Effect of SnO2 additive on the electrical contact properties of AgCuOIn2O3 composites

-

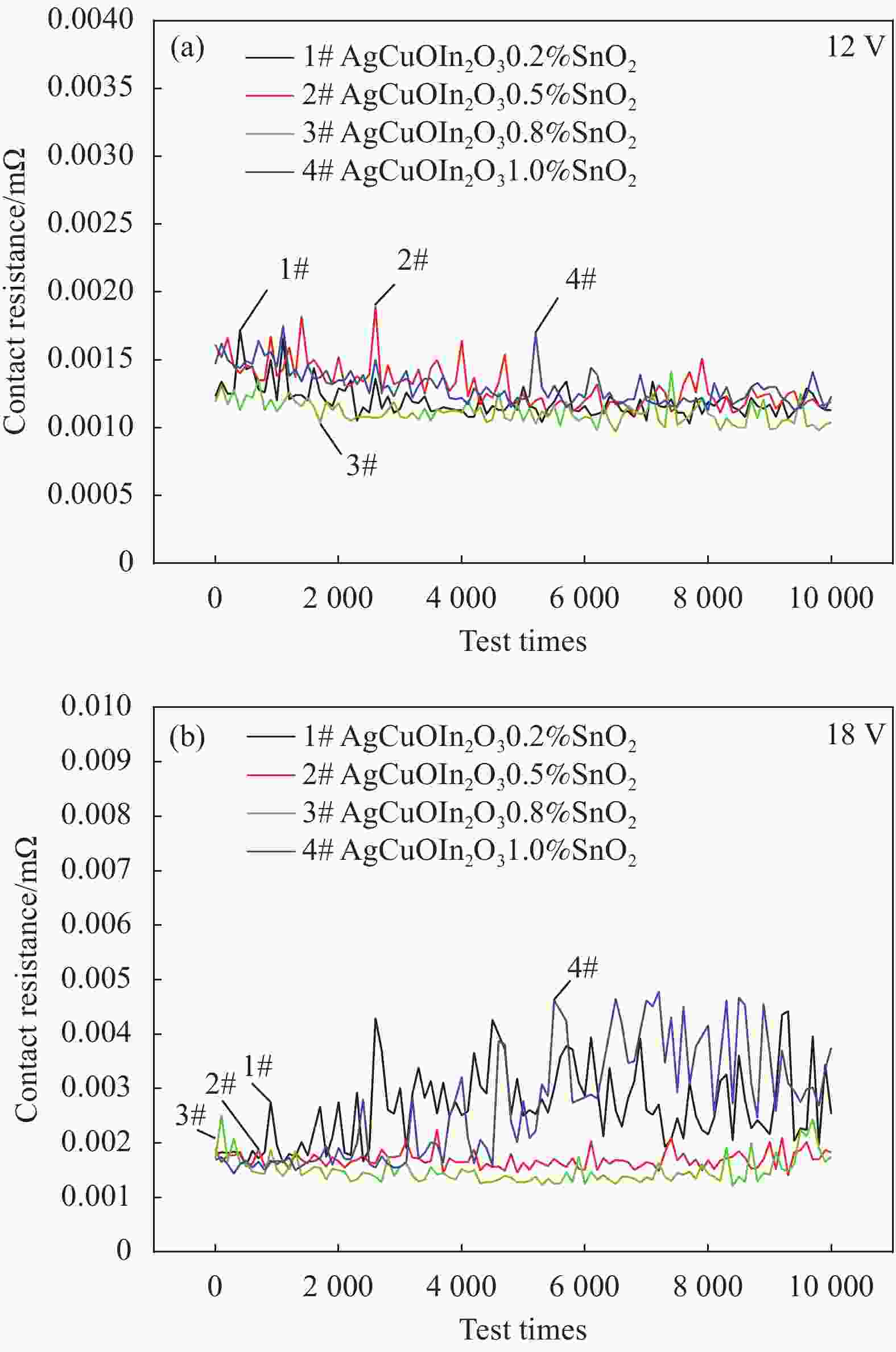

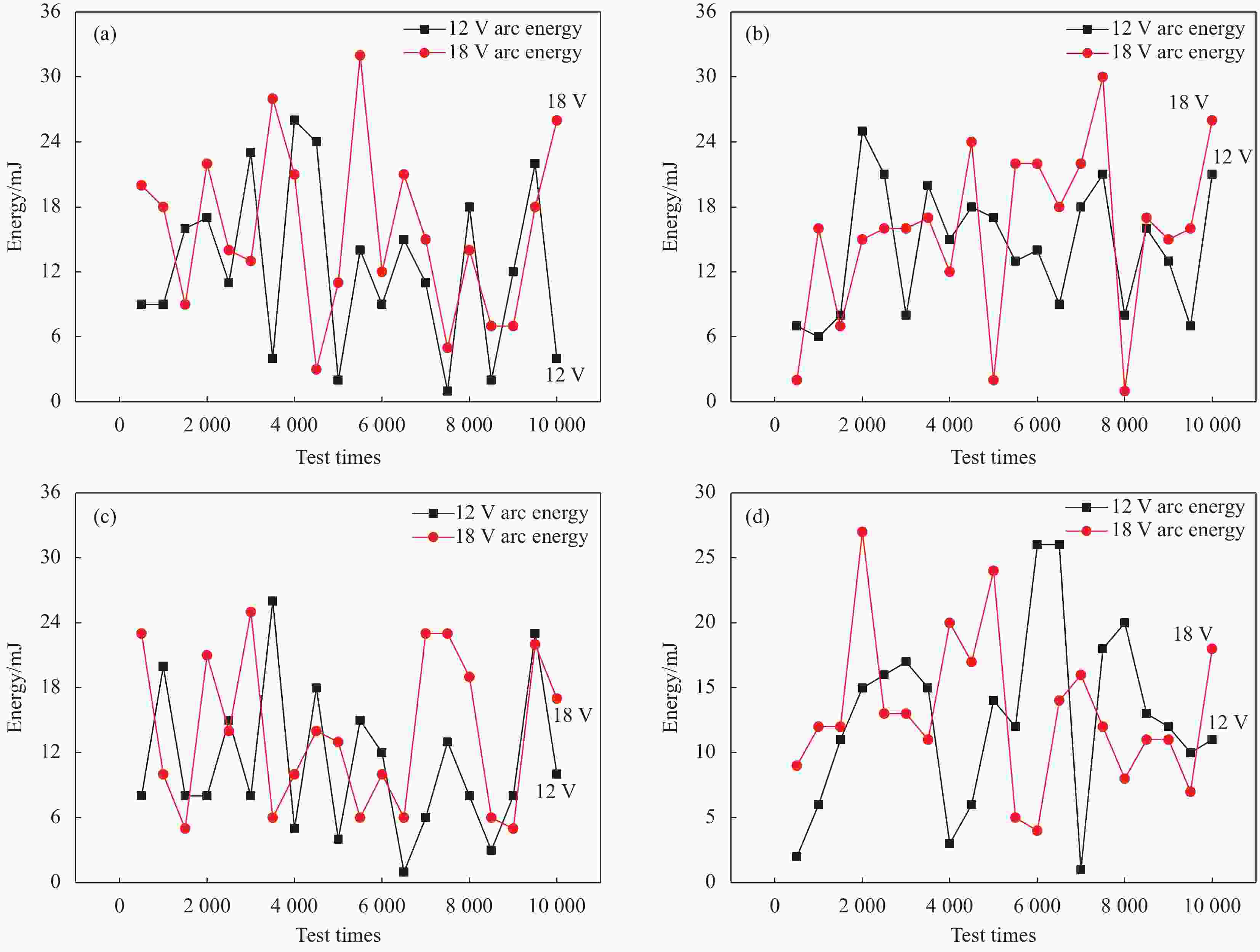

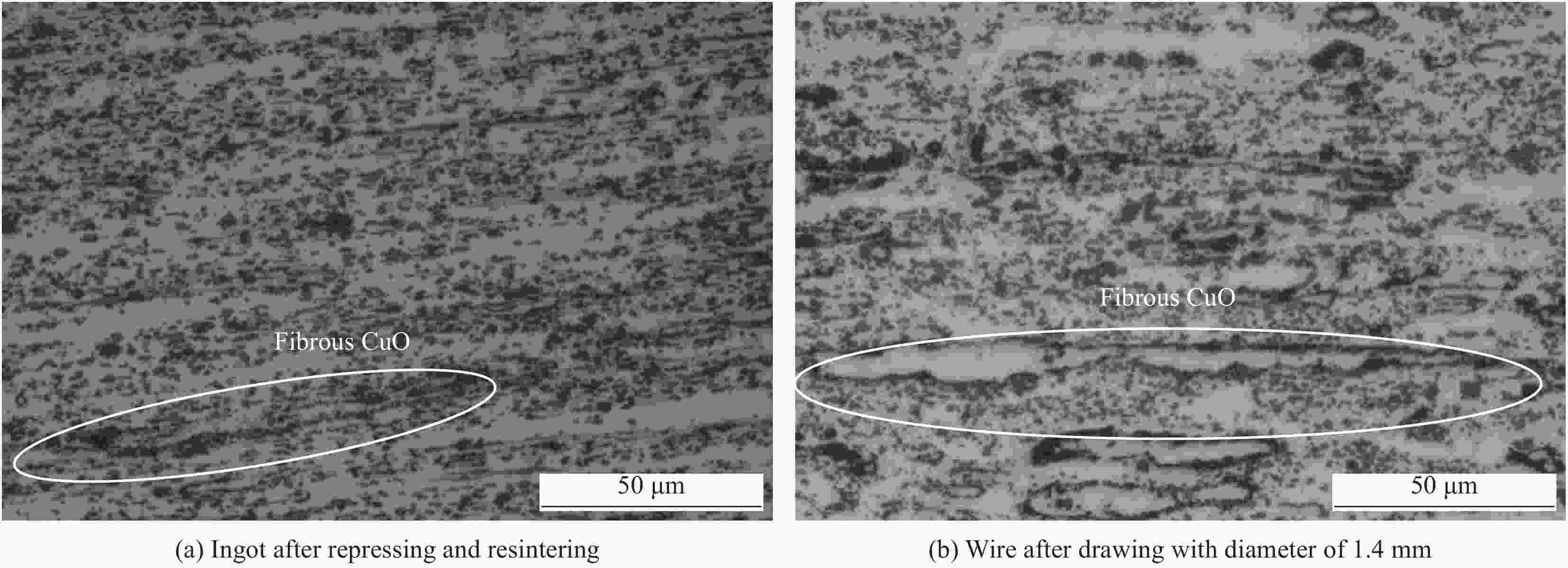

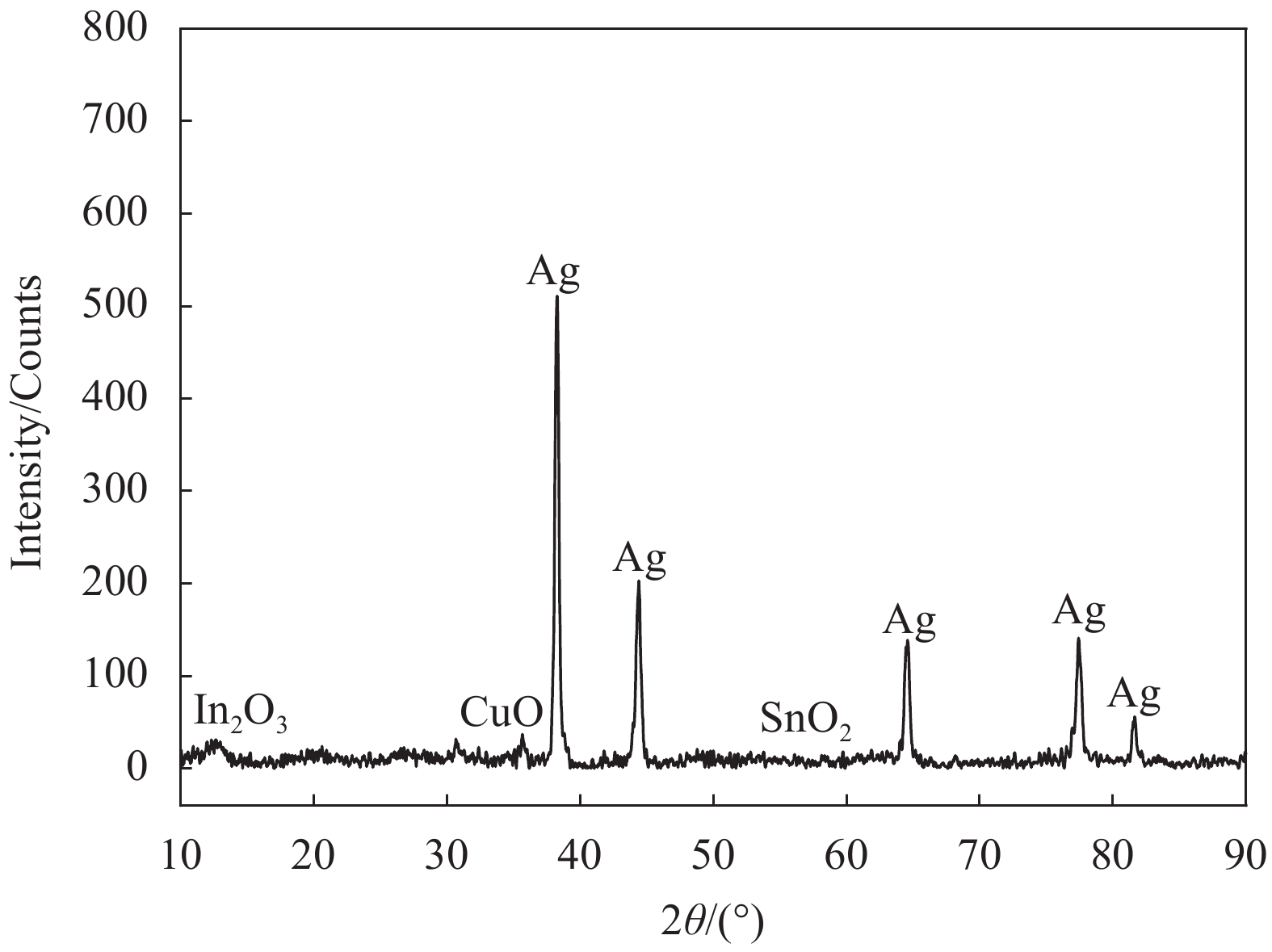

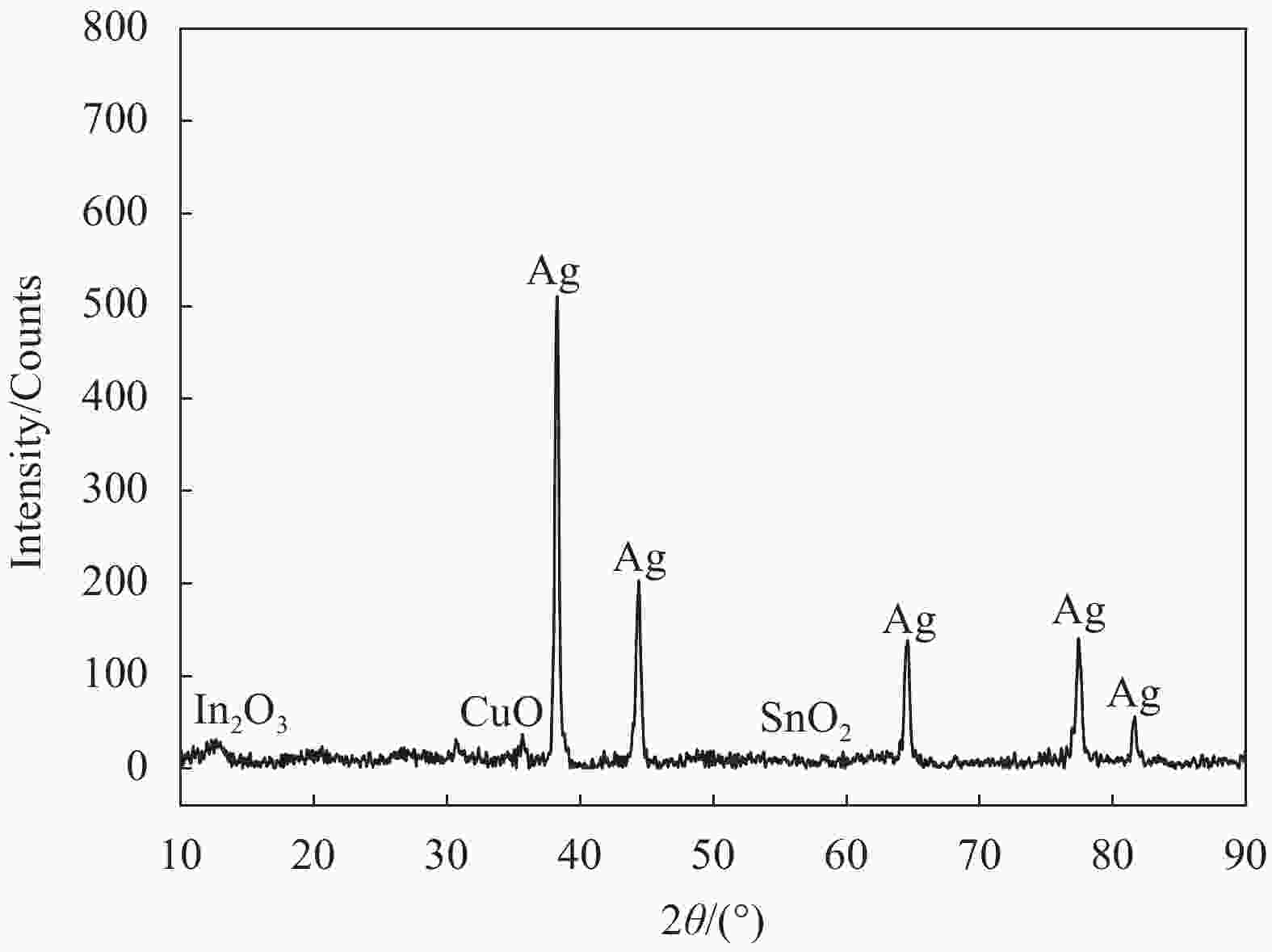

摘要: 采用反应合成法结合塑性变形工艺制备了不同SnO2含量的AgCuOIn2O3SnO2电触头材料,在JF04C触点材料测试机上对不同SnO2含量的电触头材料进行电接触实验,研究了该材料的接触电阻、抗熔焊性和材料转移特性,并通过扫描电镜对试样阴/阳表面电侵蚀下的微观形貌进行了分析。结果表明AgCuOIn2O3SnO2触头材料接触电阻小,当测试电压不超过12 V时,接触电阻随测试次数的增加呈现缓慢下降最后趋于稳定的趋势,当电压增大到18 V时,各试样的接触电阻均增大,且增幅程度不一。对于SnO2含量不变的试样,熔焊力随着测试次数的增加呈现先增大后减小的趋势,材料的燃弧能量随电压的增大而增大,随着测试次数的增加呈锯齿形波动。电接触过程材料主要为阴极转移,材料的损耗量随SnO2量的增多先增大后减小,阴/阳极触头表面呈凸凹状,且表面存在熔融金属液凝固状花样, 材料转移主要以熔桥方式进行,当SnO2含量在0.5wt%~1.0wt%时,电接触性能最为优异。Abstract: The AgCuOIn2O3SnO2 electrical contact materials with different SnO2 content were prepared by the reaction synthesis method combined with the plastic deformation process. Electrical contact experiments were carried out on electrical contact materials with different SnO2 content on the JF04C contact material testing machine, and the contact resistance, welding resistance, and material transfer characteristics of the material were studied. The microscopic morphology under erosion was analyzed. The results show that the contact resistance of AgCuOIn2O3SnO2 contact material is small. When the test voltage does not exceed 12 V, the contact resistance decreases slowly with the increase of the number of tests and finally tends to stabilize. When the voltage increases to 18 V, the contact resistance of each sample is equal increase, and the degree of increase varies. For samples with constant SnO2 content, the welding force first increases and then decreases with the increase of the number of tests. The arcing energy of the material increases with the increase of the voltage, as the number of tests increases, it fluctuates in a zigzag shape. The material in the electrical contact process is mainly cathode transfer, and the loss of the material first increases and then decreases with the increase in the amount of SnO2. The surface of the cathode/anode contacts is convex and concave, and there are molten metal solidification patterns on the surface. The material transfer is mainly carried out by melting bridge, and the electrical contact performance is best when the SnO2 content is 0.5wt%-1.0wt%.

-

图 4 0.2wt% (a)、 0.5wt% (b)和0.8wt% (c)以及1.0wt% (d) SnO2含量的AgCuOIn2O3SnO2电触头材料的燃弧能量与开闭次数的关系

Figure 4. Relationship between the arcing energy of AgCuOIn2O3SnO2 electrical contact material with 0.2wt% (a), 0.5wt% (b), 0.8wt% (c) and 1.0wt% (d) SnO2 content and the number of opening and closing under different voltage conditions

表 1 AgCuOIn2O3SnO2的原材料成分配比(200 g)

Table 1. Raw materials of AgCuOIn2O3SnO2 ingot blank composition proportion (200 g)

Composition CuO/wt% In2O3/wt% SnO2/wt% Ag Powder/g Ag2O Powder/g AgCu20

Powder/gAgIn30

Powder/gAgSn15

Powder/g#1 AgCuOIn2O30.2%SnO2 10 2 0.2 37.474 69.510 79.887 11.028 2.101 #2 AgCuOIn2O30.5%SnO2 10 2 0.5 32.478 71.356 79.887 11.028 5.251 #3 AgCuOIn2O30.8%SnO2 10 2 0.8 27.482 73.201 79.887 11.028 8.402 #4 AgCuOIn2O31.0%SnO2 10 2 1.0 24.152 74.430 79.887 11.028 10.503 表 2 AgCuOIn2O3SnO2电触头材料电接触性能试验参数

Table 2. Test parameters for electrical contact properties of AgCuOIn2O3SnO2 electrical contact materials

Test condition Test parameter Voltage/V 12, 18 Electric current/A 10 Time interval/ms 500 Test times/times 10000 Test interval/times 100 Contact pressure/cN 80 Test method Open and close test Contact distance/mm 1 表 3 AgCuOIn2O30.8%SnO2与AgCuOIn2O3材料的电接触性能数据

Table 3. Electrical contact property data of AgCuOIn2O30.8%SnO2 and AgCuOIn2O3 materials

Test Conditions AgCuOIn2O30.8%SnO2 AgCuOIn2O3 $ \bar{F} $/cN $ \bar{R} $/mΩ Δm/g $ \bar{F} $/cN $ \bar{R} $/mΩ Δm/g 12 V/10 A 3.65 0.00111 0 15.59 0.00103 0.0004 12 V/25 A 7.32 0.00172 0 10.11 0.00116 0.0003 18 V/10 A 4.66 0.00149 0 8.99 0.00246 0.0005 18 V/25 A 7.65 0.00314 0.0001 6.25 0.00227 0.0005 Notes: $ \bar{F} $—Average welding force; $ \bar{R} $—Average contact resistance; Δm—Quality loss. -

[1] THOMAS J, SCHOEPF, VOLKER B, et al. Development of silver zinc oxide for general-purpose relays[C]. 20th International Conference on Electrical Contacts. Stockholm Sweden, 2000. [2] MORIN L, JEMAA N B, JEANNOT D, et al. Contacts materials performances under break arc in automotive applications[J]. Components & Packaging Technologies IEEE Transactions on,2000,23(2):367-375. [3] SLADE P. Electrical contacts- principles and applications, marcel dekker [M]. New York: Basel Inc, 1999. [4] KOSEC L, ROTH J, BIZJAK M, et al. Internal oxidation of an Ag-1.3at%Te alloy[J]. Oxidation of Metals,2001,56(5-6):395-414. [5] LIN X Y, HAO H T, XIE M, et al. Fretting characteristics and environmental reliability of Au-Sn contact pairs[J]. Materials Science Forum,2019,953:115-120. doi: 10.4028/www.scientific.net/MSF.953.115 [6] ZHANG M, WANG X H, ZOU J T, et al. Arc erosion behaviors of AgSnO2 contact materials prepared with different SnO2 particle sizes[J]. Transactions of Nonferrous Metals Society of China,2016,26(3):783-790. doi: 10.1016/S1003-6326(16)64168-7 [7] ZHOU X L, CHEN J C, CAO J C, SUN J L, et al. Process and simulation of severe plastic deformation for AgMeO composites by reactive synthesis[J]. Rare Metal Materials and Engineering,2008(2):223-226. [8] ZHOU X L, CAO J C, CHEN J C, et al. Micro-superplastic behavior of copper oxide in AgCuO composites[J]. Rare Metal Materials and Engineering,2013,42(11):2242-2244. [9] GU J, CHEN J C, YU J, et al. Formation mechanism of SnO2 in AgSnO2 composite fabricated by reactive synthesis[J]. Rare Metal Materials and Engineering,2008(11):1947-1950. [10] 朱艳彩, 王景芹, 安立强, 等. 新型Ag/SnO2/CeO2电器触头材料的制备及其电气性能的研究[J]. 稀有金属材料与工程, 2015, 44(8):2011-2014. doi: 10.2298/SOS1302173CZHU Y C, WANG J Q, AN L Q, et al. Preparation and electrical performance of new Ag/SnO2/CeO2 electrical contact materials[J]. Rare Metal Materials and Engineer,2015,44(8):2011-2014(in Chinese). doi: 10.2298/SOS1302173C [11] 夏静, 雄志, 胡旭高, 等. 添加铟对Ag-CuO电触头材料的影响[J]. 贵金属, 2014, 35(3):35-39.XIA J, XIONG Z, HU X G, et al. Effects of indium addition on the internal oxidation of Ag-CuO alloys[J]. Precious Metals,2014,35(3):35-39(in Chinese). [12] 倪孟良, 凌国平, 刘远廷, 等. 添加剂对AgSnO2复合粉末烧结体组织的影响[J]. 电工材料, 2005(2):7-11. doi: 10.16786/j.cnki.1671-8887.eem.2005.02.002.NI M L, LING G P, LIU Y T, et al. Influences of metal oxide additions on the morphology of sintered AgSnO2 composite powders[J]. Electrical Materials,2005(2):7-11(in Chinese). doi: 10.16786/j.cnki.1671-8887.eem.2005.02.002. [13] 王家真, 王亚平, 杨志懋, 等. CuO添加剂对Ag/SnO2润湿性与界面特性的影响[J]. 稀有金属材料与工程, 2005(3):405-408.WANG J Z, WANG Y P, YANG Z M, et al. Influences of metal oxide additions on the morphology of sintered AgSnO2 composite powders[J]. Rare Metal Materials and Engineering,2005(3):405-408(in Chinese). [14] 周晓龙, 熊爱虎, 刘满门, 等. AgSnO2NiO 电触头材料电接触性能的研究[J]. 稀有金属材料与工程, 2019(9):2885-2892.ZHOU X L, XIONG A H, LIU M M, et al. Electrical contact properties of AgSnO2NiO electrical contact material[J]. Rare Metal Materials and Engineering,2019(9):2885-2892(in Chinese). [15] LI Z G. Research on the structure and properties of AgCuOIn2O3 electrical contact materials [D]. Kunming: Kunming University of Science and Technology, 2019. [16] LI G J, YANG T Y, MA Y Y, et al. The effects of oxide addi-tives the mechanical characteristics of Ag-SnO2 electrical contact materials[J]. Ceramics International,2020,46:851-860. [17] WANG Y P, LI H Y. Improved workability of the nanocomposited AgSnO2 contact material and its microstructure control during the arcing process[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Materials Science,2016,48(2):609-616. [18] WANG H, HUO J, LIU Y, et al. Effects of additives doping on the wettability and contact resistance of Ag-SnO2 contact material[J]. Rare Metal Materials and Engineering,2018,47:672-676. [19] 李进, 马光, 孙晓亮, 等. AgSnO2电接触材料的制备基础与展望[J]. 电工材料, 2011(3):3-9. doi: 10.3969/j.issn.1671-8887.2011.04.001LI J, MA G, SUN X L, WANG Z, et al. Preparation fundamental and outlook of AgSnO2 electrical contact material[J]. Electrical Materials,2011(3):3-9(in Chinese). doi: 10.3969/j.issn.1671-8887.2011.04.001 [20] 于朝清, 刘雪梅, 任小梅, 等. AgSnO2电接触材料制造技术的研究进展[J]. 贵金属, 2014, 35(S1):93-99.YU C Q, LIU X M, REN X M, et al. The research progress of AgSnO2 electrical contact materials manufacturing technology[J]. Precious Metals,2014,35(S1):93-99(in Chinese). [21] WANG J, ZHAO H D, WANG J B, et al. Effect of CuO addi-tives on the formation of SnO2-rich layers in Ag-SnO2 materials[J]. Journal of alloys and compounds,2017,696:1228-1234. doi: 10.1016/j.jallcom.2016.12.092 [22] 谢明, 王松, 付作鑫, 等. AgSnO2电接触材料研究概述[J]. 电工材料, 2013(2):36-39. doi: 10.3969/j.issn.1671-8887.2013.01.010XIE M, WANG S, FU Z X, et al. Research of AgSnO2 electri-cal contact materials[J]. Electrical Materials,2013(2):36-39(in Chinese). doi: 10.3969/j.issn.1671-8887.2013.01.010 [23] 王松, 陈永泰, 杨有才, 等. AgSnO2电接触材料的研究进展[J]. 贵金属, 2013, 34(S1):102-107.WANG S, CHEN Y T, YANG Y C, et al. Research progress of AgSnO2 electrical contact materials[J]. Precious Metals,2013,34(S1):102-107(in Chinese). [24] LIN Z J, SUN X D, LIU S H, et al. Effect of SnO2 particle size on properties of Ag-SnO2 electrical contact materials prepared by the reductive precipitation method[J]. Advanced Materials Research,2014,936:459-463. [25] BRAUMANN P, KOFFLER A. The influence of manufacturing process, metal oxide content, and additives on the switching behavior of Ag/SnO2 in relays[C]//Proceeding of the 50th IEEE Holm Conference on Electrical Contact and the 22nd International Conference on Electrical Contacts. Seattle: IEEE, 2004: 90-97. [26] 陆东梅, 杨瑞霞, 王清周. 掺杂纳米SnO2-Al2O3/Cu新型电触头复合材料的制备及耐磨性能[J]. 复合材料学报, 2016, 33(12):2815-2823.LU D M, YANG R X, WANG Q Z, et al. Fabrication and wear resistances of doped nano-SnO2-Al2O3/Cu novel electrical contact composites[J]. Acta Materiae Compositae Sinica,2016,33(12):2815-2823(in Chinese). -

下载:

下载: