A review of the effect of ceramic wastes on mechanical properties and mechanisms of cementitious composites

-

摘要: 废弃陶瓷作为一种固体废弃物,质地坚硬,主要化学组成为SiO2和Al2O3。这些特点使得废弃陶瓷经简单的物理处理后具有部分替代天然砂石骨料和作为掺合料的潜力。将废弃陶瓷应用于水泥基复合材料的生产中,可缓解天然砂石过度开采、水泥生产过程的高能耗与污染以及废弃陶瓷堆积所造成环境污染等问题。本文首先分析了各类废弃陶瓷的物理化学性质;而后,从废弃陶瓷在水泥基复合材料中的不同应用形式方面入手,综合评述了废弃陶瓷粗、细骨料以及废弃陶瓷粉对水泥基复合材料基本力学性能影响,揭示了废弃陶瓷对水泥基复合材料力学性能的影响机制;最后,讨论并给出了废弃陶瓷在水泥基复合材料中,尤其在绿色超高性能混凝土和高力学保持性能的耐高温混凝土,进一步应用和研究的建议。Abstract: As one of the solid wastes, ceramic wastes have a hard texture, and their main chemical composition are SiO2 and Al2O3. These characteristics make properly treated ceramic wastes have the potential to replace natural sand, gravel aggregates and act as admixtures. Application of ceramic wastes into cementitious composites will contribute to alleviate the problems of environmental pollution caused by the overexploitation of natural sand and gravel, high energy consumption and pollution in cement production, and the accumulation of ceramic wastes. This paper first briefly describes the physical and chemical properties of various types of ceramic wastes. Then, from the different application forms of ceramic wastes in cementitious composites, this paper comprehensively reviews the research status of the effect of ceramic waste aggregates and ceramic waste powders on the basic mechanical properties of cementitious composites, reveals the influencing mechanisms of ceramic wastes on the basic mechanical properties of cementitious composites. Finally, suggestions for further application and research of cementitious composites with ceramic wastes, especially in green and ultra-high-performance concrete and mechanical property retention after high temperature refractory concrete, are put forward based on the problems existing in the current research.

-

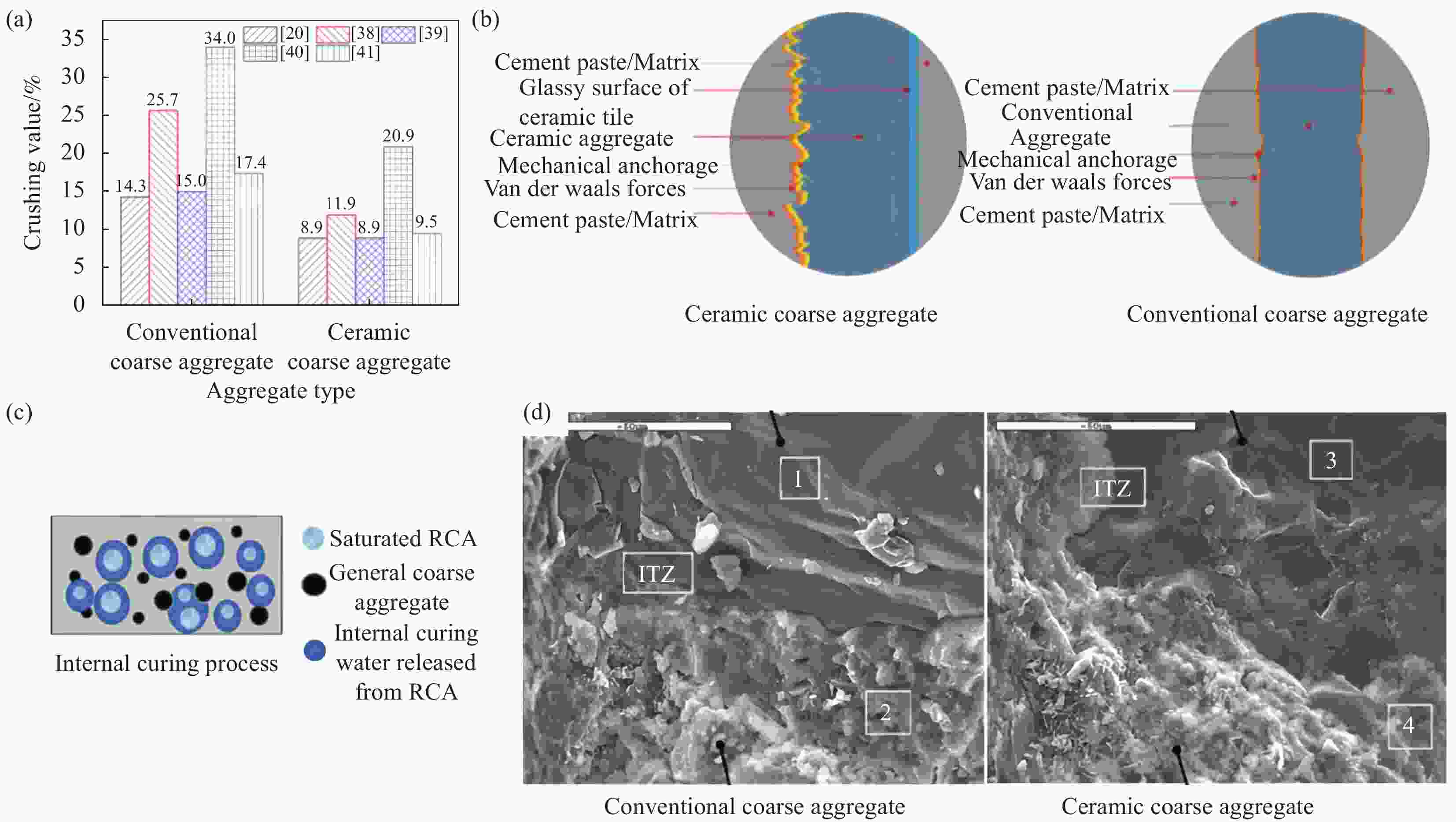

图 4 废弃陶瓷粗骨料对水泥基复合材料力学性能增强机制:(a) 天然骨料与废弃陶瓷粗骨料压碎指标[20, 38-41];(b) 水泥浆体和不同种类粗骨料的ITZ模型[80];(c) 废弃陶瓷粗骨料内养护机制[47];(d) 不同骨料与水泥基体间ITZ水化产物成分分析[93]

Figure 4. The enhancement mechanism of ceramic waste coarse aggregates on the mechanical property of cementitious composites: (a) crushing values of natural aggregate and ceramic waste coarse aggregate[20, 38-41]; (b) the ITZ model of cement matrix and different kinds of coarse aggregate[80]; (c) internal curing mechanisms of ceramic waste coarse aggregate[47];(d) analysis of hydration product composition in the ITZ of different aggregates and cement matrix [93]

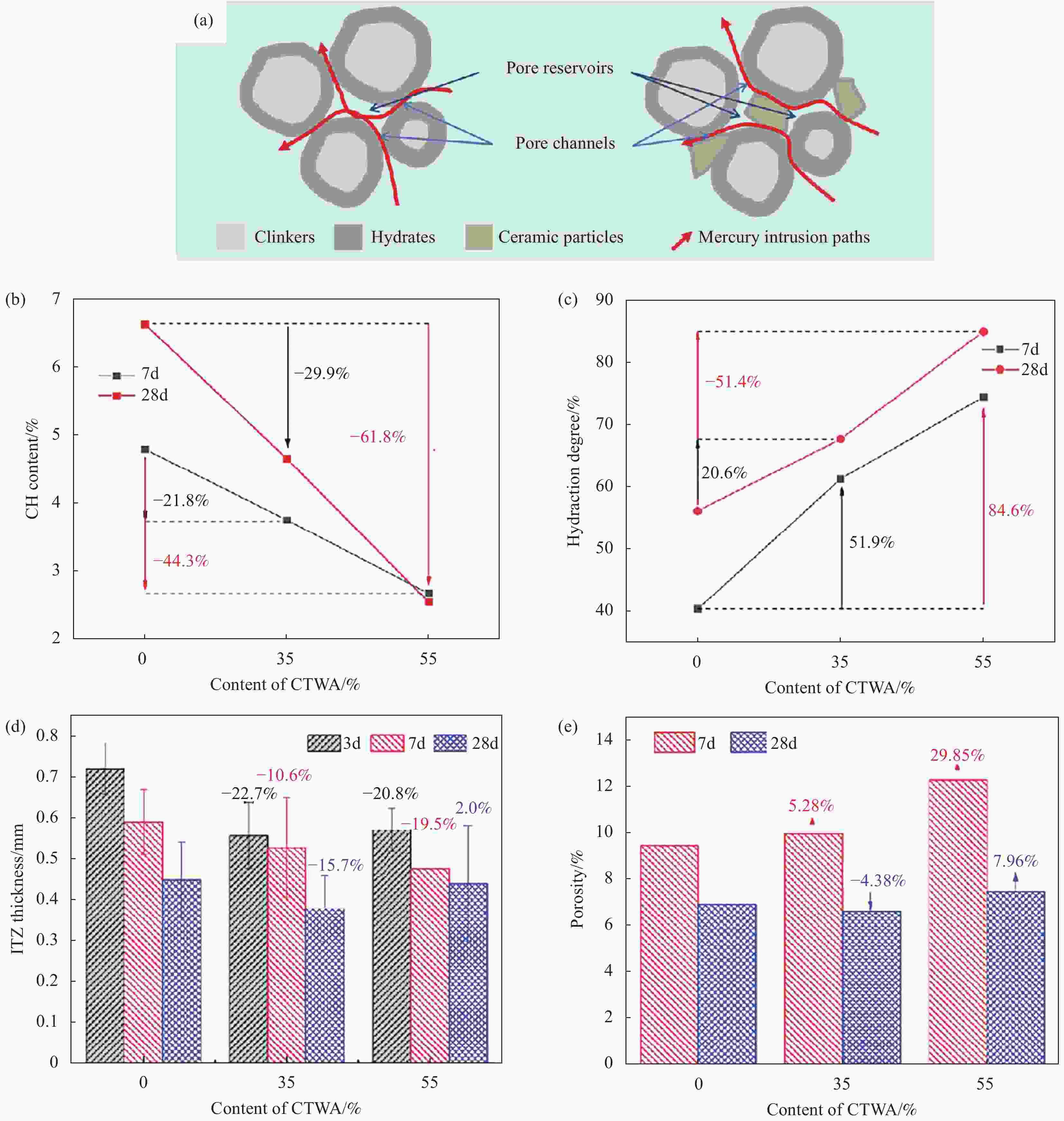

图 5 废弃陶瓷细骨料对水泥基复合材料力学性能增强机制:(a) 降低ITZ宽度 [18];(b) 降低孔隙率[19];(c) 增强骨料和水泥基体的粘结 [40];(d) 改善 ITZ [103]

Figure 5. Enhancement mechanisms of ceramic wastes fine aggregates on mechanical property of cementitious composites: (a) decrease the ITZ thickness [19]; (b) decrease the porosity [19]; (c) enhance the bonding of aggregate with cement matrix[40]; (d) improve the ITZ [103]

图 6 废弃陶瓷粉对水泥基复合材料的增强机制:(a)废弃陶瓷粉填充效应[118]; (b) 降低Ca(OH)2含量[18] ; (c) 提升水化程度[18]; (d) 降低ITZ宽度[18];(e) 降低孔隙率[18]

Figure 6. Enhancement mechanisms of ceramic waste powder on mechanical property of cementitious composites : (a) the filling effect of ceramic waste powder[118]; (b) decrease the content of Ca(OH)2[18]; (c) enhance the hydration degree[18]; (d) decrease the ITZ width[18]; (e) decrease porosity[18]

-

[1] “负重前行”, 内需变化和双碳背景下的行业走向−2022年建筑陶瓷与卫生洁具行业运行概况及2023年展望[Z]. 中国建筑陶瓷协会. 2023."Moving forward with heavy load", changes in domestic demand and the trend of the industry under the background of dual carbon - the operation overview of building ceramics and sanitary ware industry in 2022 and the outlook in 2023[J]. China Building Ceramic and Sanitaryware Association. 2023(in Chinese). [2] AWOYERA P O, NDAMBUKI J M, AKINMUSURU J O, et al. Characterization of ceramic waste aggregate concrete[J]. HBRC Journal, 2018, 14(3): 282-287. doi: 10.1016/j.hbrcj.2016.11.003 [3] MAGBOOL H M. Utilisation of ceramic waste aggregate and its effect on Eco-friendly concrete: A review[J]. Journal of Building Engineering, 2022, 47: 103815. doi: 10.1016/j.jobe.2021.103815 [4] GAUTAM L, JAIN J K, JAIN A, et al. Recycling of bone china ceramic waste as cement replacement to produce sustainable self-compacting concrete[J]. Structures, 2022, 37: 364-378. doi: 10.1016/j.istruc.2022.01.019 [5] MEENA R V, JAIN J K, BENIWAL A S, et al. Sustainable self-compacting concrete containing waste ceramic tile aggregates: Fresh, mechanical, durability, and microstructural properties[J]. Journal of Building Engineering, 2022, 57: 104941. doi: 10.1016/j.jobe.2022.104941 [6] XU F M, LIN X S, ZHOU A N. Effect of recycled ceramic aggregate on hydration heat and permeability of high performance concrete[J]. Cement and Concrete Composites, 2023, 137: 104930. doi: 10.1016/j.cemconcomp.2023.104930 [7] LIU J B, ZHANG X Z, MAI Z X, et al. Preparation and Properties of Environmentally Friendly Resin-Based Artificial Stones Fabricated from Ceramic Waste[J]. Buildings, 2023, 13(2): 570. doi: 10.3390/buildings13020570 [8] MAHMOODI O, SIAD H, LACHEMI M, et al. Optimized application of ternary brick, ceramic and concrete wastes in sustainable high strength geopolymers[J]. Journal of Cleaner Production, 2022, 338: 130650. doi: 10.1016/j.jclepro.2022.130650 [9] 栾向峰, 曹远尼, 肖理红, 等. 陶瓷废料在建筑材料中的应用进展[J]. 材料导报, 2015, 29(13): 145-150.LUAN Xiangfeng, CAO Yuanni, XIAO Lihong, et al. Progress in Application of Ceramic Waste in Building Materials[J]. Materials Reports, 2015, 29(13): 145-150(in Chinese). [10] 张智, 蔡自伟, 李凌志, 等. 再生砂超高性能混凝土力学性能[J]. 复合材料学报, 2022, 39(11): 5158-5169. doi: 10.13801/j.cnki.fhclxb.20220507.001ZHANG Zhi, CAI Ziwei, LI Lingzhi, et al. Mechanical properties of recycled sand ultra-high performance concrete[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5158-5169(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220507.001 [11] SENTHAMARAI R, MANOHARAN P D. Concrete with ceramic waste aggregate[J]. Cement and Concrete Composites, 2005, 27(9-10): 910-913. doi: 10.1016/j.cemconcomp.2005.04.003 [12] SUZUKI M, MEDDAH M S, SATO R. Use of porous ceramic waste aggregates for internal curing of high-performance concrete[J]. Cement and Concrete Research, 2009, 39(5): 373-381. doi: 10.1016/j.cemconres.2009.01.007 [13] 王功勋. 陶瓷抛光砖粉作辅助胶凝材料的火山灰性[J]. 硅酸盐学报, 2010, 38(07): 1229-1234. doi: 10.14062/j.issn.0454-5648.2010.07.028WANG Gongxun. Pozzolanic activity of ceramic polishing powder as supplementary cementitious material[J]. Journal of the Chinese Ceramic Society, 2010, 38(07): 1229-1234(in Chinese). doi: 10.14062/j.issn.0454-5648.2010.07.028 [14] JUAN-VALDES A, RODRIGUEZ-ROBLES D, GARCIA-GONZALEZ J, et al. Mechanical and microstructural properties of recycled concretes mixed with ceramic recycled cement and secondary recycled aggregates. A viable option for future concrete[J]. Construction and Building Materials, 2020, 270: 121455. [15] KESHAVARZ Z, MOSTOFINEJAD D. Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete[J]. Construction and Building Materials, 2019, 195: 218-230. doi: 10.1016/j.conbuildmat.2018.11.033 [16] SIDDIQUE S, SHRIVASTAVA S, CHAUDHARY S. Durability properties of bone china ceramic fine aggregate concrete[J]. Construction and Building Materials, 2018, 173: 323-331. doi: 10.1016/j.conbuildmat.2018.03.262 [17] SIDDIQUE S, SHRIVASTAVA S, CHAUDHARY S, et al. Strength and impact resistance properties of concrete containing fine bone china ceramic aggregate[J]. Construction and Building Materials, 2018, 169: 289-298. doi: 10.1016/j.conbuildmat.2018.02.213 [18] XU K C, HUANG W Y, ZHANG L Q, et al. Mechanical properties of low-carbon ultrahigh-performance concrete with ceramic tile waste powder[J]. Construction and Building Materials, 2021, 287: 123036. doi: 10.1016/j.conbuildmat.2021.123036 [19] ZHANG L Q, SHEN H, XU K C, et al. Effect of ceramic waste tile as a fine aggregate on the mechanical properties of low-carbon ultrahigh performance concrete[J]. Construction and Building Materials, 2023, 370: 130595. doi: 10.1016/j.conbuildmat.2023.130595 [20] ANDERSON D J, SMITH S T, AU F T K. Mechanical properties of concrete utilising waste ceramic as coarse aggregate[J]. Construction and Building Materials, 2016, 117: 20-28. doi: 10.1016/j.conbuildmat.2016.04.153 [21] TUTKUN B, BEGLARIGALE A, YAZICI H. Alkali-silica reaction of sanitary ware ceramic wastes utilized as aggregate in ordinary and high-performance mortars[J]. Construction and Building Materials, 2022, 319: 126076. doi: 10.1016/j.conbuildmat.2021.126076 [22] 朱超, 赵文韬, 余伟航, 等. 再生砖混骨料混凝土基本力学性能与本构模型[J/OL]. 复合材料学报. https://doi.org/10.13801/j.cnki.fhclxb.20230531.004.ZHU Chao, ZHAO Wentao, YU Weihang, et al. Basic mechanical properties and constitutive model of recycled brick_x0002_concrete aggregate[J/OL]. Acta Materiae Compositae Sinica. https://doi.org/10.13801/j.cnki.fhclxb.20230531.004.(in Chinese). [23] NACERI A, HAMINA M C. Use of waste brick as a partial replacement of cement in mortar[J]. Waste Management, 2009, 29(8): 2378-2384. doi: 10.1016/j.wasman.2009.03.026 [24] KANNAN D M, ABOUBAKR S H, EL-DIEB A S, et al. High performance concrete incorporating ceramic waste powder as large partial replacement of Portland cement[J]. Construction and Building Materials, 2017, 144: 35-41. doi: 10.1016/j.conbuildmat.2017.03.115 [25] SUBASI S, OZTURK H, EMIROGLU M. Utilizing of waste ceramic powders as filler material in self-consolidating concrete[J]. Construction and Building Materials, 2017, 149: 567-574. doi: 10.1016/j.conbuildmat.2017.05.180 [26] LIM N H A S, MOHAMMADHOSSEINI H, TAHIR M M, et al. Microstructure and Strength Properties of Mortar Containing Waste Ceramic Nanoparticles[J]. Arabian Journal for Science and Engineering, 2018, 43: 5305-5313. doi: 10.1007/s13369-018-3154-x [27] EL-DIEB A S, KANAAN D M. Ceramic waste powder an alternative cement replacement – Characterization and evaluation[J]. Sustainable Materials and Technologies, 2018, 17: e63. [28] HUSEIEN G F, SAM A, SHAH K W, et al. Effects of ceramic tile powder waste on properties of self-compacted alkali-activated concrete[J]. Construction and Building Materials, 2020, 236: 117574. doi: 10.1016/j.conbuildmat.2019.117574 [29] PITARCH A M, REIG L, TOMAS A E, et al. Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements[J]. Journal of Cleaner Production, 2021, 279: 123713. doi: 10.1016/j.jclepro.2020.123713 [30] CHEN X Y, ZHANG D, CHENG S K, et al. Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability and microstructure assessment[J]. Journal of Building Engineering, 2022, 52: 104418. doi: 10.1016/j.jobe.2022.104418 [31] 张立卿, 边明强, 郭绵珍, 等. 不同破坏荷载下镀铜钢纤维增强废弃陶瓷超高性能混凝土的压敏性[J/OL]. 复合材料学报. https://doi.org/10.13801/j.cnki.fhclxb.20230921.001.ZHANG Liqing, BIAN Mingqiang, GUO Mianzhen, et al. Piezoresistivity of copper-plated steel fibers reinforced ultra high performance concrete with ceramic waste powder under different failure load types[J/OL]. Acta Materiae Compositae Sinica. https://doi.org/10.13801/j.cnki.fhclxb.20230921.001.(in Chinese). [32] XU F M, LIN X S, ZHOU A N, et al. Effects of recycled ceramic aggregates on internal curing of high performance concrete[J]. Construction and Building Materials, 2022, 322: 126484. doi: 10.1016/j.conbuildmat.2022.126484 [33] SIDDIQUE S, SHRIVASTAVA S, CHAUDHARY S. Lateral force microscopic examination of interfacial transition zone in ceramic concrete[J]. Construction and Building Materials, 2017, 155: 688-725. doi: 10.1016/j.conbuildmat.2017.08.080 [34] XU J, NIU X, MA Q, et al. Mechanical properties and damage analysis of rubber cement mortar mixed with ceramic waste aggregate based on acoustic emission monitoring technology[J]. Construction and Building Materials, 2021, 309: 125084. doi: 10.1016/j.conbuildmat.2021.125084 [35] 王长远, 王功勋, 裴启文, 等. 全组分利用废瓷砖制备混凝土及其耐久性[J]. 混凝土, 2017, (11): 181-184. doi: 10.3969/j.issn.1002-3550.2017.11.043WANG Changyuan, WANG Gongxun, PEI Qiwen, et al. Preparation and durability of concrete using the w hole component of w aste ceramic tile[J]. Concrete, 2017, (11): 181-184(in Chinese). doi: 10.3969/j.issn.1002-3550.2017.11.043 [36] 万超. 再生陶瓷粗骨料混凝土基本力学性能与碳化试验研究[D]. 泉州: 华侨大学, 2011.WAN Chao. Research on Basic Mechanics Performance and Carbonization Experiment of Recycled Ceramic Coarse Aggregate Concrete[D]. Quanzhou. Huaqiao University, 2011(in Chinese) [37] SILVESTRE R, MEDEL E, GARCIA A, et al. Utilizing recycled ceramic aggregates obtained from tile industry in the design of open graded wearing course on both laboratory and in situ basis[J]. Materials & Design, 2013, 50: 471-478. [38] HALICKA A, OGRODNIK P, ZEGARDLO B. Using ceramic sanitary ware waste as concrete aggregate[J]. Construction and Building Materials, 2013, 48: 295-305. doi: 10.1016/j.conbuildmat.2013.06.063 [39] AWOYERA P O, AKINMUSURU J O, NDAMBUKI J M. Green concrete production with ceramic wastes and laterite[J]. Construction and Building Materials, 2016, 117: 29-36. doi: 10.1016/j.conbuildmat.2016.04.108 [40] ZEGARDLO B, SZELAG M, OGRODNIK P. Ultra-high strength concrete made with recycled aggregate from sanitary ceramic wastes – The method of production and the interfacial transition zone[J]. Construction and Building Materials, 2016, 122: 736-742. doi: 10.1016/j.conbuildmat.2016.06.112 [41] 王帅. 废弃卫生陶瓷再生骨料混凝土常温及高温的力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.WANG Shuai. Study on Mechanical Properties of Recycled Aggregate Concrete with Waste Sanitray Ceramic at Room Temperature and High Temperature[D]. Harbin. Harbin Institute of Technology, 2020(in Chinese) [42] ALVES A V, VIEIRA T F, DE-BRITO J, et al. Mechanical properties of structural concrete with fine recycled ceramic aggregates[J]. Construction and Building Materials, 2014, 64: 103-113. doi: 10.1016/j.conbuildmat.2014.04.037 [43] CACHIM P B. Mechanical properties of brick aggregate concrete[J]. Construction and Building Materials, 2009, 23(3): 1292-1297. doi: 10.1016/j.conbuildmat.2008.07.023 [44] NEPOMUCENO M C S, ISIDORO R A S, CATARINO J P G. Mechanical Performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste[J]. Construction and Building Materials, 2018, 165: 284-294. doi: 10.1016/j.conbuildmat.2018.01.052 [45] SIDDIQUE S, CHAUDHARY S, SHRIVASTAVA S, et al. Sustainable utilisation of ceramic waste in concrete: Exposure to adverse conditions[J]. Journal of Cleaner Production, 2019, 210: 246-255. doi: 10.1016/j.jclepro.2018.10.231 [46] VIEIRA T, ALVES A, BRITO J D, et al. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware[J]. Materials & Design, 2016, 90: 767-776. [47] XU F M, LIN X S, ZHOU A N. Microstructure change and mechanical property variation of high performance concrete with recycled ceramic aggregate as internal curing material under different environmental temperatures[J]. Construction and Building Materials, 2023, 369: 130636. doi: 10.1016/j.conbuildmat.2023.130636 [48] BUI P T, OGAWA Y, NAKARAI K, et al. Internal curing of Class-F fly-ash concrete using high-volume roof-tile waste aggregate[J]. Materials and Structures, 2017, 50(4): 203. doi: 10.1617/s11527-017-1073-z [49] AMIN M, TAYEH B A, AGWA I S. Effect of using mineral admixtures and ceramic wastes as coarse aggregates on properties of ultrahigh-performance concrete[J]. Journal of Cleaner Production, 2020, 273: 123073. doi: 10.1016/j.jclepro.2020.123073 [50] GAUTAM L, JAIN J K, KALLA P, et al. A review on the utilization of ceramic waste in sustainable construction products[J]. Materials Today Proceedings, 2021, 43: 1884-1891. doi: 10.1016/j.matpr.2020.10.829 [51] CHENG Y H, HUANG F, LIU R, et al. Test research on effects of waste ceramic polishing powder on the permeability resistance of concrete[J]. Materials and Structures, 2016, 49(3): 729-738. doi: 10.1617/s11527-015-0533-6 [52] XIONG Y, XU G, WU D, et al. Investigation of using the ceramic polishing brick powder in engineered cementitious composites[J]. Journal of Building Engineering, 2021, 43: 102489. doi: 10.1016/j.jobe.2021.102489 [53] 张立卿, 潘延念, 胡文兵, 等. 废弃瓷砖粉对超高性能混凝土的抗压强度影响规律与机制[J]. 复合材料学报, 2023, 40(03): 1611-1623. doi: 10.13801/j.cnki.fhclxb.20220630.002ZHANG Liqing, PAN Yannian, HU Wenbing, et al. Effect law and mechanism of ceramic tile powder on compressive strength of ultra high performance concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(03): 1611-1623(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220630.002 [54] 丁小蒙. 废陶瓷再生粗骨料混凝土优化设计研究[D]. 南昌: 华东交通大学, 2014.DING Xiaomeng. Waste Ceramic Recycled Coarse Aggregate Concrete Design Research[D]. Nanchang. East China Jiaotong University, 2014(in Chinese) [55] DING X M, QI J N, FANG W, et al. Improvement on properties of recycled concrete with coarse ceramic vase aggregates using KH-550 surface treating technology[J]. European Journal of Environmental and Civil Engineering, 2020, 24(1): 1-16. doi: 10.1080/19648189.2017.1363664 [56] 刘凤利. 利用废陶瓷再生砂配制再生砂浆、混凝土的试验研究[D]. 郑州: 河南大学, 2011.LIU Fengli. Experimental Study on Making Recycled Mortar and Recycled Concrete Using Recycled Ceramic Aggregate[D]. Zhengzhou. Henan University, 2011(in Chinese) [57] 马昆林, 刘建, 申景涛, 等. 砖混再生粗骨料及其在混凝土中的研究与应用进展[J]. 材料导报, 2023, 37(18): 119-130. doi: 10.11896/cldb.22010215MA Kunlin, LIU Jian, SHEN Jingtao, et al. Research and Application Progress of Mixed Recycled Coarse Aggregate and Its Application in Concrete[J]. Materials Reports, 2023, 37(18): 119-130(in Chinese). doi: 10.11896/cldb.22010215 [58] HIGASHIYAMA H, MIZUKOSHI M, SAPPAKITTIPAKORN M. Efficiency of ground granulated blast-furnace slag replacement in ceramic waste aggregate mortar[J]. Cement and Concrete Composites, 2014, 49: 43-49. doi: 10.1016/j.cemconcomp.2013.12.014 [59] PACHECO-TORGAL F, JALALI S. Reusing ceramic wastes in concrete[J]. Construction and Building Materials, 2010, 24(5): 832-838. doi: 10.1016/j.conbuildmat.2009.10.023 [60] 陈梦成, 刘宇翔, 袁明胜. 陶瓷粉再生混凝土抗压强度正交试验研究[J]. 混凝土, 2018, (02): 86-89. doi: 10.3969/j.issn.1002-3550.2018.02.024CHEN Mengcheng, LIU Yuxiang, YUAN Mingsheng. Orthogonal experimental study on the compressive strength of ceramic pow der recycled concrete[J]. Concrete, 2018, (02): 86-89(in Chinese). doi: 10.3969/j.issn.1002-3550.2018.02.024 [61] 张众, 师郡, 孙振华. 大掺量陶瓷抛光废粉绿色混凝土的配制和性能[J]. 混凝土, 2017, (11): 139-144. doi: 10.3969/j.issn.1002-3550.2017.11.033ZHANG Zhong, SHI Jun, SUN Zhenhua. Preparation and performance of green concrete blended w ith high-volume ceramic polishing powder[J]. Concrete, 2017, (11): 139-144(in Chinese). doi: 10.3969/j.issn.1002-3550.2017.11.033 [62] LAVAT A E, TREZZA M A, POGGI M. Characterization of ceramic roof tile wastes as pozzolanic admixture[J]. Waste Management, 2009, 29(5): 1666-1674. doi: 10.1016/j.wasman.2008.10.019 [63] GAUTAM L, JAIN J K, ALOMAYRI T, et al. Performance evaluation of self-compacting concrete comprising ceramic waste powder as fine aggregate[J]. Materials Today Proceedings, 2022, 61: 204-211. doi: 10.1016/j.matpr.2021.08.063 [64] SHAMSAEI M, KHAFAIEH R, AGHAYAN I. Laboratory evaluation of the mechanical properties of roller compacted concrete pavement containing ceramic and coal waste powders[J]. Clean Technologies and Environmental Policy, 2019, 21(3): 707-716. doi: 10.1007/s10098-018-1657-5 [65] HE Z M, SHEN A Q, WU H S, et al. Research progress on recycled clay brick waste as an alternative to cement for sustainable construction materials[J]. Construction and Building Materials, 2021, 274: 122113. doi: 10.1016/j.conbuildmat.2020.122113 [66] MOHAMMED S. Processing, effect and reactivity assessment of artificial pozzolans obtained from clays and clay wastes: A review[J]. Construction and Building Materials, 2017, 140: 10-19. doi: 10.1016/j.conbuildmat.2017.02.078 [67] HOPPE J, PIRES C A O, LEITE O D, et al. Characterization of Red Ceramic Waste for Application as Mineral Addition in Portland Cement[J]. Journal of Materials in Civil Engineering, 2021, 33(6): 4021108. doi: 10.1061/(ASCE)MT.1943-5533.0003719 [68] 丁一宁, 董惠文, 曹明莉. 陶瓷废弃物粉末火山灰活性的研究[J]. 建筑材料学报, 2015, 18(05): 867-872.DING Yining, DONG Huiwen, CAO Mingli. Study on Pozzolanic Activity of Ceramic waste Powder[J]. Journal of Building Materials, 2015, 18(05): 867-872(in Chinese). [69] MA Z M, TANG Q, WU H X, et al. Mechanical properties and water absorption of cement composites with various fineness and contents of waste brick powder from C&D waste[J]. Cement and Concrete Composites, 2020, 114: 103758. doi: 10.1016/j.cemconcomp.2020.103758 [70] TANG Q, MA Z M, WU H X, et al. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review[J]. Cement and Concrete Composites, 2020, 114: 103807. doi: 10.1016/j.cemconcomp.2020.103807 [71] 王功勋. 养护条件对陶瓷抛光砖粉-石灰胶凝材料强度的影响[J]. 工业建筑, 2012, 42(S1): 493-497. doi: 10.13204/j.gyjz2012.s1.203WANG Gongxun. Effect of Different Curing Conditions on the Strength of Ceramic Polishing Powder-Lime Cementitious Material[J]. Industrial Construction, 2012, 42(S1): 493-497(in Chinese). doi: 10.13204/j.gyjz2012.s1.203 [72] 黄丹, 王功勋, 卢胜男, 等. 水热条件下陶瓷抛光砖粉的水化活性[J]. 硅酸盐通报, 2016, 35(02): 561-567. doi: 10.16552/j.cnki.issn1001-1625.2016.02.046HUANG Dan, WANG Gongxun, LU Shengnan, et al. Hydration Activity of Ceramic Polishing Powder at Hydrothermal Conditions[J]. Bulletin of the Chinese Ceramic Society, 2016, 35(02): 561-567(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2016.02.046 [73] ZHAO Y, GAO J, LIU C, et al. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement[J]. Journal of Cleaner Production, 2020, 242: 118521. doi: 10.1016/j.jclepro.2019.118521 [74] 马昆林, 孟维琦, 申景涛, 等. 再生微粉性能激活研究及应用进展[J/OL]. 材料导报. https://kns.cnki.net/kcms/detail/50.1078.TB.20230506.1058.004.htmlMa Kunlin, Meng Weiqi, Shen Jingtao, et al. Advances in Research of Performance Activation of Recycled Powders and Relevant Applications[J/OL]. Materials Reports. https://kns.cnki.net/kcms/detail/50.1078.TB.20230506.1058.004.html.(in Chinese). [75] 白希选, 张迪, 陈旭勇, 等. 碱激发陶瓷粉对再生混凝土坍落度和抗压强度的影响[J]. 武汉工程大学学报, 2022, 44(01): 102-106. doi: 10.19843/j.cnki.CN42-1779/TQ.202107017BAI Xixuan, ZHANG Di, CHEN Xuyong, et al. Effect of Alkali-Activated Ceramic Powder on Slump and Compressive Strength of Recycled Concrete[J]. Journal of Wuhan Institute Technology, 2022, 44(01): 102-106(in Chinese). doi: 10.19843/j.cnki.CN42-1779/TQ.202107017 [76] MANSUR M A, WEE T H, LEE S C. Crushed Brichs as Coarse Aggregate for Concrete[J]. ACI Structural Journal, 1999, 96(4): 478-484. [77] GARBA M M. Investigations into the Proprties of Concrete Made with Crushed Bricks as Coarse Aggregate[J]. Filologia E Linguística Portuguesa, 1988, (3): 215. [78] KHALOO A R. Properties of concrete using crushed clinker brick as coarse aggregate[J]. Aci Materials Journal, 1994, 91(4): 401-407. [79] GHARIBI H, MOSTOFINEJAD D, BAHMANI H, et al. Improving thermal and mechanical properties of concrete by using ceramic electrical insulator waste as aggregates[J]. Construction and Building Materials, 2022, 338: 127647. doi: 10.1016/j.conbuildmat.2022.127647 [80] RASHID K, RAZZAQ A, AHAMD M, et al. Experimental and analytical selection of sustainable recycled concrete with ceramic waste aggregate[J]. Construction and Building Materials, 2017, 154: 829-840. doi: 10.1016/j.conbuildmat.2017.07.219 [81] MEDINA C, DE-ROJAS M I S, THOMAS C, et al. Durability of recycled concrete made with recycled ceramic sanitary ware aggregate. Inter-indicator relationships[J]. Construction and Building Materials, 2016, 105: 480-486. doi: 10.1016/j.conbuildmat.2015.12.176 [82] MEDINA C, DE-ROJAS M I S, FRIAS M. Properties of recycled ceramic aggregate concretes: Water resistance[J]. Cement and Concrete Composites, 2013, 40: 21-29. doi: 10.1016/j.cemconcomp.2013.04.005 [83] ALIABDO A A, ABD-ELMOATY A M, HASSAN H H. Utilization of crushed clay brick in concrete industry[J]. Alexandria Engineering Journal, 2014, 53(1): 151-168. doi: 10.1016/j.aej.2013.12.003 [84] ZAREEI S A, AMERI F, BAHRAMI N, et al. Green high strength concrete containing recycled waste ceramic aggregates and waste carpet fibers: Mechanical, durability, and microstructural properties[J]. Journal of Building Engineering, 2019, 26: 100914. doi: 10.1016/j.jobe.2019.100914 [85] CORREIA J R, DE-BRITO J, PEREIRA A S. Effects on concrete durability of using recycled ceramic aggregates[J]. Materials and Structures, 2006, 39(2): 169-177. doi: 10.1617/s11527-005-9014-7 [86] LAM M N T, LE D H, NGUYEN D L. Reuse of clay brick and ceramic waste in concrete: A study on compressive strength and durability using the Taguchi and Box-Behnken design method[J]. Construction and Building Materials. 2023, 373. [87] ZHANG J H, LIU X G, DING K, et al. Dynamic splitting tensile behaviors of ceramic aggregate concrete: An experimental and mesoscopic study[J]. Structural Concrete, 2022, 23(5): 3267-3283. doi: 10.1002/suco.202100542 [88] UDDIN M T, MAHMOOD A H, KAMAL M, et al. Effects of maximum size of brick aggregate on properties of concrete[J]. Construction and Building Materials, 2017, 134: 713-726. doi: 10.1016/j.conbuildmat.2016.12.164 [89] ZHANG Z Q, ZHANG Y F, YAN C G, et al. Influence of crushing index on properties of recycled aggregates pervious concrete[J]. Construction and Building Materials, 2017, 135: 112-118. doi: 10.1016/j.conbuildmat.2016.12.203 [90] 孔德玉. 天然与再生骨料混凝土水灰比统一定则(Ⅰ)——粗骨料强度的影响[J]. 建筑材料学报, 2003, (02): 129-134. doi: 10.3969/j.issn.1007-9629.2003.02.004Kong Deyu. Unified Bolomeys Formula of Concrete Made with Naturaland Recycled Coarse Aggregate (Ⅰ)———Effect of Strength of Coarse Aggregate[J]. Journal of Building Materials, 2003, (02): 129-134(in Chinese). doi: 10.3969/j.issn.1007-9629.2003.02.004 [91] LIU Q, SINGH A, XIAO J Z, et al. Workability and mechanical properties of mortar containing recycled sand from aerated concrete blocks and sintered clay bricks[J]. Resources, Conservation and Recycling, 2020, 157(1): 104728. [92] 刘超, 余伟航, 刘化威, 等. 再生砖骨料混凝土力学性能及破坏机理研究[J]. 材料导报, 2021, 35(13): 13025-13031. doi: 10.11896/cldb.20050255LIU Chao, YU Weihang, LIU Huawei, et al. Study on Mechanical Properties and Failure Mechanism of Recycled Brick Aggregate Concrete[J]. Materials Reports, 2021, 35(13): 13025-13031(in Chinese). doi: 10.11896/cldb.20050255 [93] MEDINA C, FRIAS M, DE-ROJAS M I S. Microstructure and properties of recycled concretes using ceramic sanitary ware industry waste as coarse aggregate[J]. Construction and Building Materials, 2012, 31: 112-118. doi: 10.1016/j.conbuildmat.2011.12.075 [94] MANSUR A A P, MANSUR H S. Surface interactions of chemically active ceramic tiles with polymer-modified mortars[J]. Cement and Concrete Composites, 2011, 33(7): 742-748. doi: 10.1016/j.cemconcomp.2011.04.003 [95] BINICI H. Effect of crushed ceramic and basaltic pumice as fine aggregates on concrete mortars properties[J]. Construction and Building Materials, 2007, 21(6): 1191-1197. doi: 10.1016/j.conbuildmat.2006.06.002 [96] JIMENEZ J R, AYUSO J, LOPEZ M, et al. Use of fine recycled aggregates from ceramic waste in masonry mortar manufacturing[J]. Construction and Building Materials, 2013, 40: 679-690. doi: 10.1016/j.conbuildmat.2012.11.036 [97] 李政. 纤维增韧废陶瓷骨料混凝土基本力学性能试验研究[D]. 信阳: 信阳师范学院, 2019.LI Zheng. Experimental Study on Basic Mechanical Properties of Fiber Toughened Waste Ceramic Aggregate Concrete[D]. Xinyang. Xinyang Normal University, 2019(in Chinese) [98] VILAS M R, KUMAR J J, SINGH C H, et al. Mechanical and durability performance of self-compacting concrete with waste ceramic tile as a replacement for natural river sand[J]. Materials Today Proceedings, 2022, 60: 187-193. doi: 10.1016/j.matpr.2021.12.303 [99] CAMPOS M A, PAULON V A, DE ARGOLLO-FERRAO A M. Concrete Made with Alternative Fine Aggregates: The Reuse of Porcelain Electrical Insulators[J]. Materials Science Forum, 2018, 912: 185-190. doi: 10.4028/www.scientific.net/MSF.912.185 [100] LUCAS J, DE-BRITO J, VEIGA R, et al. The effect of using sanitary ware as aggregates on rendering mortars' performance[J]. Materials & Design, 2016, 91: 155-164. [101] PEREIRA V M, CAMARINI G. Fresh and Hardened Properties of Self-Leveling Mortars with Porcelain and Red Ceramic Wastes[J]. Advance in Civil Engineering, 2018, 2018(PT.4): 6378643. [102] 刘凤利, 张承志, 刘俊华. 利用废陶瓷再生粗砂配制再生砂浆的试验研究[J]. 河南大学学报(自然科学版), 2011, 41(04): 425-428. doi: 10.15991/j.cnki.411100.2011.04.015LIU Fengli, ZHANG Chengzhi, LIU Junhua. Experimental Study on Making Recycled Aggregate Mortar with Recycled Ceramic Sand[J]. Journal of Henan University(Natural Science), 2011, 41(04): 425-428(in Chinese). doi: 10.15991/j.cnki.411100.2011.04.015 [103] TORKITTIKUL P, CHAIPANICH A. Utilization of ceramic waste as fine aggregate within Portland cement and fly ash concretes[J]. Cement and Concrete Composites, 2010, 32(6): 440-449. doi: 10.1016/j.cemconcomp.2010.02.004 [104] GUENDOUZ M, BOUKHELKHAL D. Properties of flowable sand concrete containing ceramic wastes[J]. Journal of Adhesion Science and Technology, 2019, 33(24): 2661-2683. doi: 10.1080/01694243.2019.1653594 [105] WILD S. Observations on the use of ground waste clay brick as a cement replacement material[J]. Building Research & Information, 1996, 24(1): 35-40. [106] WILD S, GAILIUS A, HANSEN H, et al. Pozzolanic properties of a variety of European clay bricks[J]. Building Research and Information, 1997, 25(3): 170-175. doi: 10.1080/096132197370435 [107] LI L G, ZHOU Z Y, ZHU J, et al. Reutilizing ceramic polishing waste as powder filler in mortar to reduce cement content by 33% and increase strength by 85%[J]. Powder Technology, 2019, 355: 119-126. doi: 10.1016/j.powtec.2019.07.043 [108] ZITO S V, IRASSAR E F, RAHHAL V F. Management of sanitary ware wastes as supplementary cementing materials in concretes[J]. Journal of Sustainable Cement-Based Materials, 2020, 9(1): 35-49. doi: 10.1080/21650373.2019.1673258 [109] GAUTAM L, JAIN J K, JAIN A, et al. Valorization of bone-china ceramic powder waste along with granite waste in self-compacting concrete[J]. Construction and Building Materials, 2022, 315: 125730. doi: 10.1016/j.conbuildmat.2021.125730 [110] 董惠文. 陶瓷废弃物作为水泥掺合料的性能研究[D]. 大连: 大连理工大学, 2015.DONG Huiwen. Study on Properties of Ceramic Waste Powder as Cement Admixture[D]. Dalian. Dalian University of Technology, 2015(in Chinese) [111] LAM M N T, NGUYEN D T, NGUYEN D L. Potential use of clay brick waste powder and ceramic waste aggregate in mortar[J]. Construction and Building Materials, 2021, 313: 125516. doi: 10.1016/j.conbuildmat.2021.125516 [112] LI L, LIU W, YOU Q, et al. Waste ceramic powder as a pozzolanic supplementary filler of cement for developing sustainable building materials[J]. Journal of Cleaner Production, 2020, 259: 120853. doi: 10.1016/j.jclepro.2020.120853 [113] HIGASHIYAMA H, YAGISHITA F, SANO M, et al. Compressive strength and resistance to chloride penetration of mortars using ceramic waste as fine aggregate[J]. Construction and Building Materials, 2012, 26(1): 96-101. doi: 10.1016/j.conbuildmat.2011.05.008 [114] RESIN R, ALWARED A, AL-HUBBOUBI S, et al. Utilization of brick waste as pozzolanic material in concrete mix[C]. MATEC Web Conf, 2018. [115] ZHENG L, ZHI G, YAO Z, et al. Mechanical Properties of Mortar with Recycled Clay-Brick-Powder[C]. ACSE, 2011. [116] LIU S H, DAI R P, CAO K J, et al. The Role of Sintered Clay Brick Powder During the Hydration Process of Cement Pastes[J]. Iranian Journal of Science and Technology-Transactions of Civil Engineering, 2017, 41(2): 159-165. doi: 10.1007/s40996-017-0049-0 [117] HEIDARI A, TAVAKOLI D. A study of the mechanical properties of ground ceramic powder concrete incorporating nano-SiO2 particles[J]. Construction and Building Materials, 2013, 38: 255-264. doi: 10.1016/j.conbuildmat.2012.07.110 [118] LI L, LIU W F, YOU Q X, et al. Relationships between microstructure and transport properties in mortar containing recycled ceramic powder[J]. Journal of Cleaner Production, 2020, 263: 121384. doi: 10.1016/j.jclepro.2020.121384 [119] WANG L Q, LIU Z Y, XU S D, et al. A Study on the Effect of Ceramic Polishing Powder on the Nucleation and Growth of Hydrates in Cement Paste[J]. Crystals, 2019, 9(10): 545. doi: 10.3390/cryst9100545 -

下载:

下载: