C/VGCNF composite nanofibres on a trifunctional epoxy resin[J]. Composites Science and Technology,2011,71(8):1060-1067. doi: 10.1016/j.compscitech.2011.03.008 [21] ZHENG N, SUN W, LIU H Y, et al. Effects of carboxylated carbon nanotubes on the phase separation behaviour and fracture-mechanical properties of an epoxy/polysulfone blend[J]. Composites Science and Technology,2018,159(3):180-188. [22] KWON S Y, KWON I M, KIM Y G, et al. A large increase in the thermal conductivity of carbon nanotube/polymer composites produced by percolation phenomena[J]. Carbon,2013,55(2):285-290. [23] 石刚, 张鉴炜, 雷博文, 等. 石墨烯微片尺寸对石墨烯纸热导率的影响[J]. 国防科技大学学报, 2016, 38(3):112-116. doi: 10.11887/j.cn.201603019SHI Gang, ZHANG Jianwei, LEI Bowen, et al. Effects of graphene sheets size on thermal conductivity of graphene paper[J]. Journal of National University of Defense Technology,2016,38(3):112-116(in Chinese). doi: 10.11887/j.cn.201603019 [24] LIU W, XU K, WANG C, et al. Carbon nanofibers reinforced soy polyol-based polyurethane nanocomposites[J]. Journal of Thermal Analysis and Calorimetry,2016,123(3):2459-2468. doi: 10.1007/s10973-015-4690-1 [25] SUN Y, ZHANG Y, XU K, et al. Thermal, mechanical properties, and low-temperature performance of fibrous nanoclay-reinforced epoxy asphalt composites and their concretes[J]. Journal of Applied Polymer Science,2015,132(12):41694. [26] 张昊明, 赵永涛, 张红松, 等. 热压烧结镀Cr碳纤维/Cu复合材料的制备及热性能[J]. 复合材料学报, 2018, 35(9):2481-2487.ZHANG Haoming, ZHAO Yongtao, ZHANG Hongsong, et al. Fabrication and thermal properties of hot press sintered Cr-coated carbon fiber/Cu composites[J]. Acta Materiae Compositae Sinica,2018,35(9):2481-2487(in Chinese). [27] 王菲菲, 王志鹏, 王红华, 等. 主链含N-烷基咔唑环结构聚芳醚酮的性能表征[J]. 应用化学, 2015, 32(4):379-385.WANG Feifei, WANG Zhipeng, WANG Honghua, et al. Properties of poly(arylene ether ketone)s containing N-alkylcarbazole in main chains[J]. Chinese Journal of Applied Chemistry,2015,32(4):379-385(in Chinese). -

下载:

下载: