Preparation and microwave absorbing properties of 2.5D woven SiCf/SiC composites

-

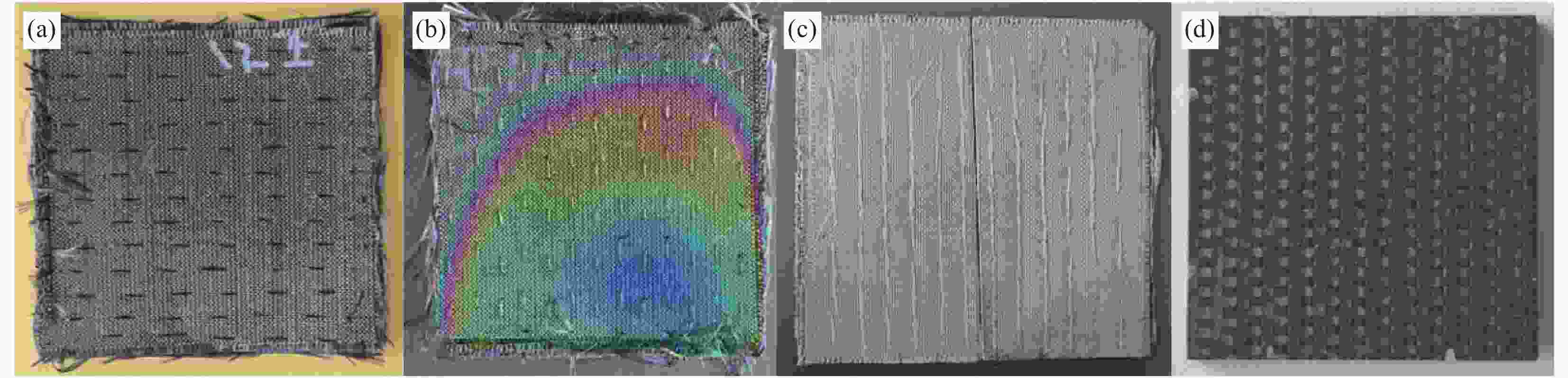

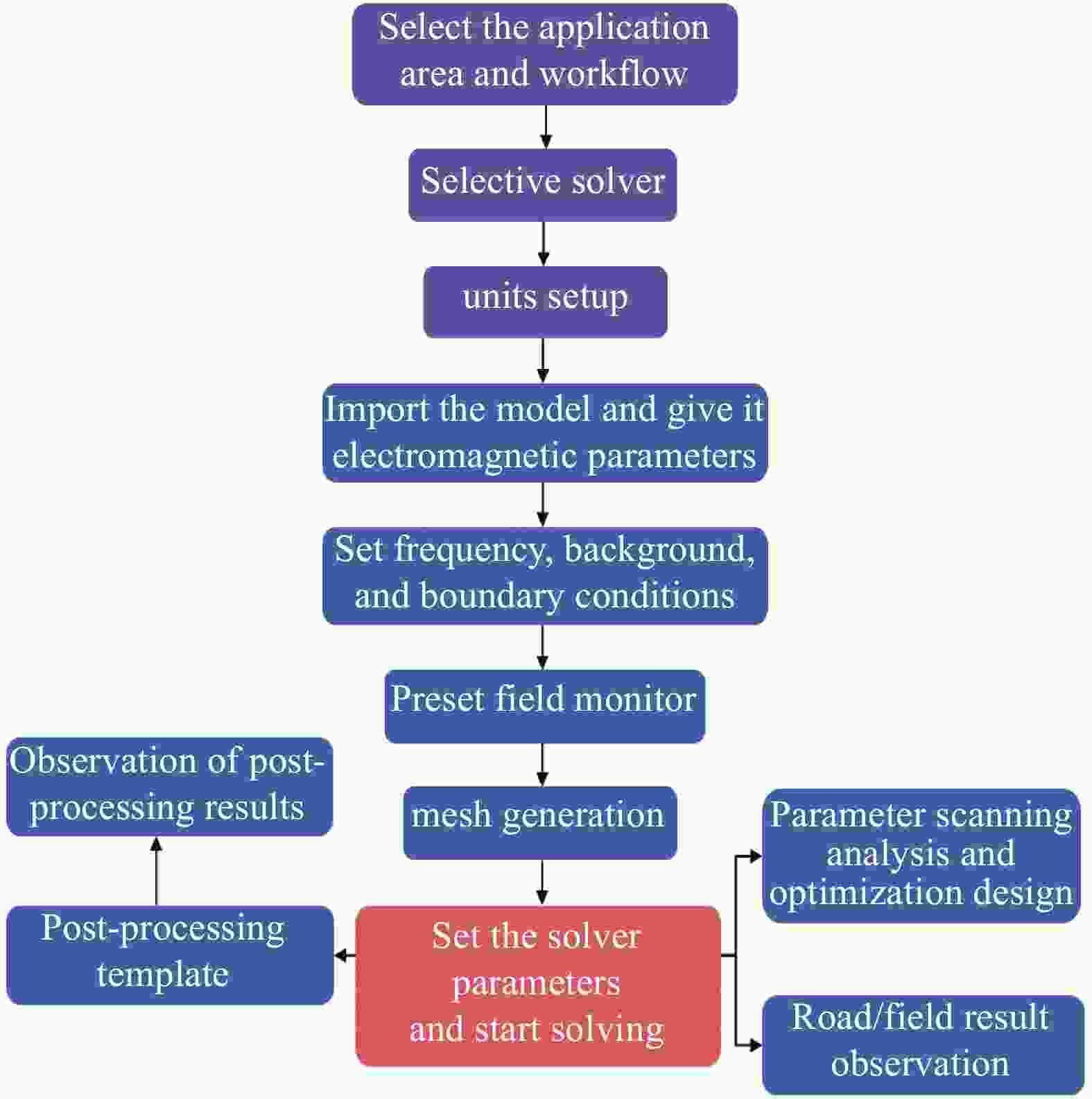

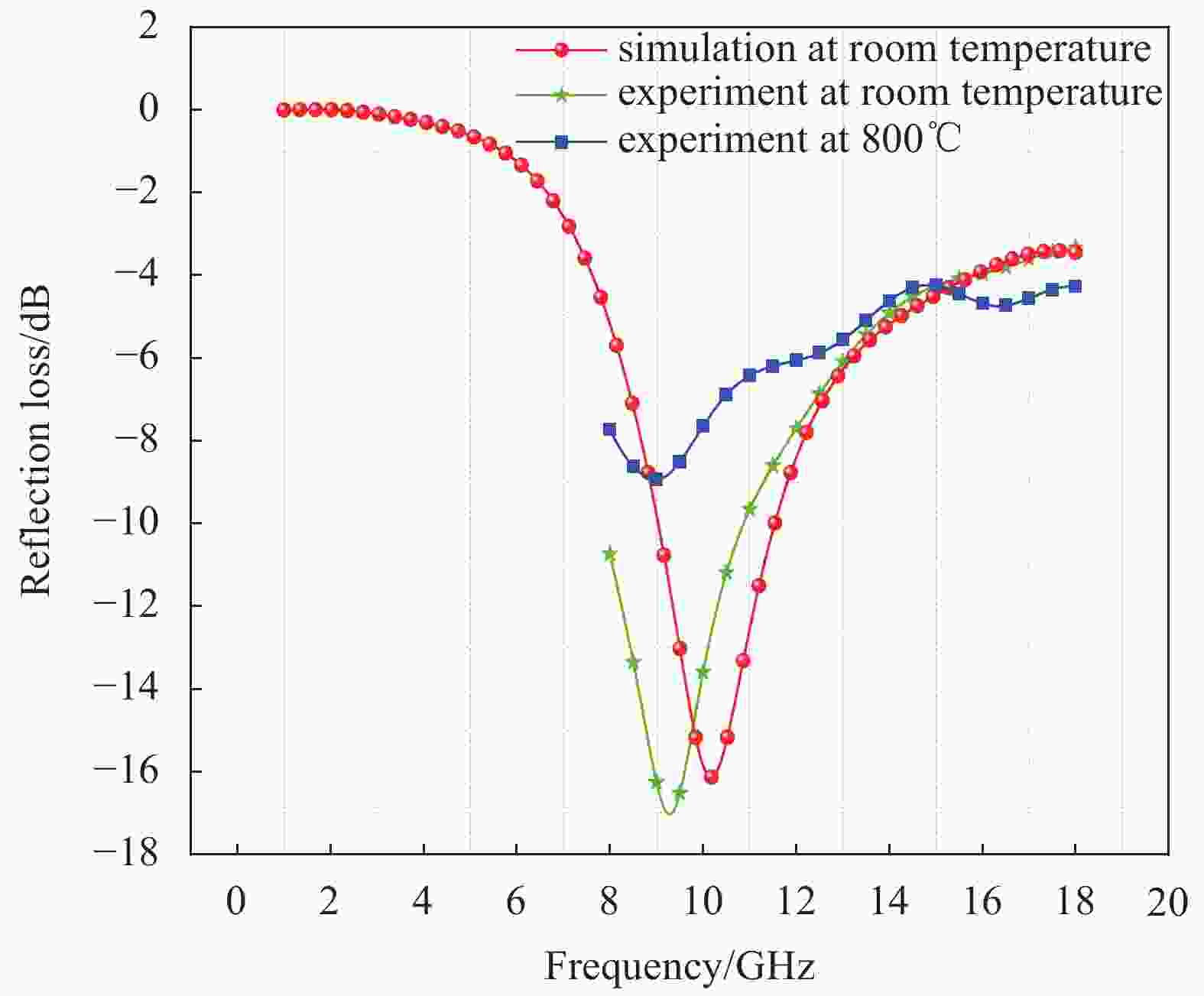

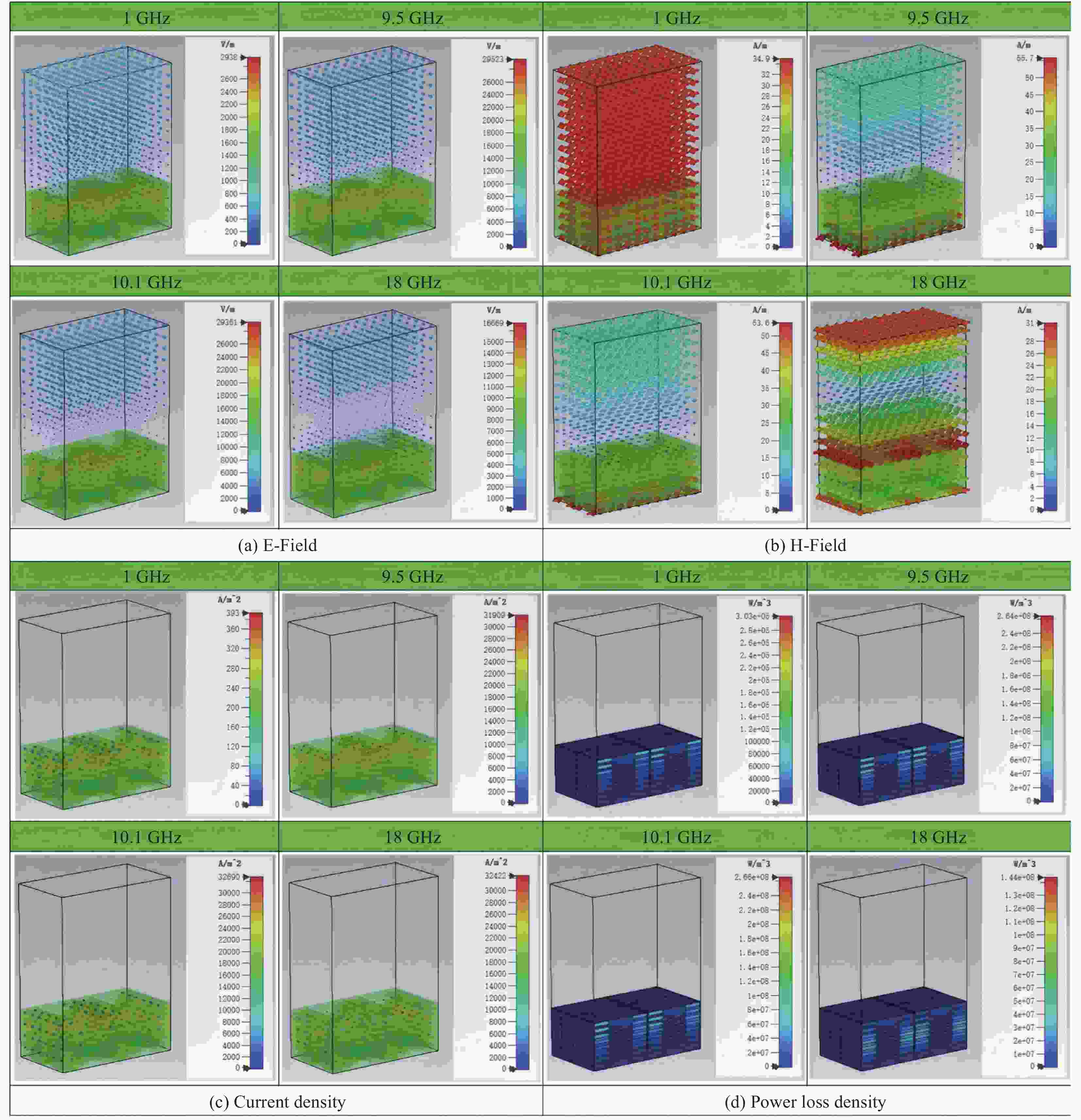

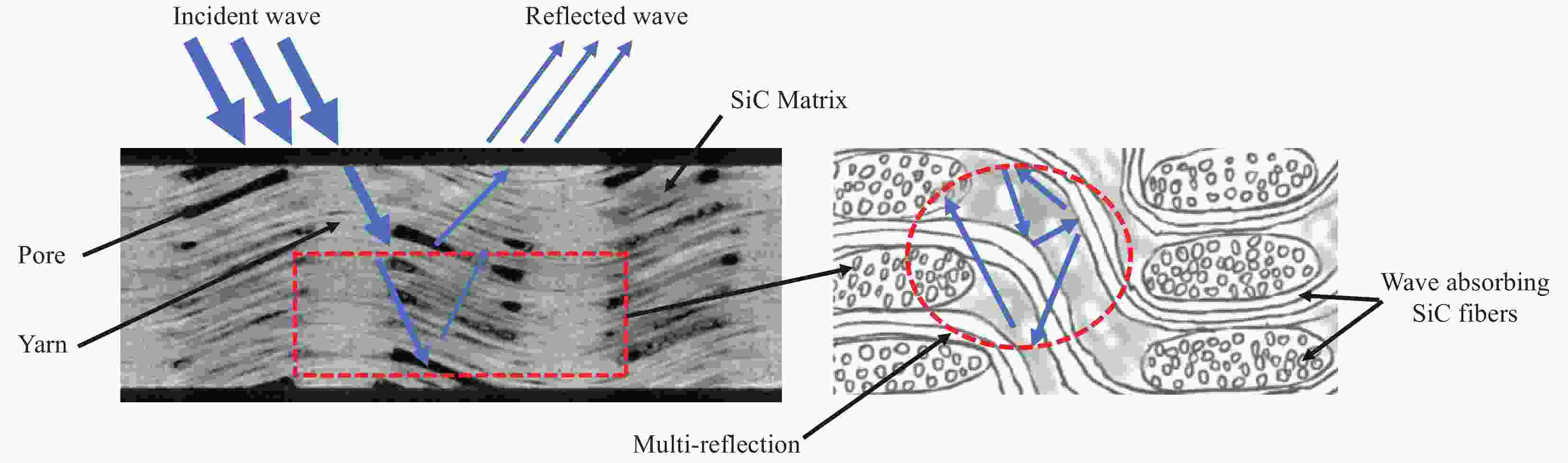

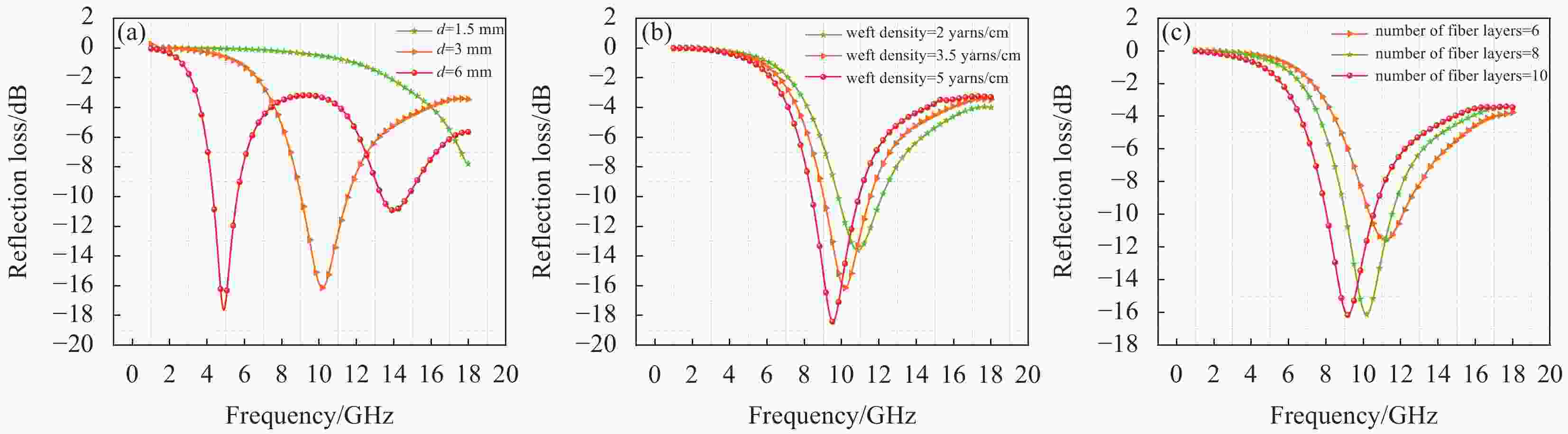

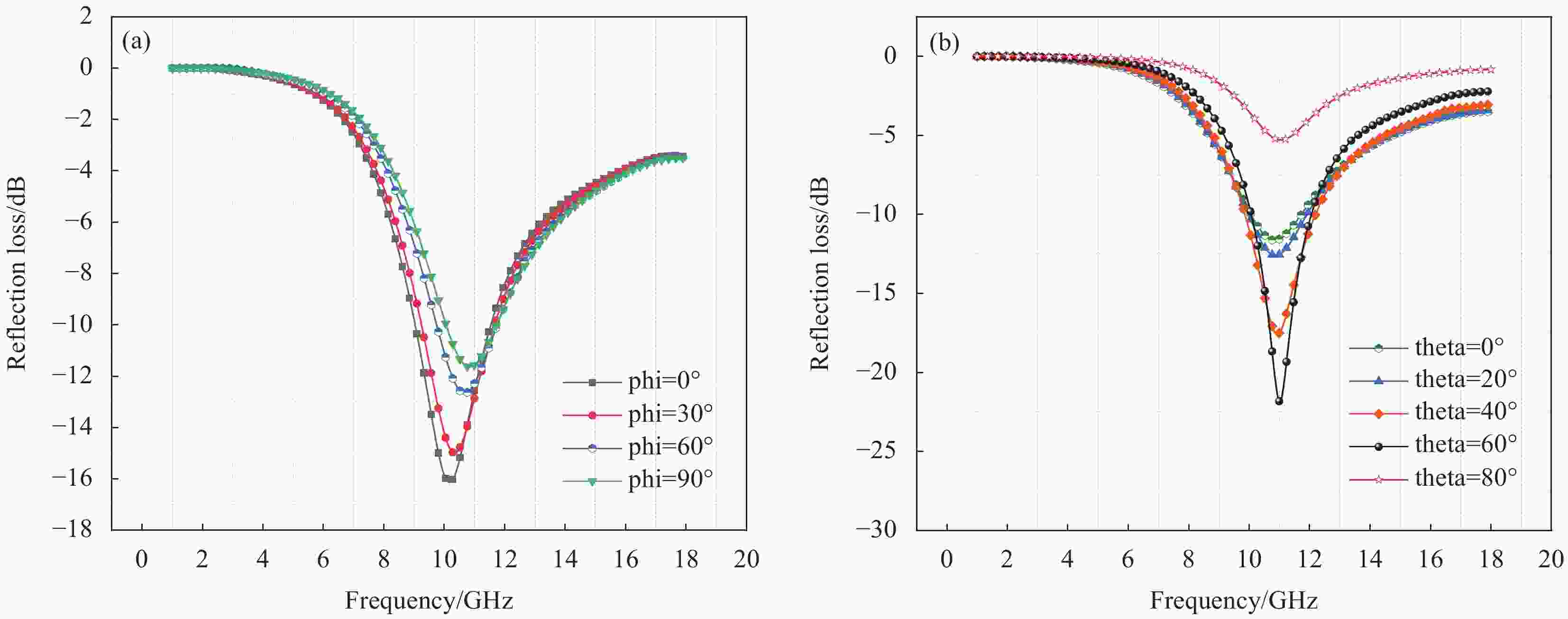

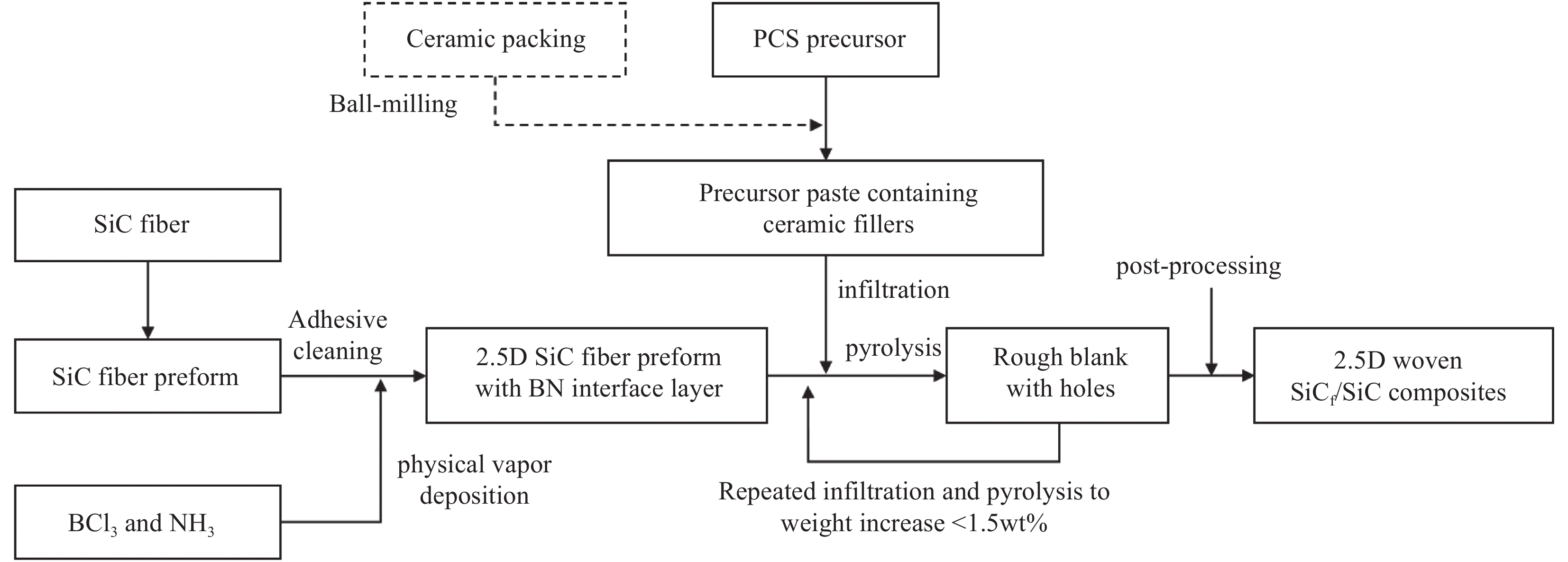

摘要: 为满足高温吸波结构复合材料要求,选用SiC纤维,设计并制备了2.5D机织SiCf/SiC复合材料,采用实验与仿真相结合的方法研究了吸波性能。利用弓形法开展了反射损耗测试,采用X射线计算机断层扫描(Micro-CT)技术提取材料几何结构参数,建立了全厚度细观模型,在CST电磁仿真软件上模拟计算了材料的反射损耗,并与实验结果进行对比分析。通过等效电磁参数理论和场分布图分析了吸波机制,并研究了几何结构参数、电磁参数、电磁波电场极化方向和入射角度对材料吸波特性的影响规律。实验结果表明,在1-18 GHz频率范围内,本文所制备的2.5D机织SiCf/SiC复合材料具有3 GHz的有效吸波带宽,在吸收峰9.3 GHz处,最大反射损耗达到−17 dB,这与仿真结果基本一致。该复合材料主要通过电损耗的方式吸收电磁波,其良好的吸波性能是结构设计和材料特性协同作用的结果,材料整体厚度和纤维介电常数是影响2.5D机织SiCf/SiC复合材料吸波性能的关键因素。Abstract: 2.5D woven SiCf/SiC composites were designed and prepared to meet the requirements of high temperature microwave absorbing structural composites, and the microwave absorbing properties were studied by combining experiment and simulation. The reflection loss of the material was measured by means of the bow method, and the geometrical parameters of the material were extracted by X-ray computed tomography (Micro-CT) to establish a full-thickness mesoscopic model. The reflection loss of the material was simulated and calculated on the CST electromagnetic simulation software, and compared with the experiment results. Based on the theory of equivalent electromagnetic parameters and field distribution map, the microwave-absorbing mechanism is analyzed, and the effects of geometric structure parameters, electromagnetic parameters, electromagnetic field polarization direction and incidence angle on the microwave-absorbing property of materials are studied.The experimental results show that the 2.5D woven SiCf/SiC composites prepared in this paper have an effective absorption bandwidth of 3 GHz in the frequency range of 1-18 GHz, and the maximum reflection loss reaches −17 dB at the absorption peak of 9.3 GHz, which is basically consistent with the simulation results.The composite absorbs electromagnetic microwave mainly through the way of electrical loss, and its good microwave absorption performance is the result of the synergistic effect of structural design and material characteristics. The overall material thickness and fiber dielectric constant are the key factors affecting the microwave absorption performance of 2.5D woven SiCf/SiC composites.

-

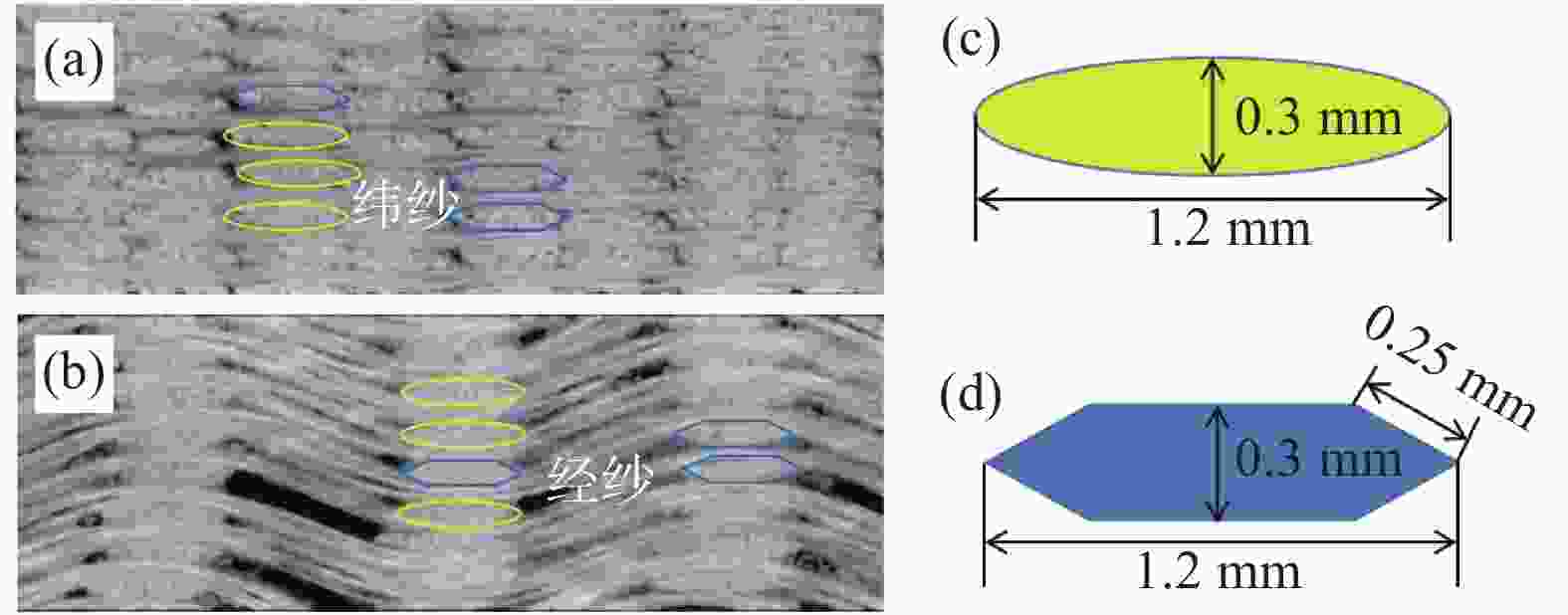

图 4 2.5D机织SiCf/SiC复合材料的Micro-CT扫描结果: (a)经向截面扫描形态; (b)纬向截面扫描形态; (c)椭圆截面几何参数; (d)扁六边形截面几何参数

Figure 4. Micro CT scanning results of 2.5D woven SiCf/SiC composites:(a) Scanning morphology of warp cross-section; (b) Scanning morphology of weft cross-section; (c) Geometric parameters of ellipse cross-section; (d) Geometric parameters of flat hexagonal cross-section

图 12 (a)纤维介电常数实部对吸波性能的影响;(b)纤维介电损耗角正切对吸波性能的影响;(c)材料厚度为3 mm时纤维混杂层数对吸波性能的影响;(d)材料厚度为6 mm时纤维混杂层数对吸波性能的影响

Figure 12. (a) The influence of the fiber real part of permittivity on the absorption performance; (b) The influence of fiber dielectric loss Angle tangent on the absorption performance; (c) The influence of fiber hybrid layers on the absorption properties when the material thickness is 3 mm; (d) The influence of fiber hybrid layers on the absorption properties of 6 mm material thickness

表 1 2.5D机织SiCf/SiC复合材料规格参数

Table 1. Specification parameters of 2.5D woven SiCf/SiC composites

Prefabricated structure dimension/

mmWarp density/

(yarn·cm−1)Weft density/

(yarn·cm−1)Yarn fineness/Tex Number of

layersVolume

fraction/%2.5D woven Angle interlock 40*40*3 9 3.5 185 8 45 -

[1] 邢原铭, 杨涛, 王恩会等. SiC复合吸波材料的研究进展[J]. 复合材料学报, 1-12.XING Yuanming, YANG Tao WANG Enhui. Research progress of SiC composite microwave absorbing materials[J]. Acta Materiae Compositae Sinica, 1-12(in Chinese). [2] FU Z, PANG A, LUO H, et al. Research progress of ceramic matrix composites for high temperature stealth technology based on multi-scale collaborative design[J]. Journal of Materials Research and Technology, 2022, 18-24 [3] 周旺. 2D-SiCf/SiC耐高温结构吸波材料力学性能研究[D]. 国防科学技术大学, 2008.ZHOU Wang. Mechanical Properties of 2D-SiCf/SiC High-temperature Structural Absorbing Materials[D]. National University of Defense Technology, 2008(in Chinese). [4] 孟庆聪. 碳化硅陶瓷复合材料的制备及其吸波性能研究[D]. 天津大学, 2016.MENG Qincong. Studies on the Preparation and Microwave Absorbing Properties of Vitrified Bonded SiC Composites[D]. Tianjin University, 2016(in Chinese). [5] 胡悦, 黄大庆, 史有强, 张昳, 何山, 丁鹤雁. 耐高温陶瓷基结构吸波复合材料研究进展[J]. 航空材料学报, 2019, 39(05): 1-12(in Chinese). doi: 10.11868/j.issn.1005-5053.2019.000139HU Yue, HUANG Daqing, SHI Youqiang, ZHANG Yi, HE Shan, DING Heyan. Research progress of high temperature resistant ceramic based structural wave absorbing composites[J]. Journal of Aeronautical Materials, 2019, 39(05): 1-12. doi: 10.11868/j.issn.1005-5053.2019.000139 [6] 刘海韬. 夹层结构SiCf/SiC雷达吸波材料设计、制备及性能研究[D]. 国防科学技术大学, 2010.LIU Haitao. Design, preparation and properties of the SiCf/SiC radar absorbing materials with sandwhich structures[D]. National University of Defense Technology, 2010(in Chinese). [7] 刘文迪, 吕丽华. 三维机织吸波复合材料的研究进展[J]. 棉纺织技术, 2020, 48(10): 81-84. doi: 10.3969/j.issn.1001-7415.2020.10.019LIU Wendi, LV Lihua. Research progress of three-dimensional woven Microwave Absorbing Composites[J]. Cotton Textile Technology, 2020, 48(10): 81-84(in Chinese). doi: 10.3969/j.issn.1001-7415.2020.10.019 [8] 穆阳. SiCf/SiC高温结构吸波复合材料的制备及性能研究[D]. 西北工业大学, 2016.MU Yang. Preparation and Properties of SiCf/SiC High-temperature Structural Microwave Absorbing Composites[D]. Northwestern Polytechnical University, 2016(in Chinese). [9] 樊威, 孟家光, 孙润军, 刘天骄, 宋文, 熊越. 混杂纤维增强结构隐身复合材料研究进展[J]. 纺织导报, 2017, (01): 66-68.FAN Wei, MENG Jiaguang, SUN Runjun, et al. Development in the Research of Hybrid Fiber Reinforced Structural Absorbing Composites[J]. China Textile Leader, 2017, (01): 66-68(in Chinese). [10] 戴海军, 李嘉禄, 孙颖, 等. 纬编双轴向织物/环氧树脂电加热复合材料电热及层间剪切性能[J]. 复合材料学报, 2020, 37(8): 1997-2004.DAI Haijun, LI Jialu, SUN Ying, et al. Electrothermal and interlaminar shear properties of weft knitted biaxial fabric/epoxy resin electrically heated Composites[J]. Acta Materiae Compositae Sinica, 2020, 37(8): 1997-2004(in Chinese). [11] MU Y, ZHOU W, HU Y, et al. Enhanced microwave absorbing properties of 2.5 D SiCf/SiC composites fabricated by a modified precursor infiltration and pyrolysis process[J]. Journal of Alloys and Compounds, 2015, 637: 261-266. doi: 10.1016/j.jallcom.2015.03.031 [12] HAN T, LUO R, CUI G, et al. Effect of fibre directionality on the microwave absorption properties of 3D braided SiCf/SiC composites[J]. Ceramics International, 2019, 45(6): 7797-7803. doi: 10.1016/j.ceramint.2019.01.085 [13] 吕丽华, 王荣蕊, 刘文迪等. 蜂窝状三维整体机织结构型吸波复合材料的设计、制备与性能[J]. 复合材料学报, 2023, 40(03): 1477-1483.LV Lihua, WANG Rongrui, LIU Wendi. et al. Design, preparation and properties of honeycomb 3D integral woven structure microwave absorbing composites[J]. Acta Materiae Compositae Sinica, 2023, 40(03): 1477-1483(in Chinese). [14] ZHANG H, ZHOU X, GAO Y, et al. Microwave absorption and bending properties of three-dimensional gradient honeycomb woven composites[J]. Polymer Composites, 2023, 44(2): 1201-1212. doi: 10.1002/pc.27164 [15] CHEN N , WEI S , SHI B , et al. Investigating the electromagnetic wave-absorbing capacity and mechanical properties of flexible radar-absorbing knitted compound materials[J]. Journal of Industrial Textiles, 2021, 51(3): 343-361. [16] 李丹丹. 2.5D碳/环氧复合材料电磁波传输性能研究[D]. 天津工业大学, 2016.LI Dandan. Study on electromagnetic wave transmission performance of 2.5D carbon/epoxy composites[D]. Tianjin Polytechnic University, 2016(in Chinese). [17] XIA Q, HAN Z, ZHANG Z, et al. High temperature microwave absorbing materials[J]. Journal of Materials Chemistry C, 2023, 54-59. [18] DU Z, LIANG J, CAI T, et al. Ultra-light planar meta-absorber with wideband and full-polarization properties[J]. Optics Express, 2021, 29(5): 6434-6444. doi: 10.1364/OE.416245 [19] 鞠文静, 周忠元, 蒋全兴等. 基于有限积分法的电磁兼容吸波材料反射率的建模仿真[J]. 东南大学学报(自然科学版), 2015, 45(03): 474-477. doi: 10.3969/j.issn.1001-0505.2015.03.011JU Wenjing, ZHOU Zhongyuan, JIANG Quanxin. et al. FIT-based simulation of reflectivity of absorbing materials for electromagnetic compatibility[J]. Journal of Southeast University (Natural Science Edition), 2015, 45(03): 474-477(in Chinese). doi: 10.3969/j.issn.1001-0505.2015.03.011 [20] 苏钦城, 赵晓明, 李卫斌等. 基于有限积分法的机织物电磁屏蔽效能仿真分析[J]. 纺织学报, 2016, 37(02): 155-160.SU Qincheng, ZHAO Xiaoming, LI Weibin. et al. Simulation analysis of woven fabric electromagnetic shielding effectiveness using finite integration technique[J]. Journal of Textile Research, 2016, 37(02): 155-160(in Chinese). [21] 杨飙. 纤维复合微波吸收材料电磁建模与分析[D]. 华中科技大学, 2015.YANG Biao. Analysis and Electromagnetic Modeling of the Fiber Reinforced Microwave Absorbing Composites[D]. Huazhong University of Science and Technology, 2015(in Chinese). [22] 孙娜, 徐阳. 基于法兰同轴测试原理的织物屏蔽效能仿真[J]. 丝绸, 2023, 60(05): 52-58. doi: 10.3969/j.issn.1001-7003.2023.05.007SUN Na, XU Yang. Simulation of Electromagnetic Shielding Effectiveness of Fabrics based on the Principle of Flange Coaxial Method Testing[J]. Journal of Silk, 2023, 60(05): 52-58(in Chinese). doi: 10.3969/j.issn.1001-7003.2023.05.007 [23] YIN J, MA W, GAO Z, et al. A Structural Design Method of 3D Electromagnetic Wave-Absorbing Woven Fabrics. Polymers 2022, 14(13), 2635. [24] WANG R, LIU W, ZHOU X, et al. Electromagnetic wave absorption and bending properties of double-layer honeycomb 3D woven composites: experiment and simulation[J]. The Journal of The Textile Institute, 2023: 1-11. [25] 刘海韬, 程海峰, 王军, 唐耿平. SiCf/SiC复合材料界面相研究进展[J]. 材料导报, 2010, 24(01): 10-14+30.LIU Haitao, CHENG Haifeng, WANG Jun, TANG Genping. Study on the Interphase of the Conti nuous SiC Fiber Reinforced SiC Composites[J]. Materials Reports, 2010, 24(01): 10-14+30(in Chinese). [26] 国防科学技术工业委员会. 雷达吸波材料反射率测试方法: GJB 2038-94[S]. 北京: 中国标准出版社, 1994.Commission of Science, Technology and Industry for National Defense (COSTIND) commission. Methods for measurement of reflectivity of radar absorbing material: GJB 2038-94 [S]. Beijing: China Standard Press, 1994 (in Chinese). [27] YAO H, YANG J, LI H, et al. Optimal design of multilayer radar absorbing materials: a simulation-optimization approach[J]. Advanced Composites and Hybrid Materials, 2023, 6(1): 43. doi: 10.1007/s42114-023-00626-3 [28] SMITH D R , VIER D C, KOSCHNY Th, et al . Electromagnetic parameter retrieval from inhomogeneous metamaterials[J]. Physical review. E, 2005, 71(3 Pt 2B): 036617. [29] CHEN Z , ZHANG Y , WANG Z . Bioinspired moth-eye multi-mechanism composite ultra-wideband microwave absorber based on the graphite powder[J]. Carbon: An International Journal Sponsored by the American Carbon Society, 2023. [30] 苏钦城. 电磁波在织物中传播的正反演仿真研究[D]. 天津工业大学, 2016.SU Qincheng. Forward and inverse study of electromagnetic wave propagation in fabric[D]. Tianjin Polytechnic University, 2016(in Chinese). [31] ZHAO B, GUO XQ, Zhao WY, et al. Yolk-Shell Ni@SnO2 Composites with a Designable Interspace to Improve the Electromagnetic Wave Absorption Properties[J]. ACS applied materials& interfaces, 2016, 8(42): 28917-28925. [32] 莫红松, 吕潇, 李光, 等. 复合材料中碳纤维的铺设方式对吸波性能的影响[A]. 第六届中国功能材料及其应用学术会议论文集(8)[C], 湖北武汉: 中国仪器仪表学会仪表材料分会, 等, 2007: 3063-3066.MO Hongsong, LV Xiao, Li Guang, et al . Effect of laying method of carbon fiber on wave absorbing properties of composite materials [A]. Proceedings of the 6th China Conference on Functional Materials and Their Applications (8) [C], Wuhan, Hubei: Branch of Instrumentation Materials of Chinese Society of Instrumentation, et al. 2007: 3063-3066 (in Chinese). [33] WANG B C, WEI J Q, YANG Y. Investigation on peak frequency of the microwave absorption for carbonyl iron/epoxy resin composite. J. Magn. Magn. Mater. 2011, 323: 1101~1103. [34] 刘海韬, 程海峰, 王军等. 高温结构吸波材料综述[J]. 材料导报, 2009, 23(19): 24-27. doi: 10.3321/j.issn:1005-023X.2009.19.006LIU Haitao, CHENG Haifeng, WANG Jun, et al. Review on High-temperat ure Struct ural Radar Absorbing Materials[J]. Materials Reports, 2009, 23(19): 24-27 (in Chinese). doi: 10.3321/j.issn:1005-023X.2009.19.006 -

下载:

下载: