Study on the in-situ growth of hyperbranched polysioxane with double bonds on the surface of aramid fiber

-

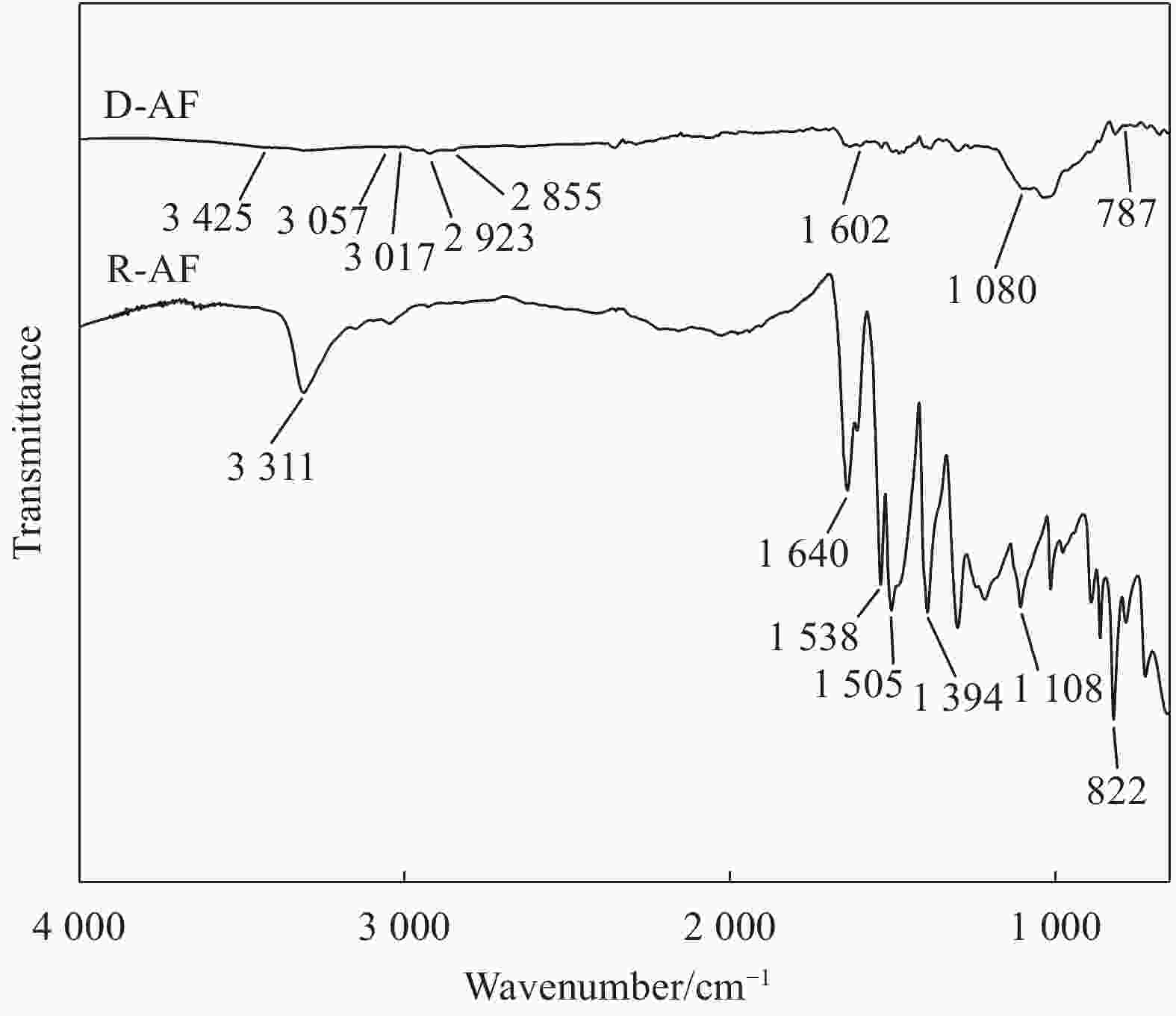

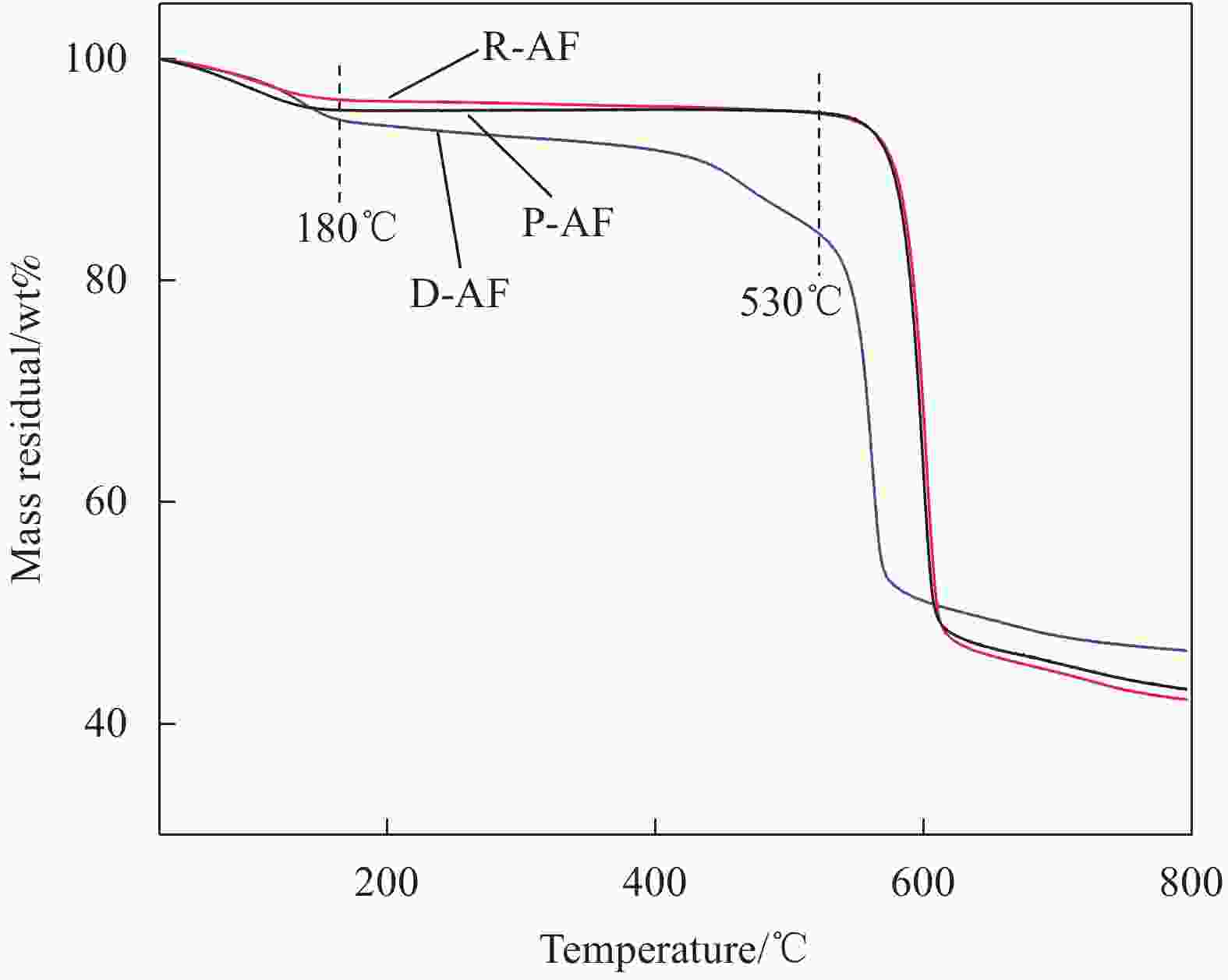

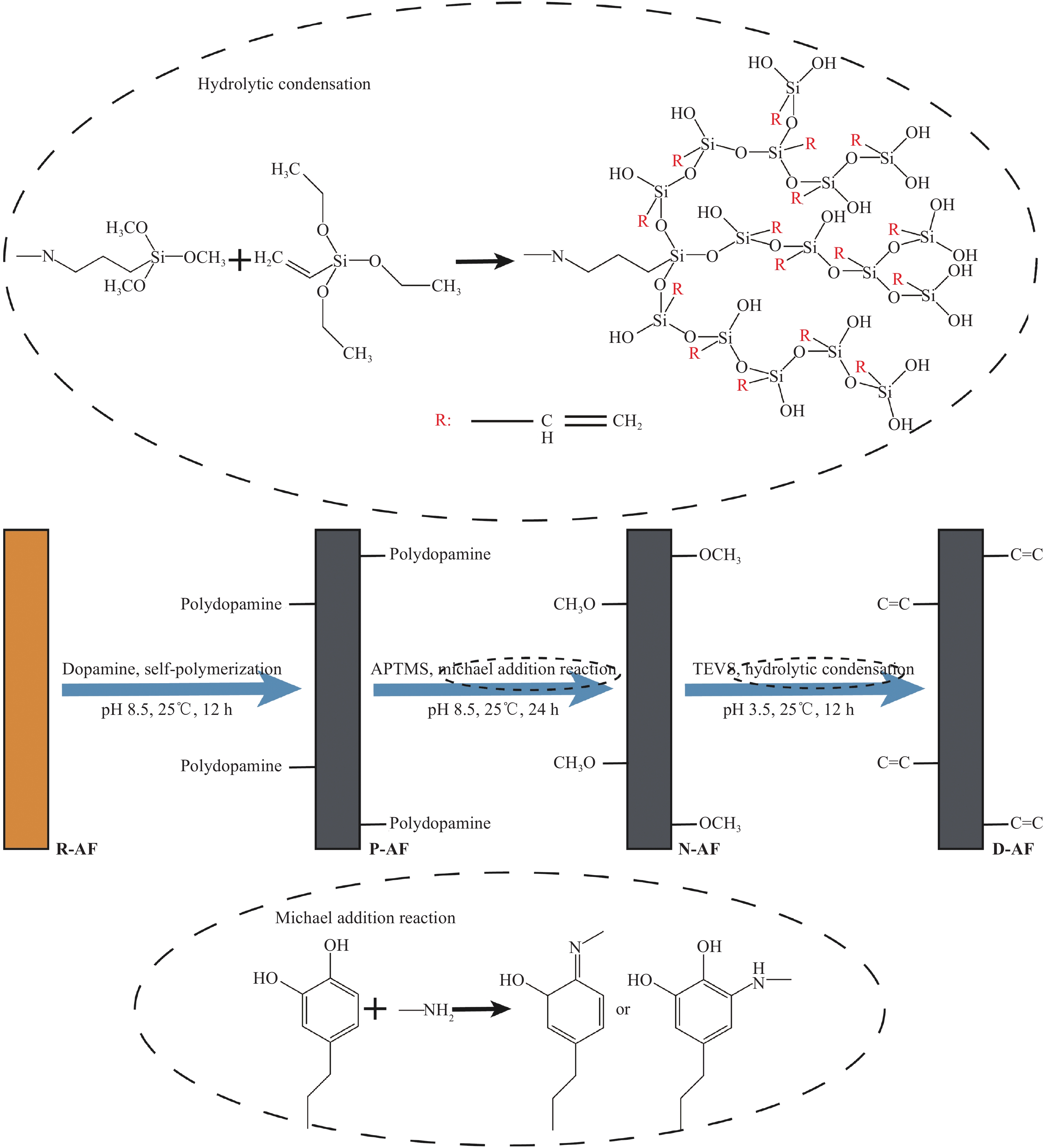

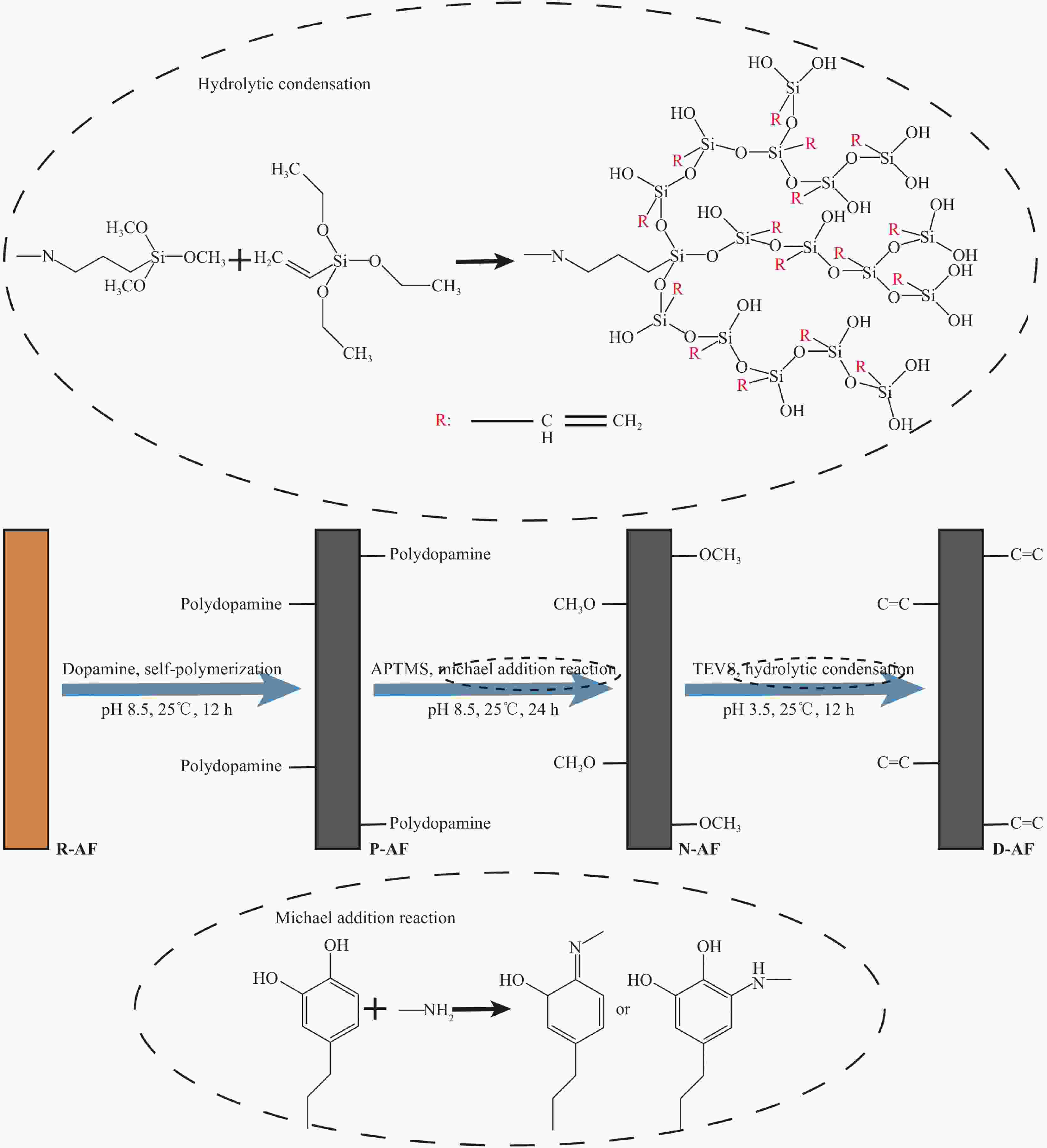

摘要: 以显著提升芳纶纤维与橡胶基体之间的界面结合强度为目标,本文开发了一种在芳纶纤维表面原位生长碳碳双键超支化聚硅氧烷的策略:首先借助多巴胺的仿生修饰建立初始层,接着采用迈克尔加成反应接枝氨基硅烷偶联剂创建中间层,最后通过脱水缩合反应实现原位生长。改性前后的芳纶纤维表面形貌和化学结构采用扫描电镜、傅里叶变换红外线光谱分析仪、X射线光电子能谱分析仪及热失重分析仪进行了测试表征。由芳纶纤维增强橡胶基复合材料的H-抽出力测试结果可得,本文采用的改性方法能够提升约66.4%的界面结合强度,其原因主要可以归结为表面粗糙度的提升及纤维束与橡胶共硫化的实现。对比分析发现,聚多巴胺初始层的采用使本改性方法具有较高的普适性和工业应用潜力。Abstract: To improve the interfacial performance between aramid fiber and rubber matrix, this paper developed a strategy of in-situ growth of hyperbranched polysiloxane with double bonds onto the surface of aramid fiber. At first, the initial layer on the surface of fiber was established by the biomimetic modification of dopamine, and then, the middle layer was created by the graft of amino silane coupling agent via Michael addition reaction. Finally, the in-situ growth of hyperbranched polysiloxane was realized through the dehydration condensation reaction. The surface morphology and chemical structures of aramid fibers before and after modification were investigated by scanning electron microscope, Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy and thermogravimetric analysis. It can be obtained from the results of H pull-out tests of aramid fiber/rubber that the method proposed in this paper can increase the interfacial bonding strength by 66.4%, which can be ascribed to the improvement of surface roughness and the co-vulcanization between fibers and rubber. Furthermore, the graft of polydopamine initial layer makes this modification method have high universality and industrial application potential.

-

表 1 橡胶配料

Table 1. Rubber formulation

Ingredients Mass fraction/wt% Styrene-butadiene rubber 41.92 Natural rubber 17.96 Carbon black 14.97 White carbon black 5.99 Zinc oxide 2.99 Stearic acid 1.20 Aromatic oil 5.99 Coumarone indene resin 5.99 Accelerant 2.40 Sulfur 2.40 -

[1] BILISIK K, ERDOGAN G, SAPANCI E. In-plane response of para-aramid/phenolic nanostitched and nanoprepreg 3D composites under tensile loading[J]. Polymer Composites,2018,40(4):1275-1286. [2] LEE Y S, WETZEL E D, WAGNER N J, et al. The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid[J]. Journal of Material Science,2003,38(13):2825-2833. doi: 10.1023/A:1024424200221 [3] QUAN D, URDÁNIZ J L, ROUGE C, et al. The enhancement of adhesively-bonded aerospace-grade composite joints using steel fibers[J]. Composite Structure,2018,198:11-18. doi: 10.1016/j.compstruct.2018.04.071 [4] LV J, CHENG Z, WU H, et al. In-situ polymerization and covalent modification on aramid fiber surface via direct fluorination for interfacial enhancement[J]. Composites Part B: Engineering,2019,182:107608. [5] PARK S J, SEO M K, MA T J, et al. Effect of chemical treatment of Kevlar fibers on mechanical interfacial properties of composites[J]. Journal of Colloid and Interface Science,2002,252(1):249-255. doi: 10.1006/jcis.2002.8479 [6] LIU L, HUANG Y D, ZHANG Z Q, et al. Ultrasonic treatment of aramid fiber surface and its effect on the interface of aramid/epoxy composites[J]. Applied Surface Science,2008,254(9):2594-2599. doi: 10.1016/j.apsusc.2007.09.091 [7] ZHANG Y, HUANG Y, LIU L, et al. Effects of γ-ray radiation grafting on aramid fibers and its composites[J]. Applied Surface Science,2008,254(10):3153-3161. doi: 10.1016/j.apsusc.2007.10.081 [8] KONDO Y, MIYAZAKI K, TAKAYANAGI K, et al. Surface treatment of PET fiber by EB-irradiation-induced graft polymerization and its effect on adhesion in natural rubber matrix[J]. European Polymer Journal,2008,44(5):1567-1576. doi: 10.1016/j.eurpolymj.2008.02.020 [9] WU Q, ZHAO R, MA Q, et al. Effects of degree of chemical interaction between carbon fibers and surface sizing on interfacial properties of epoxy composites[J]. Composites Science and Technology,2018,163:34-40. doi: 10.1016/j.compscitech.2018.05.013 [10] LIU L, JIA C, HE J, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites[J]. Composites Science and Technology,2015,121:56-72. doi: 10.1016/j.compscitech.2015.08.002 [11] DRZAL L, RICH M, KOENIG M, et al. Adhesion of graphite fibers to epoxy matrices: II. The effect of fiber finish[J]. Journal of Adhesion,1983,16(2):133-152. doi: 10.1080/00218468308074911 [12] RODRÍGUEZ-UICAB O, AVILÉS F, GONZALEZ-CHI PI, et al. Deposition of carbon nanotubes onto aramid fibers using as-received and chemically modified fibers[J]. Applied Surface Science,2016,385:379-390. doi: 10.1016/j.apsusc.2016.05.037 [13] YANG X, TU Q, SHEN X, et al. Surface modification of Poly(p-phenylene terephthalamide) fibers by polydopamine-polyethyleneimine/graphene oxide multilayer films to enhance interfacial adhesion with rubber matrix[J]. Polymer Testing,2019,78:105985. doi: 10.1016/j.polymertesting.2019.105985 [14] YANG Y, LU C, SU X, et al. Effect of nano-SiO2 modified emulsion sizing on the interfacial adhesion of carbon fibers reinforced composites[J]. Materials Letters,2007,61(17):3601-3604. doi: 10.1016/j.matlet.2006.11.121 [15] WANG B, DUAN Y, ZHANG J. Titanium dioxide nanoparticles-coated aramid fiber showing enhanced interfacial strength and UV resistance properties[J]. Material & Design,2016,103(5):330-338. [16] WANG L, SHI Y, SA R, et al. Surface modification of aramid fibers by catechol/polyamine co-deposition followed silane grafting for the enhanced interfacial adhesion to rubber matrix[J]. Industrial & Engineering Chemistry Research,2016,55(49):12547-12556. [17] YANG X, TU Q, SHEN X, et al. Study on interfacial adhesion of the aramid fbers/rubber matrix by grafting mercapto hyperbranched polysiloxane[J]. Polymer Testing,2020,81:106259. doi: 10.1016/j.polymertesting.2019.106259 [18] NIU S, YAN H, LI S, et al. A multifunctional silicon-containing hyperbranched epoxy: Controlled synthesis, toughening bismaleimide and fluorescent properties[J]. Journal of Materials Chemistry C,2016,4(28):6881-6893. doi: 10.1039/C6TC02546C [19] LAN X, HUANG W, YU Y. Synthesis, characterization and properties of the polysiloxane-based episulfide resin[J]. European Polymer Journal,2010,46:1545-1556. doi: 10.1016/j.eurpolymj.2010.04.011 [20] 张梦萌. 超支化聚合物接枝氧化石墨烯及其改性氰酸酯树脂研究[D]. 西安: 西北工业大学, 2015.ZHANG M. Graphene oxide grafted with hyperbranched polymers and its application in modification of cyanate ester resin[D]. Xi’an: Northwestern Polytechnical University, 2015(in Chinese). [21] KIM K H. Hyperbranched polymers 10 years after[J]. Journal of Polymer Science Part A: Polymer Chemistry,1998,36(11):1685-1698. doi: 10.1002/(SICI)1099-0518(199808)36:11<1685::AID-POLA1>3.0.CO;2-R [22] WU W, XU Z, LI Z. Using low generation dendrimers as monomers to construct dendronized hyperbranched polymers with high nonlinear optical performance[J]. Journal of Materials Chemistry C,2014,2(38):8122-8130. doi: 10.1039/C4TC01396D [23] YE J, LIANG G, GU A, et al. Novel phosphorus-containing hyperbranched polysiloxane and its high-performance flame-retardant cyanate ester resins[J]. Polymer Degradation & Stability,2013,98(2):597-608. doi: 10.1016/j.polymdegradstab.2012.11.015 [24] ZHUO D, GU A, LIANG G, et al. Flame retardancy materials based on a novel fully end-capped hyperbranched polysiloxane and bismaleimide/diallylbisphenol A resin with simultaneously improved integrated performance[J]. Journal of Materials Chemistry A,2011,21(18):6584-6594. doi: 10.1039/c1jm10233h [25] ZHANG H, LIANG G, GU A, et al. Facile preparation of hyperbranched polysiloxane-grafted aramid fibers with simultaneously improved UV resistance, surface activity, and thermal and mechanical properties[J]. Industrial & Engineering Chemistry Research,2014,53(7):2684-2696. [26] ZHU X, YUAN L, LIANG G. Unique surface modified aramid fibers with improved flame retardancy, tensile properties, surface activity and UV-resistance through in-situ forming hyperbranched polysiloxane-Ce0.8Ca0.2O1.8 hybrids[J]. Journal of Materials Chemistry A,2015,3:12515-12529. doi: 10.1039/C5TA01690H [27] ZHANG T, YANG J, JIANG B, et al. Study on the interfacial properties of the dual-activity silicone resin/carbon fibers composites[J]. Composites Science and Technology,2018,165:347-354. doi: 10.1016/j.compscitech.2018.07.012 [28] LI S, WU Q, CUI C. Synergetic reinforcements of epoxy composites with glass fibers and hyperbranched polymers[J]. Polymer Composite,2018,39:2871-2879. doi: 10.1002/pc.24280 [29] AN Q, WANG K, JIA Y. Film morphology, orientation and performance of dodecyl/carboxyl functional polysiloxane on cotton substrates[J]. Applied Surface Science,2011,257:4569-4574. doi: 10.1016/j.apsusc.2010.12.032 [30] HOU A, YU J, SHI Y. Preparation and surface properties of the polysiloxane material modified with fluorocarbon side chains[J]. European Polymer Journal,2008,44:1696-1700. doi: 10.1016/j.eurpolymj.2008.03.026 [31] 国家标准化管理委员会. 硫化橡胶与纤维帘线静态粘合强度的测定H抽出法: GB/T 2942—2009[S]. 北京: 中国标准出版社, 2009.Standardization administration. Rubber, vulcanized-determination of static adhesion to textile cord-H-pull test: GB/T 2942—2009[S]. Beijing: Standards Press of China, 2009(in Chinese). [32] CHEN Y, YIN Q, ZHANG X M, et al. Rational design of multifunctional properties for styrene-butadiene rubber reinforced by modified Kevlar nanofibers[J]. Composites Part B: Engineering,2019,166:196-203. doi: 10.1016/j.compositesb.2018.11.132 [33] SHARMA S, PATHAK A K, SINGH V N, et al. Excellent mechanical properties of long length multiwalled carbon nanotube bridged Kevlar fabric[J]. Carbon,2018,137:104-117. doi: 10.1016/j.carbon.2018.05.017 [34] CANÇADO LG, REINA A, KONG J, et al. Geometrical approach for the study of G′ band in the Raman spectrum of monolayer graphene, bilayer graphene, and bulk graphite[J]. Physical Review B,2008,77(24):245408. doi: 10.1103/PhysRevB.77.245408 [35] LI Y, ZHANG L, LI C. Highly transparent and scratch resistant polysiloxane coatings containing silica nanoparticles[J]. Journal of Colloid and Interface Science,2020,559:273-281. doi: 10.1016/j.jcis.2019.09.031 [36] WANG L, SHI Y, CHEN S, et al. Highly efficient mussel-like inspired modification of aramid fibers by UV-accelerated catechol/polyamine deposition followed chemical grafting for high-performance polymer composites[J]. Chemical Engineering Journal,2017,314:583-593. doi: 10.1016/j.cej.2016.12.015 [37] GUO H, WANG Q, LIU J. Improved interfacial properties for largely enhanced thermal conductivity of poly(vinylidene fluoride)-based nanocomposites via functionalized multiwall carbon nanotubes[J]. Applied Surface Science,2019,487:379-388. doi: 10.1016/j.apsusc.2019.05.070 -

下载:

下载: