Effects if corn straw ash citric acid modification treatment on the main physicochemical properties of cement-based materials

-

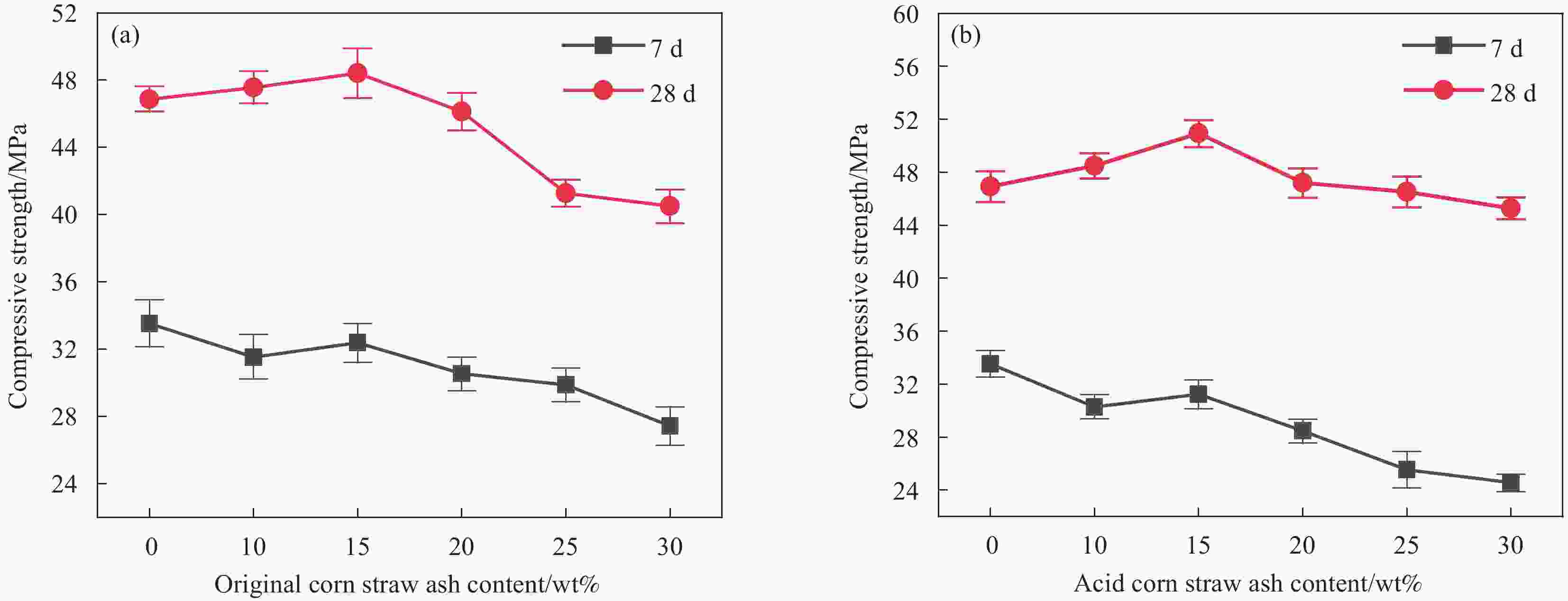

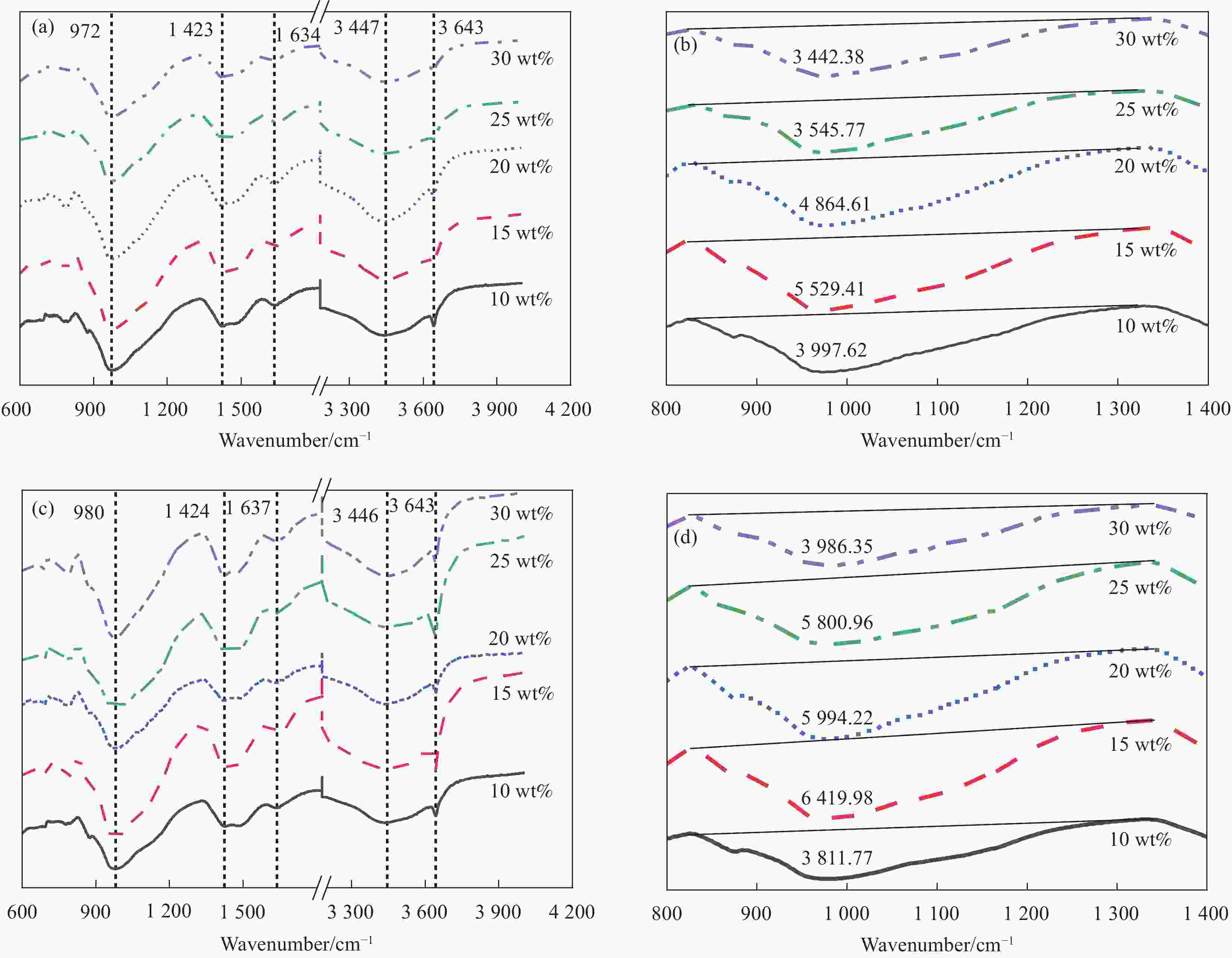

摘要: 中国是农业大国,每年都会产生大量的玉米秸秆,亟需提高其综合利用率。玉米秸秆焚烧后的残渣具有潜在的火山灰活性,可望改善混凝土的性能。然而,玉米秸秆灰含有一定的杂质,不利于混凝土的相关性能,需要进行改性处理。为了减少杂质的影响,对玉米秸秆灰进行柠檬酸浸泡处理,对比分析了原状玉米秸秆灰和酸浸玉米秸秆灰在水泥基材料中的作用机制。结果表明:采用柠檬酸改性技术可以有效地减少玉米秸秆灰中的杂质,并能够提高水泥基材料的强度。随着玉米秸秆灰掺量的增加,试样基体的水化硅酸钙峰值面积先增大后降低,而界面过渡区处水化硅酸钙的Ca/Si比值则先减小后增大。同时,试样的孔隙率不断增大,抗压强度则先增大后降低。当玉米秸秆灰掺量为15wt%时,水泥基材料的强度达到最大。与掺入原状玉米秸秆灰的试样相比,掺入酸浸玉米秸秆灰试样基体的水化硅酸钙峰值面积更大,而界面过渡区处水化硅酸钙的Ca/Si比值下降了15.25%-26.72%。另外,试样的最可几孔径更小,抗压强度提高了2.53%-12.86%。本研究可降低玉米秸秆灰杂质对混凝土相关性能的不利影响,并为玉米秸秆灰在混凝土中的应用提供了理论基础。Abstract: China is a major agricultural country that produces a large amount of corn straw every year, and there is an urgent need to improve its comprehensive utilization rate. The residue of corn straw incineration has potential volcanic ash activity and is expected to improve the performance of concrete. However, corn straw ash contains certain impurities, which are not conducive to the relevant performance of concrete and require modification treatment. In order to reduce the influence of impurities, corn straw ash was subjected to citric acid soaking treatment, and the action mechanism of original corn straw ash (OCSA) and acid-soaked corn straw ash (ACSA) in cement-based materials was compared and analyzed. The results show that the use of citric acid modification technology can effectively reduce impurities in corn straw ash and improve the strength of cement-based materials. As the content of corn straw ash increases, the peak area of hydrated calcium silicate in matrix of sample first increases and then decreases, while the Ca/Si ratio of hydrated calcium silicate at the interfacial transition zone first decreases and then increases. At the same time, the porosity of samples continues to increase, and the compressive strength first increases and then decreases. When the content of corn straw ash is 15wt%, the compressive strength of samples reaches its maximum. Compared with samples with OCSA, samples with ACSA have a higher peak area of hydrated calcium silicate in the matrix, and the Ca/Si ratio of hydrated calcium silicate at interfacial transition zone reduces by 15.25%-26.72%. In addition, the most probable pore diameter of samples is finer, and the compressive strength increases by 2.53%-12.86%. This research can reduce the adverse effects of impurities in corn straw ash on the relative properties of concrete, and provides a theoretical basis for the application of corn straw ash in concrete.

-

Key words:

- Agricultural waste treatment /

- Corn straw ash /

- Citric acid /

- Microstructure /

- Compressive strength

-

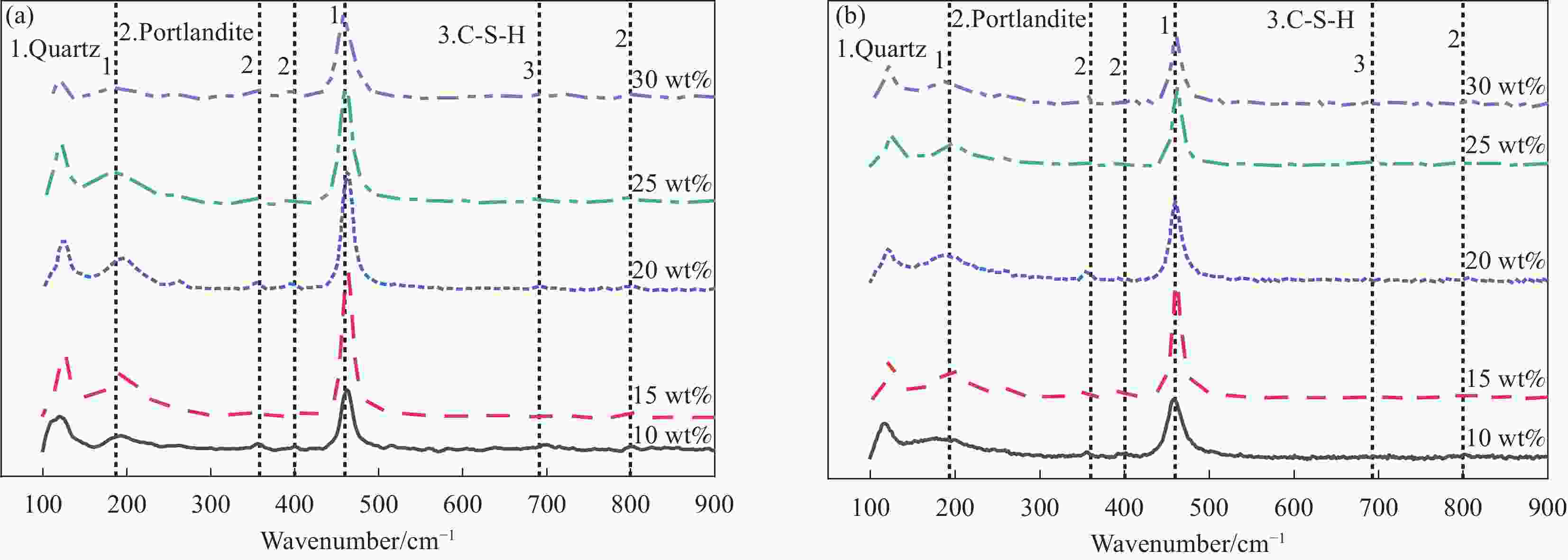

图 1 掺玉米秸秆灰胶砂的红外光谱:(a)原状玉米秸秆灰;(b)原状玉米秸秆灰在972 cm−1处的放大图;(c)酸浸玉米秸秆灰;(d)酸浸玉米秸秆灰在972 cm−1处的放大图

Figure 1. Infrared spectrum of mortars with corn straw ash: (a) original corn straw ash; (b) enlarged in original corn straw ash figure at 972 cm−1; (c) acid-soaked corn straw ash; (d) enlarged in acid-soaked corn straw ash figure at 972 cm−1

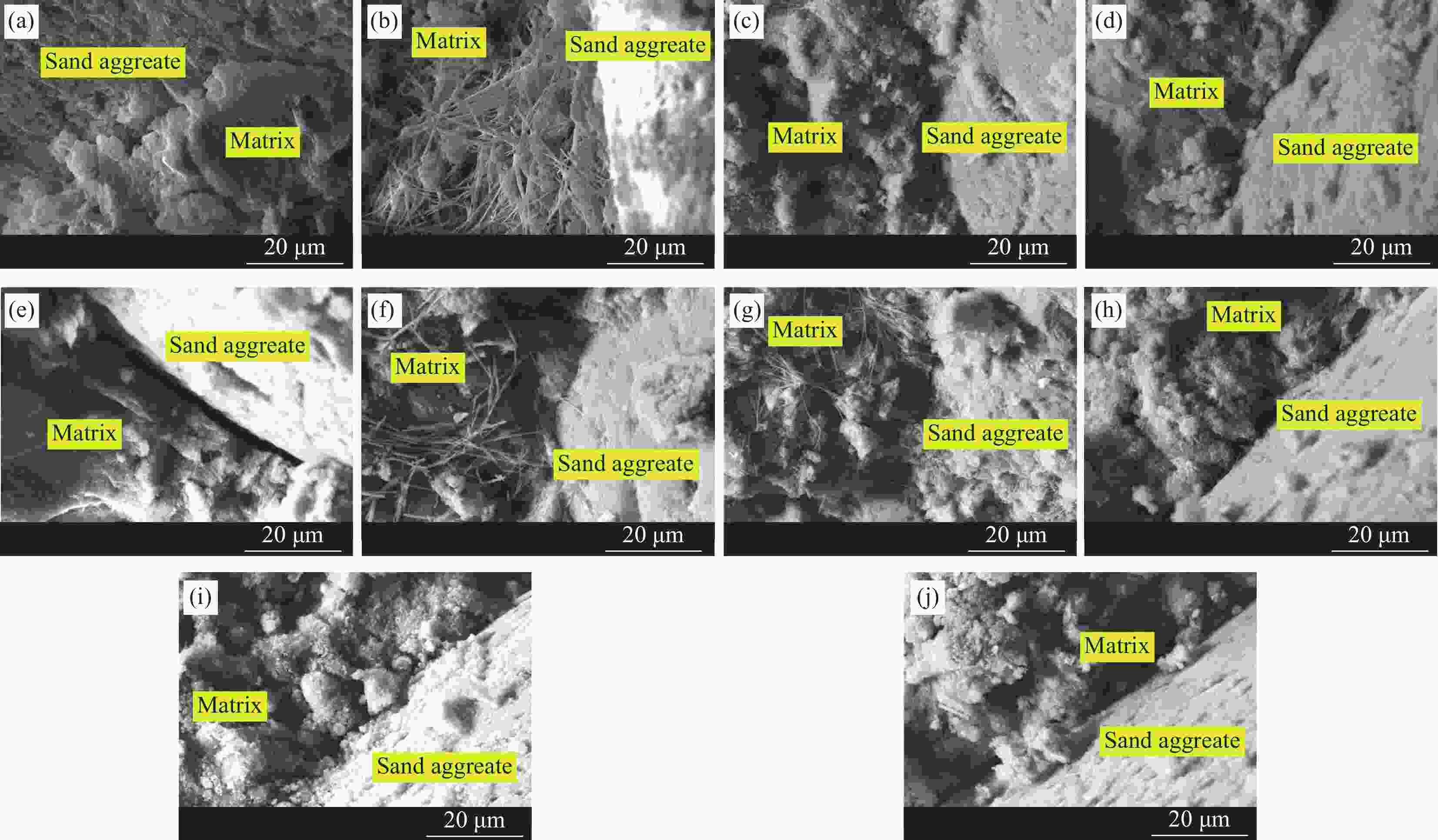

图 4 掺玉米秸秆灰胶砂中骨料界面过渡区SEM图:(a) 10wt% OCSA,×3000倍;(b) 15wt% OCSA,×3000倍;(c) 20wt% OCSA,×3000倍;(d) 25wt% OCSA,×3000倍;(e) 30wt% OCSA,×3000倍;(f) 10wt% ACSA,×3000倍;(g) 15wt% ACSA,×3000倍;(h) 20wt% ACSA,×3000倍;(i) 25wt% ACSA,×3000倍;(j) 30wt% ACSA,×3000倍

Figure 4. SEM of interfacial transition zone of aggregate in mortars with corn straw ash: (a) 10wt% OCSA, ×3000; (b) 15wt% OCSA, ×3000; (c) 20wt% OCSA, ×3000; (d) 25wt% OCSA, ×3000; (e) 30wt% OCSA, ×3000; (f) 10wt% ACSA, ×3000; (g) 15wt% ACSA, ×3000; (h) 20wt% ACSA, ×3000; (i) 25wt% ACSA, ×3000; (j) 30wt% ACSA, ×3000

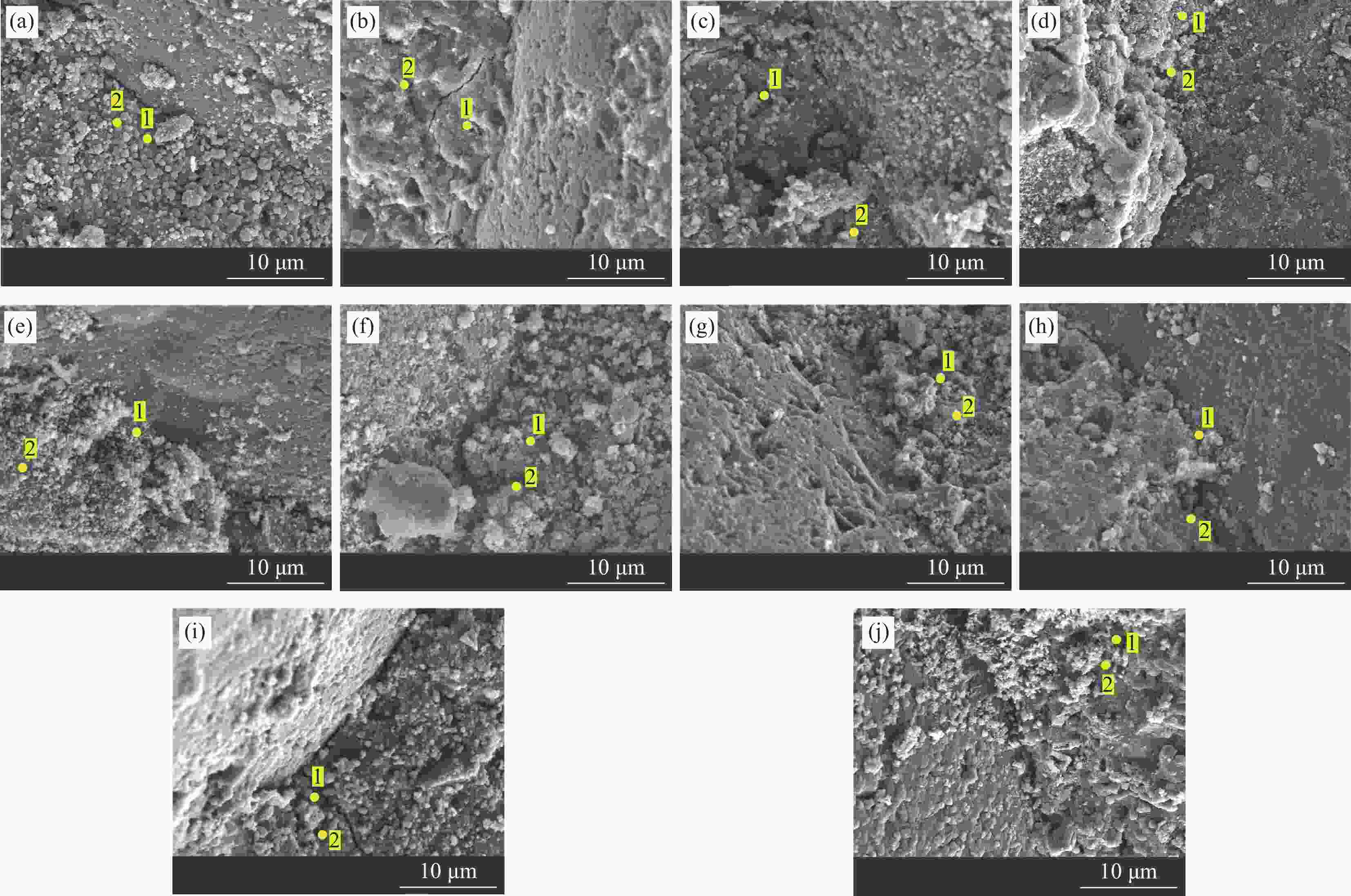

图 5 掺玉米秸秆灰胶砂中骨料界面过渡区EDX图:(a) 10wt%OCSA;(b) 15wt% OCSA;(c) 20wt% OCSA;(d) 25wt% OCSA;(e) 30wt% OCSA;(f) 10wt%ACSA;(g) 15wt%ACSA;(h) 20wt%ACSA;(i) 25wt%ACSA;(j) 30wt%ACSA

Figure 5. EDX of interfacial transition zone of aggregate in mortars with corn straw ash: (a) 10wt%OCSA; (b) 15wt% OCSA; (c) 20wt% OCSA; (d) 25wt% OCSA; (e) 30wt% OCSA; (f) 10wt%ACSA; (g) 15wt%ACSA; (h) 20wt%ACSA; (i) 25wt%ACSA; (j) 30wt%ACSA

表 1 水泥和玉米秸秆灰的主要化学成分(wt.%)

Table 1. Chemical compositions of cement and corn straw ash (wt.%)

CaO SiO2 Al2O3 K2O Fe2O3 P2O5 Cl MgO SO3 Na2O LOI Cement 64.38 21.51 5.08 - 3.74 - - 2.48 0.52 0.53 1.80 Corn straw ash 2.07 57.73 7.90 13.24 5.25 2.79 2.81 1.29 1.20 0.74 4.98 Acid-soaked corn straw ash 0.2 88.66 5.32 0.2 1.31 0.91 - - 0.8 0.1 2.5 表 2 掺玉米秸秆灰胶砂的原材料组成

Table 2. Raw materials composition of mortars with corn straw ash

Sample Cement/g Corn straw ash/g Sand/g Water/g Control 0wt%OCSA 450 0 1350 225 Origin corn straw ash(OCSA) 10wt%OCSA 405 45 1350 225 15wt%OCSA 382.5 67.5 1350 225 20wt%OCSA 360 90 1350 225 25wt%OCSA 337.5 112.5 1350 225 30wt%OCSA 315 135 1350 225 Acid corn straw ash(ACSA) 10wt%ACSA 405 45 1350 225 15wt%ACSA 382.5 67.5 1350 225 20wt%ACSA 360 90 1350 225 25wt%ACSA 337.5 112.5 1350 225 30wt%ACSA 315 135 1350 225 表 3 掺玉米秸秆灰胶砂的孔结构特征

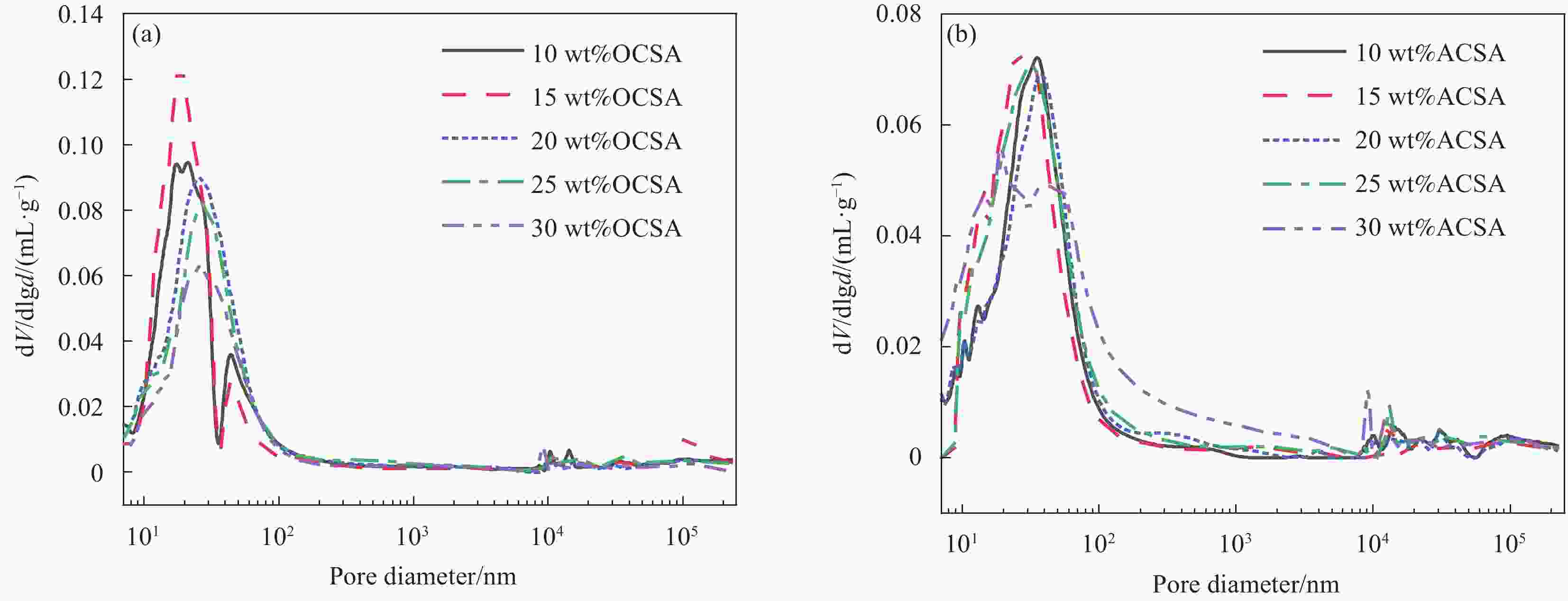

Table 3. Pore structure parameter of mortars with corn straw ash

Sample Total porosity/% Most probable pore size/nm 10wt%OCSA 10.15 9.96 15wt%OCSA 12.12 9.16 20wt%OCSA 12.39 9.67 25wt%OCSA 12.56 13.1 30wt%OCSA 13.21 13.54 10wt%ACSA 10.94 7.64 15wt%ACSA 11.09 7.12 20wt%ACSA 11.49 7.14 25wt%ACSA 12.37 9.79 30wt%ACSA 14.43 9.91 -

[1] 李春光, 徐鹏飞, 李云霞, 等. 玉米秸秆微晶纤维素/聚乳酸复合膜的制备与性能[J]. 复合材料学报, 2011, 28(4): 94-98.LI Chunguang, XU Pengfei, LI Yunxia, et al. Preparation and properties of corn stalks cellulose microcrystal reinforced poly(lactic acid) composite film[J]. Acta Materiale Compositae Sinica, 2011, 28(4): 94-98(in Chinese). [2] 范甲, 胡世琴, 魏柏, 等. 磁性γ-Fe2O3/玉米秸秆淀粉的制备及其对废水中U(VI) 吸附性能[J]. 复合材料学报, 2022, 39(10): 4898-4907.FAN Jia, HU Shiqin, WEI Bai, et al. Preparation of magnetic γ-Fe2O3/corn stalk starch and its adsorption performance for U(VI) in wastewater[J]. Acta Materiale Compositae Sinica, 2022, 39(10): 4898-4907(in Chinese). [3] 王裕银, 李国忠, 柏玉婷. 玉米秸秆微晶纤维素/聚乳酸复合膜的制备与性能[J]. 复合材料学报, 2011, 28(4): 94-98.WANG Yuyin, LI Guozhong, BAI Yuting. Performance of corn straw fibre / desulfurization gypsum composite materials[J]. Acta Materiale Compositae Sinica, 2011, 28(4): 94-98. [4] KANG S H, HONG S G, MOON J. The use of rice husk ash as reactive filler in ultra-high performance concrete[J]. Cement and Concrete Research, 2019, 115: 389. doi: 10.1016/j.cemconres.2018.09.004 [5] HUANG H, GAO X, WANG H, et al. Influence of rice husk ash on strength and permeability of ultra-high performance concrete[J]. Construction and Building Materials, 2017, 149: 621. doi: 10.1016/j.conbuildmat.2017.05.155 [6] MORETTI J P, NUNES S, SALES A. Self-compacting concrete incorporating sugarcane bagasse ash[J]. Construction and Building Materials, 2018, 172: 635-649. doi: 10.1016/j.conbuildmat.2018.03.277 [7] THOMAS B S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material – A comprehensive review[J]. Renewable and Sustainable Energy Reviews, 2018, 82: 3913. doi: 10.1016/j.rser.2017.10.081 [8] QUDOOS A, ULLAH Z, BALOCH Z. Performance Evaluation of the Fiber-Reinforced Cement Composites Blended with Wheat Straw Ash[J]. Advances in Materials Science and Engineering, 2019, 2019: 1. [9] LIMA C P F D, CORDEIRO G C. Evaluation of corn straw ash as supplementary cementitious material: Effect of acid leaching on its pozzolanic activity[J]. Cement, 2021, 4: 100007. doi: 10.1016/j.cement.2021.100007 [10] ZEIDABADI Z A, BAKHTIARI S, ABBASLOU H, et al. Synthesis. characterization and evaluation of biochar from agricultural waste biomass for use in building materials[J]. Construction and building materials, 2018, 181: 301-308. doi: 10.1016/j.conbuildmat.2018.05.271 [11] LIU Y, YU K, LU S, et al. Experimental research on an environment-friendly form-stable phase change material incorporating modified rice husk ash for thermal energy storage[J]. Journal of Energy Storage, 2020, 31: 101599. doi: 10.1016/j.est.2020.101599 [12] 国家市场监督管理总局. 通用硅酸盐水泥: GB175-2023[S]. 北京: 中国标准出版社, 2023.State administration for market regulation. Common Portland cement: GB 175—2023[S]. Beijing: Standards Press of China, 2023 (in Chinese). [13] 中华人民共和国国家质量监督检验检疫总局. 用于水泥和混凝土中的粉煤灰: GT/T 1596-2017[S]. 北京: 中国标准出版社, 2017.Inspection and Quarantine of the People's Republic of China. Fly ash used for cement and concrete: GT/T 1596-2017[S]. Beijing: Standards Press of China, 2017 (in Chinese). [14] 国家市场监督管理总局. 水泥胶砂强度检验方法(ISO法): GB/T-17671-2021[S]. 北京: 中国标准出版社, 2021.State administration for market regulation. Test method of cement mortar strength (ISO method): GB/T-17671-2021[S]. Beijing: Standards Press of China, 2021 (in Chinese). [15] QUDOOS A, KIM H G, RAHMAN A, et al. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites[J]. Construction and Building Materials, 2018, 193: 481. doi: 10.1016/j.conbuildmat.2018.10.229 [16] QUEDOU P G, WIRQUIN E, BOKHOREE C. Sustainable concrete: Potency of sugarcane bagasse ash as a cementitious material in the construction industry[J]. Case Studies in Construction Materials, 2021, 14: e00545. doi: 10.1016/j.cscm.2021.e00545 [17] ODEYEMI S O, ATOYEBI O D, AYO E K. Effect of Guinea corn husk ash on the mechanical properties of lateritic concrete [C]. In: IOP Conference series: Earth and environmental science. Nigeria, 2020, pp. 012034. [18] HARIS JAVED M, ALI SIKANDAR M, AHMAD W, et al. Effect of various biochars on physical, mechanical, and microstructural characteristics of cement pastes and mortars[J]. Journal of Building Engineering, 2022, 57: 104850. doi: 10.1016/j.jobe.2022.104850 [19] NAKANISHI E Y, FRÍAS M, MARTÍNEZ-RAMÍREZ S, et al. Characterization and properties of elephant grass ashes as supplementary cementing material in pozzolan/Ca(OH)2 pastes[J]. Construction and Building Materials, 2014, 73: 391. doi: 10.1016/j.conbuildmat.2014.09.078 [20] 赵耀. 秸秆灰-水泥基复合材料性能的研究 [D]. 济南: 济南大学, 2021.ZHAO Yao. Study on properties of cornstalk ash-cement composites. Master’s thesis [D]. Jinan: University of Jinan, 2021(in Chinese). [21] MAGLAD A M, AMIN M, ZEYAD A M, et al. Engineering properties of ultra-high strength concrete containing sugarcane bagasse and corn stalk ashes[J]. Journal of Materials Research and Technology, 2023, 23: 3196. doi: 10.1016/j.jmrt.2023.01.197 [22] QI T, WANG H, FENG G, et al. Effects of corn stalk Fly ash (CSFA) on the mechanical and deformation properties of cemented coal gangue backfill[J]. Advances in Materials Science and Engineering, 2020, 7421769: 1. [23] 刘钢, 王伟亚, 陈北齐, 等. 粉煤灰对玻化炉渣路面混凝土界面微观结构改善影响研究[J]. 新型建筑材料, 2021, 48(8): 7-11. doi: 10.3969/j.issn.1001-702X.2021.08.002LIU Gang, WANG Weiya, CHEN Beiqi, et al. Research on the effect of fly ash on the microstructure improvement of the concrete interface of vitrified slag pavement[J]. New Building Materials, 2021, 48(8): 7-11(in Chinese). doi: 10.3969/j.issn.1001-702X.2021.08.002 [24] RAHEEM A A, ADEDOKUN S I. Application of corn stalk ash as partial replacement for cement in the production of interlocking paving stones[J]. International Journal of Engineering Research in Africa, 2017, 30: 85. doi: 10.4028/www.scientific.net/JERA.30.85 [25] AHUMADA R, HOLMAN O M, KATHERINNE S N. Use of the rice and corn husk ashes as an innovative pozzolanic material in ceramic tile adhesive production[J]. Procedia Computer Science, 2022, 198: 572. doi: 10.1016/j.procs.2021.12.288 [26] SELVARANJAN K, GAMAGE J C P H, De Silva G I P, et al. Development of sustainable mortar using waste rice husk ash from rice mill plant: Physical and thermal properties[J]. Journal of Building Engineering, 2021, 43: 102614. doi: 10.1016/j.jobe.2021.102614 [27] LUHAR S, CHENG T-W, LUHAR I. Incorporation of natural waste from agricultural and aquacultural farming as supplementary materials with green concrete: A review[J]. Composites Part B:Engineering, 2019, 175: 107076. doi: 10.1016/j.compositesb.2019.107076 -

点击查看大图

点击查看大图

计量

- 文章访问数: 35

- HTML全文浏览量: 17

- 被引次数: 0

下载:

下载: