Preparation of stretchable graphene/PDMS composite films with excellent electromagnetic performance

-

摘要: 飞机、卫星等飞行器装载有多种关键电子元器件,易受强电磁场环境干扰;同时飞行器的部分结构在工作中需满足大形变、可拉伸等力学要求,因此高导电、可拉伸电磁屏蔽材料受到广泛关注。以氧化石墨烯为原料,通过流延法和高温石墨化处理制备了厚度为13.5 μm的高导电柔性石墨烯薄膜(GP-4),其电导率和电磁屏蔽效能分别为6010 S/cm和68.4 dB。以预拉伸的波纹状聚二甲基硅烷(PDMS)为基底,制备了具有双层结构的GP-4/PDMS-50.5复合膜,轴向拉伸应变高达50.5%。当GP-4/PDMS-50.5复合膜轴向拉伸应变为50.5%及拉伸循环次数为500时,该复合膜仍能保持优异的导电性能和电磁屏蔽性能。其中,复合膜的电阻与GP-4薄膜基本一致,分别为1.04 Ω和1.06 Ω;复合膜的电磁屏蔽效能高达68.5 dB 和67.7 dB。这些优良性能表明了GP-4/PDMS-50.5复合膜在柔性电子设备的电磁屏蔽领域具有巨大应用前景。Abstract: Aircraft, satellites and other aircraft with key electronic components, are susceptible to interference from strong electromagnetic field. And some structures of aircraft need to meet mechanical requirements such as large deformation and stretchability in work. Therefore, highly conductive and stretchable electromagnetic shielding materials have attracted widespread attention. Using graphene oxide as raw material and through casting method and high-temperature graphitization treatment, a highly conductive and flexible GP-4 film with the thickness of 13.5 μm was prepared, whose electrical conductivity and electromagnetic shielding efficiency were 6010 S/cm and 68.4 dB, respectively. Using polydimethylsilane (PDMS) as the base, GP-4/PDMS-50.5 composite film with stretchable bilayer structure was prepared, whose elongation was as high as 50.5%. When the axial tensile strain of the composite film is 50.5% and the number of stretching cycles is 500, the composite film could still maintain excellent conductivity and electromagnetic shielding performance. Among them, the resistance of the composite film is 1.04 Ω and 1.06 Ω, keeping constant with the GP-4 film almost. The electromagnetic shielding efficiency of the composite film is as high as 68.5 dB and 67.7 dB. These excellent properties indicate that GP-4/PDMS-50.5 composite film has great application prospects in the electromagnetic shielding field of flexible electronic devices.

-

Key words:

- graphene /

- PDMS /

- electromagnetic shielding /

- highly conductive /

- stretchable

-

图 3 光学图片:(a)PG薄膜、(b)GP-4薄膜、(c)折叠实验后GP-4薄膜的外观图和SEM图:(d)PG截面、(e)GP-4截面、(f)GP-4表面形貌

Figure 3. Digital images of (a) PG films, (b) GP-4 films (c) GP-4 films after repeated folding and (d) SEM images of cross-section surface morphology (d) PG films, (e) GP-4 films, and (f) surface morphology of GP-4 films

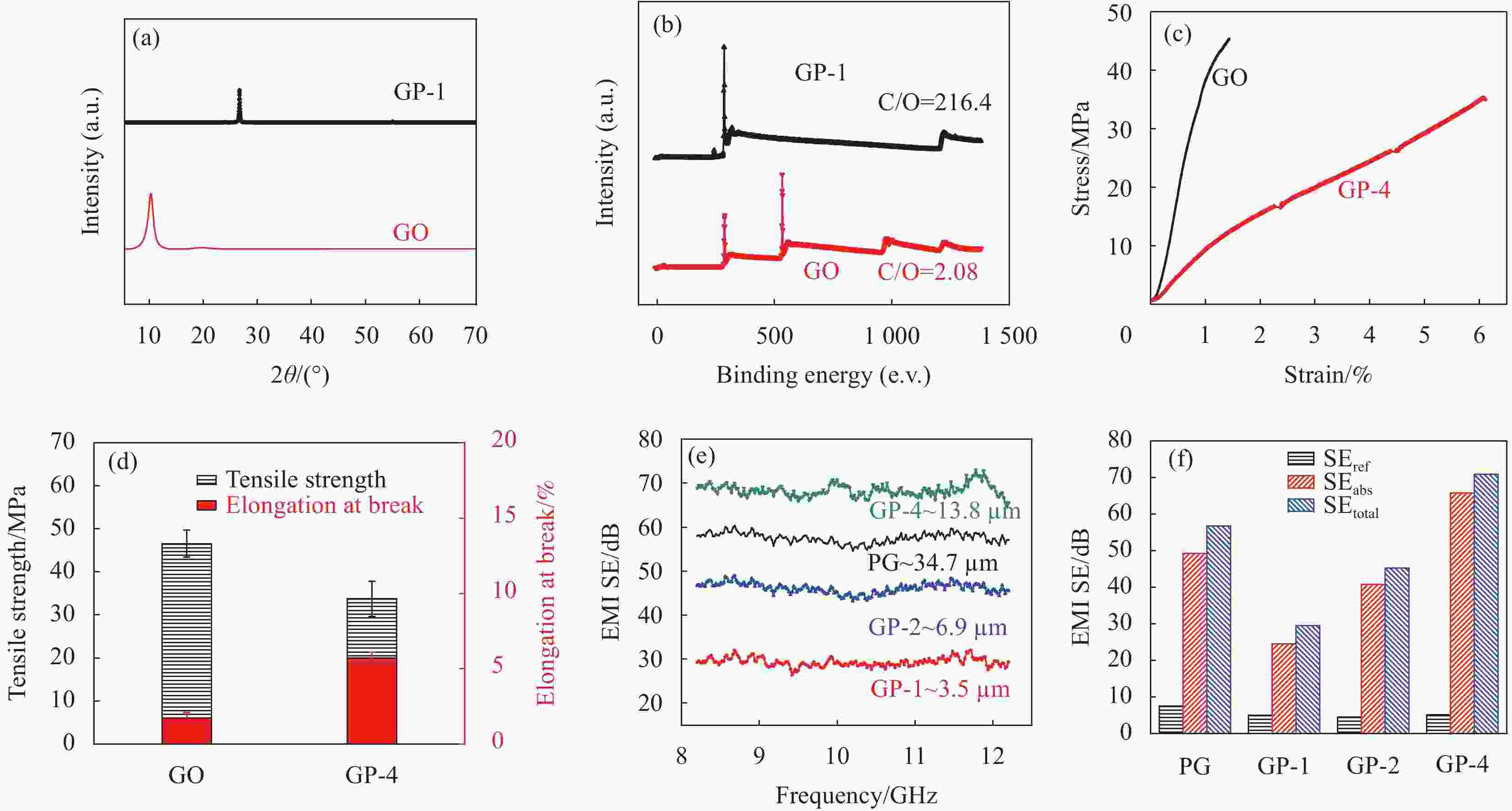

图 4 GO和致密化石墨烯薄膜的XRD图(a)、XPS谱图(b)、应力-应变曲线(c)、力学性能(d)、电磁屏蔽性能(e)和在频率为10 GHz时的吸收损耗和反射损耗图(f)

Figure 4. XRD spectra (a), XPS survey spectra (b), Stress-strain curves (c) of, (d) mechanical properties, (e) EMI SEs and (f) SEref, SEabs and SEtotal at 10 GHz of graphene films of the GO and compressed graphene films

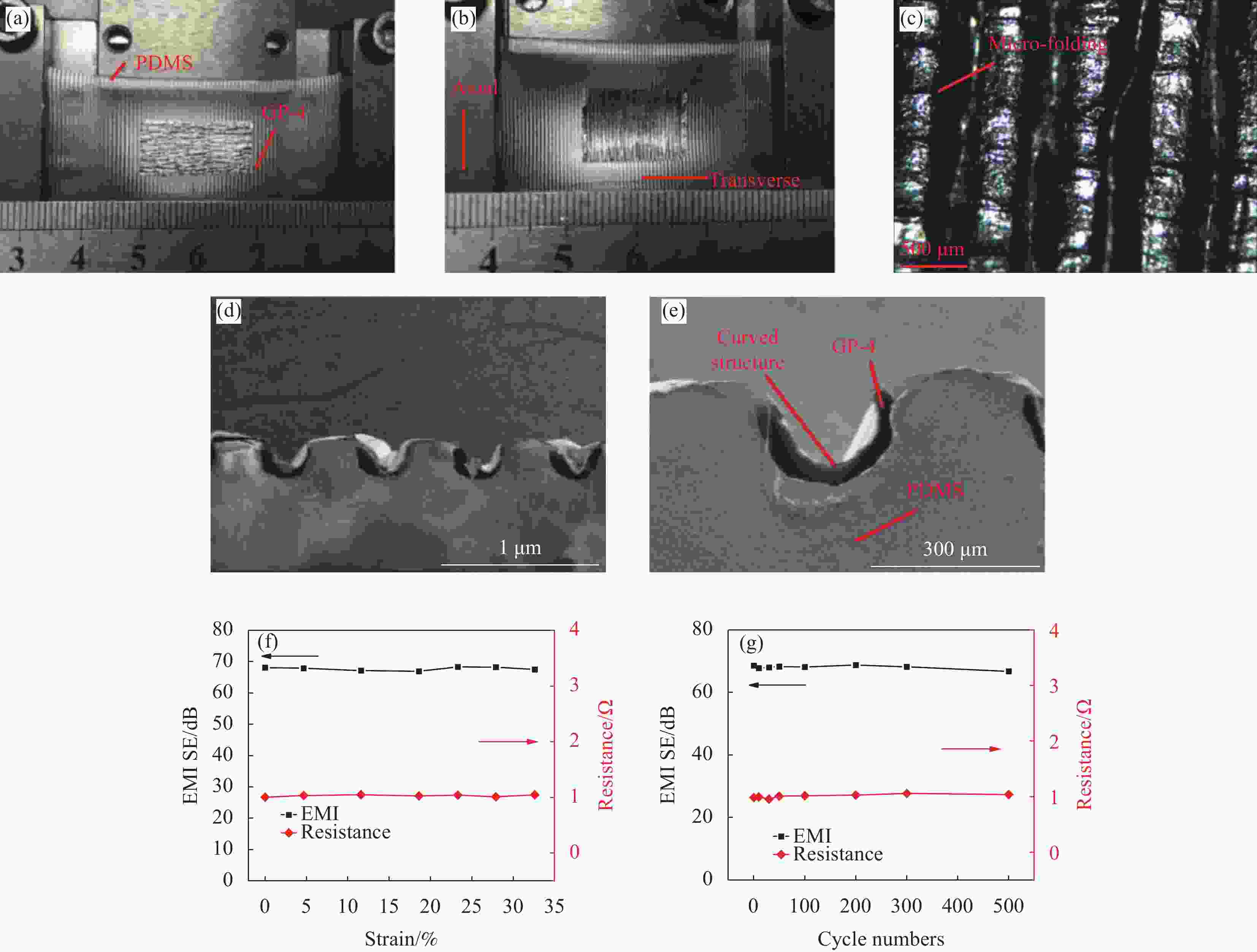

图 5 GP-4/PDMS复合膜:(a)拉伸状态的数码照片;(b)松弛状态的数码照片;(c)光学显微镜图;(d)SEM图;(e)局部SEM图,和复合膜在(f)不同拉伸应变和(g)重复拉伸次数下的导电性能和电磁屏蔽性能

Figure 5. Digital photos of GP-4/PDMS (a) with dual pre-stretched strain, (b) released status, (c) Optical microscope photos of GP-4/PDMS, (d) SEM images of GP-4/PDMS, (e) amplified SEM images of GP-4/PDMS, resistance measurement and EMI SEs of GP-4/PDMS (f) under different strains, and(g) for different cycle numbers

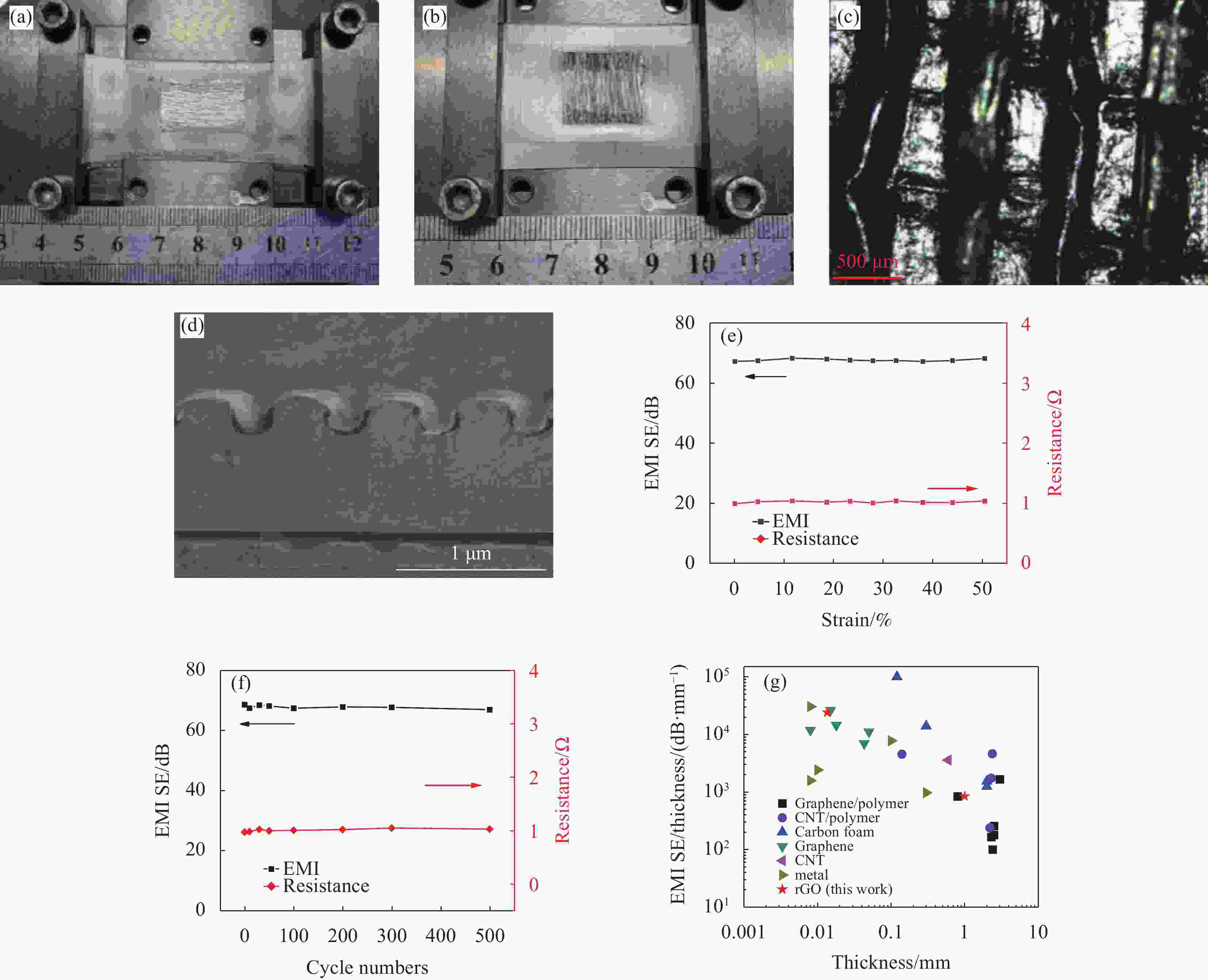

图 6 GP-4/PDMS-50.5复合膜:(a)拉伸状态的数码照片;(b)松弛状态的数码照片;(c)光学显微镜图;(d)SEM图,GP-4/PDMS-50.5复合膜在(e)不同拉伸应变和(f)重复拉伸次数下的导电性能和电磁屏蔽性能;(g)与文献其他材料电磁屏蔽性能的对比

Figure 6. Digital photos of GP-4/PDMS-50.5 (a) with dual pre-stretched strain, (b) released status, (c) Optical microscope photos of GP-4/PDMS-50.5, (d)SEM images of GP-4/PDMS-50.5, resistance measurement and EMI SEs of GP-4/PDMS-50.5 (e) under different strains, and (f) for different cycle numbers, (g) EMI SSE/t versus thickness in comparison to different materials in the previous literature; and t represents thickness

表 1 多孔状石墨烯薄膜及致密化石墨烯薄膜的缩写

Table 1. Abbreviated symbols for porous graphene films and compressed graphene films

Samples Porous graphene films Compressed graphene

film with one PGCompressed graphene

film with two PGCompressed graphene

film with four PGSymbol PG GP-1 GP-2 GP-4 Thickness/μm 34.7±0.3 3.5±0.4 6.9±0.3 13.8±0.7 -

[1] TRUNG T Q, LEE N E. Recent progress on stretchable electronic devices with intrinsically stretchable components[J]. Advanced Materials, 2017, 29(3): 1603167. doi: 10.1002/adma.201603167 [2] LIU W, Song M S, KONG B, et al. Flexible and Stretchable Energy Storage: Recent Advances and Future Perspectives[J]. Advanced Materials, 2017, 29: 1603436. doi: 10.1002/adma.201603436 [3] 宋明龙, 魏致坤. 卫星电磁兼容性设计 技术[J]. 上海航天, 2001, 18(2): 61-68.SONG Minglong, WEI Zhikun. Satellite electromagnetic compatibility design technology[J]. Shanghai Aerospace, 2001, 18(2): 61-68(in Chinese). [4] 林金永, 訾乃全, 于芳. 飞控设备抗强电磁脉冲方法研究[J]. 现代防御技术, 2012, 40(4): 79-83. doi: 10.3969/j.issn.1009-086x.2012.04.013LIN Jinyong, ZI Naiquan, YU Fang. Research on anti-strong electromagnetic pulse method of flight control equipment[J]. Modern defense technology, 2012, 40(4): 79-83(in Chinese). doi: 10.3969/j.issn.1009-086x.2012.04.013 [5] 陈旸, 许鸣, 张孙虎, 等. 复杂电磁环境下机载飞行控制器结构设计[J]. 机械制造与自动化, 2015, (5): 186-188. doi: 10.3969/j.issn.1671-5276.2015.05.050CHEN Yang, XU Ming, ZHANG Sunhu, et al. Structural design of airborne flight controller in complex electromagnetic environment[J]. Machine Manufacturing and Automation, 2015, (5): 186-188(in Chinese). doi: 10.3969/j.issn.1671-5276.2015.05.050 [6] 陈铁彪, 龚旻, 王洪波, 等. 临近空间可变形滑翔飞行器轨迹优化与性能分析[J]. 宇航学报, 2018, 39(9): 944-952. doi: 10.3873/j.issn.1000-1328.2018.09.001CHEN Tiebiao, GONG Yu, WANG Hongbo, et al. Trajectory optimization and performance analysis of deformable glide aircraft in near space[J]. Journal of Astronautics, 2018, 39(9): 944-952(in Chinese). doi: 10.3873/j.issn.1000-1328.2018.09.001 [7] 祝连庆, 孙广开, 李红, 等. 智能柔性变形机翼技术的应用与发展[J]. 机械工程学报, 2018, 54(14): 28-42.ZHU Lianqing, SUN Guangkai, LI Hong, et al. Application and development of intelligent flexible deformation wing technology[J]. Journal of Mechanical Engineering, 2018, 54(14): 28-42(in Chinese). [8] JUNG J, LEE H, HA I, et al. Highly stretchable and transparent electromagnetic interference shielding film based on silver nanowire percolation network for wearable electronics applications[J]. ACS Applied Materials & Interfaces, 2017, 9(51): 44609-44616. [9] ZHAO J, CHI Z, YANG Z, et al. Recent developments of truly stretchable thin film electronic and optoelectronic devices[J]. Nanoscale, 2018, 10(13): 5764-5792. doi: 10.1039/C7NR09472H [10] WAN Y J, ZHU P L, YU S H, et al. Anticorrosive, Ultralight, and flexible carbon-wrapped metallic nanowire hybrid sponges for highly efficient electromagnetic interference shielding[J]. Small, 2018, 14(27): 1800534. doi: 10.1002/smll.201800534 [11] TAHALYANI J, AKHTAR M J, KAMAL K. Flexible, stretchable and lightweight polyurethane and graphene nanoplatelets nanocomposite for high performance EMI shielding application[J]. Materials Today Communications, 2022, 33: 104586. doi: 10.1016/j.mtcomm.2022.104586 [12] WANG Z Y, YANG W Z, LIU R, et al. Highly stretchable graphene/ polydimethylsiloxane composite lattices with tailored structure for strain-tolerant EMI shielding performance[J]. Composites Science and Technology, 2021, 106: 108652. [13] GONG X, YU H Y, CHEN X N, et al. Superhydrophobic PDMS /PPy-Ag/ graphene/PET films with highly efficient electromagnetic interference shielding, UV shielding, self-cleaning and electrothermal deicing[J]. Materials Today Physics, 2023, 34: 101076. doi: 10.1016/j.mtphys.2023.101076 [14] DUAN S, YANG K, WANG Z, et al. Fabrication of highly stretchable conductors based on 3D printed porous poly(dimethylsiloxane) and conductive carbon nanotubes/graphene network[J]. ACS Applied Materials & Interfaces, 2016, 8(3): 2187-2192. [15] CHEN J, WANG X J, LU H, et al. Reduced graphene oxide electrodes with wrinkled surface for nonvolatile polymer memory device compatibility[J]. Small Methods, 2018, 2(7): 1800048. doi: 10.1002/smtd.201800048 [16] ZANG J F, RYU S, PUGNO N, et al. Multifunctionality and control of the crumpling and unfolding of large-area graphene[J]. Nature Materials, 2013, 12(4): 321-325. doi: 10.1038/nmat3542 [17] SHAHZAD F, ALHABEB M, HATTER C B, et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes)[J]. Science, 2016, 353: 1137-1140. doi: 10.1126/science.aag2421 [18] Qi D, LIU Z, LIU Y, et al. Suspended wavy graphene microribbons for highly stretchable microsupercapacitors[J]. Advanced Materials, 2015, 27(37): 5559-5566. doi: 10.1002/adma.201502549 [19] SON D, LEE J, QIAO S, et al. Multifunctional wearable devices for diagnosis and therapy of movement disorders[J]. Nature Nanotechnology, 2014, 9: 397-404. doi: 10.1038/nnano.2014.38 [20] HONG J Y, KIM W, CHOI D, et al. Omnidirectionally stretchable and transparent graphene electrodes[J]. ACS Nano, 2016, 10(10): 9446-9455. doi: 10.1021/acsnano.6b04493 [21] LEE Y, LE V T, KIM J G, et al. Versatile, high-power, flexible, stretchable carbon nanotube sheet heating elements tolerant to mechanical damage and severe deformation[J]. Advanced Functional Materials, 2018, 28(8): 1706007. doi: 10.1002/adfm.201706007 [22] ZHOU E Z, XI J B, LIU Y J, et al. Large-area potassium-doped highly conductive graphene films for electromagnetic interference shielding[J]. Nanoscale, 2017, 9(47): 18613-18618 doi: 10.1039/C7NR07030F [23] HONG S K, KIM K Y, KIM T Y, et al. Electromagnetic interference shielding effectiveness of monolayer graphene[J]. Nanotechnology, 2012, 23: 455704. doi: 10.1088/0957-4484/23/45/455704 [24] GAO J, LIU C, MIAO L, et al. Free-standing reduced graphene oxide paper with high electrical conductivity[J]. Journal of Electronic Materials, 2015, 45(3): 1290-1295. [25] CHEN J, LI Y, HUANG L, et al. Size fractionation of graphene oxide sheets via filtration through track-etched membranes[J]. Advanced Materials, 2015, 27(24): 3654-3660. doi: 10.1002/adma.201501271 [26] COMPTON O C, DIKIN D A, PUTZ K W, et al. Electrically conductive "alkylated" graphene paper via chemical reduction of amine-functionalized graphene oxide paper[J]. Advanced Materials, 2010, 22(8): 892-896. doi: 10.1002/adma.200902069 [27] LI W J, TANG X Z, ZHANG H B, et al. Simultaneous surface functionalization and reduction of graphene oxide with octadecylamine for electrically conductive polystyrene composites[J]. Carbon, 2011, 49(14): 4724-4730. doi: 10.1016/j.carbon.2011.06.077 [28] MA H L, ZHANG H B, HU Q H, et al. Functionalization and reduction of graphene oxide with p-phenylene diamine for electrically conductive and thermally stable polystyrene composites[J]. ACS Applied Materials & Interfaces, 2012, 4(4): 1948-1953. [29] PENG L, XU Z, LIU Z, et al. Ultrahigh thermal conductive yet superflexible graphene films[J]. Advanced Materials, 2017, 29(27): 1700589. doi: 10.1002/adma.201700589 [30] LIN S F, JU S, ZHANG J W, et al. Ultrathin flexible graphene films with high thermal conductivity and excellent EMI shielding performance using large-sized graphene oxide flakes[J]. RSC Advance, 2017, 9: 1419-1427. -

点击查看大图

点击查看大图

计量

- 文章访问数: 68

- HTML全文浏览量: 102

- 被引次数: 0

下载:

下载: