Preparation and self-healing property of phenolic modified epoxy vitrimer

-

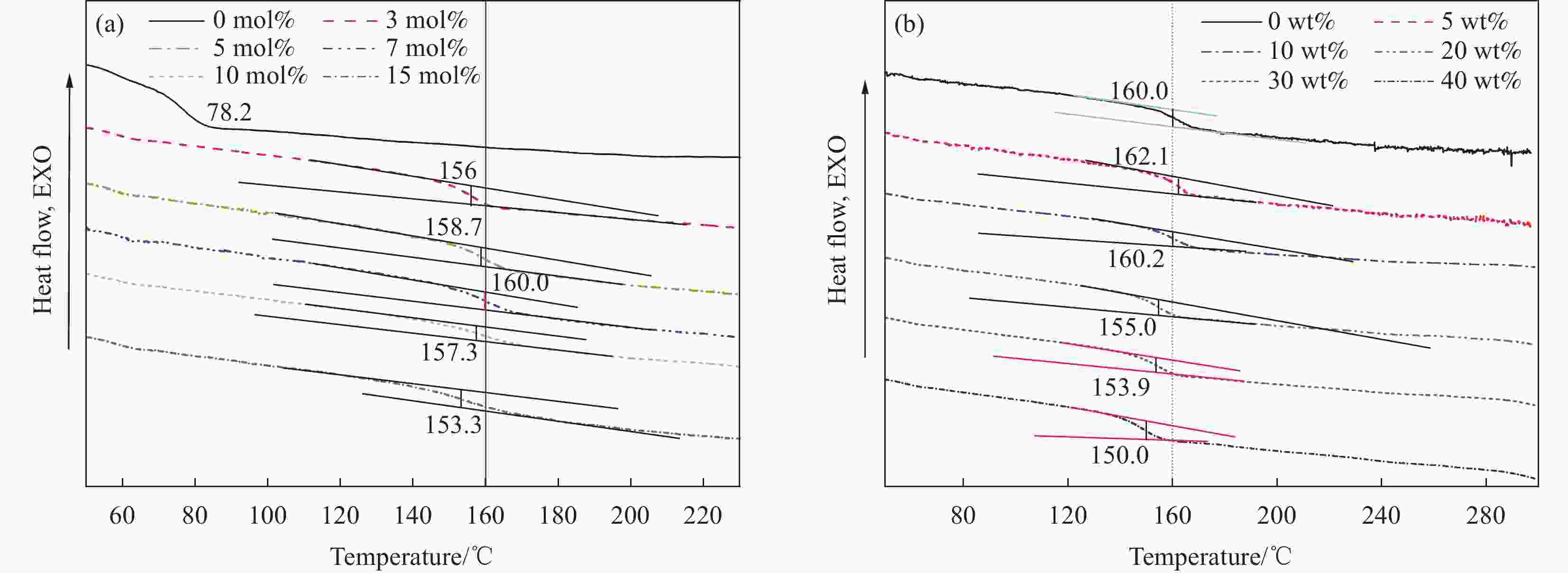

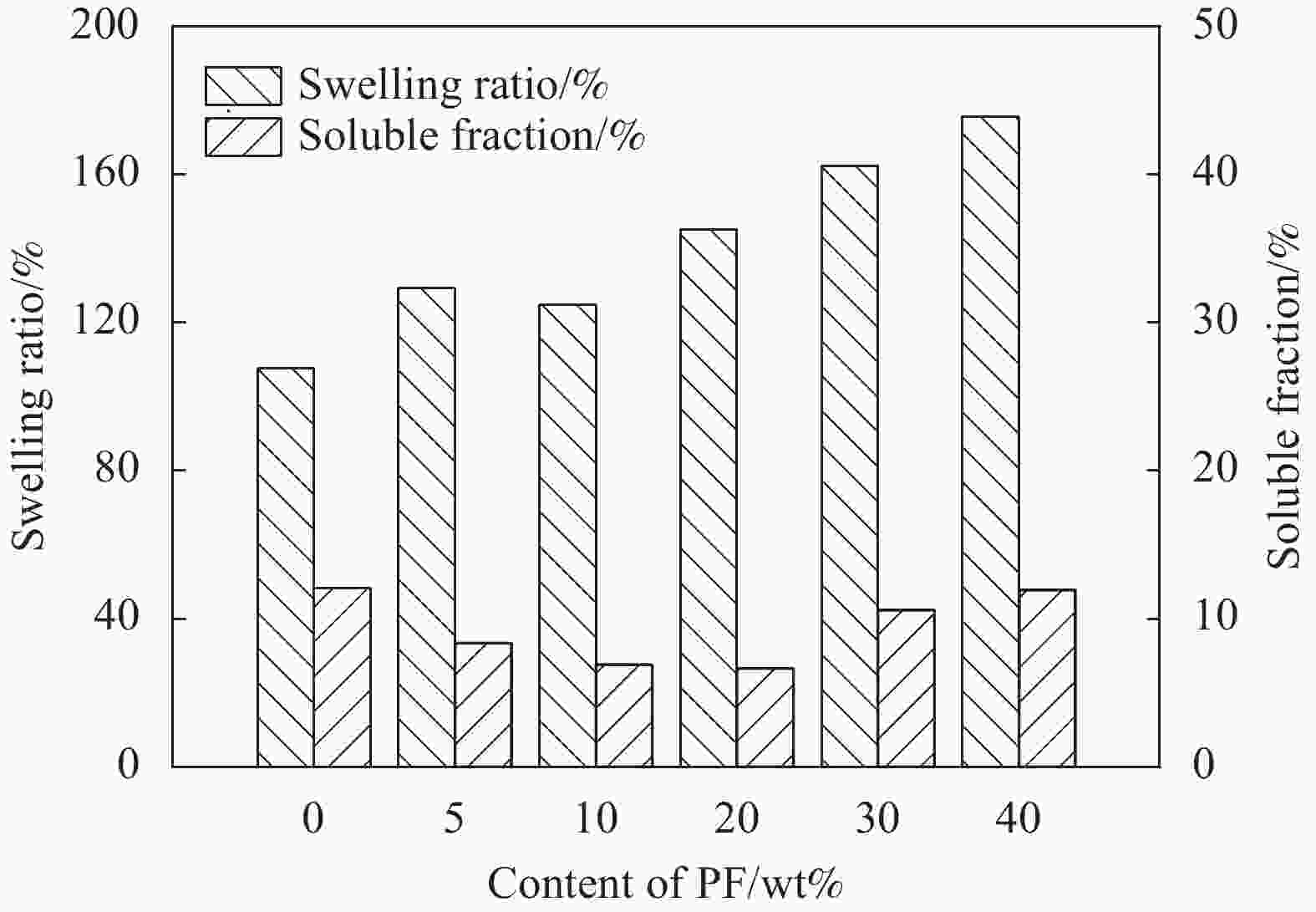

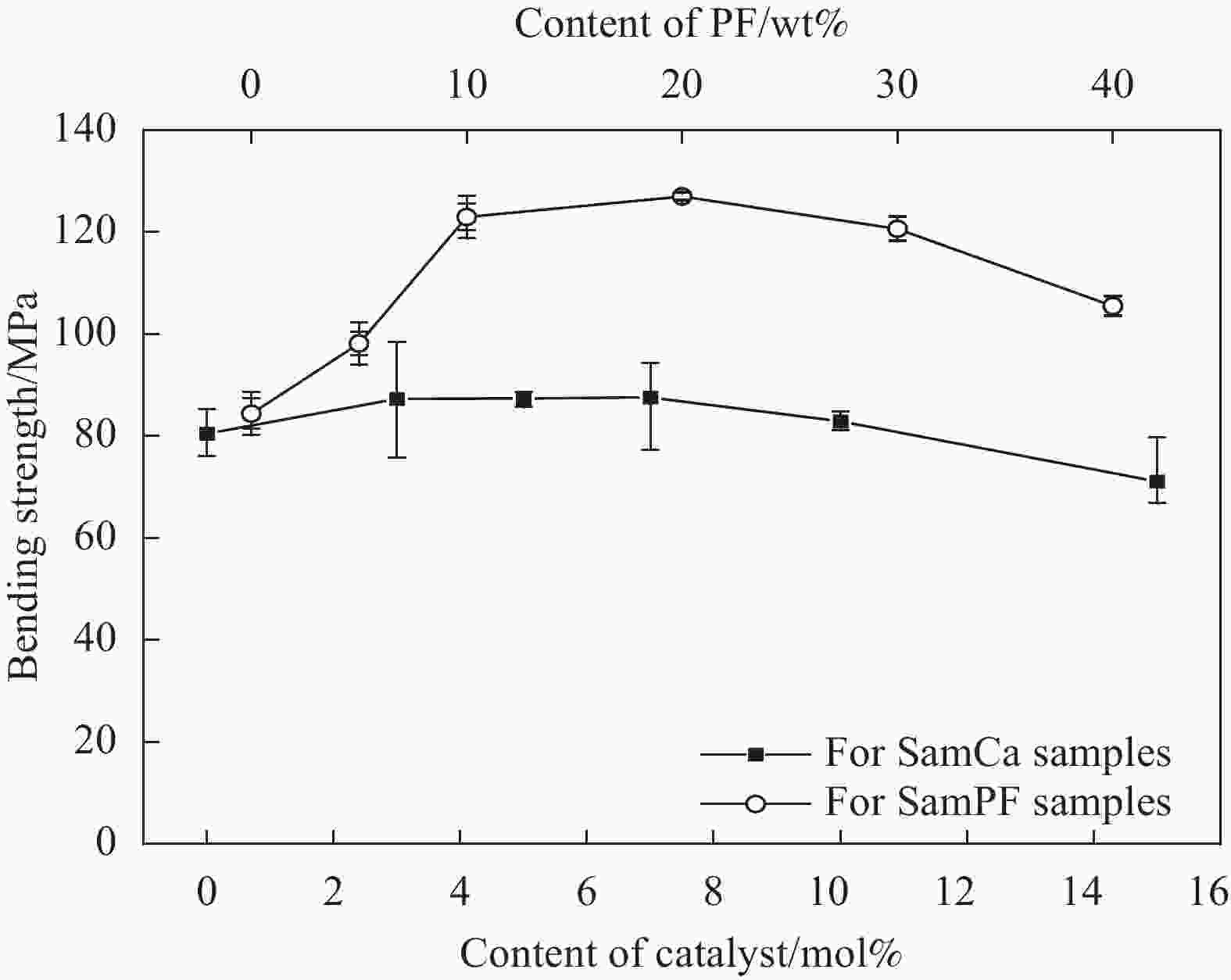

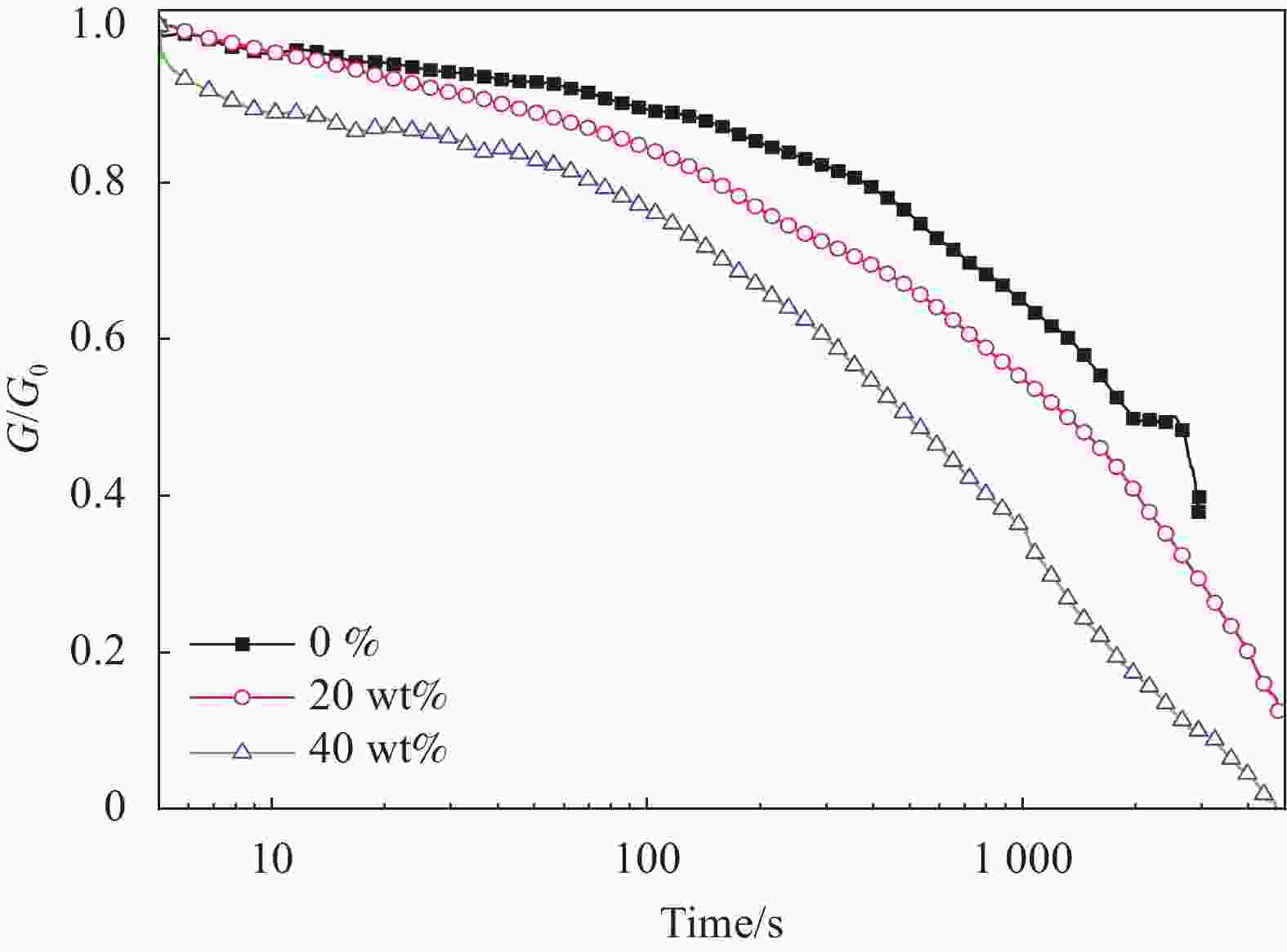

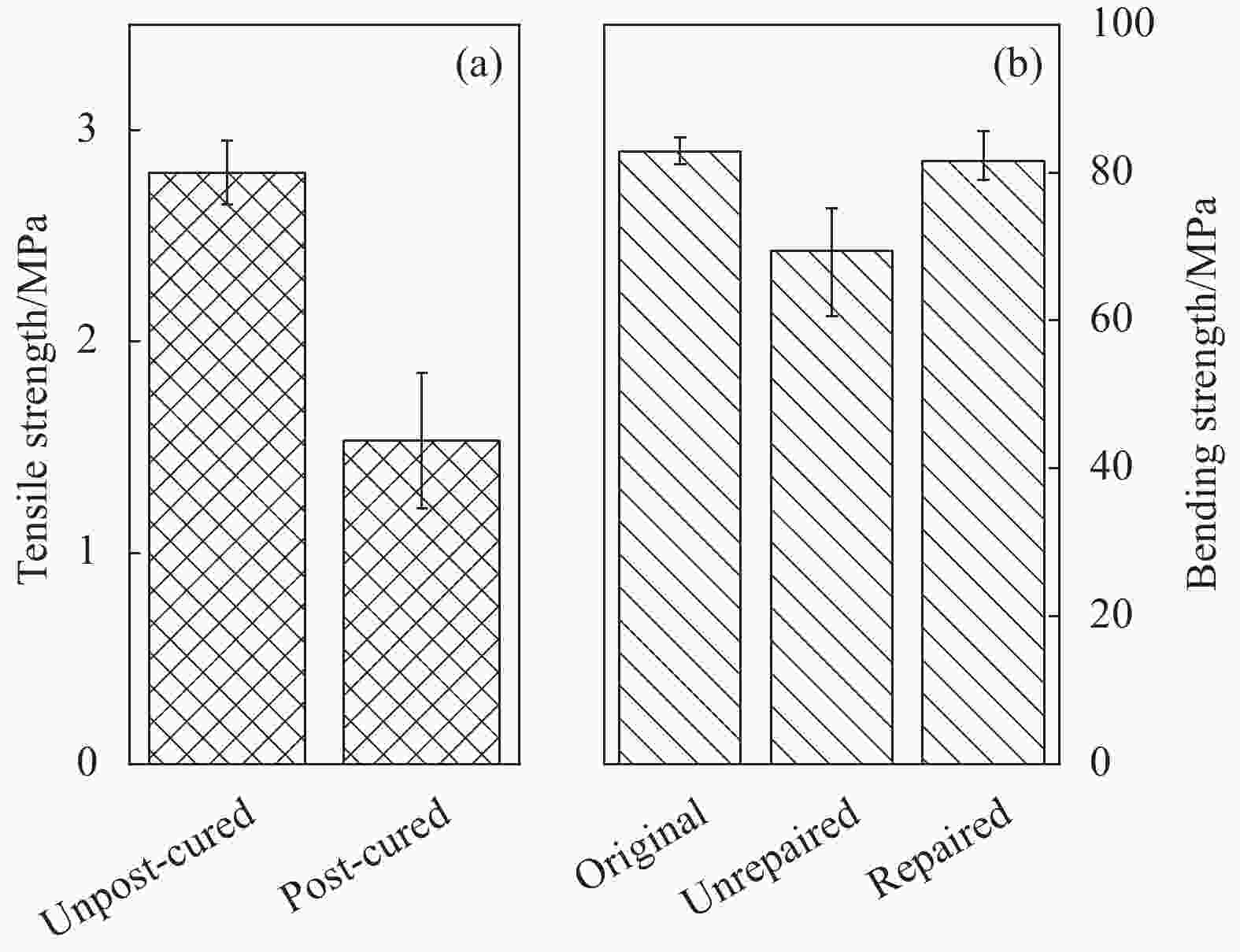

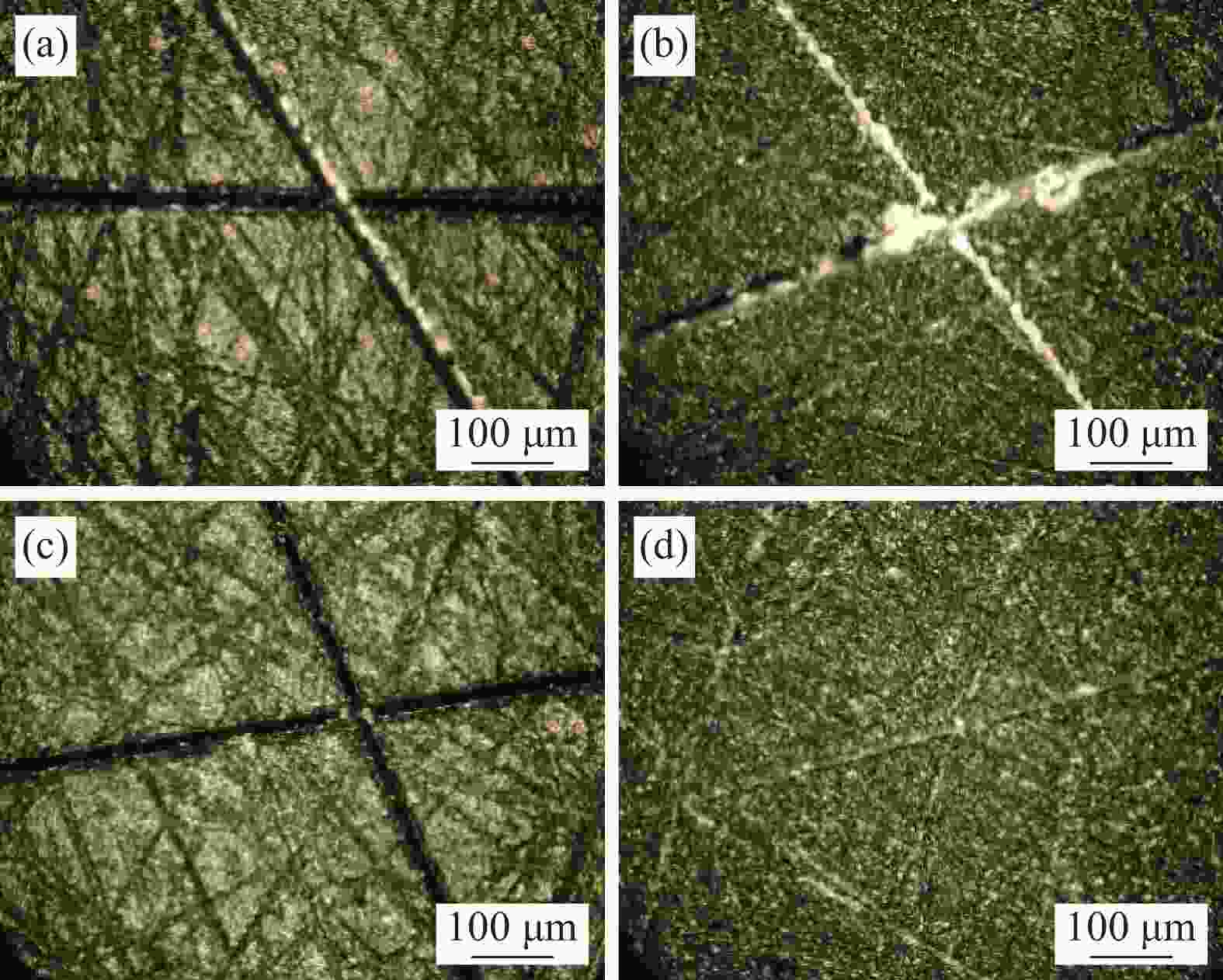

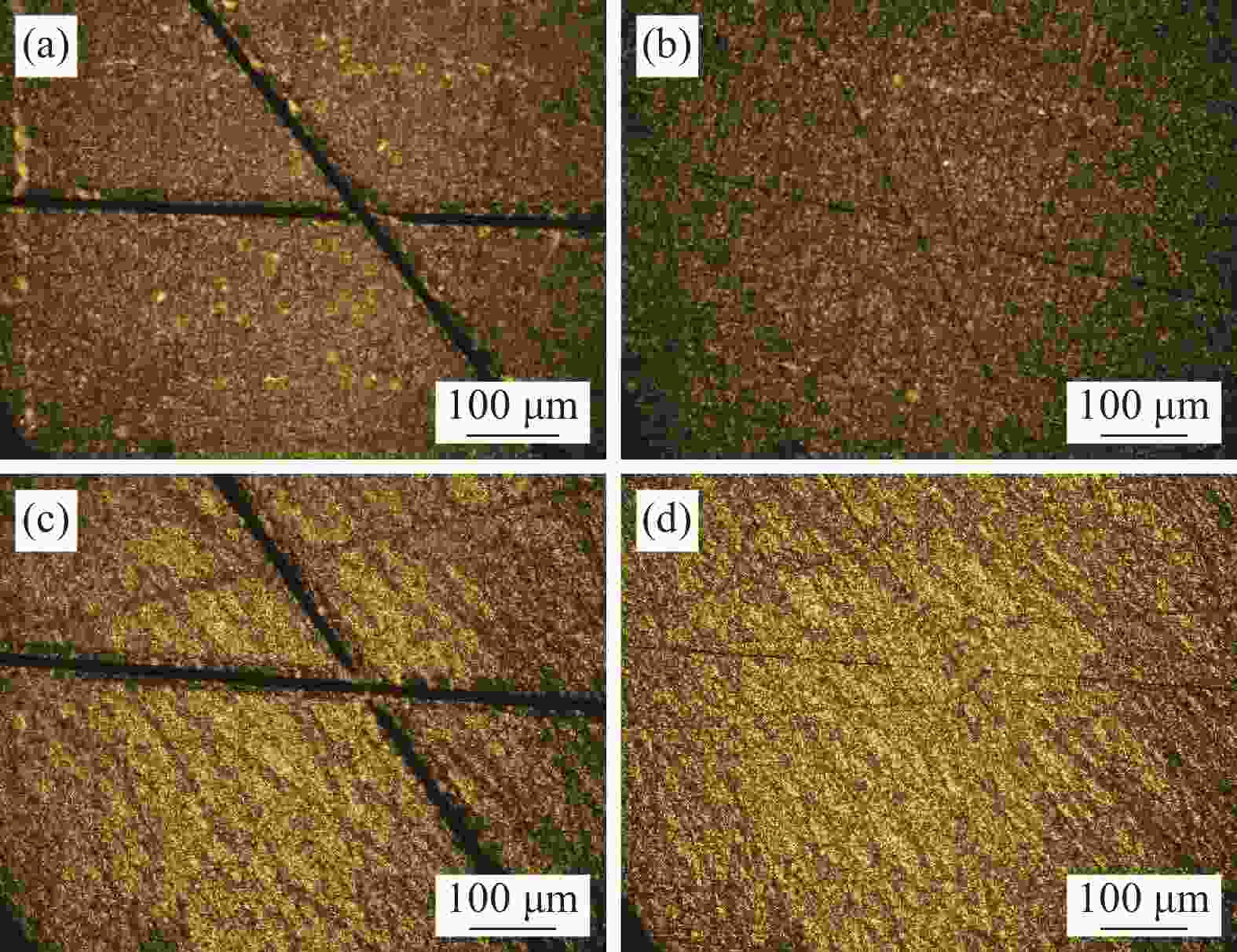

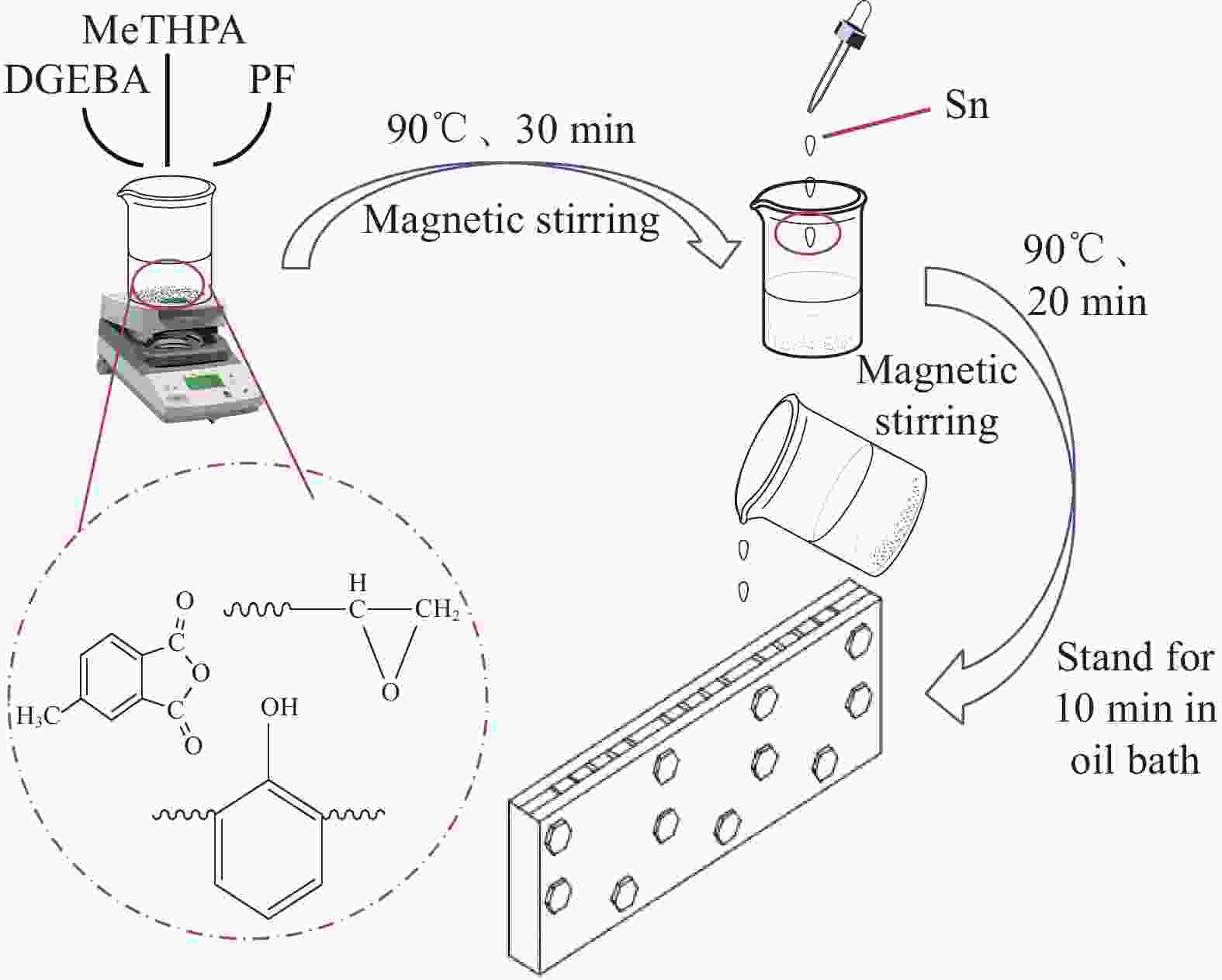

摘要: 类玻璃体(vitrimer)在保持交联的状态下还具有塑性变形能力,意味着传统的热固性树脂具有了二次热加工成型的能力,有效的减少废品率,从源头减少垃圾。利用Vitrimer具有的塑性变形能力也可以进行材料自修复而延长使用寿命,从而对环境保护、减排做出贡献。本文以异辛酸亚锡为催化剂,酚醛树脂为改性剂制备了环氧 vitrimer 材料。研究结果表明,催化剂含量的增加会使体系固化更加完全,所以对材料弯曲强度有一定的改善,最高可达到 87.5 MPa。引入酚醛树脂后弯曲强度由改性前的 87.5 MPa 提高到 126.9 MPa,拉伸强度达 63.3 MPa。但酚醛树脂的加入量过高时,材料的交联密度有所降低,其力学性能在达到顶点后出现下降趋势。对酸酐固化的环氧 vitrimer 体系松弛过程研究表明:增加催化剂含量和提高温度都可以降低材料的松弛时间,但是高温后固化会抑制松弛过程,影响自焊接强度。酚醛改性后材料的应力松弛明显快于纯酸酐固化的环氧试样。10%催化剂试样在180 ℃至190 ℃松弛速率产生一个突变,190 ℃明显的加快,而酚醛的引入则可以将突变温度Ts提前到180 ℃。在无压力条件下,样品可以实现划痕的修复。在松弛的突变温度以上修复的试样剪切强度和划痕修复效果明显提高。相对未加酚醛样品,酚醛改性样品修复效果更好。催化剂对试样修复强度和修复速度有明显影响。

-

关键词:

- 环氧类玻璃体(vitrimer) /

- 自修复 /

- 松弛行为 /

- 酚醛 /

- 回收利用

Abstract: Vitrimer can undergo plastic deformation while maintaining a cross-linked state, which means that traditional thermosetting resins have the ability to undergo secondary thermal processing and molding, which will effectively reduce scrap rates and reduce waste from the beginning. The plastic deformation of vitrimer can also endow item self-healing ability and extended its service life, and so contribute to environmental protection and emission reduction. In the paper stannous iso-octanoate as a catalyst and phenolic resin as a modifier was used to prepare anhydride cured epoxy vitrimer materials. The research results indicate that the increase in catalyst content could make the system cure more completely, so there is a certain improvement in the bending strength of the material, up to 87.5 MPa. With introduction of phenolic resin, the bending strength increases from 87.5 MPa before modification to 126.9 MPa, and the tensile strength reaches 63.3 MPa. When the amount of phenolic resin added is too high, the crosslinking density of the material decreases, and the mechanical properties of the material show a downward trend. The study on the relaxation behavior of the epoxy vitrimer system cured with pure anhydride shows that increasing the catalyst content reduces the relaxation time of the materials, but the post curing reaction at high temperature could inhibit the relaxation process and suppress the self-welding strength. The stress relaxation of epoxy vitrimer material modified with phenolic resin is significantly faster than that of epoxy vitrimer system cured with pure anhydride. The relaxation of the samples with 10% catalyst shows a sudden change, and there is a significant acceleration when the temperature rises to 190 ℃, and the introduction of phenolic resin could advance the sudden change temperature Ts to 180 ℃. Under no pressure conditions, scratches are repaired. The tensile shear strength and scratches repair effect of the samples repaired above Ts are significantly improved. Compared to samples without phenolic resin, phenolic modified samples could be repaired better. Catalyst have a significant impact on the repair strength and repair speed of the samples.-

Key words:

- Epoxy vitrimer /

- self-healing /

- mechanical relaxation behavior /

- phenolic resin /

- recycling

-

图 9 (a) SamCa试样的环氧基团残留量(□)及不同温度下试样拉伸剪切强度随催化剂含量的变化,(b) SamPF系列试样在170℃下自焊接30 min的拉伸剪切强度(□),以及SamPF 20试样拉伸剪切强度随温度的相对变化(◊)

Figure 9. Residue epoxy groups of SamCa samples (□) and their tensile shear strength vs. content of catalyst at various temperature (a), tensile shear strength vs content of phenolic resin for SamPF samples welded at 170℃ for 30 min (□) and tensile shear strength vs temperature for SamPF 20 sample (◊)

表 1 试样固化后环氧基团残余量

Table 1. Residue epoxy groups of the cured samples

Catalyst percent in SamCas/mol% 0 3 5 7 10 15 Residual epoxy groups in SamCas/% 11.2 9.9 8.3 6.4 6.2 7.6 Phenolic percent in SamPFs/wt% 0 5 10 20 30 40 Residual epoxy groups in SamPFs/% 7.9 3.8 6.9 5.1 4.4 4.0 表 2 SamPF 系列试样的拉伸力学性能

Table 2. Tensile strength of the SamPF series samples

Phenolic percent/wt% Tensile strength/

MPaElongation at break/% Modulus/

GPa0 54.4±5.5 4.5±0.4 1.1±0.12 25 58.5±4.3 5.7±0.9 1.2±0.03 10 62.3±1.1 6.1±0.3 1.1±0.06 20 63.3±0.6 6.0±0.5 1.3±0.27 30 63.0±1.3 6.2±0.7 1.2±0.22 40 59.3±3.3 6.1±0.4 1.1±0.12 表 3 试样不同温度下多次焊接的热焊接强度

Table 3. Welding strength of the samples repeated welded under different temperature

Welding times Tensile shear strength/MPa 1 2 3 4 5 SamPF 20 170℃ 1.8 1.6 1.4 1.1 1.1 190℃ 2.0 1.6 1.2 1.4 1.3 210℃ 2.2 2.1 2.0 1.8 2.0 SameCa 10 180℃ 2.4 1.3 0.9 0.7 -- -

[1] PATEL K. K. AND PUROHIT R. Future pro -spects of shape memory polymer nano-composite and epoxy based shape memory polymer-a review[J]. Materials Today:Proceedings, 2018, 5(9): 20193-20200. doi: 10.1016/j.matpr.2018.06.389 [2] MONTARNAL D. , CAPELOT M. , TOURN -ILHAC F. , LEIBLER L. Silica-like malleable materials from permanent organic networks[J]. Science. 2011, 334(6058): 965-968. [3] CAPELOT M. , UNTERLASS M. M. , TOURNILHA -C F. , LEIBLER L. Catalytic control of the vitrimer glass transition[J]. ACS Macro. Letters, 2013, 1(7): 789–792. [4] CAPELOT M. , MONTARNAL D. , TOURNILHAC F. , LEIBLER L. Metal-catalyzed transesterification for healing and assembling of thermosets[J]. J. Am. Chem. Soc. , 2012, 134(18): 7664-7667. [5] WINNE J. M. , LEIBLER L. , DU PREZ F. E. Dynamic covalent chemistry in polymer networks: a mechanistic perspective[J]. Polym. Chem. , 2019, 10(45): 6091-6108. [6] DENISSEN W. , DROESBEKE M. , NICOLAŸ R. , LEIBLER L. , WINNE J. M. , DU PREZ F. E. Chemical control of the viscoelastic properties of vinylogous urethane vitrimers[J]. Nat. Comun. , 2017, 8: 14857. [7] CHEN Z. , SHI Q. , KUANG X. , QI H. J. , WANG T. Ultrastrong intrinsic bonding for thermoset composites via bond exchange reactions[J]. Composites Part B, 2020, 194: 108054. [8] AZCUNE I, ELORZA E, RUIZ DE LUZURIAGA A, HUEGUN A, REKONDO A, GRANDE H-J. Analysis of the effect of network structure and disulfide concentration on vitrimer properties[J]. Polymers, 2023, 15(20): 4123. doi: 10.3390/polym15204123 [9] 杨伟明, 席澳千, 杨斌, 曾艳宁. 基于多重动态共价键的环氧类玻璃网络的制备与性能[J]. 高等学校化学学报, 2022, 43(11): 20220308YANG Weiming, XI Aoqian, YANG Bin, ZENG Yanning. Fabrication and properties of epoxy vitri-mer based on multiply dynamic covalent bonds[J]. Chem. J. Chinese Universities, 2022, 43(11): 20220308(in Chinese). [10] LUO Zhaoyi, YANG Bin, LIU Fanqi, PAN Xianjie, and ZENG Yanning. Recoverable rosin-based epoxy vitrimers with robust mechanical properties and high thermostability[J]. ACS Applied Polymer Materials, 2023, 5(10): 8670-8678. doi: 10.1021/acsapm.3c01373 [11] LUO Chumeng, WANG Weichao, YANG Wei, LIU Xingyu, LIN Jun, Zhang Liqun, and HE Shaojian. High-strength and multi-recyclable epoxy vitrimer containing dual-dynamic covalent bonds based on the disulfide and imine bond metathesis[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(39): 14591-14600. [12] DENISSEN W. , WINNE J. M. , DU PREZ F. E. Vitrimers: Permanent organic networks with glass-like fluidity[J]. Chem. Sci. , 2016, 7(1): 30–38. [13] YANG Yang, XU Yanshuang, JI Yan, WEI Yen. Functional epoxy vitrimers and composites[J]. Progress in Materials Science, 2021, 120: 100710. doi: 10.1016/j.pmatsci.2020.100710 [14] GUERRE M. , TAPLAN C. , WINNE J. M. , DU PREZ F. E. Vitrimers: directing chemical reactivity to control material properties[J]. Chem. Sci. , 2020, 11(18): 4855-4870. [15] LUO J. , DEMCHUK Z. , ZHAO X. , SAIT -OT. , TIAN M. , SOKOLOV A. P. , CAO P. F. Elastic vitrimers: Beyond thermoplastic and thermoset elastomers[J]. Matter, 2022, 5 (5): 1391-1422. [16] ZHANG Ze Ping, RONG Min Zhi, ZHANG Ming Qiu. Polymer engineering based on reversible covalent chemistry: A promising innovative pathway towards new materials and new functionalities[J]. Progress in Polymer Science, 2018, 80: 39-93. doi: 10.1016/j.progpolymsci.2018.03.002 [17] BRUTMAN J. P. , DELGADO P. A. , HILLMYER M. A. Polylactide vitrimers[J]. ACS Macro Letters, 2014, 3(7): 607-610. [18] YAN P. , ZHAO W. , FU X. , LIU Z. , KONG W. , ZHOU Z. M. , LEI J. X. Multifunctional polyurethane-vitrimers completely based on transcarbamoylation of carbamates: thermally-induced dual-shape memory effect and self-welding[J]. RSC Advances, 2017, 7(43): 26858-26866. [19] DENISSEN W. , RIVERO G. , NICOLAŸ R. , LEIBLER L. , WINNE J. M. , PREZ F. E. D. Vinylogous urethane vitrimers[J]. Adv. Funct. Mater. , 2015, 25(16): 2451-2457. [20] De LUZURIAG A. R. , MARTIN R. , MARKAIDE N. , REKONDO A. , CABANERO G. , RODRIGUEZ J. , ODRIOZOLA I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites[J]. Mater. Horizons, 2016, 3(3): 241-247. [21] SCHENK, V. , D’ELIA R. , OLIVIER, P. , LABASTIE, K. , DESTARAC, M. , GUERRE, M. Exploring the limits of high-Tg epoxy vitrimers produced through resin-transfer molding[J]. ACS Appl. Mater. Interfaces, 2023, 15(39): 46357−46367. [22] WU X. , YANG X. , YU R. , ZHAO X. J. , ZHANG Y. , HUANG W. A Facile access to stiff epoxy vitrimers with excellent mechanical properties via siloxane equilibration[J]. J. Mater. Chem. A, 2018, 6(22): 10184-10188. [23] HAN J. R. , LIU T. , HAO C. , ZHANG S. , GUO B. H. , ZHANG J. W. A Catalyst-free epoxy vitrimer system based on multifunctional hyperbranched polymer[J]. Macro-molecules, 2018, 51(17): 6789-6799. [24] VAIDYULA R. R. , DUGAS P. Y. , RAWSTRON E. , BOURGEATLAMI E. , MONTARN A D. Improved malleability of miniemulsion-based vitrimers through in situ generation of carboxylate surfactants[J]. Polym. Chem. , 2019, 10(23): 3001-3005. [25] SANGALETTI D. , CESERACCIU L. , MARINI L. , ATHANASSIOU A. , ZYCH A. Biobased boronic ester vitrimer resin from epoxidized linseed oil for recyclable carbon fiber composites[J]. Resources, Conservation and Recycling, 2023, 198: 107205. [26] MACIEJ PODGÓRSKI, FAIRBANKS B. D. , KIRKPATRICK B. E. , MCBRIDE M. , MARTINEZ A, DOBSON A. , BONGIARDINA N. J, BOWMAN C. N. Toward stimuli-responsive dynamic thermosets through continuous development and improvements in covalent adaptable networks (CANs)[J]. Adv. Mater. , 2020, 32(20): 1906876. [27] LIU W. , SCHMIDT D. F. , and REYNAUD E. Catalyst selection, creep, and stress relaxation in high-performance epoxy vitrimers[J]. Ind. Eng. Chem. Res. , 2017, 56(10): 2667-2672. [28] SCHEUTZ G. M. , LESSARD J. J. , SIMS M. B. , and SUMERLIN B. S. Adaptable crosslinks in polymeric materials: resolving the intersection of thermoplastics and thermosets[J]. J. Am. Chem. Soc. , 2019, 141(41): 16181-16196. [29] CAPELOT M. , UNTERLASS M. M. , TOURNILHAC F. , and LEIBLER L. Catalytic control of the vitrimer glass transition[J]. ACS Macro. Lett. , 2012, 1(7): 789-792. [30] 中国国家标准化管理委员会. 塑料弯曲性能的测定: GB/T 9341-2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Plastics-determination of flexural properties: GB/T 9341-2008[S]. Beijing: China Standards Press, 2005(in Chinese). [31] YANG Y. , PENG G R. , WU S. , HAO W G. A Repairable anhydride-epoxy system with high mechanical properties inspired by vitrimers[J]. Polymer, 2018, 159: 162-168. [32] FENG Yang, NIE Zhuguang, CHEN Jinqiu, GONG Kaijie, SHAN Yiyi, DONG Fanghong, FAN Xiao-dong, and QI Shuhua. Tuning the dynamic properties of epoxy vitrimers via bioinspired polymer–nanoparticle bond dynamics[J]. ACS Macro Letters, 2023, 12(9): 1201-1206. doi: 10.1021/acsmacrolett.3c00406 -

点击查看大图

点击查看大图

计量

- 文章访问数: 133

- HTML全文浏览量: 55

- 被引次数: 0

下载:

下载: