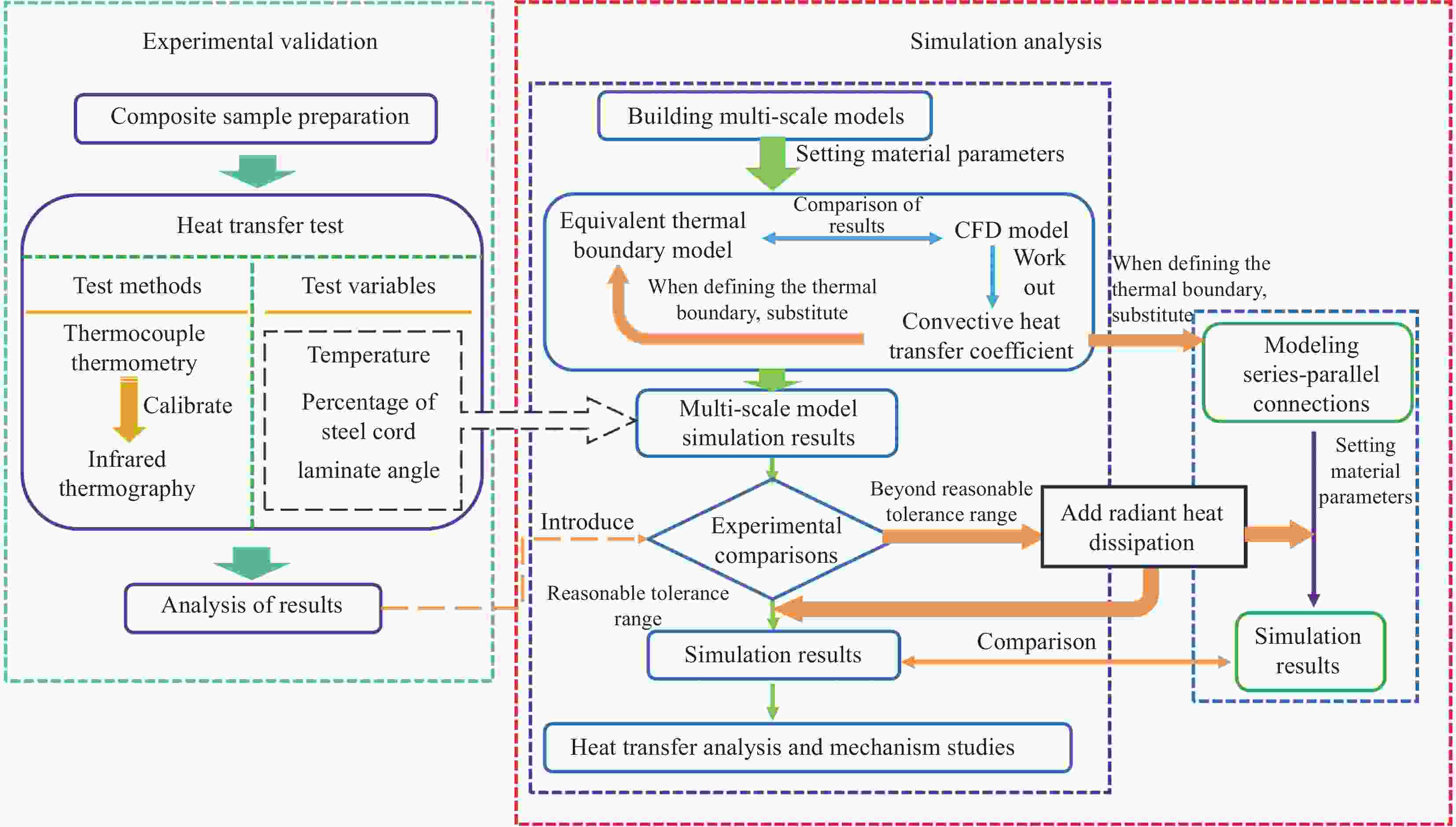

Study on the mechanism of radiation heat dissipation behavior of rubber/steel cord composites based on multi-scale simulation

-

摘要: 橡胶/钢帘线复合材料的传热与温度场分析对橡胶制品的硫化成型、热氧老化、热疲劳寿命研究具有重要意义。本文基于多尺度传热模型对不同钢帘线占比、排列角度和温升工况下的橡胶/钢帘线复合材料传热和散热机制进行研究,并通过实验验证。结果表明,橡胶/钢帘线复合材料呈现明显的各向异性传热行为,传热界面的热流聚集效应会加速热量的层间扩散,使温度分布更均匀。模拟计算得到的辐射散热发射率高达0.95,且随着钢帘线占比增大和温度升高,辐射散热行为越明显。对比串并联传热模型,多尺度传热模型预测误差从10.1%减小到2.5%。

-

关键词:

- 橡胶/钢帘线复合材料 /

- 辐射散热 /

- 多尺度模型 /

- 传热机制 /

- 流体动力学模型

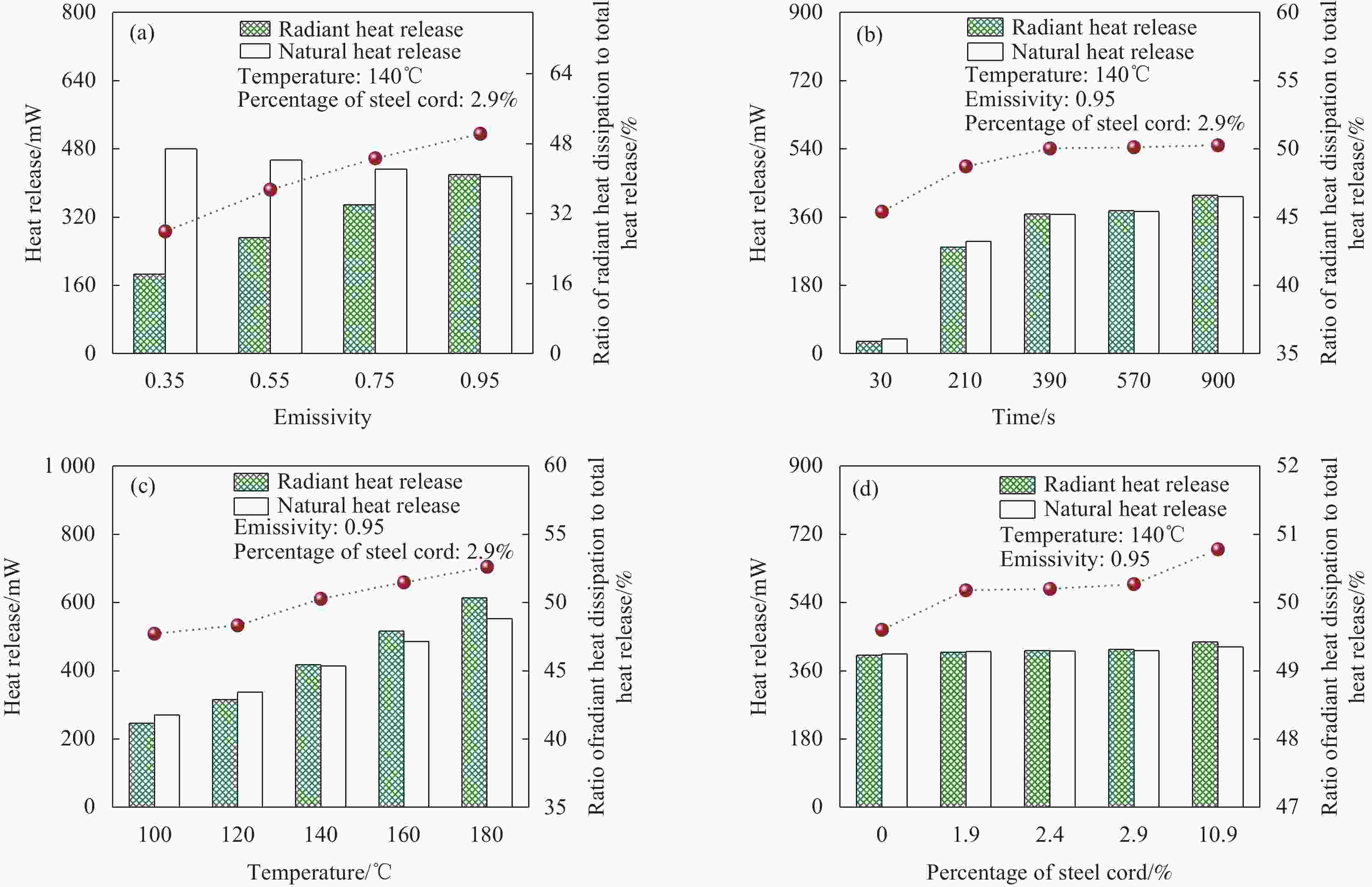

Abstract: Heat transfer and temperature field analysis of rubber steel/cord composites are important for the study of vulcanization molding, thermo-oxidative aging, and thermal fatigue life of rubber products. In this paper, the heat transfer and heat dissipation mechanisms of rubber/steel cord composites with different steel cord ratios, laminate angles and temperature rise operating conditions are investigated based on a multi-scale heat transfer model and experimentally verified. The results show that the rubber/steel cord composites exhibit obvious anisotropic heat transfer behavior, and the heat flow aggregation effect at the heat transfer interface accelerates the interlayer diffusion of heat for more uniform temperature distribution. The radiative heat dissipation emissivity obtained from the simulation is as high as 0.95, and the radiative heat dissipation behavior is more pronounced as the percentage of steel cord increases and the temperature rises. Compared to the series-parallel heat transfer model, the prediction error of the multiscale heat transfer model is reduced from 10.1% to 2.5%. -

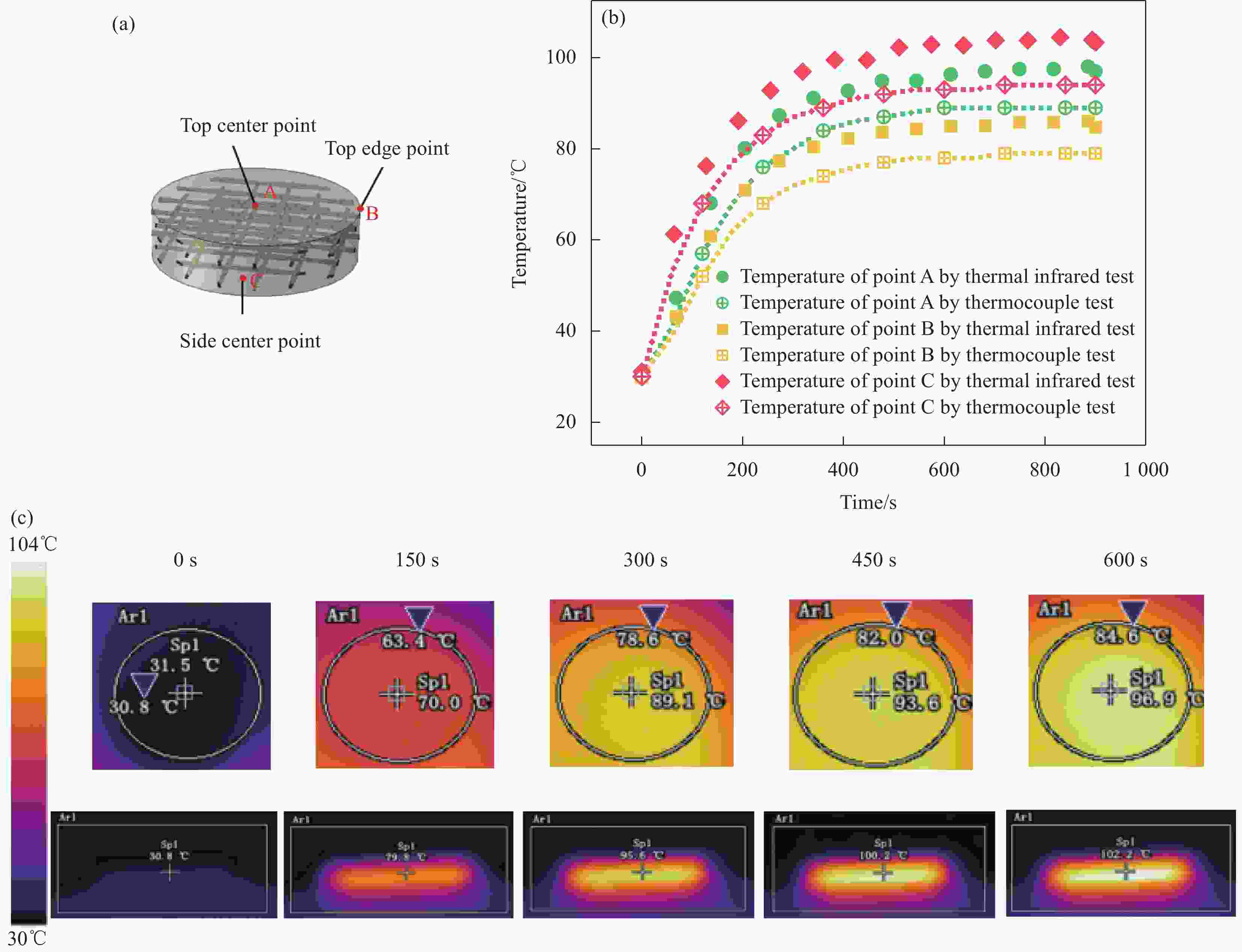

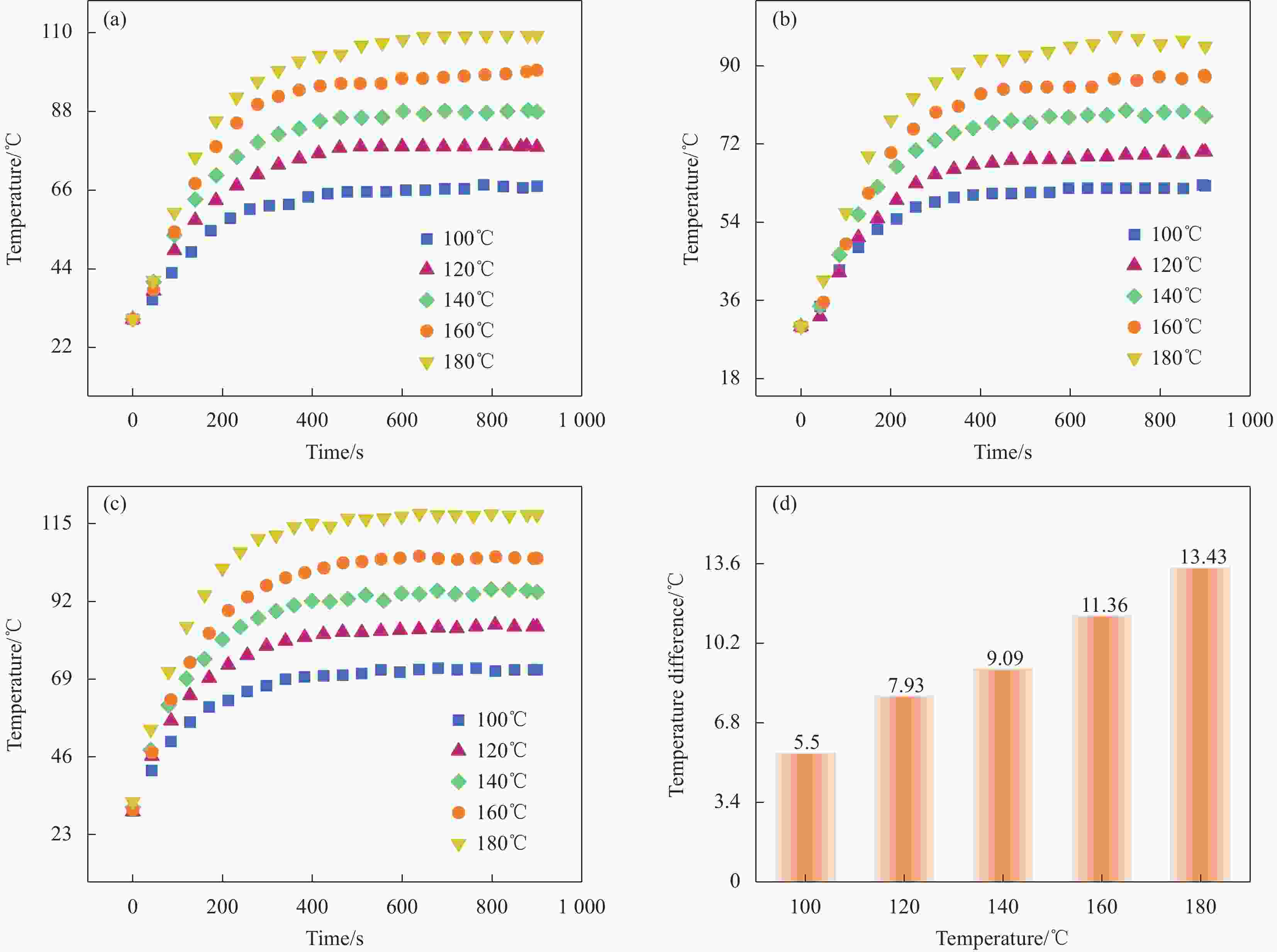

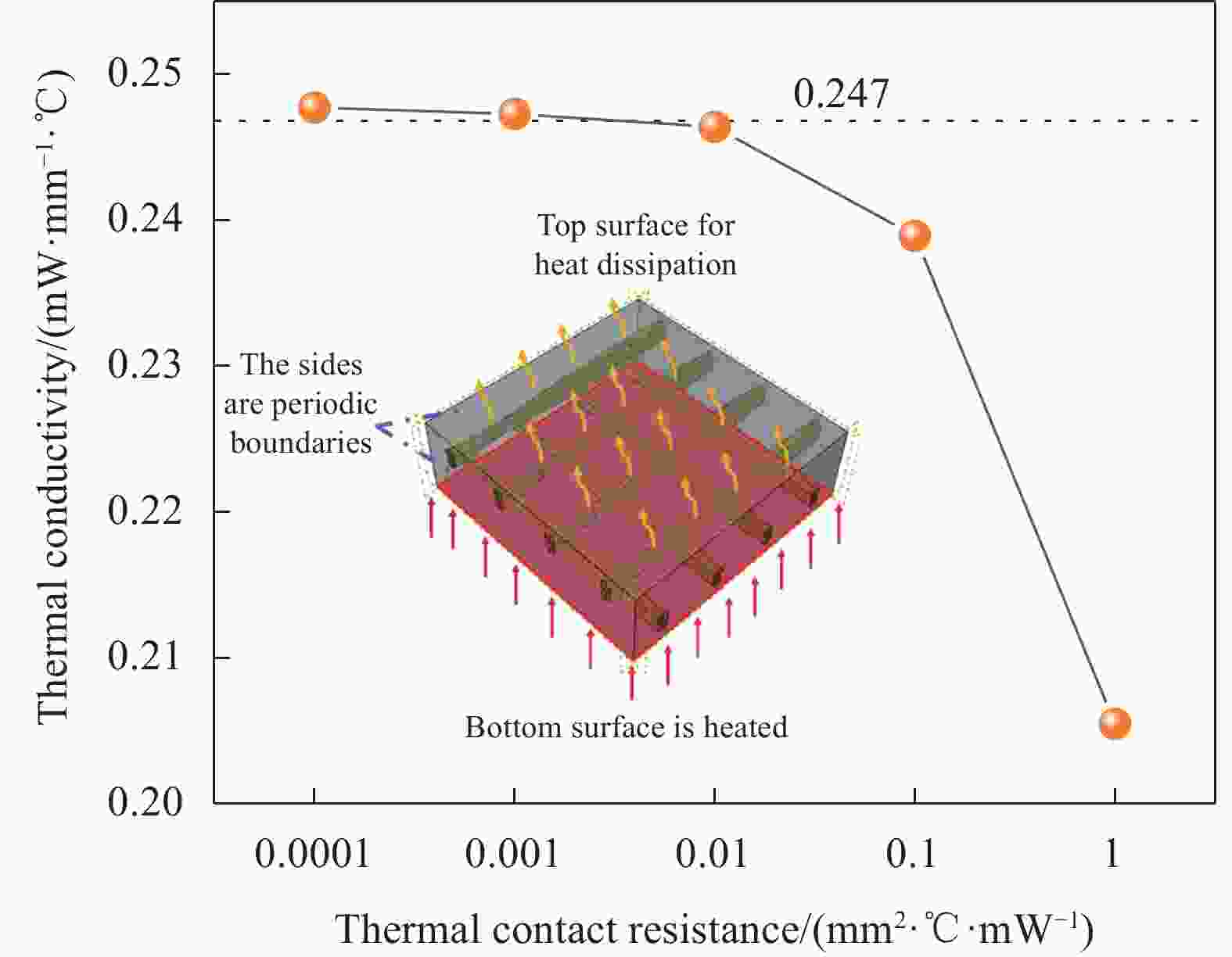

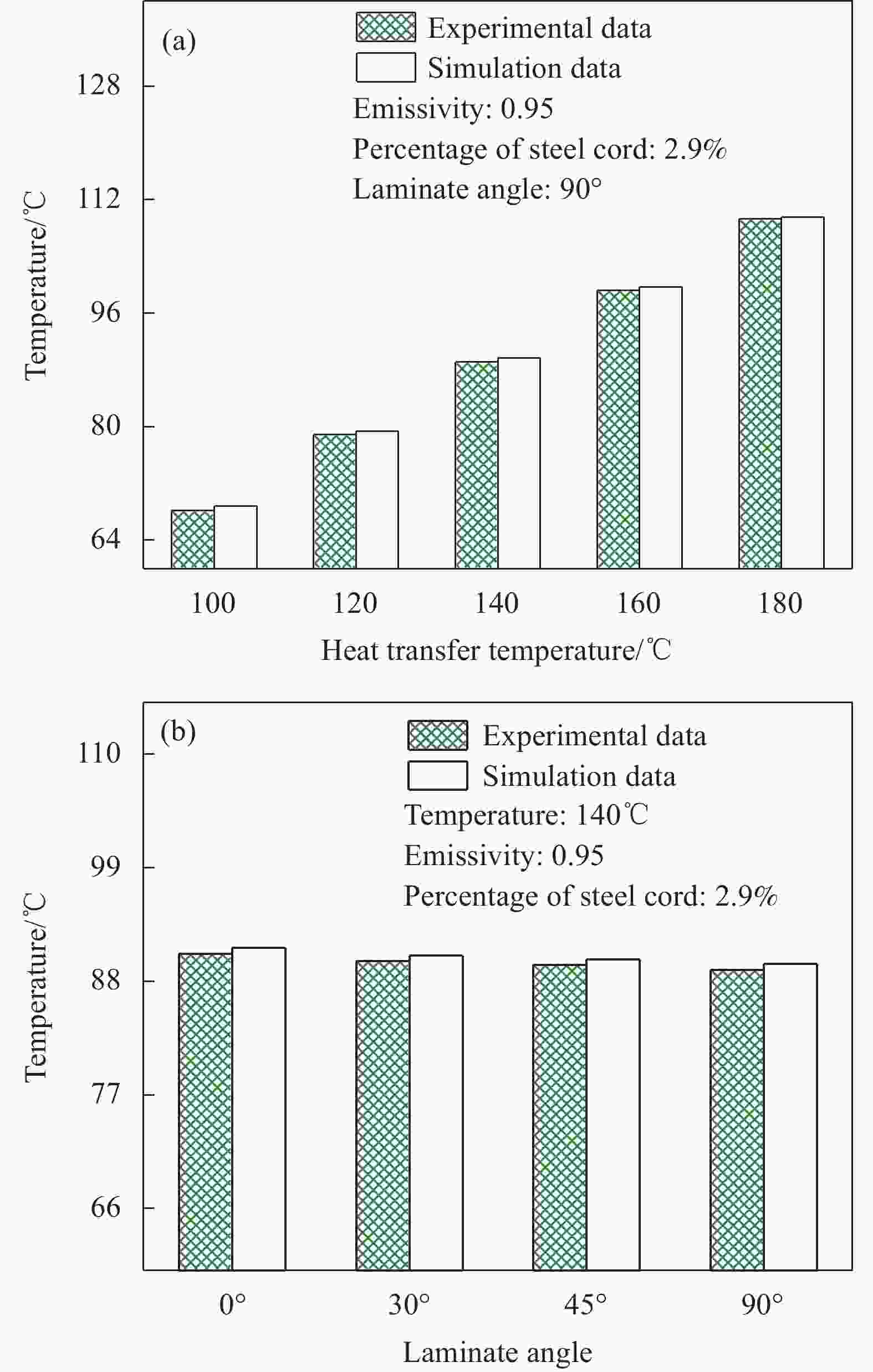

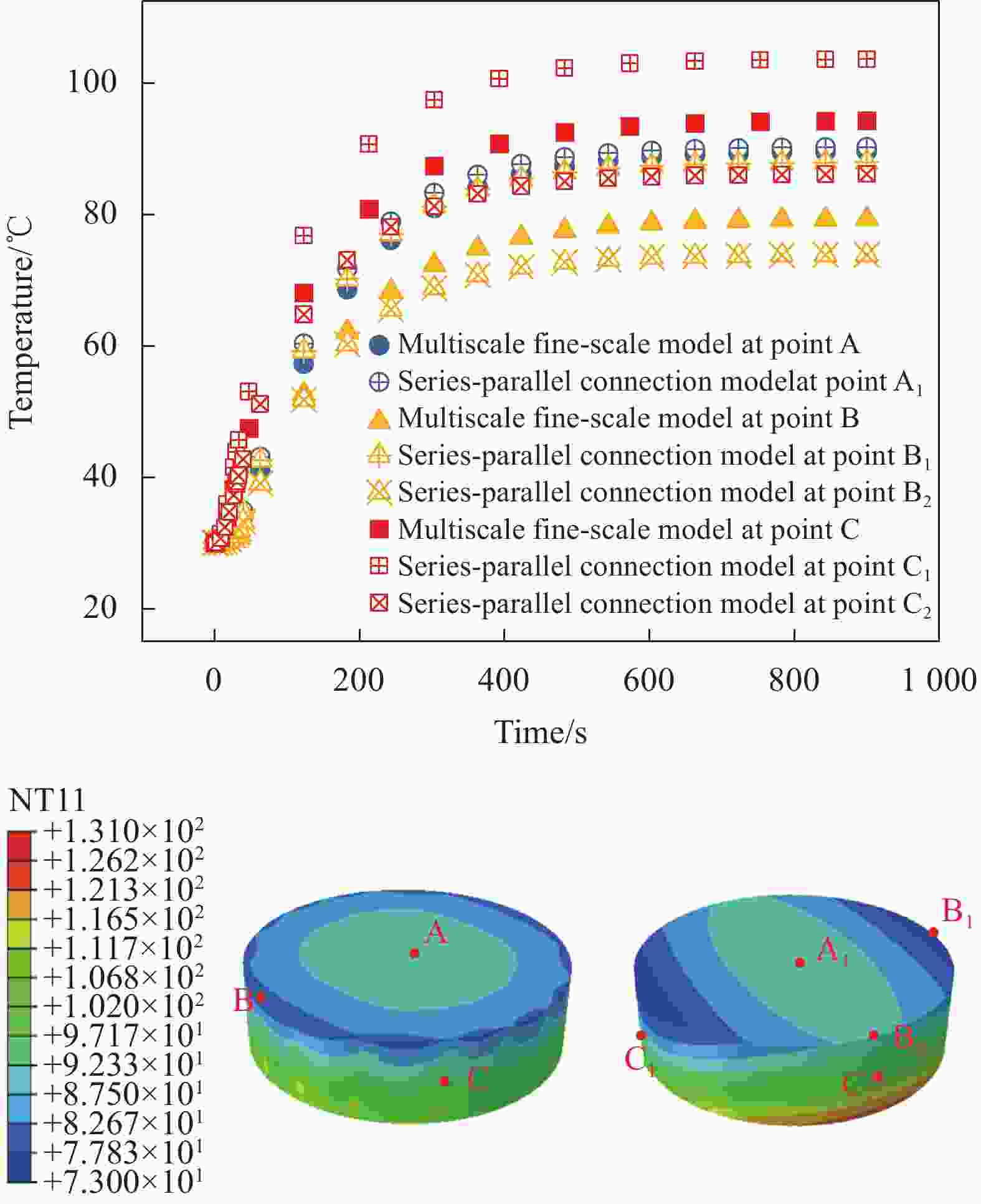

图 6 热台温度对橡胶/钢帘线复合材料温升的影响:(a)顶面中心点温度历程图;(b)顶面边缘点温度历程图;(c)侧面中心点温度历程图;(d)顶部中心点与顶面边缘点温度差值图

Figure 6. Effect of hot bench temperature on temperature rise of rubber/steel cord composites: (a) Plot of temperature history at the top center point; (b) Plot of temperature history at the top edge point; (c) Plot of temperature history at the side center point; (d) Plot of temperature difference between the top center point and the top edge point

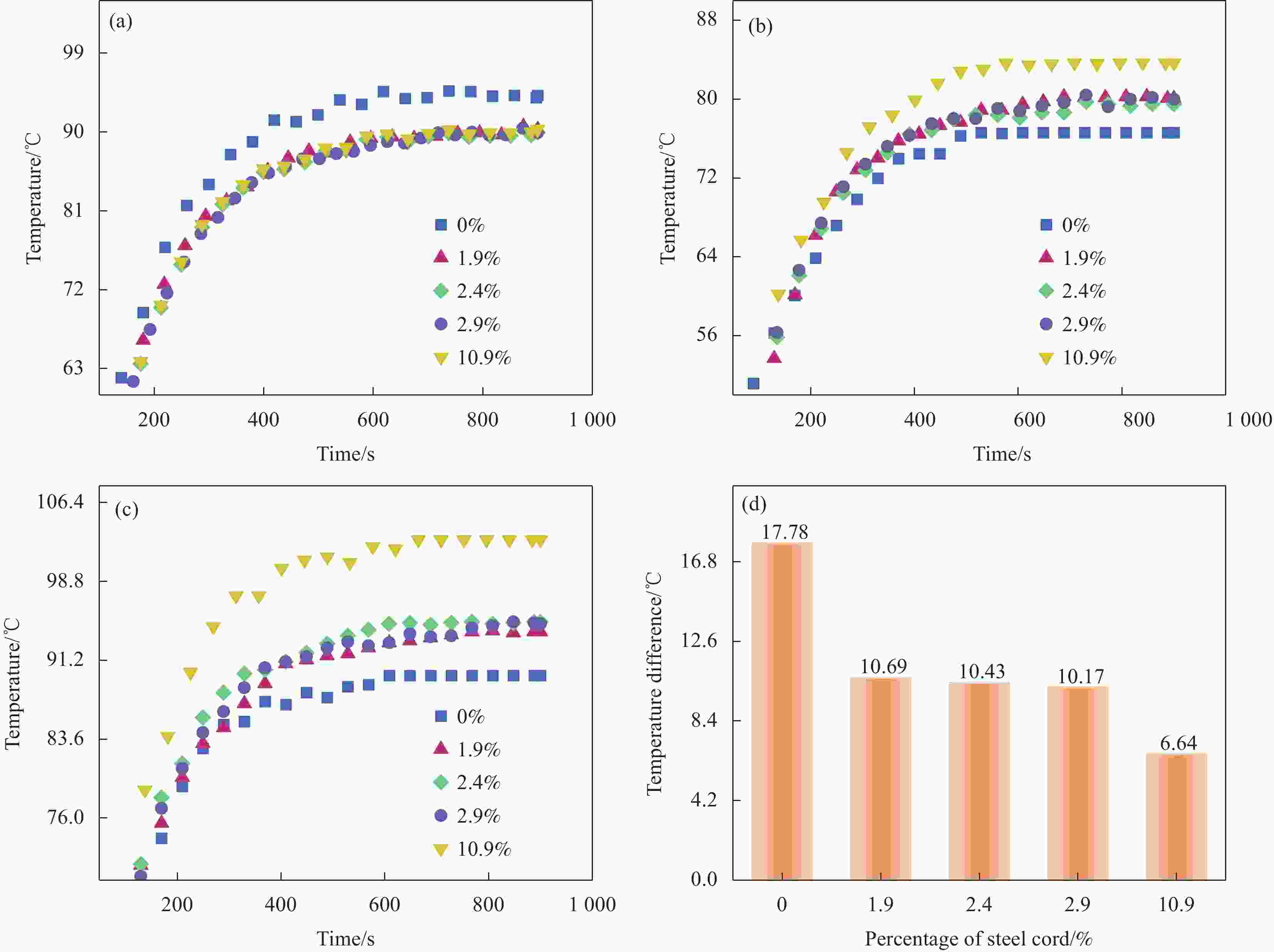

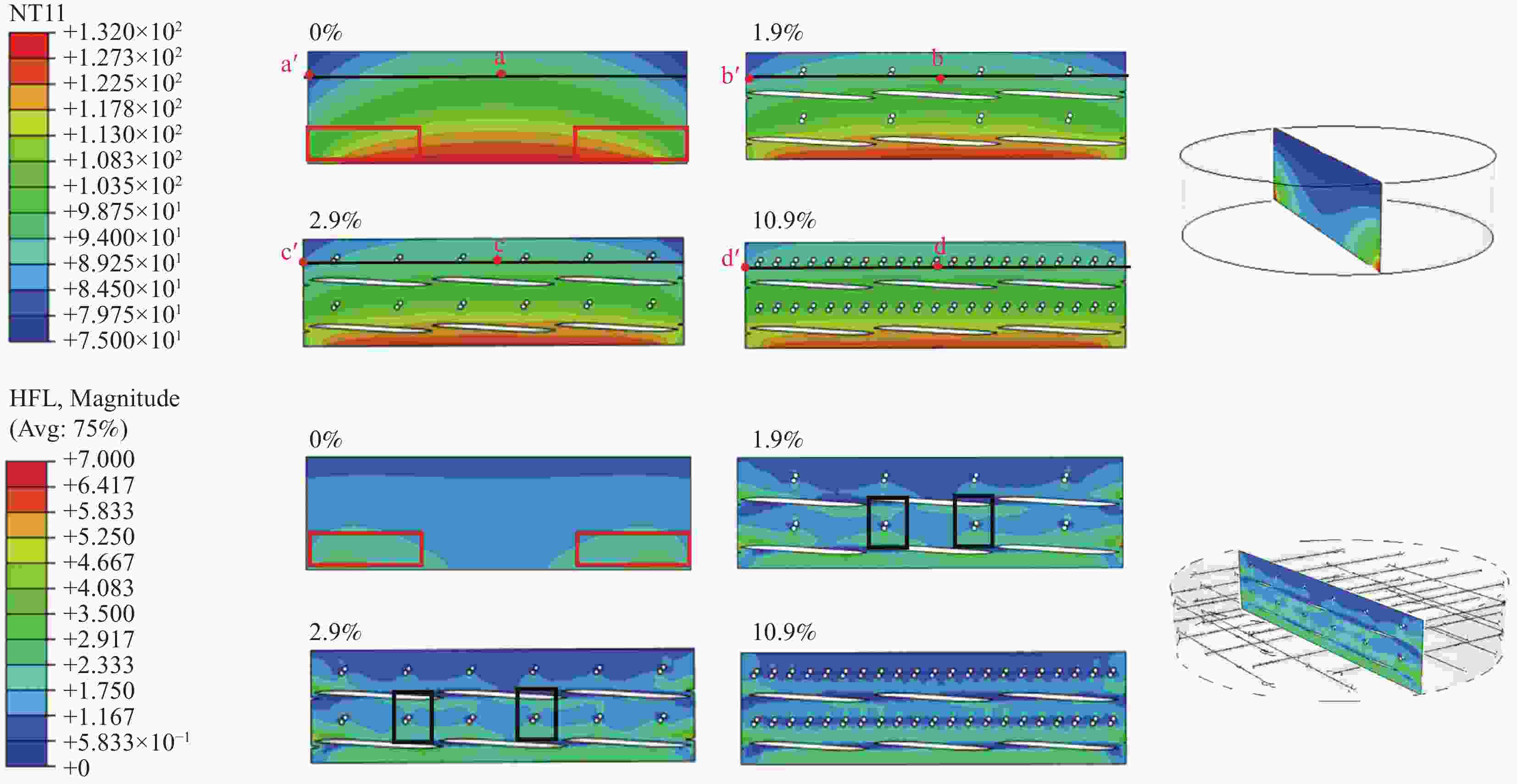

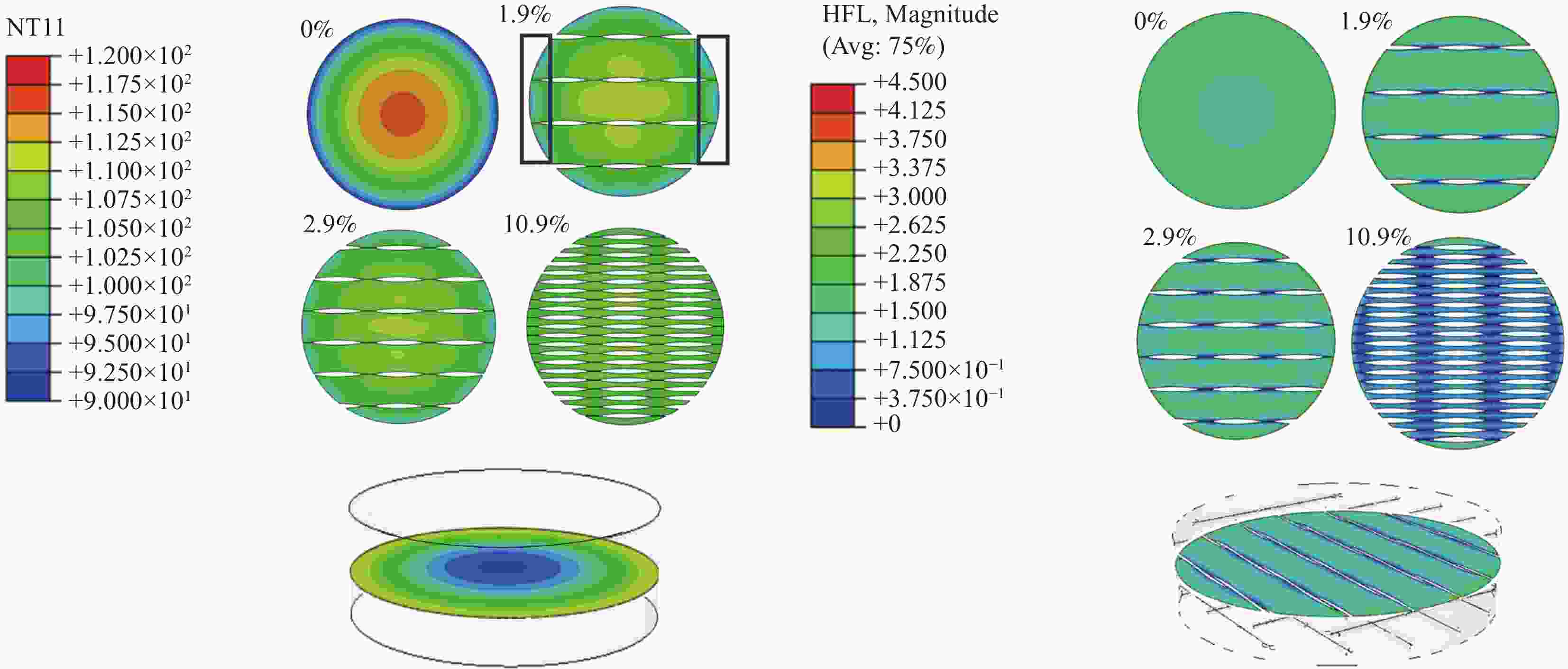

图 7 140℃条件下不同钢帘线占比橡胶/钢帘线复合材料温升影响研究:(a)顶面中心点温度历程图;(b)顶面边缘点温度历程图;(c)侧面中心点温度历程图;(d)顶面中心点与顶面边缘点温度差值图

Figure 7. Study on the effect of temperature rise of rubber/steel cord composites with different steel cord ratios at 140℃: (a) Temperature history of top center point; (b) Temperature history of top edge point; (c) Temperature history of side center point; (d) Temperature difference between top center point and top edge point

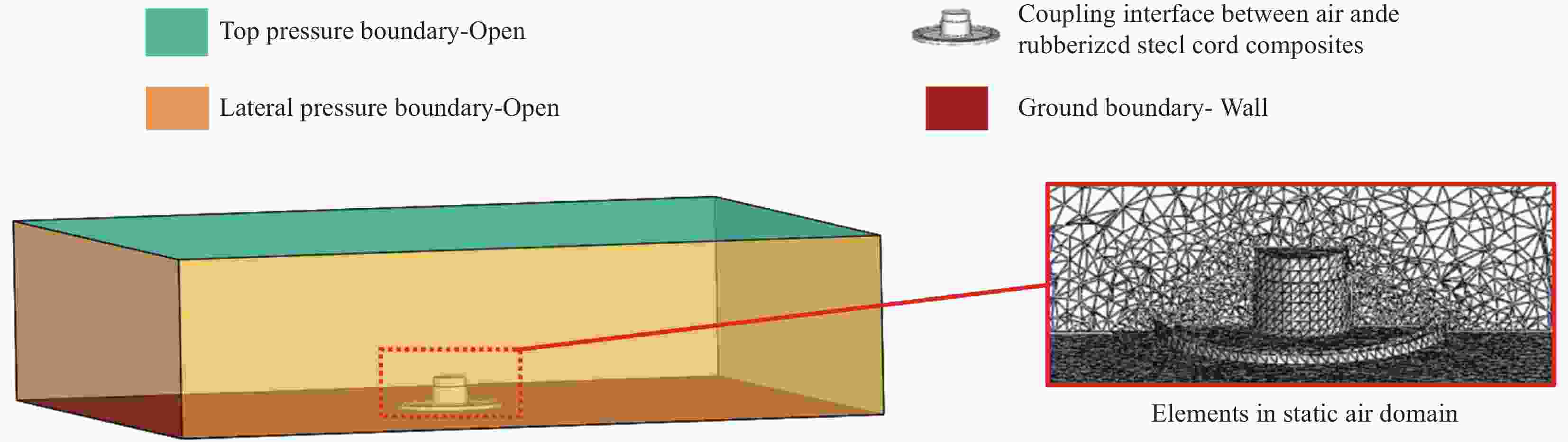

图 10 (a)橡胶/钢帘线复合材料CFD传热模型与等效热边界传热模型温度历程对比;(b)橡胶/钢帘线复合材料实验与仿真结果温度历程对比

Figure 10. (a) Comparison of CFD heat transfer model and equivalent thermal boundary heat transfer model temperature history for rubber/steel cord composites; (b) Comparison of temperature history between experimental and simulation results for rubber/steel cord composites

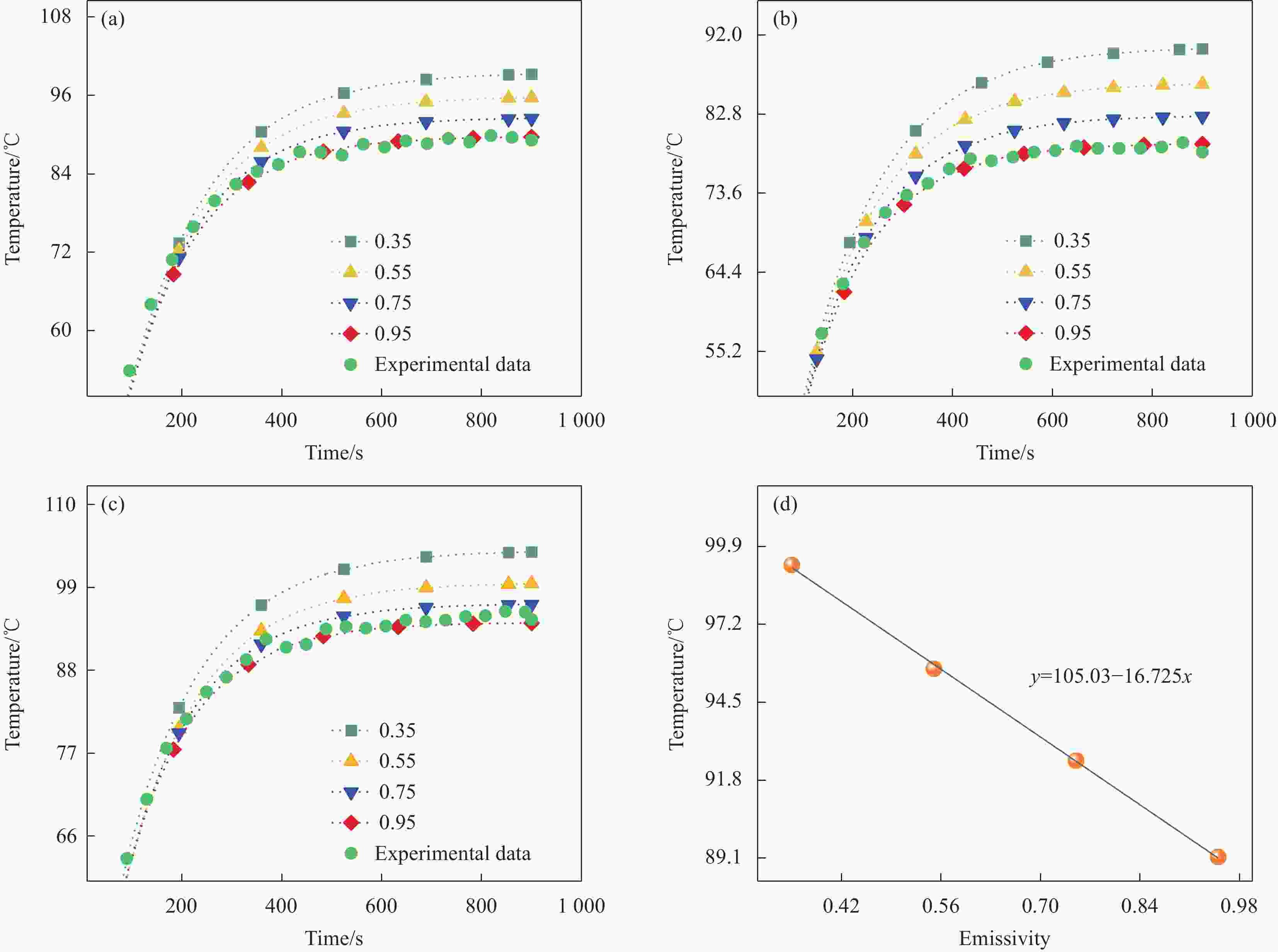

图 17 不同因素对橡胶/钢帘线复合材料辐射散热的影响:(a)发射率的影响;(b)传热时间的影响;(c)传热温度的影响;(d)钢帘线占比的影响

Figure 17. Effect of different factors on radiative heat dissipation of rubber/steel cord composites: (a) Effect of emissivity; (b) Effect of heat transfer time; (c) Effect of heat transfer temperature; (d) Effect of steel cord percentage

表 1 橡胶配方

Table 1. Rubber formulations

Raw material Parts per hundreds of rubber EPDM4045 100 NR 30 ZnO 10 C18H36O2 1 N220 40 Paraffin oil 14 Coumarone-indene resin 5 PCP 4 C6H12N2S4 0.5 S 0.5 Bonding agent 5 Teen-ager RD 1 表 2 橡胶/钢帘线复合材料结构参数

Table 2. Structural parameters of rubber/steel cord composites

Steel cord spacing/mm Percentage of

steel cord /%Laminate

angle /(°)Pure rubber - - 5 1.9

0/30/45/904 2.4 3.6 2.9 1 10.9 表 3 橡胶/钢帘线复合材料传热测试实验方案

Table 3. Experimental program for heat transfer testing of rubber/steel cord composites

Steel cord

spacing/mmPercentage of steel

cord/%Laminate

angle/(°)Heating pad

temperature /℃Environmental

temperature /℃3.6 2.9 90 100 30 3.6 2.9 90 120 30 3.6 2.9 90 140 30 3.6 2.9 90 160 30 3.6 2.9 90 180 30 Pure rubber 0 - 140 30 4 2.4 90 140 30 5 1.9 90 140 30 1 10.9 90 140 30 3.6 2.9 0 140 30 3.6 2.9 30 140 30 3.6 2.9 45 140 30 表 4 多尺度模型材料热物性参数

Table 4. Thermo-physical property parameters of materials for multi-scale modeling

Material

typeThermal conductivity/

(mW·(mm·℃)-1)Density/

(kg·m−3)Specific heat/

(J·(kg·℃)−1)Rubber 0.21 1200 1503 Steel cord 70 7810 540 -

[1] 贺婷, 杨长浩, 许宗超, 等. 不同工况下纤维/天然橡胶复合材料界面疲劳失效机制[J]. 弹性体, 2022, 32(5): 13-9.HE Ting, YANG Changhao, XU Zongchao, et al. Fatigue failure mechanism of fiber/natural rubber composite interface under different working conditions[J]. China Elastomerics, 2022, 32(5): 13-9(in Chinese). [2] 张嘉琦. 高温往复工况下橡胶密封件的密封性能研究 [D]; 洛阳: 河南科技大学, 2022.ZHANG Jiaqi. Research on the sealing performance of rubber seals under high temperature reciprocating conditions [D]. Luoyang: Henan University of Science and Technology, 2022. (in Chinese) [3] LI Z-X, KONG Y-R, CHEN X-F, et al. High-temperature Thermo-oxidative Aging of Vulcanized Natural Rubber Nanocomposites: Evolution of Microstructure and Mechanical Properties[J]. Chinese Journal of Polymer Science, 2023, 41(8): 1287-97. doi: 10.1007/s10118-023-2948-9 [4] ADAM Q, BEHNKE R, KALISKE M. A thermo-mechanical finite element material model for the rubber forming and vulcanization process: From unvulcanized to vulcanized rubber[J]. International Journal of Solids and Structures, 2020, 185-186: 365-79. doi: 10.1016/j.ijsolstr.2019.08.037 [5] SALVI W D, DE SANTO C E, MATSUMOTO A, et al. Characterization of thermal-oxidative aging mechanism of commercial tires[J]. Engineering Failure Analysis, 2023, 154: 107631. doi: 10.1016/j.engfailanal.2023.107631 [6] NYAABA W, FRIMPONG S, ANANI A. Fatigue damage investigation of ultra-large tire components[J]. International Journal of Fatigue, 2019, 119: 247-60. doi: 10.1016/j.ijfatigue.2018.07.009 [7] 姜碧羽, 齐俊伟, 刘小林. 预浸料先进拉挤成型的固化传热过程数值模拟[J]. 复合材料学报, 2020, 37(6): 1496-504.JIANG Biyu, QI Junwei, LIU Xiaolin. Numerical simulation of curing heat transfer process in advanced pultrusion molding of prepreg[J]. Acta Materiae Compositae Sinicia, 2020, 37(6): 1496-504(in Chinese). [8] NAZARI N, ALLAHBAKHSH A, BAHRAMIAN A R. Analytical effective thermal conductivity model for colloidal porous composites and nanocomposites based on novolac/graphene oxide aerogels[J]. International Journal of Energy Research, 2022, 46(12): 16608-28. doi: 10.1002/er.8323 [9] HUI X, XU Y, ZHANG W, et al. Multiscale collaborative optimization for the thermochemical and thermomechanical cure process during composite manufacture[J]. Composites Science and Technology, 2022, 224: 109455. doi: 10.1016/j.compscitech.2022.109455 [10] SU B, WU J, CUI Z, et al. Modeling of truck tire curing process by an experimental and numerical method[J]. Iranian Polymer Journal, 2015, 24(7): 583-93. doi: 10.1007/s13726-015-0349-9 [11] LI W, ZHANG X, SHANG Y, et al. Investigation of dynamic heat generation and transfer behavior and energy dissipation for nonlinear synchronous belt transmission[J]. Applied Thermal Engineering, 2018, 144: 457-68. doi: 10.1016/j.applthermaleng.2018.08.080 [12] ZHOU K, ENOS R, ZHANG D, et al. Uncertainty analysis of curing-induced dimensional variability of composite structures utilizing physics-guided Gaussian process meta-modeling[J]. Composite Structures, 2022, 280: 114816. doi: 10.1016/j.compstruct.2021.114816 [13] ZHOU L, SUN X, CHEN M, et al. Multiscale modeling and theoretical prediction for the thermal conductivity of porous plain-woven carbonized silica/phenolic composites[J]. Composite Structures, 2019, 215: 278-88. doi: 10.1016/j.compstruct.2019.02.053 [14] 杨方沁. 金属/聚合物复合结构对材料导热性能的影响研究 [D]. 杭州: 浙江工业大学 2013.YANG Fangqin. Effects of metal/polymer composite structure on thermal conductivity of materials [D]. Hangzhou: Zhejiang University of Technology, 2013. (in Chinese) [15] FANG Y, LI L-Y, MAWULé DASSEKPO J-B, et al. Heat transfer modelling of carbon nanotube reinforced composites[J]. Composites Part B:Engineering, 2021, 225: 109280. doi: 10.1016/j.compositesb.2021.109280 [16] ZHOU L, YUAN T B, YANG X S, et al. Micro-scale prediction of effective thermal conductivity of CNT/Al composites by finite element method[J]. International Journal of Thermal Sciences, 2022, 171: 107206. doi: 10.1016/j.ijthermalsci.2021.107206 [17] XU S, LIU J, ZENG Q. Towards better characterizing thermal conductivity of cement-based materials: The effects of interfacial thermal resistance and inclusion size[J]. Materials & Design, 2018, 157: 105-18. [18] 贺元骅, 赵逸明, 张俐恒, 等. 辐射对流散热下大尺寸三元锂电池热模型[J]. 中国安全科学学报, 2023, 33(6): 49-55.HE Yuanhua, ZHAO Yiming, ZHANG Liheng, et al. Thermal modeling of large-size lithium ternary batteries under radiative convection heat dissipation[J]. China Safety Science Journal, 2023, 33(6): 49-55(in Chinese). [19] YANG Z, WANG Z, YANG Z, et al. Multiscale analysis and computation for coupled conduction, convection and radiation heat transfer problem in porous materials[J]. Applied Mathematics and Computation, 2018, 326: 56-74. doi: 10.1016/j.amc.2017.12.039 [20] YANG Z, CUI J, SUN Y, et al. Multiscale computation for transient heat conduction problem with radiation boundary condition in porous materials[J]. Finite Elements in Analysis and Design, 2015, 102-103: 7-18. doi: 10.1016/j.finel.2015.04.005 [21] YANG Z, CUI J, MA Q. The second-order two-scale computation for integrated heat transfer problem with conduction, convection and radiation in periodic porous materials[J]. Discrete and Continuous Dynamical Systems - B, 2014, 19(3): 827-48. doi: 10.3934/dcdsb.2014.19.827 [22] 童自翔, 李明佳, 李冬. 导热-辐射耦合传热的多尺度分析和数值模型[J]. 航空学报, 2021, 42(9): 205-14.TONG Zixiang, LI Mingjia, LI Dong. Multi-scale analysis and numerical modeling of coupled thermal-radiative heat transfer[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(9): 205-14(in Chinese). [23] 陈则韶, 钱军, 叶一火. 复合材料等效导热系数的理论推算[J]. 中国科学技术大学学报, 1992, (4): 416-24.CHEN Zeshao, QIAN Jun, YE Yihuo. Theoretical derivation of equivalent thermal conductivity of composite materials[J]. Journal of China University of Science and Technology, 1992, (4): 416-24(in Chinese). [24] 石鹏. 活络轮胎模具传热过程仿真建模与分析 [D]. 武汉: 华中科技大学, 2021.SHI Peng. Simulation modeling and analysis of heat transfer process in live tire mold [D]. Wuhan: Huazhong University of Science and Technology 2021(in Chinese). [25] 张建. 轮胎硫化特性及影响规律研究 [D]. 镇江: 江苏大学, 2014.ZHANG Jian. Research on tire curing characteristics and influence law [D]. Zhenjiang: Jiangsu University 2014. (in Chinese) -

点击查看大图

点击查看大图

计量

- 文章访问数: 48

- HTML全文浏览量: 32

- 被引次数: 0

下载:

下载: