Preparation and wear resistance of ZrO2 toughened Al2O3 ceramic particles reinforced high chromium cast iron matrix composites by powder sintering and casting

-

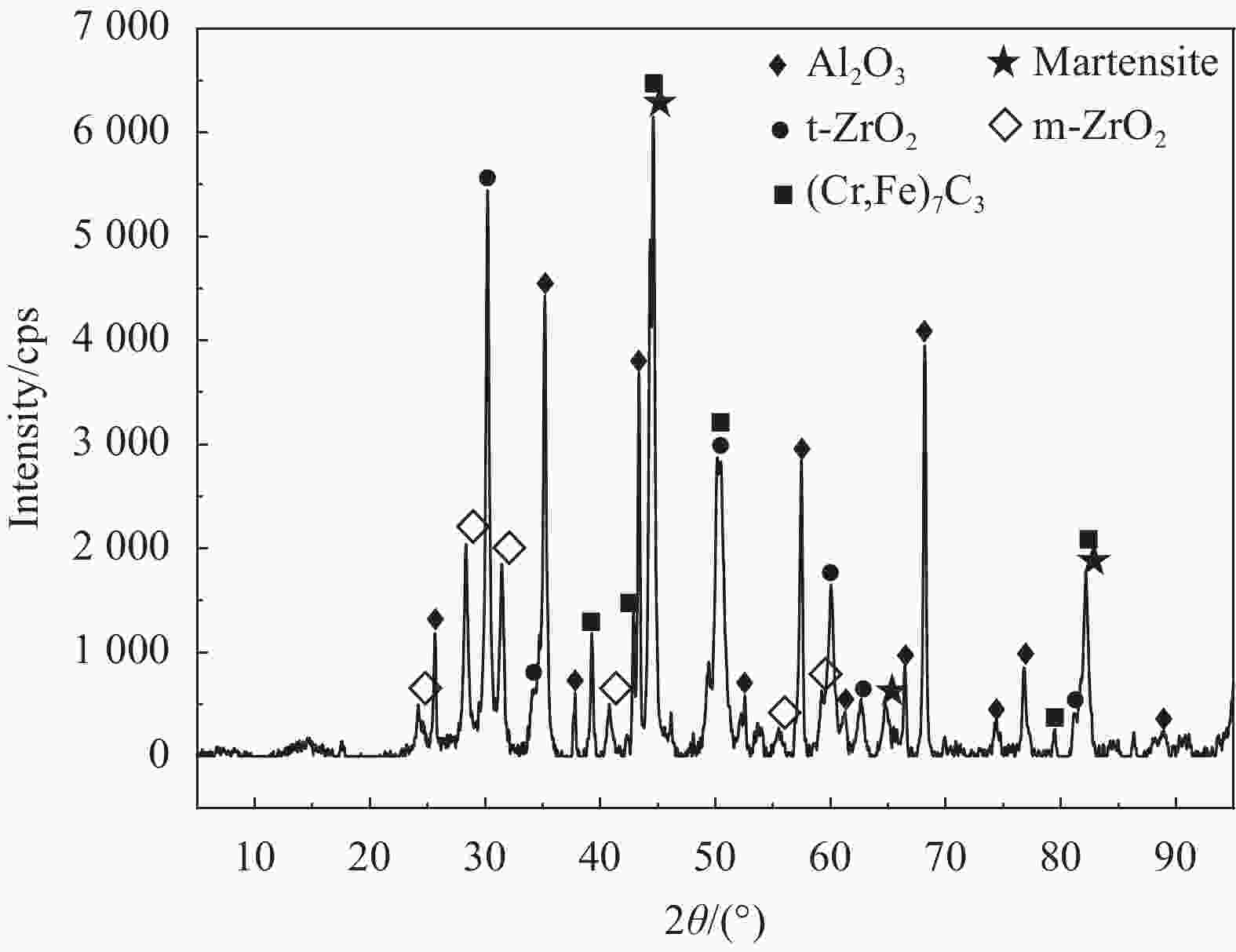

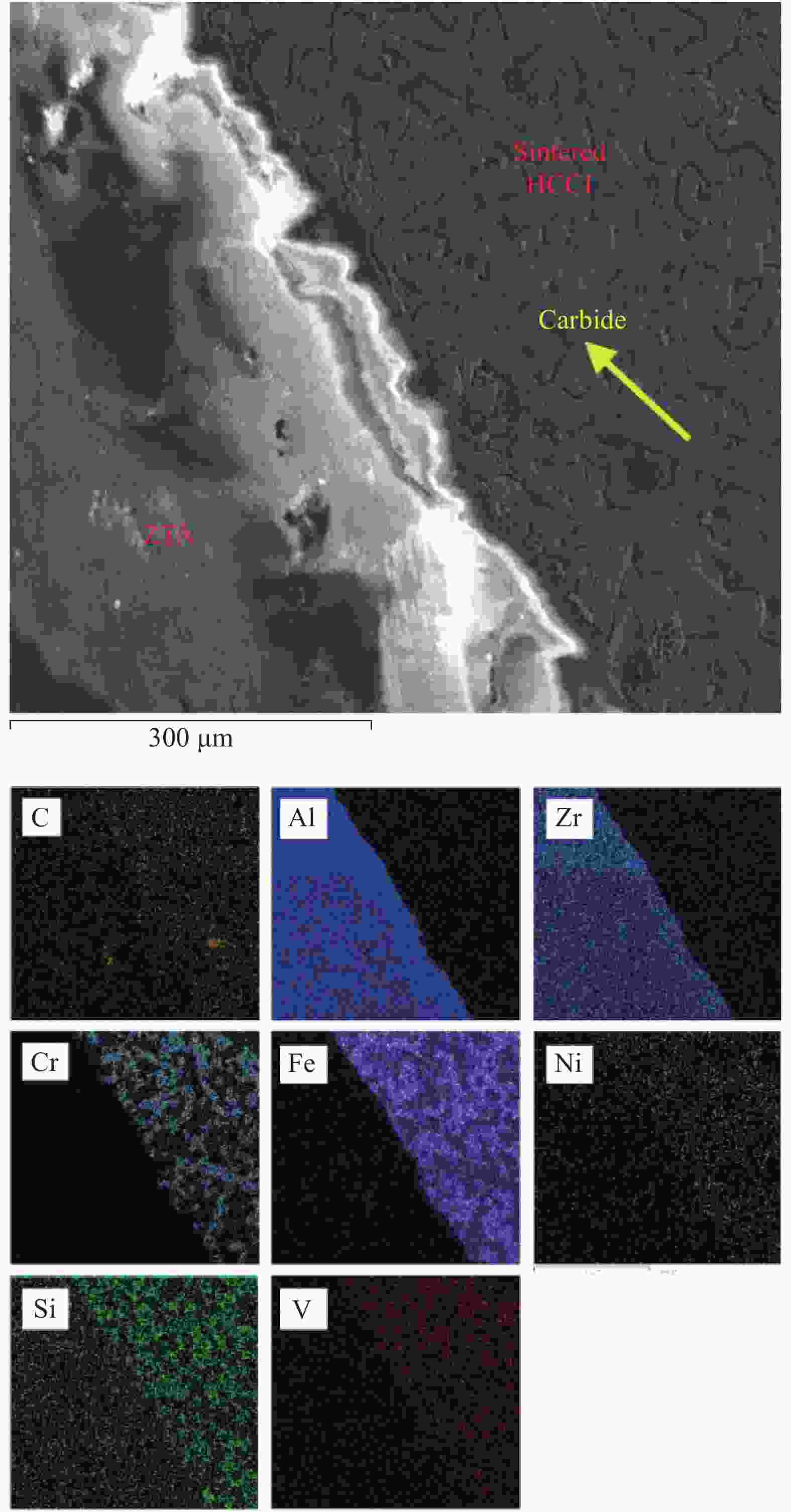

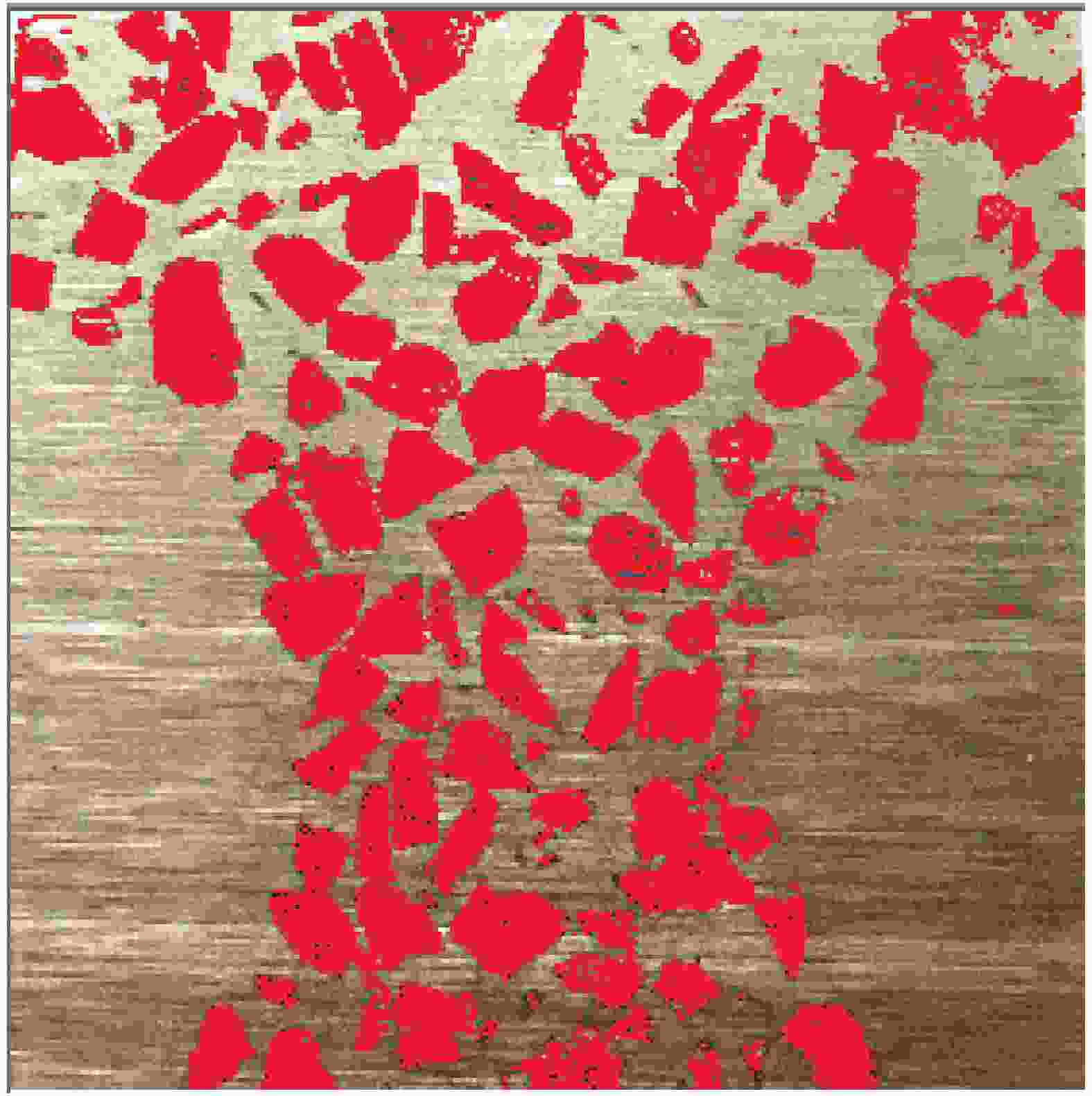

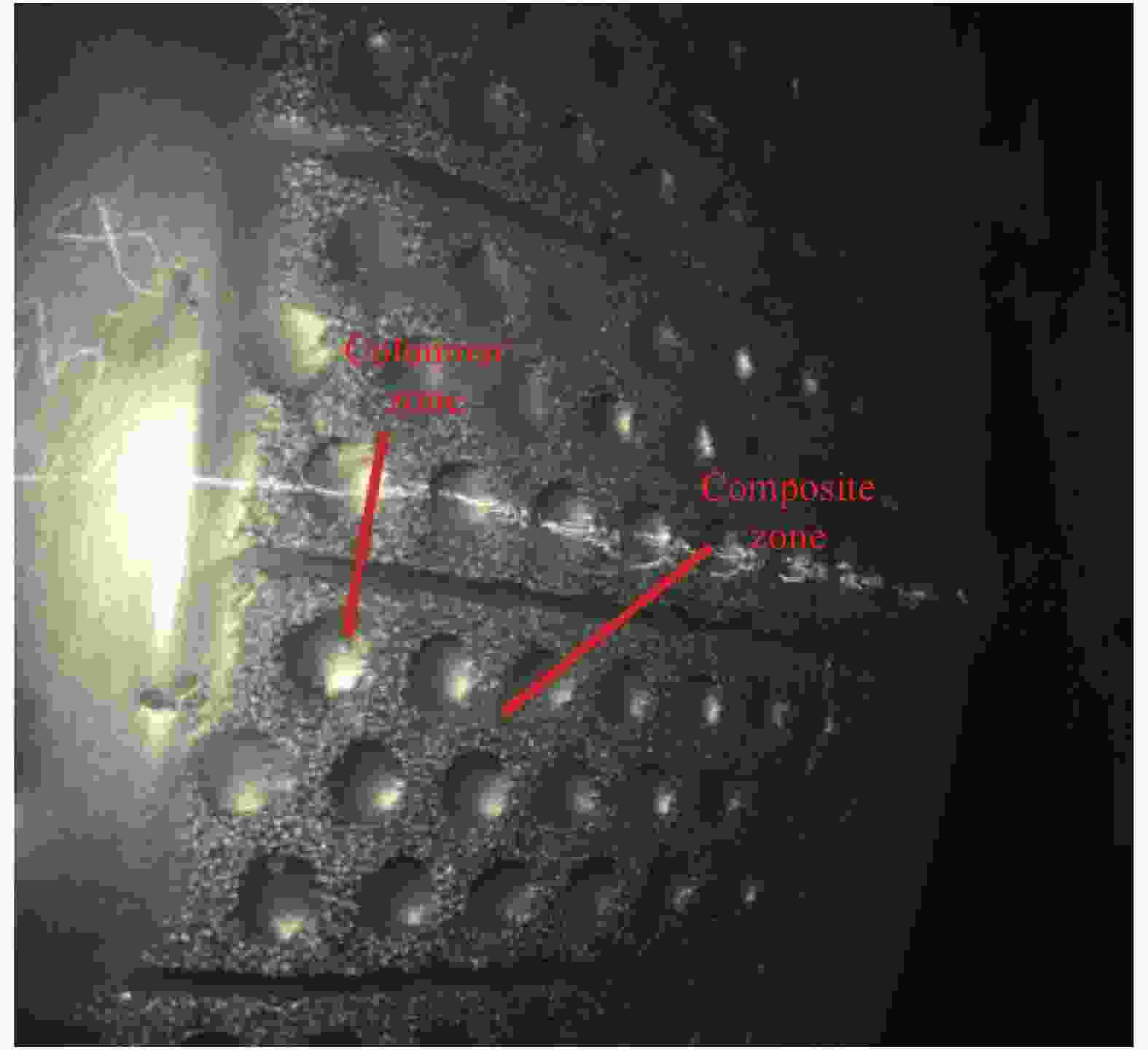

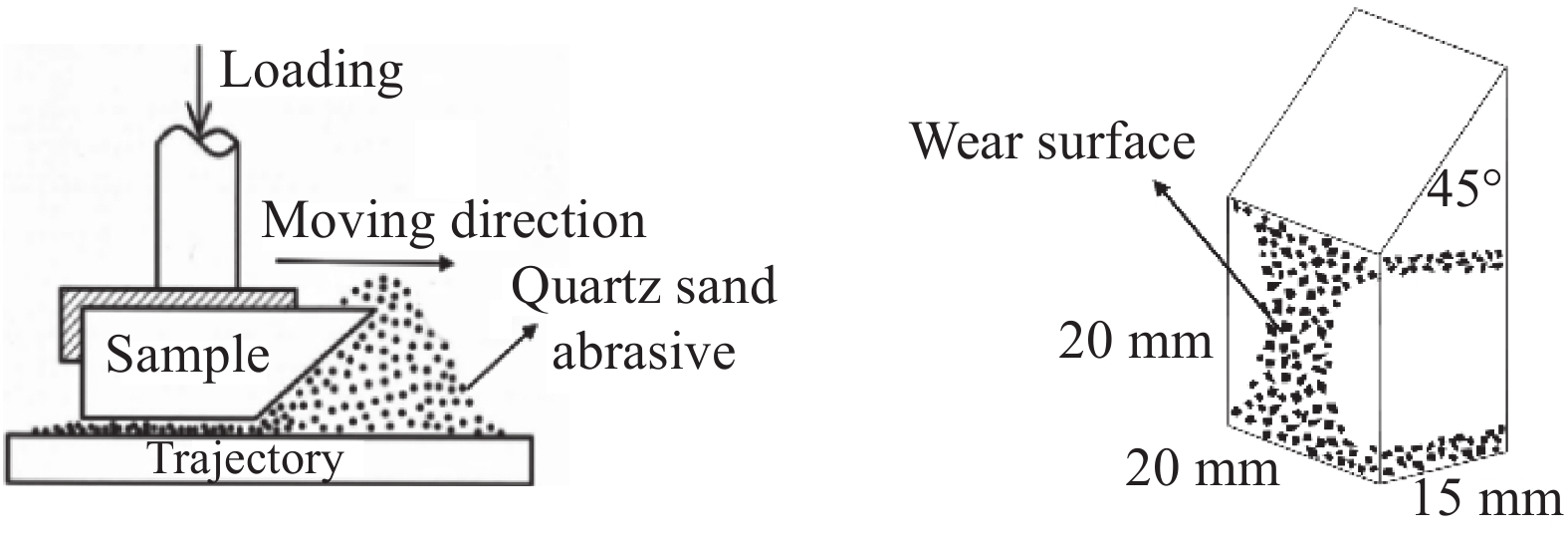

摘要: 将粒径为1~2 mm的ZrO2增韧Al2O3陶瓷颗粒(ZTAp)、高铬合金粉末和黏结剂混合真空烧结制备蜂窝状预制体,再浇注高铬铸铁液制备出ZTAp增强高铬铸铁基复合材料。采用SEM、EDS、XRD分析复合材料的界面微观结构和物相组成,通过三体磨损试验评价复合材料的耐磨性能。结果表明,烧结高铬铸铁基体在铸造过程中发生重熔,与铸造高铬铸铁基体呈冶金结合,ZTAp与金属基体界面结合致密,无裂纹、气孔等缺陷。复合材料三体耐磨性能达到高铬铸铁的3倍以上。将该复合材料应用于制备磨辊件,经过5 000 h服役,柱状区和复合区在磨辊半径方向上的磨损量分别为8.2 mm、5.9 mm,预计寿命可达到高铬铸铁磨辊的2倍以上。Abstract: The honeycomb preforms were prepared by vacuum sintering the mixture of ZrO2 toughened Al2O3 ceramic particles (ZTAp) of 1-2 mm, high chromium alloy powder and binder. ZTAp reinforced high chromium cast iron composites were then prepared by pouring high chromium cast iron. The interface microstructure and phase composition of the composites were analyzed by SEM, EDS and XRD. The wear resistance of the composite was evaluated by three-body abrasive wear test. The results show that the matrix of sintered high chromium cast iron is remelted in the process of casting and is metallurgical bonded with cast high chromium cast iron matrix. The interface between ZTAp and metal matrix is compact, and there are no defects such as cracks and pores. The three-body abrasive wear resistance of the composites is more than 3 times of that of high chromium cast iron. The composites are applied to the preparation of grinding roller parts. After 5 000 h of service, the wear loss of the columnar zone and composite zone in the direction of grinding roller radius are 8.2 mm and 5.9 mm, respectively, and the expected service life can be more than twice that of the high chromium cast iron grinding roller.

-

Key words:

- ZrO2 toughened Al2O3 /

- high chromium cast iron /

- composites /

- powder sintering /

- casting /

- three-body abrasive wear

-

表 1 ZrO2增韧Al2O3陶瓷颗粒(ZTAp)物理/力学性能

Table 1. Physical and mechanical properties of ZrO2 toughened Al2O3 ceramic particles (ZTAp)

Material Density/

(g·cm−3)Vickers

hardnessCoefficient of thermal

expansion/10−6℃−1Fracture toughness/

(MPa·m1/2)Flexural strength/

MPaZTAp 4.6 1 800-2 100 7.5-9.0 6.5-9.0 350-550 表 2 高铬合金粉末化学成分

Table 2. Chemical compositions of high chromium cast iron alloy powder

wt% Element C Cr Si Mn Ni V Mo Fe Content 3.2-3.5 26-28 0.7-1.0 1.1-1.4 2.3-2.5 0.2-0.3 0.4-0.6 Bal. 表 3 铸造渗高铬铸铁(HCCI)化学成分

Table 3. Chemical compositions of cast high chromium cast iron (HCCI)

wt% Element C Cr Si Mn Ni Mo Cu Fe Content 3.0-3.3 24-26 0.5-0.8 0.6-1.0 0.3-0.5 0.4-0.6 0.2-0.3 Bal. -

[1] 魏世忠, 徐流杰. 钢铁耐磨材料研究进展[J]. 金属学报, 2020, 56(4):523-538. doi: 10.11900/0412.1961.2019.00370WEI S Z, XIU L J. Review on research progress of steel and iron wear-resistant materials[J]. Acta Metallurgica Sinica,2020,56(4):523-538(in Chinese). doi: 10.11900/0412.1961.2019.00370 [2] 钱兵, 孙书刚, 朱昱, 等. 中速磨煤机金属陶瓷复合磨辊及磨盘的研究[J]. 中国电力, 2014, 47(10):122-125.QIAN B, SUN S G, ZHU Y, et al. Development of ceramal compound grinding roller and refiner plate of medium speed mill[J]. Electric Power,2014,47(10):122-125(in Chinese). [3] OJALA N , VALTONEN K , ANTIKAINEN A, et al. Wear performance of quenched wear resistant steels in abrasive slurry erosion[J]. Wear,2016,354–355:21-31. [4] HU Y B, CONG W L. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites[J]. Ceramics International,2018,44(17):20599-20612. doi: 10.1016/j.ceramint.2018.08.083 [5] SAHOO B P, DAS D. Tribological behaviour of ceramic and carbon nano-tube reinforced metal matrix composites-A review[J]. Materials Today: Proceedings,2018,5(9):20549-20559. doi: 10.1016/j.matpr.2018.06.433 [6] MONILA J M, NARCISO J, WEBER L, et al. Thermal con-ductivity of Al-SiC composites with monomodal and bimodal particle size distribution[J]. Materials Science and Engineering A,2008,480(1-2):483-488. [7] 周谟金, 蒋业华, 温放放. 热处理对高铬铸铁基蜂窝陶瓷复合材料耐磨性的影响[J]. 材料导报, 2017, 31(14):117-121. doi: 10.11896/j.issn.1005-023X.2017.014.025ZHOU M J, JIANG Y H, WEN F F. Effect of heat treatment on wear resistance of honeycomb ceramic preform reinforced chromium cast iron matrx composite[J]. Materials Reports,2017,31(14):117-121(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.014.025 [8] 王文龙, 刘海云, 王晓杰, 等. 浸渗法制备ZTA陶瓷/铁基复合材料研究进展[J]. 特种铸造及有色合金, 2020, 40(1):37-41.WANG W L, LIU H Y, WANG X J, et al. Research progress in ZTA ceramic/iron matrix composites prepared by infiltration method[J]. Special Casting & Nonferrous Alloys,2020,40(1):37-41(in Chinese). [9] 范瑞瑞, 张瑞, 李炎, 等. 粉末冶金法制备Al2O3颗粒增强Fe基复合材料[J]. 热加工工艺, 2011, 40(24):120-123. doi: 10.3969/j.issn.1001-3814.2011.24.038FAN R R, ZHANG R, LI Y, et al. Fabrication of Fe matrix composite reinforced with Al2O3 particles by powder metallurgical method[J]. Hot Working Technology,2011,40(24):120-123(in Chinese). doi: 10.3969/j.issn.1001-3814.2011.24.038 [10] KONOPKA K, OLSZÓWKA-MYALSKA A, SZAFRAN M. Ceramic-metal composites with an interpenetrating network[J]. Materials Chemistry & Physics, 2003, 81(2-3): 329-332. [11] 郑开宏, 高义民, 陈亮, 等. 颗粒增强铁基复合材料的三体磨料磨损性能[J]. 摩擦学学报, 2012, 32(2):176-182.ZHENG K H, GAO Y M, CHEN L, et al. Three-body abrasive wear behavior of iron matrix composites reinforced with tungsten carbide particles[J]. Tribology,2012,32(2):176-182(in Chinese). [12] KIHARA M, OGATA T, NAKAMURA K, et al. Effect of Al2O3additions on mechanical properties and microstructure of Y-TZP[J]. Journal of the Ceramic Society of Japan,1988,96:635-642. [13] QIU B, XING S, DONG Q. Fabrication and wear behavior of ZTA particles reinforced iron matrix composite produced by flow mixing and pressure compositing[J]. Wear,2019,428-429:167-177. doi: 10.1016/j.wear.2019.03.013 [14] Magotteaux International SA (BE). Cast parts with enhanced wear resistance: US, 7513295[P]. 2006-01-20. [15] 陈建, 潘复生. 合金元素影响铝/陶瓷界面润湿性的研究现状[J]. 兵器材料科学与工程, 1999(4):3-5. doi: 10.3969/j.issn.1004-244X.1999.04.001CHEN J, PAN F S. Research status of influence of alloying elements on wettability of Al/ceramic interface[J]. Ordnance Material Science and Engineering,1999(4):3-5(in Chinese). doi: 10.3969/j.issn.1004-244X.1999.04.001 [16] WITTIG D, GLAUCHE A. ANEZIRIS C G, et al. Activated pressureless melt infiltration of zirconia-based metal matrix composites[J]. Materials Science and Engineering,2008,A488(1-2):580-585. [17] 孙书刚, 钱兵, 李小武, 等. ZTA颗粒增强高铬铸铁基复合材料制备及磨损性能研究[J]. 铸造技术, 2018, 39(8):1663-1666.SUN S G, QIAN B, LI X W, et al. Preparation and wear properties of ZTA particle reinforced high chromium cast iron matrix composites[J]. Foundry Technology,2018,39(8):1663-1666(in Chinese). [18] SOBOLEV A, MIRZOEV A. Structure and stability of (Cr, Fe)7C3 ternary carbides in solid and liquid state[J]. Journal of Alloys and Compounds,2019,804:566-572. doi: 10.1016/j.jallcom.2019.06.282 [19] 肖平安, 肖璐琼, 顾景洪, 等. 15Cr系亚共晶高铬铸铁的烧结制备与性能研究[J]. 湖南大学学报(自然科学版), 2019, 46(12):58-64.XIAO P A, XIAO L Q, GU J H, et al. Study on sintering preparation and properties of 15Cr hypoeutectic high-chromium cast iron[J]. Journal of Hu'nan University (Natural Sciences),2019,46(12):58-64(in Chinese). [20] BAJWA R S, KHAN Z, BAKOLAS V, et al. Water-lubricated Ni-based composite(Ni-Al2O3, Ni-SiC and Ni-ZrO2) thin film coatings for industrial applications[J]. Acta Metallurgica Sinica,2016,29(1):1-9. [21] 贾建民, 齐纪渝, 谢敬学. MPS 中速磨煤机磨辊磨损机理研究[J]. 华北电力大学学报, 1998, 25(4):88-91.JIA J M, QI J Y, XIE J X. Research on wear mechanism of MPS type mill roll[J]. Journal of North China Electric Power University,1998,25(4):88-91(in Chinese). -

下载:

下载: