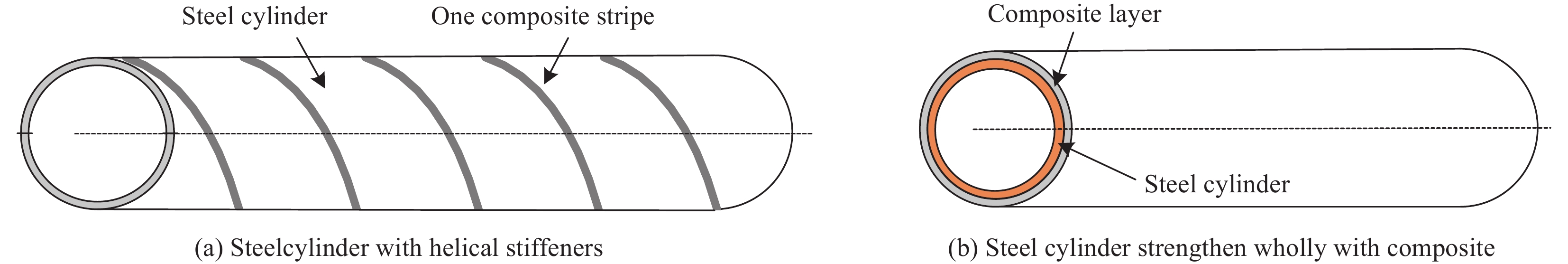

Buckling of metallic cylindrical shells stiffened with helical CFRP stripes

-

摘要: 为开展碳纤维增强树脂复合材料螺旋加强金属柱壳屈曲特性理论研究,建立了复合材料螺旋加强金属柱壳的复材层局部包裹面积比与厚度比数学关系,推导了金属内衬复材螺旋缠绕多层耐压壳抗压极限载荷理论模型。其次,开展了线性屈曲及非线性屈曲分析,并与试验结果对比分析。最后,根据推导的理论模型,形成了该类型全尺寸柱壳适用水深图谱。结果表明:插值法分析中数值分析与理论计算值的误差随复合材料包裹面积比增加而减小,最大误差为5.2%,最小误差为0.9%;试验模型中理论计算与数值分析、试验结果误差分别为3.20%、3.46%,三者具有良好一致性;内衬金属层厚度一定时,螺旋包裹适当复合材料带可适应水深范围较广,该应用对水下管路原位加强、深水管再利用等方面提供新思路。

-

关键词:

- 碳纤维增强树脂复合材料 /

- 柱壳 /

- 屈曲理论模型 /

- 有限元 /

- 螺旋肋

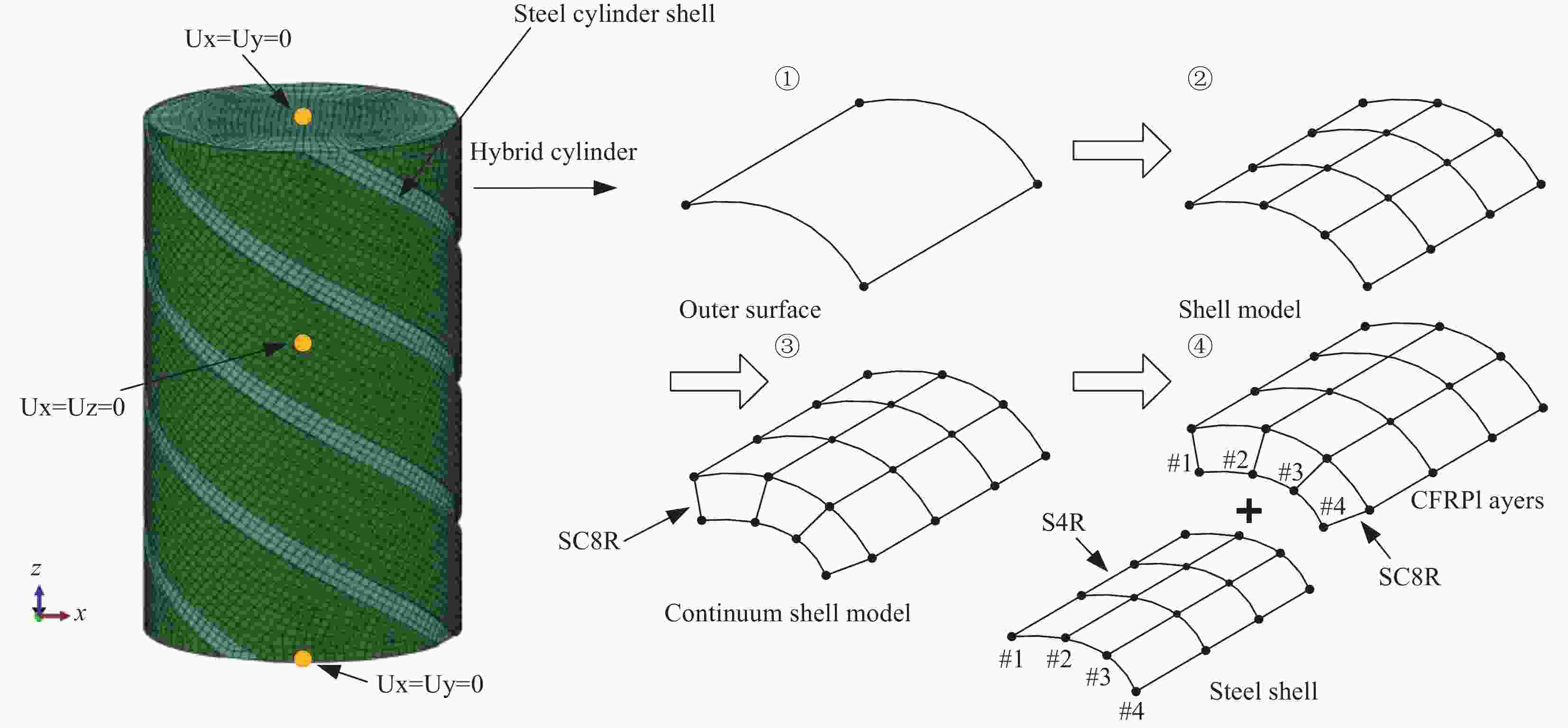

Abstract: Buckling of metallic cylindrical shells stiffened with helical composite stripes was investigated in the current study. A mathematical relationship between area ratio and thickness ratio of composite layer for externally pressurized metallic cylinder stiffened with helical composite stripes was proposed. An analytical formula for collapse load of such hybrid structure was derived. Numerical analysis and experimental verification were conducted. Furthermore, depth chart for full-scale hybrid cylinder was designed using analytical formulae. The results indicate that the maximum and minimum difference between numerical and theoretical results obtained using interpolation method are 5.2% and 0.9%, respectively. The theoretical, numerical and experimental data for samples agree favorably. The difference between theoretical and numerical results is 3.20%; The difference between theoretical and experimental results is 3.46%. Metallic cylindrical shells stiffened with multiple helical composite stripes is satisfy for a wide range of depths. Composite stripe stiffeners have vast potential for application in installed and reusable tubes.-

Key words:

- CFRP /

- cylindrical shell /

- theoretical model of buckling /

- finite element analysis /

- helical stiffener

-

表 1 碳纤维增强树脂复合材料属性

Table 1. Material properties of CFRP composites provided by the manufacturer

Strength /MPa XT 1400.09 Young’s modulus /GPa E11 115 XC 580.06 E22 7.7 YT 44.36 G12 3.72 YC 133.03 G13 3.72 S12 45.04 Poisson’s ratio v12 0.33 S13 45.04 表 2 复合材料螺旋加强与全包裹组合柱壳屈曲载荷值

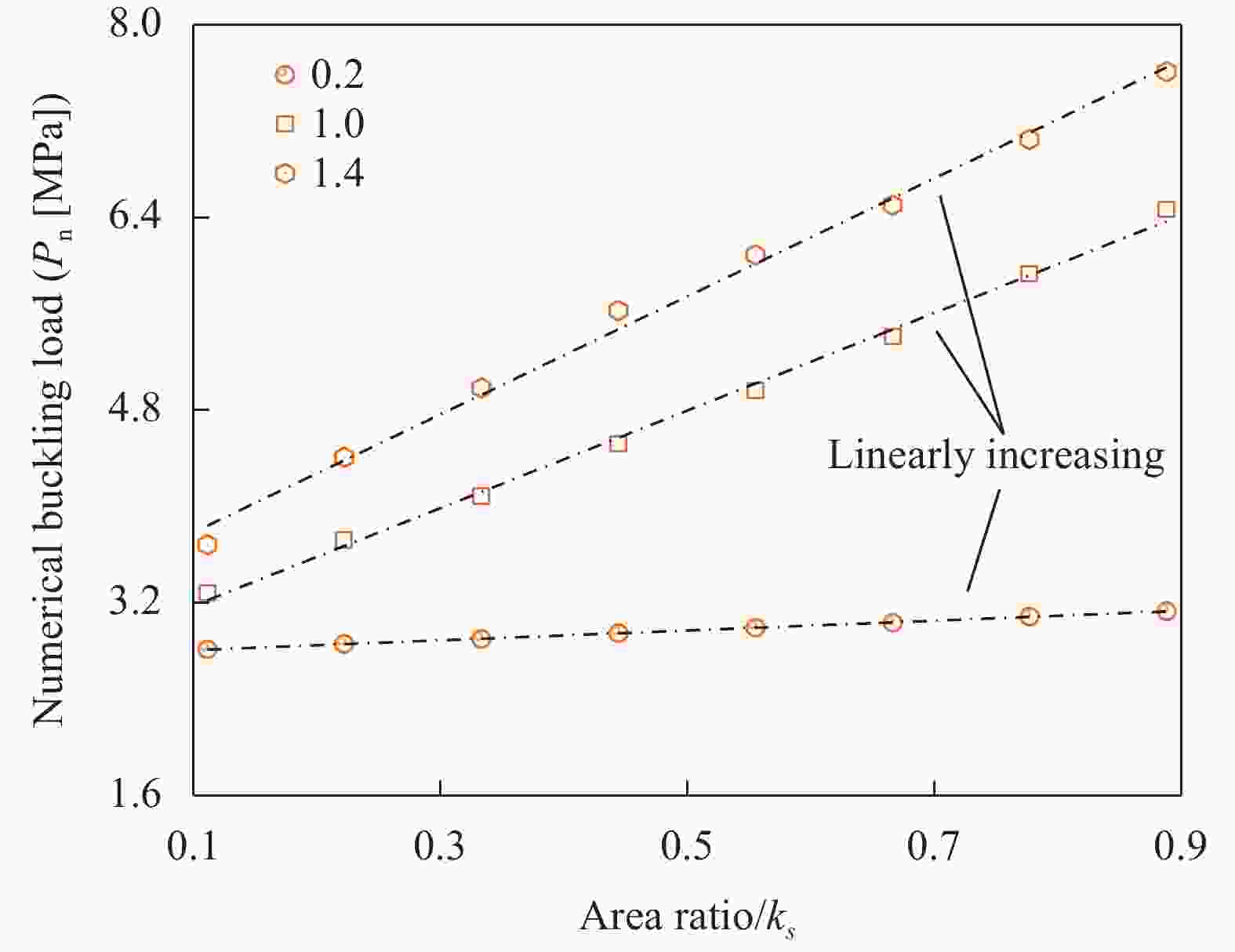

Table 2. Buckling loads of the hybrid cylinders and steel cylinders with helical stiffeners

Sample Thickness ratio PW-N/

MPal/R Area ratio PH-N/

MPaPH-N/

PW-N1 tc/ts=0.2 3.205 0.1 0.111 2.813 0.878 2 0.2 0.222 2.859 0.892 3 0.3 0.333 2.898 0.904 4 0.4 0.444 2.948 0.920 5 0.5 0.555 2.993 0.934 6 0.6 0.666 3.034 0.947 7 0.7 0.777 3.085 0.963 8 0.8 0.888 3.130 0.977 9 tc/ts=1.0 7.438 0.1 0.111 3.280 0.441 10 0.2 0.222 3.720 0.500 11 0.3 0.333 4.084 0.549 12 0.4 0.444 4.519 0.608 13 0.5 0.555 4.959 0.667 14 0.6 0.666 5.410 0.727 15 0.7 0.777 5.933 0.798 16 0.8 0.888 6.464 0.869 17 tc/ts=1.4 9.934 0.1 0.111 3.683 0.371 18 0.2 0.222 4.410 0.444 19 0.3 0.333 4.985 0.502 20 0.4 0.444 5.626 0.566 21 0.5 0.555 6.089 0.613 22 0.6 0.666 6.503 0.655 23 0.7 0.777 7.048 0.709 24 0.8 0.888 6.610 0.766 Notes: PW-N—Numerical buckling load of steel cylinder strengthen wholly with composite; PH-N—Numerical buckling load of steel cylinder with helical stiffeners; tc—Thickness of composite layer; ts—Thickness of steel layer; l—Width of composite stripes; R—Outer radius of inner steel layer. 表 3 拟合系数

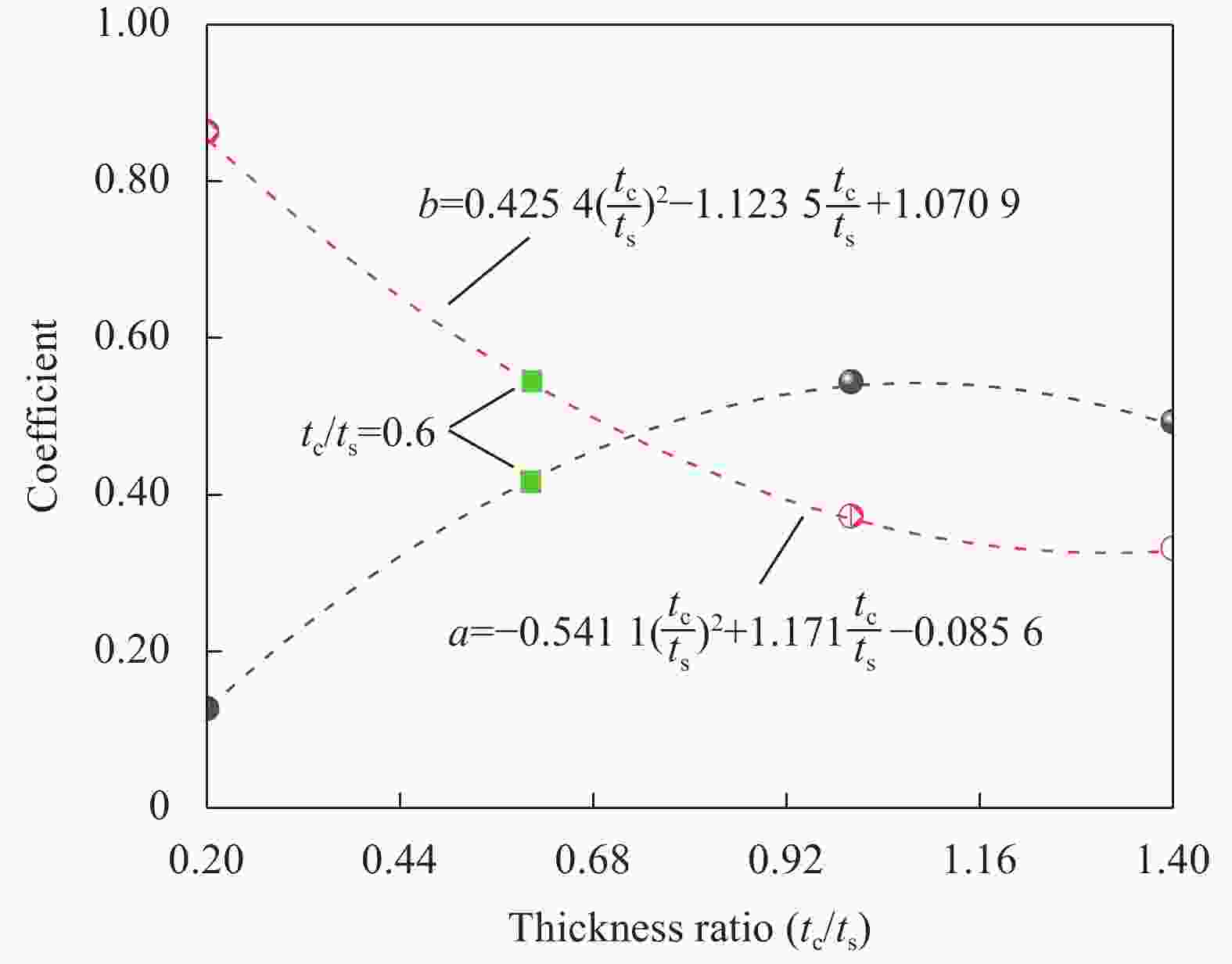

Table 3. Fitting parameters

Sample tc/ts a b 1 0.2 0.127 0.863 2 1 0.544 0.373 3 1.4 0.493 0.332 Notes: tc=Thickness of composite layer; ts=Thickness of steel layer; a, b=Coefficient of linear function. 表 4 拟合系数求解的螺旋加强载荷值(与全包裹载荷比值)(tc/ts=0.6)

Table 4. Buckling loads of helical stiffened cylinders obtained using fitting parameters (ratio of calculated values to one of hybrid cylinders) (tc/ts=0.6)

Sample l/R Area ratio PH-T/PW-T PH-T/MPa PH-N/MPa Difference (%) 1 0.1 0.111 0.597 2.832 2.988 5.2 2 0.2 0.222 0.644 3.055 3.192 4.3 3 0.3 0.333 0.691 3.277 3.365 2.6 4 0.4 0.444 0.737 3.500 3.570 2.0 5 0.5 0.555 0.784 3.722 3.775 1.4 6 0.6 0.666 0.831 3.945 3.981 0.9 7 0.7 0.777 0.878 4.167 4.216 1.2 8 0.8 0.888 0.925 4.390 4.433 1.0 Notes: PH-T—Theoretical solution for buckling load of steel cylinder with helical stiffeners. 表 5 碳纤维增强树脂复合材料螺旋加强金属柱壳载荷数值结果\理论值\试验结果

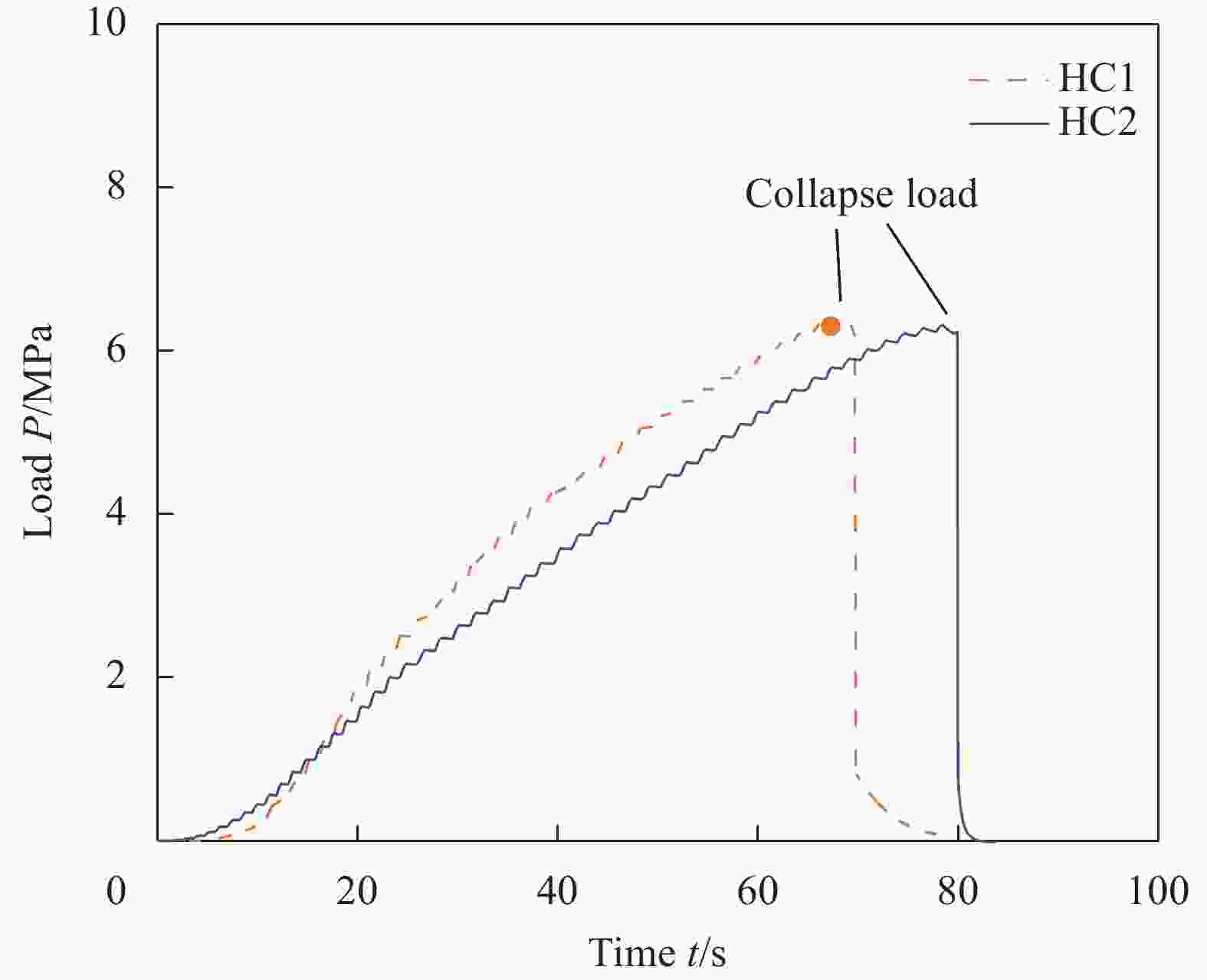

Table 5. Numerical, theoretical and experimental results of the fabricated metallic cylindrical shells stiffened with helical CFRP stripes; the ratio of calculated value to experimental value is indicated in parentheses

Sample Ptest (MPa) Pnon (MPa) PCH (MPa) Difference(%) HC1 6.018 6.109 (1.015) 5.932 (0.970) 3.46 HC2 6.214 6.094 (0.981) Notes: Ptest—Experimental results of the fabricated sample; Plinear—Linear buckling load of steel cylinder strengthen wholly with composite; Pnon—Non-linear buckling load of steel cylinder with helical stiffeners; PCH—Theoretical solution for buckling load of the fabricated sample; Difference (%) = [(6.018+6.214)/2-5.932]/5.932. 表 6 复材螺旋加强金属柱壳前20阶模态及特征值

Table 6. First 20 linear eigenvalues (MPa) and eigenmodes of cylinder stiffened with helical composite stripes

NO. 1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th Pliner 5.823 5.856 8.028 8.035 9.912 9.912 14.056 14.058 14.266 14.275 Mode

NO. 11th 12th 13th 14th 15th 16th 17th 18th 19th 20th Pliner 15.031 15.032 16.630 16.633 19.082 19.086 20.602 20.641 21.861 21.862 Mode

Notes: Plinear—Linear buckling load. -

[1] MAGNUCKI K, JASION P, RODAK M. Strength and buckling of an untypical dished head of a cylindrical pressure vessel[J]. International Journal of Pressure Vessels and Piping, 2018, 161: 17-21. doi: 10.1016/j.ijpvp.2018.02.003 [2] MAGNUCKI K, LEWINSKI J, CICHY R. Strength and buckling problems of dished heads of pressure vessels—contemporary look[J]. Journal of Pressure Vessel Technology, Transactions of the ASME, 2018, 140(4): 041201. [3] BŁACHUT J. Buckling of cylinders with imperfect length[C]//Paris: Proceedings of the ASME 2013 Pressure Vessels and Piping Conference, 2013: 1-9. [4] BŁACHUT J. Experimental perspective on the buckling of pressure vessel components[J]. Applied Mechanics Reviews, 2014, 66(1): 010803. [5] BŁACHUT J, MAGNUCKI K. Strength, stability, and optimization of pressure vessels: Review of selected problems[J]. Applied Mechanics Reviews, 2008, 61(1-6): 0608011-06080133. [6] ROSS C T F. Pressure vessels[M]. Philadelphia: Woodhead Publishing Limited, 2011. [7] KHAMLICHI A, BEZZAZI M, LIMAM A. Buckling of elastic cylindrical shells considering the effect of localized axisymmetric imperfections[J]. Thin-Walled Structures, 2004, 42(7): 1035-1047. doi: 10.1016/j.tws.2004.03.008 [8] FATEMI S M, SHOWKATI H, MAALI M. Experiments on imperfect cylindrical shells under uniform external pressure[J]. Thin-Walled Structures, 2013, 65: 14-25. doi: 10.1016/j.tws.2013.01.004 [9] IFAYEFUNMI O, FADZULLAH S H S M. Buckling behaviour of imperfect axially compressed cylinder with an axial crack[J]. International Journal of Automotive and Mechanical Engineering, 2017, 14(1): 3837-3848. doi: 10.15282/ijame.14.1.2017.3.0313 [10] BŁACHUT J. Buckling of axially compressed cylinders with imperfect length[J]. Computers and Structures, 2010, 88(5-6): 365-374. doi: 10.1016/j.compstruc.2009.11.010 [11] JASION P, MAGNUCKI K. Elastic buckling of Cassini ovaloidal shells under external pressure - Theoretical study[J]. Archives of Mechanics, 2015, 67(2): 179-192. [12] ZHANG J, WANG W M, CUI W C, et al. Buckling of longan-shaped shells under external pressure[J]. Marine Structures, 2018, 60: 218-225. doi: 10.1016/j.marstruc.2018.04.002 [13] ZHANG J, WANG W M, WANG F, et al. Elastic buckling of externally pressurized Cassini oval shells with various shape indices[J]. Thin-Walled Structures, 2018, 122: 83-89. doi: 10.1016/j.tws.2017.10.008 [14] TANG W X, ZHANG S, ZHANG J, et al. Experimental study on the failure modes of circumferentially corrugated cylinders under external hydrostatic pressure[J]. Thin-Walled Structures, 2020, 156: 106988. doi: 10.1016/j.tws.2020.106988 [15] MALINOWSKI M, BELICA T, MAGNUCKI K. Buckling and post-buckling behaviour of elastic seven-layered cylindrical shells - FEM study[J]. Thin-Walled Structures, 2015, 94: 478-484. doi: 10.1016/j.tws.2015.05.017 [16] SHOKRZADEH A R, SOHRABI M R. Strengthening effects of spiral stairway on the buckling behavior of metal tanks under wind and vacuum pressures[J]. Thin-Walled Structures, 2016, 106: 437-447. doi: 10.1016/j.tws.2016.05.023 [17] CHO S R, DO Q T, SHIN H K. Residual strength of damaged ring-stiffened cylinders subjected to external hydrostatic pressure[J]. Marine Structures, 2017, 56: 186-205. doi: 10.1016/j.marstruc.2017.08.005 [18] CHO S R, MUTTAQIE T, DO Q T, et al. Experimental investigations on the failure modes of ring-stiffened cylinders under external hydrostatic pressure[J]. International Journal of Naval Architecture and Ocean Engineering, 2018, 10(6): 711-729. doi: 10.1016/j.ijnaoe.2017.12.002 [19] SHIOMITSU D, YANAGIHARA D. Elastic local shell and stiffener-tripping buckling strength of ring-stiffened cylindrical shells under external pressure[J]. Thin-Walled Structures, 2020, 148: 106622. doi: 10.1016/j.tws.2020.106622 [20] WANG X S, LI P N, WANG R Z. Study on hydro-forming technology of manufacturing bimetallic CRA-lined pipe[J]. International Journal of Machine Tools and Manufacture, 2005, 45(4-5): 373-378. doi: 10.1016/j.ijmachtools.2004.09.015 [21] WANG Y, YANG L, BAI B, et al. Evaluation of limit deformation behavior in hydro-bulging of the double-layer sheet metal using diffuse and localized instability theories[J]. International Journal of Mechanical Sciences, 2019, 150: 145-153. doi: 10.1016/j.ijmecsci.2018.10.027 [22] CARVELLI V, PANZERI N, POGGI C. Buckling strength of GFRP under-water vehicles[J]. Composites Part B:Engineering, 2001, 32(2): 89-101. doi: 10.1016/S1359-8368(00)00063-9 [23] ÖZBEK Ö. Axial and lateral buckling analysis of kevlar/epoxy fiber-reinforced composite laminates incorporating silica nanoparticles[J]. Polymer Composites, 2021, 42(3): 1109-1122. doi: 10.1002/pc.25886 [24] DAVIES P, CHOQUEUSE D, BIGOURDAN B, et al. Composite cylinders for deep sea applications: An overview[J]. Journal of Pressure Vessel Technology, Transactions of the ASME, 2016, 138(6): 060904. [25] WEI R F, PAN G, JIANG J, et al. An efficient approach for stacking sequence optimization of symmetrical laminated composite cylindrical shells based on a genetic algorithm[J]. Thin-Walled Structures, 2019, 142: 160-170. doi: 10.1016/j.tws.2019.05.010 [26] KARBHARI V M, SEIBLE F. Fiber reinforced composites - advanced materials for the renewal of civil infrastructure[J]. Applied Composite Materials, 2000, 7(2): 95-124. [27] CHOQUEUSE D, BIGOURDAN B, DEUFF A. Hydrostatic compression behaviour of steel-composite hybrid tubes[J]. ICCM International Conferences on Composite Materials, 2009. [28] ZUO X L, ZHANG J, TANG W X, et al. Buckling behavior of steel and steel – composite cylinders under external pressure[J]. Thin-Walled Structures, 2022, 181: 110011. doi: 10.1016/j.tws.2022.110011 [29] HADI M N S. Helically reinforced HSC beams reinforced with high strength steel[J]. International Journal of Materials and Product Technology, 2005, 23(1-2): 138-148. [30] ELBASHA N M. Behaviour of over reinforced HSC helically confined beams[M]. 2005. [31] ZUO X L, TANG W X, ZHANG J, et al. Collapse of externally pressurized steel–composite hybrid cylinders: Analytical solution and experimental verification[J]. Metals, 2022, 12(10): 1591. doi: 10.3390/met12101591 -

下载:

下载: