Electromagnetic performance and microstructure of amorphous/Fe-Si soft magnetic composites

-

摘要: 本文利用成分与粒径级配两种手段优化了Fe-Si系软磁复合材料的电磁特性,并探究了软磁性能与微观组织的关系。先采用不同粉末粒径的Fe-Si粉末级配,之后利用Fe-Si-B-C非晶粉部分替代粒径相当的Fe-Si粗粉,可以获得良好的综合电磁性能。所制备的非晶/Fe-Si软磁复合材料在1 MHz内均具备良好的频率稳定性。当非晶粉∶Fe-Si粗粉∶Fe-Si细粉的质量比为25∶25∶50时,在100 kHz下的有效磁导率为47.6,100 Oe下的直流偏置能力为79.5%,100 kHz/100 mT下的功率损耗为1806 mW/cm3。相比于已报道的其他含非晶软磁复合材料,本文所报道的非晶Fe-Si-B-C/Fe-Si软磁复合材料有明显的成本和综合电磁性能上的优势。细小的Fe-Si粉末可以填充粗粉之间的空隙,有利于提高材料密度与磁导率,而非晶粉末的添加则可以明显降低功率损耗。本文制备的非晶/Fe-Si软磁复合材料具备良好的综合电磁特性,可以为工业生产提供潜在的解决方案。Abstract: This work optimizes the electromagnetic properties of Fe-Si based soft magnetic composites by both modifying the composition and particle size distribution. The relationship between soft magnetic properties and microstructure is investigated. Great comprehensive electromagnetic properties can be obtained by firstly composing the Fe-Si powders with different sizes, and then partly replacing the coarse Fe-Si powder by Fe-Si-B-C amorphous powder with similar particle size. The amorphous/Fe-Si soft magnetic composites have good frequency stability within 1 MHz. When the mass ratio among Fe-Si-B-C amorphous powder, Fe-Si coarse powder, Fe-Si fine powder is 25∶25∶50, the effective permeability at 100 kHz is 47.6, the DC bias capacity at 100 Oe is 79.5%, and the power loss at 100 kHz/100mT is 1806 mW/cm3. Compared with other reported amorphous-containing soft magnetic composites, the amorphous Fe-Si-B-C/Fe-Si soft magnetic composites in this work have significant advantages in cost and combined electromagnetic properties. The Fe-Si fine powder can fill the gap between the coarse powder, which is conducive to improving the density and permeability of the soft magnetic composite, while the addition of amorphous powder can significantly reduce the power loss. The amorphous/Fe-Si soft magnetic composites prepared in this work have good comprehensive electromagnetic properties and can provide potential solutions for industrial production.

-

图 1 (a) Fe-Si-B-C非晶粉、Fe-Si粗粉和Fe-Si细粉和的粒径分布;三种粉末的形貌与表面元素分布:(b) Fe-Si-B-C非晶粉(c) Fe-Si粗粉、(d) Fe-Si细粉

Figure 1. (a) Particle distribution of Fe-Si-B-C amorphous powder Fe-Si coarse powder and Fe-Si fine powder. Morphology and surface element distribution of the three powders: (b) Fe-Si-B-C amorphous powder, (c) Fe-Si coarse powder, and (d) Fe-Si fine powder

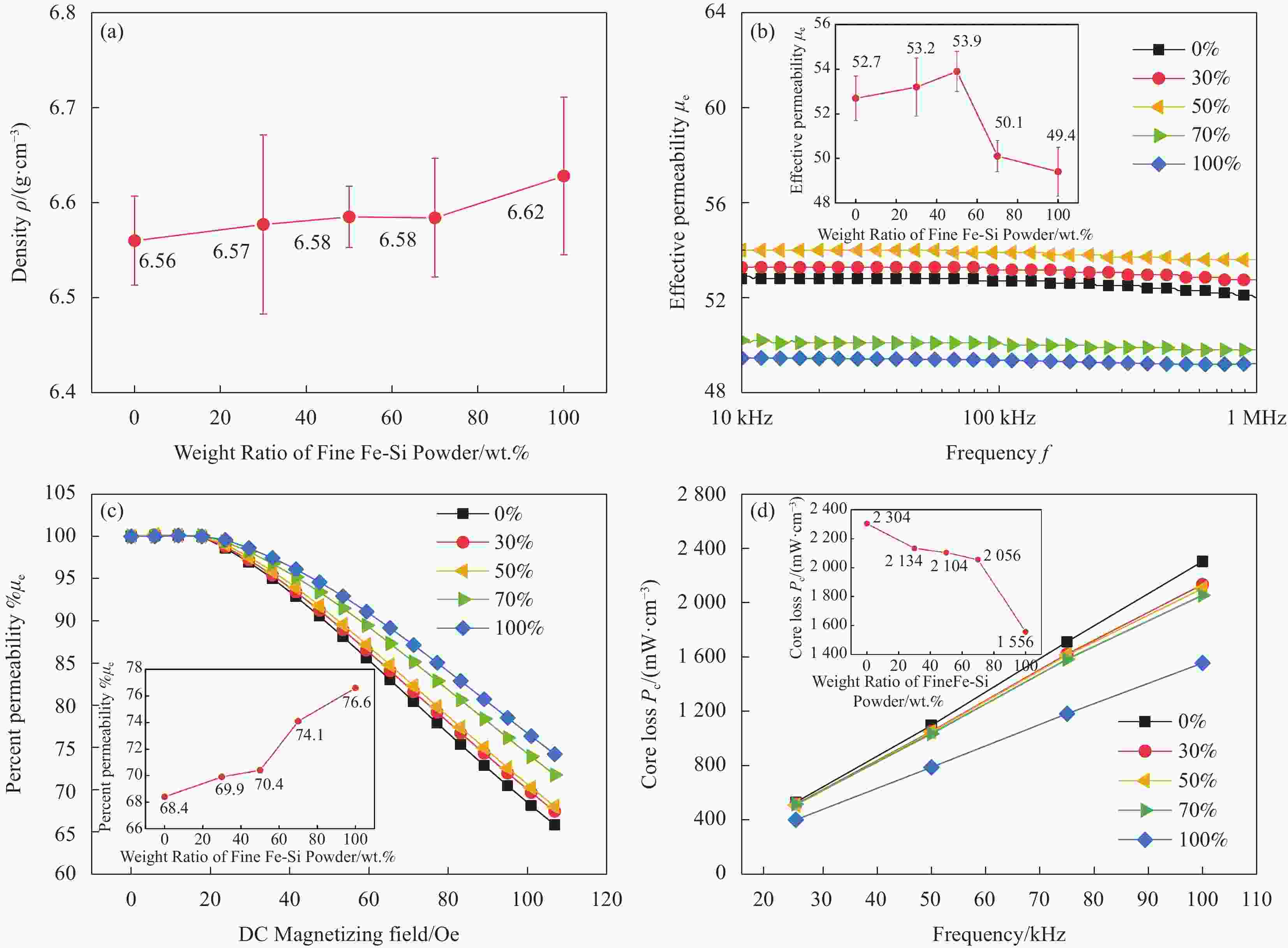

图 5 不同质量分数Fe-Si细粉添加Fe-Si级配磁粉芯的:(a)密度、(b)有效磁导率频谱、(c)直流偏置特性与(d)功率损耗

Figure 5. (a) Density, (b) dependence of effective permeability, (c) DC bias performance and (d) core loss for the Fe-Si magnetic powder cores mixed with different weight ratios of fine Fe-Si particles. The insets in b, c and d show the effective permeability at 100 kHz, percent permeability at 100 Oe, and core loss at 100 kHz, respectively

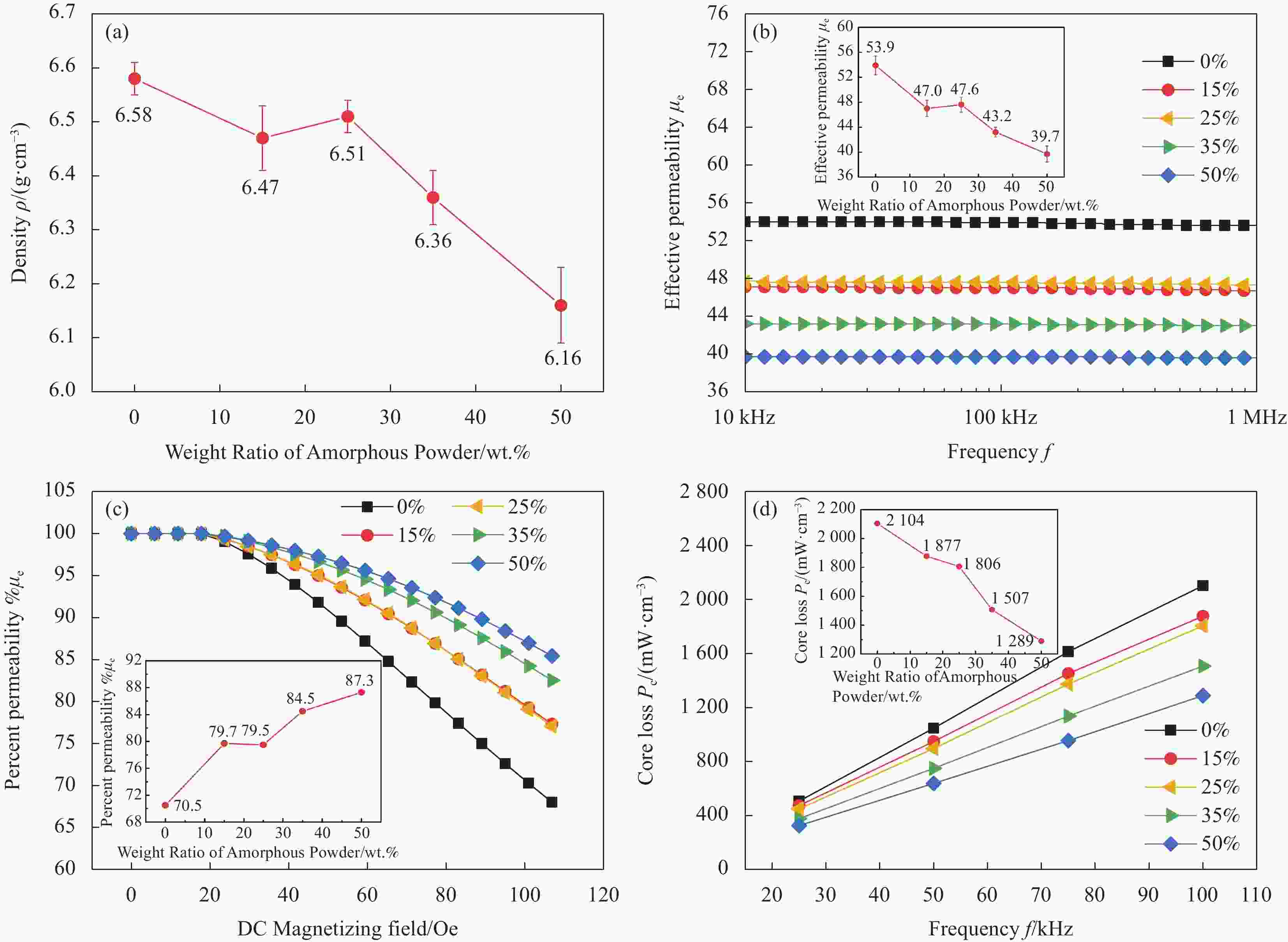

图 6 不同质量分数Fe-Si-B-C非晶粉添加的非晶/Fe-Si磁粉芯的:(a)密度、(b)有效磁导率频谱、(c)直流偏置特性与(d)功率损耗

Figure 6. (a) Density, (b) dependence of effective permeability, (c) DC bias performance and (d) core loss for the amorphous/Fe-Si magnetic powder cores mixed with different weight ratios of fine Fe-Si particles. The insets in b, c and d show the effective permeability at 100 kHz, percent permeability at 100 Oe, and core loss at 100 kHz, respectively

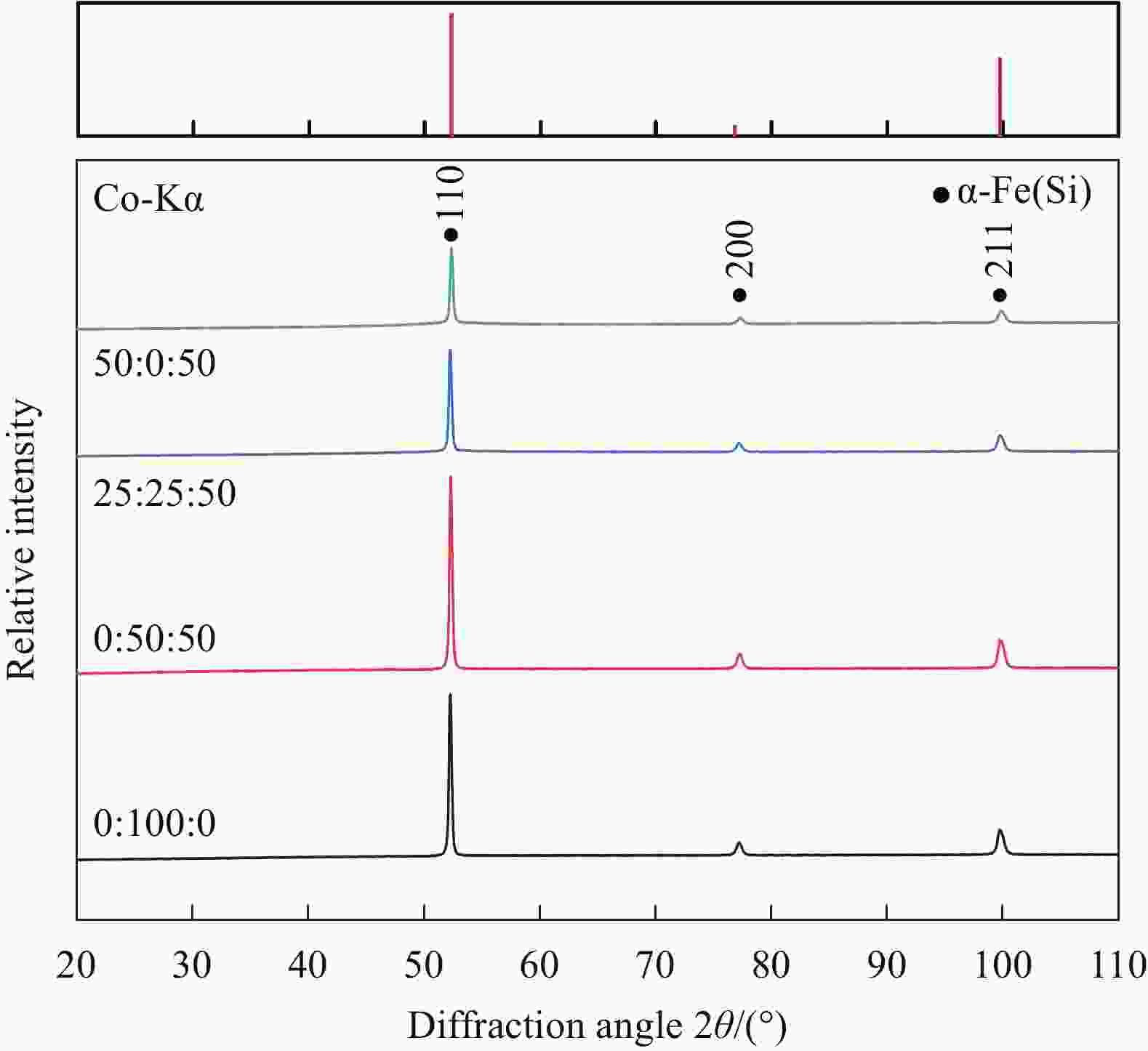

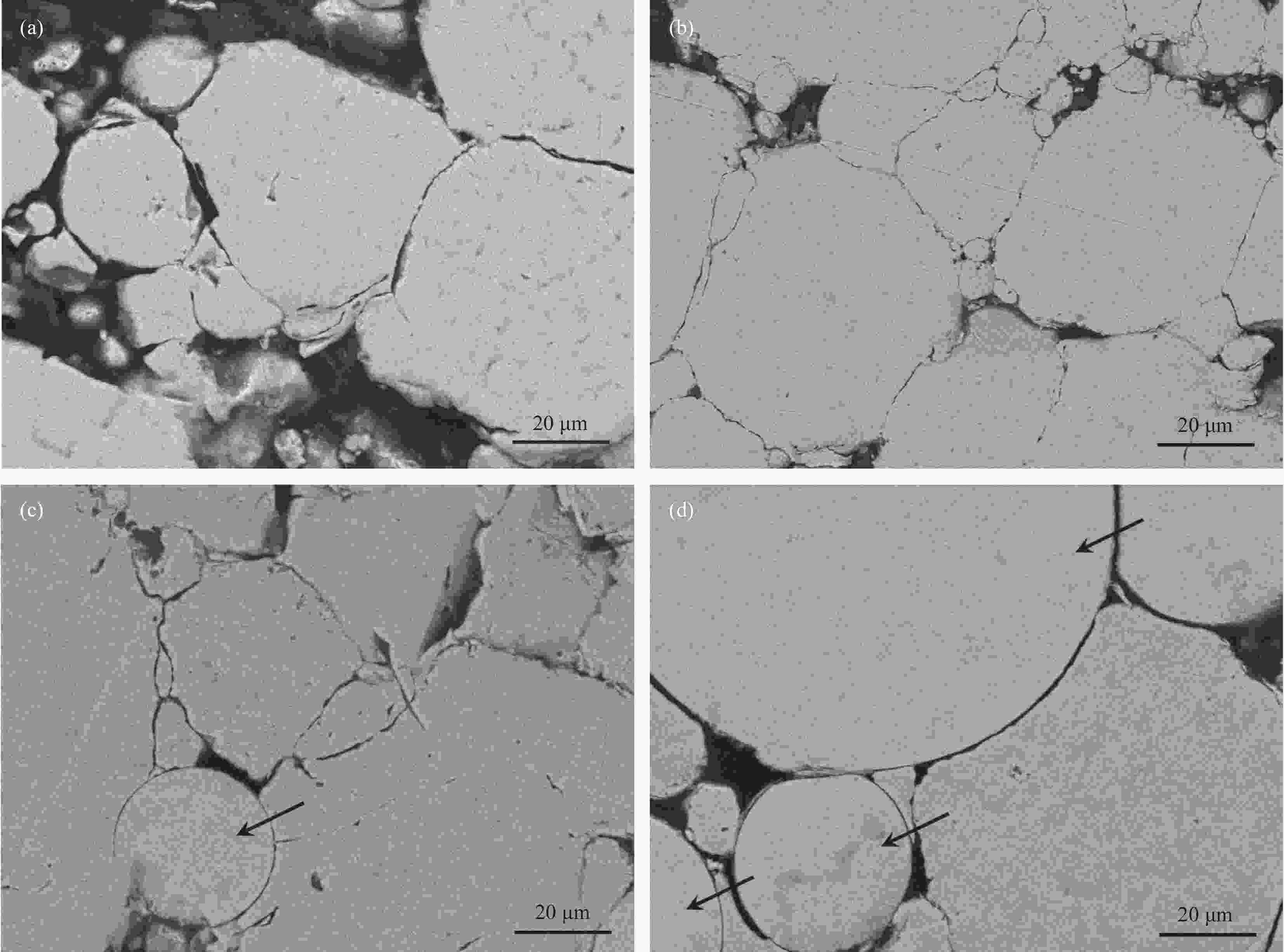

图 8 不同Fe-Si-B-C非晶粉∶Fe-Si粗粉∶Fe-Si细粉质量比磁粉芯的微观组织:(a) 0∶100∶0、(b) 0∶50∶50、(c) 25∶25∶50与(d) 50∶0∶50

Figure 8. Microstructure of the magnetic powder cores with different mass ratio among Fe-Si-B-C amorphous powder, Fe-Si coarse powder, and Fe-Si fine powder: (a) 0∶100∶0, (b) 0∶50∶50, (c) 25∶25∶50 and (d) 50∶0∶50

表 1 含非晶软磁复合材料的成本与电磁特性对比[14, 15, 22, 23]

Table 1. Comparison of cost and electromagnetic performance of some amorphous-containing soft magnetic composites[14, 15, 22, 23]

Material Material

cost/

(¥·kg−1)Electromagnetic performance Ref. μe at 100 kHz %μe at 100 kHz Pcv/ (mW·cm−3) at 50 kHz, 100 mT Pcm/(mW·g−1) at 50 kHz, 100 mT Pcv/ (mW·cm−3) at 100 kHz, 100 mT Pcm/(mW·g−1) at 100 kHz, 100 mT Amorphous Fe-Si-B-C/Fe-Si (Amorphous∶coarse Fe-Si∶fine Fe-Si = 25∶25∶50) 35~40 47.6 79.5% 898 138 1806 277 This work Amorphous Fe-Si-B-P-

Nb/Fe-Si57~62 60 78.0% / 159 / / [15] Amorphous Fe-Si-B-P-Nb 60~65 56 75.0% / / 1734 / [22] Amorphous Fe-Si-B-P-C 45~50 48 54.3% / / 770 / [14] Amorphous Fe-Si-B-P-

Nb-Cr/Fe-Co72~78 42.3 65.1% / / 1315 / [23] Notes: Pcv–Power loss per unit volume; Pcm–Power loss per unit mass -

[1] SHOKROLLAHI H, JANGHORBAN K. Soft magnetic composite materials (SMCs)[J]. Journal of Materials Processing Technology, 2007, 189(1-3): 1-12. doi: 10.1016/j.jmatprotec.2007.02.034 [2] PERIGO E A, WEIDENFELLER B, KOLLAR P. Past, present, and future of soft magnetic composites[J]. Applied Physics Reviews, 2018, 5: 031301. doi: 10.1063/1.5027045 [3] Silveyra J M, Ferrara E, Huber D L, et al. Soft magnetic materials for a sustainable and electrified world[J]. Science, 2018, 362(6413): eaao0195. doi: 10.1126/science.aao0195 [4] 余红雅, 李开沥, 黎向东, 等. 共混树脂包覆铁基磁粉芯的制备与性能[J]. 复合材料学报, 2024, 41(1): 315-322.Yu H, Li K, Li X, et al. Preparation and properties of iron based soft magnetic composites coated with mixed resin[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 315-322 (in Chinese). [5] 车声雷. 面向第三代半导体驱动电源的高频低功耗功率软磁材料研发现状 [R]. 中国功率变换器磁元件联合学术年会. 德清, 2022.CHE S. Development progress of soft magnetic materials for the third generation semiconductor high frequency power supply [R]. Power Converters & Magnetic Components Joint Annual Conference of China. Deqing, 2022 (in Chinese). [6] HE J, YUAN H, NIE M, et al. Soft magnetic materials for power inductors: State of art and future development[J]. Materials Today Electronics, 2023, 6: 100066. doi: 10.1016/j.mtelec.2023.100066 [7] FAN X A, WU Z Y, LI G Q, et al. High resistivity and low core loss of intergranular insulated Fe–6.5 wt. %Si/SiO2 composite compacts[J]. Materials & Design, 2016, 89: 1251-1258. [8] LUO Z, FAN X A, HU W, et al. Enhanced magnetic properties and reduced core loss of intergranular insulating Fe-Si soft magnetic composites with three-shell SiO2-Fe2SiO4-SiO2 insulating layer[J]. Journal of Solid State Chemistry, 2019, 270: 311-316. doi: 10.1016/j.jssc.2018.11.034 [9] LU S, WANG M, ZHAO Z. Recent advances and future developments in Fe-based amorphous soft magnetic composites[J]. Journal of Non-Crystalline Solids, 2023, 616: 122440. doi: 10.1016/j.jnoncrysol.2023.122440 [10] OTSUKA I, WADA K, MAETA Y, et al. Magnetic Properties of Fe-Based Amorphous Powders With High-Saturation Induction Produced by Spinning Water Atomization Process (SWAP)[J]. IEEE Transactions on Magnetics, 2008, 44(11): 3891-3894. doi: 10.1109/TMAG.2008.2002249 [11] ZHOU B, DONG Y, LIU L, et al. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer[J]. Journal of Magnetism and Magnetic Materials, 2019, 474: 1-8 doi: 10.1016/j.jmmm.2018.11.014 [12] 姚可夫, 施凌翔, 陈双琴, 等. 铁基软磁非晶/纳米晶合金研究进展及应用前景[J]. 物理学报, 2018, 67: 8-15.YAO K, SHI L, Chen S, et al. Research progress and application prospect of Fe-based soft magnetic amorphous/nanocrystalline alloys[J]. Acta Physica Sinica, 2018, 67: 8-15 (in Chinese). [13] FIORILLO F, BERTOTTI G, APPINO C, et al. Soft Magnetic Materials [M]. Wiley Encyclopedia of Electrical and Electronics Engineering, 1999: 1-42. [14] ZHANG Y, DONG Y, ZHOU B, et al. Poly-para-xylylene enhanced Fe-based amorphous powder cores with improved soft magnetic properties via chemical vapor deposition[J]. Materials & Design, 2020, 191: 108650. [15] CHANG C, GUO J, LI Q, et al. Improvement of soft magnetic properties of FeSiBPNb amorphous powder cores by addition of FeSi powder[J]. Journal of Alloys and Compounds, 2019, 788: 1177-1181. doi: 10.1016/j.jallcom.2019.02.301 [16] CHUJO N, KINO F, KUME K, et al. Effect of packing fraction on magnetic properties of the FeSiAl powder cores by corase powder and fine powder mixing[J]. Journal of the Japan Society of Powder and Powder Metallurgy, 2016, 63(7): 624-629. doi: 10.2497/jjspm.63.624 [17] LI S, PENG K, ZOU L. The improved magnetic properties of FeSi powders cores composed with different size particles[J]. Journal of Materials Science:Materials in Electronics, 2022, 33(2): 607-616. doi: 10.1007/s10854-021-07330-2 [18] CHEN D, LI K, YU H, et al. Effects of secondary particle size distribution on the magnetic properties of carbonyl iron powder cores[J]. Journal of Magnetism and Magnetic Materials, 2020, 497: 166062. doi: 10.1016/j.jmmm.2019.166062 [19] LUO P, YU H, WANG C, et al. Properties optimization of soft magnetic composites based on the amorphous powders with double layer inorganic coating by phosphating and sodium silicate treatment[J]. Metals, 2023, 13: 560. doi: 10.3390/met13030560 [20] 聂敏, 谈敏, 黄静, 等. FeSiCr 合金粉与羰基铁粉及其在一体成型电感中的应用对比分析[J]. 磁性材料及器件, 2020, 51: 47-50.NIE M, TAN M, HUANG J, et al. Comparative analysis on FeSiCr alloy powder and carbonyl iron powder and their application in molding inductors[J]. Journal of Magnetic Materials and Devices, 2020, 51: 47-50 (in Chinese). [21] WANG Y, XU J, LIU Y, et al. Microstructure evolution, magnetic properties and frequency characteristics of Si-rich FeSiBCuNb soft magnetic alloy induced by annealing treatment[J]. Materials Characterization, 2022, 187: 111830. doi: 10.1016/j.matchar.2022.111830 [22] GUO J, DONG Y, MAN Q, et al. Fabrication of FeSiBPNb amorphous powder cores with high DC-bias and excellent soft magnetic properties[J]. Journal of Magnetism and Magnetic Materials, 2016, 401: 432-435. doi: 10.1016/j.jmmm.2015.10.069 [23] ZHANG Y, CHI Q, CHANG L, et al. Novel Fe-based amorphous compound powder cores with enhanced DC bias performance by adding FeCo alloy powder[J]. Journal of Magnetism and Magnetic Materials, 2020, 507: 166840. doi: 10.1016/j.jmmm.2020.166840 -

点击查看大图

点击查看大图

计量

- 文章访问数: 66

- HTML全文浏览量: 54

- 被引次数: 0

下载:

下载: