Research progress in biomass-based monolithic catalytic microreactors

-

摘要: 天然生物质材料因其来源广泛、固碳能力强、机械强度较高、可再生性、环境友好性以及其具有的独特精细构造、化学组成,在多相催化领域备受青睐。生物质材料固有的孔道系统和化学组分既可以提升化学反应速率,又可以与催化剂复合参与到多相催化反应中。本文简述了竹、木和藤材等生物质材料作为催化剂载体的资源优势、结构优势和化学优势,综述了生物质基整体式催化微反应器的基本概念、催化剂类型与催化剂的复合策略与机制、催化活性与失效机制及其在水处理、能源产生、化学合成、Fischer-Tropsch合成、生物分析等先进功能领域的研究进展。最后,针对目前研究的局限性及存在的问题,在复合策略优化、功能催化剂设计、结构调控提升和稳定性能改善等方面对生物质基整体式催化微反应器未来发展趋势进行了展望,以期为“双碳”战略目标下生物质复合材料功能界面构建与高效利用提供全新的科学思路与技术借鉴。Abstract: Natural biomass materials are favored in the field of heterogeneous catalysis due to their wide resources, strong carbon sequestration capacity, high mechanical strength, renewability, environmental friendliness, as well as their unique fine structure and chemical composition. The inherent pore channel system and chemical compositions of biomass materials can not only improve the chemical reaction rate, but also participate in the heterogeneous catalytic reaction as the catalysts carrier. The resource, structural and chemical advantages of biomass such as bamboo, wood and rattan as catalyst carriers were briefly introduced in this paper. The basic concepts, types of catalysts, construction strategies and mechanisms, catalytic activity and failure mechanism of biomass-based monolithic catalytic microreactors were reviewed, as well as the research progress in advanced functional fields such as water treatment, energy generation, chemical synthesis, Fischer-Tropsch synthesis, and bioanalysis. Finally, in view of the limitations and existing problems of the current research, the future development trend of biomass-based monolithic catalytic microreactor is prospected in terms of construction strategy optimization, functional catalyst design, structure regulation improvement and stability performance improvement, in order to provide new scientific ideas and technical references for the construction and efficient utilization of functional interfaces of biomass materials under the strategic goals of carbon peak and carbon neutrality.

-

Key words:

- biomass materials /

- composites /

- catalysts /

- microreactors /

- nanomaterials

-

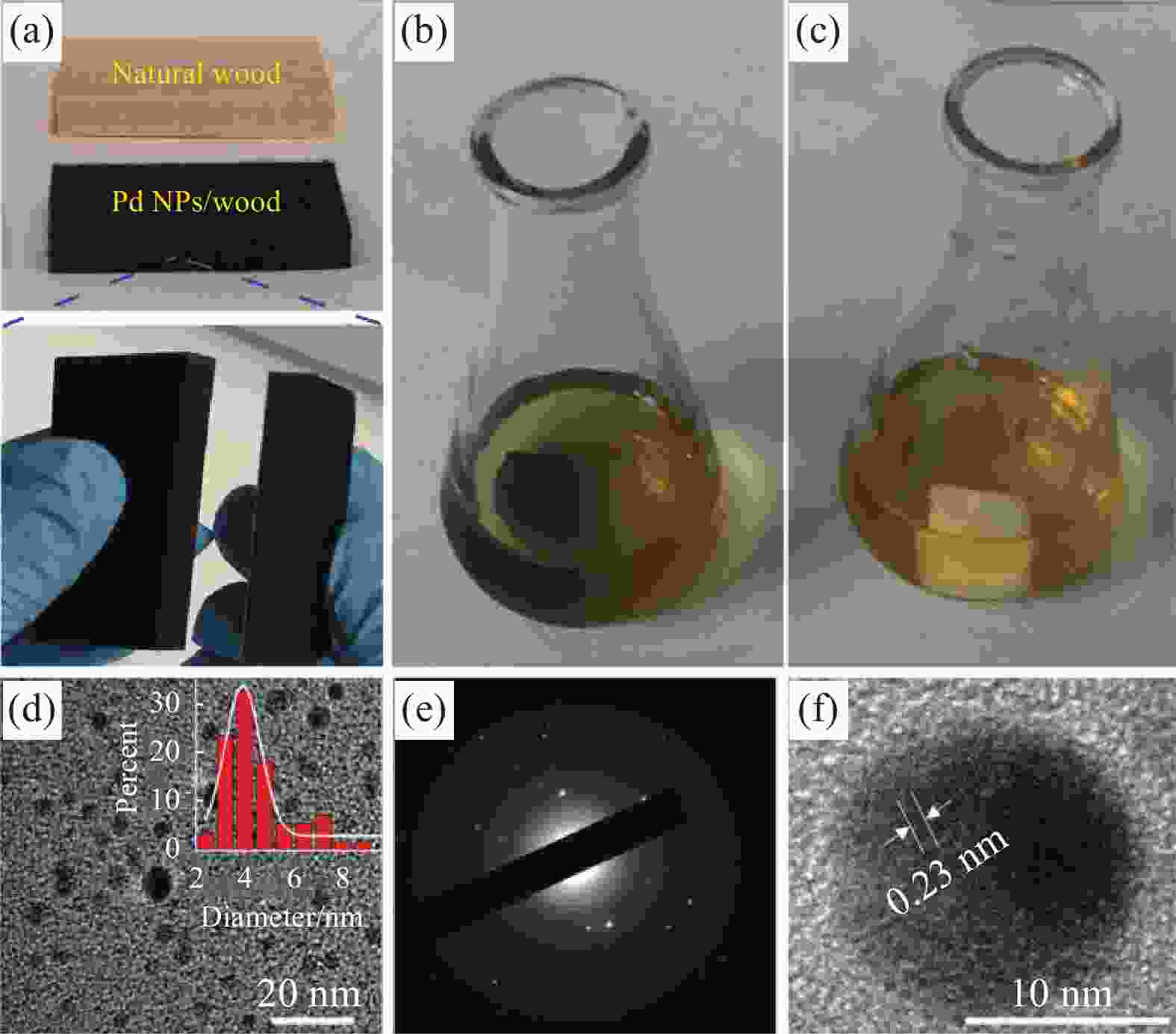

图 2 (a) 天然木材和Pd纳米颗粒(Pd NPs)/木材膜照片;(b) 天然木材浸入PdCl2水溶液中在80℃下加热12 h后的照片(木材样品颜色变黑,证实了在木材通道内Pb NPs的原位形成);(c) 脱除木质素的木材浸入PdCl2水溶液中在80℃下加热12 h后的照片(脱除木质素的木材颜色未变黑);(d) 木材中Pb NPs的TEM图像(插图为其粒径分布图);(e) Pb NPs/木材的SAED图像;(f) HRTEM图像显示Pb的(111)晶格面间距离为0.23 nm[6]

Figure 2. (a) Photos of natural wood and the Pd nanoparticles (Pd NPs)/wood membrane; (b) Photo of a piece of natural wood immersed in an aqueous solution of PdCl2 and heated for 12 h at 80℃ (The wood sample became black in color confirming the in situ formation of Pd NPs forming within the wood channels); (c) Photo of a piece of a white wood (with lignin removed) which was treated with an aqueous solution of PdCl2 and heated for 12 h at 80℃ (The result indicates that the wood without lignin does not undergo a color change); (d) TEM image of Pd NPs within the wood (Inset shows the size distribution graph of the Pd NPs); (e) SAED image of the Pd NPs/wood; (f) HRTEM image exhibits the (111) lattice plane of Pd with an interplanar distance of 0.23 nm[6]

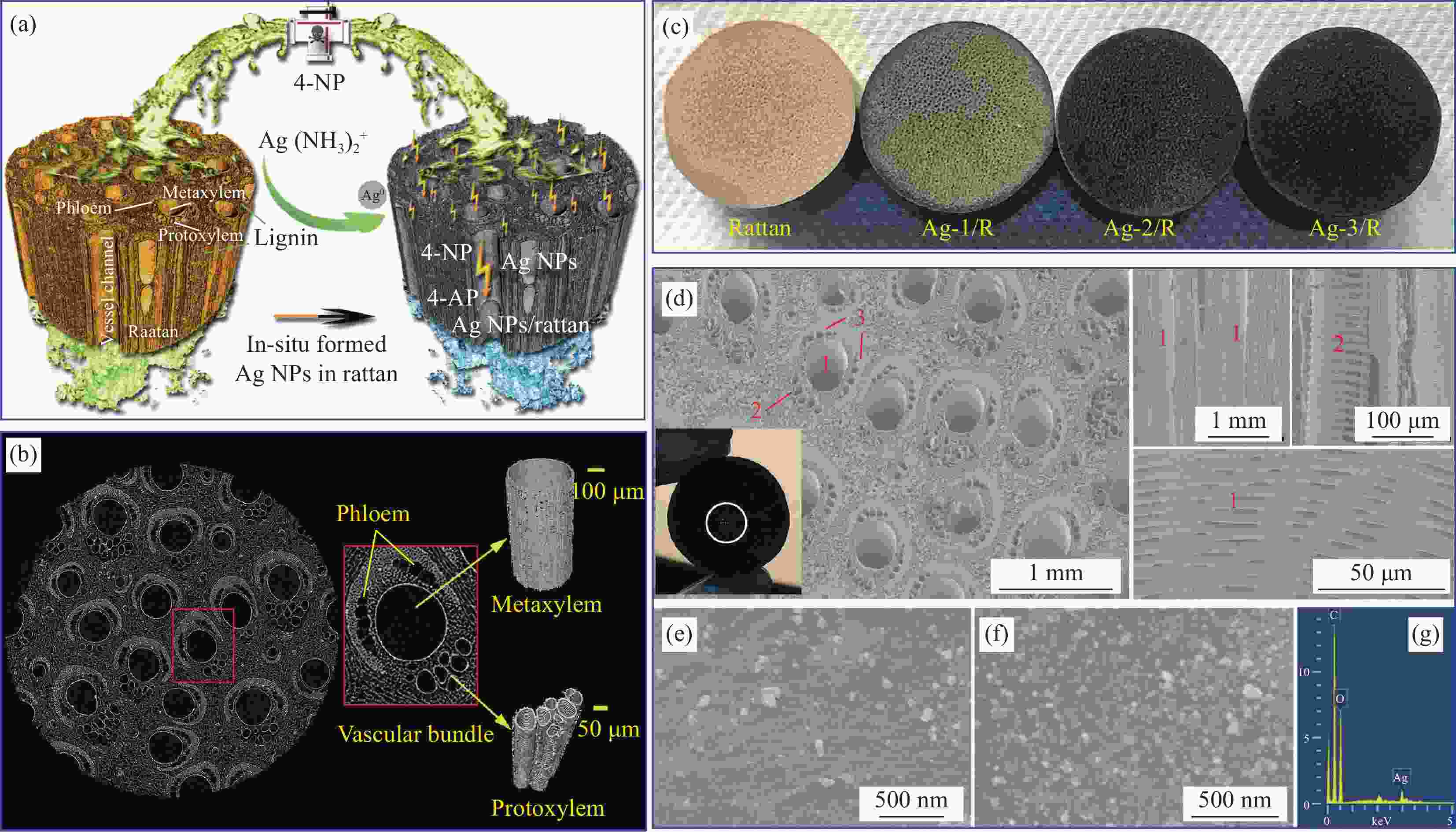

图 3 (a) 多孔Ag/藤材复合微反应器的合成过程及其重力驱动催化还原对硝基苯酚(4-NP)示意图;(b) Ag-3/R的Nano-CT图像以及Ag纳米颗粒(Ag NPs)沉积在后生木质部和原生木质部微通道上的三维Nano-CT图像;(c) 原始藤材和Ag/藤材复合微反应器数码图像;(d) 原始藤材及其局部放大SEM图像;Ag-2/R (e) 和Ag-3/R (f)的SEM图像;(g) Ag-3/R的EDS图谱[23]

Figure 3. (a) Schematic of the synthetic procedure of the porous Ag/rattan filter and its gravity-driven catalytic function in the 4-nitrophenoxide (4-NP) reduction reaction; (b) Nano-CT images of Ag-3/R and 3D nano-CT images (without the vegetal biomass) of Ag nanoparticles (Ag NPs) depositions onto the microchannels of metaxylem and protoxylem; (c) Digital images of naked rattan and Ag/rattan nanocomposites; (d) SEM image of naked rattan and magnified SEM images; SEM images of Ag-2/R (e) and Ag-3/R (f); (g) EDS spectrum for the Ag-3/R nanocomposite[23]

Ag-x/R is Ag-x/rattan, where x=1, 2, 3 represent Ag/rattan prepared by Ag(NH3)2NO3 at concentrations of 10, 50, and 100 mmol/L, respectively; 4-AP—4-Aminopyridine

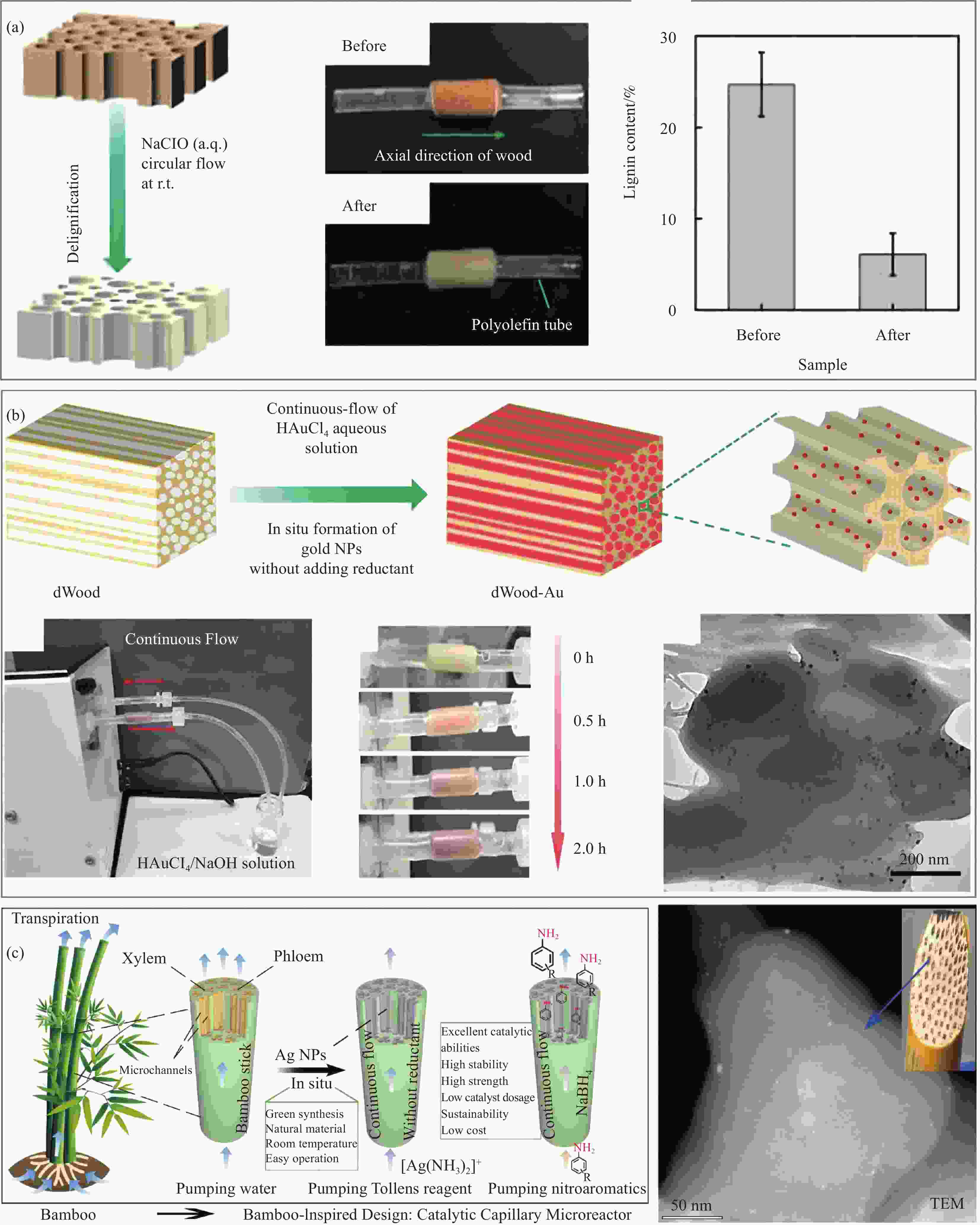

图 7 (a) NaClO水溶液循环流动脱除木材中的木质素以及脱木质素前后的木质素含量;(b) 木材孔道中连续流负载Au NPs的示意图、实验照片以及Au/木材复合材料的TEM图像[45];(c) 在未添加任何还原剂的条件下竹材微通道中连续流负载Ag NPs的示意图以及Ag/竹材复合材料的HAADF-STEM图像[46]

Figure 7. (a) Delignification of wood by the circular flow of NaClO aqueous solution and lignin content of wood before and after delignification; (b) Scheme of the continuous-flow generation of Au NPs on the channel of wood, photo graphs of the continuous flow system and TEM image of the Au/wood[45]; (c) Continuous-flow synthesis of Ag NPs on the walls of microchannels of bamboo without adding any external reductant and its HAADF-STEM image[46]

dWood—Delignified wood; RT—Room temperature

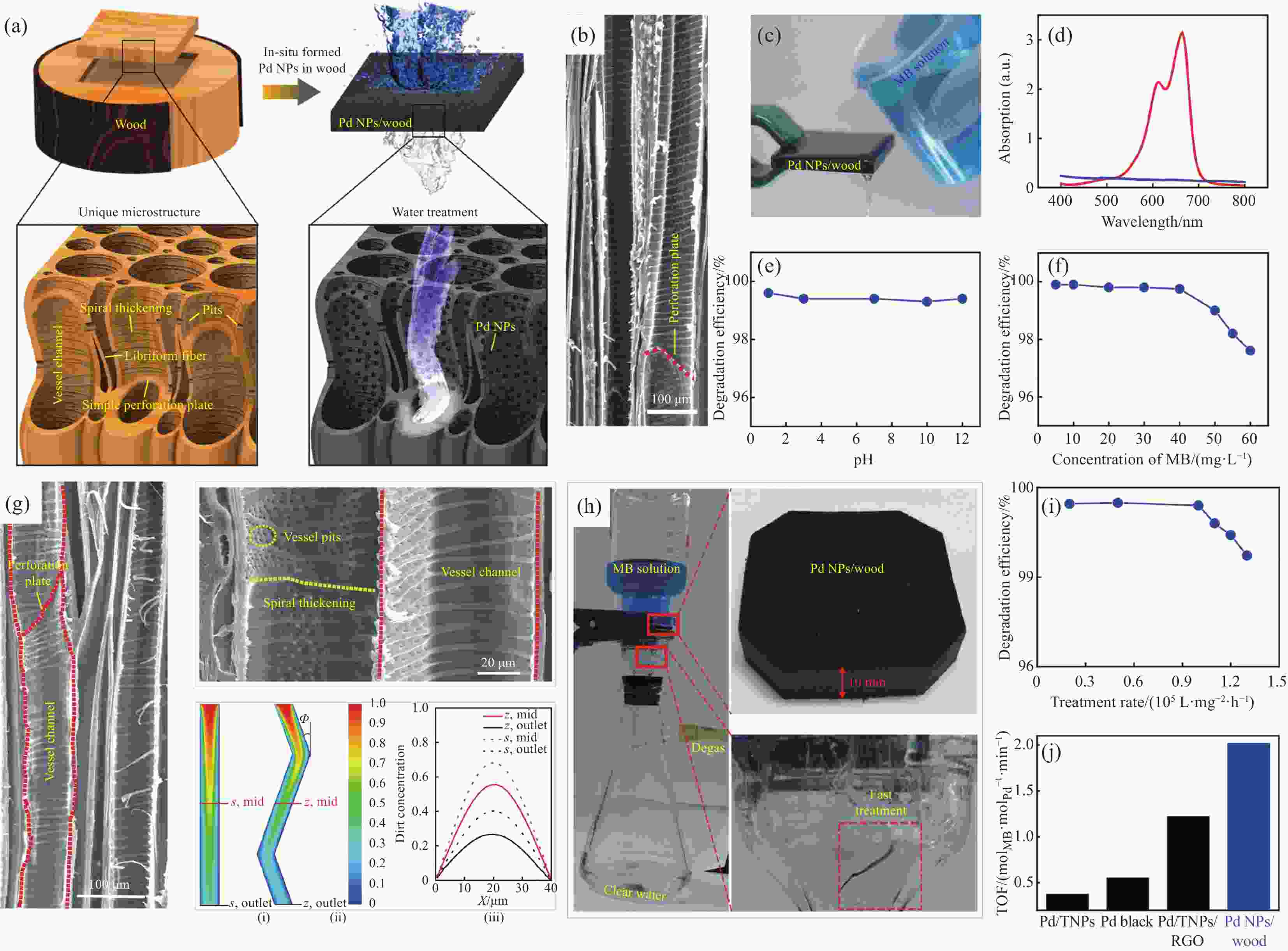

图 8 (a) Pd NPs修饰的椴木复合反应器用于水处理;(b)木材长通道中导管和穿孔板的SEM图像;(c) Pd NPs/木材膜复合催化水处理演示;(d)亚甲基蓝溶液流过Pd NPs/木材膜前(红色线)后(蓝色线)的UV-vis光谱图;不同pH值(e)和不同浓度(f)亚甲基蓝溶液的降解效率;(g) 显示在木材的径向截面长而不规则的通道的SEM图像;(h)真空辅助下水处理实验装置图,黑色的Pd NPs/木材膜用作过滤器;(i)不同处理速率下的降解效率;(j)与文献报道的其他Pd基复合材料相比,Pd NPs/木材膜的TOF (转化频率)值比较[6]

Figure 8. (a) Basswood decorated with Pd NPs for water treatment; (b) SEM image of the long wood channels with vessels and perforation plates; (c) Demonstration of water treatment using a Pd NPs/wood membrane; (d) UV-vis spectra of the methylene blue solution before and after flowing through Pd NPs/wood membrane; The degradation efficiency at different pH values (e) and concentrations (f) of the methylene blue solution, respectively; (g) SEM images showing long and irregular channels in the radial section of the wood; (h) Experimental setup for the water treatment tests, where vacuum is applied to control water flow rates (The black Pd NPs/wood membrane (Thickness=10 mm; Effective diameter=34 mm), which was used as a filter); (i) Degradation efficiency as a function of various treatment rates; (j) Turnover frequency (TOF) of the Pd NPs/wood membrane compared to other Pd-based materials reported in the literature[6]

MB—Methylene blue; TNPs—Tetrahedral Pd nanocrystals; RGO—Reduced graphene oxide; s—Straight; z—Zigzag

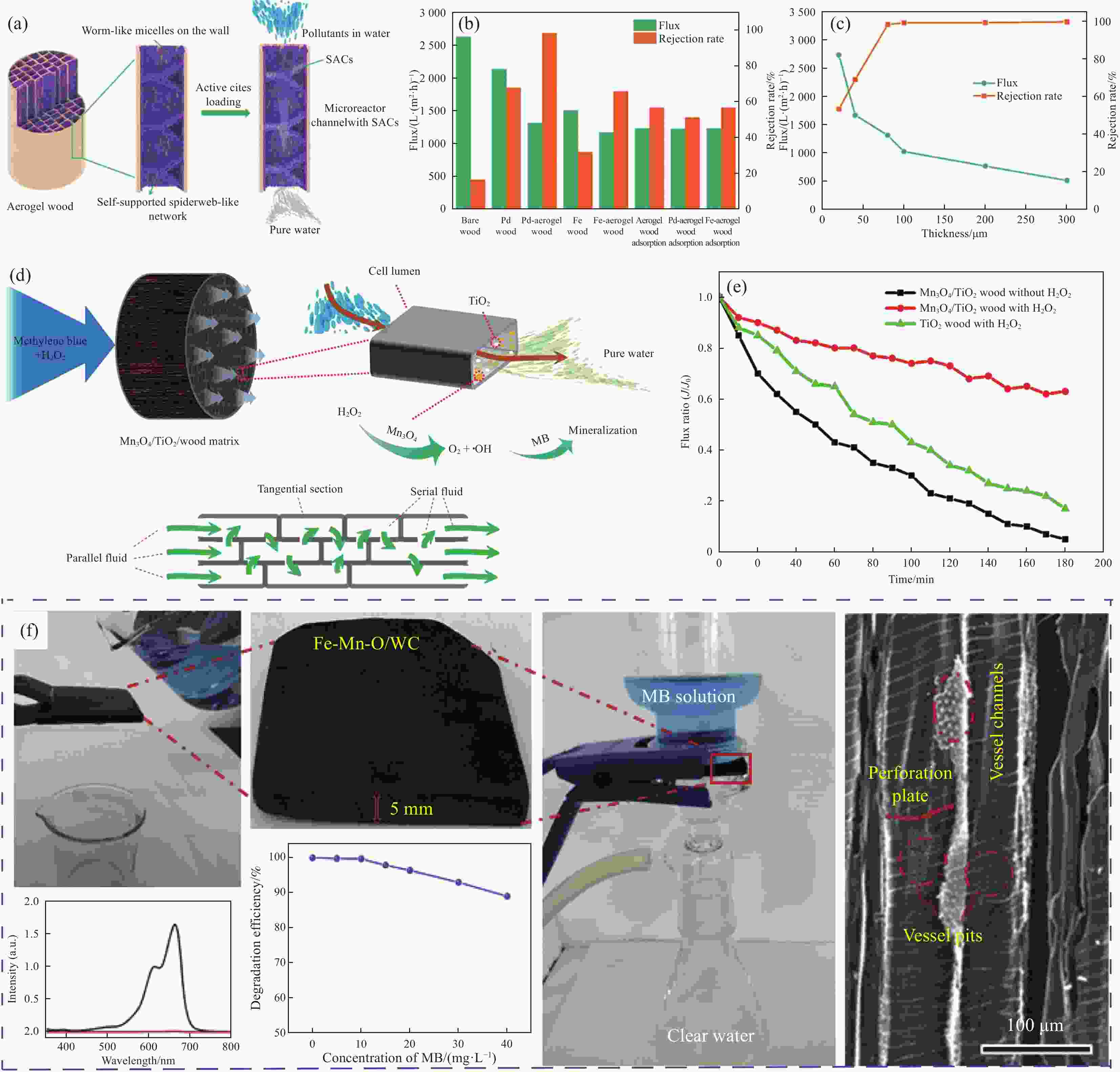

图 9 (a)反应溶液流经微通道示意图;(b)不同结构和催化位点微反应器的催化和吸附性能比较;(c)不同厚度Pd/木材气凝胶复合微反应器的催化性能比较[30];(d) Mn3O4/TiO2/木材复合微反应器的催化降解示意图;(e) TiO2/木材在H2O2和Mn3O4/TiO2/木材在H2O2和无H2O2作用下的通量比[34];(f)不同浓度亚甲基蓝溶液的降解效率及自制亚甲基蓝降解过滤装置的照片[55]

Figure 9. (a) Schematic illustration of the reaction solution flowing through the microchannel; (b) Comparison of the catalytic and adsorption performance of microreactors with different structures and catalytic sites; (c) Comparison of the catalytic performance of Pd-aerogel wood microreactors with different wood thicknesses[30]; (d) Model of the catalytic degradation process in Mn3O4/TiO2/wood matrix as a microreactor; (e) Flux ratio of TiO2/wood with H2O2 and Mn3O4/TiO2/wood matrix with and without H2O2[34]; (f) Degradation efficiency at different concentrations of the methylene blue solution and the photographs of the home-made filtration device for methylene blue degradation[55]

WC—Wood carbon

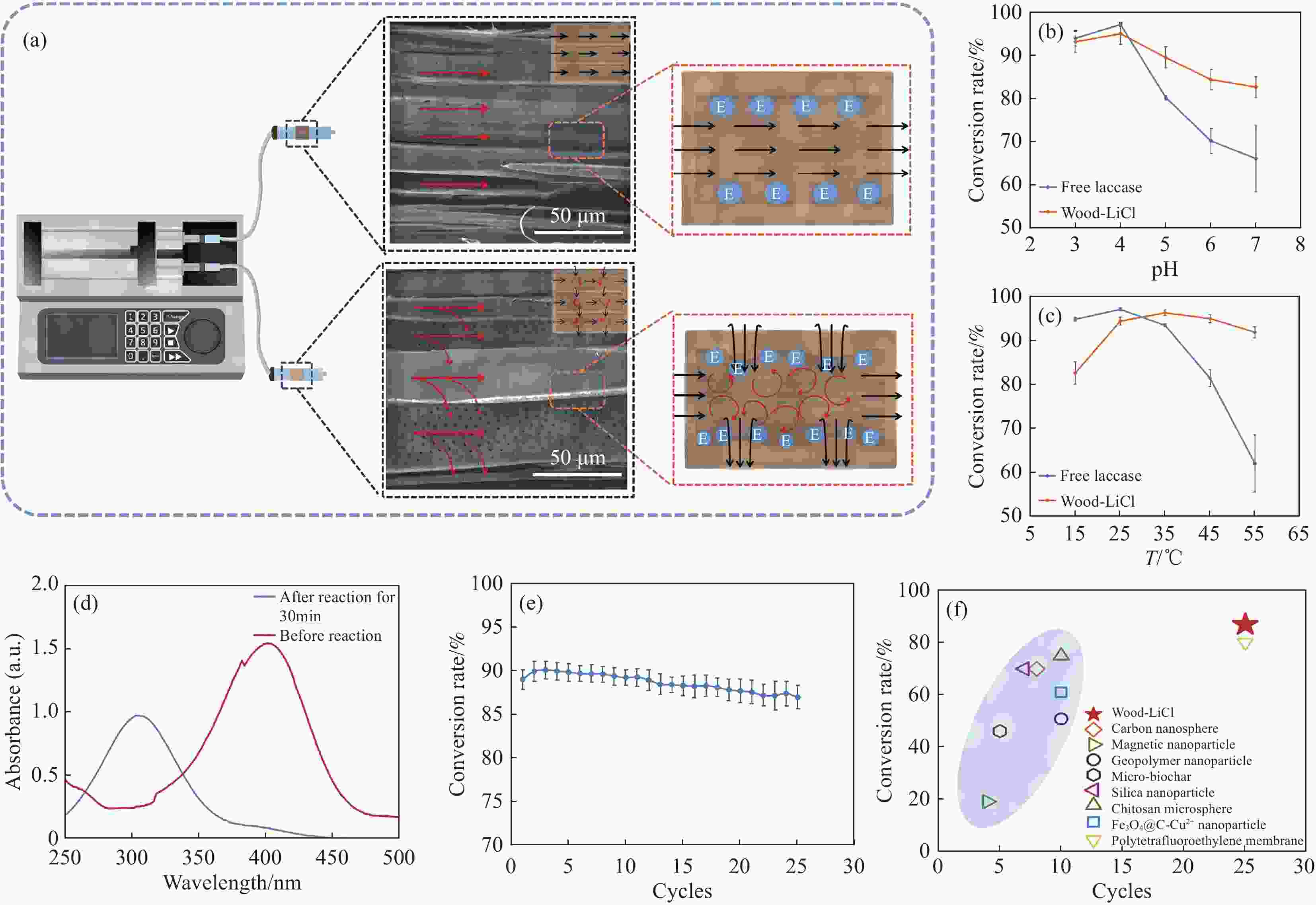

图 10 (a)连续流催化生物反应器的构建与通道内流体运动;反应pH (b)和反应温度(c)对游离酶和固定化酶反应的影响;(d)反应前后4-NP溶液的UV-vis图谱;(e)木材微流控反应器再利用性能;(f)与其他固定化漆酶材料的性能比较[56]

Figure 10. (a) Construction of continuous fluid catalytic bioreactor and fluid movement in the channel; Effect of pH (b) and temperature (c) on the reaction of free and immobilized enzymes; (d) UV spectrum variation of the 4-NP degradation reaction catalyzed by fluid; (e) Determination of wood microfluidic reactor reusability; (f) Comparison with other immobilized laccase materials[56]

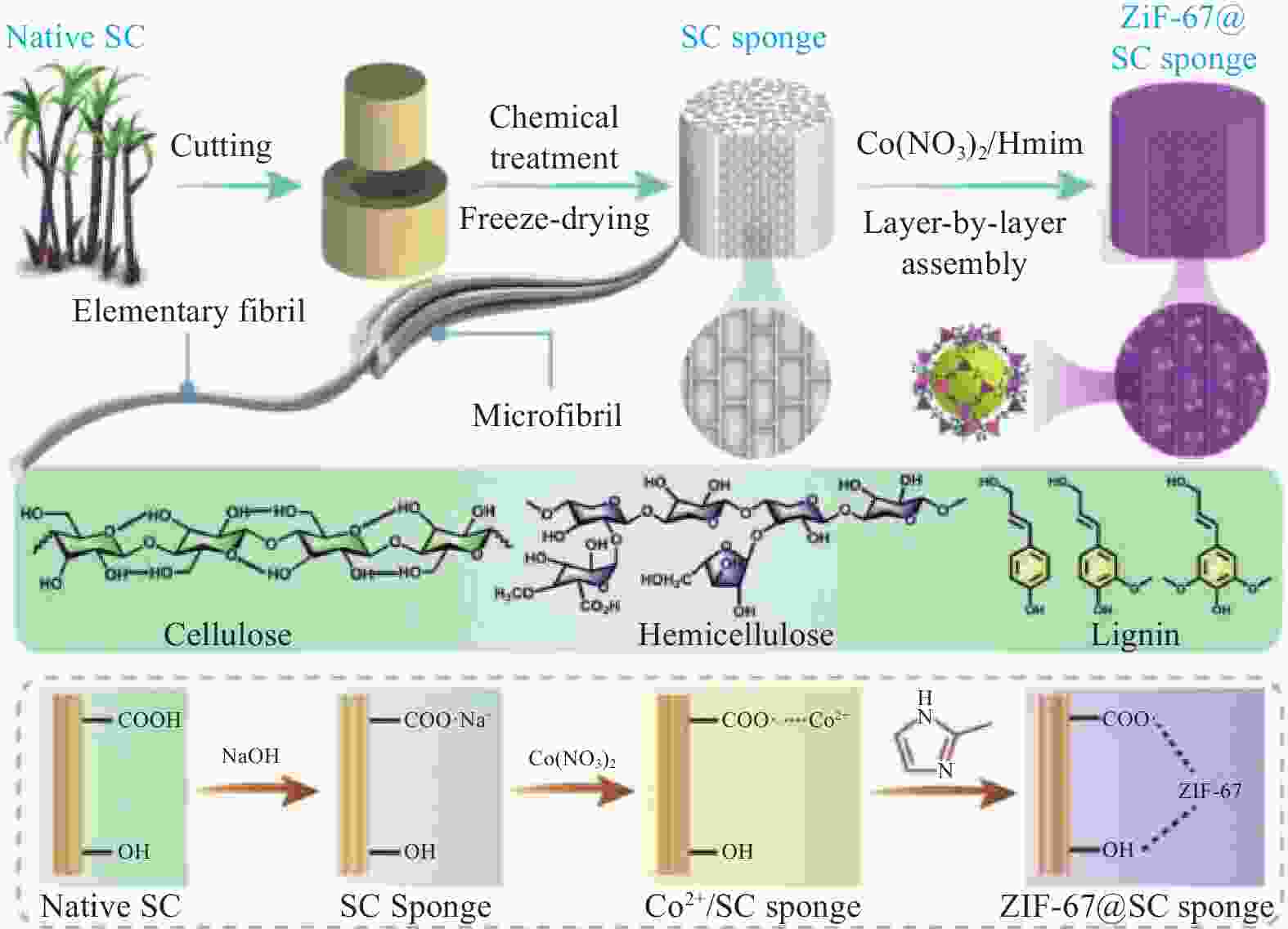

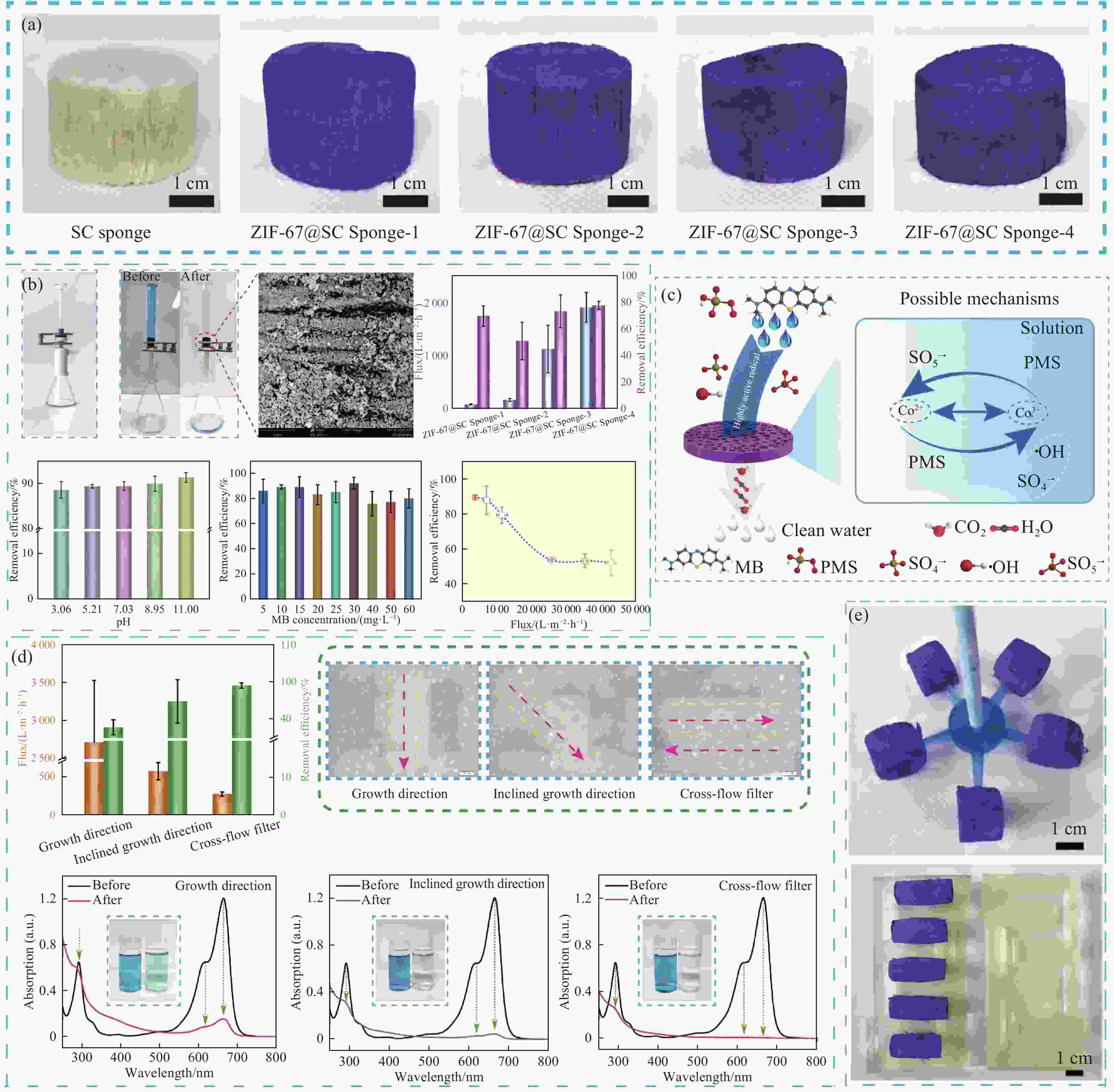

图 11 (a)原始SC海绵和ZIF-67@SC sponge-1、ZIF-67@SC sponge-2、ZIF-67@SC sponge-3及 ZIF-67@SC sponge-4复合材料 (末尾数字表示制备时间);(b) ZIF-67@SC海绵复合微反应器在不同运行条件下的连续流催化性能;(c) ZIF-67@SC海绵复合微反应器催化活化PMS产生活性自由基的机制示意图;(d)设计的3种甘蔗微反应器对亚甲基蓝的催化降解性能比较;(e)组装而成的催化搅拌器(上)和连续流催化过滤器(下)[32]

Figure 11. (a) Digital photographs of the SC sponge, ZIF-67@SC sponge-1, ZIF-67@SC sponge-2, ZIF-67@SC sponge-3, and ZIF-67@SC sponge-4 composites (The end number means the assembly time); (b) Catalytic performance of flow filtration of ZIF-67@SC sponge catalytic microreactor and the influence of operating conditions on catalytic activity; (c) Schematic illustration of the mechanism for ZIF-67@SC sponge catalytic filter activating PMS to generate active free radicals; (d) Comparison of the performance of three different sugarcane filter designs in terms of the catalytic degradation of methylene blue; (e) Digital photos of the reactor with the catalytic agitator (up) and a homemade flow-through catalytic filtration device (down)[32]

PMS—Peroxymonosulfate

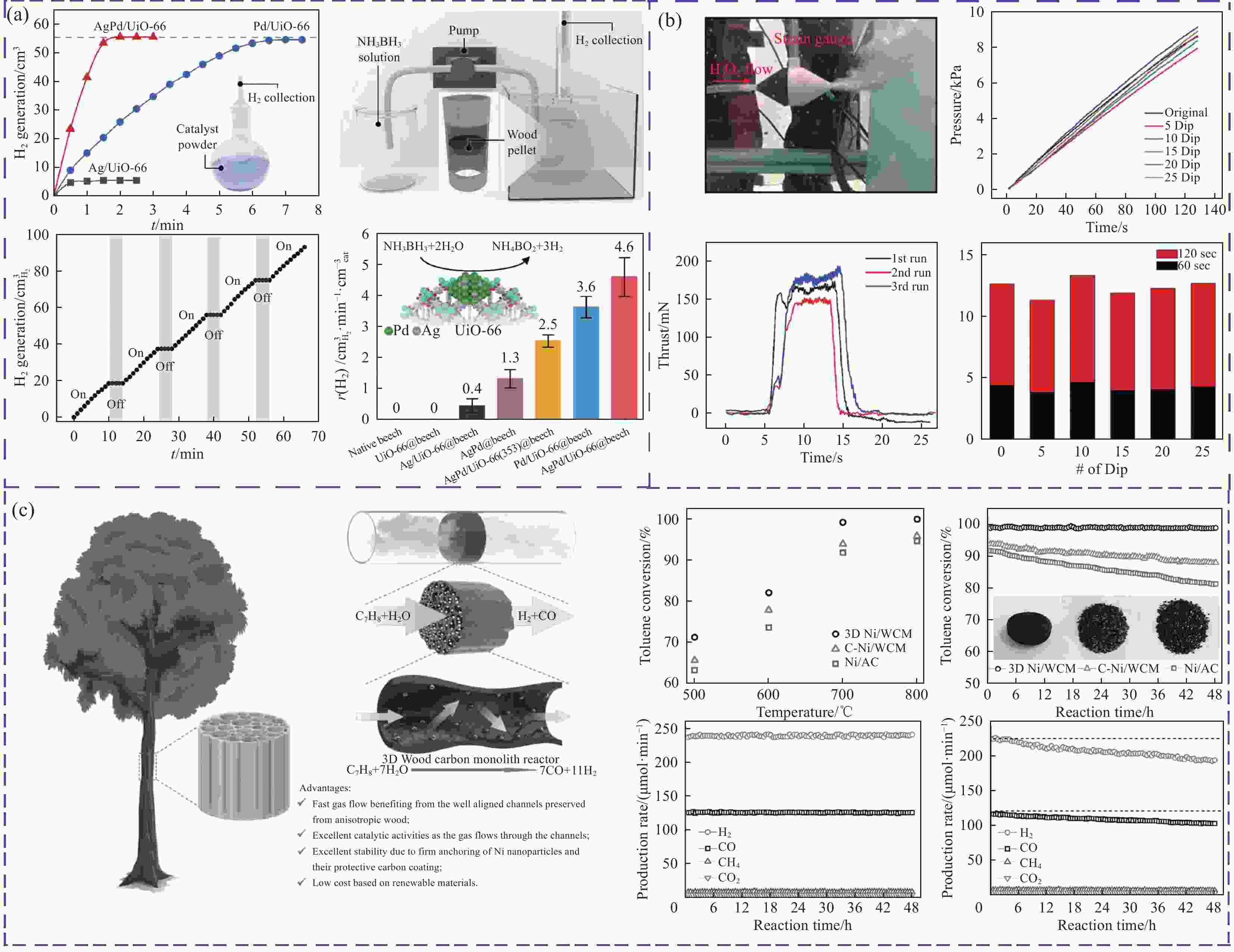

图 12 (a)氨硼烷催化分解制氢性能[28];(b) Pt/木材碳膜复合催化剂的水下推进性能[27];(c)基于三维Ni/木材碳整体式催化微反应器(WCM)的生物质焦油重整性能[37]

Figure 12. (a) Hydrogen generation performance in ammonia borane catalytic decomposition[28]; (b) Performance of the Pt/activated carbonized wood catalyst for practical underwater propulsion applications[27]; (c) Performance of the flow-through reactor with a low tortuosity for biomass tar reforming based on 3D Ni/wood-carbon monolith (WCM)[37]

r(H2)—Hydrogen generation rate; AC—Activated carbon

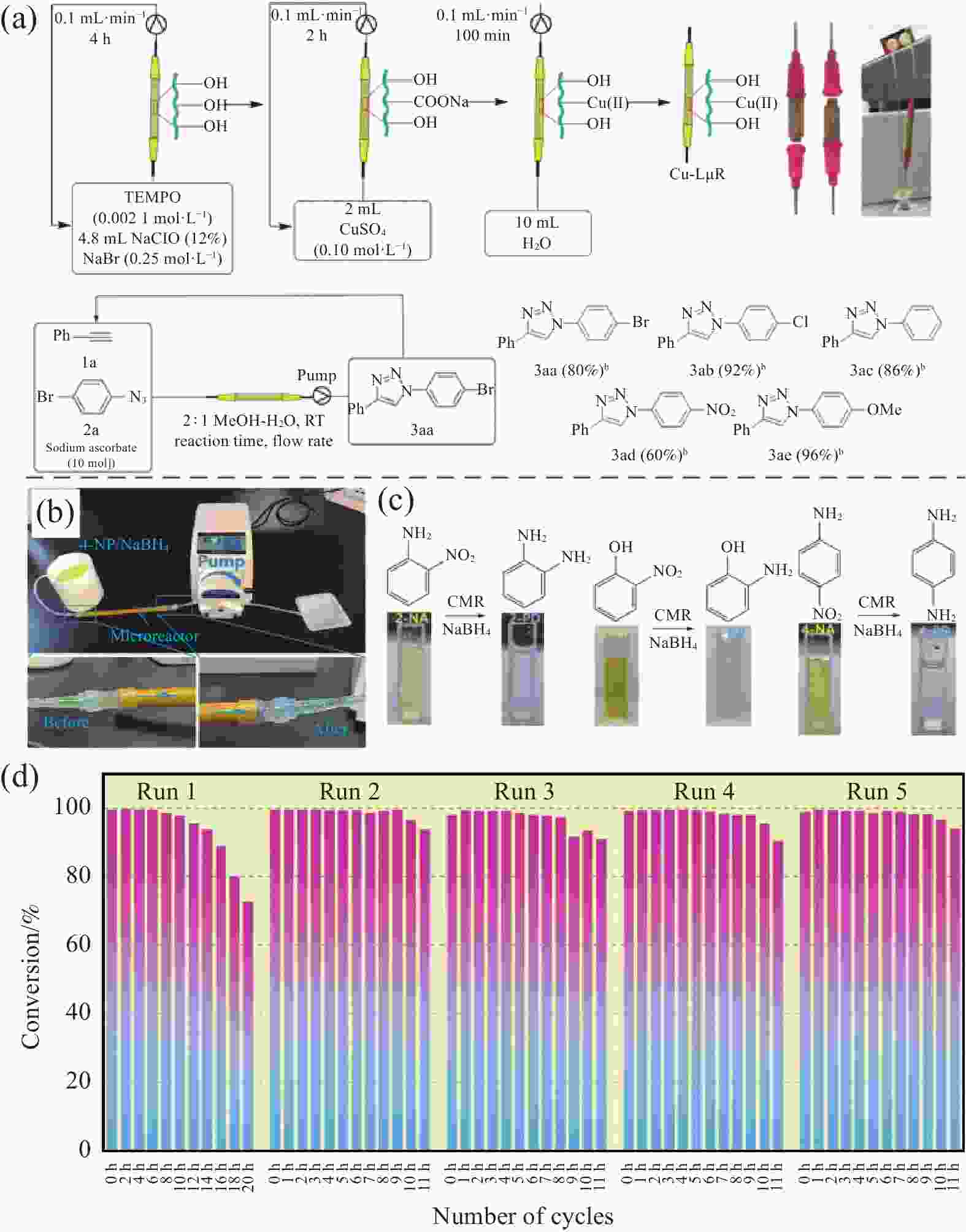

图 13 (a) 铜功能化的竹基微反应器用于连续流叠氮化物和末端炔烃之间进行铜(I)催化的1, 3-偶极环加成(CuAAC)点击反应[64];(b) Ag/竹材CMR的照片;(c) Ag-3/竹材CMR催化转化2-NP、2-NA和4-NA;(d) Ag-3/竹材CMR的长期稳定性和可重用性[46]

Figure 13. (a) Copper functionalized bamboo microreactor for copper(I)-catalyzed 1, 3-dipolar cycloaddition between azide and terminal alkyne (CuAAC) in continuous-flow[64]; (b) Photographs of the flow Ag/bamboo CMR during a catalytic process; (c) Catalytic conversion of 2-NP, 2-NA, and 4-NA in the Ag-3/bamboo CMR; (d) Long-term stability and reusability of the Ag-3/bamboo CMR[46]

Cu-LuR—Copper-functionalized lignocellulosic microreactor; TEMPO—2, 2, 6, 6-tetramethylpiperidinyl-1-oxide; MeOH—Methanol; CMR—Catalytic microreactor; 2-NP—2-nitrophenol; 2-NA—2-nitroaniline; 4-NA—4-nitroaniline

图 14 (a)三维Co@C/CW复合催化剂的合成过程及Fischer-Tropsch合成中多通道催化作用示意图;(b) Co@C/CW-100复合催化剂在不同气时空速下的CO转化率和选择性;(c) Co@C/CW-100复合催化剂随时间变化的CO转化率(T= 240℃、P= 2.0 MPa、H2/CO = 2、GHSV = 10 L·h−1·gcat−1);与其他已报道的MOFs、ZIF衍生催化剂进行了CO转化率(d) 和 C5+选择性(e)的比较[31]

Figure 14. (a) Schematic of the synthesis of 3D Co@C/CW catalysts and multi-channel catalysis during Fischer-Tropsch synthesis; (b) CO conversion and selectivity of Co@C/CW-100 catalyst at different GHSV; (c) CO conversions with time on stream of Co@C/CW-100 (T = 240 ℃, P = 2.0 MPa, H2/CO = 2, GHSV = 10 L·h−1·gcat−1); CO conversion (d) and C5+ selectivity (e) compared with other reported MOFs, ZIF derivative catalyst[31]

GHSV—Gas hourly space velocity; Co@C—Co-MOF-74-derived Co@carbon; Co@NC—ZIF-67-derived Co@carbon; Co/C-550-8—Co/carbon-550℃-8 h; Co/C-900-8—Co/carbon-900℃-8 h; Co/C-800-8—Co/carbon-800℃-8 h; 8CTAB-Co@C—8CTAB-Co@carbon (8 stands for m(CTAB)/n(Co(NO3)·6H2O)); 5%Co@MIL-53Al—Co@MIL-53(Al) containing 5% Co; 10%Co@MIL-53Al—Co@MIL-53(Al) containing 10% Co; Fe-MIL-88B(NH2/C)—Fe-MIL-88B-NH2 derived Fe-MIL-88B(NH2)/carbon; Co PCN-920—ZIF-8@ZIF-67 pyrolyzed at 920℃; ZIF-67-920—ZIF-67 pyrolyzed at 920℃

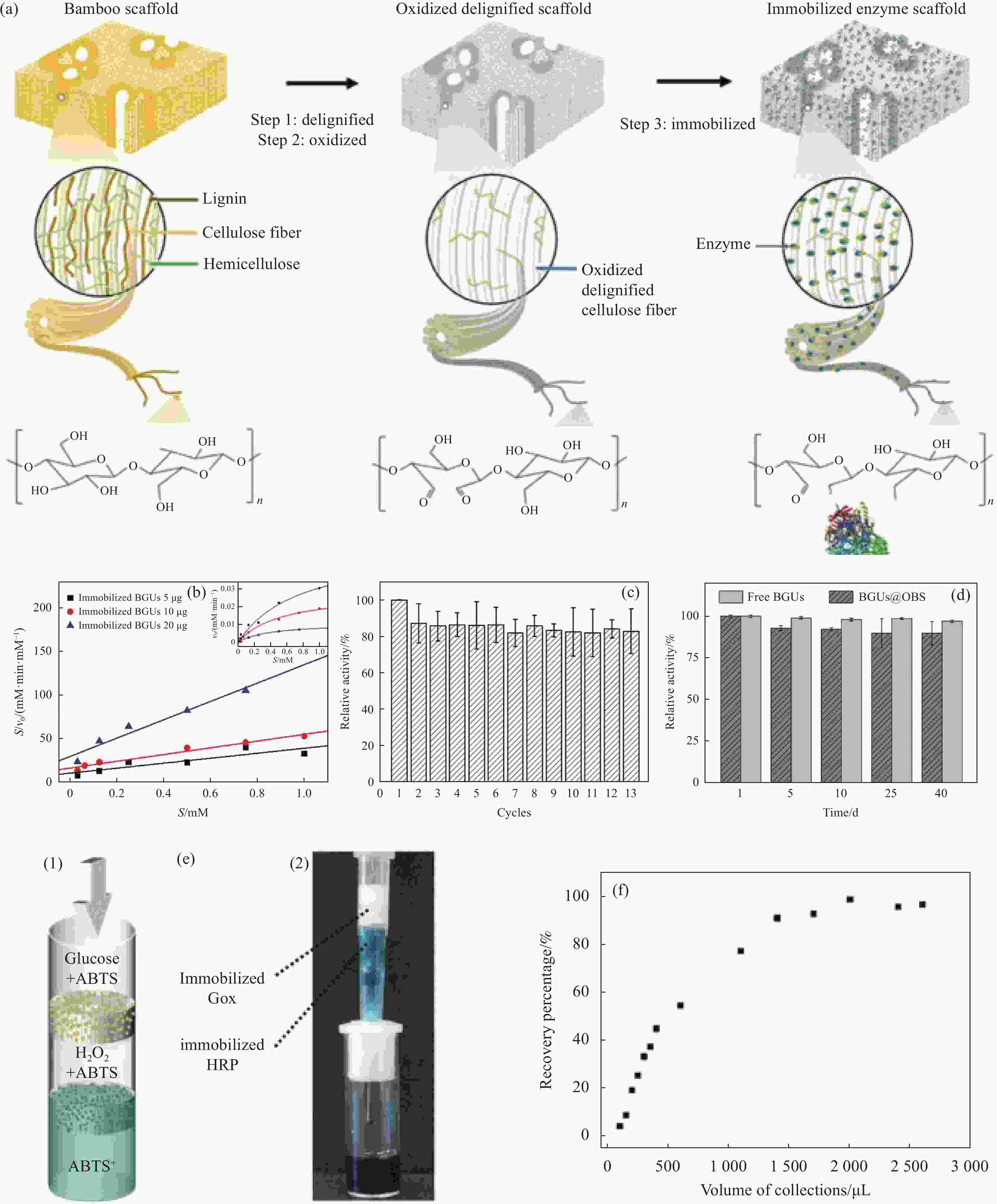

图 15 (a)脱木素竹材支架上的酶固定作为绿色层级生物反应器;(b)用不同数量BGUs固定OBS进行的Hanes-Woolf实验图和Michaelis-Menten方程拟合(插图);(c) BGU@OBS的可重用性;(d)游离BGU和BGU@OBS的储存稳定性(~4℃保存40天);(e) GOx@OBS和HRP@OBS串联催化的生物反应器原理图(1)和光学照片(2);(f)流速为10 L/min时回收率与收集体积的函数关系[66]

Figure 15. (a) Enzyme immobilization on a delignified bamboo scaffold as a green hierarchical bioreactor; (b) Hanes-Woolf plots of experiments performed with OBS immobilized with different amounts of BGUs and the fitting of the Michaelis-Menten equation (insert); (c) Reusability of BGU@OBS; (d) Storage stability of free BGU and BGU@OBS (~4℃ for 40 days); (e) Schematic diagram (1) and optical photograph (2) of the bioreactor for tandem catalysis with GOx@OBS and HRP@OBS; (f) Recovery percentage as a function of collection volume at 10 mL/min flow rate[66]

BGUs—β-glucuronidases; v0—Reaction rate; S—Reactant concentration; OBS—Oxidized bamboo scaffold; ABTS—2, 2'-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid); HRP—Enzymes peroxidase from horseradish; GOx—Glucose oxidase from Aspergillus niger

-

[1] 江泽慧, 叶柃, 费本华. 竹缠绕复合材料的研发、应用及产业化现状与前景[J]. 世界竹藤通讯, 2020, 18(2): 1-11.JIANG Zehui, YE Ling, FEI Benhua. Development, application and industrialization of bamboo winding composites: Status and prospect[J]. World Bamboo and Rattan, 2020, 18(2): 1-11(in Chinese). [2] 李坚, 高丽坤. 新型木质基电催化析氧析氢材料的研究进展[J]. 福建林学院学报, 2021, 41(4): 337-342.LI Jian, GAO Likun. Research progress on novel wood-based electrocatalysts in oxygen and hydrogen evolution reactions[J]. Journal of Fujian Agriculture and Forestry University, 2021, 41(4): 337-342(in Chinese). [3] 卿彦. “双碳”战略目标下木竹基先进功能材料研究进展[J]. 中南林业科技大学学报, 2022, 42(12): 13-25.QING Yan. Advanced functional materials derived from natural wood and bamboo resources under the double carbon strategy in China[J]. Journal of Central South University of Forestry & Technology, 2022, 42(12): 13-25(in Chinese). [4] 吴义强. 木材科学与技术研究新进展[J]. 中南林业科技大学学报, 2021, 41(1): 1-28.WU Yiqiang. Newly advances in wood science and technology[J]. Journal of Central South University of Forestry & Technology, 2021, 41(1): 1-28(in Chinese). [5] LI J, REN D, WU Z, et al. Flame retardant and visible light-activated Fe-doped TiO2 thin films anchored to wood surfaces for the photocatalytic degradation of gaseous formaldehyde[J]. Journal of Colloid and Interface Science, 2018, 530: 78-87. doi: 10.1016/j.jcis.2018.06.066 [6] CHEN F, GONG A S, ZHU M, et al. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment[J]. ACS Nano, 2017, 11(4): 4275-4282. doi: 10.1021/acsnano.7b01350 [7] YU Z L, QIN B, MA Z Y, et al. Emerging bioinspired artificial woods[J]. Advanced Materials, 2021, 33(28): 2001086. doi: 10.1002/adma.202001086 [8] 王成毓, 孙淼. 仿生人工木材的研究进展[J]. 林业工程学报, 2022, 7(3): 1-10.WANG Chengyu, SUN Miao. Research of bioinspired artificial wood[J]. Journal of Forestry Engineering, 2022, 7(3): 1-10(in Chinese). [9] ZHAO H, WANG J, MENG Y, et al. Bamboo and rattan: Nature-based solutions for sustainable development[J]. The Innovation, 2022, 3(6): 100337. doi: 10.1016/j.xinn.2022.100337 [10] 江泽慧, 竹材解剖学研究进展[J]. 世界林业研究, 2020, 33(3): 1-6.JIANG Zehui. Research advances in bamboo anatomy[J]. World Forestry Research , 2020, 33(3): 1-6(in Chinese). [11] 李坚, 甘文涛, 王立娟. 木材仿生智能材料研究进展[J]. 木材科学与技术, 2021, 35(4): 1-14. doi: 10.12326/j.2096-9694.2021051LI Jian, GAN Wentao, WANG Lijuan. Research progress on wood biomimetic intelligent materials[J]. Wood Science and Technology, 2021, 35(4): 1-14(in Chinese). doi: 10.12326/j.2096-9694.2021051 [12] 李坚. 大自然的启发−木材仿生与智能响应[J]. 科技导报, 2016, 34(19): 1-1.LI Jian. Inspired by nature—Wood bionics and intelligent response[J]. Science & Technology Review, 2016, 34(19): 1-1(in Chinese). [13] CHEN C, KUANG Y, ZHU S, et al. Structure–property–function relationships of natural and engineered wood[J]. Nature Reviews Materials, 2020, 5(9): 642-666. doi: 10.1038/s41578-020-0195-z [14] WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials[J]. Nature Materials, 2015, 14(1): 23-36. doi: 10.1038/nmat4089 [15] 刘嵘. 毛竹材细胞壁的纹孔特征研究[D]. 北京: 中国林业科学研究院, 2017.LIU Rong. Characteristics of pits in bamboo cell walls[D]. Beijing: Chinese Academy of Forestry, 2017(in Chinese). [16] 卢芸, 梁振烜, 付宗营, 等. 木材细胞壁纳米技术研究进展与展望[J]. 林业工程学报, 2022, 7(5): 1-11.LU Yun, LIANG Zhenxuan, FU Zongying, et al. Research advances and prospect of wood cell wall nanotechnology[J]. Journal of Forestry Engineering, 2022, 7(5): 1-11(in Chinese). [17] WANG Z, JIA C, XIANG H, et al. Palladium nanoparticle-loaded mesostructural natural woods for efficient water treatment[J]. Polymers, 2023, 15(3): 658. doi: 10.3390/polym15030658 [18] ZHANG Q, ZHANG X, CHI M, et al. Catalytical and antibacterial sugarcane filter decorated with sliver nanoparticle for water treatment[J]. Industrial Crops and Products, 2021, 164: 113392. doi: 10.1016/j.indcrop.2021.113392 [19] HE S, CHEN C, CHEN G, et al. High-performance, scalable wood-based filtration device with a reversed-tree design[J]. Chemistry of Materials, 2020, 32(5): 1887-1895. doi: 10.1021/acs.chemmater.9b04516 [20] YU Y, HUO H, ZHANG Q, et al. Nano silver decorating three-dimensional porous wood used as a catalyst for enhancing azo dyes hydrogenation in wastewater[J]. Industrial Crops and Products, 2022, 175: 114268. doi: 10.1016/j.indcrop.2021.114268 [21] CHENG Z, GUAN H, MENG J, et al. Dual-functional porous wood filter for simultaneous oil/water separation and organic pollutant removal[J]. ACS Omega, 2020, 5(23): 14096-14103. doi: 10.1021/acsomega.0c01606 [22] DU X, SHI L, PANG J, et al. Fabrication of superwetting and antimicrobial wood-based mesoporous composite decorated with silver nanoparticles for purifying the polluted-water with oils, dyes and bacteria[J]. Journal of Environmental Chemical Engineering, 2022, 10(2): 107152. doi: 10.1016/j.jece.2022.107152 [23] LI J, MA R, LU Y, et al. A gravity-driven high-flux catalytic filter prepared using a naturally three-dimensional porous rattan biotemplate decorated with Ag nanoparticles[J]. Green Chemistry, 2020, 22(20): 6846-6854. doi: 10.1039/D0GC01709D [24] ZHANG Q, LI M, LUO B, et al. In situ growth gold nanoparticles in three-dimensional sugarcane membrane for flow catalytical and antibacterial application[J]. Journal of Hazardous Materials, 2021, 402: 123445. doi: 10.1016/j.jhazmat.2020.123445 [25] YU Y, ZHANG Q, CHI M, et al. Porous wood decorated with gold nanoparticles as flow-through membrane reactor for catalytic hydrogenation of methylene blue and 4-nitrophenol[J]. Cellulose, 2021, 28(11): 7283-7294. doi: 10.1007/s10570-021-03934-3 [26] CHE W, XIAO Z, WANG Z, et al. Wood-based mesoporous filter decorated with silver nanoparticles for water purification[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(5): 5134-5141. doi: 10.1021/acssuschemeng.8b06001 [27] CHEN B, GSALLA A, GAUR A, et al. Porous wood monoliths decorated with platinum nano-urchins as catalysts for underwater micro-vehicle propulsion via H2O2 decomposition[J]. ACS Applied Nano Materials, 2019, 2(7): 4143-4149. doi: 10.1021/acsanm.9b00593 [28] TU K, BÜCHELE S, MITCHELL S, et al. Natural wood-based catalytic membrane microreactors for continuous hydrogen generation[J]. ACS Applied Materials & Interfaces, 2022, 14(6): 8417-8426. doi: 10.1021/acsami.1c22850 [29] 李玲玲, 刘宇, 宋术岩, 等. 配位环境可调的Cu单原子的合成及催化加氢性能研究[J]. 化学学报, 2022, 80(1): 16-21. doi: 10.6023/A21100467LI Lingling, LIU Yu, SONG Shuyan, et al. Synthesis of Cu single atom with adjustable coordination environment and its catalytic hydrogenation performance[J]. Acta Chimica Sinica, 2022, 80(1): 16-21(in Chinese). doi: 10.6023/A21100467 [30] LIU G, HE Z, BA Y, et al. 3D spiderweb-like nanowire networks loading single-atom catalysts in capillary array as high-efficiency microreactor[J]. Chemical Engineering Journal, 2023, 453: 139700. doi: 10.1016/j.cej.2022.139700 [31] QIN H, ZHOU Y, HUANG Q, et al. Metal organic framework (MOF)/wood derived multi-cylinders high-power 3D reactor[J]. ACS Applied Materials & Interfaces, 2021, 13(4): 5460-5468. doi: 10.1021/acsami.0c21664 [32] LIU D, JIANG P, XU X, et al. MOFs decorated sugarcane catalytic filter for water purification[J]. Chemical Engineering Journal, 2022, 431: 133992. doi: 10.1016/j.cej.2021.133992 [33] XU X, LIU D, JI Z, et al. Three-dimensional cellulose-based hierarchical porous continuous flow catalytic reactor for water purification[J]. Materials Today Communications, 2022, 33: 104907. doi: 10.1016/j.mtcomm.2022.104907 [34] LIU G, CHEN D, LIU R, et al. Antifouling wood matrix with natural water transfer and microreaction channels for water treatment[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(7): 6782-6791. doi: 10.1021/acssuschemeng.8b06060 [35] HAI J, CHEN F, SU J, et al. Porous wood members-based amplified colorimetric sensor for Hg2+ detection through Hg2+-triggered methylene blue reduction reactions[J]. Analytical Chemistry, 2018, 90(7): 4909-4915. doi: 10.1021/acs.analchem.8b00710 [36] WANG Z, LONG F, GAO H, et al. A robust wood-inspired catalytic system for highly efficient reduction of 4-nitrophenol[J]. Chemical Research in Chinese Universities, 2023, 39(1): 109-114. doi: 10.1007/s40242-023-2338-4 [37] WANG Y, SUN G, DAI J, et al. A high-performance, low-tortuosity wood-carbon monolith reactor[J]. Advanced Materials, 2017, 29(2): 1604257. doi: 10.1002/adma.201604257 [38] SHU F, WU J, JIANG G, et al. A hierarchically porous and hygroscopic carbon-based catalyst from natural wood for efficient catalytic reduction of industrial high-concentration 4-nitrophenol[J]. Separation and Purification Technology, 2022, 300: 121823. doi: 10.1016/j.seppur.2022.121823 [39] ZHANG Q, SOMERVILLE R J, CHEN L, et al. Carbonized wood impregnated with bimetallic nanoparticles as a monolithic continuous-flow microreactor for the reduction of 4-nitrophenol[J]. Journal of Hazardous Materials, 2023, 443: 130270. doi: 10.1016/j.jhazmat.2022.130270 [40] KUSADA K, KITAGAWA H. Continuous-flow syntheses of alloy nanoparticles[J]. Materials Horizons, 2022, 9(2): 547-558. doi: 10.1039/D1MH01413G [41] ROBERTS E J, KARADAGHI L R, WANG L, et al. Continuous flow methods of fabricating catalytically active metal nanoparticles[J]. ACS Applied Materials & Interfaces, 2019, 11(31): 27479-27502. doi: 10.1021/acsami.9b07268 [42] XIE Z T, ASOH T A, UETAKE Y, et al. Dual roles of cellulose monolith in the continuous-flow generation and support of gold nanoparticles for green catalyst[J]. Carbohydrate Polymers, 2020, 247: 116723. doi: 10.1016/j.carbpol.2020.116723 [43] XIE Z T, ASOH T A, UYAMA H. Monolithic cellulose supported metal nanoparticles as green flow reactor with high catalytic efficiency[J]. Carbohydrate Polymers, 2019, 214: 195-203. doi: 10.1016/j.carbpol.2019.03.036 [44] XIE Z T, ASOH T A, UYAMA H. Superfast flow reactor derived from the used cigarette filter for the degradation of pollutants in water[J]. Journal of Hazardous Materials, 2020, 400: 123303. doi: 10.1016/j.jhazmat.2020.123303 [45] XIE Z T, ASOH T A, UYAMA H. Facile fabrication of a flow reactor from natural wood[J]. Chemistry Letters, 2020, 49(10): 1232-1235. doi: 10.1246/cl.200466 [46] LI J, MA R, LU Y, et al. Bamboo-inspired design of a stable and high-efficiency catalytic capillary microreactor for nitroaromatics reduction[J]. Applied Catalysis B: Environmentals, 2022, 310: 121297. doi: 10.1016/j.apcatb.2022.121297 [47] KOBAYASHI J, MORI Y, OKAMOTO K, et al. A microfluidic device for conducting gas-liquid-solid hydrogenation reactions[J]. Science, 2004, 304(5675): 1305-1308. doi: 10.1126/science.1096956 [48] LI J, MA R, YAO S, et al. Ultrafine Pd nanoparticles encapsulated in mesoporous TiO2 region selectively confined in bamboo microchannels: An ultrastable continuous-flow catalytic hydrogenation microreactor[J]. Small Structures, 2023, 4(10): 2300137. doi: 10.1002/sstr.202300137 [49] 张慧颖, 于淑艳, 李从举. 高分子聚合物基碳纳米膜的电催化降解污水性能及机制[J]. 化学学报, 2023, 81(4): 420-430.ZHANG Huiyin, YU Shuyan, LI Congju. Electrocatalytic degradation of wastewater by polymer-based carbon nanomembranes and mechanism[J]. Acta Chimica Sinica, 2023, 81(4): 420-430(in Chinese). [50] WI-AFEDZI T, KWON E, TUAN D D, et al. Copper hexacyanoferrate nanocrystal as a highly efficient non-noble metal catalyst for reduction of 4-nitrophenol in water[J]. Science of the Total Environment, 2020, 703: 134781. doi: 10.1016/j.scitotenv.2019.134781 [51] SANKAR M, DIMITRATOS N, MIEDZIAK P J, et al. Designing bimetallic catalysts for a green and sustainable future[J]. Chemical Society Reviews, 2012, 41(24): 8099-8139. doi: 10.1039/c2cs35296f [52] ZHOU J, DUAN B, FANG Z, et al. Interfacial assembly of mussel-inspired Au@Ag@polydopamine core-shell nanoparticles for recyclable nanocatalysts[J]. Advanced Materials, 2014, 26(5): 701-705. doi: 10.1002/adma.201303032 [53] ZHU X, HU J, LIU G, et al. Unique 3D interpenetrating capillary network of wood veneer for highly efficient cross flow filtration[J]. Journal of Materials Science, 2021, 56(4): 3155-3167. doi: 10.1007/s10853-020-05478-6 [54] THOMAS N, DIONYSIOU D D, PILLAI S C. Heterogeneous Fenton catalysts: A review of recent advances[J]. Journal of Hazardous Materials, 2021, 404: 124082. doi: 10.1016/j.jhazmat.2020.124082 [55] XIA H, ZHANG Z, LIU J, et al. Novel Fe-Mn-O nanosheets/wood carbon hybrid with tunable surface properties as a superior catalyst for Fenton-like oxidation[J]. Applied Catalysis B: Environmentals, 2019, 259: 118058. doi: 10.1016/j.apcatb.2019.118058 [56] SHEN Y S, YAO X H, HE C X, et al. A wood-based fluid catalytic reactor with directional channels and porous inner walls for efficient degradation of 4-NP by immobilized laccase[J]. Industrial Crops and Products, 2022, 178: 114589. doi: 10.1016/j.indcrop.2022.114589 [57] ZHANG Z, JIN M, CHEN G, et al. Enzymes immobilized in wood-derived cellulose scaffold for constructing a novel modular bioreactor[J]. Green Chemical Engineering, 2023, 4(1): 39-48. doi: 10.1016/j.gce.2022.03.001 [58] 李小娟, 叶梓瑜, 谢书涵, 等. 氮氯共掺杂多孔碳活化过一硫酸盐降解苯酚的性能及机制研究[J]. 化学学报, 2022, 80(9): 1238-1249.LI Xiaojuan, YE Ziyu, XIE Shuhan, et al. Study on performance and mechanism of phenol degradation through peroxymonosulfate activation by nitrogen/chlorine Co-doped porous carbon materials[J]. Acta Chimica Sinica, 2022, 80(9): 1238-1249(in Chinese). [59] 刘军辉, 郭旭明, 宋亚坤, 等. 催化氨硼烷水解制氢研究进展[J]. 应用化学, 2021, 38(2): 157-169.LIU Junhui, GUO Xuming, SONG Yakun, et al. Recent advances in hydrogen generation by catalytic hydrolysis of ammonia borane[J]. Chinese Journal of Applied Chemistry, 2021, 38(2): 157-169(in Chinese). [60] 尚双, 兰奎, 王艳, 等. 生物质焦油重整催化剂的研究进展[J]. 生物质化学工程, 2020, 54(6): 65-73. doi: 10.3969/j.issn.1673-5854.2020.06.011SHANG Shuang, LAN Kui, WANG Yan, et al. Research progress on catalyst for tar reforming in biomass gasification[J]. Biomass Chemical Engineering, 2020, 54(6): 65-73(in Chinese). doi: 10.3969/j.issn.1673-5854.2020.06.011 [61] XU H, SHEN Z, ZHANG S, et al. Arming wood carbon with carbon-coated mesoporous nickel-silica nanolayer as monolithic composite catalyst for steam reforming of toluene[J]. Journal of Colloid and Interface Science, 2021, 599: 650-660. doi: 10.1016/j.jcis.2021.04.112 [62] FROST C G, MUTTON L. Heterogeneous catalytic synthesis using microreactor technology[J]. Green Chemistry, 2010, 12(10): 1687-1703. doi: 10.1039/c0gc00133c [63] 阮曼, 赵艳霞, 何圣贵. 纳米尺寸氧化钇团簇阴离子与正丁烷反应的研究[J]. 化学学报, 2021, 79(4): 490-499. doi: 10.6023/A20110511RUAN Man, ZHAO Yanxia, HE Shenggui. Study on the reaction of nanosized yttrium oxide cluster anions with n-butane in the gas phase[J]. Acta Chimica Sinica, 2021, 79(4): 490-499(in Chineses). doi: 10.6023/A20110511 [64] DRUVAL S DE SÁ, RODRIGO D A B, CARLOS E R R, et al. Fabrication of lignocellulose-based microreactors: Copper-functionalized bamboo for continuous-flow CuAAC click reactions[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(3): 3267-3273. [65] LACKNER F, LIU H, ŠTIGLIC A D, et al. 3D printed porous nanocellulose-based scaffolds as carriers for immobilization of glycosyltransferases[J]. ACS Applied Bio Materials, 2022, 5(12): 5728-5740. doi: 10.1021/acsabm.2c00763 [66] REN Y, ZHANG L, SUN T, et al. Enzyme immobilization on a delignified bamboo scaffold as a green hierarchical bioreactor[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(19): 6244-6254. doi: 10.1021/acssuschemeng.2c00346 [67] GOLDHAHN C, TAUT J A, SCHUBERT M, et al. Enzyme immobilization inside the porous wood structure: A natural scaffold for continuous-flow biocatalysis[J]. RSC Advances, 2020, 10(35): 20608-20619. doi: 10.1039/C9RA10633B -

下载:

下载: